Ongoing Challenges of Laser-Based Powder Bed Fusion Processing of Al Alloys and Potential Solutions from the Literature—A Review

Abstract

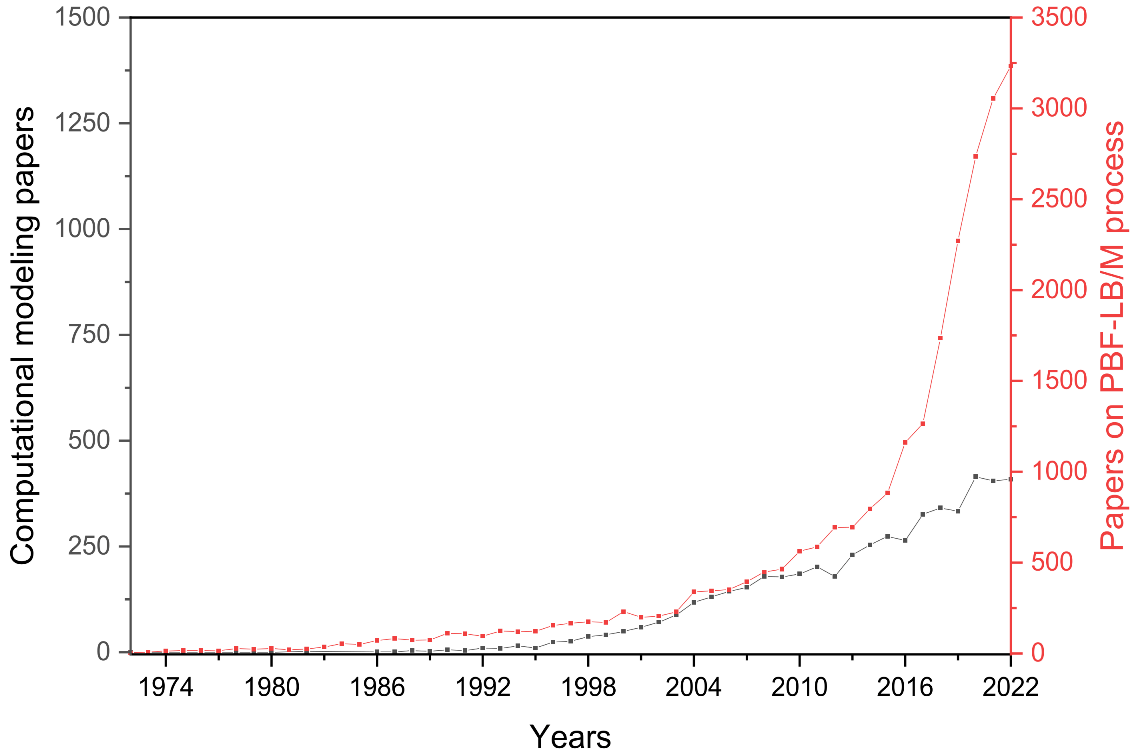

1. Introduction

- The predictions of solidification behaviour, microstructural features and mechanical performances;

- The procedures concerning powder characterisation and the effects of reuse on powder properties;

- The process parameter optimisation and defect prediction methods.

- Consolidation phenomena;

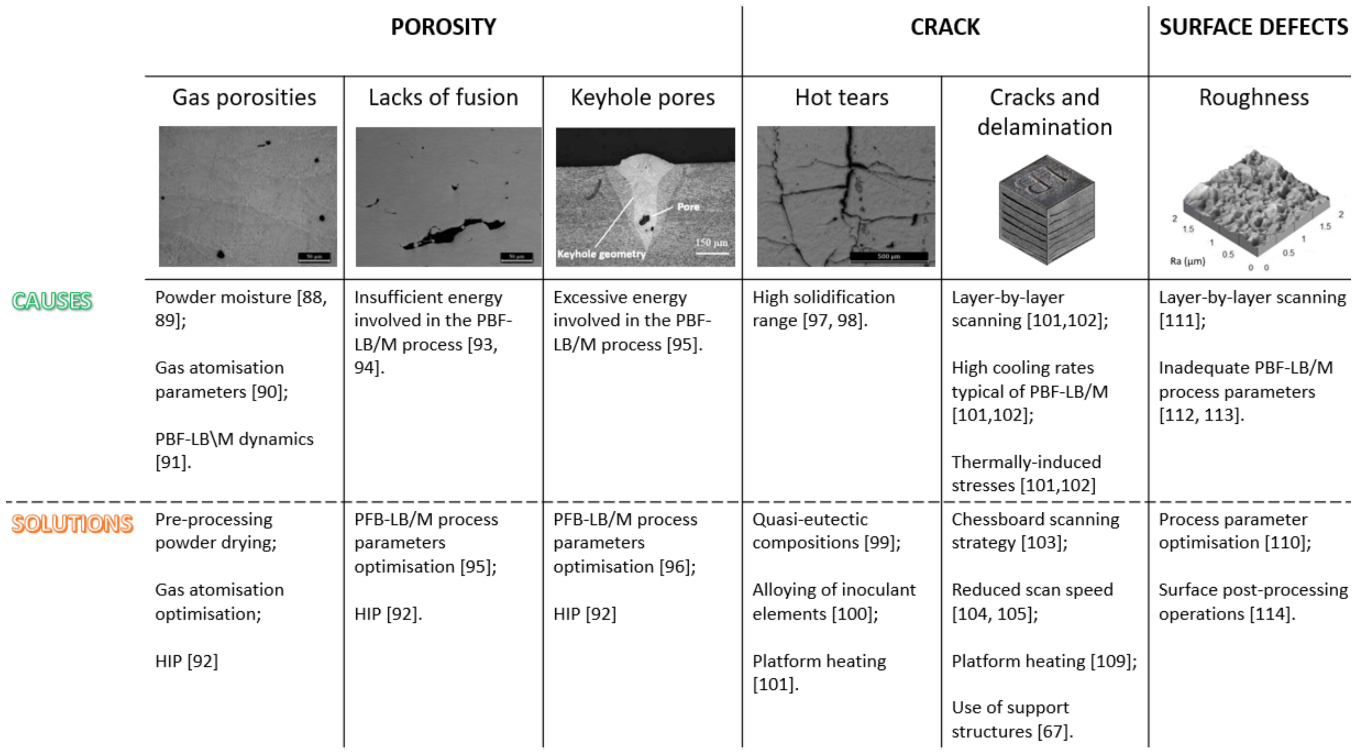

- Defect formation mechanisms and defect mitigation approaches;

- Application of machine learning for in-situ process optimisation.

- Approaches for defect investigation;

- Post-processing procedure for defect mitigation;

- Heat treatments;

- Surface post-treatments.

