Design of Refractory Alloys for Desired Thermal Conductivity via AI-Assisted In-Silico Microstructure Realization

Abstract

:1. Introduction

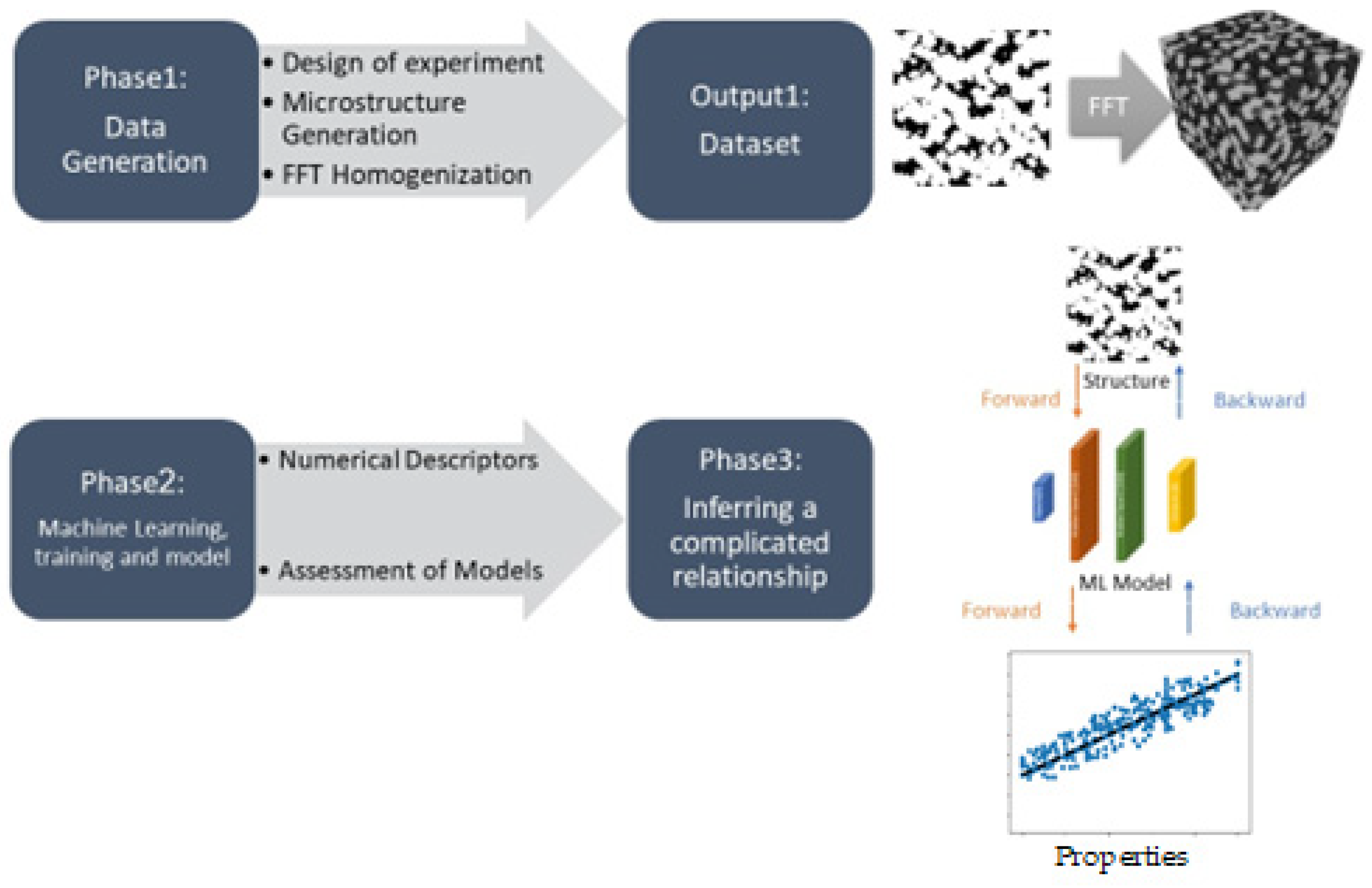

2. Methods

