Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications

Abstract

:1. Introduction

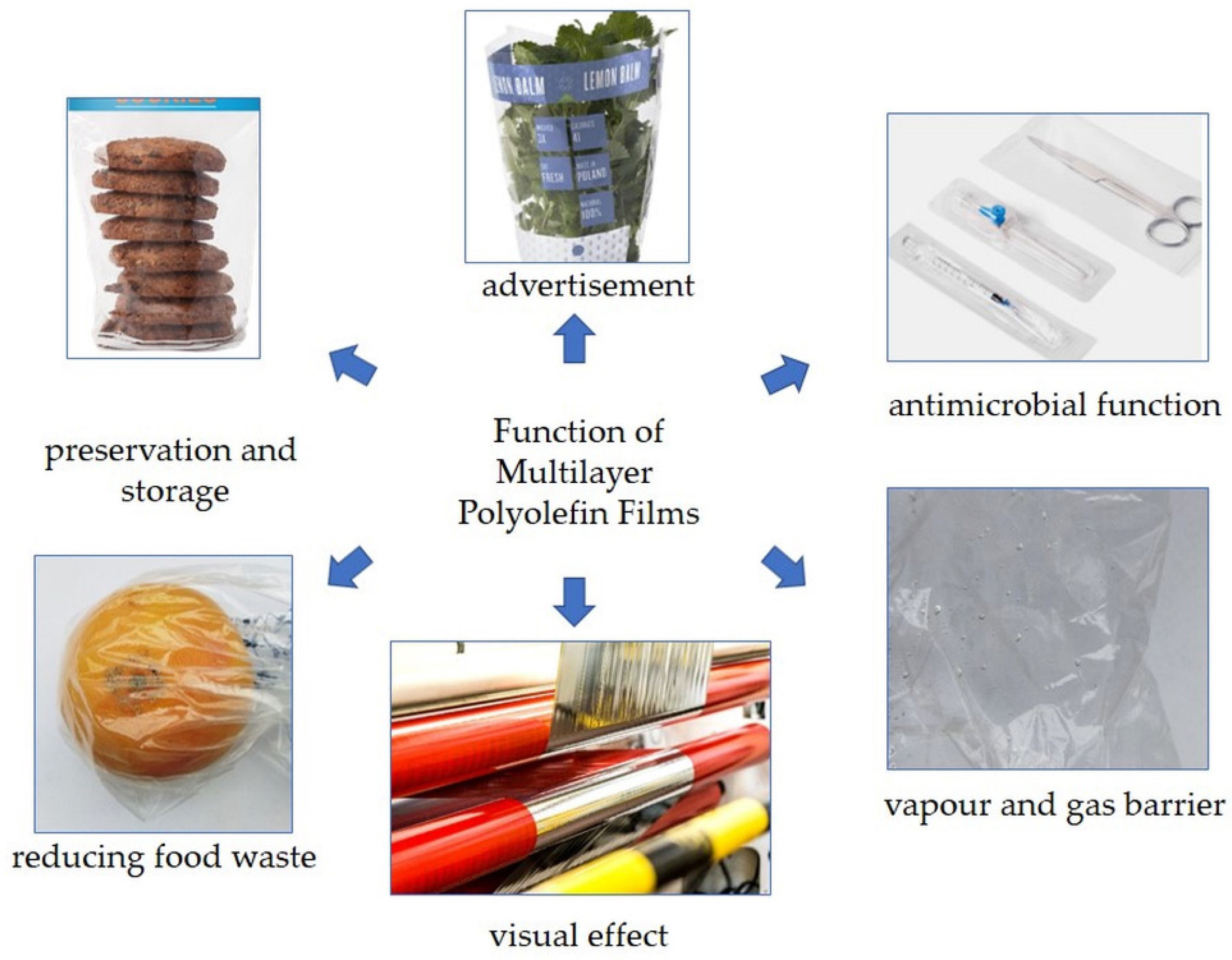

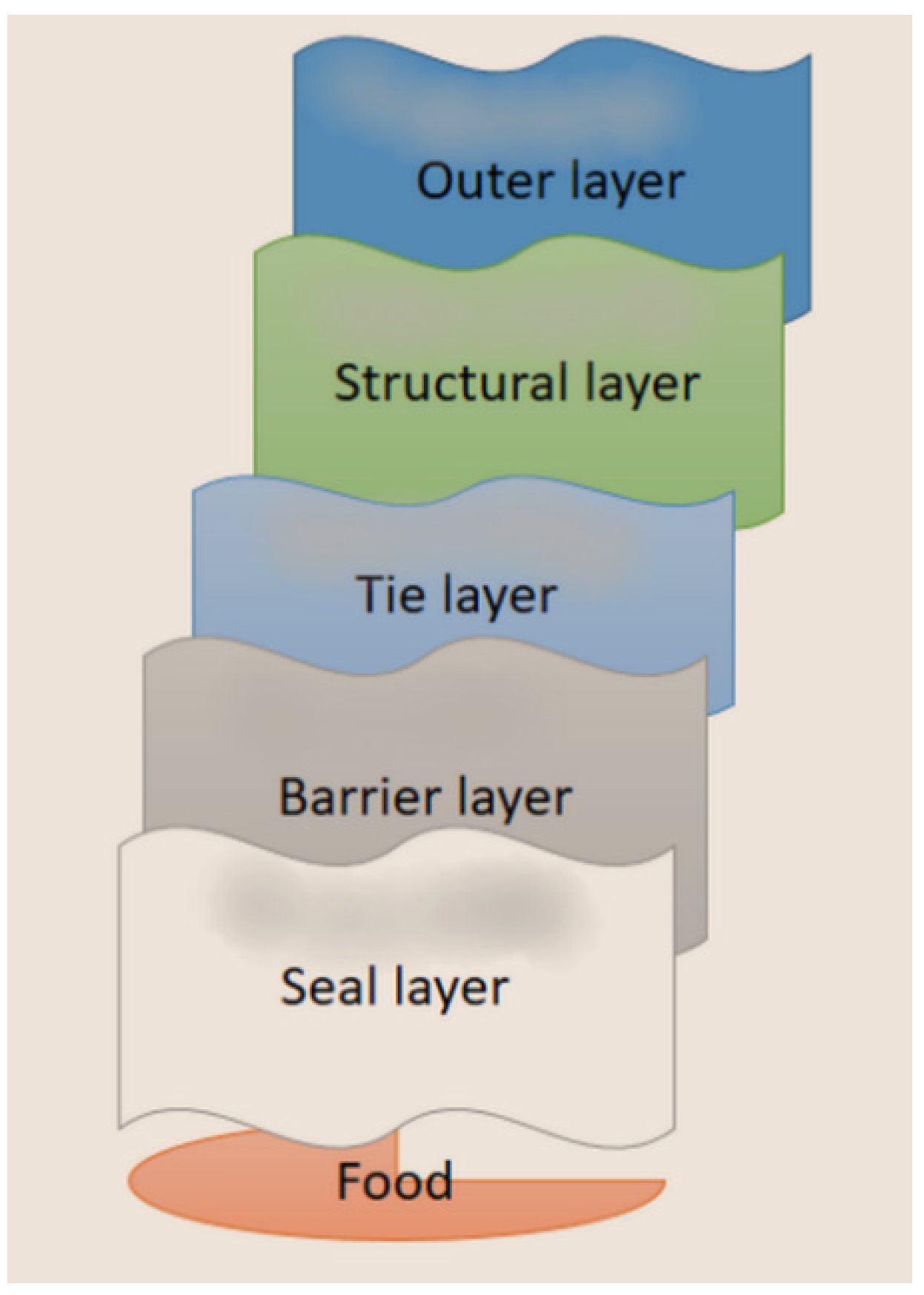

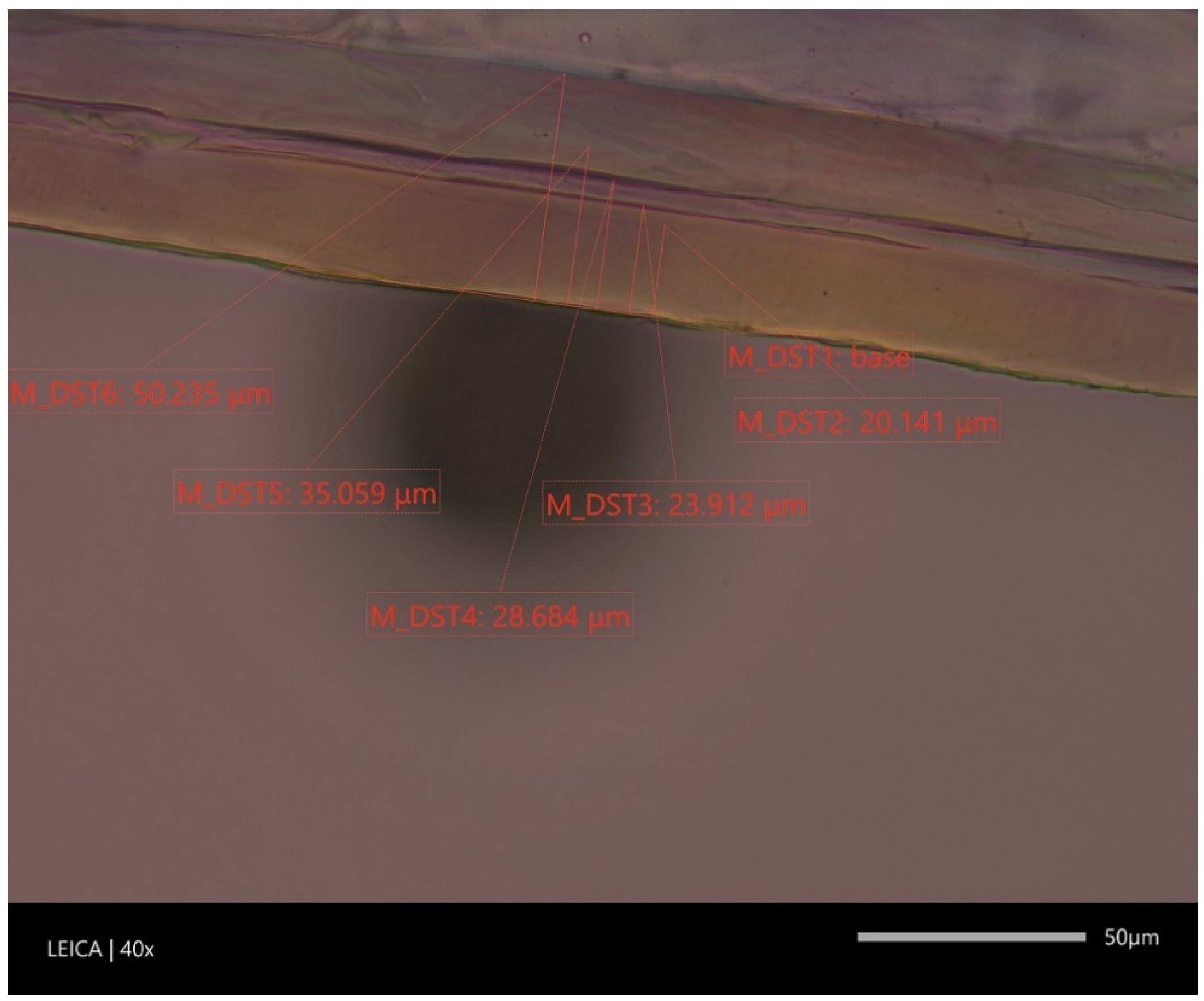

2. Structure of Multilayer Packaging

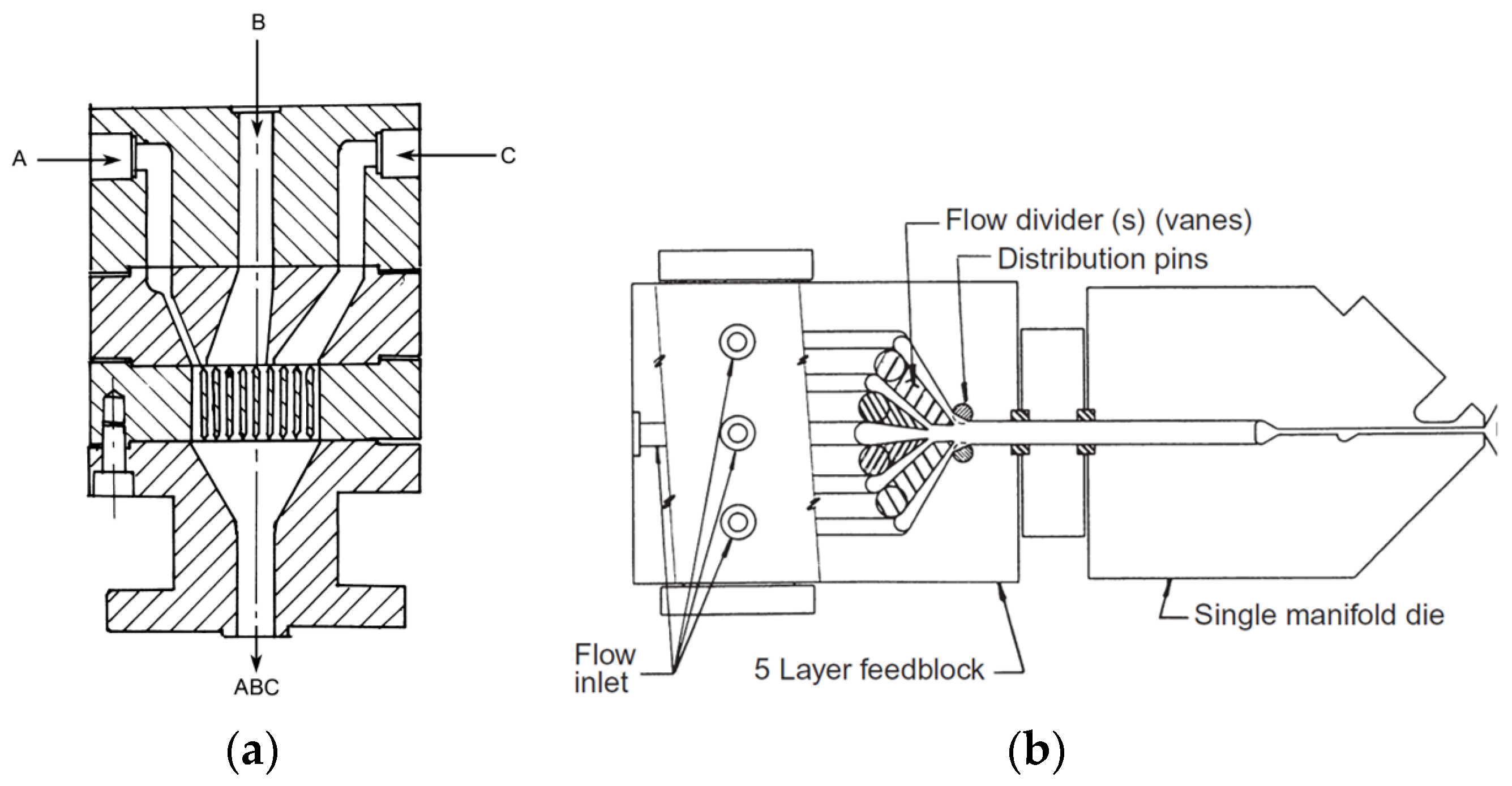

3. Methods for Producing a Multilayer Film

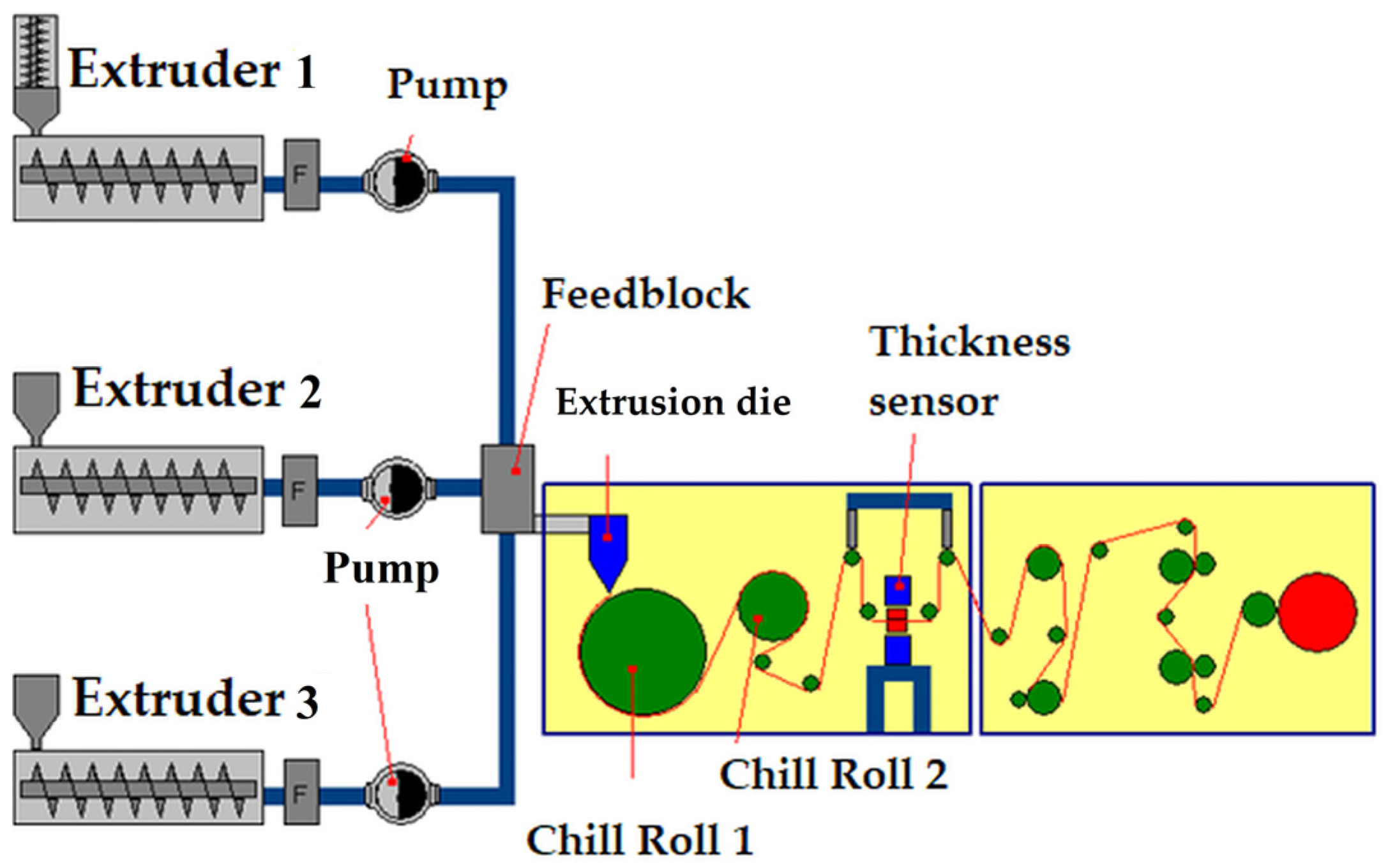

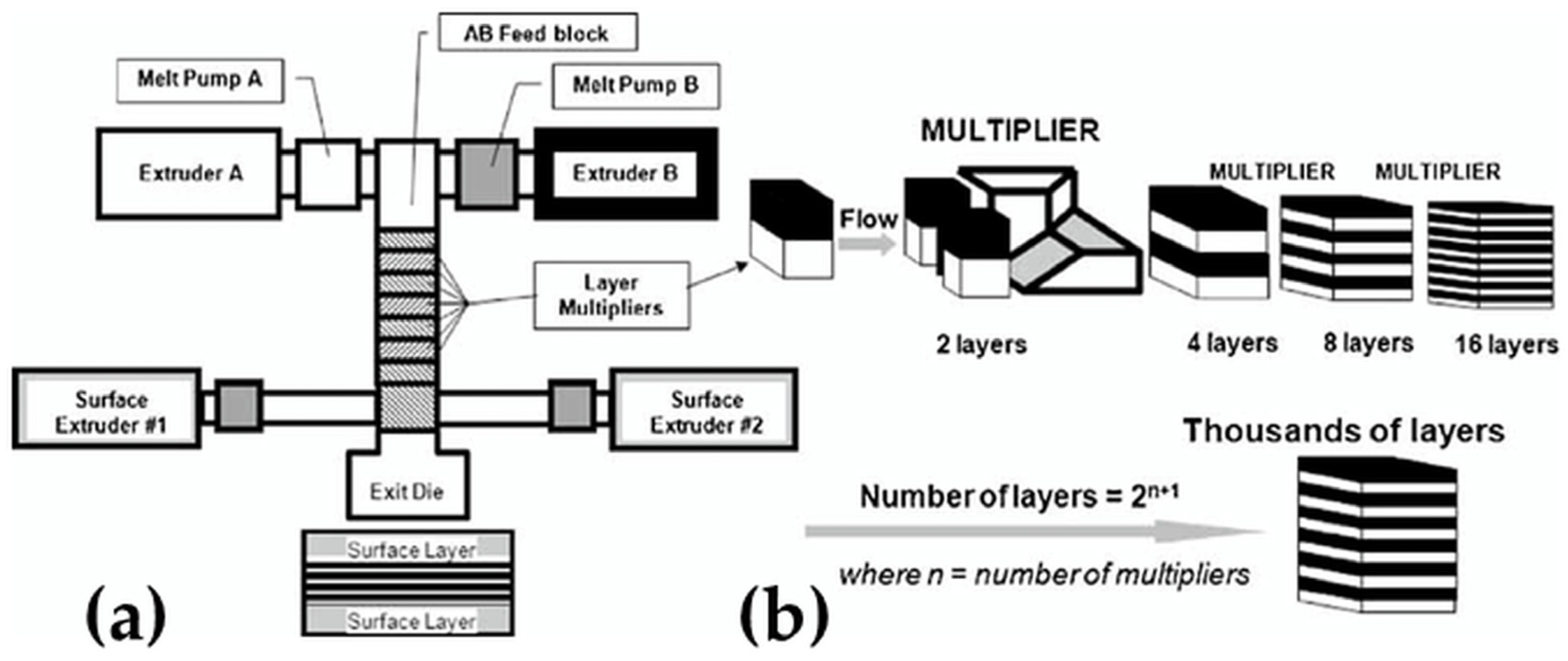

3.1. Feedblock Process

3.2. Multimanifold Process