2. Pre-Processing

2.1. Deep Insight into Developing Novel Compositions Tailored for PBF-LB/M

- Thermophysical data availability

- Selection of solidification models suitable for the PBF-LB/M process

- Reliability in predicting alloy processability and mechanical properties

2.2. Powder Characterisation in Virgin and Reused Conditions

2.3. Process Parameters Optimisation and Defect Prediction

3. During Processing

3.1. Consolidation Phenomena

3.2. Defects: Solutions to Their Mitigation and Unsolved Problems

3.3. In-Situ Prediction of Defect Formation and Forward-Looking Machine Learning

4. Post-Processing

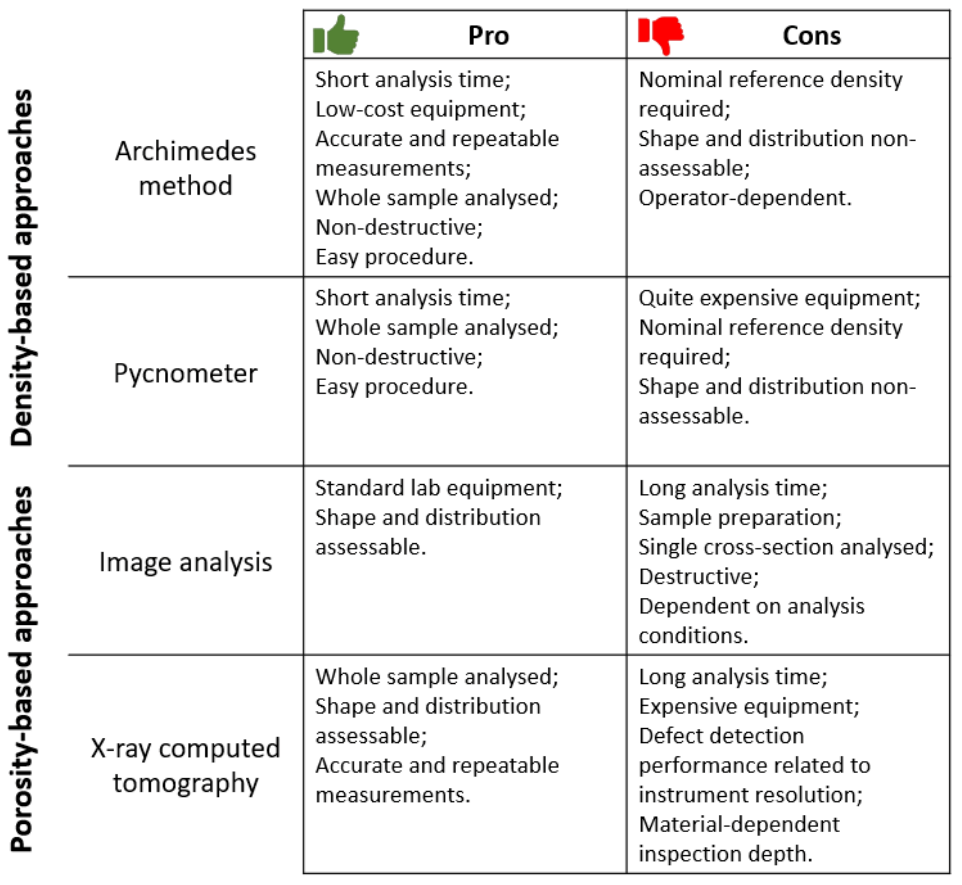

4.1. Defect Investigation in Bulk Samples

4.2. A Promising Post-Processing Procedure for Defect Mitigation

- The effect of HIP on fatigue behaviour of the final component

- Surface defect formation

- Pore opening and blistering effect after heat treatment

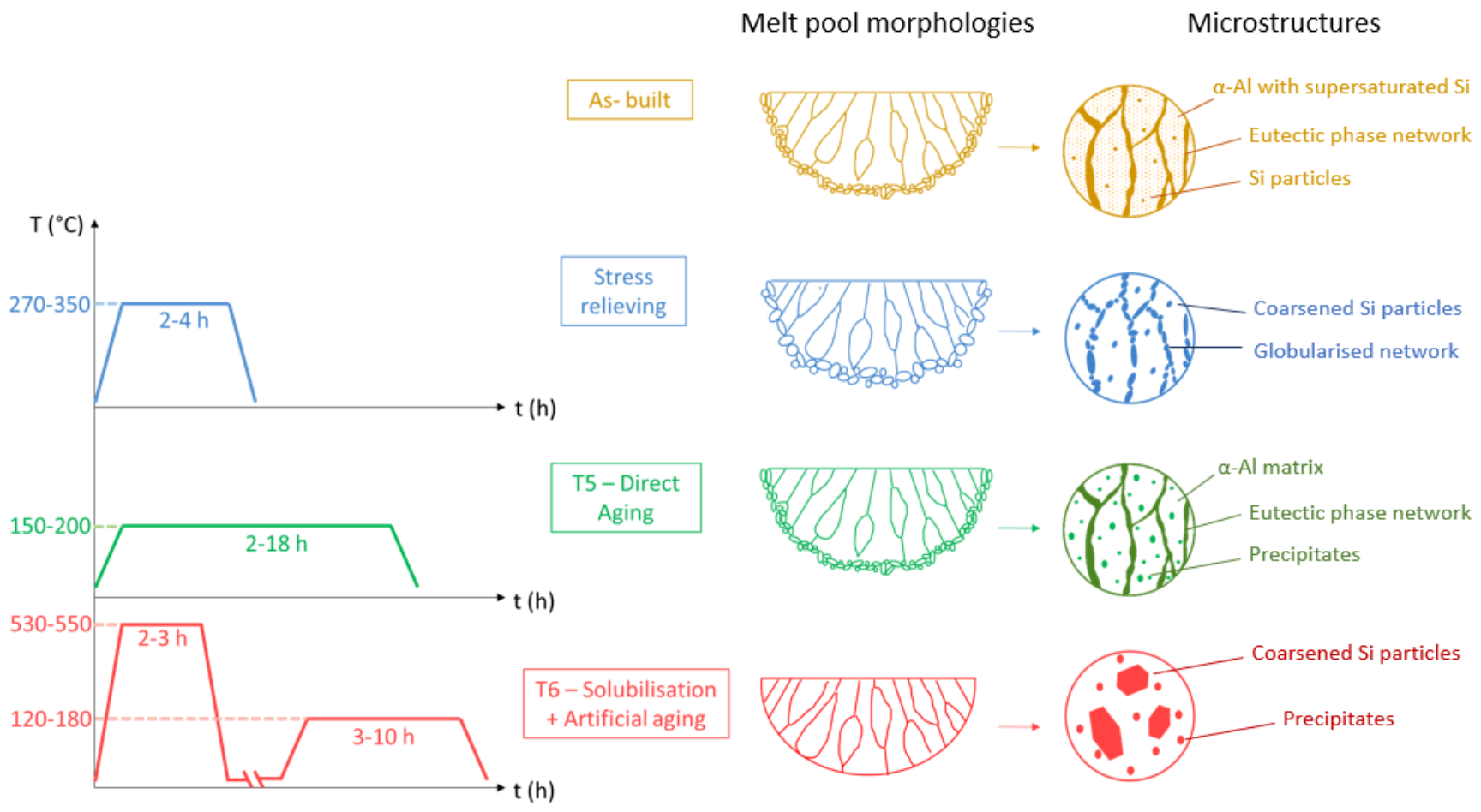

4.3. Heat Treatments

4.4. Surface Post-Treatments

- Material removal;

- No material removal;

- Coating;

- Hybrid treatments.

5. Conclusions

- (1)

- Design of novel compositions:

- (a)

- Developing of analytical and computational models to provide a time and cost-saving approach for designing and optimising alloy compositions;

- (b)

- The availability of the thermophysical data underlying the simulations;

- (c)

- The model selection for the simulation of solidification mechanisms in PBF-LB/M processes;

- (d)

- The transition from merely predicting the phases formed during the additive process to predicting their impact on the microstructure;

- (e)

- Reducing the high degree of uncertainty of these models in the prediction of processability and mechanical properties.

- (2)

- Powder characterisations:

- (a)

- The absence of a univocal standard for the characterisation of AM powders;

- (b)

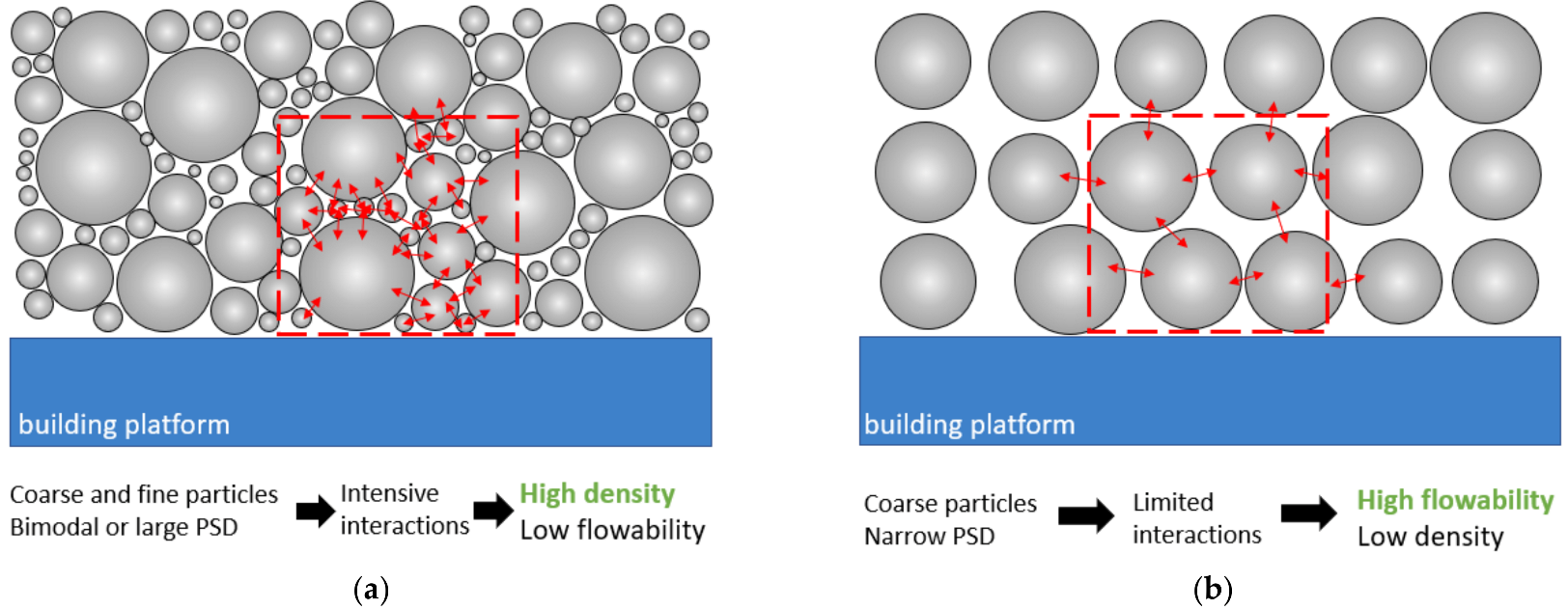

- Quantifying suitable PSD and powder morphology to ensure a proper trade-off between flowability and packing properties;