2.1. Data Generation

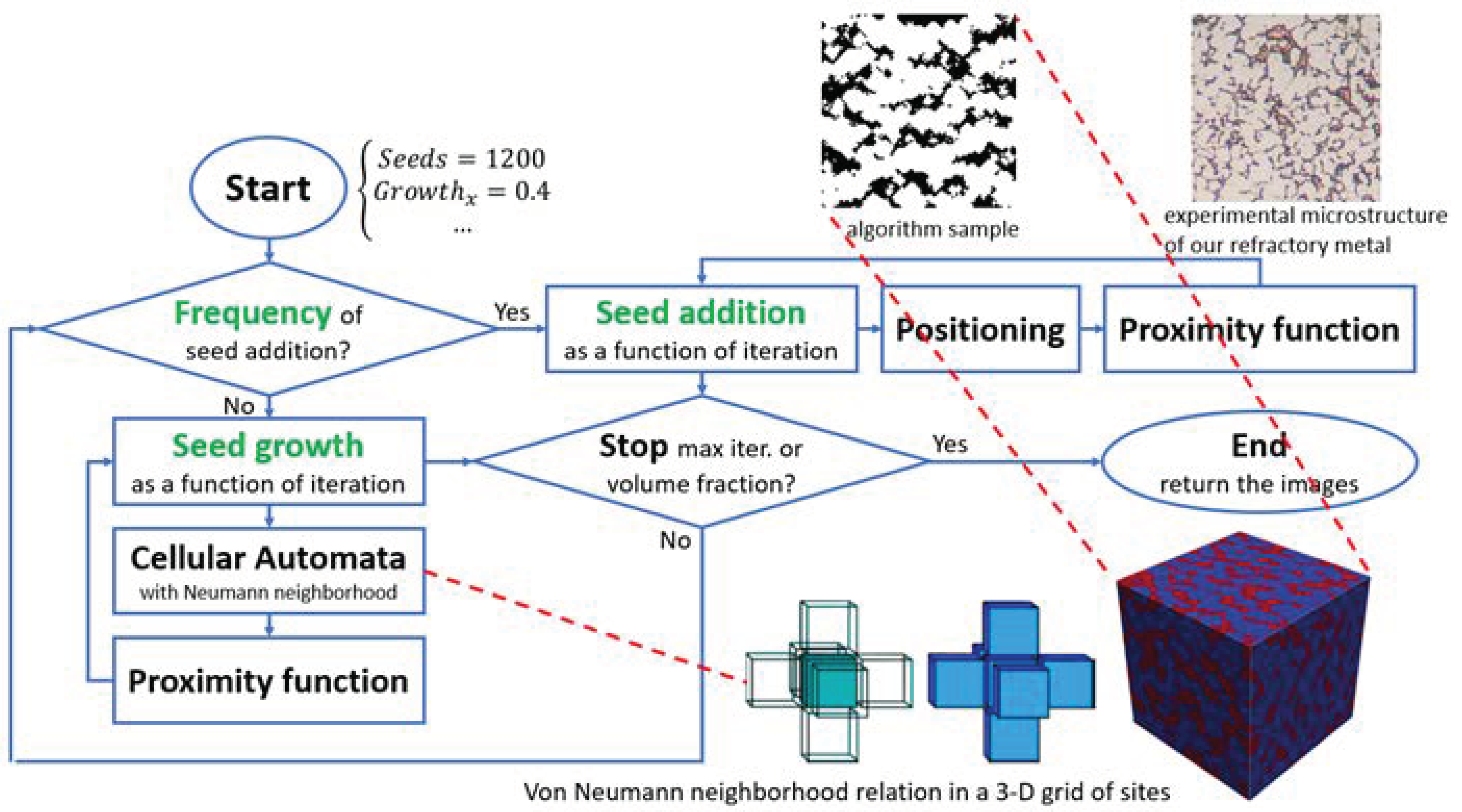

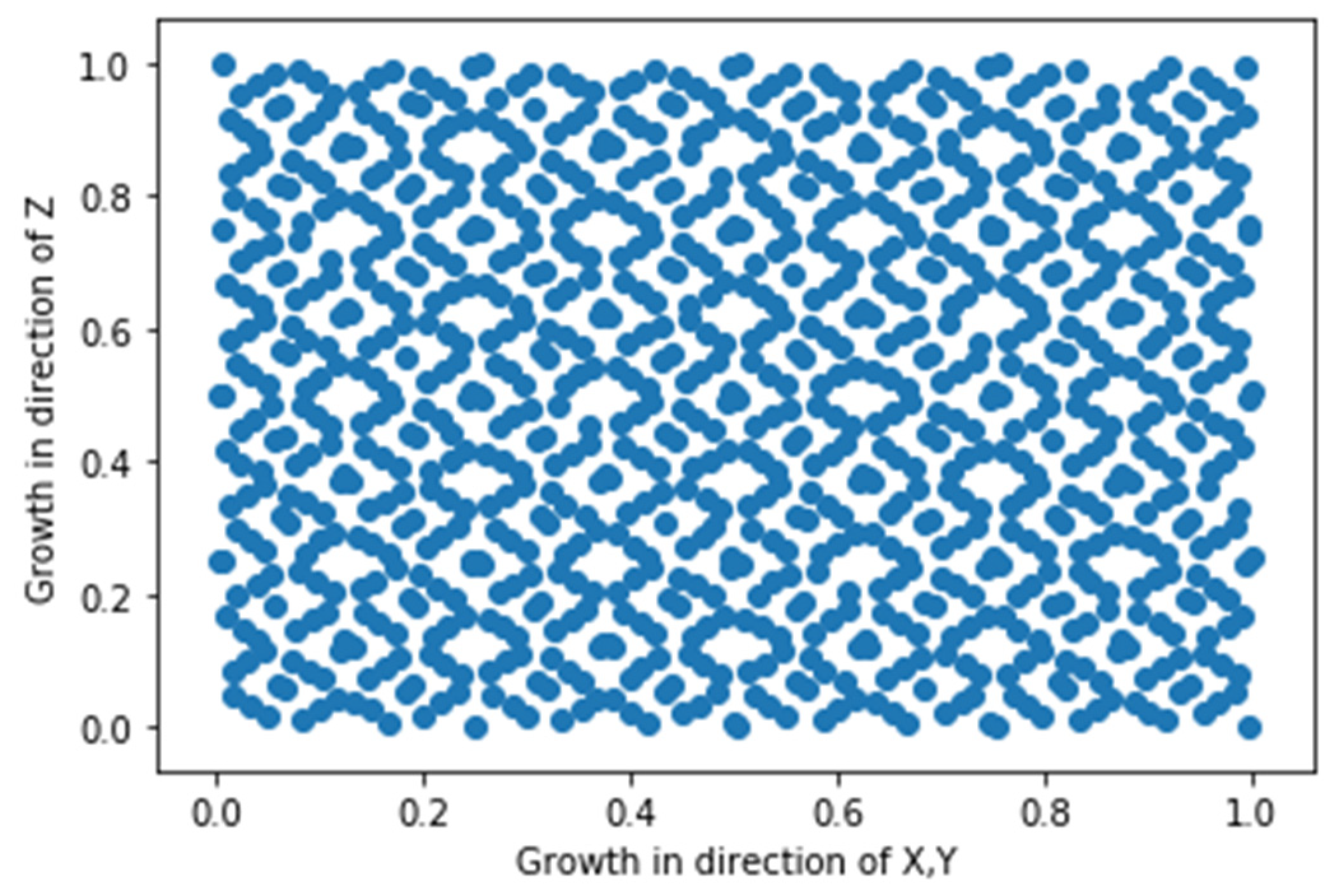

2.1.1. Realization of the Set of Microstructures

2.1.2. Calculating TC of the Generated Microstructures

