Response Surface Methodology Analysis of Energy Harvesting System over Pathway Tiles

Abstract

:1. Introduction

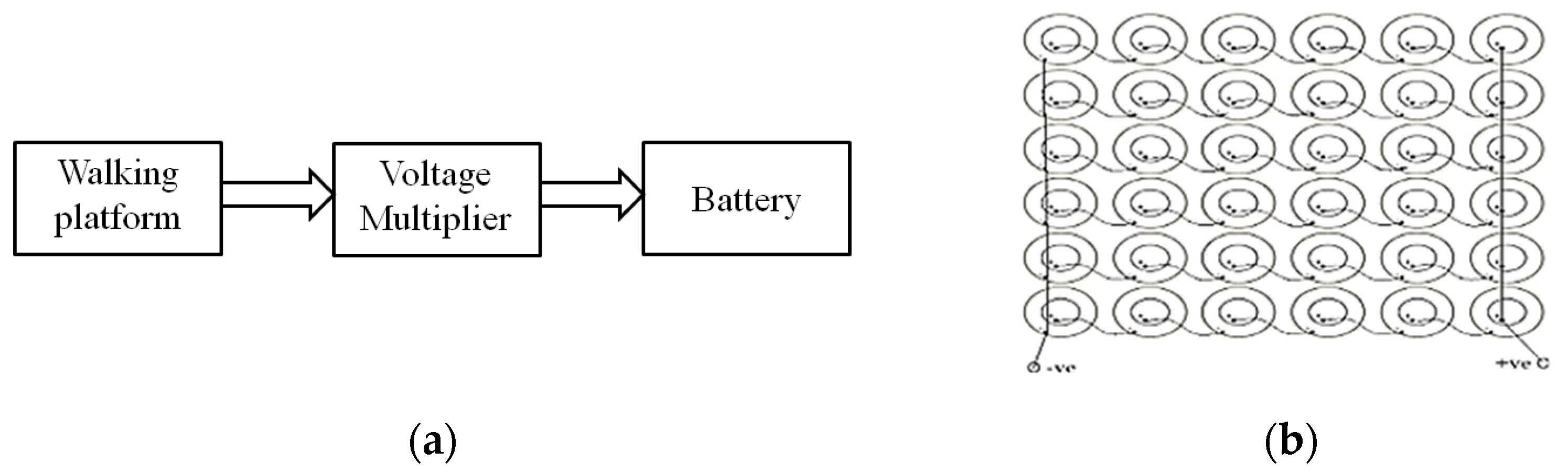

2. Materials and Methods

Experimental Details

3. Methodology

Statistical Assessment and Mathematical Modeling

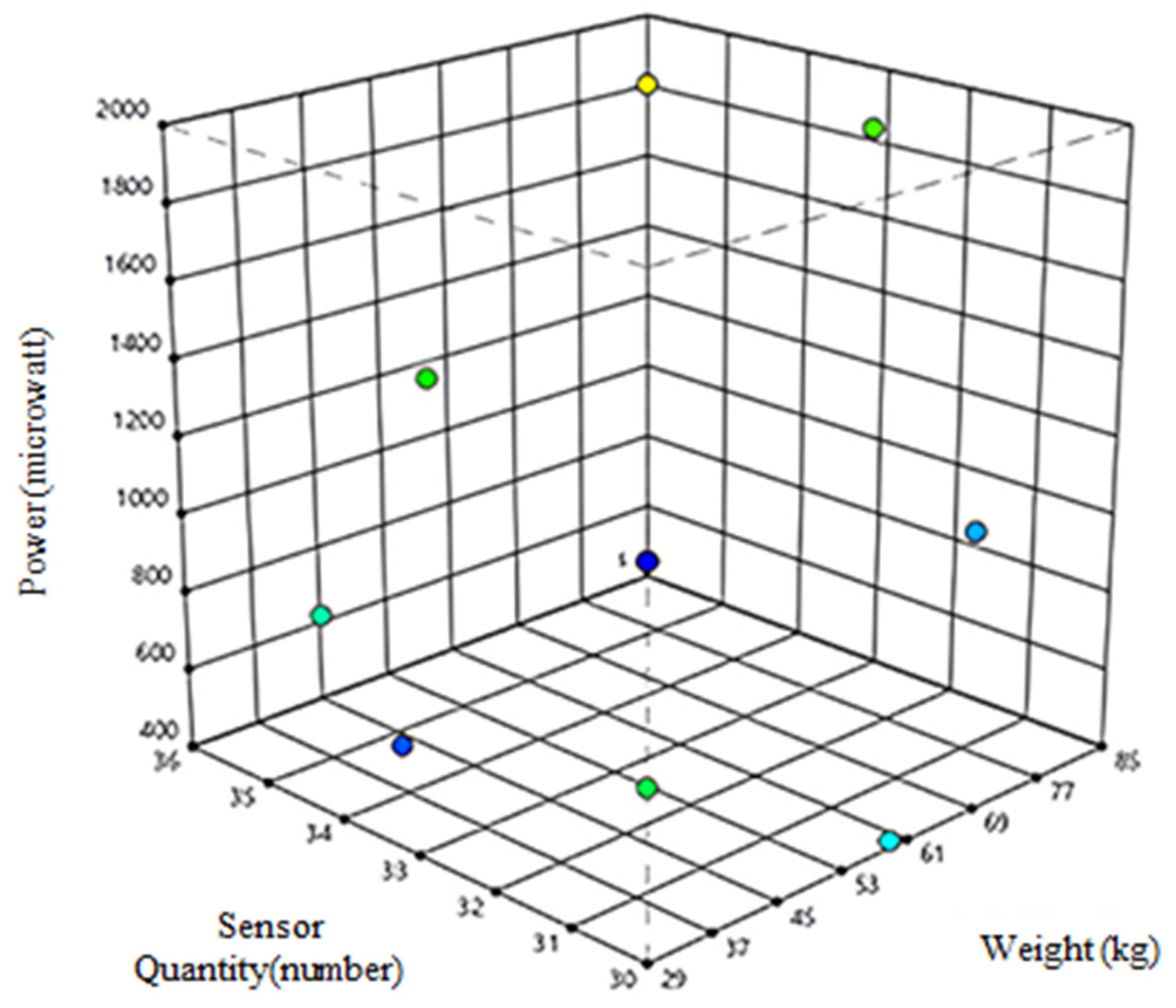

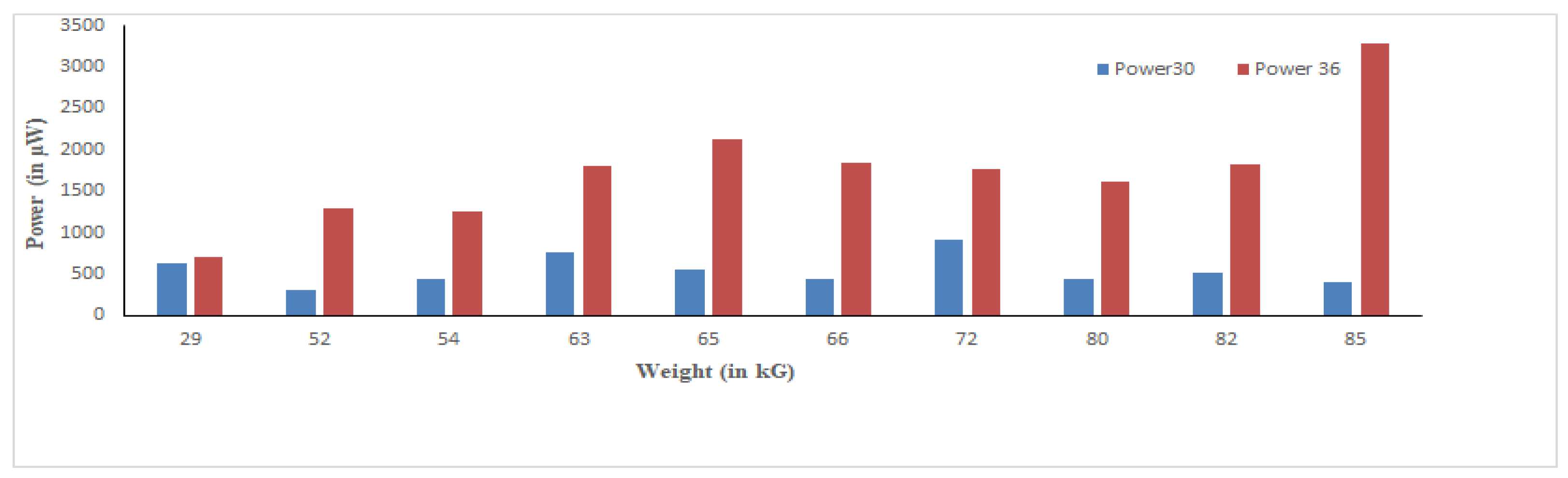

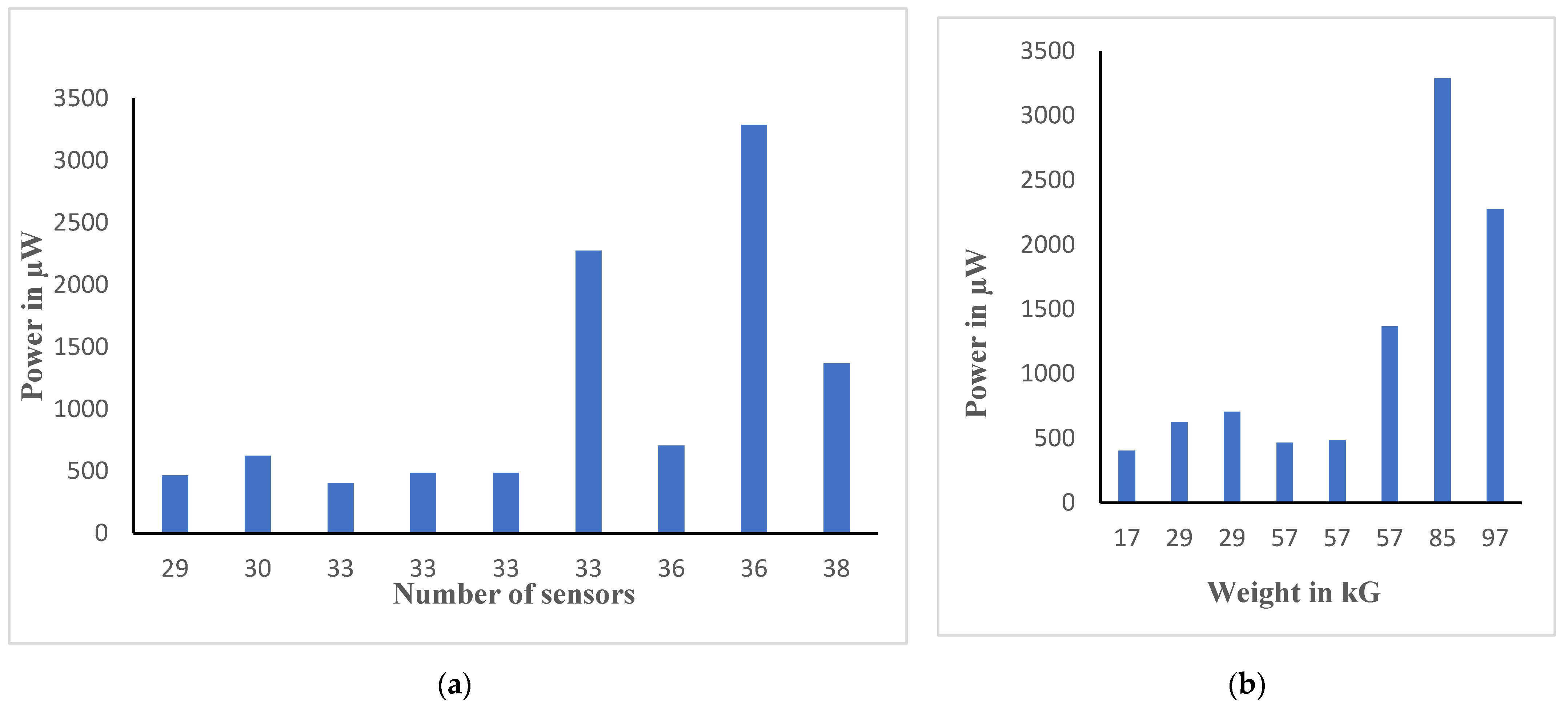

4. Results and Discussion

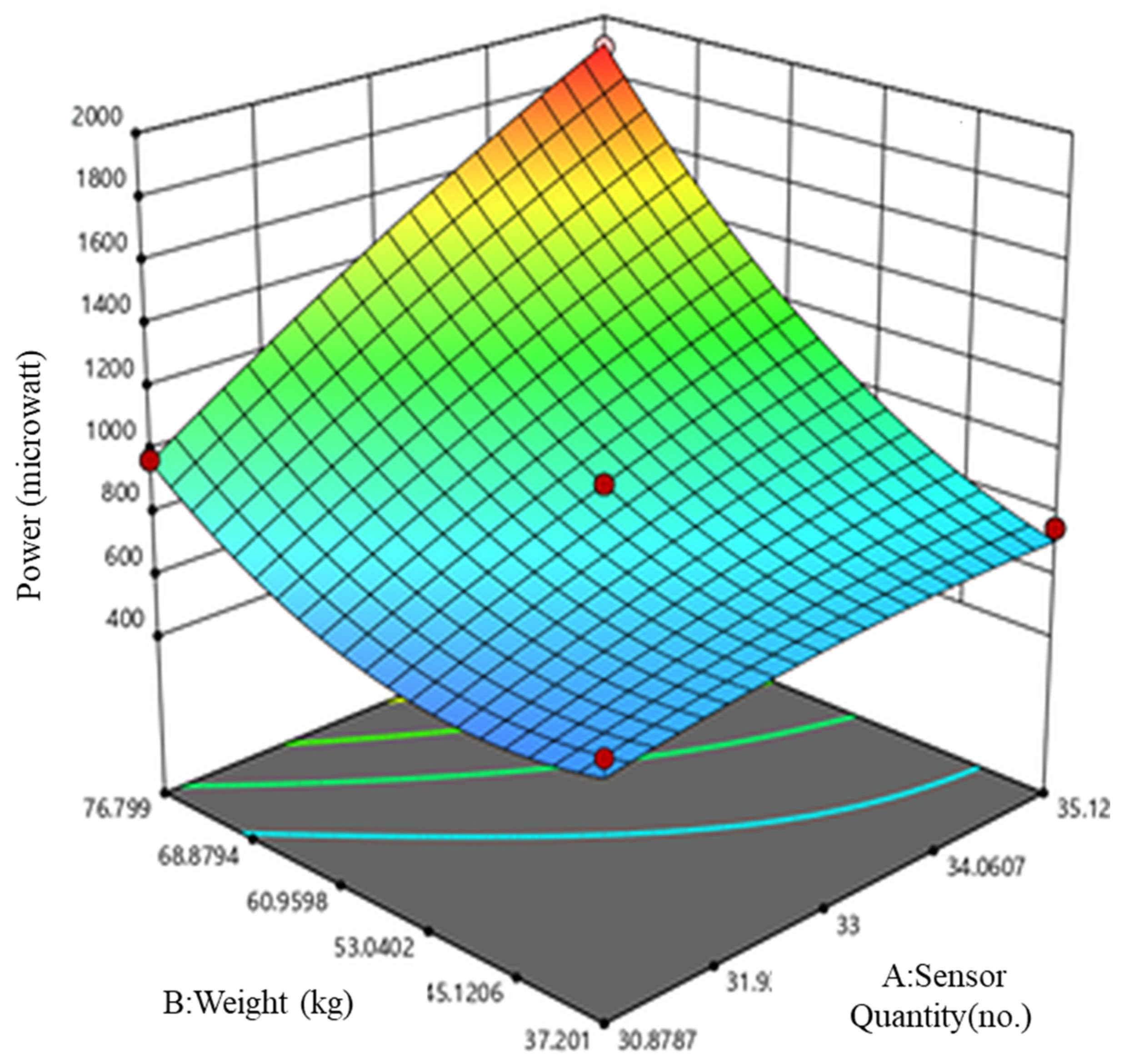

4.1. Software Validation and Optimization of Tiles

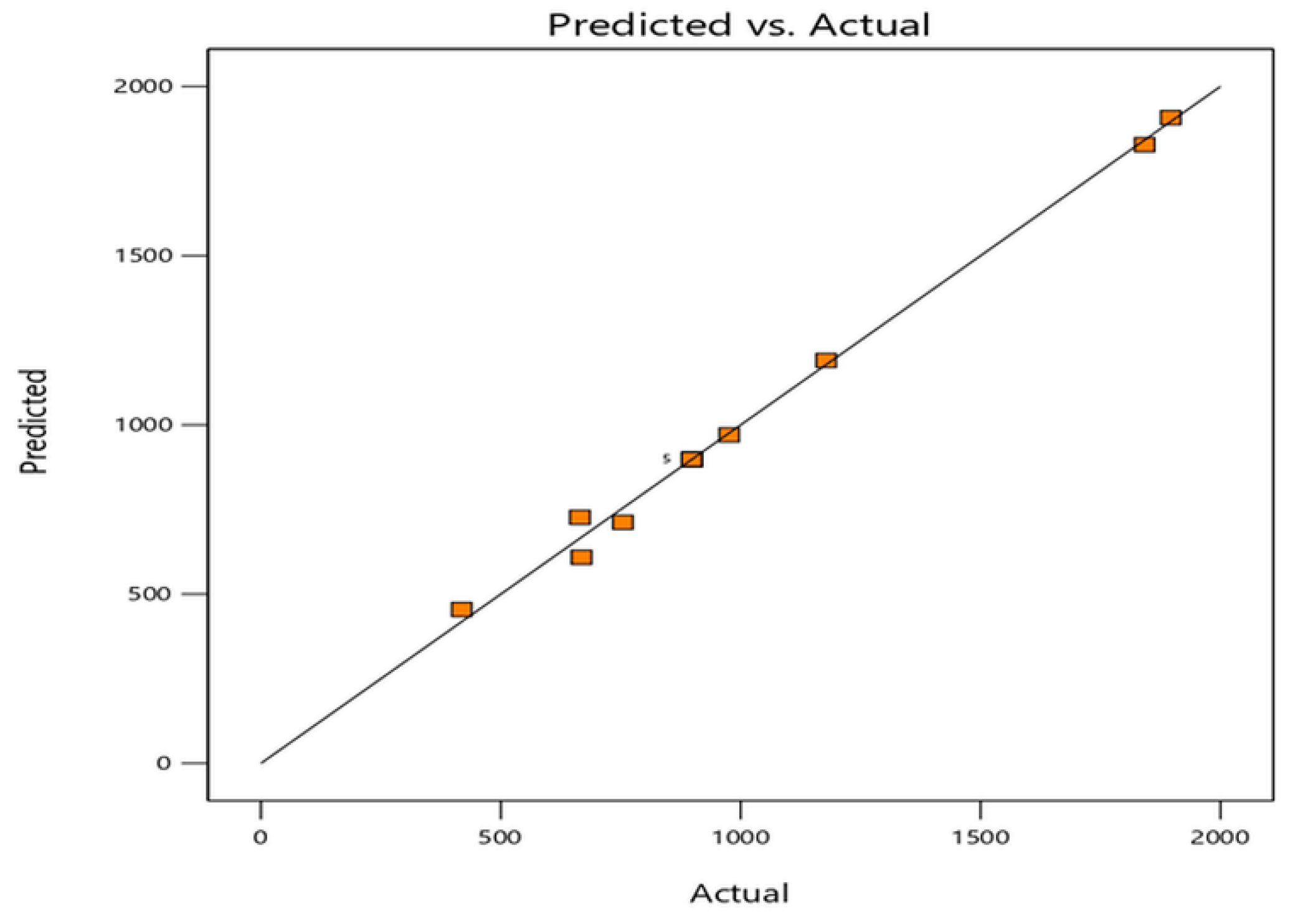

4.2. Development of Regression Model

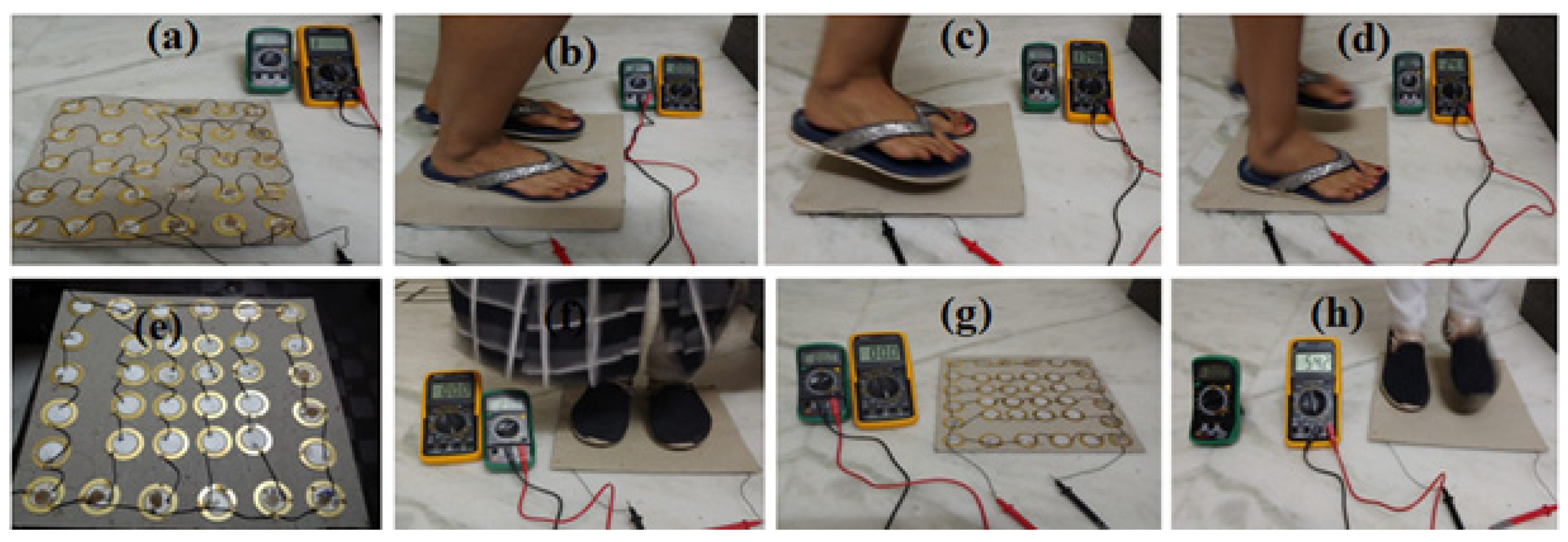

