Spent Coffee as a Composite Filler for Wastewater Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Density

2.2. Water Content

2.3. Water Absorption

2.4. Water Contact Angle

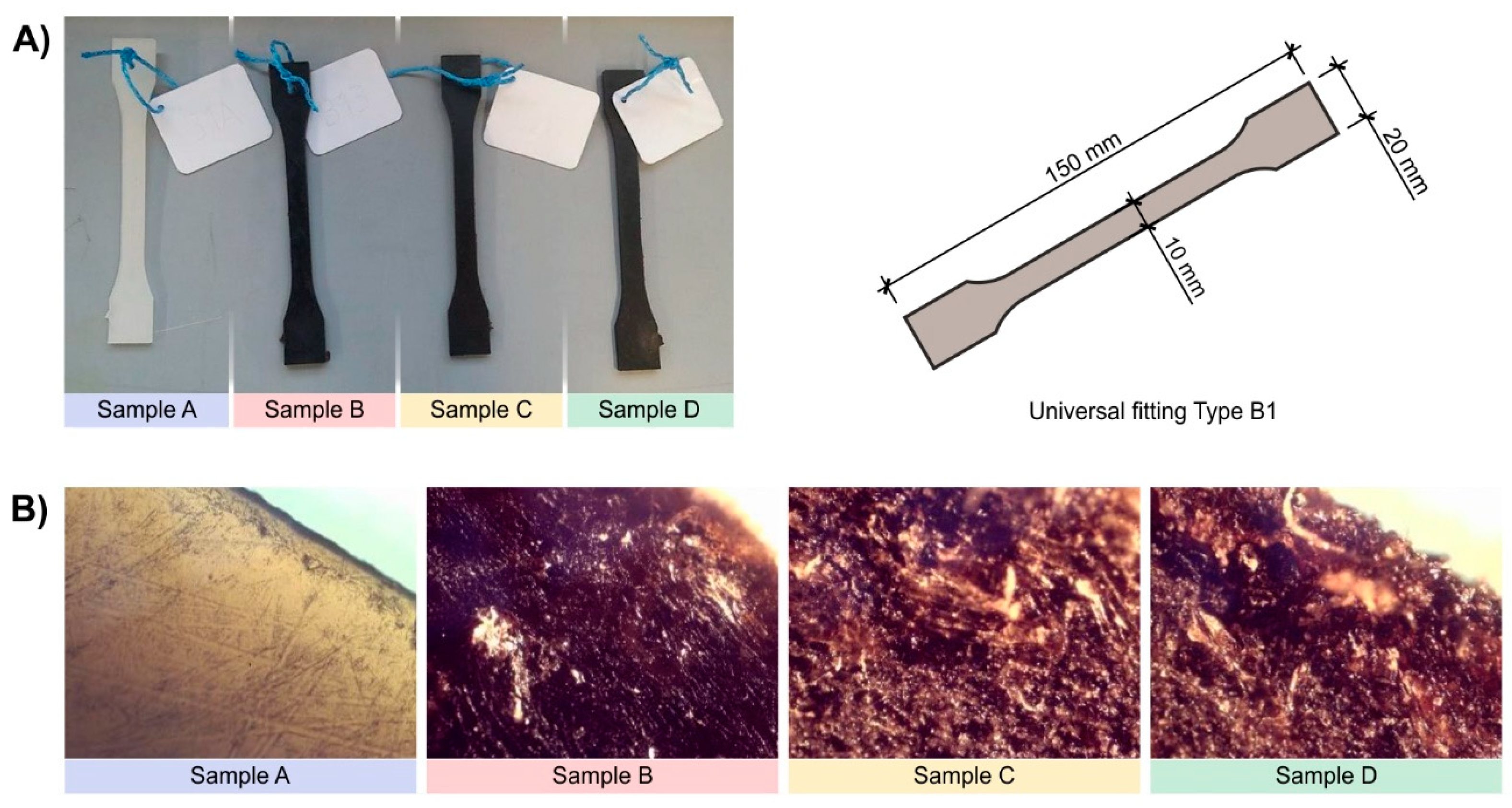

2.5. Tensile Strength

2.6. Impact Bending Test

2.7. Exposure of Samples in the Bioreactor

2.8. Microbiological Studies

2.9. Determination of Biofilm Dry Matter

3. Results

3.1. Density

3.2. Water Content

3.3. Water Absorption

3.4. Contact Angle

3.5. Tensile Strength Tests of Composites

3.6. Impact Bending Test

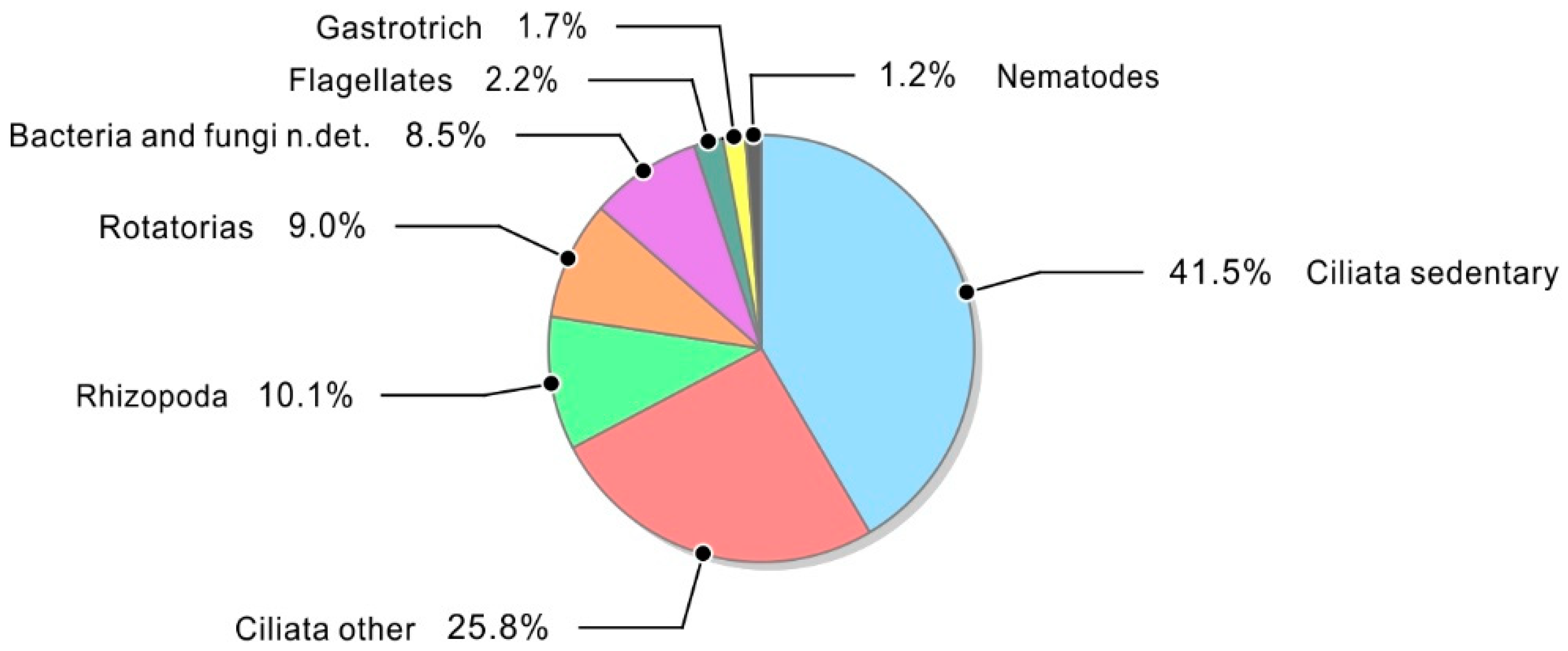

3.7. Activated Sludge Research

3.8. Microbiological Tests of Composites