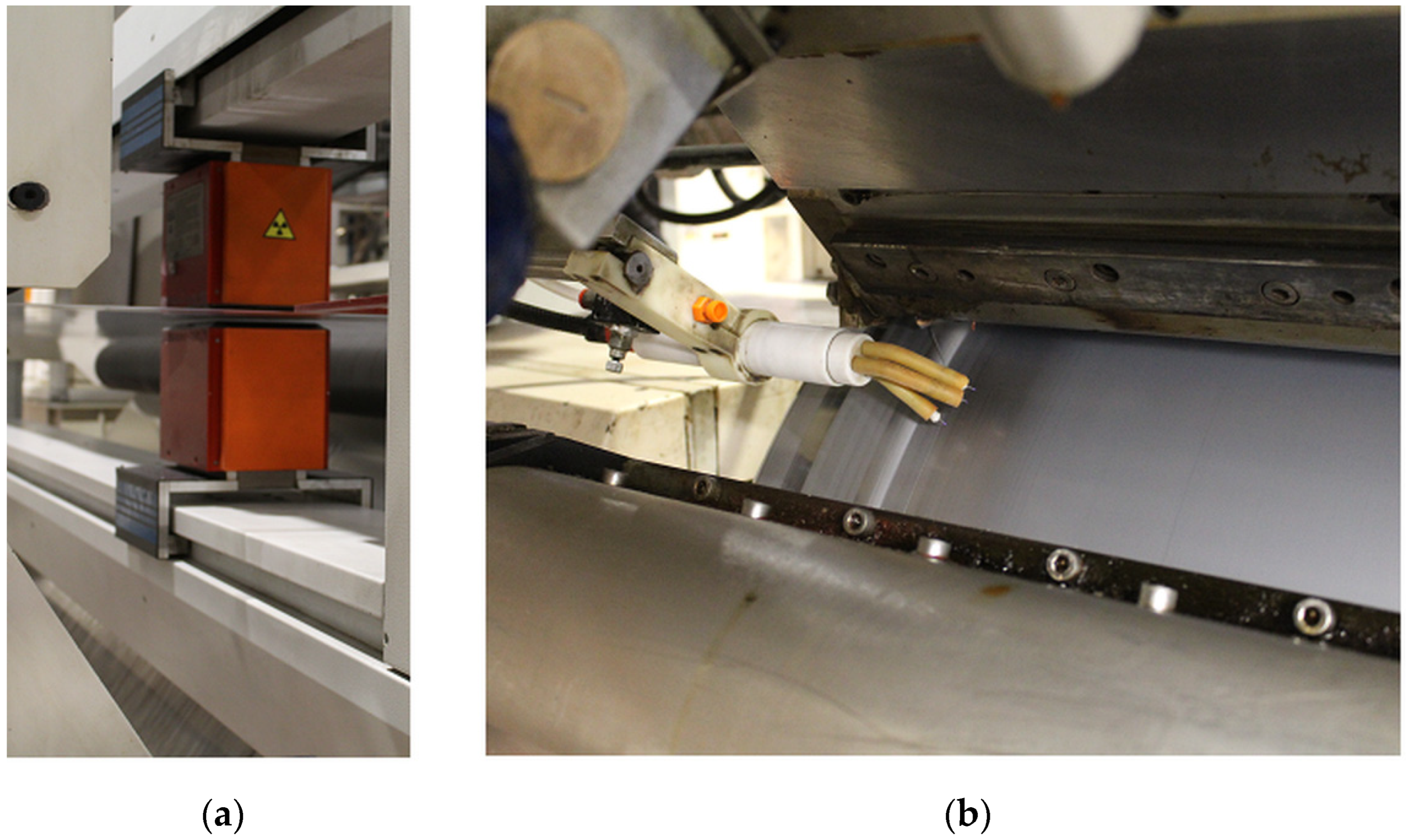

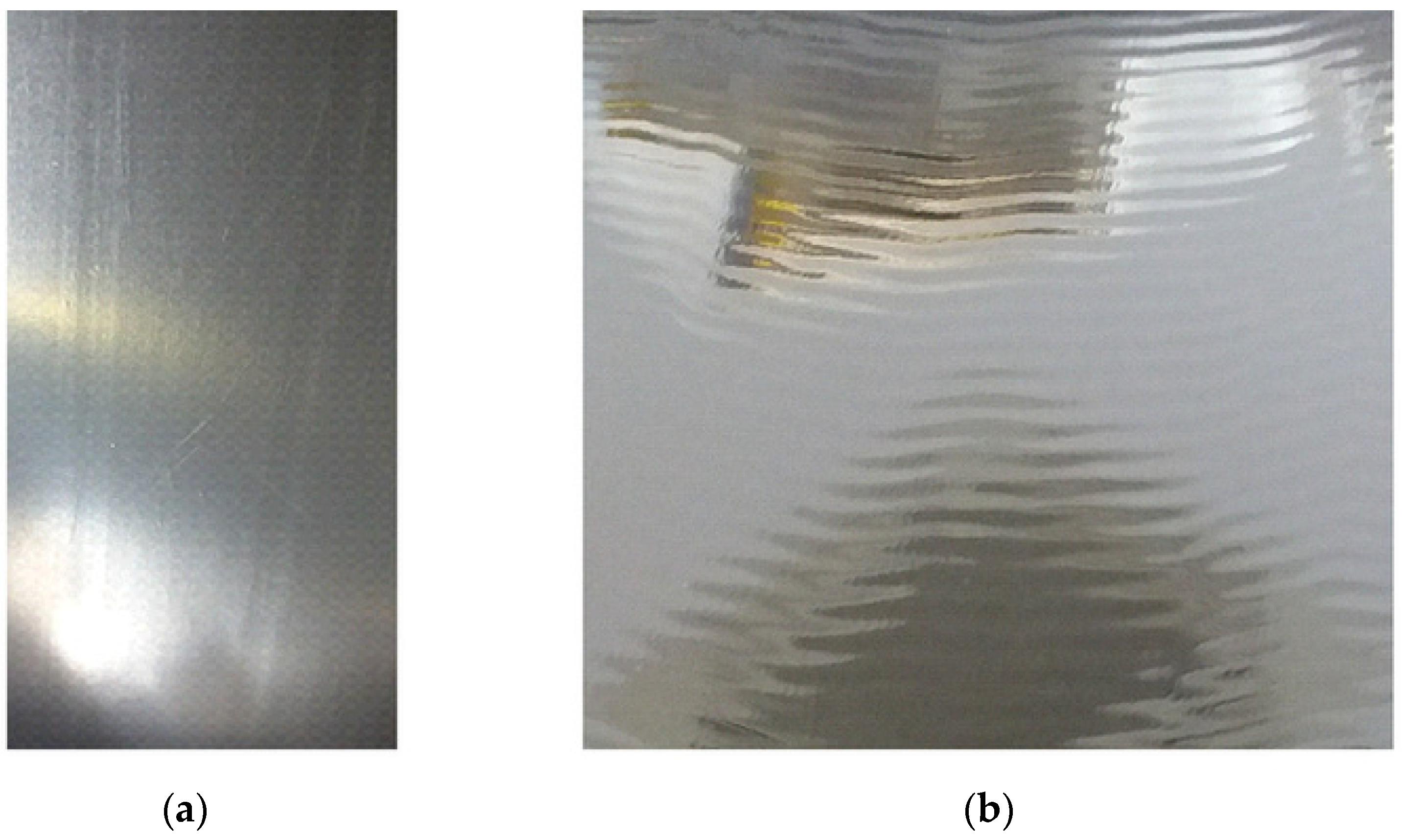

4. Technological Problems in the Production of Polyolefin-Based Multilayer Films

5. Additives and Modifiers of Casting Film

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An Overview of Plastic Waste Generation and Management in Food Packaging Industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2017, 3, 1. [Google Scholar] [CrossRef] [Green Version]

- Scarfato, P.; Di Maio, L.; Garofalo, E.; Incarnato, L. Three-layered coextruded cast films based on conventional and metallocene poly(ethylene/α-olefin) copolymers. J. Plast. Film Sheeting 2014, 30, 284–299. [Google Scholar] [CrossRef]

- Boone, J.; Lox, F.; Pottie, S. Deficiencies of polypropylene in its use as a food-packaging material—A review. Packag. Technol. Sci. 1993, 6, 277–281. [Google Scholar] [CrossRef]

- Karabegović, E.; Đuzelić, R. The Optimization of Thermoforming Process Parameters in the Packaging of Medical Products. Adv. Technol. Mater. 2019, 44, 21–24. [Google Scholar] [CrossRef]

- Dobrucka, R.; Przekop, R. New perspectives in active and intelligent food packaging. J. Food Process. Preserv. 2019, 43, e14194. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J.; Liu, X. Novel Functionalized BN Nanosheets/Epoxy Composites with Advanced Thermal Conductivity and Mechanical Properties. ACS Appl. Mater. Interfaces 2020, 12, 6503–6515. [Google Scholar] [CrossRef]

