Removal of Phosphorus with the Use of Marl and Travertine and Their Thermally Modified Forms—Factors Affecting the Sorption Capacity of Materials and the Kinetics of the Sorption Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reactive Materials

2.2. Batch Experiments

3. Result and Discussion

3.1. Factors Determining the Sorption Capacity of the Tested Materials

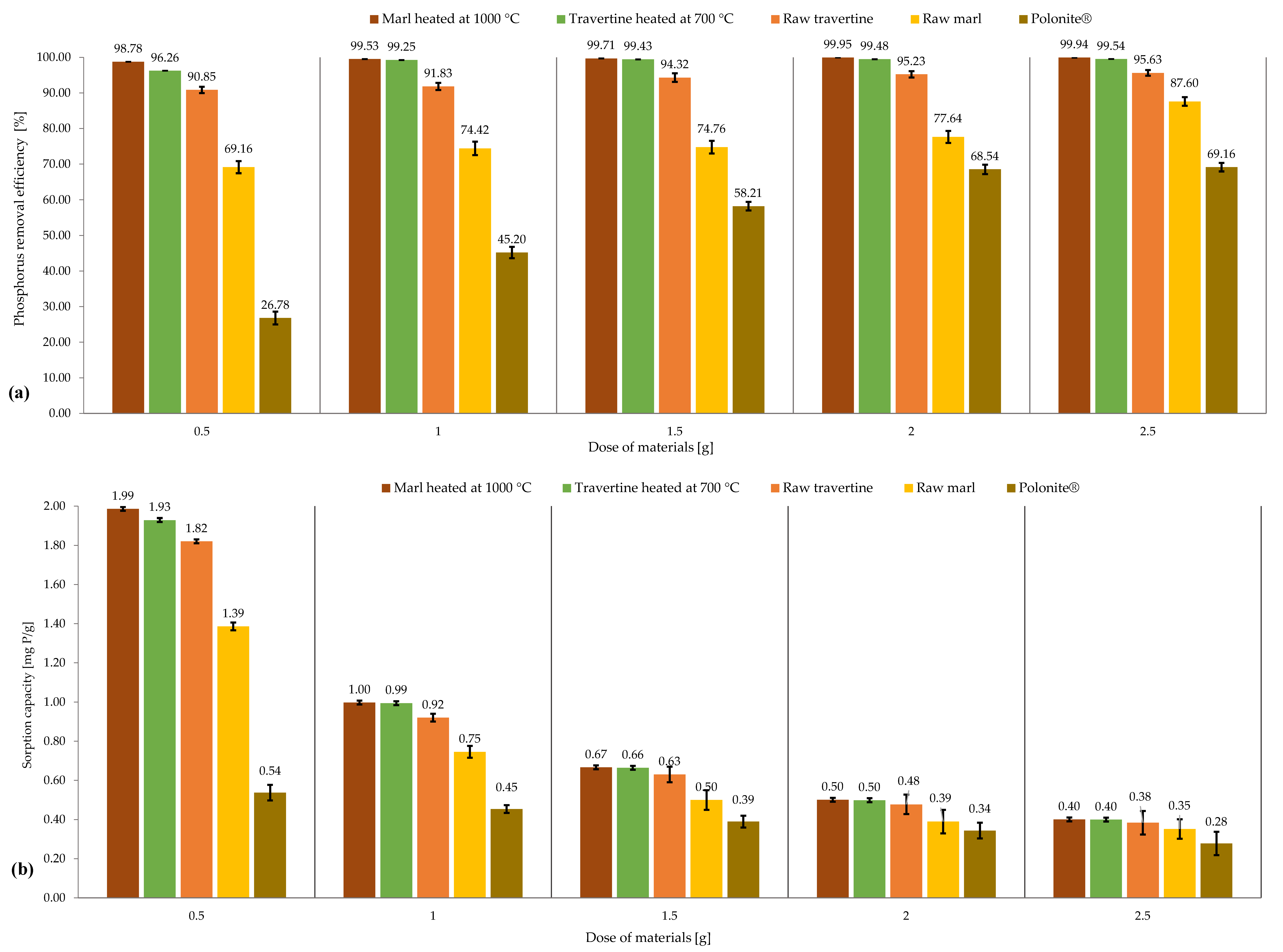

3.1.1. Doses of the Materials

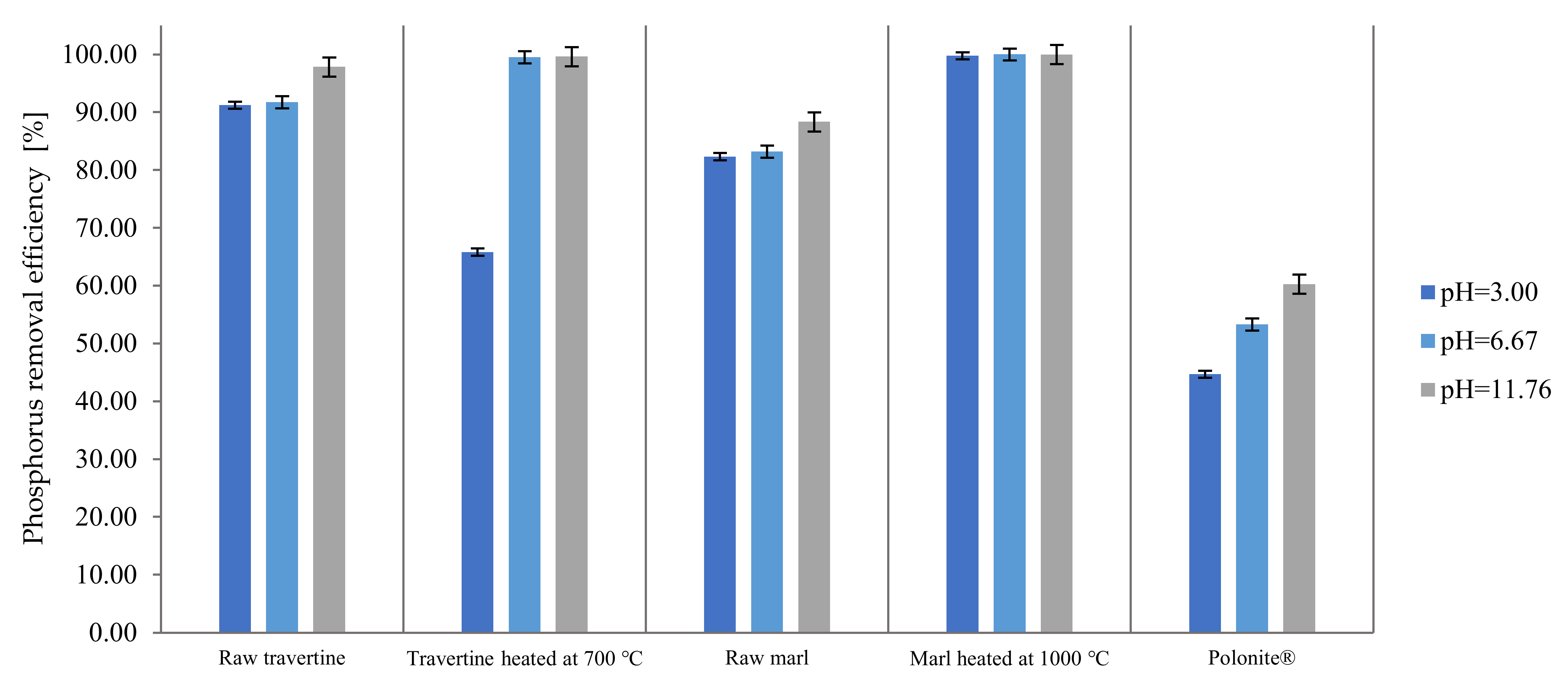

3.1.2. The Initial pH of the Solution

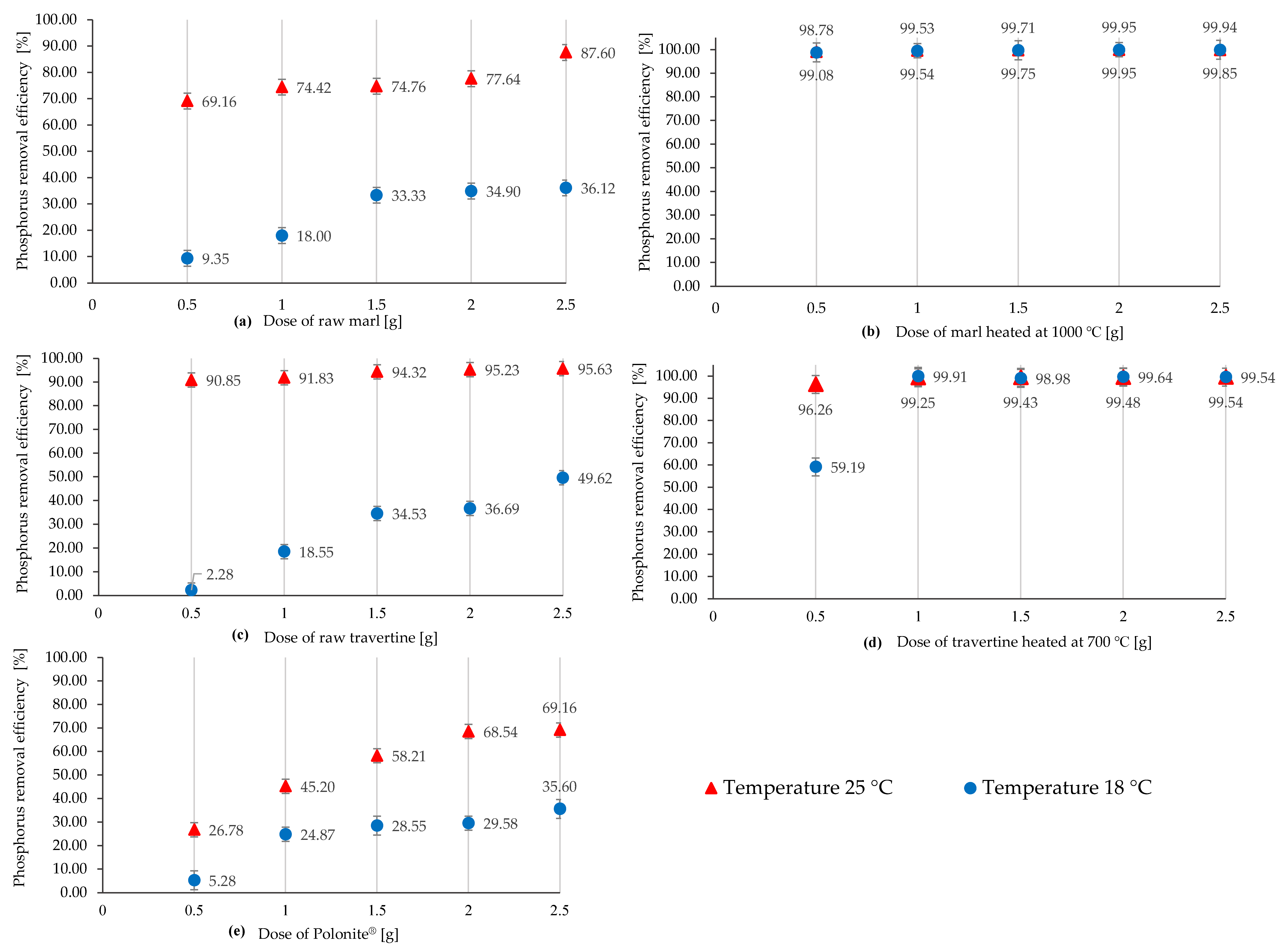

3.1.3. Process Temperature

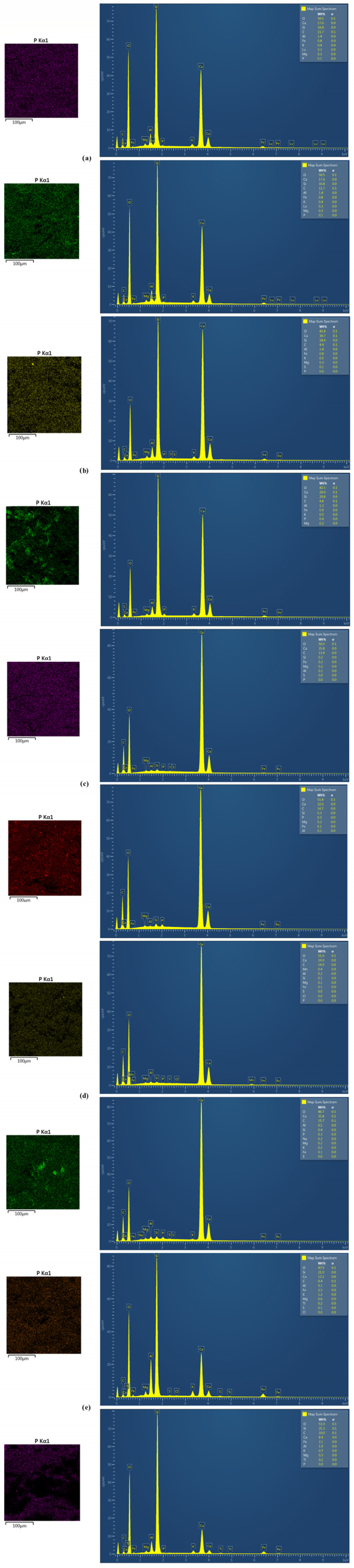

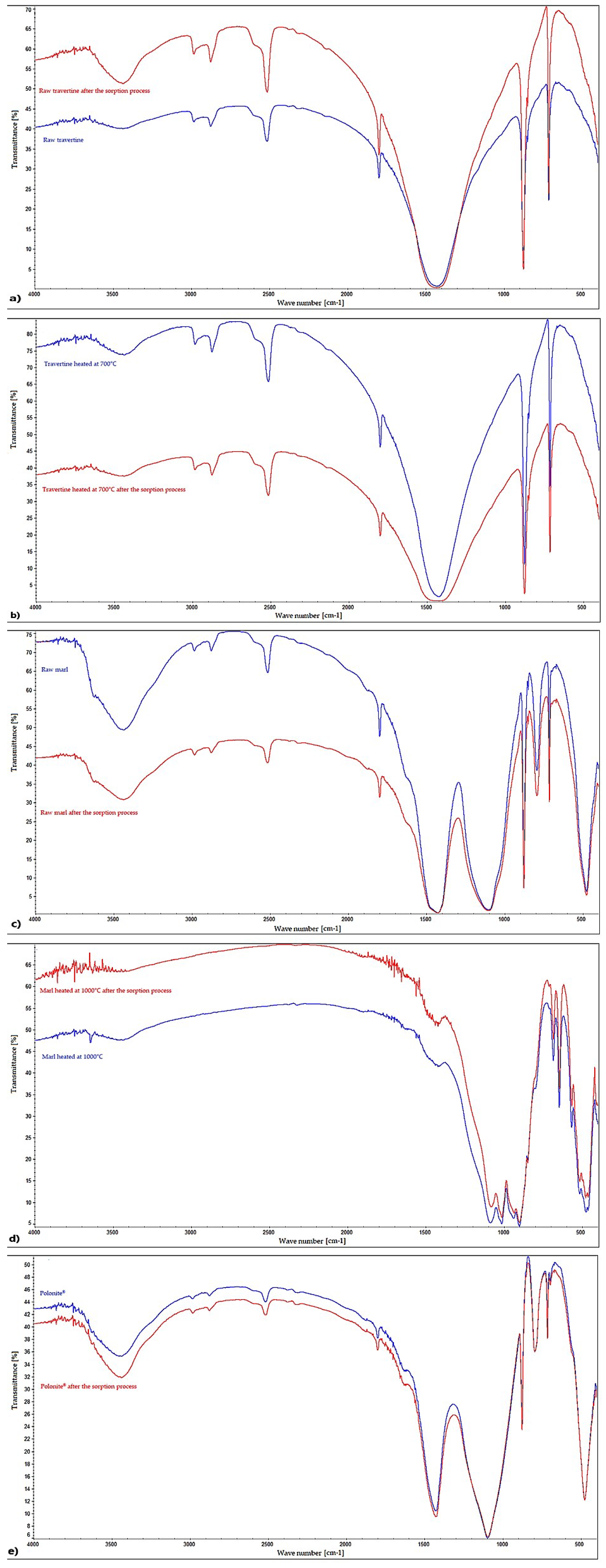

3.1.4. Structure and Morphological Analysis of Materials

3.2. Adsorption Isotherms and Determination of the Maximum Sorption Capacity of Materials

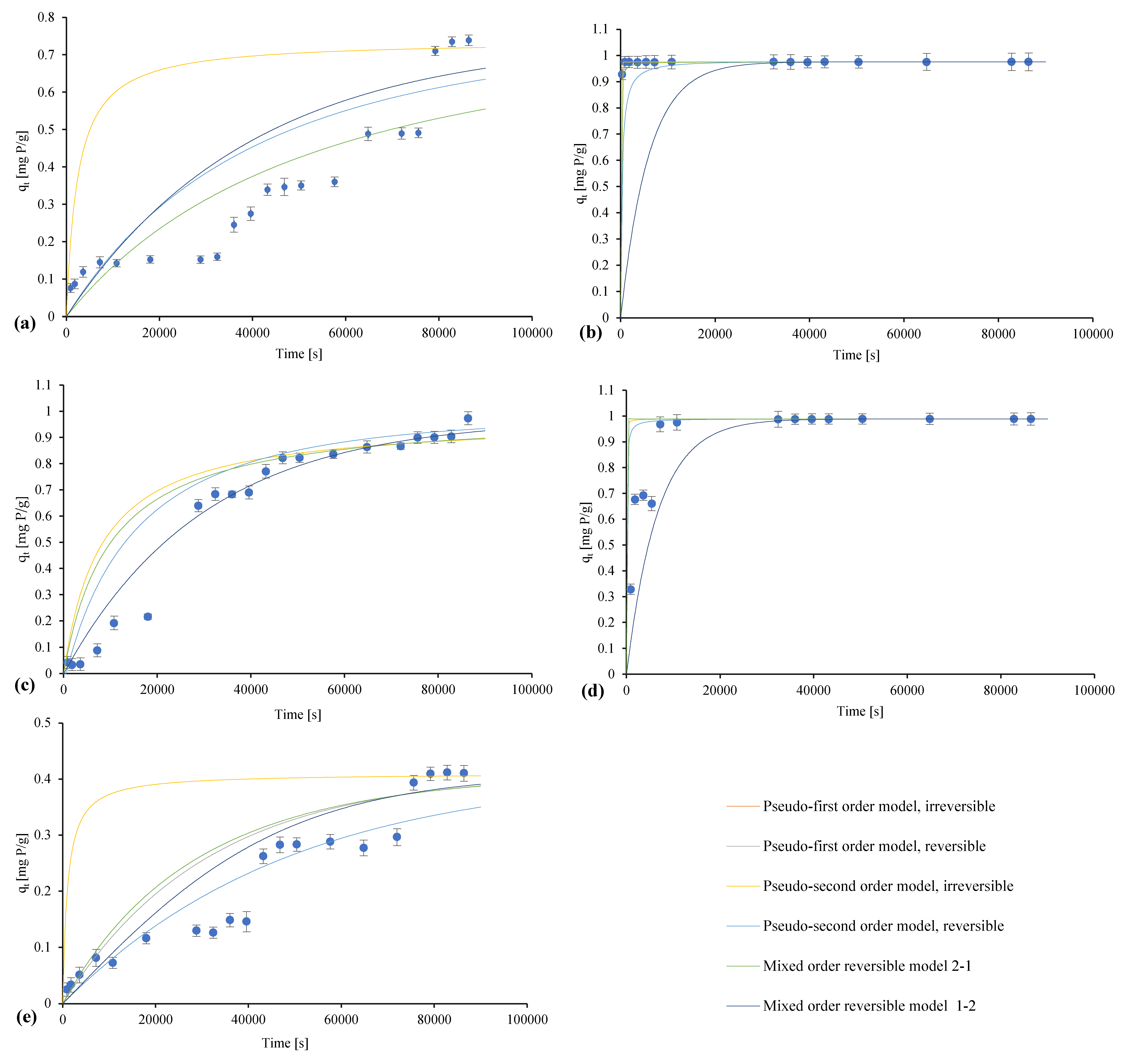

3.3. Adsorption kinetics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Parameters | Description | Unit |