2.2. ML Model Training

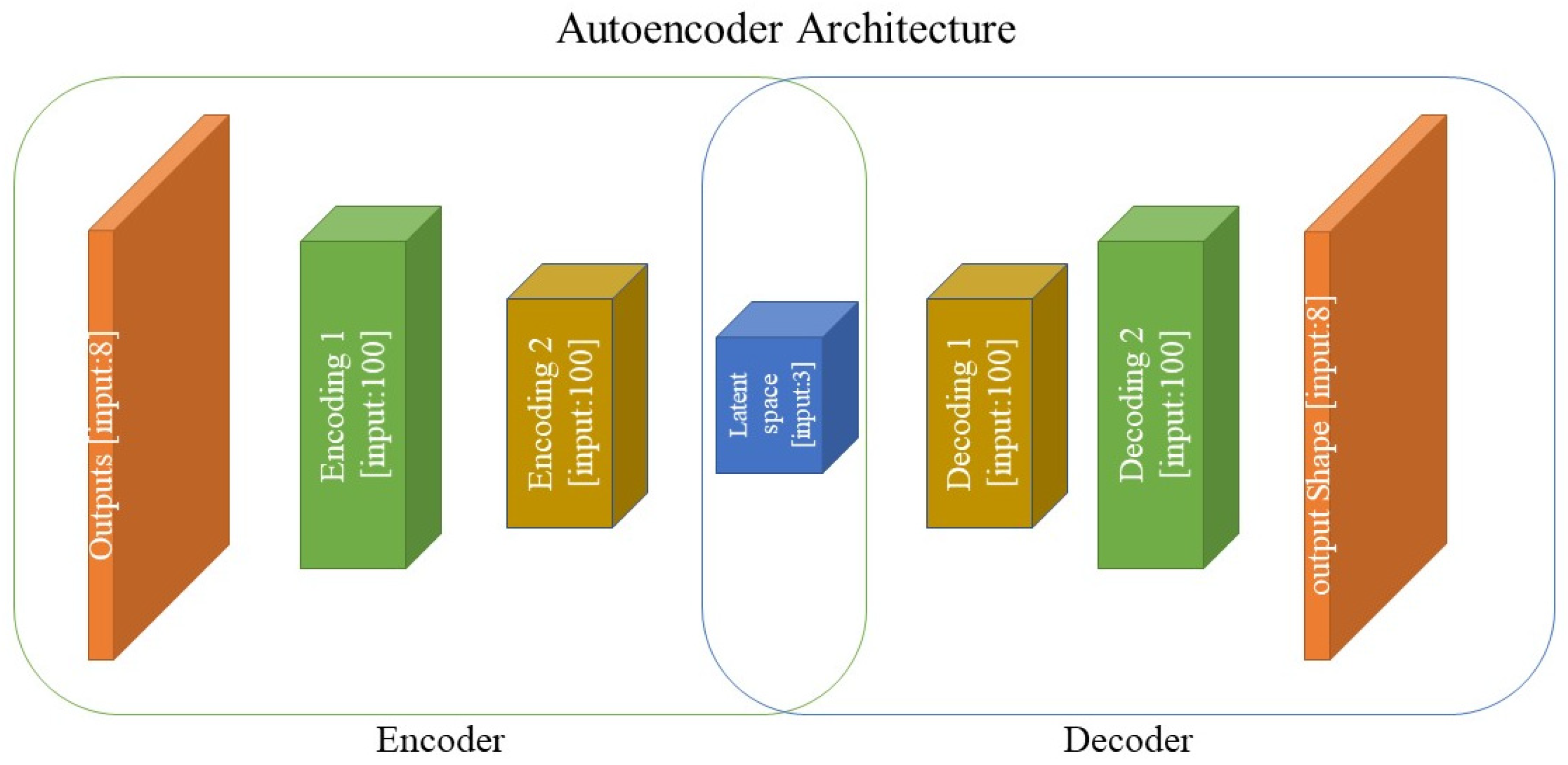

2.3. Inferring a Complex Microstructure–Property Relationship

3. Results and Discussion

3.1. Generated Dataset

3.2. Optimized Surrogate Model