Efficient Day-and-Night NO2 Abatement by Polyaniline/TiO2 Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Sample Characterization

2.3. NO2 Abatement

2.4. Reusability Tests

3. Results and Discussion

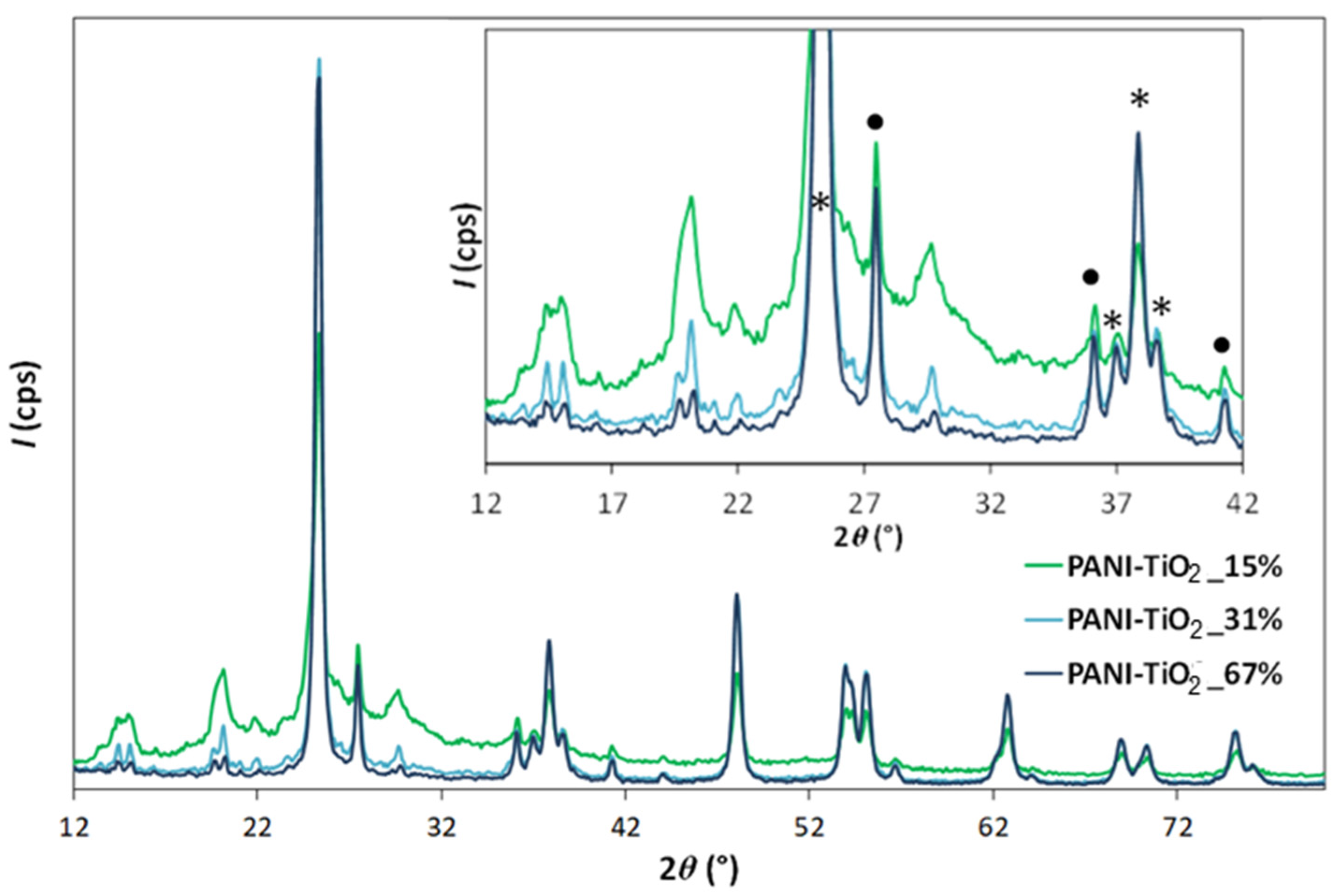

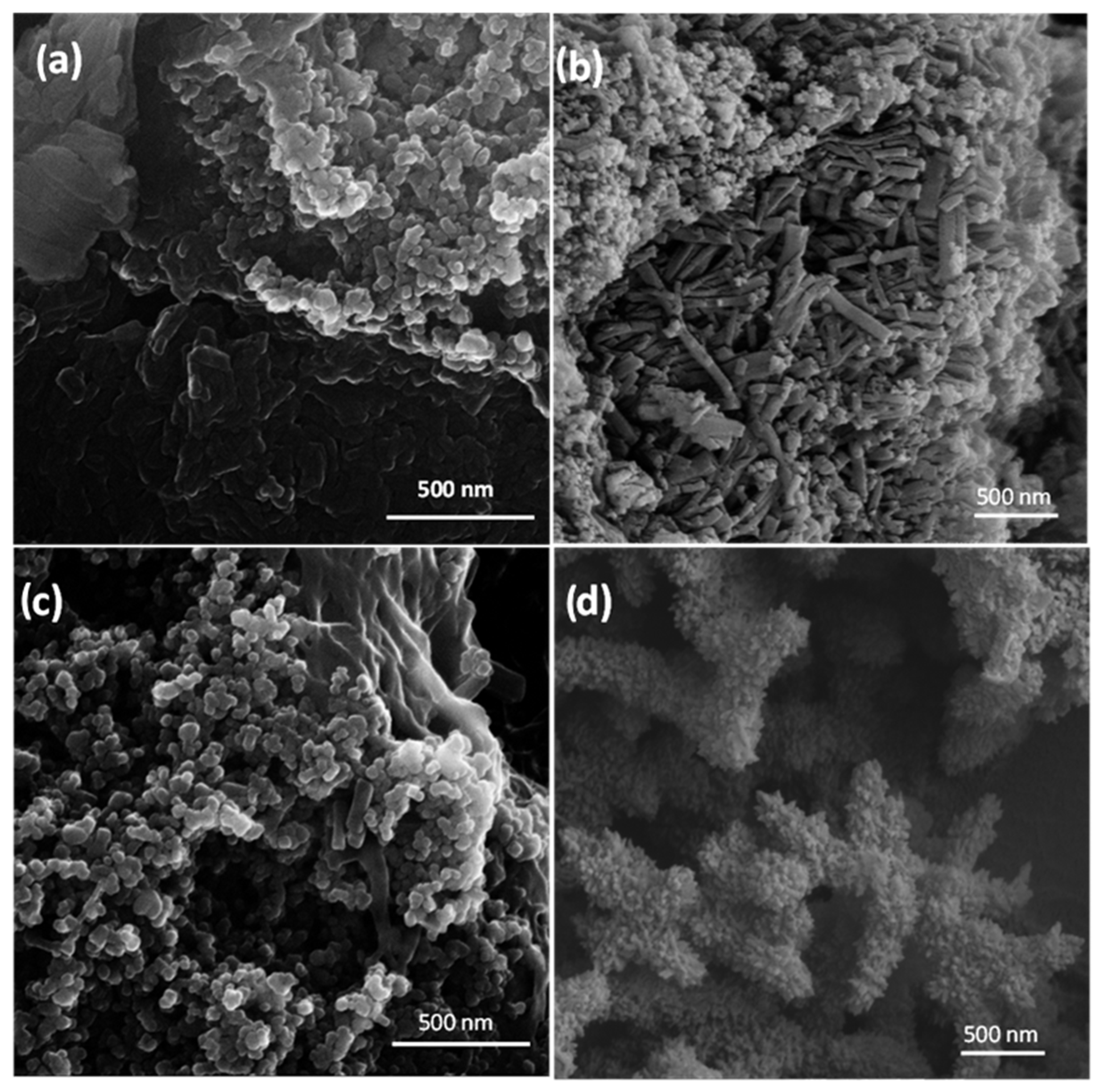