| PR (%) | phosphorus removal efficiency | [%] |

| qe,calc | equilibrium concentration of the adsorbed substance predicted by the isotherm model | [mg P/g] |

| qe | equilibrium concentration of the adsorbed substance | [mg P/g] |

| qm | maximum sorption capacity | [mg P/g] |

| qt | sorption capacity after time t | [mg P/g] |

| Ce | equilibrium concentration of the sorbed substance | [mg P/L] |

| K | equilibrium constant | [-] |

| n, m | heterogeneity parameters of the sorbent surface | [-] |

| t | time | [s] |

| Co | initial concentration of phosphorus | [mg P/L] |

| Ct | concentration of phosphorus after time t | [mg P/L] |

| V | volume of solution | [L] |

| M | mass of material | [g] |

| k1 | rate constant | [1/min], [g/(mg P·min)] |

| R2 | coefficient of determination | [-] |

| Adj R2 | adjusted coefficient of determination | [-] |

| z | corresponding variable | [-] |

| Abbreviation | Description | |

| SEM | scanning electron microscopy | |

| SEM-EDS | scanning electron microscopy—energy dispersive spectroscopy | |

| BET | Brunauer, Emmett, and Teller (the method of determination of the specific surface area) | |

| FT-IR | Fourier transform infrared spectroscopy | |

| RM | raw marl | |

| HM | heated marl at 1000℃ | |

| P | Polonite® |

References

- Chen, M.P.; Graedel, T.E. A half-century of global phosphorus flows, stocks, production, consumption, recycling, and environmental impacts. Glob. Environ. Change-Human Policy Dimens. 2016, 36, 139–152. [Google Scholar] [CrossRef]

- Sasabuchi, I.T.M.; Krieger, K.S.; Nunes, R.S.; Ferreira, A.C.; Xavier, G.T.M.; Urzedo, A.L.; Carvalho, W.A.; Fadini, P.S. Sustainability in phosphorus use: A bibliographic review focusing on the current situation in the state of sao paulo, brazil. Quim. Nova 2022, XY, 1–14. [Google Scholar] [CrossRef]

- Bąk, B.W.B.Z.; Blaschke, A.; Bolewski, H.; Gruszczyk, I.; Pollo, B.; Radwanek-Bąk, E. Wutcen, Surowce Mineralne Świata. Fosfor–P2O5; Wydawnictwo Geologiczne: Warszawa, Poland, 1987. [Google Scholar]