4.3. Prototype Tile Validation

4.4. Summary of Research Findings

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mukherji, R.; Mathur, V.; Bhati, A.; Mukherji, M. Assessment of 50 kWp rooftop solar photovoltaic plant at The ICFAI University, Jaipur: A case study. Environ. Prog. Sustain. Energy 2020, 39, e13353. [Google Scholar] [CrossRef]

- Kessides, I.N. Nuclear power and sustainable energy policy: Promises and perils. World Bank Res. Obs. 2010, 25, 323–362. [Google Scholar] [CrossRef] [Green Version]

- The International Energy Agency (IEA). World Energy Outlook. 2021. Available online: https://iea.blob.core.windows.net/assets/1de6d91e-e23f-4e02-b1fb-51fdd6283b22/India_Energy_Outlook_2021.pdf (accessed on 3 January 2022).

- Sharma, S.; Kiran, R.; Azad, P.; Vaish, R. A review of piezoelectric energy harvesting tiles: Available designs and future perspective. Energy Convers. Manag. 2022, 254, 115272. [Google Scholar] [CrossRef]

- Ahad, M.; Kim, S.; Shen, J.; Rice, D.; Stern, I. Power generation improvement for piezoelectric energy harvesting for roadsides sustainability. In Proceedings of the SoutheastCon, Concord, NC, USA, 30 March–2 April 2017; IEEE: Piscatvie, NJ, USA, 2017; pp. 1–2. [Google Scholar] [CrossRef]