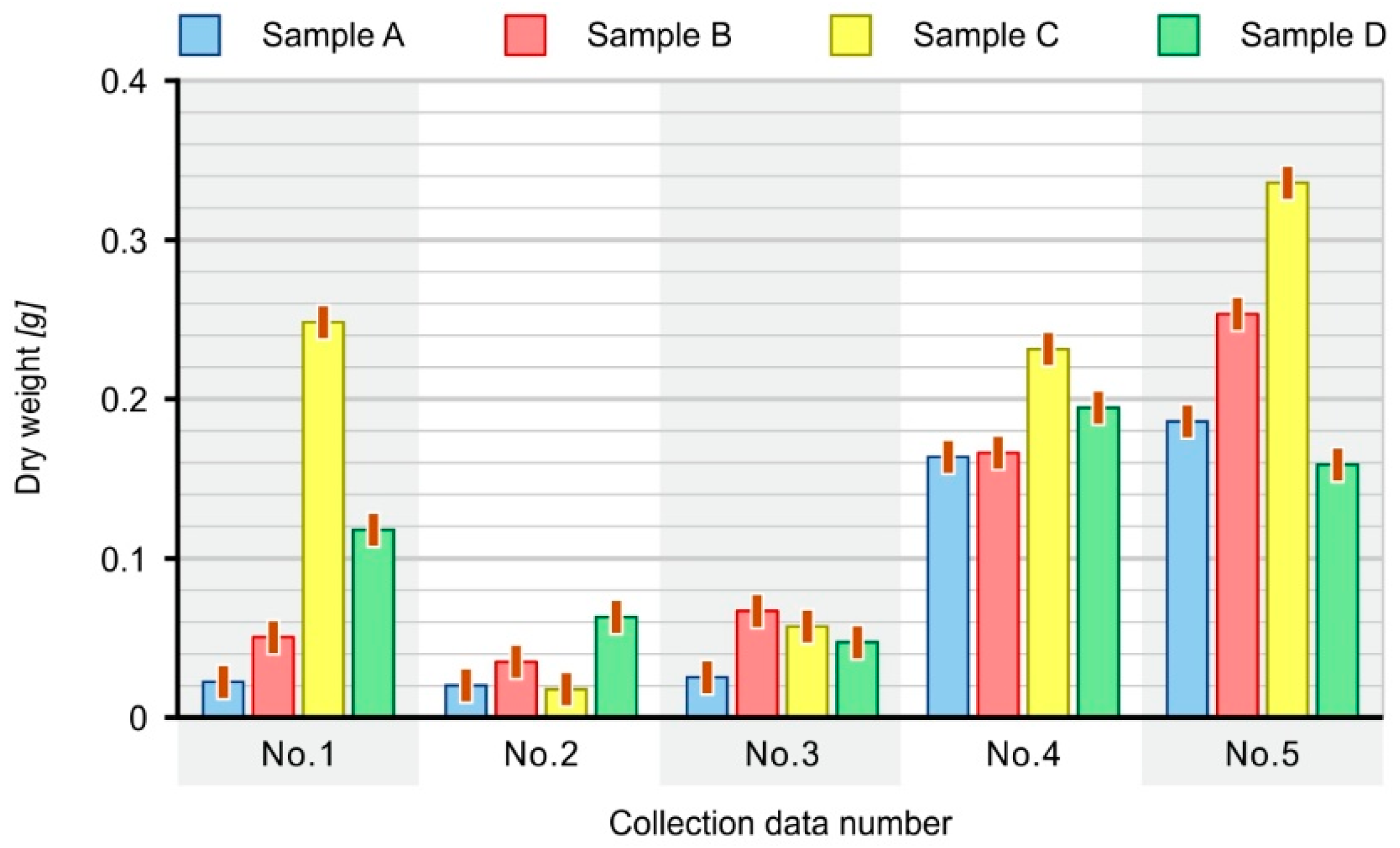

3.9. Biofilm Dry Matter

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, S.; Cai, M.; Liu, Y.; Wang, C.; Lv, K.; Chen, X. S-Scheme Photocatalyst TaON/Bi2WO6 Nanofibers with Oxygen Vacancies for Efficient Abatement of Antibiotics and Cr (VI): Intermediate Eco-Toxicity Analysis and Mechanistic Insights. Chinese J. Catal. 2022, 43, 2652–2664. [Google Scholar] [CrossRef]

- Li, X.; Liu, T.; Zhang, Y.; Cai, J.; He, M.; Li, M.; Chen, Z.; Zhang, L. Growth of BiOBr/ZIF-67 Nanocomposites on Carbon Fiber Cloth as Filter-Membrane-Shaped Photocatalyst for Degrading Pollutants in Flowing Wastewater. Adv. Fiber Mater. 2022, 4, 1620–1631. [Google Scholar] [CrossRef]

- Li, S.; Wang, C.; Ca, M.; Liu, Y.; Dong, K.; Zhang, J. Designing Oxygen Vacancy Mediated Bismuth Molybdate (Bi2MoO6)/N-Rich Carbon Nitride (C3N5) S-Scheme Heterojunctions for Boosted Photocatalytic Removal of Tetracycline Antibiotic and Cr(VI): Intermediate Toxicity and Mechanism Insight. J. Colloid. Interface Sci. 2022, 624, 219–232. [Google Scholar] [CrossRef]

- Piculell, M. New Dimensions of Moving Bed Biofilm Carriers. Influence of Biofilm Thickness and Control Possibilities. Ph.D. Thesis, Lund University, Lund, Sweden, June 2016. [Google Scholar]