- (c)

- Studying and sharing the effect of atomisation parameters on powder properties;

- (d)

- Understanding the factors with the strongest influence on powder reuse to carry out repeatable and quantifiable studies.

- (3)

- Process parameters optimisation:

- (a)

- Implementing a univocal rule for calculating the optimum layer thickness considering the thermophysical properties, the characteristics of the powder and the PBF-LB/M machine features

- (1)

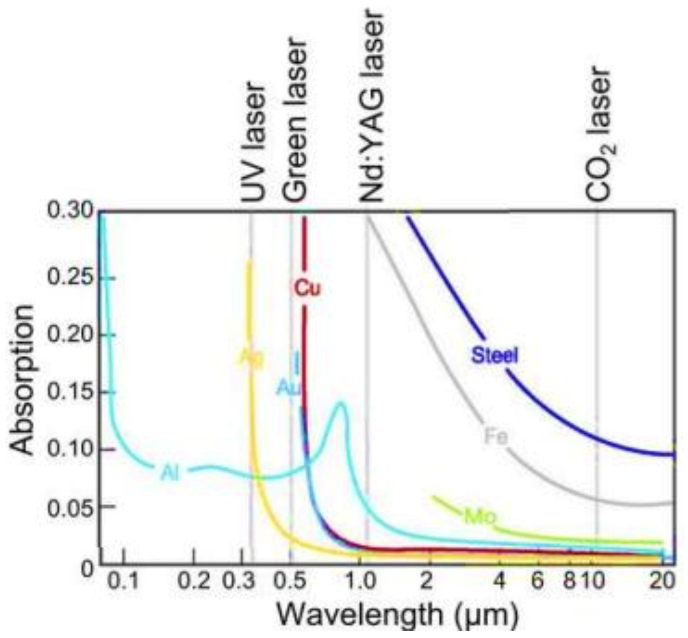

- The poor absorbance of powders at YAG laser wavelengths. This problem is usually overcome by using very high VEDs. However, a solution that is still rarely used in the literature but for which there are several industrial patents is the use of green lasers.

- (2)

- The generation of hot tears and/or cracks and delamination. These problems are often solved by acting on the chemical composition or some process conditions, such as using heated platforms or support structures.

- (3)

- The heterogeneous and anisotropic microstructure caused by the directional thermal flow and rapid cooling rates involved in the PBF-LB/M process. The microstructure anisotropy negatively affects the mechanical behaviour of the Al-based parts, especially if multi-axial loads are applied.

- (4)

- The formation of PBF-LB/M typical pores that may have a detrimental effect on the mechanical properties of the final component.

- (1)

- Defect investigation methodologies with their benefits and disadvantages.

- (2)

- Porosity closure techniques such as HIP. In particular, two HIP weaknesses were identified:

- (a)

- The possible breaking and opening of near-surface pores, leaving surface defects known as notches.

- (b)

- The opening of pores and the blister effect that can occur when heat treatments are performed after the HIP process.

- (3)

- The development of heat treatments that relieve residual stresses and decrease microstructural anisotropy without, however, deteriorating the typical microstructure of the PBF-LB/M process or drastically reducing the ductility of the samples.

- (4)

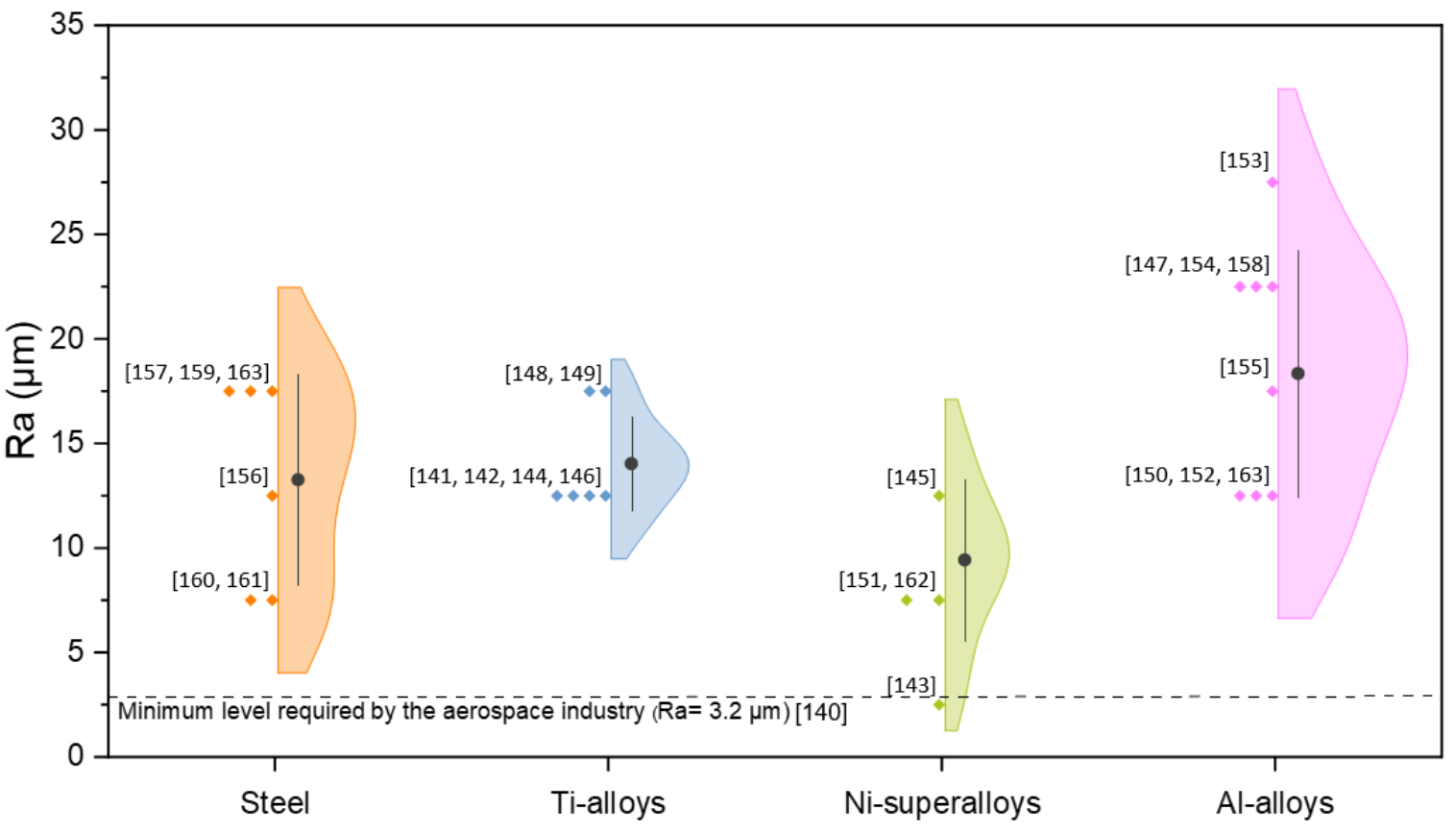

- Providing and designing surface treatments that make the sample roughness suitable for more restrictive applications, such as in the aerospace industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Avateffazeli, M.; CarRion, P.E.; Shachi-Amirkhiz, B.; Pirgazi, H.; Mohammadi, M.; Shamsaei, N.; Haghshenas, M. Correlation between tensile properties, microstructure, and processing routes of an Al-Cu-Mg-Ag-TiB2 (A205) alloy: Additive manufacturing and casting. Mater. Sci. Eng. A 2022, 841, 142989. [Google Scholar] [CrossRef]

