Laboratory Study of the Effects of the Mixer Type and Mixing Time on the Volumetric Properties and Performance of a HMA with 30 Percent Reclaimed Asphalt Pavement

Abstract

:1. Introduction

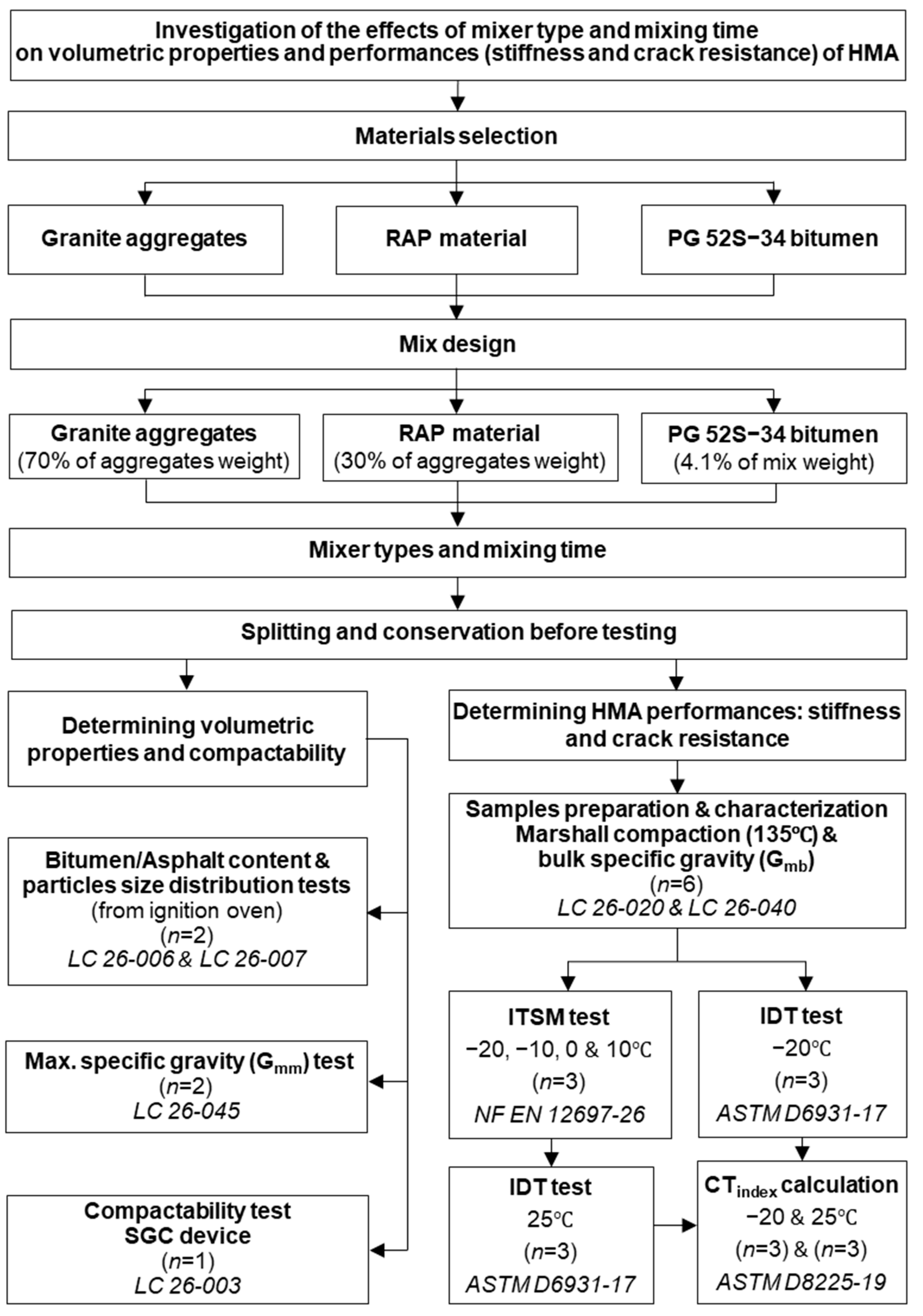

2. Experimental Program

3. Materials, Methods, and Tests Selected

3.1. Materials

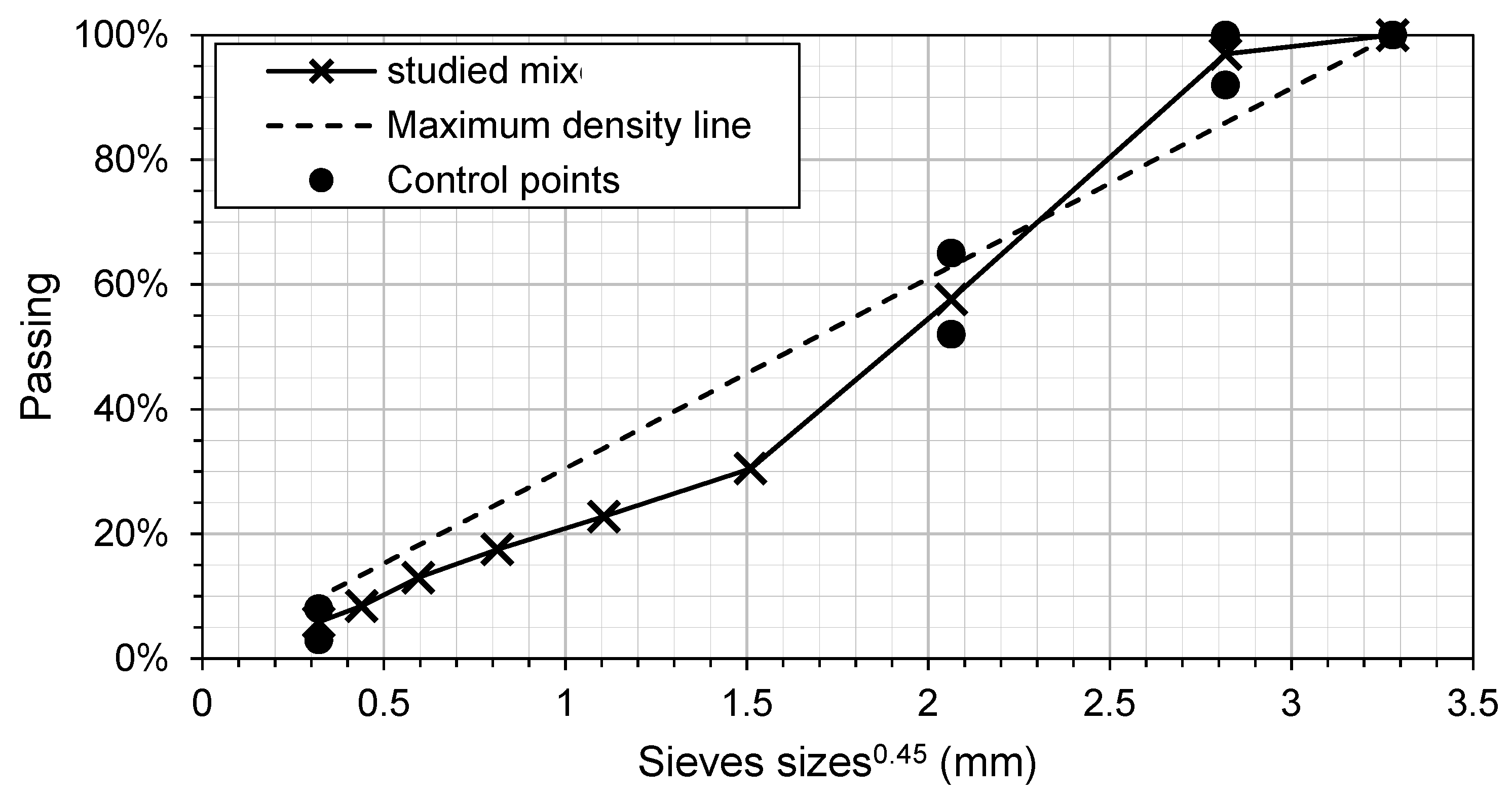

3.2. Preparations of Raw Materials, Mix Design, and HMA Selection

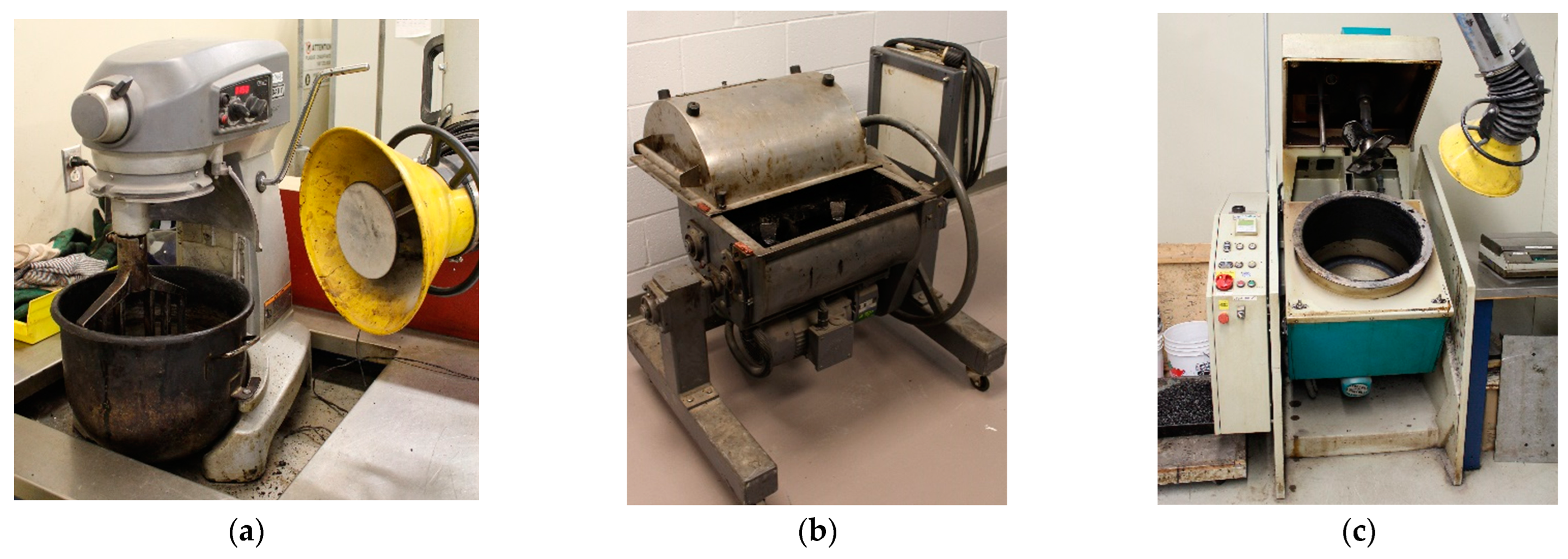

3.3. Mixer Types and Mixing Times

3.4. Conditioning of Materials and Mixing Conditions

3.5. Batch Size, Splitting, and Conservation before testing

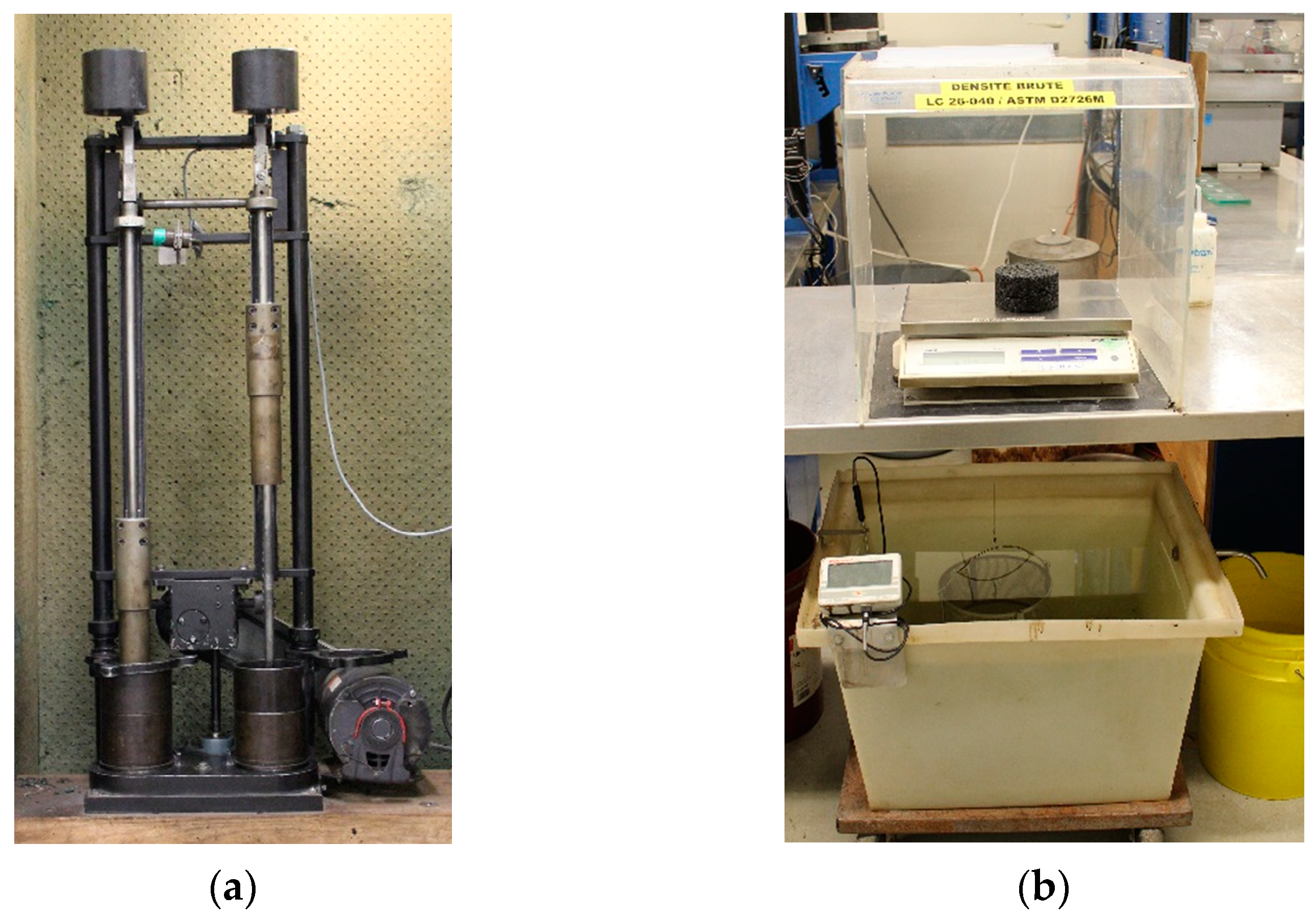

3.6. Determining HMA Volumetric Properties and Compactability

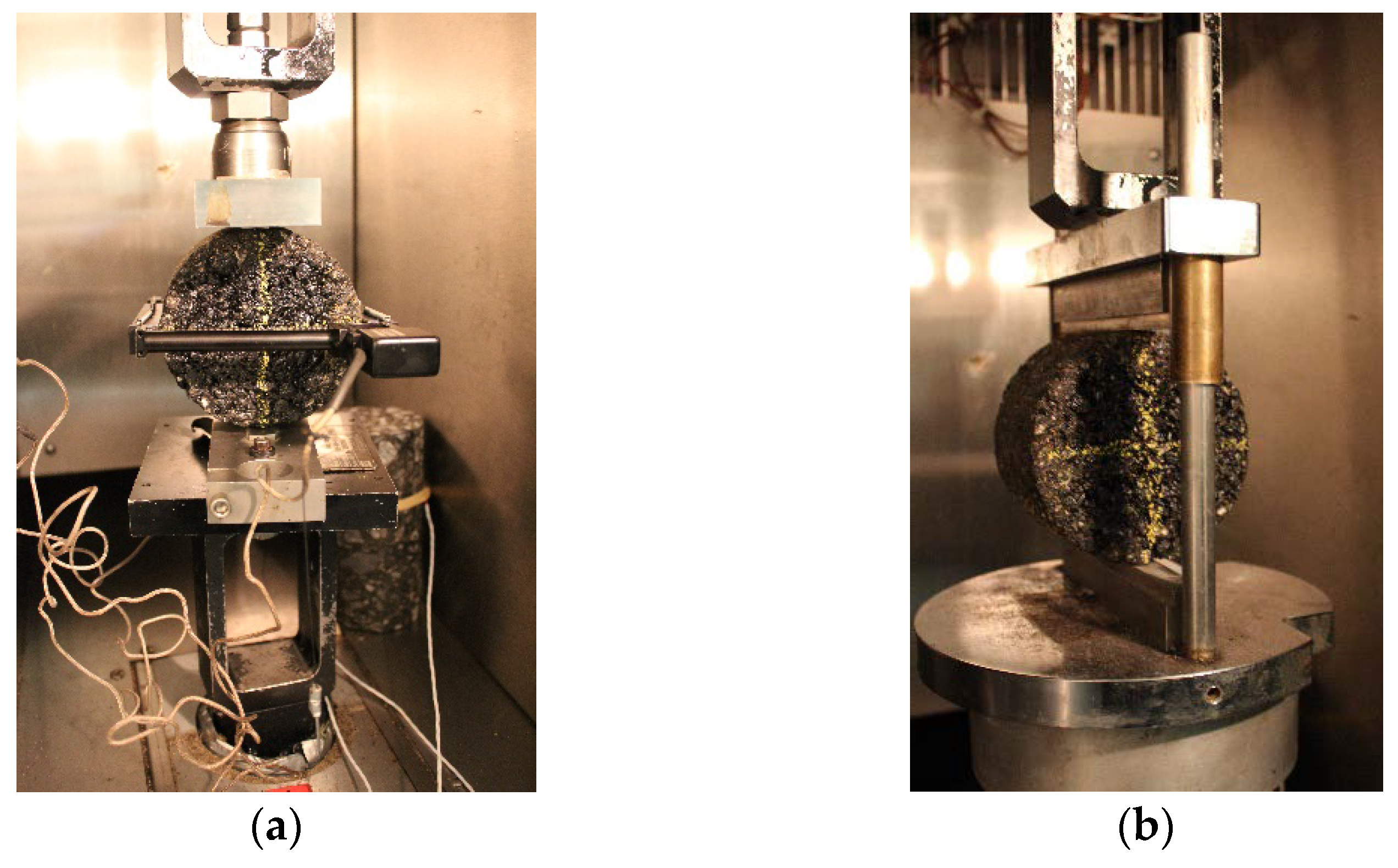

3.7. Specimen Preparation and Determining HMA Performance (Stiffness and Crack Resistance)

4. Results and Analysis

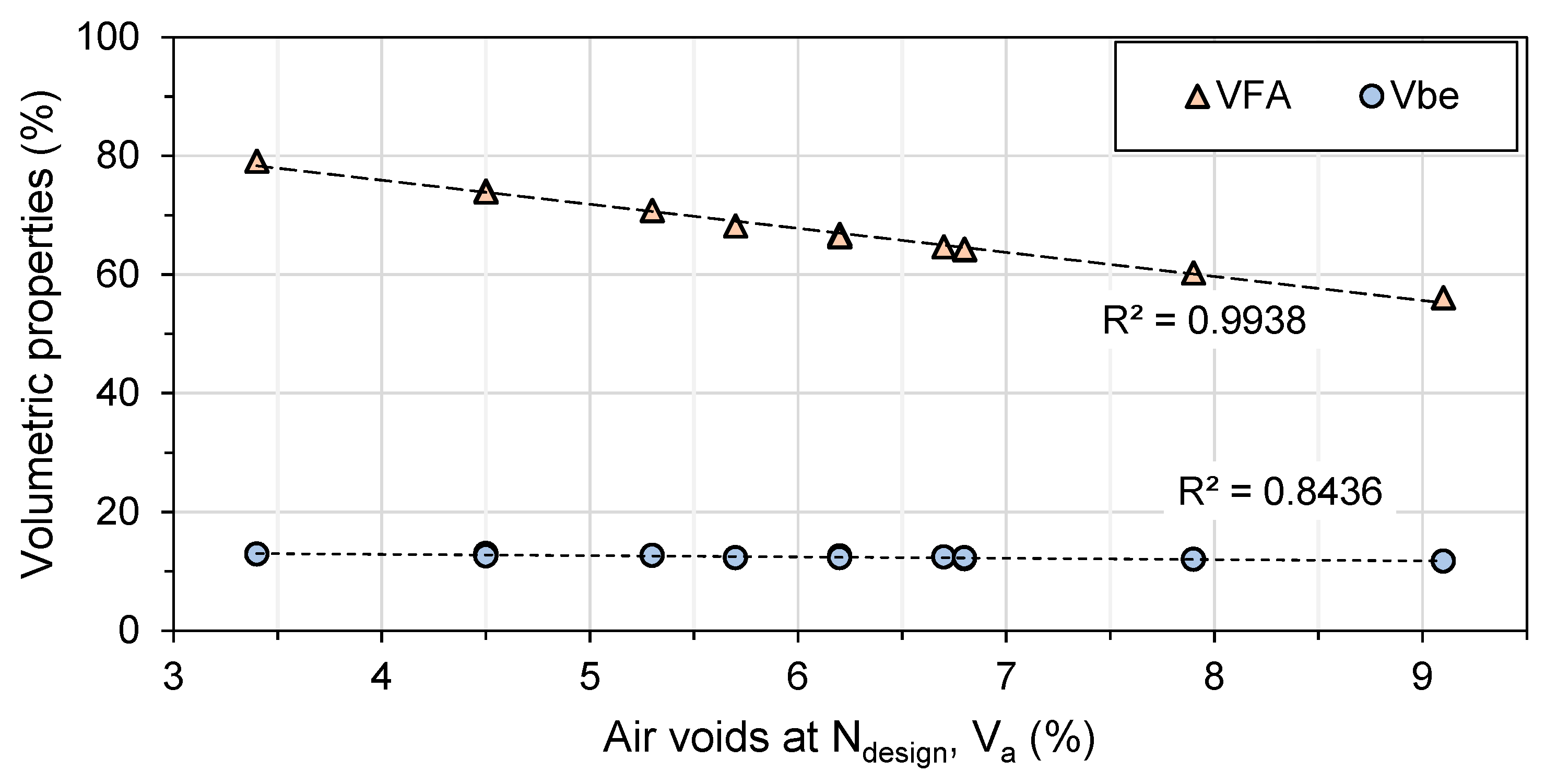

4.1. HMA Volumetric Properties and Compactability