- Sharmila, D. Comparative Analysis of Activated Sludge Process and Moving Bed Bio-Reactor (MBBR) Technology of Nesapakkam Sewage Treatment Plant-40mld. Int. J. Eng. Sci. Comput. 2017, 7, 3985–3989. [Google Scholar]

- Kruszelnicka, I.; Ginter-Kramarczyk, D.; Michalkiewicz, M.; Klozinski, A.; Zajchowski, S.; Jakubowska, P.; Tomaszewska, J. Wood—Polymer Composites in Moving Bed Technology. Polimery 2014, 59, 739–746. [Google Scholar] [CrossRef]

- Barton, J.; Niemczyk, A.; Czaja, K.; Korach, Ł.; Sacher-Majewska, B. Polymer Composites, Biocomposites and Nanocomposites. Production, Composition, Properties and Application Fields. Chemik 2014, 68, 280–287. [Google Scholar]

- Huang, L.; Mu, B.; Yi, X.; Li, S.; Wang, Q. Sustainable Use of Coffee Husks For Reinforcing Polyethylene Composites. J. Polym. Environ. 2018, 26, 48–58. [Google Scholar] [CrossRef]

- Chu, Z.; Zheng, P.; Yang, Y.; Wang, C.; Yang, Z. Compressible Nanowood/Polymer Composite Adsorbents for Wastewater Purification Applications. Compos. Sci. Technol. 2020, 198, 108320. [Google Scholar] [CrossRef]

- Kawan, J.A.; Abu Hasan, H.; Suja, F.; Jaafar, O.; Abd-Rahman, R. A Review on Sewage Treatment and Polishing Using Moving Bed Bioreactor (MBBR). J. Eng. Sci. Technol. 2016, 11, 1098–1120. [Google Scholar]

- Kruszelnicka, I.; Ginter-Kramarczyk, D.; Karpezo, E. The Moving Bed Biofilm Reactor in the Wastewater Treatment—the History, Application and Perspectives. Instal 2014, 5, 64–67. [Google Scholar]

- McQuarrie, J.P.; Boltz, J.P. Moving Bed Biofilm Reactor Technology: Process Applications, Design, and Performance. Water Environ. Res. 2011, 83, 560–575. [Google Scholar] [CrossRef]

- Żubrowska-Sudoł, M. Zastosowanie Złoża Ruchomego (Moving Bed) w Technologii Oczyszczania Ścieków. Gaz Woda Tech. Sanit. 2004, 7–8, 266–269. [Google Scholar]

- Podedworna, J.; Żubrowska-Sudoł, M. Position of Moving Bed Technology in the Process of Biological Wastewater Treatment. Gaz Woda Tech. Sanit. 2014, 4, 132–137. [Google Scholar]

- Kruszelnicka, I.; Ginter-Kramarczyk, D.; Michakiewicz, M.; Zajchowski, S.; Kloziński, A.; Tomaszewska, J. The Use of Wood-Polymer Composites in a Moving Bed Biofilm Reactor Technology (Rapid Communication). Polymers 2014, 59, 423–426. [Google Scholar] [CrossRef]

- Podedworna, J.; Żubrowska-Sudoł, M. Możliwość Ograniczenia Pojemności Reaktorów Biologicznych Poprzez Zastosowanie Złoża Ruchomego. Gaz Woda Tech. Sanit. 2006, 3, 19–22. [Google Scholar]

- Casas, M.E.; Chhetri, R.K.; Ooi, G.; Hansen, K.M.S.; Litty, K.; Christensson, M.; Kragelund, C.; Andersen, H.R.; Bester, K. Biodegradation of pharmaceuticals in hospital wastewater by staged Moving Bed Biofilm Reactors (MBBR). Water Res. 2015, 83, 293–302. [Google Scholar] [CrossRef]

- Mazioti, A.A.; Stasinakis, A.S.; Pantazi, Y.; Andersen, H.R. Biodegradation of Benzotriazoles and Hydroxy-Benzothiazole in Wastewater by Activated Sludge and Moving Bed Biofilm Reactor Systems. Bioresour. Technol. 2015, 192, 627–635. [Google Scholar] [CrossRef]

- Bering, S.; Mazur, J.; Tarnowski, K.; Janus, M.; Mozia, S.; Morawski, A.W. The Use of Moving Bed Bio-Reactor to Laundry Wastewater Treatment. E3S Web Conf. 2017, 22, 00015. [Google Scholar] [CrossRef] [Green Version]

- Vaidhegi, K.; Sandhiya, P.; Santhiya, M. Moving Bed Biofilm Reactor—A New Perspective in Pulp and Paper Waste Water Treatment. J. Eng. Res. Appl. 2016, 6, 9–13. [Google Scholar]