of Direct Structure–Property Relationship

3.3. Inverse Design via Modified Autoencoder

3.4. Connection of Computational Results to Real Process and Experiment

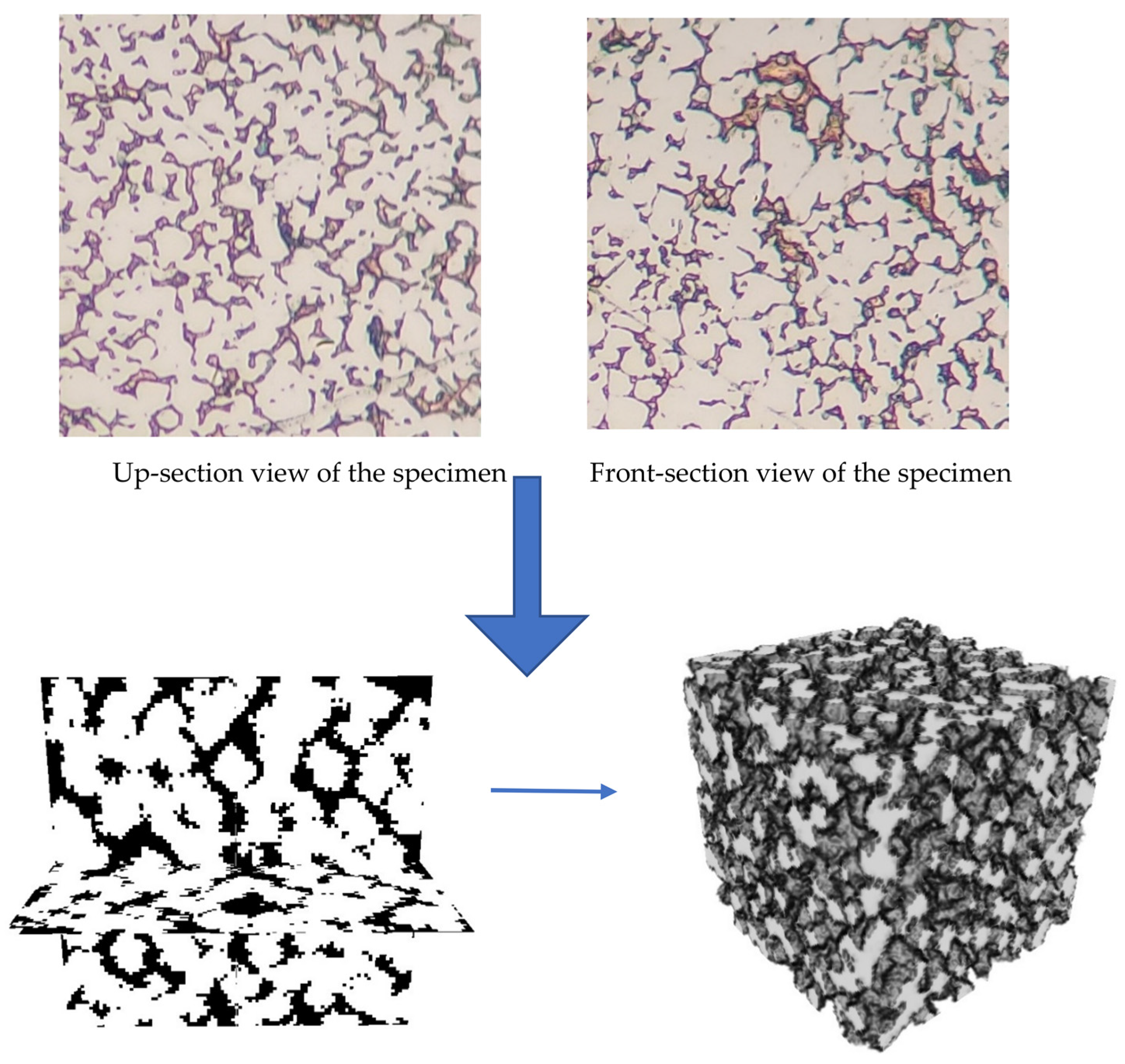