- Debroy, T.; Mukherjee, T.; Milewski, J.O.; Elmer, J.W.; Ribic, B.; Blecher, J.J.; Zhang, W. Scientific, technological and economic issues in metal printing and their solutions. Nat. Mater. 2019, 18, 1026–1032. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Zhang, C.; Yu, Q. Stress intensity-dependent relation between overload plastic zone and fatigue retardation in Al-alloy. Theor. Appl. Fract. Mech. 2022, 121, 103520. [Google Scholar] [CrossRef]

- Rometsch, P.A.; Zhu, Y.; Wu, X.; Huang, A. Review of high-strength aluminium alloys for additive manufacturing by laser powder bed fusion. Mater. Des. 2022, 219, 110779. [Google Scholar] [CrossRef]

- Chi, Y.; Murali, N.; Liu, J.; Liese, M.; Li, X. Wire arc additive manufacturing (WAAM) of nanotreated aluminum alloy 6061. Rapid Prototyp. J. 2022. [Google Scholar] [CrossRef]

- Andersson, J.-O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Saunders, N.; Guo, U.K.Z.; Li, X.; Miodownik, A.P.; Schillé, J.-P. Using JMatPro to model materials properties and behavior. JOM 2003, 55, 60–65. [Google Scholar] [CrossRef]

- Drexler, A.; Oberwinkler, B.; Primig, S.; Turk, C.; Povoden-Karadeniz, E.; Heinemann, A.; Ecker, W.; Stockinger, M. Experimental and numerical investigations of the γ″ and γ′ precipitation kinetics in Alloy 718. Mater. Sci. Eng. A 2018, 723, 314–323. [Google Scholar]

- Chen, S.-L.; Daniel, S.; Zhang, F.; Chang, Y.A.; Yan, X.-Y.; Xie, F.-Y.; Schmid-Fetzer, R.; Oates, W.A. The PANDAT software package and its applications. Calphad 2002, 26, 175–188. [Google Scholar] [CrossRef]

- Sundman, B.; Kattner, U.R.; Palumbo, M.; Fries, S.G. OpenCalphad—A free thermodynamic software. Integr. Mater. Manuf. Innov. 2015, 4, 1–15. [Google Scholar] [CrossRef]

- Otis, R.; Liu, Z.-K. Pycalphad: CALPHAD-based Computational Thermodynamics in Python. J. Open Res. Softw. 2017, 5, 1. [Google Scholar] [CrossRef]

- Iida, R.G.T. The Thermophysical Properties of Metallic Liquids: Volume 1: Fundamentals; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- Mohr, M.; Wunderlich, R.; Novakovic, R.; Ricci, E.; Fecht, H.J. Precise Measurements of Thermophysical Properties of Liquid Ti–6Al–4V (Ti64) Alloy On Board the International Space Station. Adv. Eng. Mater. 2020, 22, 2000169. [Google Scholar] [CrossRef]

- Scaglione, F.; Arnaboldi, S.; Viscardi, C.; Baricco, M.; Palumbo, M. Solidification Calculations of Precious Alloys and Al-Base Alloys for Additive Manufacturing. Metals 2022, 12, 322. [Google Scholar] [CrossRef]

- Novakovic, R.; Giuranno, D.; Lee, J.; Mohr, M.; Delsante, S.; Borzone, G.; Miani, F.; Fecht, H.-J. Thermophysical Properties of Fe-Si and Cu-Pb Melts and Their Effects on Solidification Related Processes. Metals 2022, 12, 336. [Google Scholar] [CrossRef]

- Williamson, J.C. Liquid–Liquid Demonstrations: Phase Equilibria and the Lever Rule. J. Chem. Educ. 2021, 98, 2356–2363. [Google Scholar] [CrossRef]

- McKeown, J.T.; Kulovits, A.K.; Liu, C.; Zweiacker, K.; Reed, B.W.; LaGrange, T.; Wiezorek, J.M.; Campbell, G.H. In situ transmission electron microscopy of crystal growth-mode transitions during rapid solidification of a hypoeutectic Al–Cu alloy. Acta Mater. 2014, 65, 56–68. [Google Scholar] [CrossRef]

- Bocklund, B.; Bobbio, L.D.; Otis, R.A.; Beese, A.M.; Liu, Z.-K. Experimental validation of Scheil–Gulliver simulations for gradient path planning in additively manufactured functionally graded materials. Materialia 2020, 11, 100689. [Google Scholar] [CrossRef]

- Avazkonandeh-Gharavol, M.H.; Haddad-Sabzevar, M.; Fredriksson, H. Effect of partition coefficient on microsegregation during solidification of aluminium alloys. Int. J. Miner. Met. Mater. 2014, 21, 980–989. [Google Scholar] [CrossRef]

- Keller, T.; Lindwall, G.; Ghosh, S.; Ma, L.; Lane, B.M.; Zhang, F.; Kattner, U.R.; Lass, E.A.; Heigel, J.C.; Idell, Y.; et al. Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys. Acta Mater. 2017, 139, 244–253. [Google Scholar] [CrossRef]

- Thapliyal, S.; Mageshwari, K.; Shivakant, S.; Le, Z.; Holden, H.; Sharon, P.; Yongho, S.; Rajiv, S.M. An integrated computational materials engineering-anchored closed-loop method for design of aluminum alloys for additive manufacturing. Materialia 2020, 9, 100574. [Google Scholar] [CrossRef]

- Zhang, F.; Liang, S.; Zhang, C.; Chen, S.; Lv, D.; Cao, W.; Kou, S. Prediction of Cracking Susceptibility of Commercial Aluminum Alloys during Solidification. Metals 2021, 11, 1479. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, P.; Kou, S. Solidification cracking susceptibility of quaternary aluminium alloys. Sci. Technol. Weld. Join. 2021, 26, 244–257. [Google Scholar] [CrossRef]

- Sehhat, M.H.; Mahdianikhotbesara, A. Powder spreading in laser-powder bed fusion process. Granul. Matter 2021, 23, 1–18. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskeryb, I.; Ashcroftb, I.; Tuckb, C.; Everitt, N.M. The role of powder properties on the processability of Aluminium alloys in selective laser melting. In Proceedings of the Lasers in Manufacturing Conference 2015, München, Germany, 22–25 June 2015. [Google Scholar]

- Moghimian, P.; Poirié, T.; Habibnejad-Korayem, M.; Zavala, J.A.; Kroeger, J.; Marion, F.; Larouche, F. Metal powders in additive manufacturing: A review on reusability and recyclability of common titanium, nickel and aluminum alloys. Addit. Manuf. 2021, 43, 102017. [Google Scholar] [CrossRef]

- Olakanmi, E.O.T.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Vock, S.; Klöden, B.; Kirchner, A.; Weißgärber, T.; Kieback, B. Powders for powder bed fusion: A review. Prog. Addit. Manuf. 2019, 4, 383–397. [Google Scholar] [CrossRef]

- Parteli, E.J.; Pöschel, T. Particle-based simulation of powder application in additive manufacturing. Powder Technol. 2016, 288, 96–102. [Google Scholar] [CrossRef]

- Prescott, J.K.; Barnum, R.A. On powder flowability: Part I. Pharm. Technol. Eur. 2001, 13, 60–84. [Google Scholar]

- Schulze, D. Powders and Bulk Solids. In Behavior, Characterization, Storage and Flow; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar] [CrossRef]

- Zhao, Y.; Cui, Y.; Hasebe, Y.; Bian, H.; Yamanaka, K.; Aoyagi, K.; Hagisawa, T.; Chiba, A. Controlling factors determining flowability of powders for additive manufacturing: A combined experimental and simulation study. Powder Technol. 2021, 393, 482–493. [Google Scholar] [CrossRef]

- Habibnejad-Korayem, M.; Zhang, J.; Zou, Y. Effect of particle size distribution on the flowability of plasma atomized Ti-6Al-4V powders. Powder Technol. 2021, 392, 536–543. [Google Scholar] [CrossRef]

- Pleass, C.; Jothi, S. Influence of powder characteristics and additive manufacturing process parameters on the microstructure and mechanical behaviour of Inconel 625 fabricated by Selective Laser Melting. Addit. Manuf. 2018, 24, 419–431. [Google Scholar] [CrossRef]