- Kolwzan, B. Analysis of Biofilms—Their Formation and Functioning. Ochr. Sr. 2011, 33, 3–14. [Google Scholar]

- Kruszelnicka, I.; Ginter-Kramarczyk, D.; Litwińska, M.; Poszwa, P. Kształty Nośników w Technologii MBBR (Shapes of the MBBR Technology Carriers). Instal 2016, 6, 55–59. [Google Scholar]

- Khan, F.; Zahid, M.; Hanif, M.A.; Tabasum, A.; Mushtaq, F.; Noreen, S.; Mansha, A. Chapter 21—Photocatalytic Polymeric Composites for Wastewater Treatment. In Aquananotechnology; Elsevier: Amsterdam, The Netherlands, 2021; pp. 467–490. [Google Scholar] [CrossRef]

- Enesca, A.; Cazan, C. Polymer Composite-Based Materials with Photocatalytic Applications in Wastewater Organic Pollutant Removal: A Mini Review. Polymers 2022, 14, 3291. [Google Scholar] [CrossRef]

- Mittal, P.; Jana, S.; Mohanty, K. Synthesis of Low-Cost Hydrophilic Ceramic-Polymeric Composite Membrane for Treatment of Oily Wastewater. Desalination 2011, 282, 54–62. [Google Scholar] [CrossRef]

- Gupta, S.K.; Nayunigari, M.K.; Misra, R.; Ansari, F.A.; Dionysiou, D.D.; Maity, A.; Bux, F. Synthesis and Performance Evaluation of a New Polymeric Composite for the Treatment of Textile Wastewater. Ind. Eng. Chem. Res. 2016, 55, 13–20. [Google Scholar] [CrossRef] [Green Version]

- Lebedev, V.; Tykhomyrova, T.; Lytvynenko, O.; Grekova, A.; Avina, S. Sorption Characteristics Studies of Eco-Friendly Polymer Composites. E3S Web Conf. 2021, 280, 11001. [Google Scholar] [CrossRef]

- Sisti, L.; Celli, A.; Totaro, G.; Cinelli, P.; Signori, F.; Lazzeri, A.; Bikaki, M.; Corvini, P.; Ferri, M.; Tassoni, A.; et al. Monomers, Materials and Energy from Coffee by-Products: A Review. Sustainability 2021, 13, 6921. [Google Scholar] [CrossRef]

- Cestari, S.P.; Mendes, L.C.; da Silva, D.F.; Chimanowsky, J.P.; Altstädt, V.; Demchuk, V.; Lang, A.; Leonhardt, R.G.; Keller, J.H. Properties of Recycled High Density Polyethylene and Coffee Dregs Composites. Polimeros 2013, 23, 733–737. [Google Scholar] [CrossRef] [Green Version]

- Cesari, S.P.; Mendes, L.C. Thermal Properties and Morphology of High-Density Polyethylene Filled with Coffee Dregs. J. Therm. Anal. Calorim. 2013, 114, 1–4. [Google Scholar] [CrossRef]

- Hejna, A. Coffee Silverskin as a Potential Bio-Based Antioxidant for Polymer Materials: Brief Review. Proceedings 2021, 69, 20. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Kuzmin, A. Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. J. Compos. Sci. 2021, 5, 44. [Google Scholar] [CrossRef]

- Dominici, F.; García, D.G.; Fombuena, V.; Luzi, F.; Puglia, D.; Torre, L.; Balart, R. Bio-Polyethylene-Based Composites Reinforced with Alkali and Palmitoyl Chloride-Treated Coffee Silverskin. Molecules 2019, 24, 3113. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.-S.; Kim, J.-G. Adsorption Characteristics of Spent Coffee Grounds as an Alternative Adsorbent for Cadmium in Solution. Environments 2020, 7, 24. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, V.-T.; Vo, T.-D.-H.; Nguyen, T.-B.; Dat, N.D.; Huu, B.T.; Nguyen, X.-C.; Tran, T.; Le, T.-N.-C.; Duong, T.-G.-H.; Bui, M.-T.; et al. Adsorption of Norfloxacin from Aqueous Solution on Biochar Derived from Spent Coffee Ground: Master Variables and Response Surface Method Optimized Adsorption Process. Chemosphere 2022, 288, 132577. [Google Scholar] [CrossRef] [PubMed]