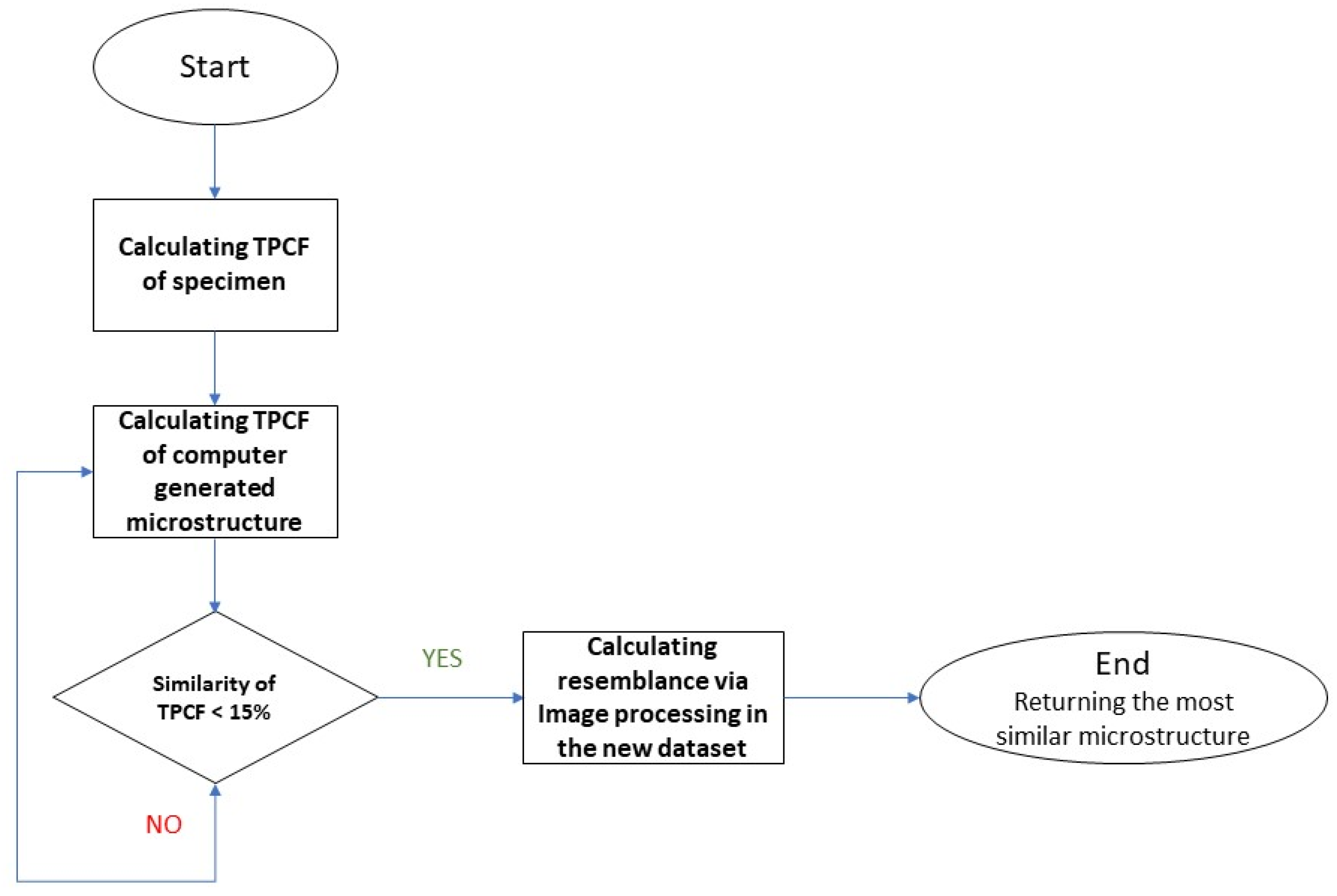

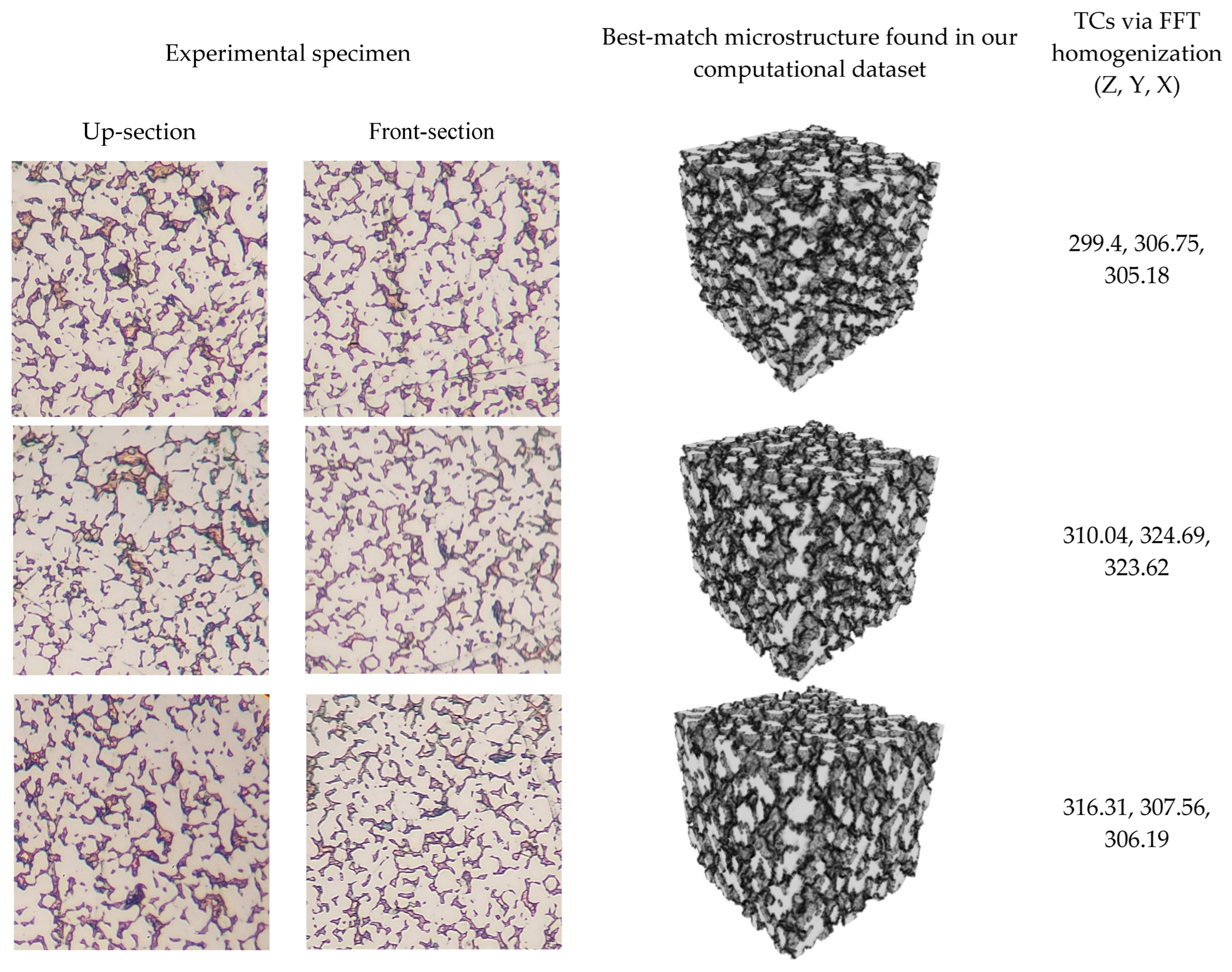

3.4.1. Characterizing Real Manufactured Microstructures Using Its Cut-Section Images and Our Generated Computational Dataset