- Rumman, H.; Guangul, F.M.; Abdu, A.; Usman, M.; Alkharusi, A. Harvesting Electricity using Piezoelectric Material in Malls. In Proceedings of the 2019 4th MEC International Conference on Big Data and Smart City (ICBDSC), Muscat, Oman, 15–16 January 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Kar, S.; Samanth, K.; Raghunandana, K. Cost effectiveness of piezo electric energy harvesting. Mater. Today Proc. 2021, 43, 101–104. [Google Scholar] [CrossRef]

- Adhikari, J.; Kumar, R.; Jain, S.C. Modeling and parametric analysis for performance improvement in piezoelectric energy harvesting tile. Ferroelectrics 2021, 573, 201–213. [Google Scholar] [CrossRef]

- Gothwal, P.; Palliwal, P. Optimized Hybrid Electricity Generation. In Proceedings of the Second International Conference on Smart Energy and Communication, Jaipur, India, 20–21 March 2020; Springer: Singapore, 2021; pp. 335–339. [Google Scholar] [CrossRef]

- Cigno, E.; Magagnoli, C.; Pierce, M.; Iglesias, P. Fabrication and evaluation of energy harvesting floor using piezoelectric frequency up-converting mechanism. Sens. Actuators A Phys. 2018, 279, 321–330. [Google Scholar] [CrossRef]

- Xiong, H.; Wang, L. Piezoelectric energy harvester for public roadway: On-site installation and evaluation. Appl. Energy 2016, 174, 101–107. [Google Scholar] [CrossRef]

- Vizzari, D.; Gennesseaux, E.; Lavaud, S.; Bouron, S.; Chailleux, E. Pavement energy harvesting technologies: A critical review. RILEM Tech. Lett. 2021, 6, 93–104. [Google Scholar] [CrossRef]

- Gholikhani, M.; Roshani, H.; Dessouky, S.; Papagiannakis, A.T. A critical review of roadway energy harvesting technologies. Appl. Energy 2020, 261, 114388. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Mistewicz, K.; In-na, P.; Sahu, M.; Rajaitha, P.M.; Kim, H.J. Piezoelectric energy harvesting systems for biomedical applications. Nano Energy 2022, 100, 107514. [Google Scholar] [CrossRef]