- Gond, R.K.; Gupta, M.K. Development and Characterization of PLA-Based Green Nanocomposite Films for Sustainable Packaging Applications. J. Nat. Fibers 2022, 19, 15738–15750. [Google Scholar] [CrossRef]

- Reichert, A.A.; Sá, M.R.; Castilhos de Freitas, T.; Barbosa, R.; Alves, T.S.; Backes, E.H.; Alano, J.H.; Oliveira, A.D. Barrier, Mechanical and Morphological Properties of Biodegradable Films Based on Corn Starch Incorporated with Cellulose Obtained from Pineapple Crowns. J. Nat. Fibers 2021, 19, 8541–8554. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, B.; Long, J.; Kuang, Y.; Chen, X.; Hou, M.; Gao, J.; Zhou, S.; Fan, B.; He, Y.; et al. Interfacial Laser-Induced Graphene Enabling High-Performance Liquid−Solid Triboelectric Nanogenerator. Adv. Mater. 2021, 33, 2104290. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—The Facts. 2021. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 30 November 2022).

- Schmidt, J.; Grau, L.; Auer, M.; Maletz, R.; Woidasky, J. Multilayer Packaging in a Circular Economy. Polymers 2022, 14, 1825. [Google Scholar] [CrossRef] [PubMed]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Kirchberger, M.; Jääskeläinen, P.; Gahleitner, M. Non-Oriented Polypropylene Film. EP001439957B1, 6 July 2005. pp. 1–9. [Google Scholar]

- Rytöluoto, I.; Niittymäki, M.; Seri, P.; Naderiallaf, H.; Lahti, K.; Saarimäki, E.; Flyktman, T.; Paajanen, M. Biaxially oriented silica–polypropylene nanocomposites for HVDC film capacitors: Morphology-dielectric property relationships, and critical evaluation of the current progress and limitations. J. Mater. Chem. A 2022, 10, 3025–3043. [Google Scholar] [CrossRef]

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Environmental impacts of polypropylene (PP) production and prospects of its recycling in the GCC region. Mater. Today Proc. 2022, 56, 2245–2251. [Google Scholar] [CrossRef]

- Horváth, Z.; Menyhárd, A.; Doshev, P.; Gahleitner, M.; Vörös, G.; Varga, J.; Pukánszky, B. Effect of the Molecular Structure of the Polymer and Nucleation on the Optical Properties of Polypropylene Homo- and Copolymers. ACS Appl. Mater. Interfaces 2014, 6, 7456–7463. [Google Scholar] [CrossRef] [Green Version]

- Manjula, B.; Reddy, A.B.; Sadiku, E.R.; Sivanjineyulu, V.; Molelekwa, G.F.; Jayaramudu, J.; Raj Kumar, K. Use of Polyolefins in Hygienic Applications. In Polyolefin Fibres; Elsevier: Amsterdam, The Netherlands, 2017; pp. 539–560. [Google Scholar]

- Kupolati, W.K.; Sadiku, E.R.; Ibrahim, I.D.; Adeboje, A.O.; Kambole, C.; Ojo, O.O.S.; Eze, A.A.; Paige-Green, P.; Ndambuki, J.M. The use of polyolefins in geotextiles and engineering applications. In Polyolefin Fibres; Elsevier: Amsterdam, The Netherlands, 2017; pp. 497–516. [Google Scholar]

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef]

- Bauer, A.-S.; Tacker, M.; Uysal-Unalan, I.; Cruz, R.M.S.; Varzakas, T.; Krauter, V. Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review. Foods 2021, 10, 2702. [Google Scholar] [CrossRef]

- Chikhalikar, K.; Banik, S.; Azad, L.B.; Jadhav, K.; Mahajan, S.; Ahmad, Z.; Kulkarni, S.; Gupta, S.; Doshi, P.; Pol, H.; et al. Extrusion film casting of long chain branched polypropylene. Polym. Eng. Sci. 2015, 55, 1977–1987. [Google Scholar] [CrossRef]

- Di Sacco, F.; Gahleitner, M.; Wang, J.; Portale, G. Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion. Polymers 2020, 12, 1636. [Google Scholar] [CrossRef]

- Cabrera, G.; Li, J.; Maazouz, A.; Lamnawar, K. A Journey from Processing to Recycling of Multilayer Waste Films: A Review of Main Challenges and Prospects. Polymers 2022, 14, 2319. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Nguyen, H.-L.; Tran, T.H.; Hao, L.T.; Jeon, H.; Koo, J.M.; Shin, G.; Hwang, D.S.; Hwang, S.Y.; Park, J.; Oh, D.X. Biorenewable, transparent, and oxygen/moisture barrier nanocellulose/nanochitin-based coating on polypropylene for food packaging applications. Carbohydr. Polym. 2021, 271, 118421. [Google Scholar] [CrossRef] [PubMed]

- Resch, K.; Wallner, G.M.; Teichert, C.; Maier, G.; Gahleitner, M. Optical properties of highly transparent polypropylene cast films: Influence of material structure, additives, and processing conditions. Polym. Eng. Sci. 2006, 46, 520–531. [Google Scholar] [CrossRef]

- Ponting, M.; Burt, T.M.; Korley, L.T.J.; Andrews, J.; Hiltner, A.; Baer, E. Gradient Multilayer Films by Forced Assembly Coextrusion. Ind. Eng. Chem. Res. 2010, 49, 12111–12118. [Google Scholar] [CrossRef]

- Yang, Y.-H.; Haile, M.; Park, Y.T.; Malek, F.A.; Grunlan, J.C. Super Gas Barrier of All-Polymer Multilayer Thin Films. Macromolecules 2011, 44, 1450–1459. [Google Scholar] [CrossRef]

- Butler, T.I.; Morris, B.A. PE-Based Multilayer Film Structures. In Multilayer Flexible Packaging, 2nd ed.; John, R., Wagner, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780323371001. [Google Scholar]

- Morris, B. The Science and Technology of Flexible Packaging: Multilayer Films from Resin and Process to End Use; Andrew, W., Ed.; Elsevier: Norwich, UK, 2017; ISBN 978-0-323-24273-8. [Google Scholar]

- Wang, Q.; Chen, W.; Zhu, W.; McClements, D.J.; Liu, X.; Liu, F. A review of multilayer and composite films and coatings for active biodegradable packaging. NPJ Sci. Food 2022, 6, 18. [Google Scholar] [CrossRef]

- Tihminlioglu, F.; Atik, İ.D.; Özen, B. Water vapor and oxygen-barrier performance of corn–zein coated polypropylene films. J. Food Eng. 2010, 96, 342–347. [Google Scholar] [CrossRef] [Green Version]

- Gaston, F.; Dupuy, N.; Marque, S.R.A.; Barbaroux, M.; Dorey, S. One year monitoring by FTIR of γ-irradiated multilayer film PE/EVOH/PE. Radiat. Phys. Chem. 2016, 125, 115–121. [Google Scholar] [CrossRef]

- Alipour, N.; Gedde, U.W.; Hedenqvist, M.S.; Yu, S.; Roth, S.; Brüning, K.; Vieyres, A.; Schneider, K. Structure and properties of polyethylene-based and EVOH-based multilayered films with layer thicknesses of 150 nm and greater. Eur. Polym. J. 2015, 64, 36–51. [Google Scholar] [CrossRef]

- Alizadeh Sani, M.; Maleki, M.; Eghbaljoo-Gharehgheshlaghi, H.; Khezerlou, A.; Mohammadian, E.; Liu, Q.; Jafari, S.M. Titanium dioxide nanoparticles as multifunctional surface-active materials for smart/active nanocomposite packaging films. Adv. Colloid Interface Sci. 2022, 300, 102593. [Google Scholar] [CrossRef]