3.4.2. VF and Defect Effects

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stiapis, C.S.; Skouras, E.D.; Burganos, V.N. Prediction of toxin removal efficiency of novel hemodialysis multilayered mixed-matrix membranes. Sep. Purif. Technol. 2020, 250, 117272. [Google Scholar] [CrossRef]

- Hamedani, H.A.; Baniassadi, M.; Sheidaei, A.; Pourboghrat, F.; Rémond, Y.; Khaleel, M.; Garmestani, H. Three-Dimensional Reconstruction and Microstructure Modeling of Porosity-Graded Cathode Using Focused Ion Beam and Homogenization Techniques. Fuel Cells 2014, 14, 91–95. [Google Scholar] [CrossRef]

- Tabei, S.; Sheidaei, A.; Baniassadi, M.; Pourboghrat, F.; Garmestani, H. Microstructure reconstruction and homogenization of porous Ni-YSZ composites for temperature dependent properties. J. Power Sources 2013, 235, 74–80. [Google Scholar] [CrossRef]

- Sheidaei, A.; Baniassadi, M.; Banu, M.; Askeland, P.; Pahlavanpour, M.; Kuuttila, N.; Pourboghrat, F.; Drzal, L.; Garmestani, H. 3-D microstructure reconstruction of polymer nano-composite using FIB–SEM and statistical correlation function. Compos. Sci. Technol. 2013, 80, 47–54. [Google Scholar] [CrossRef]

- Requena, G.; Fiedler, G.; Seiser, B.; Degischer, P.; Di Michiel, M.; Buslaps, T. 3D-Quantification of the distribution of continuous fibres in unidirectionally reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 152–163. [Google Scholar] [CrossRef]

- Piasecki, R.; Olchawa, W.; Frączek, D.; Bartecka, A. A Two-Stage Reconstruction of Microstructures with Arbitrarily Shaped Inclusions. Materials 2020, 13, 2748. [Google Scholar] [CrossRef]

- Yarali, E.; Baniassadi, M.; Baghani, M. Homogenization and heat transfer analysis of coiled carbon nanotube reinforced polyethylene nanocomposite. Iran. J. Mech. Eng. 2021, 23, 6–21. [Google Scholar] [CrossRef]

- Xu, H.; Li, Y.; Brinson, C.; Chen, W. A Descriptor-Based Design Methodology for Developing Heterogeneous Microstructural Materials System. J. Mech. Des. 2014, 136, 051007. [Google Scholar] [CrossRef] [Green Version]

- Cahn, J.W. Phase Separation by Spinodal Decomposition in Isotropic Systems. J. Chem. Phys. 1965, 42, 93–99. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Y.; Wang, C.; Lee, W.-K.; Dong, B.; Odom, T.W.; Sun, C.; Chen, W. Characterization and Design of Functional Quasi-Random Nanostructured Materials Using Spectral Density Function. J. Mech. Des. 2017, 139, 071401. [Google Scholar] [CrossRef]

- Cang, R.; Xu, Y.; Chen, S.; Liu, Y.; Jiao, Y.; Ren, M.Y. Microstructure Representation and Reconstruction of Heterogeneous Materials Via Deep Belief Network for Computational Material Design. J. Mech. Des. 2017, 139, 071404. [Google Scholar] [CrossRef]

- Sundararaghavan, V.; Zabaras, N. Classification and reconstruction of three-dimensional microstructures using support vector machines. Comput. Mater. Sci. 2005, 32, 223–239. [Google Scholar] [CrossRef]

- Bostanabad, R.; Bui, A.T.; Xie, W.; Apley, D.W.; Chen, W. Stochastic microstructure characterization and reconstruction via supervised learning. Acta Mater. 2016, 103, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Wei, L.-Y.; Levoy, M. Fast texture synthesis using tree-structured vector quantization. In Proceedings of the SIGGRAPH00: The 27th International Conference on Computer Graphics and Interactive Techniques Conference, New Orleans, LA, USA, 23–28 July 2000; pp. 479–488. [Google Scholar] [CrossRef] [Green Version]

- Bostanabad, R.; Zhang, Y.; Li, X.; Kearney, T.; Brinson, L.C.; Apley, D.W.; Liu, W.K.; Chen, W. Computational microstructure characterization and reconstruction: Review of the state-of-the-art techniques. Prog. Mater. Sci. 2018, 95, 1–41. [Google Scholar] [CrossRef]

- Sundararaghavan, V. Reconstruction of three-dimensional anisotropic microstructures from two-dimensional micrographs imaged on orthogonal planes. Integr. Mater. Manuf. Innov. 2014, 3, 240–250. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Li, X.; Brinson, L.C.; Choudhary, A.N.; Chen, W.; Agrawal, A. Microstructural materials design via deep adversarial learning methodology. J. Mech. Des. Trans. ASME 2018, 140, 111416. [Google Scholar] [CrossRef] [Green Version]