- Grubbs, J.; Sousa, B.C.; Cote, D. Exploration of the Effects of Metallic Powder Handling and Storage Conditions on Flow-ability and Moisture Content for Additive Manufacturing Applications. Metals 2022, 12, 603. [Google Scholar]

- Marchetti, L.; Mellin, P.; Hulme, C.N. Negative impact of humidity on the flowability of steel powders. Part. Sci. Technol. 2021, 40, 722–736. [Google Scholar] [CrossRef]

- Mellin, P.; Rashidi, M.; Fischer, M.; Nyborg, L.; Marchetti, L.; Hulme-Smith, C.; Uhlirsch, M.; Strondl, A. Moisture in Metal Powder and Its Implication for Processability in L-PBF and Elsewhere. BHM Berg-Hüttenmänn. Mon. 2021, 166, 33–39. [Google Scholar] [CrossRef]

- Cordova, L.; Bor, T.; de Smit, M.; Campos, M.; Tinga, T. Measuring the spreadability of pre-treated and moisturized powders for laser powder bed fusion. Addit. Manuf. 2020, 32, 101082. [Google Scholar] [CrossRef]

- Fiegl, T.; Franke, M.; Raza, A.; Hryha, E.; Körner, C. Effect of AlSi10Mg0.4 long-term reused powder in PBF-LB/M on the mechanical properties. Mater. Des. 2021, 212, 110176. [Google Scholar] [CrossRef]

- Rock, C.; Ledford, C.; Garcia-Avila, M.; West, H.; Miller, V.M.; Pankow, M.; Dehoff, R.; Horn, T. The Influence of Powder Reuse on the Properties of Nickel Super Alloy ATI 718TM in Laser Powder Bed Fusion Additive Manufacturing. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2021, 52, 676–688. [Google Scholar] [CrossRef]

- Del Re, F.; Contaldi, V.; Astarita, A.; Palumbo, B.; Squillace, A.; Corrado, P.; Di Petta, P. Statistical approach for assessing the effect of powder reuse on the final quality of AlSi10Mg parts produced by laser powder bed fusion additive manufacturing. J. Adv. Manuf. Technol. 2018, 97, 2231–2240. [Google Scholar] [CrossRef]

- Nezhadfar, P.D.; Thompson, S.; Saharan, A.; Phan, N.; Shamsaei, N. Structural integrity of additively manufactured aluminum alloys: Effects of build orientation. Addit. Manuf. 2021, 47, 102292. [Google Scholar] [CrossRef]

- Raza, A.; Fiegl, T.; Hanif, I.; Markström, A.; Franke, M.; Körner, C.; Hryha, E. Degradation of AlSi10Mg powder during laser based powder bed fusion processing. Mater. Des. 2020, 198, 109358. [Google Scholar] [CrossRef]

- Martucci, A.; Tam, P.L.; Aversa, A.; Lombardi, M.; Nyborg, L. The effect of powder reuse on the surface chemical composition of the Scalmalloy powder in Powder Bed Fusion—Laser Beam process. Surf. Interface Anal. 2022, 1–8. [Google Scholar] [CrossRef]

- Shvab, R.; Leicht, A.; Hryha, E.N. Characterization of the virgin and recycled nickel alloy HX powder used for selective laser melting. In Proceedings of the World PM 2016 Congress and Exhibition, Hamburg, Germany, 9–13 October 2016. [Google Scholar]

- Hryha, E.; Shvab, R.; Gruber, H.; Leicht, A.; Nyborg, L. Surface Oxide State on Metal Powder and its Changes during Additive Manufacturing: An Overview. Addit. Manuf. 2018. [Google Scholar]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Choo, E.; Gao, N. Comparison between Virgin and Recycled 316L SS and AlSi10Mg Powders Used for Laser Powder Bed Fusion Additive Manufacturing. Metals 2020, 10, 1625. [Google Scholar] [CrossRef]

- Amir, B.; Grinberg, E.; Gale, Y.; Sadot, O.; Samuha, S. Influences of platform heating and post-processing stress relief treatment on the mechanical properties and microstructure of selective-laser-melted AlSi10Mg alloys. Mater. Sci. Eng. A 2021, 822, 141612. [Google Scholar] [CrossRef]

- Panahizadeh, V.; Ghasemi, A.H.; Asl, Y.D.; Davoudi, M. Optimization of LB-PBF process parameters to achieve best relative density and surface roughness for Ti6Al4V samples: Using NSGA-II algorithm. Rapid Prototyp. J. 2022, 28, 1821–1833. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- Craeghs, T.; Clijsters, S.; Yasa, E.; Kruth, J.P. Online quality control of selective laser melting. In Proceedings of the 2011 22nd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference SFF 2011, Austin, TX, USA, 8–10 August 2011; pp. 212–226. [Google Scholar]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.-P.R.; Schoenung, J.M. On the limitations of Volumetric Energy Density as a design parameter for Selective Laser Melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- Aversa, A.; Moshiri, M.; Librera, E.; Hadi, M.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Biamino, S.; Lombardi, M.; et al. Single scan track analyses on aluminium based powders. J. Mater. Process. Technol. 2018, 255, 17–25. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Gheysen, J.; Marteleur, M.; van der Rest, C.; Simar, A. Efficient optimization methodology for laser powder bed fusion parameters to manufacture dense and mechanically sound parts validated on AlSi12 alloy. Mater. Des. 2020, 199, 109433. [Google Scholar] [CrossRef]

- Martucci, A.; Marinucci, F.; Sivo, A.; Aversa, A.; Manfredi, D.; Bondioli, F.; Fino, P.; Lombardi, M. An automatic on top analysis of single scan tracks to evaluate the laser powder bed fusion building parameters. Materials 2021, 14, 5171. [Google Scholar] [CrossRef] [PubMed]

- Bosio, F.; Aversa, A.; Lorusso, M.; Marola, S.; Gianoglio, D.; Battezzati, L.; Fino, P.; Manfredi, D.; Lombardi, M. A time-saving and cost-effective method to process alloys by Laser Powder Bed Fusion. Mater. Des. 2019, 181, 107949. [Google Scholar] [CrossRef]

- Martucci, A.; Aversa, A.; Bondioli, F.; Fino, P.; Lombardi, M. Synergic strategies to improve the PBF-LB\M processability of a cracking-sensitive alloy. Mater. Des. 2022, 224, 111396. [Google Scholar] [CrossRef]

- Leicht, A.; Fischer, M.; Klement, U.; Nyborg, L.; Hryha, E. Increasing the Productivity of Laser Powder Bed Fusion for Stainless Steel 316L through Increased Layer Thickness. J. Mater. Eng. Perform. 2020, 30, 575–584. [Google Scholar] [CrossRef]

- Badrossamay, M.; Rezaei, A.; Foroozmehr, E.; Maleki, A.; Foroozmehr, A. Effects of increasing powder layer thickness on the microstructure, mechanical properties, and failure mechanism of IN718 superalloy fabricated by laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2021, 118, 1703–1717. [Google Scholar] [CrossRef]

- Balbaa, M.; Ghasemi, A.; Fereiduni, E.; Elbestawi, M.; Jadhav, S.; Kruth, J.-P. Role of powder particle size on laser powder bed fusion processability of AlSi10mg alloy. Addit. Manuf. 2020, 37, 101630. [Google Scholar] [CrossRef]

- Mindt, H.W.; Megahed, M.; Lavery, N.P.; Holmes, M.A.; Brown, S.G.R. Powder Bed Layer Characteristics: The Overseen First-Order Process Input. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 3811–3822. [Google Scholar] [CrossRef]

- Samantaray, M.; Thatoi, D.N.; Sahoo, S. Modeling and Optimization of Process Parameters for Laser Powder Bed Fusion of AlSi10Mg Alloy. Lasers Manuf. Mater. Process. 2019, 6, 356–373. [Google Scholar] [CrossRef]

- Pinomaa, T.; Yashchuk, I.; Lindroos, M.; Andersson, T.; Provatas, N.; Laukkanen, A. Process-Structure-Properties-Performance Modeling for Selective Laser Melting. Metals 2019, 9, 1138. [Google Scholar] [CrossRef]

- Letenneur, M.; Kreitcberg, A.; Brailovski, V. Optimization of Laser Powder Bed Fusion Processing Using a Combination of Melt Pool Modeling and Design of Experiment Approaches: Density Control. J. Manuf. Mater. Process. 2019, 3, 21. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Guagliano, M. Application of artificial intelligence to optimize the process parameters effects on tensile properties of Ti-6Al-4V fabricated by laser powder-bed fusion. Int. J. Mech. Mater. Des. 2021, 18, 199–222. [Google Scholar] [CrossRef]