- Huang, J.-Y.; Chieng, Y.Y.; Li, X.; Zhou, W. Experimental and Mathematical Assessment of Migration from Multilayer Food Packaging Containing a Novel Clay/Polymer Nanocomposite. Food Bioprocess Technol. 2015, 8, 382–393. [Google Scholar] [CrossRef]

- Dole, P.; Voulzatis, Y.; Vitrac, O.; Reynier, A.; Hankemeier, T.; Aucejo, S.; Feigenbaum, A. Modelling of migration from multi-layers and functional barriers: Estimation of parameters. Food Addit. Contam. 2006, 23, 1038–1052. [Google Scholar] [CrossRef] [PubMed]

- Paul, M.; Morris, B.; Weinhold, J.; Hausmann, K. The effect of stretching and tie layer composition on adhesion strength of multi-layered films. J. Plast. Film Sheeting 2022, 38, 351–368. [Google Scholar] [CrossRef]

- Ghazaryan, G.; Hausmann, K.; Tervoort, T.A. Influence of solid-state biaxial orientation on the adhesion between poly(ethylene terephthalate)/tie layer/isotactic polypropylene multilayer films. J. Polym. Sci. 2020, 58, 446–454. [Google Scholar] [CrossRef]

- Anukiruthika, T.; Sethupathy, P.; Wilson, A.; Kashampur, K.; Moses, J.A.; Anandharamakrishnan, C. Multilayer packaging: Advances in preparation techniques and emerging food applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1156–1186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soares, C.T.; De, M.; Ek, M.; Östmark, E.; Gällstedt, M.; Karlsson, S. Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios. Resour. Conserv. Recycl. 2022, 176, 105905. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Del Nobile, M.A. A simple model to predict the oxygen transport properties of multilayer films. J. Food Eng. 2011, 102, 170–176. [Google Scholar] [CrossRef]

- Lazić, V.L.; Budinski-Simendić, J.; Gvozdenović, J.J.; Simendić, B. Barrier properties of coated and laminated polyolefin films for food packaging. Acta Phys. Pol. A 2010, 117, 855–858. [Google Scholar] [CrossRef]

- Mueller, K.; Schoenweitz, C.; Langowski, H.-C. Thin Laminate Films for Barrier Packaging Application—Influence of Down Gauging and Substrate Surface Properties on the Permeation Properties. Packag. Technol. Sci. 2012, 25, 137–148. [Google Scholar] [CrossRef]

- Zabihzadeh Khajavi, M.; Ebrahimi, A.; Yousefi, M.; Ahmadi, S.; Farhoodi, M.; Mirza Alizadeh, A.; Taslikh, M. Strategies for Producing Improved Oxygen Barrier Materials Appropriate for the Food Packaging Sector. Food Eng. Rev. 2020, 12, 346–363. [Google Scholar] [CrossRef]

- Barlow, C.Y.; Morgan, D.C. Polymer film packaging for food: An environmental assessment. Resour. Conserv. Recycl. 2013, 78, 74–80. [Google Scholar] [CrossRef]

- Langowski, H.-C. Permeation of Gases and Condensable Substances through Monolayer and Multilayer Structures. In Plastic Packaging; Wiley-VCH: Weinheim, Germany, 2008; pp. 297–347. [Google Scholar]

- Polymer Database. Multilayer Films (Flexible Packaging Materials). 2015. Available online: https://www.polymerdatabase.com/Films/MultilayerFilms.html (accessed on 30 November 2022).

- Schmid, M.; Dallmann, K.; Bugnicourt, E.; Cordoni, D.; Wild, F.; Lazzeri, A.; Noller, K. Properties of Whey-Protein-Coated Films and Laminates as Novel Recyclable Food Packaging Materials with Excellent Barrier Properties. Int. J. Polym. Sci. 2012, 2012, 562381. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.-I.; Krochta, J.M. Oxygen barrier performance of whey-protein-coated plastic films as affected by temperature, relative humidity, base film and protein type. J. Food Eng. 2006, 77, 739–745. [Google Scholar] [CrossRef]

- Maes, C.; Luyten, W.; Herremans, G.; Peeters, R.; Carleer, R.; Buntinx, M. Recent Updates on the Barrier Properties of Ethylene Vinyl Alcohol Copolymer (EVOH): A Review. Polym. Rev. 2018, 58, 209–246. [Google Scholar] [CrossRef] [Green Version]

- Lagarón, J.M.; Giménez, E.; Altava, B.; Del-Valle, V.; Gavara, R. Characterization of extruded ethylene-vinyl alcohol copolymer based barrier blends with interest in food packaging applications. Macromol. Symp. 2003, 198, 473–482. [Google Scholar] [CrossRef]

- Kim, S.W.; Choi, H.M. Enhancement of thermal, mechanical, and barrier properties of ethylene vinyl alcohol copolymer by incorporation of graphene nanosheets. High Perform. Polym. 2015, 27, 694–704. [Google Scholar] [CrossRef]

- Ali Dadfar, S.M.; Alemzadeh, I.; Reza Dadfar, S.M.; Vosoughi, M. Studies on the oxygen barrier and mechanical properties of low density polyethylene/organoclay nanocomposite films in the presence of ethylene vinyl acetate copolymer as a new type of compatibilizer. Mater. Des. 2011, 32, 1806–1813. [Google Scholar] [CrossRef]

- Dorey, S.; Gaston, F.; Girard-Perier, N.; Dupuy, N.; Marque, S.R.A.; Delaunay, L. Generation of O 2 -Permeation Barrier during the Gamma-Irradiation of Polyethylene/Ethylene-Vinyl Alcohol/Polyethylene Multilayer Film. Ind. Eng. Chem. Res. 2019, 58, 14115–14123. [Google Scholar] [CrossRef]

- Zhang, G.; Lee, P.C.; Jenkins, S.; Dooley, J.; Baer, E. The effect of confined spherulite morphology of high-density polyethylene and polypropylene on their gas barrier properties in multilayered film systems. Polymer 2014, 55, 4521–4530. [Google Scholar] [CrossRef]

- Decker, J.J.; Meyers, K.P.; Paul, D.R.; Schiraldi, D.A.; Hiltner, A.; Nazarenko, S. Polyethylene-based nanocomposites containing organoclay: A new approach to enhance gas barrier via multilayer coextrusion and interdiffusion. Polymer 2015, 61, 42–54. [Google Scholar] [CrossRef]

- Sánchez-Valdes, S.; Ortega-Ortiz, H.; Ramos-de Valle, L.F.; Medellín-Rodríguez, F.J.; Guedea-Miranda, R. Mechanical and antimicrobial properties of multilayer films with a polyethylene/silver nanocomposite layer. J. Appl. Polym. Sci. 2008, 111, 953–962. [Google Scholar] [CrossRef]

- Ha, J.-U.; Kim, Y.-M.; Lee, D.-S. Multilayered antimicrobial polyethylene films applied to the packaging of ground beef. Packag. Technol. Sci. 2001, 14, 55–62. [Google Scholar] [CrossRef]

- Marcous, A.; Rasouli, S.; Ardestani, F. Inhibition of Staphylococcus aureus growth in fresh calf minced meat using low density Polyethylene films package promoted by titanium dioxide and zinc oxide nanoparticles. J. Part. Sci. Technol. 2017, 3, 1–11. [Google Scholar] [CrossRef]

- Simal-Gandara, J.; Sarria-Vidal, M.; Koorevaar, A.; Rijk, R. Tests of potential functional barriers for laminated multilayer food packages. Part I: Low molecular weight permeants. Food Addit. Contam. 2000, 17, 703–711. [Google Scholar] [CrossRef] [PubMed]

- Gholami, F.; Pakzad, L.; Behzadfar, E. Morphological, interfacial and rheological properties in multilayer polymers: A review. Polymer 2020, 208, 122950. [Google Scholar] [CrossRef]

- Vlachopoulos, J.; Strutt, D. Rheology of Molten Polymers. In Multilayer Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 77–96. [Google Scholar]

