Effect of Superfine Cement Modification on Properties of Coral Aggregate Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

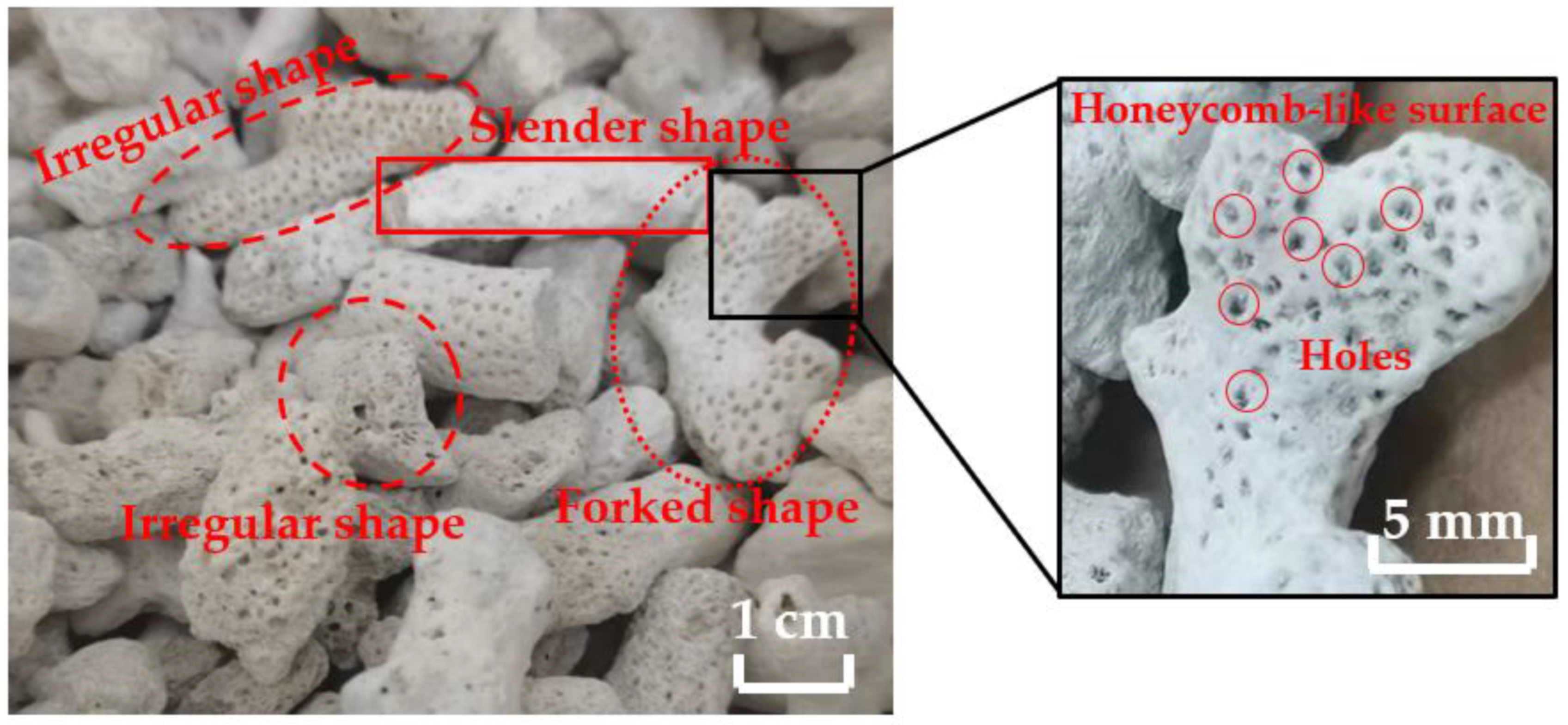

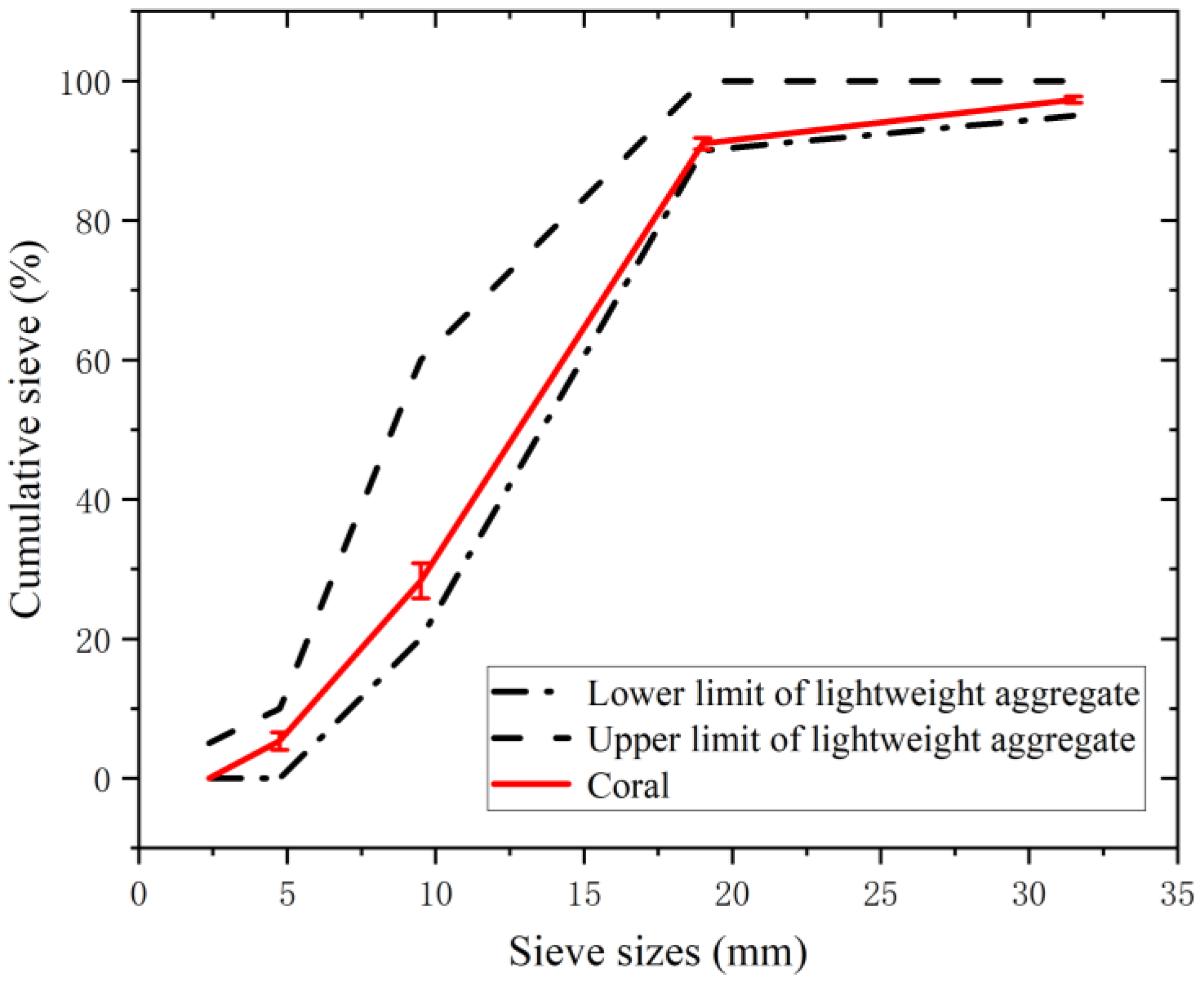

2.1.1. Coral

2.1.2. Cement and Superfine Cement

2.1.3. Seawater

2.1.4. Sea Sand

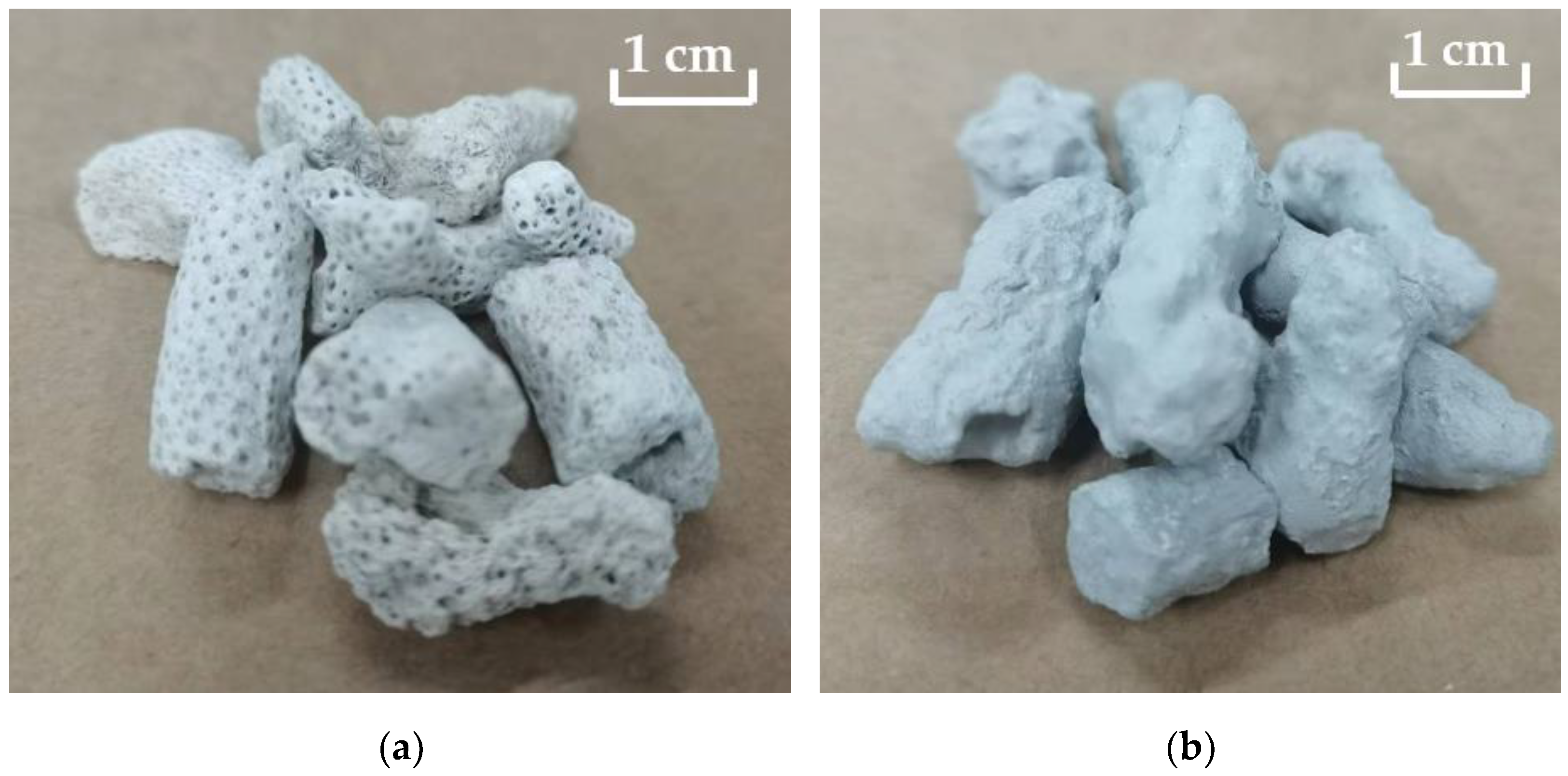

2.2. Coral Aggregate Modification

2.3. Physical and Mechanical Property Test

3. Results and Discussion

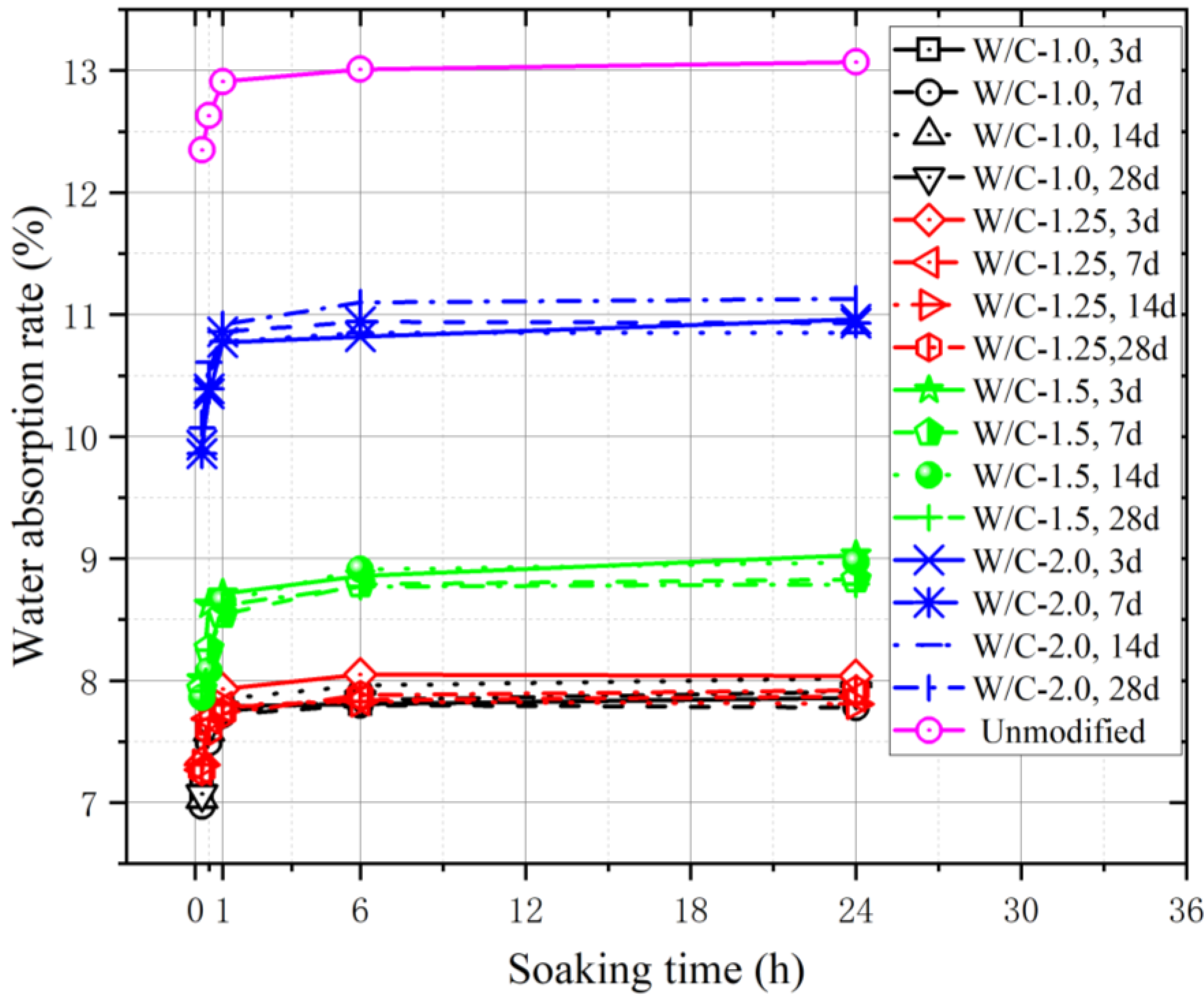

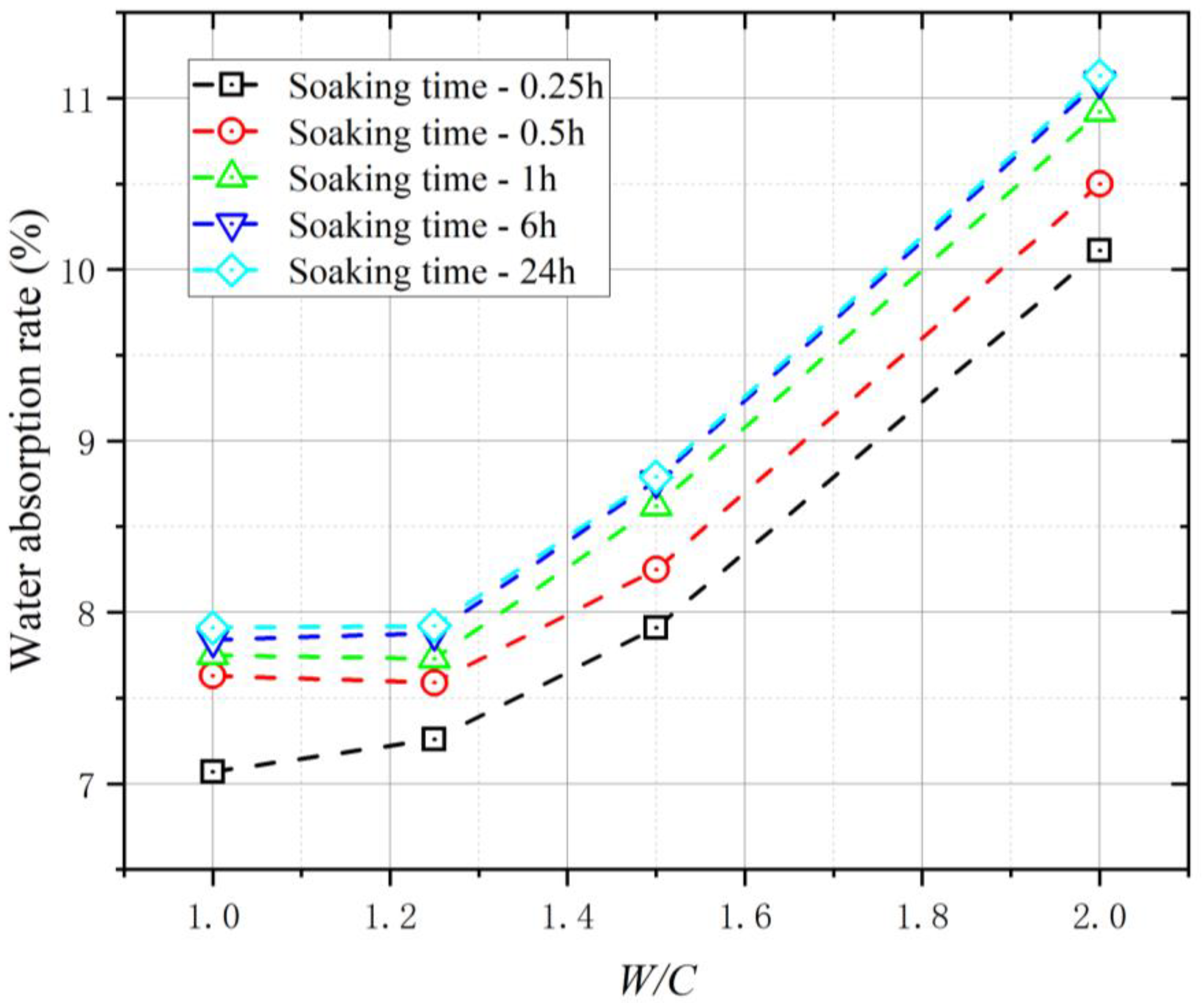

3.1. Water Absorption of Coral Aggregate

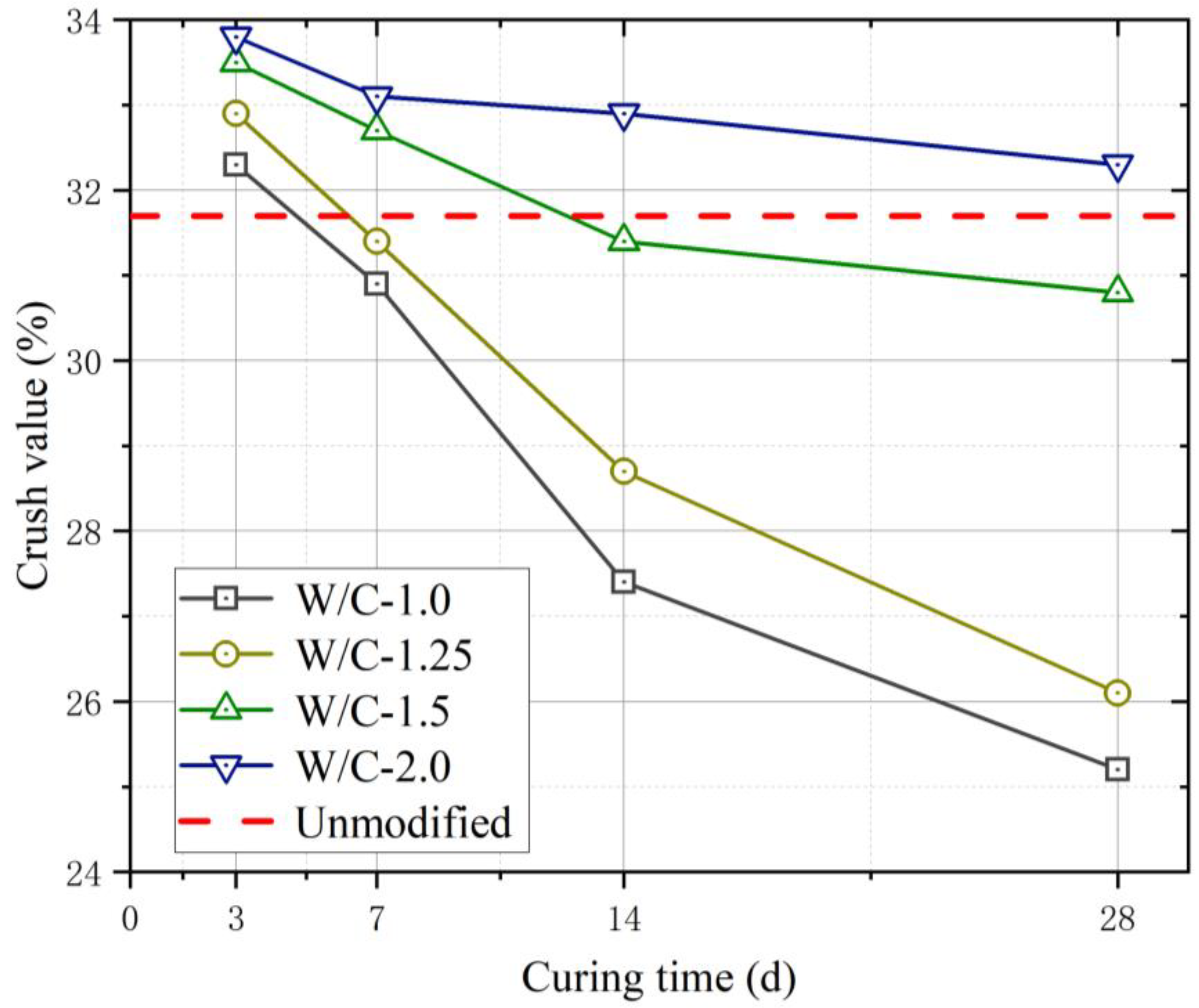

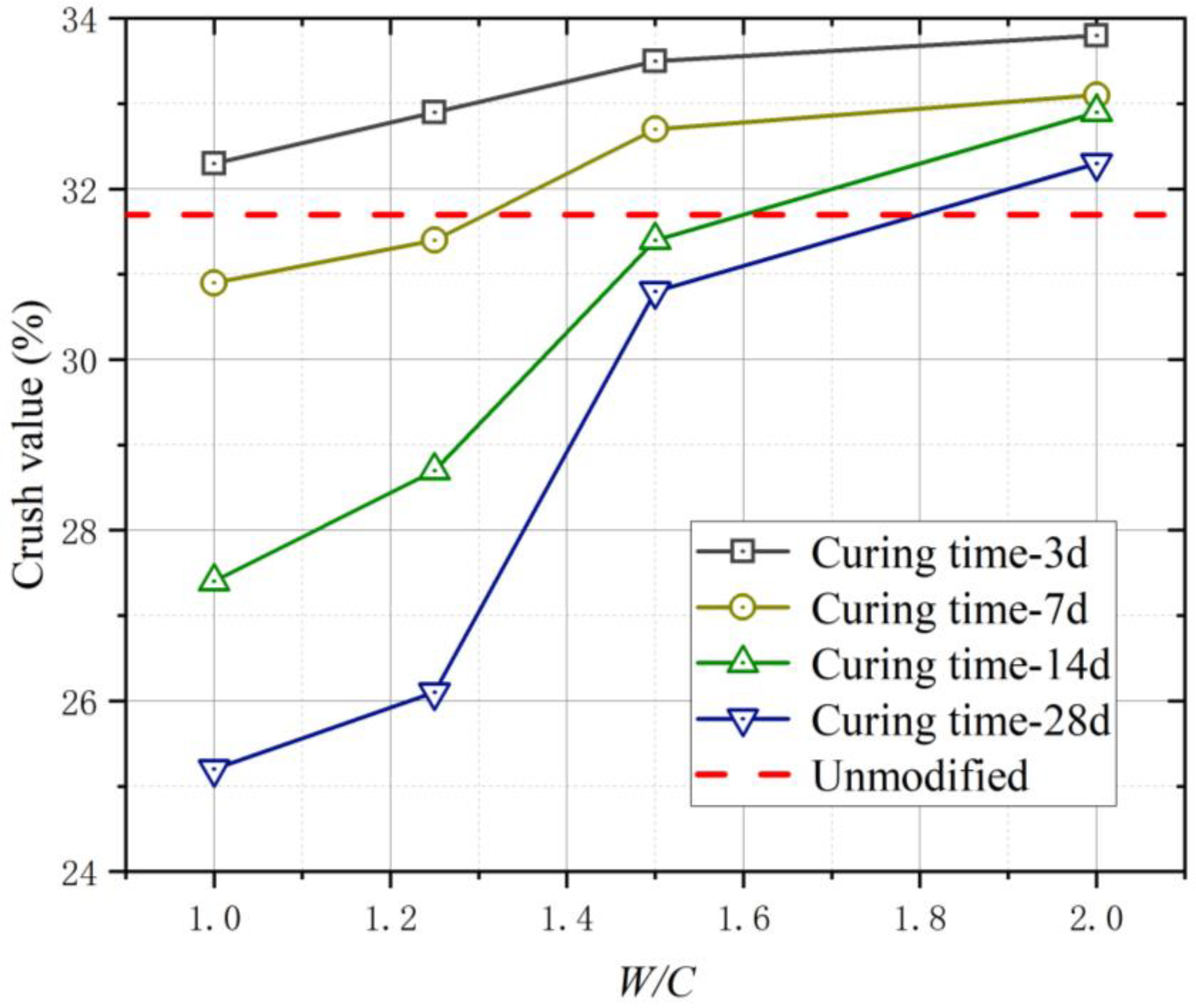

3.2. Strength of Coral Aggregates

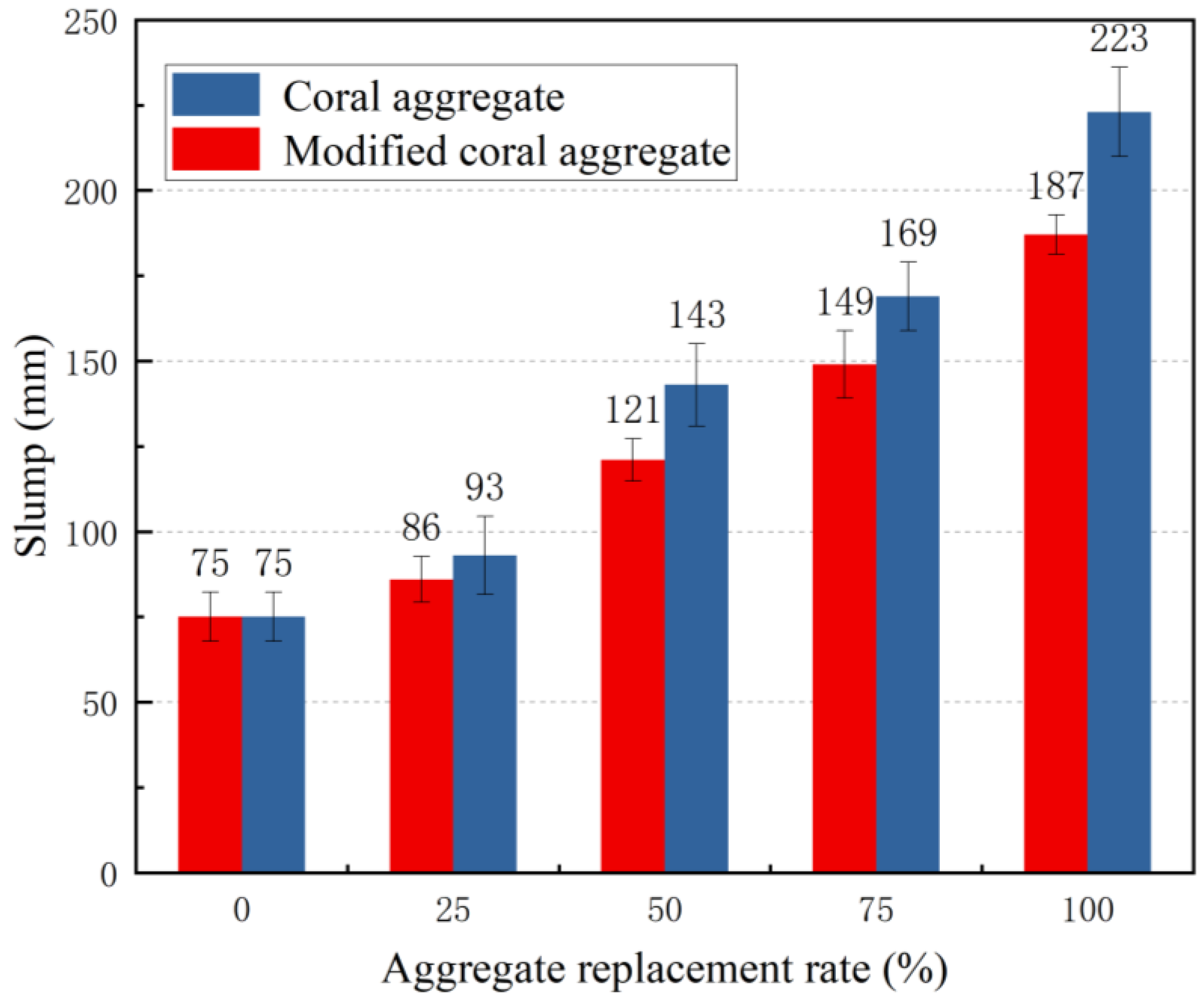

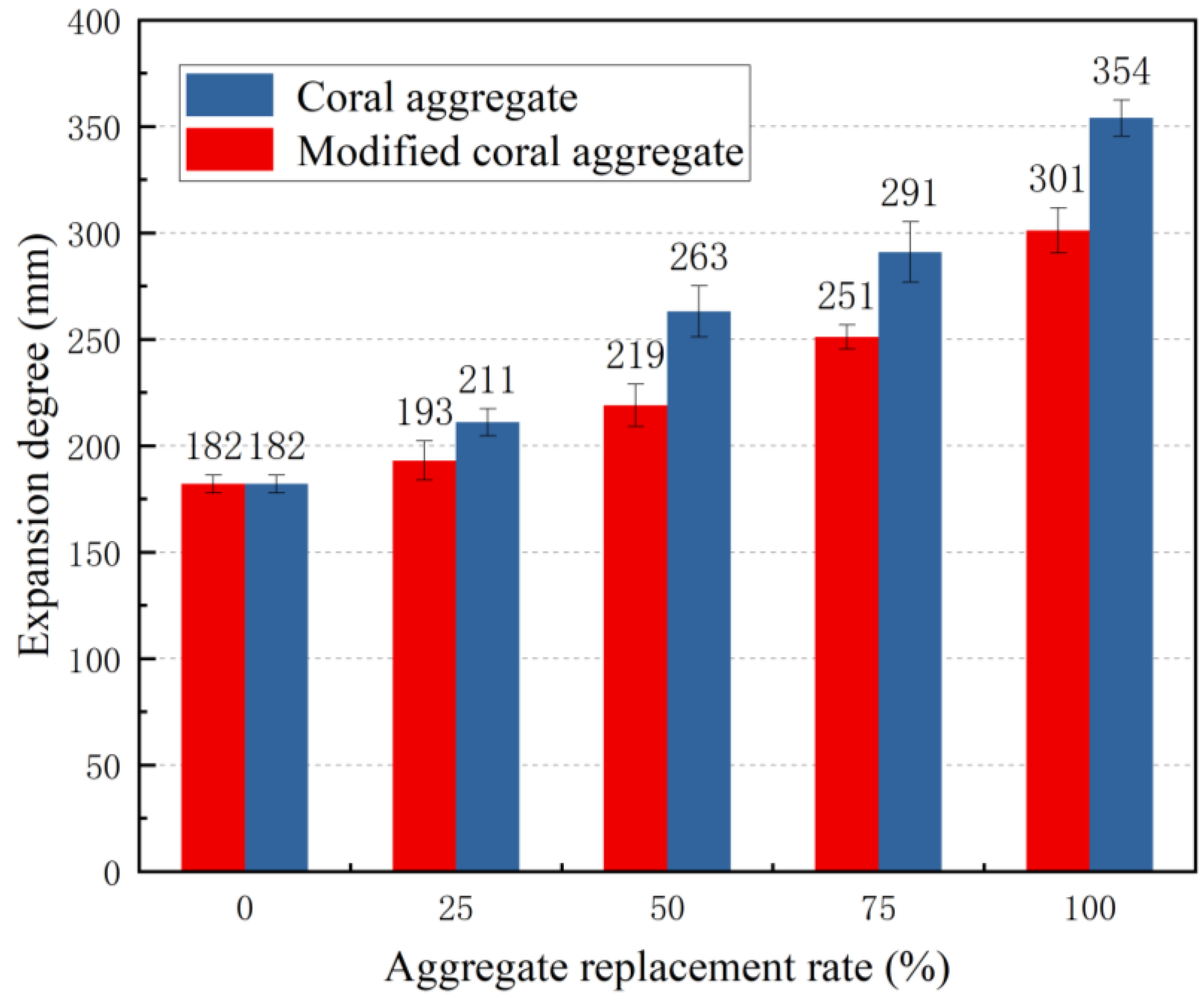

3.3. Workability of Concrete

3.4. Axial Compressive Strength of Concrete

4. Conclusions

- (1)

- The water absorption of the modified coral aggregates increased with the slurry W/C. When the W/C was less than 1.25, the variation in the water absorption rate was not apparent; when the W/C exceeded 1.25, the slurry was overly