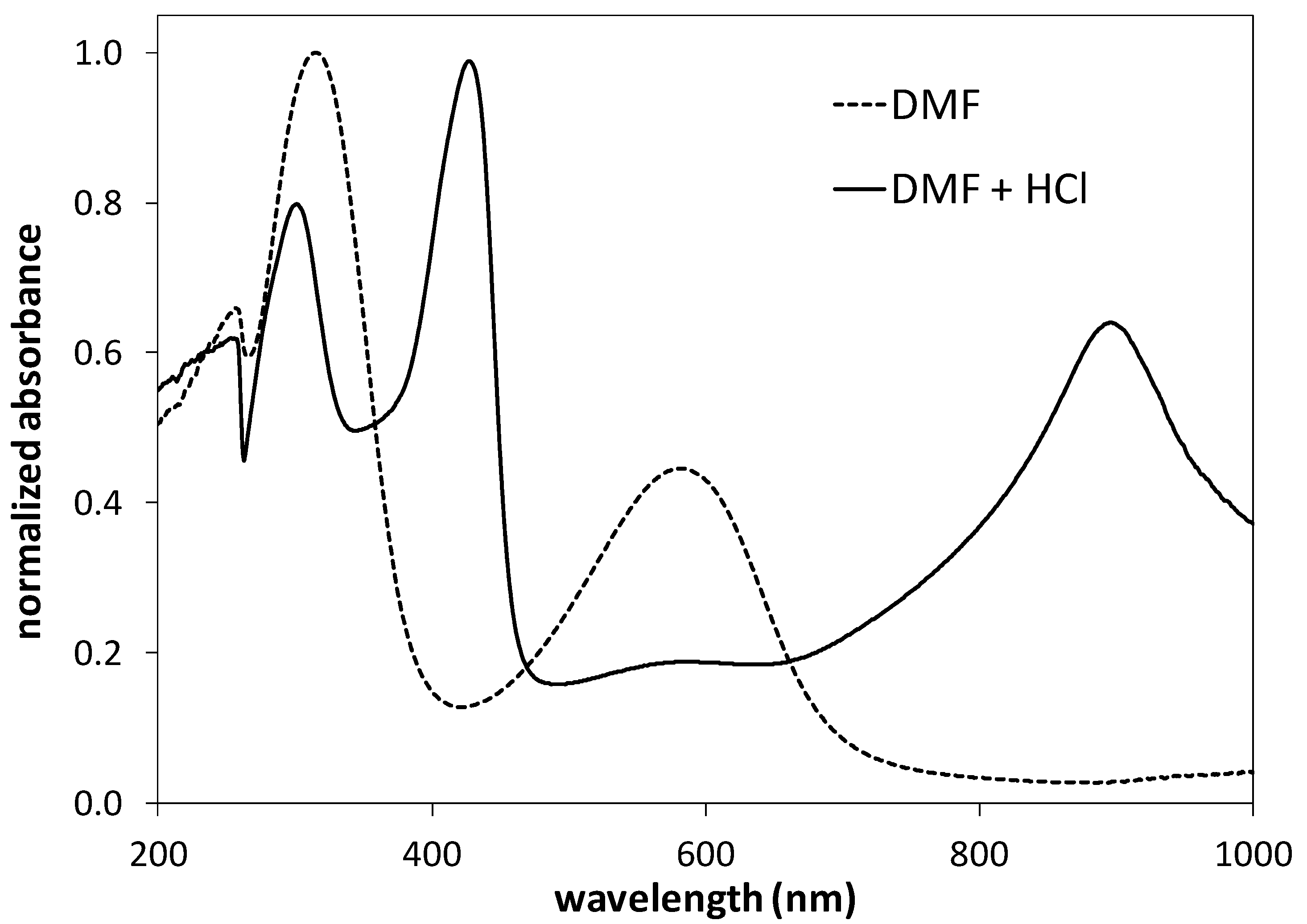

3.1. Materials Characterization