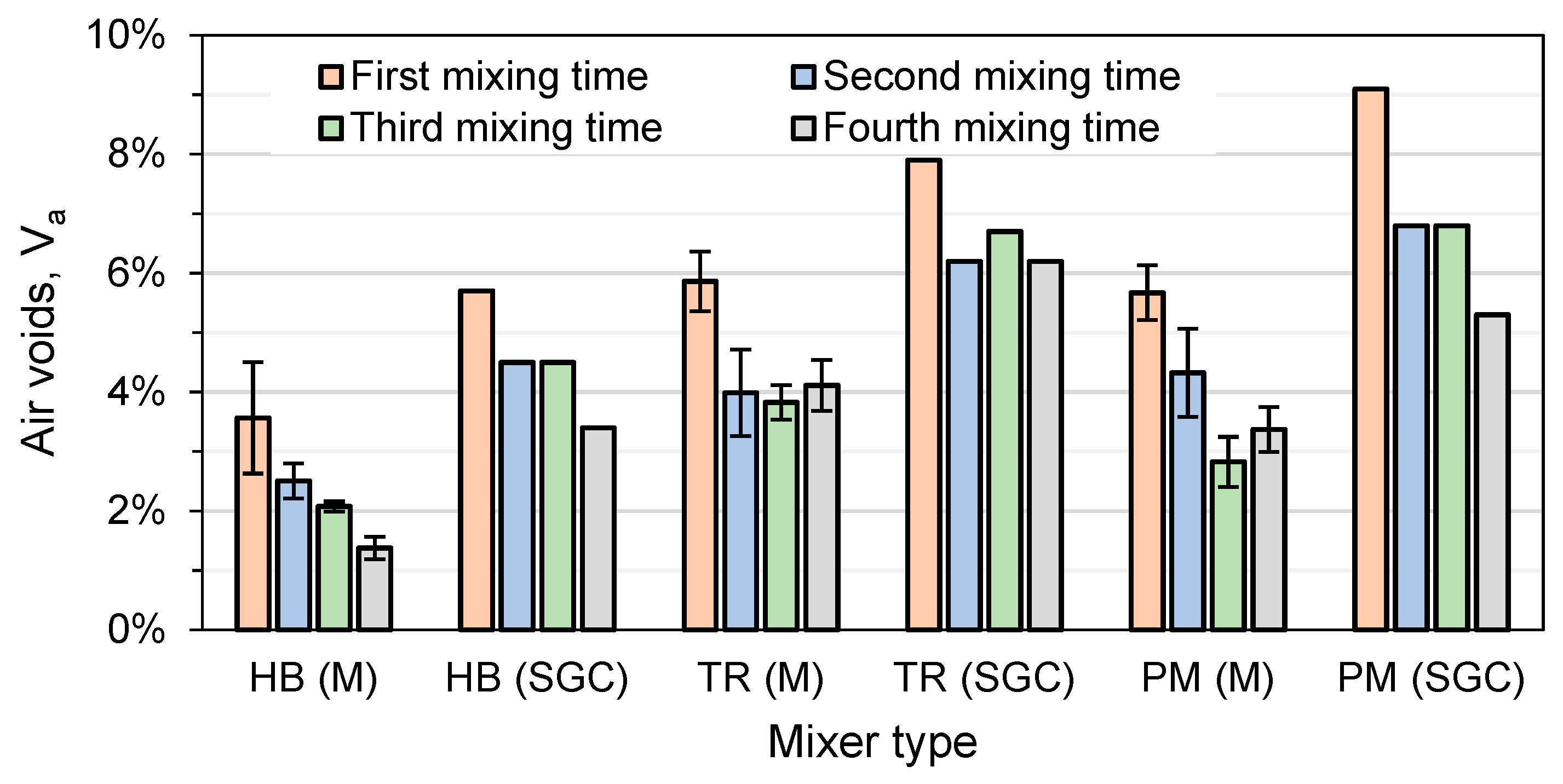

4.1.1. Air Voids Evaluation

4.1.2. Bitumen Content and Gradation

4.2. HMA Performance

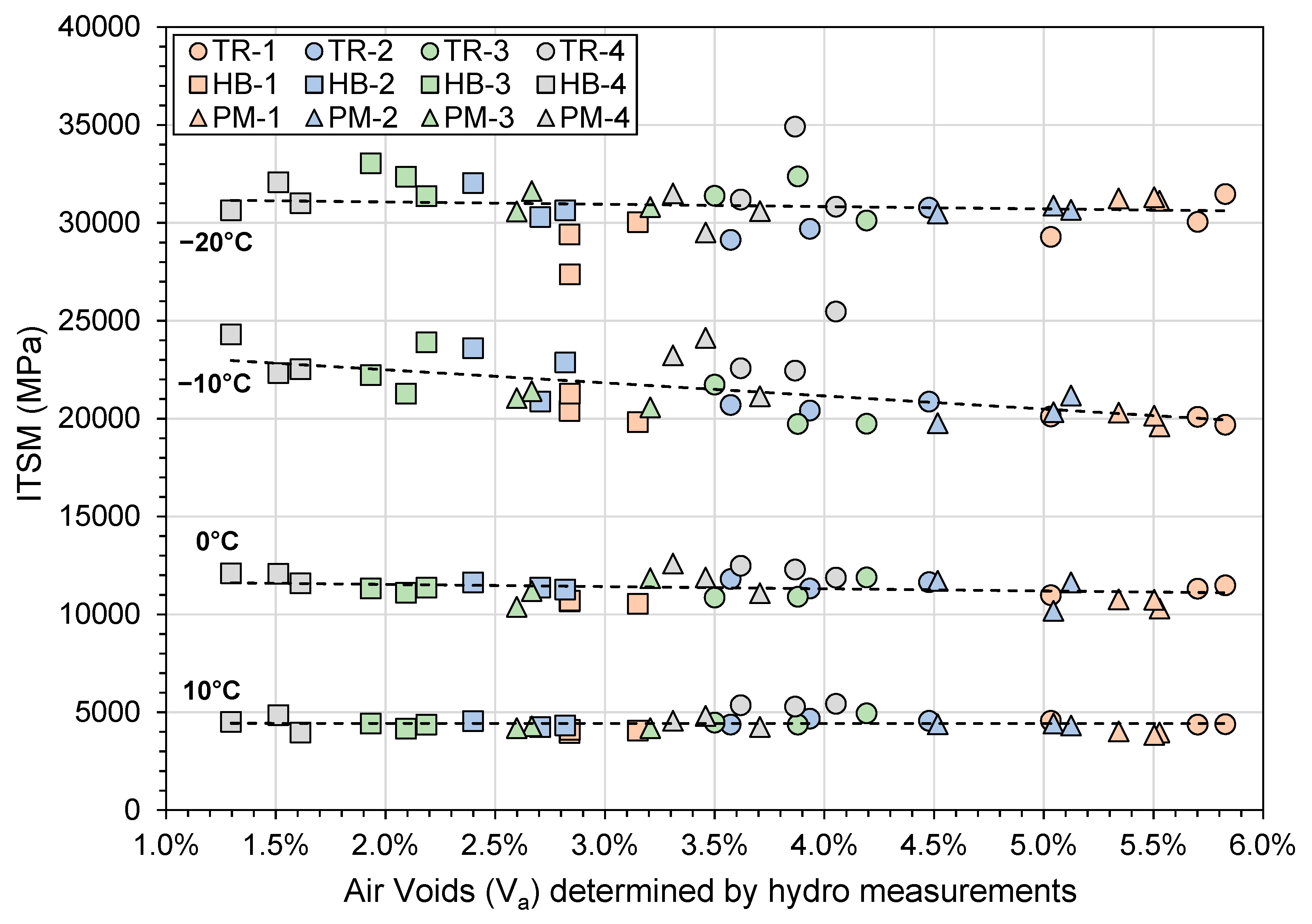

4.2.1. Indirect Tensile Strength Modulus (ITSM)

4.2.2. Effect of Air Voids on ITSM Results

4.2.3. Indirect Tensile Strength (IDT)

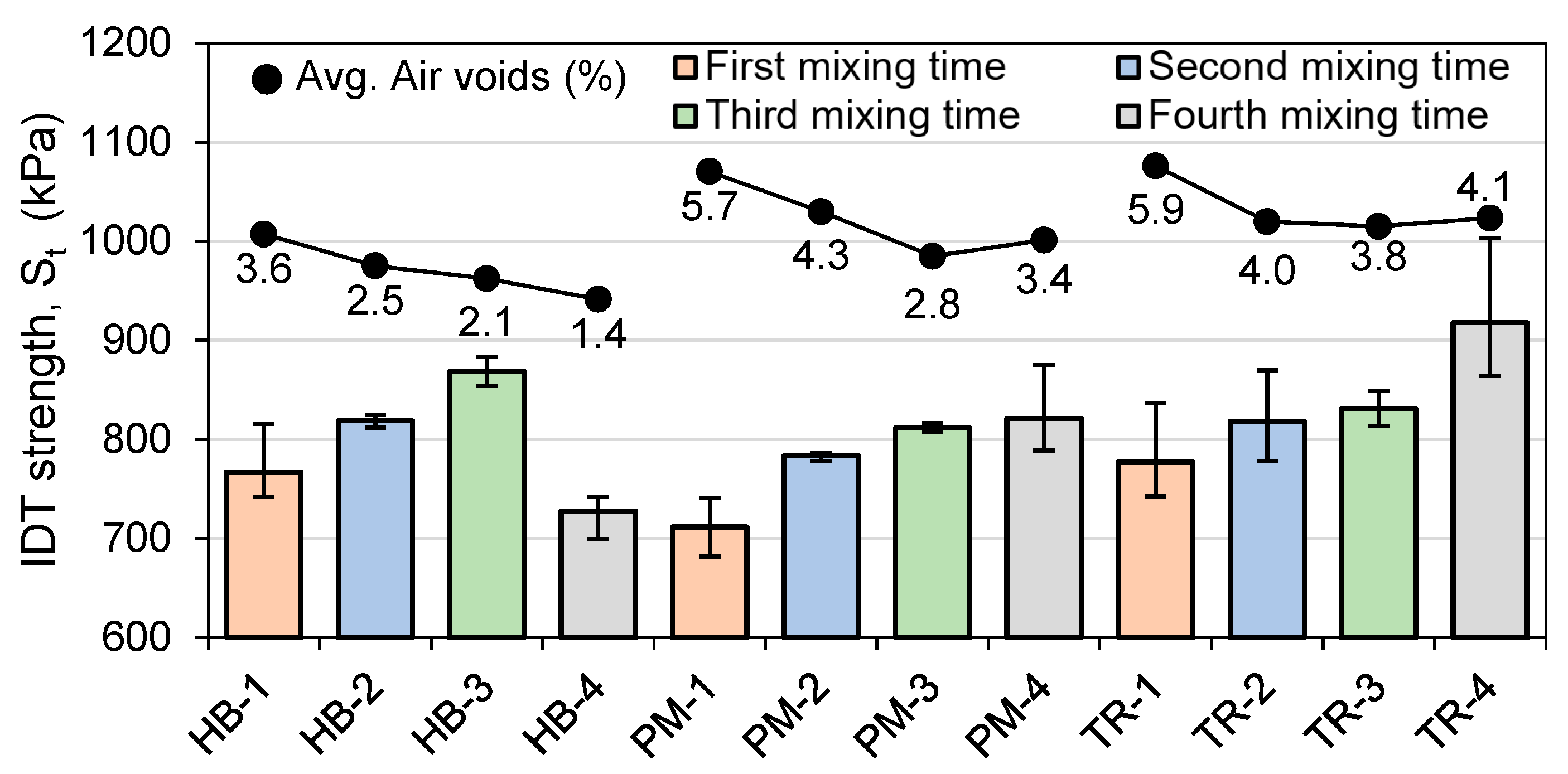

4.2.4. Crack Tolerance Index (CTindex)

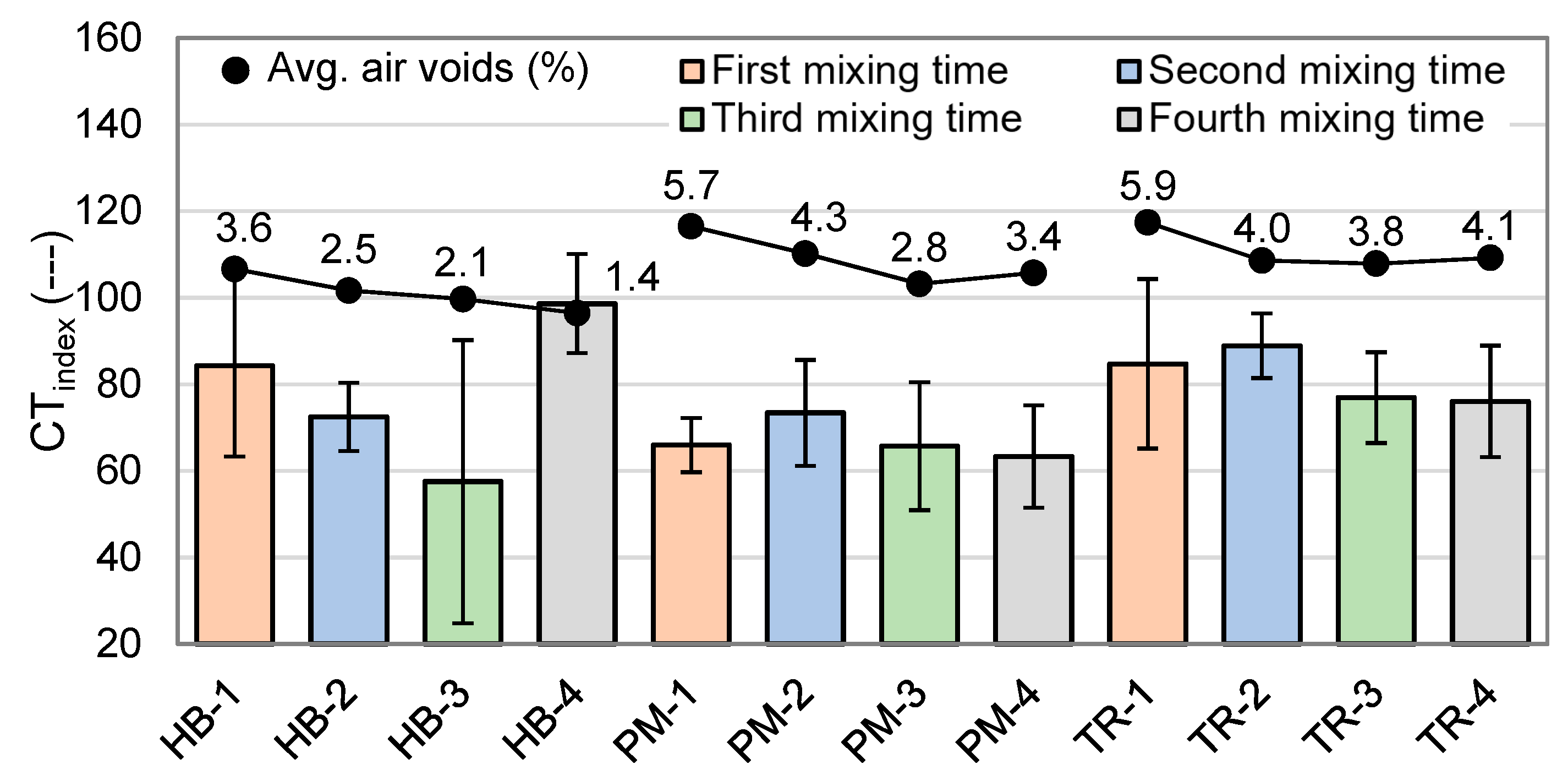

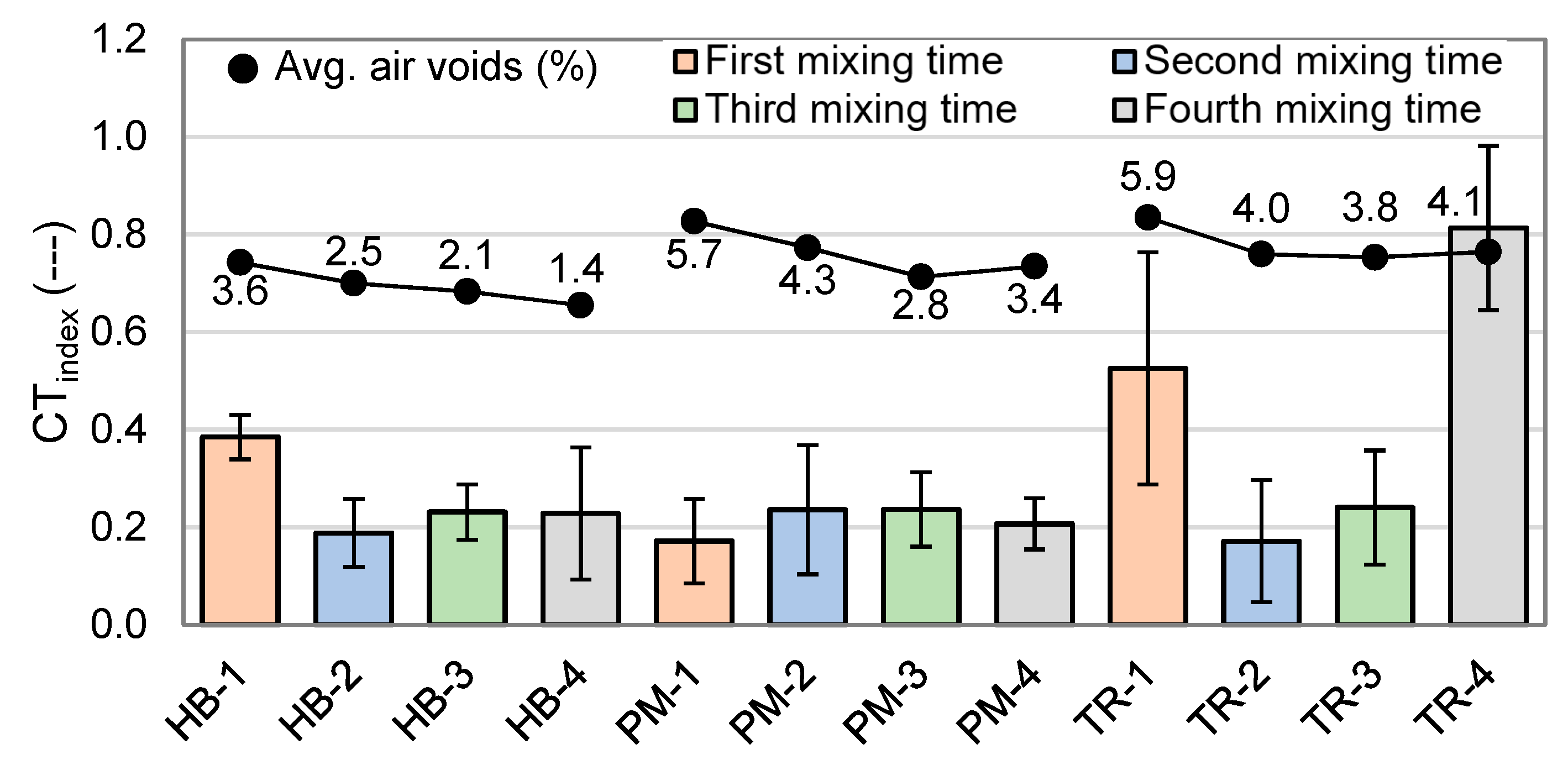

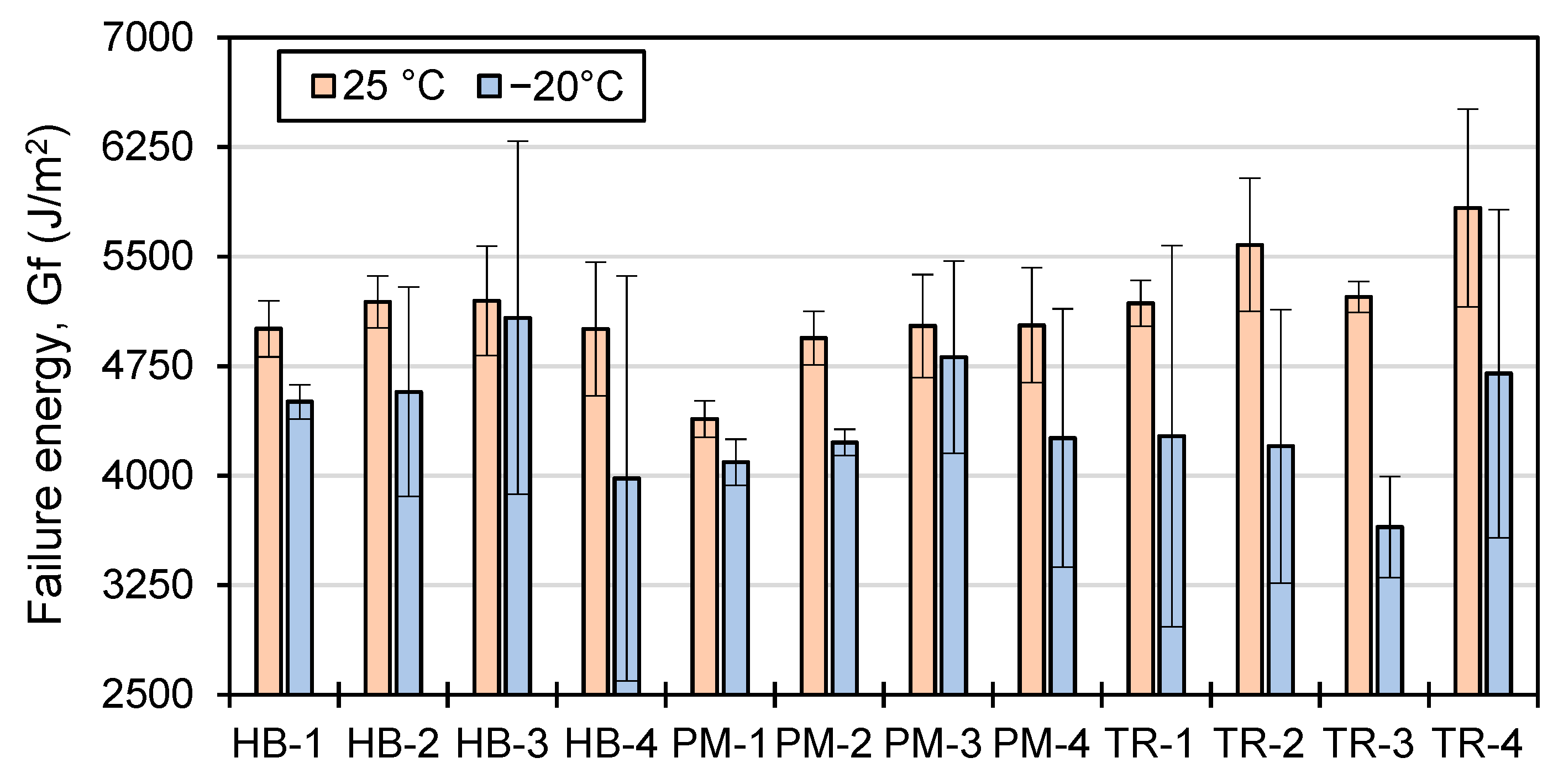

4.2.5. Work of Failure (Wf) and Failure Energy (Gf)

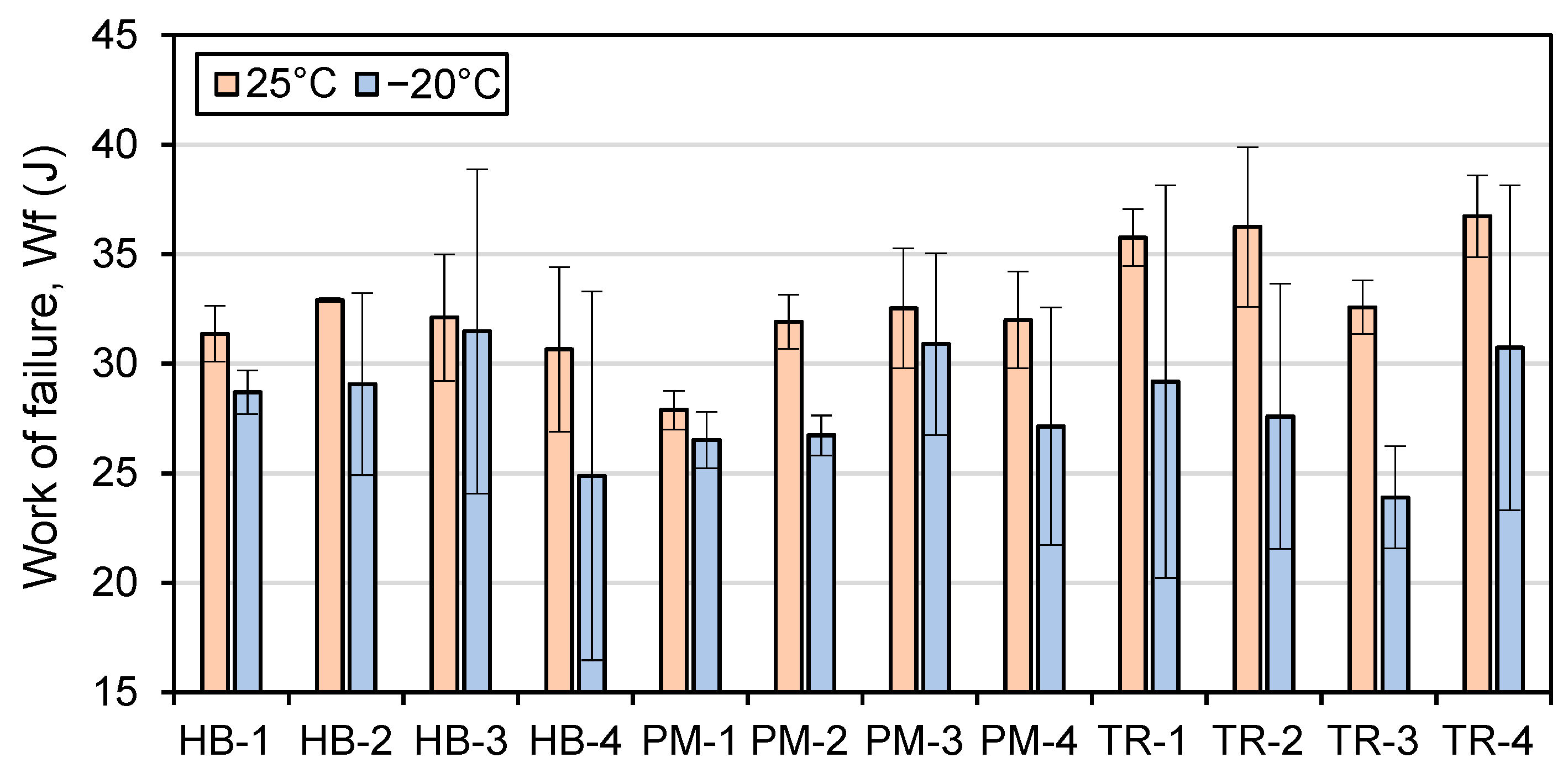

5. Conclusions

- For volumetric properties, Gmm and Va generally decrease with the increase in mixing time. The TR mixer reaches a point of stability after reaching a certain mixing time. On the other hand, Pba, VMA, Vbe, VFA, and particles that are smaller than 80µm increased with the mixing time for all mixer types, but the HB and PM mixers have a greater impact on these properties.