thin, which prevented the formation of a slurry shell on the surface of the coral aggregate; consequently, the water absorption increased significantly with the W/C. After the coral aggregates were modified by superfine cement slurry, the water absorption of the aggregate reduced significantly, and the coral aggregate reached the saturated surface dry state after soaking for 1 h.

- (2)

- The Cr of the modified coral aggregate was higher than that of the unmodified coral aggregate when the curing time was shorter. When the W/C of the cement slurry exceeded 1.25, the Cr of the modified coral aggregate started to be lower than that of the unmodified coral aggregate after 7 d of curing and then decreased significantly as the curing time increased. A slurry with a W/C greater than 1.25 could not be solidified for a long time; hence, a compact slurry protective layer could not be formed on the aggregate surface. The Cr of the aggregates did not change significantly as curing progressed.

- (3)

- As the coral aggregate replacement rate increased, the slump and expansion of the concrete increased; meanwhile, at the same replacement rate, the slump and expansion of the modified coral concrete were significantly lower than those before modification. The slump and expansion of the modified concrete decreased by approximately 16.14% and 14.97% at 100% replacement rate, respectively. The dense slurry shell formed on the surface of the modified aggregate significantly reduced the water absorption and discharge effects of the coral aggregates, and the water secretion rate of the modified concrete was 47.4% lower compared with that before the modification.

- (4)

- After the axial compression failure, the gravel aggregate concrete, coral aggregate concrete, and modified coral aggregate concrete exhibited damage along the diagonal direction of the specimens. Compared with the gravel aggregate concrete, the coral aggregate concrete showed more vertical cracks. The axial compressive strength of the coral aggregate concrete was approximately 60% that of the gravel aggregate concrete. The effect of superfine cement modification on improving the compressive properties of the coral aggregate concrete was insignificant.