- Liu, H.; Lin, X.; Zhang, S.; Huan, Y.; Huang, S.; Cheng, X. Enhanced performance of piezoelectric composite nanogenerator based on gradient porous PZT ceramic structure for energy harvesting. J. Mater. Chem. A 2020, 8, 19631–19640. [Google Scholar] [CrossRef]

- Lee, H.; Kim, H.; Kim, D.Y.; Seo, Y. Pure piezoelectricity generation by a flexible nanogenerator based on lead zirconate titanate nanofibers. ACS Omega 2019, 4, 2610–2617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hajra, S.; Oh, Y.; Sahu, M.; Lee, K.; Kim, H.-G.; Panigrahi, B.K.; Mistewicz, K.; Kim, H.J. Piezoelectric nanogenerator based on flexible PDMS–BiMgFeCeO 6 composites for sound detection and biomechanical energy harvesting. Sustain. Energy Fuels 2021, 5, 6049–6058. [Google Scholar] [CrossRef]

- Niu, X.; Jia, W.; Qian, S.; Zhu, J.; Zhang, J.; Hou, X.; Mu, J.; Geng, W.; Cho, J.; He, J.; et al. High-performance PZT-based stretchable piezoelectric nanogenerator. ACS Sustain. Chem. Eng. 2018, 7, 979–985. [Google Scholar] [CrossRef]

- Isarakorn, D.; Jayasvasti, S.; Panthongsy, P.; Janphuang, P.; Hamamoto, K. Design and evaluation of double-stage energy harvesting floor tile. Sustainability 2019, 11, 5582. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Shi, Q.; He, T.; Yi, Z.; Ma, Y.; Yang, B.; Chen, T.; Lee, C. Self-powered and self-functional cotton sock using piezoelectric and triboelectric hybrid mechanism for healthcare and sports monitoring. ACS Nano 2019, 13, 1940–1952. [Google Scholar] [CrossRef]

- Shreeshayana, R.; Raghavendra, L.; Manjunath, V.G. Piezoelectric Energy Harvesting using PZT in Floor Tile Design. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2017, 6, 8872–8879. [Google Scholar]

- Sharpes, N.; Vučković, D.; Priya, S. Floor tile energy harvester for self-powered wireless occupancy sensing. Energy Harvest. Syst. 2016, 3, 43–60. [Google Scholar] [CrossRef]

- Abdal-Kadhim, A.M.; Leong, K.S. Piezoelectric impact-driven energy harvester. In Proceedings of the 2016 IEEE International Conference on Power and Energy (PECon), Melaka, Malaysia, 28–29 November 2016; IEEE: Piscatvie, NJ, USA, 2016; pp. 407–411. [Google Scholar]

- Boby, K.; Paul, A.; Anumol, C.V.; Thomas, J.A.; Nimisha, K.K. Footstep Power Generation Using Piezo Electric Transducers. Int. J. Eng. Innov. Technol. IJEIT 2014, 3, 264. [Google Scholar]

- Patil, A.; Jadhav, M.; Joshi, S.; Britto, E.; Vasaikar, A. Energy harvesting using piezoelectricity. In Proceedings of the 2015 International Conference on Energy Systems and Applications, Pune, India, 30 October–1 November 2015; pp. 517–521. [Google Scholar] [CrossRef]

- Asry, A.M.M.; Mustafa, F.; Ishak, M.; Ahmad, A. Power generation by using piezoelectric transducer with bending mechanism support. Int. J. Power Electron. Drive Syst. 2019, 10, 562–567. [Google Scholar] [CrossRef]

- Maghsoudi Nia, E.; Wan Abdullah Zawawi, N.A.; Mahinder Singh, B.S. Design of a pavement using piezoelectric materials. Mater. Werkst. 2019, 50, 320–328. [Google Scholar] [CrossRef]

- Li, X.; Strezov, V. Modelling piezoelectric energy harvesting potential in an educational building. Energy Convers. Manage. 2014, 85, 35–442. [Google Scholar] [CrossRef]

- Wang, S.H.; Tsai, M.C.; Wu, T.H. The Analysis and Design of a High Efficiency Piezoelectric Harvesting Floor with Impacting Force Mechanism. Crystals 2021, 11, 380. [Google Scholar] [CrossRef]