- Increasing the mixing time for all types of mixers can improve the compactability of the material, making it easier to apply on the field. The voids in the material when compacted using the Marshall method (40 blows on each side) are generally lower than those obtained using the SGC compactor at Ndesign. Again, the HB and PM mixers have a greater impact on compactability.

- The mechanical properties of the mixes were found to be influenced more by the mixing conditions than the voids. The voids had a greater impact on the stiffness of the mix in ITSM tests at a temperature of −10 °C, but other factors, such as the mix’s volumetric properties and the mobilization of RAP bitumen, also affected the stiffness of the mix. In IDT tests, stiffness was affected by the type of mixer and mixing time, but no correlation with the voids can be observed. The CTindex had good results at 25 °C, but no crack resistance was observed at −20 °C due to the brittle nature of the HMA. The energy stored during the test indicated that more energy was stored at 25 °C, even though a higher maximum load was achieved at −20 °C.

- The ANOVA indicates that the ITSM results are the most affected by the mixing time and type. The results suggest that as the testing temperature increases, the mixing time has a more pronounced effect on ITSM and other performance parameters. This implies that at higher temperatures, the mixing time has a more significant impact on the stiffness and strength of the asphalt mixture.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The challenges of using reclaimed asphalt pavement for new asphalt mixtures: A review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Cheng, H.; Sun, L.; Sun, Y.; Liu, N. Multi-performance evaluation of recycled warm-mix asphalt mixtures with high reclaimed asphalt pavement contents. J. Clean. Prod. 2022, 377, 134209. [Google Scholar] [CrossRef]