- Kalczyński, E. Fosfor w środowisku, jego znaczenie i możliwości odzysku z osadów ściekowych. Forum Eksploatatora 2015, 6, 35–41. [Google Scholar]

- Christensen, M.L.; Cvitanich, C.; Quist-Jensen, C.A.; Thau, M.; Malmgren-Hansen, B. Precipitation and recovery of phosphorus from the wastewater hydrolysis tank. Sci. Total Environ. 2022, 813, 15. [Google Scholar] [CrossRef]

- Golroudbary, A.S.R.; El Wali, M.; Kraslawski, A. Environmental sustainability of phosphorus recycling from wastewater, manure and solid wastes. Sci. Total Environ. 2019, 672, 515–524. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, A.T.; Nemery, J.; Gratiot, N.; Dao, T.S.; Le, T.T.M.; Baduel, C.; Garnier, J. Does eutrophication enhance greenhouse gas emissions in urbanized tropical estuaries? Environ. Pollut. 2022, 303, 119105. [Google Scholar] [CrossRef] [PubMed]

- Neverova-Dziopak, E. Podstawy Zarządzania Procesem Eutrofizacji Antropogenicznej; Wydawnictwa AGH: Kraków, Poland, 2010. [Google Scholar]

- Sun, S.F.; Han, J.L.; Hu, M.F.; Gao, M.C.; Qiu, Q.; Zhang, S.B.; Qiu, L.P.; Ma, J. Removal of phosphorus from wastewater by Diutina rugosa BL3: Efficiency and pathway. Sci. Total Environ. 2021, 801, 10. [Google Scholar] [CrossRef]

- Kowalewski, Z. Weryfikacja Możliwości Zastosowania Integralnego Kryterium do Oceny Stanu Troficznego wód Płynących; AGH Akademia Górniczo Hutnicza: Kraków, Poland, 2012. [Google Scholar]

- Xia, W.J.; Xu, L.Z.J.; Yu, L.Q.; Zhang, Q.; Zhao, Y.H.; Xiong, J.R.; Zhu, X.Y.; Fan, N.S.; Huang, B.C.; Jin, R.C. Conversion of municipal wastewater-derived waste to an adsorbent for phosphorus recovery from secondary effluent. Sci. Total Environ. 2020, 705, 8. [Google Scholar] [CrossRef]

- Morse, G.K.; Brett, S.W.; Guy, J.A.; Lester, J.N. Review: Phosphorus removal and recovery technologies. Sci. Total Environ. 1998, 212, 69–81. [Google Scholar] [CrossRef]

- Schindler, D.W.; Carpenter, S.R.; Chapra, S.C.; Hecky, R.E.; Orihel, D.M. Reducing Phosphorus to Curb Lake Eutrophication is a Success. Environ. Sci. Technol. 2016, 50, 8923–8929. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Buates, J.; Imai, T. Assessment of plant growth performance and nutrient release for application of phosphorus-loaded layered double hydroxides as fertilizer. Environ. Technol. Innov. 2021, 22, 15. [Google Scholar] [CrossRef]

- Usman, M.O.; Aturagaba, G.; Ntale, M.; Nyakairu, G.W. A review of adsorption techniques for removal of phosphates from wastewater. Water Sci. Technol. 2022, 20, 3113–3132. [Google Scholar] [CrossRef]

- Europejska, K. Komunikat konsultacyjny w sprawie zrównoważonego stosowania fosforu. 2013. Available online: https://eur-lex.europa.eu/legal-content/PL/ALL/?uri=CELEX%3A52013DC0517 (accessed on 4 January 2023).

- Gubernat, S.; Masłoń, A.; Czarnota, J.; Koszelnik, P. Reactive Materials in the Removal of Phosphorus Compounds from Wastewater-A Review. Materials 2020, 13, 3377. [Google Scholar] [CrossRef]

- Nardis, B.O.; Franca, J.R.; Carneiro, J.S.D.; Soares, J.R.; Guilherme, L.R.G.; Silva, C.A.; Melo, L.C.A. Production of engineered-biochar under different pyrolysis conditions for phosphorus removal from aqueous solution. Sci. Total Environ. 2022, 816, 12. [Google Scholar] [CrossRef]

- Do, D.D. Adsorption Analysis: Equilibria and Kinetics; Imperial College Press: London, UK, 1998; Volume 2. [Google Scholar]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Warchoł, J. Investigation and Modeling of Ion Sorption Equilibrium in the Liquid-Solid System; Polish Academy of Sciences: Łódź, Poland, 2012. [Google Scholar]

- Marczewski, A.W.; Jaroniec, M. A New Isotherm Equation for Single-Solute Adsorption from Dilute Solutions on Energetically Heterogeneous Solids. Mon. Ftir Chem. 1983, 114, 711–715. [Google Scholar] [CrossRef]

- Chutkowski, M.; Petrus, R.; Warchoł, P.; Koszelnik, P. Sorption equilibrium in processes of metal ion removal from aqueous environment. Statistical verification of mathematical models. Przemysł Chem. 2008, 87, 436–438. [Google Scholar]

- Lagergren, S. About the Theory of So-Called Adsorption of Soluble Substances. K. Sven. Vetensk. Handl. 1898, 24, 1–39. [Google Scholar]

- Ho, Y.S.; McKay, G. Pseudo-second order model for sorption processes. Process Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Petrus, R.; Chutkowski, J.W.M. Kinetics of aqueous environment pollutants sorption on natural sorbents. Pr. Nauk. Inst. Inżynierii Chem. Pol. Akad. Nauk. 2006, 7, 33–52. [Google Scholar]

- Hamisi, R.; Renman, A.; Renman, G.; Worman, A.; Thunvik, R. Long-term phosphorus sorption and leaching in sand filters for onsite treatment systems. Sci. Total Environ. 2022, 833, 14. [Google Scholar] [CrossRef]

- Bus, A.; Karczmarczyka, A.; Baryla, A. Phosphorus reactive materials for permeable reactive barrier filling—Lifespan estimations. Desalin. Water Treat. 2022, 245, 9–15. [Google Scholar] [CrossRef]

- Renman, A.; Renman, G. Removal of Phosphorus from Hypolimnetic Lake Water by Reactive Filter Material in a Recirculating System-Laboratory Trial. Water 2022, 14, 819. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Chi, Y.Z.; Li, S.Y.; Fu, C.L.; Yuan, H.Y.; Wang, X.K.; Chen, F.Q. Chemical phosphorus removal optimization from coating wastewater using iron-calcium salt. Desalin. Water Treat. 2022, 264, 164–171. [Google Scholar] [CrossRef]

- Yahya, K.; Ba, M.; Msadok, I.; Mlayah, A.; Srasra, E.; Hamdi, N. Removal of phosphate from synthetic wastewater: A comparative study between both activated clays using an experimental design methodology. Water Environ. Res. 2022, 94, 15. [Google Scholar] [CrossRef]

- Ma, X.L.; Li, S.Q.; Ren, H.; Zhang, Y.; Ma, Z.C. Egg White-Mediated Fabrication of Mg/Al-LDH-Hard Biochar Composite for Phosphate Adsorption. Molecules 2022, 27, 8951. [Google Scholar] [CrossRef] [PubMed]

- Luo, D.; Wang, L.Y.; Nan, H.Y.; Cao, Y.J.; Wang, H.; Kumar, T.V.; Wang, C.Q. Phosphorus adsorption by functionalized biochar: A review. Environ. Chem. Lett. 2022, 28, 1–28. [Google Scholar] [CrossRef]

- Almanassra, I.W.; McKay, G.; Kochkodan, V.; Atieh, M.A.; Al-Ansari, T. A state of the art review on phosphate removal from water by biochars. Chem. Eng. J. 2021, 409, 15. [Google Scholar] [CrossRef]