- Shahabi-Ghahfarokhi, S.; Rahmati-Abkenar, M.; Matson, J.G.; Karimi, H.; Yu, C.; Hogland, W.; Klavinš, M.; Ketzer, M. Removal and Potential Recovery of Dissolved Metals from Acid Sulfate Soil Drainage by Spent Coffee-Grounds and Dissolved Organic Carbon. Environ. Adv. 2022, 8, 100193. [Google Scholar] [CrossRef]

- Auguścik-Królikowska, M.; Ryszkowska, J.; Ambroziak, A.; Szczepkowski, L.; Oliwa, R.; Oleksy, M. The Structure and Properties of Viscoelastic Polyurethane Foams with Fillers from Coffee Grounds. Polimery 2020, 65, 708–718. [Google Scholar] [CrossRef]

- EN ISO 62:2008; Plastics—Determination of Water Absorption. European Committee for Standardization (CEN): Brussels, Belgium, 2008. Available online: https://standards.iteh.ai/catalog/standards/cen/0124d789-9744-4b81-a450-24ed3e478bda/en-iso-62-2008 (accessed on 19 January 2023).

- EN ISO 527-2:2012; Plastic—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrsion Plastics. European Committee for Standardization (CEN): Brussels, Belgium, 2012. Available online: https://www.iso.org/standard/56046.html (accessed on 19 January 2023).

- PN-EN ISO 148-1:2017-02; Metals—Charpy Impact Test—Part 1: Test Method. European Committee for Standardization (CEN): Brussels, Belgium, 2017. Available online: https://infostore.saiglobal.com/en-us/Standards/PN-EN-ISO-148-1-2017-947085_SAIG_PKN_PKN_2227167/ (accessed on 19 January 2023).

- Shchegolkova, N.M.; Krasnov, G.S.; Belova, A.A.; Dmitriev, A.A.; Kharitonov, S.L.; Klimina, K.M.; Melnikova, N.V.; Kudryavtseva, A.V. Microbial Community Structure of Activated Sludge in Treatment Plants with Different Wastewater Compositions. Front. Microbiol. 2016, 7, 90. [Google Scholar] [CrossRef] [Green Version]

- Pajdak-Stós, A.; Sobczyk, M.; Fiałkowska, E.; Kocerba-Soroka, W.; Fyda, J. The Effect of Three Different Predatory Ciliate Species on Activated Sludge Microfauna. Eur. J. Protistol. 2017, 58, 87–93. [Google Scholar] [CrossRef]

- Eikelboom, D.H.; Van Buijsen, H.J.J. Podręcznik Mikroskopowego Badania osadu Czynnego; Seidel-Przywecki: Szczecin, Poland, 1999. [Google Scholar]

- Fiałkowska, E.; Fyda, J.; Pajdak-Stós, A.; Wiąckowski, K. Osad Czynny: Biologia i Analiza Mikroskopowa; Seidel-Przywecki: Szczecin, Poland, 2010. [Google Scholar]

- García-García, D.; Carbonell, A.; Samper, M.D.; García-Sanoguera, D.; Balart, R. Green Composites Based on Polypropylene Matrix and Hydrophobized Spend Coffee Ground (SCG) Powder. Compos. B Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Kufel, A.; Kuciel, S. Composites Based on Polypropylene Modified with Natural Fillers to Increase Stiffness. Tech. Trans. 2019, 1, 187–195. [Google Scholar] [CrossRef]

- Tan, M.Y.; Nicholas Kuan, H.T.; Lee, M.C. Characterization of Alkaline Treatment and Fiber Content on the Physical, Thermal, and Mechanical Properties of Ground Coffee Waste/Oxobiodegradable HDPE Biocomposites. Int. J. Polym. Sci. 2017, 3, 6258151. [Google Scholar] [CrossRef] [Green Version]

- Jaramillo, L.Y.; Vásquez-Rendón, M.; Upegui, S.; Posada, J.C.; Romero-Sáez, M. Polyethylene-Coffee Husk Eco-Composites for Production of Value-Added Consumer Products. Sustain. Environ. Res. 2021, 31, 34. [Google Scholar] [CrossRef]

| Type of Sample | Matrix PE-HD [mass %] | Type of Filling | Amount of Filler [mass %] |