- Mohanapriya, R. Generating electricity by footpath power generator floor tiles. Inf. Technol. Ind. 2021, 9, 576–582. [Google Scholar] [CrossRef]

- Sarker, M.R.; Mohamed, R.; Saad, M.H.M.; Tahir, M.; Hussain, A.; Mohamed, A. A Hybrid Optimization Approach for the Enhancement of Efficiency of a Piezoelectric Energy Harvesting System. Electronics 2021, 10, 75. [Google Scholar] [CrossRef]

- Singh, J.; Kaur, R.; Singh, D. Energy harvesting in wireless sensor networks: A taxonomic survey. Int. J. Energy Res. 2021, 45, 118–140. [Google Scholar] [CrossRef]

- Xie, X.; Wang, Q. A mathematical model for piezoelectric ring energy harvesting technology from vehicle tires. Int. J. Eng. Sci. 2015, 94, 113–127. [Google Scholar] [CrossRef]

- Ahmed, S.U.; Sabir, A.; Ashraf, T.; Haider, M.A.; Perveen, F.; Farooqui, Z.; Uddin, R. Energy Harvesting through Floor Tiles. In Proceedings of the 2019 International Conference on Innovative Computing (ICIC), Seoul, Republic of Korea, 26–29 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

| Ref. | Technology | Number of Sensors | Output (Power, Voltage, and Current) | Force |

|---|---|---|---|---|

| [23] | PZT-based | - | 50 V | 80 N |

| [5] | PZT-based | 72 | 15–18 V, 0.1 µA | - |

| [9,10] | PZT based | 29, 30 | 6 µW | 75 kG |

| [21] | PZT-based | 54 with 9500 uF capacitor | Charges in 90 min up to 5.75 V at 4 Hz | - |

| [24] | PZT-based with additional circuitry | 200 | 450 mW | |

| [25] | PZT-based | 36 | 50 V | 50 kG |

| [26] | PZT with bending mechanism | Single sensor with different diameters (30, 40, and 50 mm) | 19, 34.4, and 50.4 V | 3D printer technology |

| [27,28] | STEP technology using wireless-based PZT | Switch on the light and fan | Per footstep | |

| Novel PZT material | 42 V and 11 μA | Per footstep | ||

| Novel PZT with LED | 10 | 300 μJ | - | |

| [29] | S-sock using hybrid polymer and PZT chip | - | 1.71 mW output power at 2 Hz and 59.7 MΩ | - |

| [30] | piezo sensor-based cantilever | - | energy (0.278 mJ) | one footstep |

| [31] | triboelectric energy harvester (TEH) | 25 V for 0.5 g acceleration at 8 Hz | ||

| [32] | PZT with boost converter | - | 6.94 V for 300 mV input at 60 Hz AC | - |

| [33] | Piezoelectric (PE) and electromagnetic harvester (EM) for WSN | 1–3.34 V | ||

| [34] | 44 PZTs with cantilever | 35 mWrms | 50 kG |

| Source | Sequential p-Value | Adjusted R2 | Predicted R2 | Remarks |

|---|---|---|---|---|

| Linear | 0.0004 | 0.7495 | 0.5596 | |

| 2FI | 0.0448 | 0.8264 | 0.6868 | |

| Quadratic | <0.0001 | 0.96916 | 0.9650 | Suggested |

| Cubic | 0.1133 | 0.9951 | 0.8683 | Aliased |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gothwal, P.; Kumar, A.; Rathore, D.; Mukherji, R.; Vetriselvi, T.; Anandan, S. Response Surface Methodology Analysis of Energy Harvesting System over Pathway Tiles. Materials 2023, 16, 1146. https://doi.org/10.3390/ma16031146

Gothwal P, Kumar A, Rathore D, Mukherji R, Vetriselvi T, Anandan S. Response Surface Methodology Analysis of Energy Harvesting System over Pathway Tiles. Materials. 2023; 16(3):1146. https://doi.org/10.3390/ma16031146

Chicago/Turabian StyleGothwal, P., A. Kumar, D. Rathore, R. Mukherji, T. Vetriselvi, and S. Anandan. 2023. "Response Surface Methodology Analysis of Energy Harvesting System over Pathway Tiles" Materials 16, no. 3: 1146. https://doi.org/10.3390/ma16031146

APA StyleGothwal, P., Kumar, A., Rathore, D., Mukherji, R., Vetriselvi, T., & Anandan, S. (2023). Response Surface Methodology Analysis of Energy Harvesting System over Pathway Tiles. Materials, 16(3), 1146. https://doi.org/10.3390/ma16031146