- Zhao, R.; Hu, Y.C.; Ding, W.; Ren, K.; Gou, X.Y.; Zhao, C.; Zheng, H.L. Simultaneous oxidation and adsorption of phosphite by magnetic La-2(CO3)(3)/CoFe2O4/biochar composite with peroxymonosulfate. Chem. Eng. J. 2023, 451, 10. [Google Scholar] [CrossRef]

- Lv, N.; Li, X.F. Phosphorus removal from wastewater using Ca-modified attapulgite: Fixed-bed column performance and breakthrough curves analysis. J. Environ. Manag. 2023, 328, 7. [Google Scholar] [CrossRef]

- Gubernat, S.; Czarnota, J.; Masłoń, A.; Koszelnik, P. Effectiveness of wastewater post-treatment in filter columns with the use of mineral materials. J. Civ. Eng. Environ. Archit. 2020, 37, 47–58. [Google Scholar] [CrossRef]

- Karczmarczyk, A.; Bus, A.; Baryla, A. Forms of phosphorus bound to reactive material - results from a flow-through experiment with the focus on P reuse. Desalin. Water Treat. 2022, 258, 261–265. [Google Scholar] [CrossRef]

- Alshorifi, F.T.; Ali, S.L.; Salama, R.S. Promotional Synergistic Effect of Cs-Au NPs on the Performance of Cs-Au/MgFe2O4 Catalysts in Catalysis 3,4-Dihydropyrimidin-2(1H)-Ones and Degradation of RhB Dye. J. Inorg. Organomet. Polym. Mater. 2022, 32, 3765–3776. [Google Scholar] [CrossRef]

- Alshorifi, F.T.; Tobbala, D.E.; El-Bahy, S.M.; Nassan, M.A.; Salama, R.S. The role of phosphotungstic acid in enhancing the catalytic performance of UiO-66 (Zr) and its applications as an efficient solid acid catalyst for coumarins and dihydropyrimidinones synthesis. Catal. Commun. 2022, 169, 10. [Google Scholar] [CrossRef]

- Salama, R.S.; El-Bahy, S.M.; Mannaa, M.A. Sulfamic acid supported on mesoporous MCM-41 as a novel, efficient and reusable heterogenous solid acid catalyst for synthesis of xanthene, dihydropyrimidinone and coumarin derivatives. Colloids Surf. A Physicochem. Eng. 2021, 628, 12. [Google Scholar] [CrossRef]

- Gubernat, S.; Masłoń, A.; Czarnota, J.; Koszelnik, P. Phosphorus removal from wastewater using marl and travertine and their thermal modifications. Desalin. Water Treat. 2022, 275, 35–46. [Google Scholar] [CrossRef]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef] [Green Version]

- Freundlich, H.M.F. Over the adsorption in solution. J. Phys. Chem. 1906, 57, 385–470. [Google Scholar]

- Li, L.Y.; Zhang, H.; Wang, D.Q. Influencing Factors of Limestone Sorption and Its Usage in Advanced Wastewater Treatment for Phosphorus Removal; Chinese German Cent Environ Technol & Knowl Transfer-Cetk: Hefei, China, 2012; pp. 316–321. [Google Scholar]

- Zhang, Y.; Kou, X.Y.; Lu, H.S.; Lv, X. J, The feasibility of adopting zeolite in phosphorus removal from aqueous solutions. Desalin. Water Treat. 2014, 52, 4298–4304. [Google Scholar] [CrossRef]

- Wang, Y.; He, H.; Zhang, N.; Shimizu, K.; Lei, Z.F.; Zhang, Z.Y. Efficient capture of phosphate from aqueous solution using acid activated akadama clay and mechanisms analysis. Water Sci. Technol. 2018, 78, 1603–1614. [Google Scholar] [CrossRef]

- Karaca, S.; Gurses, A.; Ejder, M.; Acikyildiz, M. Adsorptive removal of phosphate from aqueous solutions using raw and calcinated dolomite. J. Hazard. Mater. 2006, 128, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Karageorgiou, K.; Paschalis, M.; Anastassakis, G.N. Removal of phosphate species from solution by adsorption onto calcite used as natural adsorbent. J. Hazard. Mater. 2007, 139, 447–452. [Google Scholar] [CrossRef]

- Zapater-Pereyra, M.; Malloci, E.; van Bruggen, M.A.; Lens, P.N.L. Use of marine and engineered materials for the removal of phosphorus from secondary effluent. Ecol. Eng. 2014, 73, 635–642. [Google Scholar] [CrossRef]

- Abeynaike, A.; Wang, L.Y.; Jones, M.I.; Patterson, D.A. Pyrolysed powdered mussel shells for eutrophication control: Effect of particle size and powder concentration on the mechanism and extent of phosphate removal. Asia-Pac. J. Chem. Eng. 2011, 6, 231–243. [Google Scholar] [CrossRef]

- Altundogan, H.S.; Tumen, F. Removal of phosphates from aqueous solutions by using bauxite. I: Effect of pH on the adsorption of various phosphates. J. Chem. Technol. Biotechnol. 2002, 77, 77–85. [Google Scholar] [CrossRef] [Green Version]

- Altundogan, H.S.; Tumen, F. Removal of phosphates from aqueous solutions by using bauxite II: The activation study. J. Chem. Technol. Biotechnol. 2003, 78, 824–833. [Google Scholar] [CrossRef] [Green Version]

- Yin, H.B.; Yun, Y.; Zhang, Y.L.; Fan, C.X. Phosphate removal from wastewaters by a naturally occurring, calcium-rich sepiolite. J. Hazard. Mater. 2011, 198, 362–369. [Google Scholar] [CrossRef]

- Xiong, W.H.; Peng, J. Development and characterization of ferrihydrite-modified diatomite as a phosphorus adsorbent. Water Res. 2008, 42, 4869–4877. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.Y.; Zhang, B.H.; Li, C.J.; Zhang, Z.J.; Kong, H.N. Simultaneous removal of ammonium and phosphate by zeolite synthesized from fly ash as influenced by salt treatment. J. Colloid Interface Sci. 2006, 304, 300–306. [Google Scholar] [CrossRef]

- Zhang, L.A.; Hong, S.; He, J.; Gan, F.X.; Ho, Y.S. Adsorption characteristic studies of phosphorus onto laterite. Desalin. Water Treat. 2011, 25, 98–105. [Google Scholar] [CrossRef]

- Siwek, H.; Bartkowiak, A.; Wlodarczyk, M. Adsorption of Phosphates from Aqueous Solutions on Alginate/Goethite Hydrogel Composite. Water 2019, 11, 633. [Google Scholar] [CrossRef] [Green Version]

- Agyeia, M.; Strydomb, C.A.; Potgieterc, J.H. The removal of phosphate ions from aqueous solution by fly ash, slag, ordinary Portland cement and related blends. Cem. Concr. Res. 2002, 32, 1889–1897. [Google Scholar] [CrossRef] [Green Version]

- Jia, C.R.; Dai, Y.R.; Wu, C.Y.; Wu, Z.B.; Liang, W. Adsorption characteristics of used cement for phosphorus removal from wastewater. Fresenius Environ. Bull. 2013, 22, 2910–2915. [Google Scholar]

- Shao, Q.; Zhang, Y.; Liu, Z.; Long, L.Z.; Liu, Z.Z.; Chen, Y.Q.; Hu, X.M.; Lu, M.M.; Huang, L.Z. Phosphorus and nitrogen recovery from wastewater by ceramsite: Adsorption mechanism, plant cultivation and sustainability analysis. Sci. Total Environ. 2022, 805, 12. [Google Scholar] [CrossRef] [PubMed]

- Johansson, L. Industrial by-products and natural substrata as phosphorus sorbents. Environ. Technol. 1999, 20, 309–316. [Google Scholar] [CrossRef]