|---|---|---|---|

| A | 100 | - | 0 |

| B | 80 | Spent coffee (SCG) | 20 |

| C | 70 | Spent coffee (SCG) | 30 |

| D | 60 | Spent coffee (SCG) | 40 |

| Type of Sample | Exposure in the Bioreactor |

|---|---|

| 0 | Placing samples in a bioreactor |

| 1 | After 42 days |

| 2 | After 61 days |

| 3 | After 165 days |

| 4 | After 223 days |

| 5 | After 328 days |

| Type of Sample | Sample Density [g/cm3] |

|---|---|

| A | 0.9021 ± 0.0442 |

| B | 0.9527 ± 0.0380 |

| C | 0.9856 ±0.0334 |

| D | 1.0162 ± 0.4212 |

| Parameter | Unit | Average Value |

|---|---|---|

| pH | - | 7.35 |

| Total suspension | mg/L | 5540 |

| Mineral suspension | mg/L | 1184 |

| Organic suspension | mg/L | 4356 |

| Settling after 30 min. | mL/1000 mL | 960 + gas |

| Settling after 60 min. | mL/1000 mL | 890 + gas |

| Settling after 120 min.. | mL/1000 mL | 750 + gas |

| Activated sludge index | mL/g | 172.5 |

| Microorganisms | Genus or Species | Estimated Number of Microorganisms | ||||

|---|---|---|---|---|---|---|

| Sampling Number | ||||||

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | ||

| Rhizopoda | Arcella vulgaris | 3 | 3 | 1 | 4 | 2 |

| Amoeba proteus | 1 | 1 | 1 | 1 | 0 | |

| Flagellata | Peranema trichophorum | 0 | 1 | 1 | 1 | 1 |

| Bodo sp. | 0 | 0 | 0 | 1 | 0 | |

| Ciliata | Carchesium polypinum | 3 | 1 | 3 | 2 | 0 |

| Epistylis lacustris | 1 | 4 | 0 | 3 | 2 | |

| Epistylis plicatilis | 0 | 4 | 5 | 3 | 0 | |

| Epistylis rotans | 1 | 4 | 0 | 3 | 1 | |

| Epistylis coronata | 0 | 4 | 3 | 3 | 0 | |

| Epistylis chrysemydis | 0 | 4 | 3 | 2 | 0 | |

| Opercularia coarctata | 1 | 1 | 0 | 3 | 2 | |

| Vorticella campanula | 0 | 1 | 3 | 2 | 0 | |

| Vorticella convallaria | 0 | 1 | 3 | 2 | 2 | |

| Vorticella microstoma | 3 | 1 | 3 | 2 | 1 | |

| Acineta tuberosa | 1 | 0 | 1 | 1 | 1 | |

| Podophrya fixa | 1 | 0 | 0 | 0 | 0 | |

| Tokophrya infusionum | 1 | 1 | 1 | 1 | 1 | |

| Tokophrya lemnarum | 0 | 1 | 1 | 0 | 1 | |

| Aspidisca sp. | 5 | 2 | 3 | 2 | 2 | |

| Spirostomum sp. | 1 | 1 | 1 | 1 | 0 | |

| Euplotes sp. | 1 | 0 | 0 | 2 | 1 | |

| Litonotus sp. | 1 | 1 | 2 | 1 | 1 | |

| Glaucoma scintillans | 1 | 1 | 1 | 1 | 2 | |

| Paramecium bursaria | 1 | 1 | 1 | 3 | 1 | |

| Stentor sp. | 0 | 0 | 1 | 0 | 0 | |

| Chilodonella sp. | 0 | 0 | 0 | 0 | 1 | |

| Colpidium colpoda | 0 | 0 | 0 | 1 | 0 | |

| Oxytricha sp. | 0 | 0 | 0 | 0 | 1 | |

| Discophyra elongata | 0 | 0 | 0 | 0 | 0 | |

| Paramecium caudatum | 0 | 0 | 1 | 2 | 0 | |

| Rotatoria | Rotaria rotatoria | 2 | 2 | 1 | 3 | 1 |

| Lecane sp. | 1 | 1 | 1 | 1 | 0 | |

| Cephalodella sp. | 0 | 0 | 1 | 1 | 0 | |

| Gastrotricha | Gastrotricha n.det. | 1 | 0 | 1 | 0 | 0 |

| Nematoda | Nematoda n.det. | 1 | 0 | 0 | 0 | 0 |

| Bacteria and Fungi | Filamentous bacteria and fungi n.det | 2 | 1 | 2 | 2 | 3 |

| Bacteria | Free swimming bacteria n.det | 2 | 2 | 2 | 3 | 2 |

| Sum of points Number of taxa | 35 | 44 | 47 | 57 | 29 | |

| 22 | 24 | 26 | 29 | 20 | ||

| Microorganisms | Genus or Species | Estimated Number of Microorganisms | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sampling Number | |||||||||||||||||||||