- Zhang, J.; Lodge, T.P.; Macosko, C.W. Interfacial slip reduces polymer-polymer adhesion during coextrusion. J. Rheol. 2006, 50, 41–57. [Google Scholar] [CrossRef] [Green Version]

- Jordan, A.M.; Lee, B.; Kim, K.; Ludtke, E.; Lhost, O.; Jaffer, S.A.; Bates, F.S.; Macosko, C.W. Rheology of polymer multilayers: Slip in shear, hardening in extension. J. Rheol. 2019, 63, 751–761. [Google Scholar] [CrossRef]

- Dhadwal, R.; Banik, S.; Doshi, P.; Pol, H. Effect of viscoelastic relaxation modes on stability of extrusion film casting process modeled using multi-mode Phan-Thien-Tanner constitutive equation. Appl. Math. Model. 2017, 47, 487–500. [Google Scholar] [CrossRef]

- Lin, Y.; Hiltner, A.; Baer, E. A new method for achieving nanoscale reinforcement of biaxially oriented polypropylene film. Polymer 2010, 51, 4218–4224. [Google Scholar] [CrossRef]

- Sadeghi, F.; Carreau, P.J. Properties of uniaxially stretched polypropylene films. Can. J. Chem. Eng. 2008, 86, 1103–1110. [Google Scholar] [CrossRef]

- Khariwala, D.; Ling, M.; Hiltner, A.; Baer, E. Effect of the tie-layer thickness on the delamination and tensile properties of polypropylene/tie-layer/nylon 6 multilayers. J. Appl. Polym. Sci. 2011, 121, 1999–2012. [Google Scholar] [CrossRef]

- Agassant, J.F.; Demay, Y.; Sollogoub, C.; Silagy, D. Cast Film Extrusion. Int. Polym. Process. 2005, 20, 136–148. [Google Scholar] [CrossRef]

- Anderson, P.D.; Dooley, J.; Meijer, H.E.H. Viscoelastic Effects in Multilayer Polymer Extrusion. Appl. Rheol. 2006, 16, 198–205. [Google Scholar] [CrossRef]

- Langhe, D.; Ponting, M. Manufacturing and Novel Applications of Multilayer Polymer Films; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780323371254. [Google Scholar]

- Mount, E.M. Coextrusion Equipment for Multilayer Flat Films and Sheets; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780323371001. [Google Scholar]

- Kostic, M.M.; Reifschneider, L.G. Extrusion Die Design. Encycl. Chem. Process. 2006, 10, 633–649. [Google Scholar] [CrossRef]

- Wagner, J.R. Blown Film, Cast Film, and Lamination Processes; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780323371001. [Google Scholar]

- Calhoun, A. Polypropylene. In Multilayer Flex. Packaging, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 35–45. [Google Scholar] [CrossRef]

- Pielichowski, K.; Njuguna, J. Thermal Degradation of Polymeric Materials; Rapra Technology: Shrewsbury, UK, 2005; ISBN 1-85957-498-X. [Google Scholar]

- Ponting, M.; Hiltner, A.; Baer, E. Polymer Nanostructures by Forced Assembly: Process, Structure, and Properties. Macromol. Symp. 2010, 294, 19–32. [Google Scholar] [CrossRef]

- Li, Z.; Olah, A.; Baer, E. Micro- and nano-layered processing of new polymeric systems. Prog. Polym. Sci. 2020, 102, 101210. [Google Scholar] [CrossRef]

- Khan, J.G.; Dalu, R.S.; Gadekar, S. Defects in Extrusion Process and Their. Int. J. Mech. Eng. Robot. Res. 2014, 3, 187. [Google Scholar]

- Lamberti, G.; Titomanlio, G. Width distribution along draw direction in the film casting process. In Proceedings of the In Proceedings of the International Polymer Processing Society 15th Annual Meeting (PPS-15), Hertogenbosch, The Netherlands, 31 May–4 June 1999. [Google Scholar]

- Canning, K.; Co, A. Edge effects in film casting of molten polymers. J. Plast. Film. Sheeting 2000, 16, 188–203. [Google Scholar] [CrossRef]

- Lithner, D.; Larsson, Å.; Dave, G. Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Sci. Total Environ. 2011, 409, 3309–3324. [Google Scholar] [CrossRef]

- Walker, T.W.; Frelka, N.; Shen, Z.; Chew, A.K.; Banick, J.; Grey, S.; Kim, M.S.; Dumesic, J.A.; Van Lehn, R.C.; Huber, G.W. Recycling of multilayer plastic packaging materials by solvent-targeted recovery and precipitation. Sci. Adv. 2020, 6, eaba7599. [Google Scholar] [CrossRef]

- Caner, C.; Harte, B. Effect of high-pressure processing on the migration of antioxidant Irganox 1076 from polypropylene film into a food simulant. J. Sci. Food Agric. 2005, 85, 39–46. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, D.; Wadsworth, L.C. Corona treatment of polyolefin films—A review. Adv. Polym. Technol. 1999, 18, 171–180. [Google Scholar] [CrossRef]

- Botkin, J.H. The stabilization of polypropylene & TPO: An overview. In Proceedings of the Society of Plastics Engineers 14th Annual SPE TPO Automotive Engineered Polyolefins Conference, Detroit, MI, USA, 1–3 October 2012. [Google Scholar]

- Bensaad, F.; Belhaneche-Bensemra, N. Effects of calcium stearate as pro-oxidant agent on the natural aging of polypropylene. J. Polym. Eng. 2018, 38, 715–721. [Google Scholar] [CrossRef]

- Mandal, D.K.; Bhunia, H.; Bajpai, P.K.; Kumar, A.; Madhu, G.; Nando, G.B. Biodegradation of Pro-oxidant Filled Polypropylene Films and Evaluation of the Ecotoxicological Impact. J. Polym. Environ. 2018, 26, 1061–1071. [Google Scholar] [CrossRef]

- Khelassi, A.; Belhaneche-Bensemra, N. Investigation of pro-oxidant agents’ effects on the ageing of polypropylene bags. Int. J. Environ. Stud. 2020, 77, 264–274. [Google Scholar] [CrossRef]

- Zatloukal, M.; De Witte, J.; Lavallée, C.; Saha, P. Investigation of PPA interactions with polymer melts in single layer extrusion and coextrusion flows. Plast. Rubber Compos. 2007, 36, 248–253. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Antiblocking, Release, and Slip Additives; Elsevier: North York, ON, Canada, 2021; ISBN 978-1-927885-77-2. [Google Scholar]

- Chen, J.; Li, J.; Hu, T.; Walther, B. Fundamental study of erucamide used as a slip agent. J. Vac. Sci. Technol. A Vac. Surf. Film. 2007, 25, 886–892. [Google Scholar] [CrossRef]

- Liauw, C.M.; Childs, A.; Allen, N.S.; Edge, M.; Franklin, K.R.; Collopy, D.G. Effect of interactions between stabilisers and silica used for anti-blocking applications on UV and thermal stability of polyolefin film. 2. Degradation studies. Polym. Degrad. Stab. 1999, 65, 207–215. [Google Scholar] [CrossRef]

- Zilles, J.U. Anti-block Additives. In Polymers and Polymeric Composites: A Reference Series; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–13. [Google Scholar]

- Quijada-Garrido, I.; Barrales-Rienda, J.M.; Espinoza, L.A.; Fierro, J.L.G. Desorption of Erucamide Vapor in Vacuum from Erucamide/Isotactic Polypropylene Films. Macromolecules 1996, 29, 8791–8797. [Google Scholar] [CrossRef]

- Wakabayashi, M.; Kohno, T.; Tanaka, Y.; Kanai, T. Study on the Bleeding Mechanism of Slip Agents in a Polypropylene Film using Molecular Dynamics. Int. Polym. Process. 2009, 24, 133–139. [Google Scholar] [CrossRef] [Green Version]

- Crosby, C.R.; Chatterjee, A.M. Effect of Formulation Parameters on Optical and Frictional Properties of Tubular Water Quenched Polypropylene Films. J. Plast. Film Sheeting 2001, 17, 128–151. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Moretto, H.-H.; Schulze, M.; Wagner, G. Silicones. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2000. [Google Scholar]

- Yilgor, E.; Yilgor, I.; Suzer, S. Modification of polyolefins with silicone copolymers. I. Processing behavior and surface characterization of PP and HDPE blended with silicone copolymers. J. Appl. Polym. Sci. 2002, 83, 1625–1634. [Google Scholar] [CrossRef] [Green Version]

- Van Essche, G.; Kromminga, T.; Schmidt, A. New highly efficient silica anti-blocking aids for PE and PP films. J. Plast. Film Sheeting 2000, 16, 155–168. [Google Scholar] [CrossRef]

- Lawrence Industries. SPHERILEX®—Next Generation Antiblocking Agents for Polymer Films. 2021. Available online: https://www.l-i.co.uk/blog/blog-archive/spherilex-antiblocking-agents-polymer-films (accessed on 30 November 2022).