- Bus, A.; Karczmarczyk, A. Properties of lime-siliceous rock opoka as reactive material to remove phosphorous from water and wastewater. Infrastrukt. I Ekol. Teren. Wiej. (Infrastruct. Ecol. Rural. Areas) 2014, 1, 227–238. [Google Scholar]

- Alvarez-Ayuso, E.; Querol, X.; Plana, F.; Alastuey, A.; Moreno, N.; Izquierdo, M.; Font, O.; Moreno, T.; Diez, S.; Vazquez, E.; et al. Environmental, physical and structural characterisation of geopolymer matrixes synthesised from coal (co-)combustion fly ashes. J. Hazard. Mater. 2008, 154, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, V.F.F.; MacKenzie, K.J.D.; Thaumaturgo, C. Synthesis and characterisation of materials based on inorganic polymers of alumina and silica: Sodium polysialate polymers. Int. J. Inorg. Mater. 2000, 2, 309–317. [Google Scholar] [CrossRef]

- Boke, H.; Cizer, O.; Ipekoglu, B.; Ugurlu, E.; Serifaki, K.; Toprak, G. Characteristics of lime produced from limestone containing diatoms. Constr. Build. Mater. 2008, 22, 866–874. [Google Scholar] [CrossRef] [Green Version]

- Sdiri, A.; Higashi, T.; Hatta, T.; Jamoussi, F.; Tase, N. Mineralogical and spectroscopic characterization, and potential environmental use of limestone from the Abiod formation, Tunisia. Environ. Earth Sci. 2010, 61, 1275–1287. [Google Scholar] [CrossRef]

- Tchadjie, L.N.; Djobo, J.N.Y.; Ranjbar, N.; Tchakoute, H.K.; Kenne, B.B.D.; Elimbi, A.; Njopwouo, D. Potential of using granite waste as raw material for geopolymer synthesis. Ceram. Int. 2016, 42, 3046–3055. [Google Scholar] [CrossRef]

- Rocha, C.; Peterson, J.A.; Jalandoni, A.; Chianelli, R.R.; Ma, L. Paleoenvironmental investigations, chemical analysis and characterization of underwater strata of Marigondon Cave. Quat. Int. 2017, 431, 223–231. [Google Scholar] [CrossRef]

- Zhang, W.; Gago-Ferrero, P.; Gao, Q.J.; Ahrens, L.; Blum, K.; Rostvall, A.; Bjorlenius, B.; Andersson, P.L.; Wiberg, K.; Haglund, P.; et al. Evaluation of five filter media in column experiment on the removal of selected organic micropollutants and phosphorus from household wastewater. J. Environ. Manag. 2019, 246, 920–928. [Google Scholar] [CrossRef]

- Mabroum, S.; Taha, Y.; Benzaazoua, M.; Hakkou, R. Recycling of marls from phosphate by-products to produce alkali-activated geopolymers. In Proceedings of the International Conference on Phosphates (ICP)—Fundamentals, Processes and Technologies (ICP), Mohammed VI Polytechn Univ, Benguerir, Mexico, 15–17 October 2020; Elsevier: Amsterdam, The Netherlands; Mohammed VI Polytechn Univ: Benguerir, Mexico, 2020; pp. 1931–1936. [Google Scholar]

- Gustafsson, J.P.; Renman, A.; Renman, G.; Poll, K. Phosphate removal by mineral-based sorbents used in filters for small-scale wastewater treatment. Water Res. 2008, 42, 189–197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rakhimova, N.R.; Rakhimov, R.Z.; Morozov, V.P.; Gaifullin, A.R.; Potapova, L.I.; Gubaidullina, A.M.; Osin, Y.N. Marl-based geopolymers incorporated with limestone: A feasibility study. J. Non-Cryst. Solids 2018, 492, 1–10. [Google Scholar] [CrossRef]

- Destainville, A.; Champion, E.; Bernache-Assollant, D.; Laborde, E. Synthesis, characterization and thermal behavior of apatitic tricalcium phosphate. Mater. Chem. Phys. 2003, 80, 269–277. [Google Scholar] [CrossRef]

- Dalahmeh, S.S.; Stenstrom, Y.; Jebrane, M.; Hylander, L.D.; Daniel, G.; Heinmaa, I. Efficiency of Iron- and Calcium-Impregnated Biochar in Adsorbing Phosphate From Wastewater in Onsite Wastewater Treatment Systems. Front. Environ. Sci. 2020, 8, 538539. [Google Scholar] [CrossRef]

- Bekiaris, G.; Peltre, C.; Jensen, L.S.; Bruun, S. Using FTIR-photoacoustic spectroscopy for phosphorus speciation analysis of biochars. Spectroc. Acta Pt. A-Mol. Biomol. Spectr. 2016, 168, 29–36. [Google Scholar] [CrossRef]

- Bartczak, P. Assessment of the Sorption Capacity of Natural Materials in Removing Selected Inorganic and Organic Compounds, Taking into Account Water Applications. Ph.D. Thesis, Politechnika Poznańska, Poznań, Poland, 2017. [Google Scholar]

- Choi, J.W.; Lee, S.Y.; Lee, S.H.; Kim, J.E.; Park, K.Y.; Kim, D.J.; Hong, S.W. Comparison of Surface-Modified Adsorbents for Phosphate Removal in Water. Water Air Soil Pollut. 2012, 223, 2881–2890. [Google Scholar] [CrossRef]

- Kumar, K.V.; de Castro, M.M.; Martinez-Escandell, M.; Molina-Sabio, M.; Rodriguez-Reinoso, F. A site energy distribution function from Toth isotherm for adsorption of gases on heterogeneous surfaces. Phys. Chem. Chem. Phys. 2011, 13, 5753–5759. [Google Scholar] [CrossRef]

- Tseng, R.L.; Wu, F.C. Inferring the favorable adsorption level and the concurrent multi-stage process with the Freundlich constant. J. Hazard. Mater. 2008, 155, 277–287. [Google Scholar] [CrossRef] [PubMed]

- Boujelben, N.; Bouzid, J.; Elouear, Z.; Feki, A.; Jamoussi, F.; Montiel, A. Phosphorus removal from aqueous solution using iron coated natural and engineered sorbents. J. Hazard. Mater. 2008, 151, 103–110. [Google Scholar] [CrossRef]

- Karczmarczyk, A.; Woja, K.; Bliska, P.; Baryła, A.; Bus, A. The efficiency of filtration materials (Polonite® and Leca®) supporting phosphorus removal in on site treatment systems with wastewater infiltration. Infrastrukt. I Ekol. Teren. Wiej. (Infrastruct. Ecol. Rural. Areas) 2017, 4, 1401–1413. [Google Scholar]

- Gunawan, E.K.; Warmadewanthi, X.; Liu, J.C. Removal of phosphate and fluoride from optoelectronic wastewater by calcite. Int. J. Environ. Technol. Manag. 2010, 12, 308–321. [Google Scholar] [CrossRef]

- Bellier, N.; Chazarenc, F.; Comeau, Y. Phosphorus removal from wastewater by mineral apatite. Water Res. 2006, 40, 2965–2971. [Google Scholar] [CrossRef]

- Molle, P.; Lienard, A.; Grasmick, A.; Iwema, A.; Kabbabi, A. Apatite as an interesting seed to remove phosphorus from wastewater in constructed wetlands. Water Sci. Technol. 2005, 51, 193–203. [Google Scholar] [CrossRef] [PubMed]

- Cucarella, V.; Zaleski, T.; Mazurek, R. Phosphorus sorption capacity of different types of opoka. J. Environ. Qual. 2009, 38, 381–392. [Google Scholar] [CrossRef]