- Bilodeau, K. Comportement Thermomécanique Des Matériaux Traités Au Liant Hydraulique Et Des Bétons Compactés Routiers Incluant Des Fraisâts Bitumineux Et Des Fibres Métalliques. Ph.D. Thesis, ENTPE, Vaulx-en-Velin Cedex, France, 2012. (In French). [Google Scholar]

- Visintine, B.; Khosla, N.P.; Tayebali, A. Effects of higher percentage of recycled asphalt pavement on pavement performance. Road Mater. Pavement Des. 2013, 14, 432–437. [Google Scholar] [CrossRef]

- Li, X.; Marasteanu, M.O.; Williams, R.C.; Clyne, T.R. Effect of reclaimed asphalt pavement (proportion and type) and binder grade on asphalt mixtures. Transp. Res. Rec. 2008, 2051, 90–97. [Google Scholar] [CrossRef]

- McDaniel, R.S.; Soleymani, H.; Anderson, R.M.; Turner, P.; Peterson, R. Incorporation of Reclaimed Asphalt Pavement in the Superpave System; NCHRP 9-12; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2000. [Google Scholar]

- McDaniel, R.S.; Soleymani, H.; Slah, A. Use of reclaimed asphalt (RAP) under Superpave specifications. In Final Report, a Regional Pooled Fund Project; Purdue University: West Lafayette, Indiana, 2002. [Google Scholar]

- Hajj, E.Y.; Sebaaly, P.E.; Shrestha, R. Laboratory evaluation of mixes containing recycled asphalt pavement (RAP). Road Mater. Pavement Des. 2009, 10, 495–517. [Google Scholar] [CrossRef]

- Carter, A.; Donovan, H.; MacInnis, K.; Strynadka, T. Hot Mix Asphalt, 1st ed.; Canadian Technical Asphalt Association: West Kelowna, BC, Canada, 2018. [Google Scholar]

- Boriack, P.C. A Laboratory Study on the Effect of High RAP and High Asphalt Binder Content on the Performance of Asphalt Concrete. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2014. [Google Scholar]

- Maupin, G.W.; Diefenderfer, S.D.; Gillespie, J.S. 2008. Evaluation of Using Higher Percentages of Recycled Asphalt Pavement in Asphalt Mixes in Virginia; (No. VTRC 08-R22); Virginia Transportation Research Council: Charlottesville, VA, USA, 2008. [Google Scholar]