- Espinosa, K.; Castillo, L.A.; Barbosa, S.E. Polypropylene/Talc Nanocomposites Films as Low-Cost Barrier Materials for Food Packaging. In Food Packaging; Elsevier: Amsterdam, The Netherlands, 2017; pp. 603–636. [Google Scholar]

- Espinosa, K.R.; Castillo, L.A.; Barbosa, S.E. Blown nanocomposite films from polypropylene and talc. Influence of talc nanoparticles on biaxial properties. Mater. Des. 2016, 111, 25–35. [Google Scholar] [CrossRef]

- Świetlicki, M.; Chocyk, D.; Klepka, T.; Prószyński, A.; Kwaśniewska, A.; Borc, J.; Gładyszewski, G. The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions. Materials 2020, 13, 698. [Google Scholar] [CrossRef] [Green Version]

- AMPACET. Antioxidant Masterbatch for Polymer Stabilization. 2022. Available online: https://www.ampacet.com/faqs/use-of-antioxidant-masterbatch/ (accessed on 20 December 2022).

| Property | Moplen EP310D | PPH 6080 | Borealis RD364CF | Braskem RP 225M |

|---|---|---|---|---|

| Melt flow index (230 °C/2, 16 kg), [g/10 min] | 0.95 | 9.0 | 8.0 | 8.0 |

| Vicat softening point (VST/B, 50N), [°C] | 150 | 152 | 138 | 134 |

| Film Tensile Strength at Yield, ISO 527-3, D 882, [MPa] | ||||

| -MD | 16.0 | 23.0 | 40.0 | 20.0 |

| -TD | 16.0 | 23.0 | 30.0 | 19.0 |

| Type | impact copolymer | homopolymer | random copolymer | random copolymer |

| Application | cast film extrusion | blown film | cast film extrusion | blown, cast film extrusion |

| Property | Malen E FGNX 23-D022 | Sabic 6318B LLDPE | Borealis FT7230 | Braskem EB 853 LDPE |

|---|---|---|---|---|

| Melt flow index (190 °C/2, 16 kg), [g/10 min] | 1.95 | 2.8 | 4.0 | 2.7 |

| Vicat softening point (VST/B, 50N), [°C] | 90 | 99 | 91 | 89 |

| Film Tensile Strength at Yield ISO 527-1, 3, [MPa] | ||||

| -MD | 20.0 | 13.0 | 20.0 | 27.0 |

| -TD | 19.0 | 10.0 | 18.0 | 20.0 |

| Type | low density polyethylene | hexene copolymer linear low density polyethylen | low density polyethylene | low density polyethylene |

| Application | cast film extrusion | cast film extrusion | blown film extrusion | blown film extrusion |

| Structure | Composition [%] | Number of Layer | Function | Application |

|---|---|---|---|---|

| PP/PP/PP | 15/70/15 | 3 | non-barrier | Bags |

| LDPE/LDPE/LDPE/ LDPE/LDPE | 26/15/16/15/28 | 5 | non-barrier | Bags |

| LDPE/Tie/EVOH/Tie/LDPE | 30/12/10/8/40 | 5 | barrier | Meat Bags |

| LLDPE/HDPE/Tie/EVOH/Tie/HDPE/LLDPE | 20/20/5/10/5/20/20 | 7 | barrier | Meat Bags |

| Technological Problem | Solution Method |

|---|---|

| Scratches | Rolls not turning: Check the roll speed and adjust accordingly Check the balance |

| Low MD Elongation | Extrusion temperature: Increase extrusion temperature |

| Layers delamination | Use the resin with a similar MFR |

| Low MD Tear Strength | Use a resin with a lower density Increase the chill roll temperature Decrease the extrusion temperature |

| Low Stiffness | Use a resin with a higher density Increase the chill roll temperature |

| Name/Producer | Type | Function |

|---|---|---|

| Tospearl™ 145FL (Momentive, United States) | 4.5-micron silicone resin | anti-blocking agent |

| SPHERILEX 30 AB (Evonik, Germany) | precipitated amorphous silica | anti-blocking agent improved moisture vapor barriers |

| Constab AB 06001 PP (Kafrit Group, Germany) | 10% synthetic silica (5 µm) in homopolymer | anti-blocking masterbatches |

| CALCIPORE® 80T AL. (Reverte, Spain) | ultramicronized, treated calcium carbonate | anti-blocking agent, production of breathable film |

| Crodamide™ ER (Croda, United Kingdom) | erucamide | slip and anti-blocking agent |

| Chemstat® HTSA #18–20M (PCC, Germany) | oleyl palmitamide | slip and anti-block, antistatic, mold release |

| Dynamar™ FX 5911X (3M, United States) | fluoropolymer | reduced die lip build-up, better gauge control |

| Ionphase™ fSTAT (Croda, United Kingdom) | proprietary | anti-static additive |

| Linanox 1010 (Linchemical, China) | phenolic antioxidant | antioxidant |

| ThermProtect 1001265-N (Ampacet, United States) | phenolic and phosphite antioxidents | antioxidant |

| Linsorb 236 (Linchemical, China) | benzotriazole | UV absorber |

| SABOSTAB® UV 81 (SABO S.p.A., Italy) | benzophenones | UV absorber |

| SABOSTAB® UV 94 (SABO S.p.A., Italy) | hindered amine light stabilizer | UV light stabilizers |

| LOWILITE™ GR 6294 (SI Group, United States) | hindered amine light stabilizer | UV light stabilizers |

| Ampacet Antifog (Ampacet, United States) | masterbatches | anti-fog additives |

| Atmer™ 110 (Croda, United Kingdom) | ethoxylated sorbitan ester | anti-fog additives |

| Plexar PX2600 (LyondellBasell, Netherlands) | chemically modified resins | tie-layer adhesive |

| AFFINITYTM KC8852G (DOW, United States) | ethylene-octene copolymer | polyolefin plastomer |

| ZELAS™ R-TPO (Mitsubishi Chemical Corporation, Japan) | olefin-based thermoplastic elastomer | polyolefin elastomer |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziadowiec, D.; Matykiewicz, D.; Szostak, M.; Andrzejewski, J. Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications. Materials 2023, 16, 1071. https://doi.org/10.3390/ma16031071

Dziadowiec D, Matykiewicz D, Szostak M, Andrzejewski J. Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications. Materials. 2023; 16(3):1071. https://doi.org/10.3390/ma16031071

Chicago/Turabian StyleDziadowiec, Damian, Danuta Matykiewicz, Marek Szostak, and Jacek Andrzejewski. 2023. "Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications" Materials 16, no. 3: 1071. https://doi.org/10.3390/ma16031071

APA StyleDziadowiec, D., Matykiewicz, D., Szostak, M., & Andrzejewski, J. (2023). Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications. Materials, 16(3), 1071. https://doi.org/10.3390/ma16031071