- Drizo, A.; Frost, C.A.; Grace, J.; Smith, K.A. Physico-chemical screening of phosphate-removing substrates for use in constructed wetland systems. Water Res. 1999, 33, 3595–3602. [Google Scholar] [CrossRef]

- Masłoń, A.; Czarnota, J. Efficiency of Brick Dust and Powdered Ceramsite in the Phosphorus Removal from Wastewater. J. Ecol. Eng. 2020, 21, 63–71. [Google Scholar] [CrossRef]

- Kuroki, V.; Bosco, G.E.; Fadini, P.S.; Mozeto, A.A.; Cestari, A.R.; Carvalho, W.A. Use of a La(III)-modified bentonite for effective phosphate removal from aqueous media. J. Hazard. Mater. 2014, 274, 124–131. [Google Scholar] [CrossRef]

- Qiu, B.B.; Duan, F. Synthesis of industrial solid wastes/biochar composites and their use for adsorption of phosphate: From surface properties to sorption mechanism. Colloids Surf. A Physicochem. Eng. 2019, 571, 86–93. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Huang, H.M.; Lv, X.M.; Zhao, N.; Guo, G.J.; Zhang, D.D. Removal of phosphate from aqueous solution by dolomite-modified biochar derived from urban dewatered sewage sludge. Sci. Total Environ. 2019, 687, 460–469. [Google Scholar] [CrossRef] [PubMed]

- Lama, N.H.; Ma, H.T.; Bashir, M.J.K.; Eppe, G.; Avti, P.; Nguyen, T.T. Removal of phosphate from wastewater using coal slag. Int. J. Environ. Anal. Chem. 2020, 101, 2668–2678. [Google Scholar] [CrossRef]

- Renman, G.; Renman, A. Sustainable use of crushed autoclaved aerated concrete (CAAC) as a filter medium in wastewater purification. In Proceedings of the WASCON 2012 Proceedings, Gothenburg, Sweden, 30 May–1 June 2012. [Google Scholar]

- Li, Y.Z.; Liu, C.J.; Luan, Z.K.; Peng, X.J.; Zhu, C.L.; Chen, Z.Y.; Zhang, Z.G.; Fan, J.H.; Jia, Z.P. Phosphate removal from aqueous solutions using raw and activated red mud and fly ash. J. Hazard. Mater. 2006, 137, 374–383. [Google Scholar] [CrossRef] [PubMed]

- Bus, A.; Kaczmarczyk, A.; Baryła, A. Choosing of reactive material for phosphorous removal from water and wastewater on the example of lightweight aggregate Pollytag®. Inżynieria Ekol. 2014, 39, 33–41. [Google Scholar]

- Kasprzyk, M.; Gajewska, M. Phosphorus removal by application of natural and semi-natural materials for possible recovery according to assumptions of circular economy and closed circuit of P. Sci. Total Environ. 2019, 650, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Sočo, E.; Domoń, A.; Papciak, D.; Michel, M.M.; Cieniek, B.; Pająk, D. Characteristics of the Properties of Absodan Plus Sorbent and Its Ability to Remove Phosphates and Chromates from Aqueous Solutions. Materials 2022, 15, 3540. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.G.; Xu, Y.Y.; Yu, H.Q.; Xin, X.D.; Wei, Q.; Du, B. Adsorption of phosphate from aqueous solution by hydroxy-aluminum, hydroxy-iron and hydroxy-iron-aluminum pillared bentonites. J. Hazard. Mater. 2010, 179, 244–250. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Wang, X.L.; Li, S.M.; Liu, Y.Y.; An, Y.C.; Zheng, X.T. Preferable Adsorption of Nitrogen and Phosphorus from Agricultural Wastewater Using Thermally Modified Zeolite-Diatomite Composite Adsorbent. Water 2019, 11, 2053. [Google Scholar] [CrossRef] [Green Version]

| Material | Fraction [mm] | Density [g/cm3] | Specific Surface Area BET [m2/g] | Total Pore Volume [cm3/g] | Average Pore Radius [Å] |

|---|---|---|---|---|---|

| Raw travertine | 1–2 | 2.79 | 0.18 | 0.0013 | 1380 |

| Raw marl | 1–2 | 2.76 | 24.41 | 0.2021 | 1660 |

| Travertine heated at 700 °C | 1–2 | 2.72 | 0.26 | 0.0022 | 1740 |

| Marl heated at 1000 °C | 1–2 | 2.89 | 0.91 | 0.0085 | 1870 |

| Polonite® | 1–2 | 2.53 | 10.62 | 0.0626 | 1180 |

| Material | Elemental Composition [%] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Na | Mg | Al | Si | P | S | Cl | K | Ca | Ti | Fe | |

| Raw travertine | 13.36 | 50.01 | - | 0.18 | 0.14 | 0.22 | 0.01 | 0.03 | - | - | 35.84 | - | 0.21 |

| Travertine heated at 700 °C | 14.05 | 50.99 | - | 0.12 | 0.18 | 0.12 | 0.01 | 0.02 | 0.02 | - | 33.98 | - | 0.09 |

| Raw marl | 14.59 | 53.73 | 0.05 | 0.24 | 1.15 | 14.88 | - | - | - | 0.28 | 14.62 | - | 0.47 |

| Marl heated at 1000 °C | 4.4 | 43.42 | - | 0.33 | 1.42 | 18.44 | 0.02 | 0.06 | 0.49 | 30.66 | - | 0.76 | |

| Polonite® | 9.36 | 47.88 | - | 0.62 | 5.13 | 20.97 | - | 0.06 | 0.04 | 1.16 | 12.07 | 0.23 | 2.47 |

| Isotherm Model | Model Parameters | Raw Travertine | Travertine Heated at 700 °C | Raw Marl | Marl Heated at 1000 °C | Polonite® | |

|---|---|---|---|---|---|---|---|

| Langmuir | qm | [mg P/g] | 34.13 | 4314.61 | 43.89 | 80.44 | 36.26 |

| K | [L/mg] | 3.83 × 10−3 | 1.28 × 10−5 | 6.23 × 10−3 | 1.28 × 10−3 | 4.06 × 10−3 | |

| R2 | [-] | 0.973 | 0.993 | 0.968 | 0.955 | 0.992 | |

| Adj R2 | [-] | 0.969 | 0.992 | 0.964 | 0.949 | 0.991 | |

| Freundlich | K | [mg P/g] | 0.42 | 0.07 | 1.71 | 0.59 | 0.50 |

| n | [-] | 1.53 | 1.04 | 2.13 | 1.58 | 1.56 | |

| R2 | [-] | 0.975 | 0.992 | 0.944 | 0.885 | 0.980 | |

| Adj R2 | [-] | 0.971 | 0.991 | 0.936 | 0.869 | 0.977 | |

| Langmuir–Freundlich | qm | [mg P/g] | 59.32 | 536.03 | 61.34 | 65.09 | 32.52 |

| K | [-] | 1.19 × 10−3 | 1.11 × 10−4 | 2.42 × 10−3 | 1.93 × 10−3 | 5.11 × 10−3 | |

| n | [-] | 0.80 | 1.01 | 0.71 | 1.16 | 1.09 | |

| R2 | [-] | 0.976 | 0.992 | 0.953 | 0.895 | 0.993 | |

| Adj R2 | [-] | 0.968 | 0.990 | 0.938 | 0.860 | 0.990 | |

| Tóth | qm | [mg P/g] | 125.35 | 282.34 | 92.25 | 57.03 | 33.28 |

| K | [-] | 1.90 × 10−3 | 1.95 × 10−4 | 9.89 × 10−3 | 1.57 × 10−3 | 4.20 × 10−3 | |

| n | [-] | 0.42 | 3.88 | 0.40 | 1.56 | 1.12 | |

| R2 | [-] | 0.977 | 0.993 | 0.957 | 0.895 | 0.992 | |

| Adj R2 | [-] | 0.969 | 0.991 | 0.943 | 0.860 | 0.990 | |

| Radke–Praunitz | qm | [mg P/g] | 17.12 | 15.65 | 15.82 | 9.31 | 37.69 |

| K | [-] | 1.11 × 10−2 | 7.11 × 10−3 | 3.85 × 10−2 | 2.89 × 10−2 | 3.78 × 10−3 | |

| n | [-] | 0.65 | 0.03 | 0.72 | 0.46 | 1.05 | |

| R2 | [-] | 0.977 | 0.993 | 0.960 | 0.886 | 0.992 | |

| Adj R2 | [-] | 0.970 | 0.991 | 0.946 | 0.848 | 0.990 | |

| Marczewski–Jaroniec | qm | [mg P/g] | 140.48 | 12309.86 | 123.92 | 121.63 | 54.33 |