- Chow, J.; Badra, M. Recycled Asphalt Pavement (RAP) Scoping Study: Recycled Asphalt Pavement Toolkit; Final Report, Metro Vancouver; National Zero Waste Council: Vancouver, BC, Canada, 2018. [Google Scholar]

- Roque, R.; Zhang, Z.; Sankar, B. Determination of crack growth rate parameter of asphalt mixtures using the superpave IDT. J. Assoc. Asph. Paving Technol. 1999, 68, 941–952. [Google Scholar]

- Radeef, H.R.; Hassan, N.A.; Abidin, A.R.Z.; Mahmud, M.Z.H.; Yaacob, H.; Mashros, N.; Mohamed, A. Effect of aging and moisture damage on the cracking resistance of rubberized asphalt mixture. Mater. Today Proc. 2021, 42, 2853–2858. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H.; Wang, D.; Riccardi, C.; Wistuba, M.P. Comparison of low-temperature fracture and strength properties of asphalt mixture obtained from IDT and SCB under different testing configurations. Road Mater. Pavement Des. 2018, 19, 591–604. [Google Scholar] [CrossRef]

- Chowdhury, P.S.; Noojilla, S.L.A.; Reddy, M.A. Evaluation of fatigue characteristics of asphalt mixtures using Cracking Tolerance index (CTIndex). Constr. Build. Mater. 2022, 342, 128030. [Google Scholar] [CrossRef]

- Ramli, M.I.; Pasra, M.; Amiruddin, A.A. The sustainable performance challenge of asphalt mixture using polypropylene due to environmental weather. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 419, p. 012075. [Google Scholar]

- Cominsky, R.J.; Huber, G.A.; Kennedy, T.W.; Anderson, M. The Superpave Mix Design Manual for New Construction and Overlays; (No. SHRP-A-407); Strategic Highway Research Program: Washington, DC, USA, 1994. [Google Scholar]

- Badeli, S.; Solatiyan, E.; Carter, A.; Eng, P. Flexible Warm Mix Asphalt for Rural Roads in Canada—Laboratory Results and Case Studies; Canadian Technical Asphalt Association: Montreal, QC, Canada, 2019. [Google Scholar]

- Hassan, N.A.; Khan, R.; Raaberg, J.; Presti, D.L. Effect of mixing time on reclaimed asphalt mixtures: An investigation by means of imaging techniques. Constr. Build. Mater. 2015, 99, 54–61. [Google Scholar] [CrossRef]

- Yildirim, Y.; Solaimanian, M.; Kennedy, T.W. 2000. Mixing and Compaction Temperatures for Hot Mix Asphalt Concrete; (No. 1250-5); University of Texas at Austin: Austin, TX, USA; Center for Transportation Research: Austin, TX, USA, 2000. [Google Scholar]

- Izaks, R.; Haritonovs, V.; Klasa, I.; Zaumanis, M.J.P.E. Hot mix asphalt with high RAP content. Procedia Eng. 2015, 114, 676–684. [Google Scholar] [CrossRef] [Green Version]

- Al-Qadi, I.L.; Aurangzeb, Q.; Carpenter, S.H.; Pine, W.J.; Trepanier, J. Impact of High RAP Contents on Structural and Performance Properties of Asphalt Mixtures; University of Illinois Urbana-Champaign: Champaign, IL, USA, 2012. [Google Scholar]

- Yan, C.; Zhang, Y.; Bahia, H.U. Comparison between SCB-IFIT, un-notched SCB-IFIT and IDEAL-CT for measuring cracking resistance of asphalt mixtures. Constr. Build. Mater. 2020, 252, 119060. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2017, 18, 405–427. [Google Scholar] [CrossRef]

| Test | Units | Quebec Test Method | Results | |

|---|---|---|---|---|

| Coarse Aggregates (5–10 mm) | Fine Aggregates (0–5 mm) | |||

| Micro-Deval (MD) | % | LC 21-070 and LC 21-101 | 9 | 6 |

| Los Angeles (LA) | % | LC 21-400 | 27 | --- |

| Micro-Deval (MD) modif | % | LC 21-080 | --- | 23 |

| Crushed particles | % | LC 21-100 | 100 | 100 |

| Flakiness index | % | LC 21-265 | 12.8 | --- |

| Elongation index | % | LC 21-265 | 33.1 | --- |

| Bulk specific gravity (Gsb) | --- | LC 21-065 and LC 21-067 | 2.732 | 2.718 |

| Absorption (abs) | % | 0.44 | 0.23 | |

| Test | Units | Standard | Results | |

|---|---|---|---|---|

| RAP Extracted Bitumen * | Virgin Bitumen | |||

| High-temperature grading (H) | °C | AASTHO T315 | 84.0 | 52.7 |

| Low-temperature grading (L) | °C | AASTHO T313 | −24.0 | −34.9 |

| Performance grade (PG Hn-L) | --- | --- | PG 82-22 | PG 52S-34 |

| Mixing temperature (Tmix) | °C | AASTHO T316 | 174 | 136 |

| Compaction temperature (Tcomp) | °C | AASTHO T316 | 161 | 125 |

| Test | Units | Quebec Test Method | Results |

|---|---|---|---|

| Bitumen/asphalt content (AC) | % | LC 26-100 | 5.1 |

| Maximum specific gravity (Gmm) | --- | LC 26-045 | 2.523 |

| Water absorption (abs) | % | LC 21-065 and LC 21-067 | 0.0 |

| Total specific surface area (SSA) | m2/kg | LC 21-040 | 9.97 |

| Aggregate bulk specific gravity (Gsb) | --- | LC 21-065 and LC 21-067 | 2.714 |

| Conditioning before Mixing | Mixer Type | Mixing Time | Mix | |||

|---|---|---|---|---|---|---|

| Aggregates | RAP | Bitumen | Model | 1st | 2nd | |

| (ID) | (s) | (s) | (ID) | |||

| 185 °C | 60 °C | 145 °C | Countertop (Hobart: HB) | 45 | 30 | HB-1 |

| 60 | HB-2 | |||||

| 120 | HB-3 | |||||

| 240 | HB-4 | |||||

| 185 °C | 60 °C | 145 °C | Pugmill (PM) | 30 | 15 | PM-1 |

| 30 | PM-2 | |||||

| 60 | PM-3 | |||||

| 120 | PM-4 | |||||

| 145 °C | 145 °C | 145 °C | Thermoregulated (TR) | 60 | 40 | TR-1 |

| 80 | TR-2 | |||||

| 160 | TR-3 | |||||

| 320 | TR-4 | |||||

| Mix (ID) | Gmm (n = 2) (---) | Pba (n = 2) | Gmb 1 (n = 1) | Va (n = 1) | Vbe 2 (n = 2) | VMA (n = 2) | VFA (n = 2) |

|---|---|---|---|---|---|---|---|

| (%) | (---) | (%) | (%) | (%) | (%) | ||

| TR-1 | 2.524 | 0.41 | 2.325 | 7.9 | 12.0 | 19.9 | 60.3 |

| TR-2 | 2.514 | 0.24 | 2.357 | 6.2 | 12.6 | 18.8 | 66.8 |

| TR-3 | 2.519 | 0.33 | 2.349 | 6.7 | 12.4 | 19.1 | 64.7 |

| TR-4 | 2.522 | 0.38 | 2.365 | 6.2 | 12.3 | 18.5 | 66.4 |

| HB-1 | 2.526 | 0.44 | 2.381 | 5.7 | 12.3 | 18.0 | 68.2 |

| HB-2 | 2.509 | 0.13 | 2.395 | 4.5 | 13.0 | 17.5 | 74.1 |

| HB-3 | 2.518 | 0.29 | 2.406 | 4.5 | 12.6 | 17.1 | 73.9 |

| HB-4 | 2.514 | 0.23 | 2.429 | 3.4 | 12.9 | 16.3 | 79.1 |

| PM-1 | 2.530 | 0.54 | 2.299 | 9.1 | 11.7 | 20.8 | 56.1 |

| PM-2 | 2.525 | 0.39 | 2.353 | 6.8 | 12.1 | 18.9 | 64.2 |

| PM-3 | 2.521 | 0.32 | 2.349 | 6.8 | 12.3 | 19.0 | 64.3 |

| PM-4 | 2.515 | 0.32 | 2.383 | 5.3 | 12.7 | 18.0 | 70.8 |

| Mix (ID) | Va at Number of Gyrations (%) (n = 1) | |||||

|---|---|---|---|---|---|---|

| 10 | 60 | 80 | 100 | 120 | 200 | |

| TR-1 | 16.5 | 9.0 | 7.9 | 7.2 | 6.6 | 5.0 |

| TR-2 | 15.1 | 7.4 | 6.2 | 5.5 | 4.8 | 3.4 |

| TR-3 | 15.5 | 7.8 | 6.7 | 5.9 | 5.4 | 3.8 |

| TR-4 | 15.1 | 7.3 | 6.2 | 5.4 | 4.8 | 3.4 |

| HB-1 | 14.4 | 6.8 | 5.7 | 4.9 | 4.4 | 2.9 |

| HB-2 | 13.5 | 5.6 | 4.5 | 3.7 | 3.1 | 1.7 |

| HB-3 | 13.5 | 5.5 | 4.5 | 3.7 | 3.1 | 1.8 |

| HB-4 | 12.4 | 4.4 | 3.4 | 2.7 | 2.2 | 1.2 |

| PM-1 | 17.6 | 10.2 | 9.1 | 8.4 | 7.8 | 6.3 |

| PM-2 | 15.6 | 7.9 | 6.8 | 6.0 | 5.4 | 3.9 |

| PM-3 | 15.5 | 7.8 | 6.8 | 6.0 | 5.4 | 3.9 |

| PM-4 | 14.1 | 6.3 | 5.3 | 4.5 | 3.9 | 2.5 |

| Nname Spec. | Nini ≥11.0 | --- --- | Ndesign 7.0–4.0 | --- --- | --- --- | Nmax ≥2.0 |