- Oliveira, J.; Miranda, R.; Fernandes, F.B. Welding and Joining of NiTi Shape Memory Alloys: A Review. Prog. Mater. Sci. 2017, 88, 412–466. [Google Scholar] [CrossRef]

- Prasad, H.S.; Brueckner, F.; Volpp, J.; Kaplan, A.F.H. Laser metal deposition of copper on diverse metals using green laser sources. Int. J. Adv. Manuf. Technol. 2020, 107, 1559–1568. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Patel, S.; Vlasea, M. Melting modes in laser powder bed fusion. Materialia 2020, 9, 100591. [Google Scholar] [CrossRef]

- Trapp, J.; Rubenchik, A.M.; Guss, G.; Matthews, M.J. In situ absorptivity measurements of metallic powders during laser powder-bed fusion additive manufacturing. Appl. Mater. Today 2017, 9, 341–349. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental Analysis of Residual Stresses on AlSi10Mg Parts Produced by Means of Selective Laser Melting (SLM). Procedia CIRP 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Kempen, K.; Vrancken, B.; Buls, S.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Selective Laser Melting of Crack-Free High Density M2 High Speed Steel Parts by Baseplate Preheating. J. Manuf. Sci. Eng. Trans. ASME 2014, 136, 061026. [Google Scholar] [CrossRef]

- Zhao, L.; Song, L.; Macías, J.G.S.; Zhu, Y.; Huang, M.; Simar, A.; Li, Z. Review on the correlation between microstructure and mechanical performance for laser powder bed fusion AlSi10Mg. Addit. Manuf. 2022, 56, 102914. [Google Scholar] [CrossRef]

- Macías, J.G.S.; Douillard, T.; Zhao, L.; Maire, E.; Pyka, G.; Simar, A. Influence on microstructure, strength and ductility of build platform temperature during laser powder bed fusion of AlSi10Mg. Acta Mater. 2020, 201, 231–243. [Google Scholar] [CrossRef]

- Li, P.; Kim, Y.; Bobel, A.; Hector, L.; Sachdev, A.; Kumar, S.; Bower, A. Microstructural origin of the anisotropic flow stress of laser powder bed fused AlSi10Mg. Acta Mater. 2021, 220, 117346. [Google Scholar] [CrossRef]

- Ferro, P.; Meneghello, R.; Razavi, S.M.J.; Berto, F.; Savio, G. Porosity Inducing Process Parameters in Selective Laser Melted AlSi10Mg Aluminium Alloy. Phys. Mesomech. 2020, 23, 256–262. [Google Scholar] [CrossRef]

- Galy, C.; Le Guen, E.; Lacoste, E.; Arvieu, C. Main defects observed in aluminum alloy parts produced by SLM: From causes to consequences. Addit. Manuf. 2018, 22, 165–175. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, 1–21. [Google Scholar] [CrossRef]

- Rabin, B.; Smolik, G.; Korth, G. Characterization of entrapped gases in rapidly solidified powders. Mater. Sci. Eng. A 1990, 124, 1–7. [Google Scholar] [CrossRef]

- Wang, A.; Wang, H.; Wu, Y.; Wang, H. 3D printing of aluminum alloys using laser powder deposition: A review. Int. J. Adv. Manuf. Technol. 2021, 116, 1–37. [Google Scholar] [CrossRef]

- Hafenstein, S.; Hitzler, L.; Sert, E.; Öchsner, A.; Merkel, M.; Werner, E. Hot Isostatic Pressing of Aluminum–Silicon Alloys Fabricated by Laser Powder-Bed Fusion. Technologies 2020, 8, 48. [Google Scholar] [CrossRef]

- Liu, Q.C.; Elambasseril, J.; Sun, S.J.; Leary, M.; Brandt, M.; Sharp, P.K. The Effect of Manufacturing Defects on the Fatigue Behaviour of Ti-6Al-4V Specimens Fabricated Using Selective Laser Melting. Adv. Mater. Res. 2014, 891–892, 1519–1524. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Tan, Q.; Liu, Y.; Fan, Z.; Zhang, J.; Yin, Y.; Zhang, M.-X. Effect of processing parameters on the densification of an additively manufactured 2024 Al alloy. J. Mater. Sci. Technol. 2020, 58, 34–45. [Google Scholar] [CrossRef]

- Kouraytem, N.; Li, X.; Cunningham, R.; Zhao, C.; Parab, N.; Sun, T.; Rollett, A.D.; Spear, A.D.; Tan, W. Effect of Laser-Matter Interaction on Molten Pool Flow and Keyhole Dynamics. Phys. Rev. Appl. 2019, 11, 064054. [Google Scholar] [CrossRef]

- Huang, Y.; Fleming, T.G.; Clark, S.J.; Marussi, S.; Fezzaa, K.; Thiyagalingam, J.; Leung, C.L.A.; Lee, P.D. Keyhole fluctuation and pore formation mechanisms during laser powder bed fusion additive manufacturing. Nat. Commun. 2022, 13, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Del Guercio, G.; McCartney, D.; Aboulkhair, N.; Robertson, S.; Maclachlan, R.; Tuck, C.; Simonelli, M. Cracking behaviour of high-strength AA2024 aluminium alloy produced by Laser Powder Bed Fusion. Addit. Manuf. 2022, 54, 102776. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Zhou, Z.; Zhan, Q. Enhanced strength and ductility in Al-Zn-Mg-Cu alloys fabricated by laser powder bed fusion using a synergistic grain-refining strategy. J. Mater. Sci. Technol. 2022, 124, 41–52. [Google Scholar] [CrossRef]

- Riener, K.; Pfalz, T.; Funcke, F.; Leichtfried, G. Processability of high-strength aluminum 6182 series alloy via laser powder bed fusion (LPBF). Int. J. Adv. Manuf. Technol. 2022, 119, 4963–4977. [Google Scholar] [CrossRef]

- Chen, C.; Chang, S.; Zhu, J.; Xiao, Z.; Zhu, H.; Zeng, X. Residual stress of typical parts in laser powder bed fusion. J. Manuf. Process. 2020, 59, 621–628. [Google Scholar] [CrossRef]

- Li, Y.; Gan, W.; Zhou, W.; Li, D. Review on residual stress and its effects on manufacturing of aluminium alloy structural panels with typical multi-processes. Chin. J. Aeronaut. 2022, in press. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Deckers, J.; Yasa, E.; Wauthlé, R. Assessing and comparing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proc. Inst. Mech. Eng. Part J. Eng. Manuf. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Deng, J.; Chen, C.; Zhang, W.; Li, Y.; Li, R.; Zhou, K. Densification, Microstructure, and Mechanical Properties of Additively Manufactured 2124 Al–Cu Alloy by Selective Laser Melting. Materials 2020, 13, 4423. [Google Scholar] [CrossRef] [PubMed]

- Levkulich, N.; Semiatin, S.; Gockel, J.; Middendorf, J.; DeWald, A.; Klingbeil, N. The effect of process parameters on residual stress evolution and distortion in the laser powder bed fusion of Ti-6Al-4V. Addit. Manuf. 2019, 28, 475–484. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Pirch, N.; Wissenbach, K.; Schrage, J. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting. J. Laser Appl. 2014, 26, 012004. [Google Scholar] [CrossRef]

- Li, G.; Li, X.; Guo, C.; Zhou, Y.; Tan, Q.; Qu, W.; Li, X.; Hu, X.; Zhang, M.-X.; Zhu, Q. Investigation into the effect of energy density on densification, surface roughness and loss of alloying elements of 7075 aluminium alloy processed by laser powder bed fusion. Opt. Laser Technol. 2021, 147, 107621. [Google Scholar] [CrossRef]

- Nasab, M.H.; Gastaldi, D.; Lecis, N.F.; Vedani, M. On morphological surface features of the parts printed by selective laser melting (SLM). Addit. Manuf. 2018, 24, 373–377. [Google Scholar] [CrossRef]

- Li, B.-Q.; Li, Z.; Bai, P.; Liu, B.; Kuai, Z. Research on Surface Roughness of AlSi10Mg Parts Fabricated by Laser Powder Bed Fusion. Metals 2018, 8, 524. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018, 2, 64. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Bandini, M.; Guagliano, M.; Bagherifard, S. Individual and synergistic effects of thermal and mechanical surface post-treatments on wear and corrosion behavior of laser powder bed fusion AlSi10Mg. J. Mater. Process. Technol. 2021, 302, 117479. [Google Scholar] [CrossRef]