| K | [-] | 1.91 × 10−1 | 4.17 × 10−5 | 7.94 | 3.17 × 10−4 | 2.71 × 10 | |

| n | [-] | 0.29 | 0.28 | 0.26 | 4.89 | 0.43 | |

| m | [-] | 2.25 | 1.25 | 3.36 | 0.72 | 21.23 | |

| R2 | [-] | 0.978 | 0.992 | 0.960 | 0.891 | 0.995 | |

| Adj R2 | [-] | 0.964 | 0.987 | 0.936 | 0.826 | 0.992 | |

| Material | Adsorption Isotherm Parameters According to Langmuir Model * Marczewski–Jaroniec Model ** Tóth Model | Literature | |

|---|---|---|---|

| qm [mg P/g] | R2 [-] | ||

| limestone | 1.09 | - | [84] |

| calcite | 40.65 | 0.99 | [83] |

| goethite | 27.00 | 0.99 | [58] |

| apatite | 4.76 | 0.97 | [85] |

| opoka heated at 900 °C | 181.82 | 0.99 | [86] |

| travertine | 140.48 * | 0.98 | own research |

| travertine heated at 700 °C | 282.34 ** | 0.99 | own research |

| marl | 43.89 | 0.97 | own research |

| marl heated at 1000 °C | 80.44 | 0.95 | own research |

| shale | 0.65 | - | [87] |

| laterite | 1.14 | 0.99 | [57] |

| acadama clay | 6.09 | 0.96 | [47] |

| diatomite | 10.2 | 0.99 | [55] |

| diatomite modified with ferrihydrite | 37.3 | 0.99 | [55] |

| powdered ceramsite | 0.59 | 0.99 | [88] |

| brick dust | 0.46 | 0.99 | [88] |

| lanthanum III modified bentonite | 14.00 | 0.99 | [89] |

| biochar | 2.39 | 0.96 | [90] |

| Jebel Haidoudi clay | 133.88 | 0.99 | [31] |

| Douiret clay | 129.30 | 0.96 | [31] |

| biochar with dolomite | 29.18 | 0.98 | [91] |

| coal slag | 21.63 | 0.51 | [92] |

| autoclaved concrete | 70.90 | 0.94 | [93] |

| red mud | 113.87 | 0.96 | [94] |

| fly ash | 63.22 | 0.99 | [94] |

| Pollytag® | 32.24 | 0.93 | [95] |

| Polonite® | 40.90 | - | [82] |

| Polonite® | 36.26 | 0.97 | own research |

| 54.33 * | 0.99 | ||

| Leca® | 5.10 | - | [82] |

| Rockfos® | 256.4 | 0.99 | [96] |

| Kinetic Model | Model Parameters | Raw Travertine | Travertine Heated at 700 ℃ | Raw Marl | Marl Heated at 1000 ℃ | Polonite® | |

|---|---|---|---|---|---|---|---|

| Pseudo-first-order model, irreversible | R2 | [-] | 0.9703 | 0.8436 | 0.7240 | 0.3092 | 0.8079 |

| k1 | [1/min] | 3.35 × 10−5 | 1.51 × 10−4 | 2.55 × 10−5 | 1.70 × 10−4 | 3.23 × 10−5 | |

| Pseudo-first-order model, reversible | R2 | [-] | 0.9703 | 0.8436 | 0.7240 | 0.3092 | 0.8079 |

| k1 | [1/min] | 3.30 × 10−5 | 1.50 × 10−4 | 2.20 × 10−5 | 1.69 × 10−4 | 2.92 × 10−5 | |

| Pseudo-second-order model, irreversible | R2 | [-] | 0.8589 | 0.8710 | 0.3643 | 0.8862 | 0.4144 |

| k1 | [g/(mg P·min)] | 1.29 × 10−4 | 1.17 × 10−1 | 5.59 × 10−4 | 9.57 × 10−1 | 2.39 × 10−3 | |

| Pseudo-second-order model, reversible | R2 | [-] | 0.9242 | 0.8724 | 0.7189 | 0.7732 | 0.8748 |

| k1 | [g/(mg P·min)] | 5.00 × 10−5 | 1.78 × 10−2 | 1.66 × 10−5 | 3.63 × 10−3 | 1.00 × 10−5 | |

| Mixed order reversible model 2–1 | R2 | [-] | 0.8855 | 0.8722 | 0.7522 | 0.8715 | 0.7923 |

| k1 | [g/(mg P·min)] | 9.96 × 10−5 | 1.90 × 10−2 | 1.36 × 10−5 | 2.89 × 10−2 | 1.34 × 10−5 | |

| Mixed order reversible model 1–2 | R2 | [-] | 0.97034 | 0.84366 | 0.72401 | 0.30914 | 0.84910 |

| k1 | [g/(mg P·min)] | 3.35 × 10−5 | 1.51 × 10−4 | 2.55 × 10−5 | 1.70 × 10−4 | 1.00 × 10−6 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gubernat, S.; Masłoń, A.; Czarnota, J.; Koszelnik, P.; Chutkowski, M.; Tupaj, M.; Gumieniak, J.; Kramek, A.; Galek, T. Removal of Phosphorus with the Use of Marl and Travertine and Their Thermally Modified Forms—Factors Affecting the Sorption Capacity of Materials and the Kinetics of the Sorption Process. Materials 2023, 16, 1225. https://doi.org/10.3390/ma16031225

Gubernat S, Masłoń A, Czarnota J, Koszelnik P, Chutkowski M, Tupaj M, Gumieniak J, Kramek A, Galek T. Removal of Phosphorus with the Use of Marl and Travertine and Their Thermally Modified Forms—Factors Affecting the Sorption Capacity of Materials and the Kinetics of the Sorption Process. Materials. 2023; 16(3):1225. https://doi.org/10.3390/ma16031225

Chicago/Turabian StyleGubernat, Sylwia, Adam Masłoń, Joanna Czarnota, Piotr Koszelnik, Marcin Chutkowski, Mirosław Tupaj, Justyna Gumieniak, Agnieszka Kramek, and Tomasz Galek. 2023. "Removal of Phosphorus with the Use of Marl and Travertine and Their Thermally Modified Forms—Factors Affecting the Sorption Capacity of Materials and the Kinetics of the Sorption Process" Materials 16, no. 3: 1225. https://doi.org/10.3390/ma16031225

APA StyleGubernat, S., Masłoń, A., Czarnota, J., Koszelnik, P., Chutkowski, M., Tupaj, M., Gumieniak, J., Kramek, A., & Galek, T. (2023). Removal of Phosphorus with the Use of Marl and Travertine and Their Thermally Modified Forms—Factors Affecting the Sorption Capacity of Materials and the Kinetics of the Sorption Process. Materials, 16(3), 1225. https://doi.org/10.3390/ma16031225