| Mix (ID) | AC 1 (%) (n = 2) | Particle Size Distribution (n = 2) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (µm) | |||||||||

| 14 | 10 | 5 | 2.5 | 1.25 | 630 | 315 | 160 | 80 | ||

| TR-1 | 5.37 | 100 | 97 | 57 | 30 | 21 | 17 | 13 | 9 | 6.1 |

| TR-2 | 5.45 | 100 | 97 | 56 | 30 | 21 | 17 | 13 | 9 | 6.4 |

| TR-3 | 5.41 | 100 | 96 | 57 | 30 | 21 | 17 | 13 | 9 | 6.5 |

| TR-4 | 5.42 | 100 | 97 | 57 | 29 | 21 | 17 | 13 | 9 | 6.5 |

| HB-1 | 5.50 | 100 | 96 | 58 | 31 | 22 | 18 | 13 | 10 | 6.9 |

| HB-2 | 5.44 | 100 | 97 | 57 | 31 | 22 | 17 | 13 | 10 | 6.9 |

| HB-3 | 5.48 | 100 | 97 | 58 | 32 | 23 | 19 | 15 | 11 | 7.7 |

| HB-4 | 5.42 | 100 | 97 | 57 | 31 | 22 | 18 | 14 | 11 | 8.1 |

| PM-1 | 5.45 | 100 | 96 | 53 | 27 | 19 | 15 | 11 | 8 | 5.7 |

| PM-2 | 5.41 | 100 | 96 | 56 | 30 | 22 | 18 | 13 | 10 | 7.0 |

| PM-3 | 5.42 | 100 | 96 | 58 | 31 | 23 | 18 | 14 | 10 | 7.1 |

| PM-4 | 5.44 | 100 | 97 | 58 | 32 | 23 | 18 | 14 | 10 | 7.3 |

| Ref. | 5.60 | 100 | 97 | 58 | 30 | 23 | 18 | 13 | 8 | 5.8 |

| Spec. | --- | 100 | 100 | 65 | 46.1 2 | 36.7 2 | 26.8 2 | 18.1 2 | --- | 7 |

| 100 | 92 | 52 | 46.1 2 | 30.7 2 | 22.8 2 | 18.1 2 | --- | 4 | ||

| Mix | Testing Temperature (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| −20 (n = 3) | −10 (n = 3) | 0 (n = 3) | 10 (n = 3) | ||||||

| E′ | σ | E′ | σ | E′ | σ | E′ | σ | ||

| ITSM (MPa) | PM-1 | 30,821 | 92 | 20,009 | 372 | 10,598 | 270 | 3935 | 91 |

| PM-2 | 31,883 | 197 | 20,421 | 713 | 11,180 | 864 | 4374 | 51 | |

| PM-3 | 32,000 | 546 | 21,004 | 418 | 11,139 | 730 | 4215 | 53 | |

| PM-4 | 33,000 | 998 | 22,830 | 1531 | 11,846 | 757 | 4539 | 287 | |

| HB-1 | 29,765 | 1399 | 20,489 | 736 | 10,630 | 91 | 4030 | 6 | |

| HB-2 | 31,221 | 920 | 22,444 | 1410 | 11,419 | 188 | 4368 | 162 | |

| HB-3 | 32,827 | 846 | 22,456 | 1326 | 11,260 | 140 | 4313 | 142 | |

| HB-4 | 31,397 | 957 | 23,046 | 1211 | 11,915 | 94 | 4439 | 86 | |

| TR-1 | 28,576 | 1113 | 19,959 | 236 | 11,255 | 255 | 4436 | 106 | |

| TR-2 | 29,887 | 834 | 20,655 | 227 | 11,585 | 247 | 4528 | 155 | |

| TR-3 | 31,562 | 1130 | 20,395 | 115 | 11,212 | 585 | 4592 | 308 | |

| TR-4 | 32,304 | 2262 | 23,493 | 1708 | 12,211 | 310 | 5356 | 72 | |

| −20 °C | −10 °C | |||||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Crit | F-Value | p-Value | F-Crit | |

| All mixer | 3.159 | 0.002 | 1.952 | 8.607 | 0.000 | 1.952 |

| TR | 2.290 | 0.109 | 3.098 | 14.840 | 0.000 | 3.098 |

| HB | 9.892 | 0.000 | 3.098 | 6.126 | 0.004 | 3.098 |

| PM | 0.825 | 0.495 | 3.098 | 7.024 | 0.002 | 3.098 |

| Mixer type | 0 °C | 10 °C | ||||

| F-value | p-value | F-crit | F-value | p-value | F-crit | |

| All mixers | 6.161 | 0.000 | 1.952 | 19.221 | 0.000 | 1.952 |

| TR | 8.319 | 0.001 | 3.098 | 8.319 | 0.000 | 3.098 |

| HB | 14.138 | 0.000 | 3.098 | 3.242 | 0.044 | 3.098 |

| PM | 3.844 | 0.025 | 3.098 | 16.007 | 0.000 | 3.098 |

| −20 °C | 25 °C | |||||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Crit | F-Value | p-Value | F-Crit | |

| All mixers | 0.693 | 0.733 | 2.216 | 4.100 | 0.002 | 2.216 |

| TR | 0.755 | 0.550 | 4.066 | 2.120 | 0.176 | 4.066 |

| HB | 0.826 | 0.516 | 4.066 | 0.468 | 0.713 | 4.066 |

| PM | 1.043 | 0.425 | 4.066 | 5.037 | 0.030 | 4.066 |

| −20 °C | 25 °C | |||||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Crit | F-Value | p-Value | F-Crit | |

| All mixer | 1.038 | 0.446 | 2.216 | 1.405 | 0.234 | 2.216 |

| TR | 0.863 | 0.499 | 4.066 | 1.078 | 0.412 | 4.066 |

| HB | 4.667 | 0.036 | 4.066 | 0.946 | 0.463 | 4.066 |

| PM | 0.338 | 0.799 | 4.066 | 0.525 | 0.678 | 4.066 |

| Mixer Type | −20 °C | 25 °C | |||||

|---|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Crit | F-Value | p-Value | F-Crit | ||

| Wf | All mixers | 0.693 | 0.733 | 2.216 | 4.100 | 0.002 | 2.216 |

| TR | 0.755 | 0.550 | 4.066 | 2.120 | 0.176 | 4.066 | |

| HB | 0.826 | 0.516 | 4.066 | 0.468 | 0.713 | 4.066 | |

| PM | 1.043 | 0.425 | 4.066 | 5.037 | 0.030 | 4.066 | |

| Gf | All mixers | 0.756 | 0.678 | 2.216 | 3.195 | 0.008 | 2.216 |

| TR | 0.717 | 0.569 | 4.066 | 1.637 | 0.256 | 4.066 | |

| HB | 0.823 | 0.517 | 4.066 | 0.336 | 0.800 | 4.066 | |

| PM | 0.971 | 0.453 | 4.066 | 4.297 | 0.044 | 4.066 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bérubé, M.-A.; Lamothe, S.; Bilodeau, K.; Carter, A. Laboratory Study of the Effects of the Mixer Type and Mixing Time on the Volumetric Properties and Performance of a HMA with 30 Percent Reclaimed Asphalt Pavement. Materials 2023, 16, 1300. https://doi.org/10.3390/ma16031300

Bérubé M-A, Lamothe S, Bilodeau K, Carter A. Laboratory Study of the Effects of the Mixer Type and Mixing Time on the Volumetric Properties and Performance of a HMA with 30 Percent Reclaimed Asphalt Pavement. Materials. 2023; 16(3):1300. https://doi.org/10.3390/ma16031300

Chicago/Turabian StyleBérubé, Marc-André, Sébastien Lamothe, Kevin Bilodeau, and Alan Carter. 2023. "Laboratory Study of the Effects of the Mixer Type and Mixing Time on the Volumetric Properties and Performance of a HMA with 30 Percent Reclaimed Asphalt Pavement" Materials 16, no. 3: 1300. https://doi.org/10.3390/ma16031300

APA StyleBérubé, M.-A., Lamothe, S., Bilodeau, K., & Carter, A. (2023). Laboratory Study of the Effects of the Mixer Type and Mixing Time on the Volumetric Properties and Performance of a HMA with 30 Percent Reclaimed Asphalt Pavement. Materials, 16(3), 1300. https://doi.org/10.3390/ma16031300