- Guo, Q.; Zhao, C.; Escano, L.I.; Young, Z.; Xiong, L.; Fezzaa, K.; Everhart, W.; Brown, B.; Sun, T.; Chen, L. Transient dynamics of powder spattering in laser powder bed fusion additive manufacturing process revealed by in-situ high-speed high-energy x-ray imaging. Acta Mater. 2018, 151, 169–180. [Google Scholar] [CrossRef]

- Hojjatzadeh, S.M.H.; Parab, N.D.; Guo, Q.; Qu, M.; Xiong, L.; Zhao, C.; Escano, L.I.; Fezzaa, K.; Everhart, W.; Sun, T.; et al. Direct observation of pore formation mechanisms during LPBF additive manufacturing process and high energy density laser welding. Int. J. Mach. Tools Manuf. 2020, 153, 103555. [Google Scholar] [CrossRef]

- Qu, M.; Guo, Q.; Escano, L.I.; Clark, S.J.; Fezzaa, K.; Chen, L. Mitigating keyhole pore formation by nanoparticles during laser powder bed fusion additive manufacturing. Addit. Manuf. Lett. 2022, 3, 100068. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y. Physics based compressive sensing to monitor temperature and melt flow in laser powder bed fusion. Addit. Manuf. 2021, 47, 102304. [Google Scholar] [CrossRef]

- Kenel, C.; Grolimund, D.; Fife, J.; Samson, V.; Van Petegem, S.; Van Swygenhoven, H.; Leinenbach, C. Combined in situ synchrotron micro X-ray diffraction and high-speed imaging on rapidly heated and solidified Ti–48Al under additive manufacturing conditions. Scr. Mater. 2016, 114, 117–120. [Google Scholar] [CrossRef]

- Dowling, L.; Kennedy, J.; O’Shaughnessy, S.; Trimble, D. A review of critical repeatability and reproducibility issues in powder bed fusion. Mater. Des. 2019, 186, 108346. [Google Scholar] [CrossRef]

- Wang, P.; Yang, Y.; Moghaddam, N.S. Process modeling in laser powder bed fusion towards defect detection and quality control via machine learning: The state-of-the-art and research challenges. J. Manuf. Process. 2021, 73, 961–984. [Google Scholar] [CrossRef]

- Spierings, A.B.; Schneider, M.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Wits, W.W.; Carmignato, S.; Zanini, F.; Vaneker, T.H. Porosity testing methods for the quality assessment of selective laser melted parts. CIRP Ann.—Manuf. Technol. 2016, 65, 201–204. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Prog. Mater. Sci. 2020, 117, 100724. [Google Scholar] [CrossRef]

- du Plessis, A.; Macdonald, E. Hot isostatic pressing in metal additive manufacturing: X-ray tomography reveals details of pore closure. Addit. Manuf. 2020, 34, 101191. [Google Scholar] [CrossRef]

- Atkinson, H.V.; Davies, S. Fundamental aspects of hot isostatic pressing: An overview. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2000, 31, 2981–3000. [Google Scholar] [CrossRef]

- du Plessis, A.; Rossouw, P. Investigation of Porosity Changes in Cast Ti6Al4V Rods After Hot Isostatic Pressing. J. Mater. Eng. Perform. 2015, 24, 3137–3141. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, J.J.; Kim, K.H.; Kim, N.J.; Lee, S.; Lee, E.W. Effects of HIPping on high-cycle fatigue properties of investment cast A356 aluminum alloys. Mater. Sci. Eng. A 2003, 340, 123–129. [Google Scholar] [CrossRef]

- Schneller, W.; Leitner, M.; Springer, S.; Grün, F.; Taschauer, M. Effect of HIP Treatment on Microstructure and Fatigue Strength of Selectively Laser Melted AlSi10Mg. J. Manuf. Mater. Process. 2019, 3, 16. [Google Scholar] [CrossRef]

- Kosonen, T.; Kakko, K.; Raitanen, N. Evaluation of pore re-opening after HIP in LPBF Ti-6Al-4V. Powder Metall. 2021, 64, 1–9. [Google Scholar] [CrossRef]

- Ertugrul, O.; Öter, Z.; Yılmaz, M.S.; Şahin, E.; Coşkun, M.; Tarakçı, G.; Koç, E. Effect of HIP process and subsequent heat treatment on microstructure and mechanical properties of direct metal laser sintered AlSi10Mg alloy. Rapid Prototyp. J. 2020, 26, 1421–1434. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, C.; Zhu, H. Effect of direct aging and annealing on the microstructure and mechanical properties of AlSi10Mg fabricated by selective laser melting. Rapid Prototyp. J. 2022, 29, 118–127. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Davies, C.; Huang, A.; Wu, X. Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting. Mater. Des. 2018, 154, 275–290. [Google Scholar] [CrossRef]

- Martucci, A.; Aversa, A.; Manfredi, D.; Bondioli, F.; Biamino, S.; Ugues, D.; Lombardi, M.; Fino, P. Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®. Materials 2022, 15, 3123. [Google Scholar] [CrossRef]

- Mehta, B.; Svanberg, A.; Nyborg, L. Laser powder bed fusion of an al-mg-sc-zr alloy: Manufacturing, peak hardening re-sponse and thermal stability at peak hardness. Metals 2022, 12, 57. [Google Scholar] [CrossRef]

- Martucci, A.; Mehta, B.; Lombardi, M.; Nyborg, L. The Influence of Processing Parameters on the Al-Mn Enriched Nano-Precipitates Formation in a Novel Al-Mn-Cr-Zr Alloy Tailored for Power Bed Fusion-Laser Beam Process. Metals 2022, 12, 1387. [Google Scholar] [CrossRef]

- Bosio, F.; Fino, P.; Manfredi, D.; Lombardi, M. Strengthening strategies for an Al alloy processed by in-situ alloying during laser powder bed fusion. Mater. Des. 2021, 212, 110247. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Zhang, M.-X.; Zhu, Q. Novel approach to additively manufacture high-strength Al alloys by laser powder bed fusion through addition of hybrid grain refiners. Addit. Manuf. 2021, 48, 102400. [Google Scholar] [CrossRef]

- Tonelli, L.; Liverani, E.; Morri, A.; Ceschini, L. Role of Direct Aging and Solution Treatment on Hardness, Microstructure and Residual Stress of the A357 (AlSi7Mg0.6) Alloy Produced by Powder Bed Fusion. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2021, 52, 2484–2496. [Google Scholar] [CrossRef]

- Fiocchi, J.; Tuissi, A.; Biffi, C. Heat treatment of aluminium alloys produced by laser powder bed fusion: A review. Mater. Des. 2021, 204, 109651. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Surface Morphology in Selective Laser Melting of Metal Powders. Phys. Procedia 2011, 12, 264–270. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Makhetha, W.M.I.; Becker, T.H.; Sacks, N. Post-Processing Framework for As-Built LPBF Ti-6Al-4V Parts Towards Meeting Industry Functional Requirements. JOM 2022, 74, 764–776. [Google Scholar] [CrossRef]

- Kahlin, M.; Ansell, H.; Basu, D.; Kerwin, A.; Newton, L.; Smith, B.; Moverare, J. Improved fatigue strength of additively manufactured Ti6Al4V by surface post processing. Int. J. Fatigue 2020, 134, 105497. [Google Scholar] [CrossRef]

- Yu, H.; Li, F.; Wang, Z.; Zeng, X. Fatigue performances of selective laser melted Ti-6Al-4V alloy: Influence of surface finishing, hot isostatic pressing and heat treatments. Int. J. Fatigue 2019, 120, 175–183. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Dzhemelinskyi, V.V.; Martinez, S.; Mordyuk, B.N.; Lamikiz, A. Surface Shot Peening Post-processing of Inconel 718 Alloy Parts Printed by Laser Powder Bed Fusion Additive Manufacturing. J. Mater. Eng. Perform. 2021, 30, 6982–6995. [Google Scholar] [CrossRef]

- Dong, G.; Marleau-Finley, J.; Zhao, Y.F. Investigation of electrochemical post-processing procedure for Ti-6Al-4V lattice structure manufactured by direct metal laser sintering (DMLS). Int. J. Adv. Manuf. Technol. 2019, 104, 3401–3417. [Google Scholar] [CrossRef]