- (5)

- Based on the test results, it is suggested that the W/C of superfine cement shall be 1.25. The coral aggregate shall be cured for not less than 7 days after modification, and the soaking time of the modified coral aggregate shall not be less than 1 h.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, Z.; Wu, G.; Zhao, X.-L.; Zhu, H.; Lian, J.-L. Durability test on the flexural performance of seawater sea-sand concrete beams completely reinforced with FRP bars. Constr. Build. Mater. 2018, 192, 671–682. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.-L.; Xian, G.; Wu, G.; Raman, R.S.; Al-Saadi, S. Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sand concrete environment. Constr. Build. Mater. 2017, 156, 985–1004. [Google Scholar] [CrossRef]

- El-Hassan, H.; El-Maaddawy, T.; Al-Sallamin, A.; Al-Saidy, A. Durability of glass fiber-reinforced polymer bars conditioned in moist seawater-contaminated concrete under sustained load. Constr. Build. Mater. 2018, 175, 1–13. [Google Scholar] [CrossRef]

- Hua, J.; Wang, F.; Xue, X.; Ding, Z.; Chen, Z. Residual monotonic mechanical properties of bimetallic steel bar with fatigue damage. J. Build. Eng. 2022, 55, 104703. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, J.; Zhou, X.; Xue, X. Post–fire properties of stainless–clad bimetallic steel produced by explosive welding process. J. Constr. Steel Res. 2023, 201, 107690. [Google Scholar] [CrossRef]

- Hua, J.; Wang, F.; Xue, X.; Fan, H.; Yan, W. Fatigue properties of bimetallic steel bar: An experimental and numerical study. Eng. Fail. Anal. 2022, 136, 106212. [Google Scholar] [CrossRef]

- Hua, J.; Wang, F.; Xue, X. Study on fatigue properties of post-fire bimetallic steel bar with different cooling methods. Structures 2022, 40, 633–645. [Google Scholar] [CrossRef]

- Shi, Y.; Luo, Z.; Zhou, X.; Xue, X.; Xiang, Y. Post-fire performance of bonding interface in explosion-welded stainless-clad bimetallic steel. J. Constr. Steel Res. 2022, 193, 107285. [Google Scholar] [CrossRef]

- Luo, Z.; Shi, Y.; Xue, X.; Zhou, X.; Yao, X. Nonlinear patch resistance performance of hybrid titanium-clad bimetallic steel plate girder with web opening. J. Build. Eng. 2023, 65, 105703. [Google Scholar] [CrossRef]

- Shi, Y.; Luo, Z.; Zhou, X.; Xue, X.; Li, J. Post-fire mechanical properties of titanium–clad bimetallic steel in different cooling approaches. J. Constr. Steel Res. 2022, 191, 107169. [Google Scholar] [CrossRef]

- Luo, Z.; Shi, Y.; Xue, X.; Xu, L.; Zhang, H. Design recommendations on longitudinally stiffened titanium-clad bimetallic steel plate girder. J. Constr. Steel Res. 2023, 201, 107748. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano Silica and Metakaolin Effects on the Behavior of Concrete Containing Rubber Crumbs. Civileng 2020, 1, 17. [Google Scholar] [CrossRef]

- Liu, G.; Hua, J.; Wang, N.; Deng, W.; Xue, X. Material Alternatives for Concrete Structures on Remote Islands: Based on Life-Cycle-Cost Analysis. Adv. Civ. Eng. 2022, 2022, 7329408. [Google Scholar] [CrossRef]

- Wang, F.; Hua, J.; Xue, X.; Wang, N.; Yao, Y. Effects of Polyoxymethylene Fiber on Mechanical Properties of Seawater Sea-Sand Concrete with Different Ages. Polymers 2022, 14, 3472. [Google Scholar] [CrossRef]