- Su, S.; Hong, Z.; Huang, Y.; Wang, P.; Li, X.; Wu, J.; Wu, Y. Integrated Numerical Simulations and Experimental Measurements for the Sintering Process of Injection-Molded Ti-6Al-4V Alloy. Materials 2022, 15, 8109. [Google Scholar] [CrossRef]

- Hashemi, M.S.; Baniassadi, M.; Baghani, M.; George, D.; Remond, Y.; Sheidaei, A. A novel machine learning based computational framework for homogenization of heterogeneous soft materials: Application to liver tissue. Biomech. Model. Mechanobiol. 2020, 19, 1131–1142. [Google Scholar] [CrossRef]

- Hashemi, M.S.; Safdari, M.; Sheidaei, A. A supervised machine learning approach for accelerating the design of particulate composites: Application to thermal conductivity. Comput. Mater. Sci. 2021, 197, 110664. [Google Scholar] [CrossRef]

- Anantharanga, A.T.; Hashemi, M.S.; Sheidaei, A. Linking properties to microstructure in liquid metal embedded elastomers via machine learning. Comput. Mater. Sci. 2023, 218, 111983. [Google Scholar] [CrossRef]

- Bessa, M.A.; Bostanabad, R.; Liu, Z.; Hu, A.; Apley, D.W.; Brinson, C.; Chen, W.; Liu, W.K. A framework for data-driven analysis of materials under uncertainty: Countering the curse of dimensionality. Comput. Methods Appl. Mech. Eng. 2017, 320, 633–667. [Google Scholar] [CrossRef]

- Liu, Z.; Bessa, M.; Liu, W.K. Self-consistent clustering analysis: An efficient multi-scale scheme for inelastic heterogeneous materials. Comput. Methods Appl. Mech. Eng. 2016, 306, 319–341. [Google Scholar] [CrossRef]

- Mondal, A.; Agrawal, D.; Upadhyaya, A. Microwave Sintering of Refractory Metals/alloys: W, Mo, Re, W-Cu, W-Ni-Cu and W-Ni-Fe Alloys. J. Microw. Power Electromagn. Energy 2016, 44, 28–44. [Google Scholar] [CrossRef] [PubMed]

- Ellis, J.L.; Goetzel, C.G. Cermets. In Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM: Materials Park, OH, USA, 1990; pp. 978–1007. [Google Scholar] [CrossRef]

- Roosta, M.; Baharvandi, H.; Abdizade, H. An experimental investigation on the fabrication of W-Cu composite through hot-press. Int. J. Ind. Chem. 2012, 3, 10. [Google Scholar] [CrossRef] [Green Version]

- Abyzov, A.M.; Kidalov, S.V.; Shakhov, F.M. High thermal conductivity composite of diamond particles with tungsten coating in a copper matrix for heat sink application. Appl. Therm. Eng. 2012, 48, 72–80. [Google Scholar] [CrossRef]

- Amirjan, M.; Parvin, N.; Zangeneh-Madar, K. Mutual dependency of mechanical properties and contiguity in W–Cu composites. Mater. Sci. Eng. A 2010, 527, 6922–6929. [Google Scholar] [CrossRef]

- Shahidi, K.Z.; Faraji, G. Fabrication of W-Cu composite by wire crumpling and subsequent melt infiltration. Mater. Lett. 2022, 321, 132432. [Google Scholar] [CrossRef]

- Wang, Y.; Zhuo, L.; Yin, E. Progress, challenges and potentials/trends of tungsten-copper (W Cu) composites/pseudo-alloys: Fabrication, regulation and application. Int. J. Refract. Met. Hard Mater. 2021, 100, 105648. [Google Scholar] [CrossRef]

- Lin, J.T.; Bhattacharyya, D.; Kecman, V. Multiple regression and neural networks analyses in composites machining. Compos. Sci. Technol. 2003, 63, 539–548. [Google Scholar] [CrossRef]

- Jung, K.-C.; Chang, S.-H. Advanced deep learning model-based impact characterization method for composite laminates. Compos. Sci. Technol. 2021, 207, 108713. [Google Scholar] [CrossRef]

- Di Benedetto, R.; Botelho, E.; Janotti, A.; Junior, A.A.; Gomes, G. Development of an artificial neural network for predicting energy absorption capability of thermoplastic commingled composites. Compos. Struct. 2021, 257, 113131. [Google Scholar] [CrossRef]

- Baniassadi, M.; Garmestani, H.; Li, D.; Ahzi, S.; Khaleel, M.; Sun, X. Three-phase solid oxide fuel cell anode microstructure realization using two-point correlation functions. Acta Mater. 2011, 59, 30–43. [Google Scholar] [CrossRef]

- Torquato, S. Random Heterogeneous Materials; Springer: Berlin/Heidelberg, Germany, 2002; Volume 16. [Google Scholar] [CrossRef]

- Moshki, A.; Hajighasemi, M.R.; Atai, A.A.; Jebellat, E.; Ghazavizadeh, A. Optimal design of 3D architected porous/nonporous microstructures of multifunctional multiphase composites for maximized thermomechanical properties. Comput. Mech. 2022, 69, 979–996. [Google Scholar] [CrossRef]

- Sobol, I. Uniformly distributed sequences with an additional uniform property. USSR Comput. Math. Math. Phys. 1976, 16, 236–242. [Google Scholar] [CrossRef]

- Johnson, M.; Moore, L.; Ylvisaker, D. Minimax and maximin distance designs. J. Stat. Plan. Inference 1990, 26, 131–148. [Google Scholar] [CrossRef]