- Mumtaz, K.; Hopkinson, N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyp. J. 2009, 15, 96–103. [Google Scholar] [CrossRef]

- Bezuidenhout, M.; Haar, G.T.; Becker, T.; Rudolph, S.M.-A.; Damm, O.; Sacks, N. The effect of HF-HNO 3 chemical polishing on the surface roughness and fatigue life of laser powder bed fusion produced Ti6Al4V. Mater. Today Commun. 2020, 25, 101396. [Google Scholar] [CrossRef]

- Leis, A.; Weber, R.; Graf, T. Process Window for Highly Efficient Laser-Based Powder Bed Fusion of AlSi10Mg with Reduced Pore Formation. Materials 2021, 14, 5255. [Google Scholar] [CrossRef]

- Urlea, V.; Brailovski, V. Electropolishing and electropolishing-related allowances for powder bed selectively laser-melted Ti-6Al-4V alloy components. J. Mater. Process. Technol. 2017, 242, 1–11. [Google Scholar] [CrossRef]

- Vaithilingam, J.; Elisabetta, P.; Ruth, D.G.; Richard, J.H.; Steve, E.; Felicity, R.R.; Steven, D.C. Surface chemistry of Ti6Al4V components fabricated using selective laser melting for biomedical ap-plications. Mater. Sci. Eng. C 2016, 67, 294–303. [Google Scholar] [CrossRef]

- Parts, A.; Alves, J.L. Effect of Scan Strategies and Use of Support Structures on Surface Quality and Hardness of L-PBF. Materials 2020, 13, 2248. [Google Scholar]

- Kasperovich, G.; Becker, R.; Artzt, K.; Barriobero-Vila, P.; Requena, G.; Haubrich, J. The effect of build direction and geometric optimization in laser powder bed fusion of Inconel 718 structures with internal channels. Mater. Des. 2021, 207, 109858. [Google Scholar] [CrossRef]

- Lorenzetti, L.; Tonelli, L.; Ceschini, L.; Liverani, E.; Martini, C. A357 aluminium alloy produced by LPBF: Tribological be-haviour in dry sliding conditions. Wear 2022, 510–511, 204488. [Google Scholar] [CrossRef]

- Cordova, L.; Bor, T.; de Smit, M.; Carmignato, S.; Campos, M.; Tinga, T. Effects of powder reuse on the microstructure and mechanical behaviour of Al–Mg–Sc–Zr alloy processed by laser powder bed fusion (LPBF). Addit. Manuf. 2020, 36, 101625. [Google Scholar] [CrossRef]

- Wu, H.; Ren, Y.; Ren, J.; Cai, A.; Song, M.; Liu, Y. Effect of melting modes on microstructure and tribological properties of selective laser melted AlSi10Mg alloy. Virtual and Physical Prototyping. 2020, 15, 570–582. [Google Scholar] [CrossRef]

- Bailey, C.M.; Morrow, J.A.; Stallbaumer-cyr, E.M.; Weeks, C.; Derby, M.M. Effects of Build Angle on Additively Manu-factured Aluminum Alloy Surface Roughness and Wettability. J. Manuf. Sci. Eng. 2022, 144, 1–15. [Google Scholar] [CrossRef]

- Rossi, S.; Deflorian, F.; Venturini, F. Improvement of surface finishing and corrosion resistance of prototypes produced by direct metal laser sintering. J. Mater. Process. Technol. 2004, 148, 301–309. [Google Scholar] [CrossRef]

- Ahmed, F.; Ali, U.; Dyuti, S.; Marzbanrad, E.; Choi, K.; Mahmoodkhani, Y.; Toyserkani, E. Study of powder recycling and its e ff ect on printed parts during laser powder-bed fusion of 17-4 PH stainless steel. J. Mater. Process. Technol. 2020, 278, 116522. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; Wei, H.; Zhang, C.; Chen, X.; Zhang, K. Effect of processing parameters on overhanging surface roughness during laser powder bed fusion of AlSi10Mg. J. Manuf. Process. 2020, 61, 440–453. [Google Scholar] [CrossRef]

- Yang, K.; Kim, M.; Kim, D.; Suhr, J. Investigation of laser powder bed fusion manufacturing and post-processing for surface quality of as-built 17-4PH stainless steel. Surf. Coat. Technol. 2021, 422, 127492. [Google Scholar] [CrossRef]

- Romano, S.; Nezhadfar, P.D.; Shamsaei, N.; Sei, M.; Beretta, S. High cycle fatigue behavior and life prediction for additively manufactured 17-4 PH stainless steel: Effect of sub-surface porosity and surface roughness. Theor. Appl. Fract. Mech. 2020, 106, 102477. [Google Scholar] [CrossRef]

- Cao, L.; Tran, H.-C.; Lo, Y.-L.; Le, T.-N.; Chiu, K.-C.; Hsu, Y.-Y. Optimization of surface roughness and dimensional accuracy in LPBF additive manufacturing Build platform. Opt. Laser Technol. 2021, 142, 107246. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, C.; Wang, D.; Liu, W.; Fang, X.; Wellmann, D.; Zhao, Y.; Tian, Y. A Review on Laser Powder Bed Fusion of Inconel 625. Appl. Sci. 2020, 10, 81. [Google Scholar] [CrossRef]

- Ghosh, A.; Biswas, S.; Turner, T.; Kietzig, A.; Brochu, M. Surface, microstructure, and tensile defor-mation characterization of LPBF SS316L microstruts micromachined with femtosecond laser. Mater. Des. 2021, 210, 110045. [Google Scholar] [CrossRef]

- Musekamp, J.; Reiber, T.; Hoche, H.C.; Oechsner, M.; Weigold, M.; Abele, E. Influence of LPBF-surface characteristics on fatigue properties of Scalmalloy®. Metals 2021, 11, 1961. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2020, 37, 101619. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Sabouri, F.; Guagliano, M. Effects of hybrid post-treatments on fatigue behaviour of notched LPBF AlSi10Mg: Experimental and deep learning approaches. Procedia Struct. Integr. 2021, 34, 141–153. [Google Scholar] [CrossRef]

- Subramaniyan, A.K.; Reddy, A.S.; Mathias, S.; Shrivastava, A.; Raghupatruni, P. Influence of post-processing techniques on the microstructure, properties and surface integrity of Al[sbnd]Si[sbnd]Mg alloy processed by laser powder bed fusion technique. Surf. Coat. Technol. 2021, 425, 127679. [Google Scholar] [CrossRef]

- Uzan, N.E.; Ramati, S.; Shneck, R.; Frage, N.; Yeheskel, O. On the effect of shot-peening on fatigue resistance of AlSi10Mg specimens fabricated by additive manufacturing using selective laser melting (AM-SLM). Addit. Manuf. 2018, 21, 458–464. [Google Scholar] [CrossRef]

| Materials | X-ray Voltage | ||||

|---|---|---|---|---|---|

| 130 kV | 150 kV | 190 kV | 225 kV | 450 kV | |

| Steel\Ceramic | 5 mm | <8 mm | <25 mm | <40 mm | <70 mm |

| Aluminium | <30 mm | <50 mm | <90 mm | <150 mm | <250 mm |

| Plastic | <90 mm | <130 mm | <200 mm | <250 mm | <450 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martucci, A.; Aversa, A.; Lombardi, M. Ongoing Challenges of Laser-Based Powder Bed Fusion Processing of Al Alloys and Potential Solutions from the Literature—A Review. Materials 2023, 16, 1084. https://doi.org/10.3390/ma16031084

Martucci A, Aversa A, Lombardi M. Ongoing Challenges of Laser-Based Powder Bed Fusion Processing of Al Alloys and Potential Solutions from the Literature—A Review. Materials. 2023; 16(3):1084. https://doi.org/10.3390/ma16031084

Chicago/Turabian StyleMartucci, Alessandra, Alberta Aversa, and Mariangela Lombardi. 2023. "Ongoing Challenges of Laser-Based Powder Bed Fusion Processing of Al Alloys and Potential Solutions from the Literature—A Review" Materials 16, no. 3: 1084. https://doi.org/10.3390/ma16031084

APA StyleMartucci, A., Aversa, A., & Lombardi, M. (2023). Ongoing Challenges of Laser-Based Powder Bed Fusion Processing of Al Alloys and Potential Solutions from the Literature—A Review. Materials, 16(3), 1084. https://doi.org/10.3390/ma16031084