- Xue, X.; Wang, F.; Hua, J.; Wang, N.; Huang, L.; Chen, Z.; Yao, Y. Effects of Polyoxymethylene Fiber on Fresh and Hardened Properties of Seawater Sea-Sand Concrete. Polymers 2022, 14, 4969. [Google Scholar] [CrossRef]

- Hua, J.; Yang, Z.; Xue, X.; Huang, L.; Wang, N.; Chen, Z. Bond properties of bimetallic steel bar in seawater sea-sand concrete at different ages. Constr. Build. Mater. 2022, 323, 126539. [Google Scholar] [CrossRef]

- Howdyshell, P.A. The Use of Coral as an Aggregate for Portland Cement Concrete Structures; U.S. Army Construction Engineering Research Laboratory: Champaign, IL, USA, 1974. [Google Scholar]

- Wu, Z.; Yu, H.; Ma, H.; Zhang, J.; Da, B. Physical and mechanical properties of coral aggregates in the South China Sea. J. Build. Eng. 2022, 63, 105478. [Google Scholar] [CrossRef]

- Ma, H.; Yue, C.; Yu, H.; Mei, Q.; Chen, L.; Zhang, J.; Zhang, Y.; Jiang, X. Experimental study and numerical simulation of impact compression mechanical properties of high strength coral aggregate seawater concrete. Int. J. Impact Eng. 2020, 137, 103466. [Google Scholar] [CrossRef]

- Chen, B.; Yu, H.; Zhang, J.; Ma, H. Evolution law of crack propagation and crack mode in coral aggregate concrete under compression: Experimental study and 3D mesoscopic analysis. Theor. Appl. Fract. Mech. 2022, 122, 103663. [Google Scholar] [CrossRef]

- Cai, Y.; Ren, H.-Q.; Long, Z.-L.; Guo, R.-Q.; Du, K.-M.; Chen, S.-S.; Zheng, Z.-H. Comparison study on the impact compression mechanical properties of coral aggregate concrete and ordinary Portland concrete. Structures 2022, 44, 1403–1415. [Google Scholar] [CrossRef]

- Zhou, W.; Feng, P.; Lin, H. Constitutive relations of coral aggregate concrete under uniaxial and triaxial compression. Constr. Build. Mater. 2020, 251, 118957. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Wang, W.; Zuo, X.; Wu, J. Evaluation and optimization of various treatment methods for enhancing the properties of brick-concrete recycled coarse aggregate. J. Adhes. Sci. Technol. 2022, 36, 1060–1080. [Google Scholar] [CrossRef]

- Yang, J.; Shaban, W.M.; Elbaz, K.; Thomas, B.S.; Xie, J.; Li, L. Properties of concrete containing strengthened crushed brick aggregate by pozzolan slurry. Constr. Build. Mater. 2020, 247, 118612. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F.; Taherinezhad, J. Chloride ion permeability improvement of recycled aggregate concrete using pretreated recycled aggregates by silica fume slurry. Constr. Build. Mater. 2021, 270, 121498. [Google Scholar] [CrossRef]

- Ashraf, W.; Noor, M. Performance-Evaluation of Concrete Properties for Different Combined Aggregate Gradation Approaches. Procedia Eng. 2011, 14, 2627–2634. [Google Scholar] [CrossRef] [Green Version]

- Sokhansefat, G.; Ley, M.T.; Cook, M.D.; Alturki, R.; Moradian, M. Investigation of concrete workability through characterization of aggregate gradation in hardened concrete using X-ray computed tomography. Cem. Concr. Compos. 2019, 98, 150–161. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, J.; Ying, M.; Ni, J.; Li, M. Effect of particle-size gradation on cyclic shear properties of recycled concrete aggregate. Constr. Build. Mater. 2021, 301, 124143. [Google Scholar] [CrossRef]

- Wang, J.; Sun, H.; Yu, L.; Liu, S.; Geng, D.; Yuan, L.; Zhou, Z.; Cheng, X.; Du, P. Improvement of intrinsic self-healing ability of concrete by adjusting aggregate gradation and sand ratio. Constr. Build. Mater. 2021, 309, 124959. [Google Scholar] [CrossRef]

- GB/T 17431.1-2010; Lightweight Aggregates and Its Test Methods. Part 1: Lightweight Aggregates. China Standard Press: Beijing, China, 2010.

- Chen, J.; Kwan, A. Superfine cement for improving packing density, rheology and strength of cement paste. Cem. Concr. Compos. 2012, 34, 1–10. [Google Scholar] [CrossRef]

- Li, W.; Shaikh, F.U.; Wang, L.; Lu, Y.; Wang, B.; Jiang, C.; Su, Y. Experimental study on shear property and rheological characteristic of superfine cement grouts with nano-SiO2 addition. Constr. Build. Mater. 2019, 228, 117046. [Google Scholar] [CrossRef]

- GB 175-2007; Common Portland Cement. China Standard Press: Beijing, China, 2007.

- Ahmed, A.; Guo, S.; Zhang, Z.; Shi, C.; Zhu, D. A review on durability of fiber reinforced polymer (FRP) bars reinforced seawater sea sand concrete. Constr. Build. Mater. 2020, 256, 119484. [Google Scholar] [CrossRef]

- Ding, Y.; Azevedo, C.; Aguiar, J.; Jalali, S. Study on residual behaviour and flexural toughness of fibre cocktail reinforced self compacting high performance concrete after exposure to high temperature. Constr. Build. Mater. 2012, 26, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Kucche, K.J.; Jamkar, S.S.; Sadgir, P.A. Quality of water for making concrete: A review of literature. Int. J. Sci. Res. Publ. 2015, 5, 1–10. [Google Scholar]

- Wegian, F.M. Effect of seawater for mixing and curing on structural concrete. IES J. Part A: Civ. Struct. Eng. 2010, 3, 235–243. [Google Scholar] [CrossRef]

- ASTM D1141-1998(2013); Standard Practice for the Preparation of Substitute Ocean Water. ASTM International: West Conshohocken, PA, USA, 2013.

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Su, R.; Li, X.; Xu, S.-Y. Axial behavior of circular CFST encased seawater sea-sand concrete filled PVC/GFRP tube columns. Constr. Build. Mater. 2022, 353, 129159. [Google Scholar] [CrossRef]

- Kazemi, H.; Yekrangnia, M.; Shakiba, M.; Bazli, M.; Oskouei, A.V. Bond-slip behaviour between GFRP/steel bars and seawater concrete after exposure to environmental conditions. Eng. Struct. 2022, 268, 114796. [Google Scholar] [CrossRef]

- Zhao, Y.; Hu, X.; Shi, C.; Zhang, Z.; Zhu, D. A review on seawater sea-sand concrete: Mixture proportion, hydration, microstructure and properties. Constr. Build. Mater. 2021, 295, 123602. [Google Scholar] [CrossRef]

- GB/T 14684-2011; Sand for Construction. China Standard Press: Beijing, China, 2011.