- Santiago, J.; Claeys-Bruno, M.; Sergent, M. Construction of space-filling designs using WSP algorithm for high dimensional spaces. Chemom. Intell. Lab. Syst. 2012, 113, 26–31. [Google Scholar] [CrossRef]

- Linghu, J.; Dong, H.; Cui, J. Ensemble wavelet-learning approach for predicting the effective mechanical properties of concrete composite materials. Comput. Mech. 2022, 70, 335–365. [Google Scholar] [CrossRef]

- Benkhira, E.-H.; Fakhar, R.; Hachlaf, A.; Mandyly, Y. Numerical treatment of a static thermo-electro-elastic contact problem with friction. In Computational Mechanics; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Moulinec, H.; Suquet, P. A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput. Methods Appl. Mech. Eng. 1998, 157, 69–94. [Google Scholar] [CrossRef]

- Dehnavi, F.N.; Safdari, M.; Abrinia, K.; Sheidaei, A.; Baniassadi, M. Numerical study of the conductive liquid metal elastomeric composites. Mater. Today Commun. 2020, 23, 100878. [Google Scholar] [CrossRef]

- Sepasdar, R.; Karpatne, A.; Shakiba, M. A data-driven approach to full-field nonlinear stress distribution and failure pattern prediction in composites using deep learning. Comput. Methods Appl. Mech. Eng. 2022, 397, 115126. [Google Scholar] [CrossRef]

| Input Parameters | Preliminary Test to Find the Optimal Values of Input Parameters | Exact Values and Range of Input Parameters after the Initial Test |

|---|---|---|

| Frequency of additional seeds | −1000–(−2000) | −1600–(−1900) |

| Growth rate | 0.0001–1 | 0.0001–1 |

| Initial seeds | 50–10,000 | 2000 |

| VF of tungsten | 0.7 | 0.7 |

| Growth Probabilities in X and Y Direction (Equal) and Z Direction | Average TC (W/mK) with N = 200 | Average TC (W/mK) with N = 100 | |

|---|---|---|---|

| 0.5 | 0.5 | 327.18 | 334.41 |

| 0.75 | 0.25 | 308.15 | 307.31 |

| 0.25 | 0.75 | 322.45 | 321.52 |

| 0.375 | 0.375 | 317.83 | 316.83 |

| 0.875 | 0.875 | 311.89 | 311.76 |

| 0.625 | 0.125 | 327.05 | 326.97 |

| 0.125 | 0.625 | 311.81 | 310.61 |

| 0.1875 | 0.3125 | 317.23 | 317.19 |

| 0.6875 | 0.8125 | 302.66 | 300.98 |

| 0.9375 | 0.0625 | 313.66 | 312.26 |

| Number of Neurons | Mean Square Error (MSE) | |

|---|---|---|

| 3-hidden layer | 100, 50, 25 | 0.0295574 |

| 100, 100, 50 | 0.0920061 | |

| 100, 100, 25 | 0.0531873 | |

| 100, 50, 50 | 0.0277496 | |

| 100, 25, 25 | 0.0671589 | |

| 100, 100, 100 | 0.0265248 | |

| 50, 50, 25 | 0.0278472 | |

| 50, 25, 25 | 0.0285401 | |

| 50, 50, 50 | 0.0675849 | |

| 25, 25, 25 | 0.02805 | |

| 2-hidden layer | 100, 100 | 0.0261359 |

| 100, 50 | 0.0307351 | |

| 100, 25 | 0.0567823 | |

| 50, 50 | 0.0559963 | |

| 50, 25 | 0.0290273 | |

| 25, 25 | 0.0367758 | |

| 1-hidden layer | 100 | 0.0757515 |

| 50 | 0.0397491 | |

| 25 | 0.0428257 |

| Realization of 1000 RVEs | FFT Homogenization/RVE | Surrogate Model Training and Prediction/RVE | Inverse Design |

|---|---|---|---|

| 90 | 270 | 2 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seyed Mahmoud, S.M.A.; Faraji, G.; Baghani, M.; Hashemi, M.S.; Sheidaei, A.; Baniassadi, M. Design of Refractory Alloys for Desired Thermal Conductivity via AI-Assisted In-Silico Microstructure Realization. Materials 2023, 16, 1088. https://doi.org/10.3390/ma16031088

Seyed Mahmoud SMA, Faraji G, Baghani M, Hashemi MS, Sheidaei A, Baniassadi M. Design of Refractory Alloys for Desired Thermal Conductivity via AI-Assisted In-Silico Microstructure Realization. Materials. 2023; 16(3):1088. https://doi.org/10.3390/ma16031088

Chicago/Turabian StyleSeyed Mahmoud, Seyed Mohammad Ali, Ghader Faraji, Mostafa Baghani, Mohammad Saber Hashemi, Azadeh Sheidaei, and Majid Baniassadi. 2023. "Design of Refractory Alloys for Desired Thermal Conductivity via AI-Assisted In-Silico Microstructure Realization" Materials 16, no. 3: 1088. https://doi.org/10.3390/ma16031088

APA StyleSeyed Mahmoud, S. M. A., Faraji, G., Baghani, M., Hashemi, M. S., Sheidaei, A., & Baniassadi, M. (2023). Design of Refractory Alloys for Desired Thermal Conductivity via AI-Assisted In-Silico Microstructure Realization. Materials, 16(3), 1088. https://doi.org/10.3390/ma16031088