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | |||||||||||||||||

| Sample | Sample | Sample | Sample | Sample | |||||||||||||||||

| A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | ||

| Rhizopoda | Arcella vulgaris | 1 | 1 | 4 | 1 | 1 | 1 | 2 | 2 | 0 | 1 | 1 | 1 | 1 | 0 | 2 | 2 | 1 | 1 | 1 | 1 |

| Amoeba proteus | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Flagellata | Peranema trichophorum | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 0 | 1 | 2 | 0 |

| Bodo sp. | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | |

| Ciliata | Carchesium polypinum | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

| Epistylis lacustris | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Epistylis plicatilis | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | |

| Epistylis rotans | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Epistylis coronata | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | |

| Epistylis chrysemydis | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | |

| Opercularia coarctata | 1 | 2 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 5 | 4 | 2 | 3 | 3 | 3 | 1 | 2 | 2 | 2 | |

| Vorticella campanula | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | |

| Vorticella convallaria | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 2 | |

| Vorticella microstoma | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 2 | 0 | 0 | |

| Trichodina pediculus | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 3 | |

| Acineta tuberosa | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Acineta flava | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Tokophrya infusionum | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | |

| Tokophrya lemnarum | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 2 | 1 | 1 | 2 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | |

| Aspidisca costata | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 2 | 1 | 1 | |

| Chilodonella cucullulus | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Litonotus sp. | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | |

| Glaucoma scintillans | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 2 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | |

| Paramecium caudatum | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 2 | 2 | 1 | 1 | 1 | 1 | 1 | |

| Paramecium bursaria | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stylonychia mytilus | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 3 | 0 | 0 | 1 | 2 | |

| Discophyra elongata | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 3 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | |

| Thuricola folliculata | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | |

| Euplotes affinis | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Spirostomum sp. | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | |

| Colpidium colpoda | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Amphileptus daparedei | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Stentor sp. | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | |

| Oxytricha sp. | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Rotatoria | Rotaria rotatoria | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 4 | 4 | 4 | 4 |

| Lecane sp. | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | |

| Cephalodella sp. | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Oligochaeta | Tubifex tubifex | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | - | - | - | - | - | - | - | - |

| Aeolosoma sp. | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | |

| Gastrotricha | Gastrotricha n. det. | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 |

| Nematoda | Nematoda n. det. | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| Bacteria and Fungi | Filamentous bacteria and fungi n.det. | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1 | 2 |

| Bacteria | Free—swimming bacteria n.det. | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 1 | 2 | 3 | 2 | 3 | 4 | 4 | 4 | 2 | 3 | 3 | 3 |

| Sum of points | 38 | 44 | 46 | 46 | 35 | 42 | 45 | 51 | 40 | 45 | 50 | 55 | 50 | 52 | 55 | 59 | 44 | 50 | 53 | 55 | |

| Number of taxa | 17 | 20 | 21 | 23 | 19 | 21 | 22 | 24 | 21 | 23 | 23 | 26 | 31 | 25 | 26 | 30 | 21 | 20 | 24 | 23 | |

| Type of Sample | Points | |||||

|---|---|---|---|---|---|---|

| Sampling Number | ||||||

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | Sum of Points | |

| A | 38 | 35 | 40 | 50 | 44 | 246 |

| B | 44 | 42 | 45 | 52 | 50 | 274 |

| C | 46 | 45 | 50 | 55 | 53 | 292 |

| D | 46 | 51 | 51 | 59 | 55 | 312 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kruszelnicka, I.; Michałkiewicz, M.; Ginter-Kramarczyk, D.; Muszyński, P.; Materna, K.; Wojcieszak, M.; Mizera, K.; Ryszkowska, J. Spent Coffee as a Composite Filler for Wastewater Treatment. Materials 2023, 16, 1181. https://doi.org/10.3390/ma16031181

Kruszelnicka I, Michałkiewicz M, Ginter-Kramarczyk D, Muszyński P, Materna K, Wojcieszak M, Mizera K, Ryszkowska J. Spent Coffee as a Composite Filler for Wastewater Treatment. Materials. 2023; 16(3):1181. https://doi.org/10.3390/ma16031181

Chicago/Turabian StyleKruszelnicka, Izabela, Michał Michałkiewicz, Dobrochna Ginter-Kramarczyk, Przemysław Muszyński, Katarzyna Materna, Marta Wojcieszak, Kamila Mizera, and Joanna Ryszkowska. 2023. "Spent Coffee as a Composite Filler for Wastewater Treatment" Materials 16, no. 3: 1181. https://doi.org/10.3390/ma16031181