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659–669. [Google Scholar] [CrossRef]

- Farzampour, A. Compressive behavior of concrete under environmental effects. In Compressive Strength of Concrete; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- GB/T 17431.2-2010; Lightweight Aggregates and Its Test Methods Part 2: Test Methods for Lightweight Aggregates. China Standard Press: Beijing, China, 2010.

- DL/T 5141-2014; Code for Testing Aggregates of Hydraulic Concrete. China Electric Power Press: Beijing, China, 2014.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Standard Press: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Construction of the PR China: Beijing, China, 2019.

- Xue, X.; Shi, Y.; Zhou, X.; Wang, J.; Xu, Y. Experimental study on the properties of Q960 ultra–high–strength steel after fire exposure. Structures 2023, 47, 2081–2098. [Google Scholar] [CrossRef]

- Hua, J.; Wang, F.; Xue, X.; Sun, Y.; Gao, Y. Post-fire ultra-low cycle fatigue properties of high-strength steel via different cooling methods. Thin-Walled Struct. 2023, 183, 110406. [Google Scholar] [CrossRef]

- Damineli, B.L.; Quattrone, M.; Angulo, S.C.; Taqueda, M.E.S.; John, V.M. Rapid method for measuring the water absorption of recycled aggregates. Mater. Struct. 2016, 49, 4069–4084. [Google Scholar] [CrossRef]

- Eckert, M.; Oliveira, M. Mitigation of the negative effects of recycled aggregate water absorption in concrete technology. Constr. Build. Mater. 2017, 133, 416–424. [Google Scholar] [CrossRef]

- Hassan, H.M.Z.; Wu, K.; Huang, W.; Chen, S.; Zhang, Q.; Xie, J.; Cai, X. Study on the influence of aggregate strength and shape on the performance of asphalt mixture. Constr. Build. Mater. 2021, 294, 123599. [Google Scholar] [CrossRef]

- Zou, G.; Zhang, J.; Liu, X.; Lin, Y.; Yu, H. Design and performance of emulsified asphalt mixtures containing construction and demolition waste. Constr. Build. Mater. 2020, 239, 117846. [Google Scholar] [CrossRef]

- Miao, Y.; Yu, W.; Hou, Y.; Liu, C.; Wang, L. Influences of Clay Brick Particles on the Performance of Cement Stabilized Recycled Aggregate as Pavement Base. Sustainability 2018, 10, 3505. [Google Scholar] [CrossRef] [Green Version]

- Joshi, T.; Dave, U. Construction of pervious concrete pavement stretch, Ahmedabad, India—Case study. Case Stud. Constr. Mater. 2022, 16, e00622. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, K.; Zhang, J.; Guo, J. Experimental Study on Performance Influencing Factors and Reasonable Mixture Ratio of Desert Sand Ceramsite Lightweight Aggregate Concrete. Adv. Civ. Eng. 2020, 2020, 8613932. [Google Scholar] [CrossRef]

| Physical Properties | Coral Aggregate | ||||

|---|---|---|---|---|---|

| Sample 1 | Sample 2 | Sample 3 | Average | Standard Deviation | |

| Bulk density (kg/m3) | 998 | 1065 | 1007 | 1023 | 36 |

| Apparent density (kg/m3) | 2437 | 2509 | 2481 | 2475 | 36 |

| Porosity (%) | 59.0 | 57.6 | 59.4 | 58.7 | 1.0 |

| Crush index (%) | 31.9 | 31.3 | 32.0 | 31.7 | 0.4 |

| Water absorption (%) | 12.96 | 12.88 | 13.09 | 12.98 | 0.11 |

| Specific Surface Area (m2∙kg−1) | Particle Size Distribution (μm) | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|

| D50 | D90 | Average | 3 d | 28 d | 3 d | 28 d | |

| 800 | ≤3.5 | ≤10 | 3.5 | ≥40 | ≥70 | ≥8 | ≥11 |

| Specific Surface Area (m2∙kg−1) | Standard Consistency (%) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial | Final | 3 d | 28 d | 3 d | 28 d | ||

| 360 | 28.00 | 225 | 295 | 33.6 | 55.7 | 6.3 | 8.6 |

| Chemical | NaCl | MgCl2 | Na2SO4 | CaCl2 |

|---|---|---|---|---|

| Concentration (g/L) | 24.53 | 5.2 | 4.09 | 1.16 |

| Sieve Diameter | 4.75 mm | 2.36 mm | 1.18 mm | 600 μm | 300 μm |

|---|---|---|---|---|---|

| Cumulative percentages of sieve residue (%) | 4.0 | 14.0 | 29.4 | 49.0 | 68.6 |

| Number | Replacement Rate of Aggregate | Water | Cement | Sea Sand | Aggregates | Water Reducer | ||

|---|---|---|---|---|---|---|---|---|

| Gravel | Coral | Modified Coral | ||||||

| P0 | 0% | 200 | 500 | 830 | 1074 | 0 | 0 | 0.05% |

| P25W | 25% | 200 | 500 | 830 | 805.5 | 175.3 | 0 | |

| P25G | 200 | 500 | 830 | 805.5 | 0 | 175.3 | ||

| P50W | 50% | 200 | 500 | 830 | 537 | 350.6 | 0 | |

| P50G | 200 | 500 | 830 | 537 | 0 | 350.6 | ||

| P75W | 75% | 200 | 500 | 830 | 268.5 | 525.8 | 0 | |

| P75G | 200 | 500 | 830 | 268.5 | 0 | 525.8 | ||

| P100W | 100% | 200 | 500 | 830 | 0 | 701.1 | 0 | |

| P100G | 200 | 500 | 830 | 0 | 0 | 701.1 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Hua, J.; Xue, X.; Wang, N.; Yan, F.; Feng, D. Effect of Superfine Cement Modification on Properties of Coral Aggregate Concrete. Materials 2023, 16, 1103. https://doi.org/10.3390/ma16031103

Wang F, Hua J, Xue X, Wang N, Yan F, Feng D. Effect of Superfine Cement Modification on Properties of Coral Aggregate Concrete. Materials. 2023; 16(3):1103. https://doi.org/10.3390/ma16031103

Chicago/Turabian StyleWang, Fei, Jianmin Hua, Xuanyi Xue, Neng Wang, Feidong Yan, and Dou Feng. 2023. "Effect of Superfine Cement Modification on Properties of Coral Aggregate Concrete" Materials 16, no. 3: 1103. https://doi.org/10.3390/ma16031103

APA StyleWang, F., Hua, J., Xue, X., Wang, N., Yan, F., & Feng, D. (2023). Effect of Superfine Cement Modification on Properties of Coral Aggregate Concrete. Materials, 16(3), 1103. https://doi.org/10.3390/ma16031103