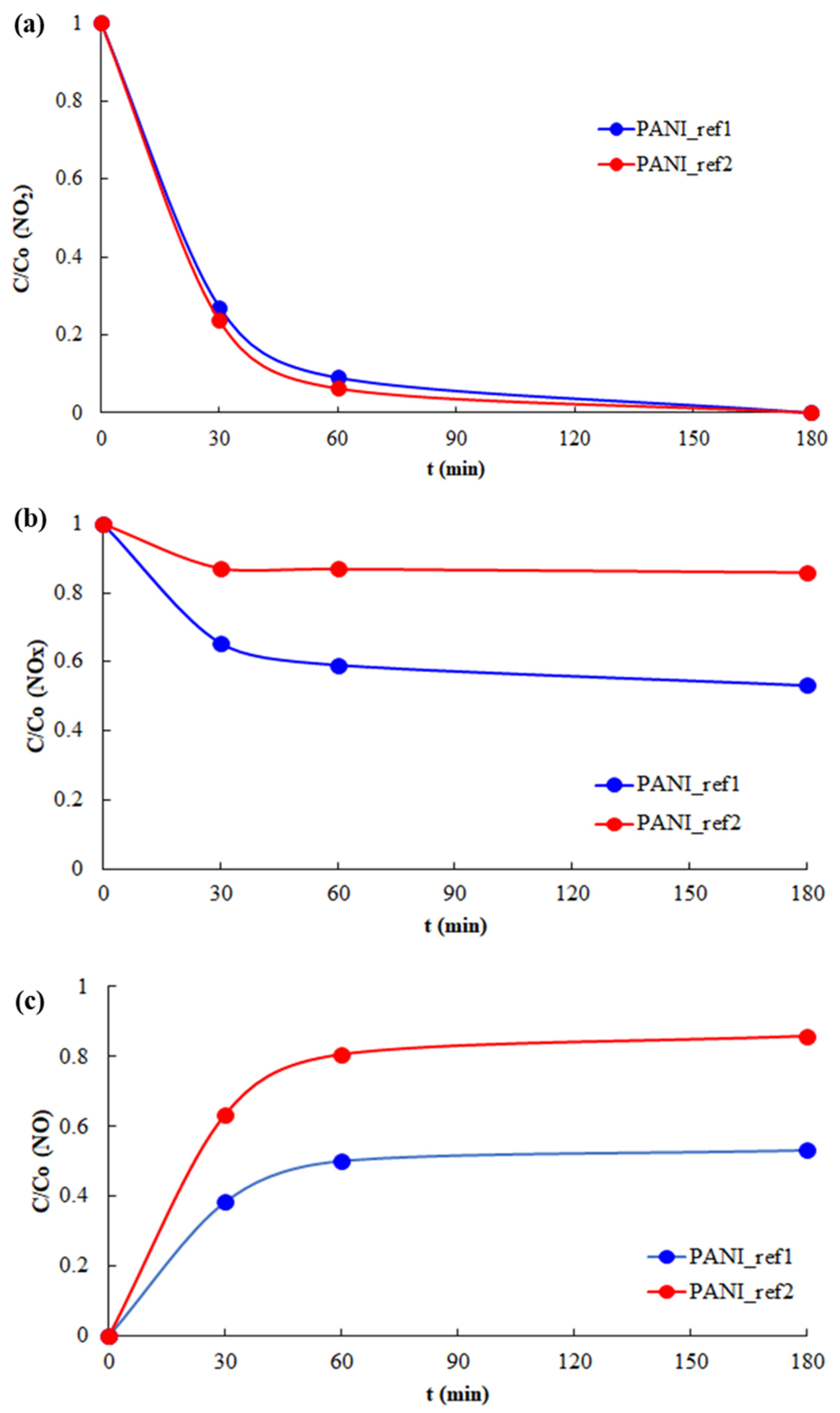

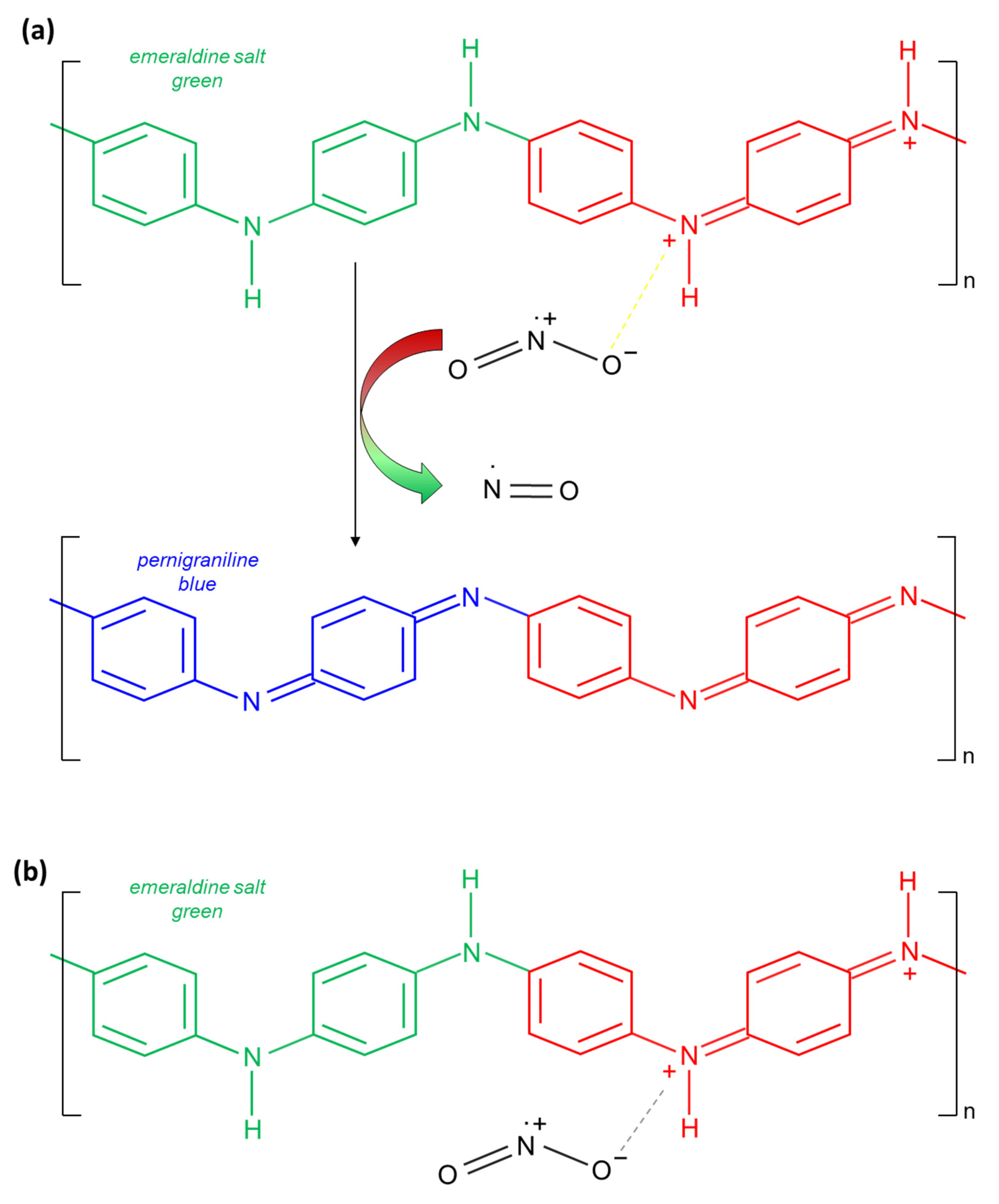

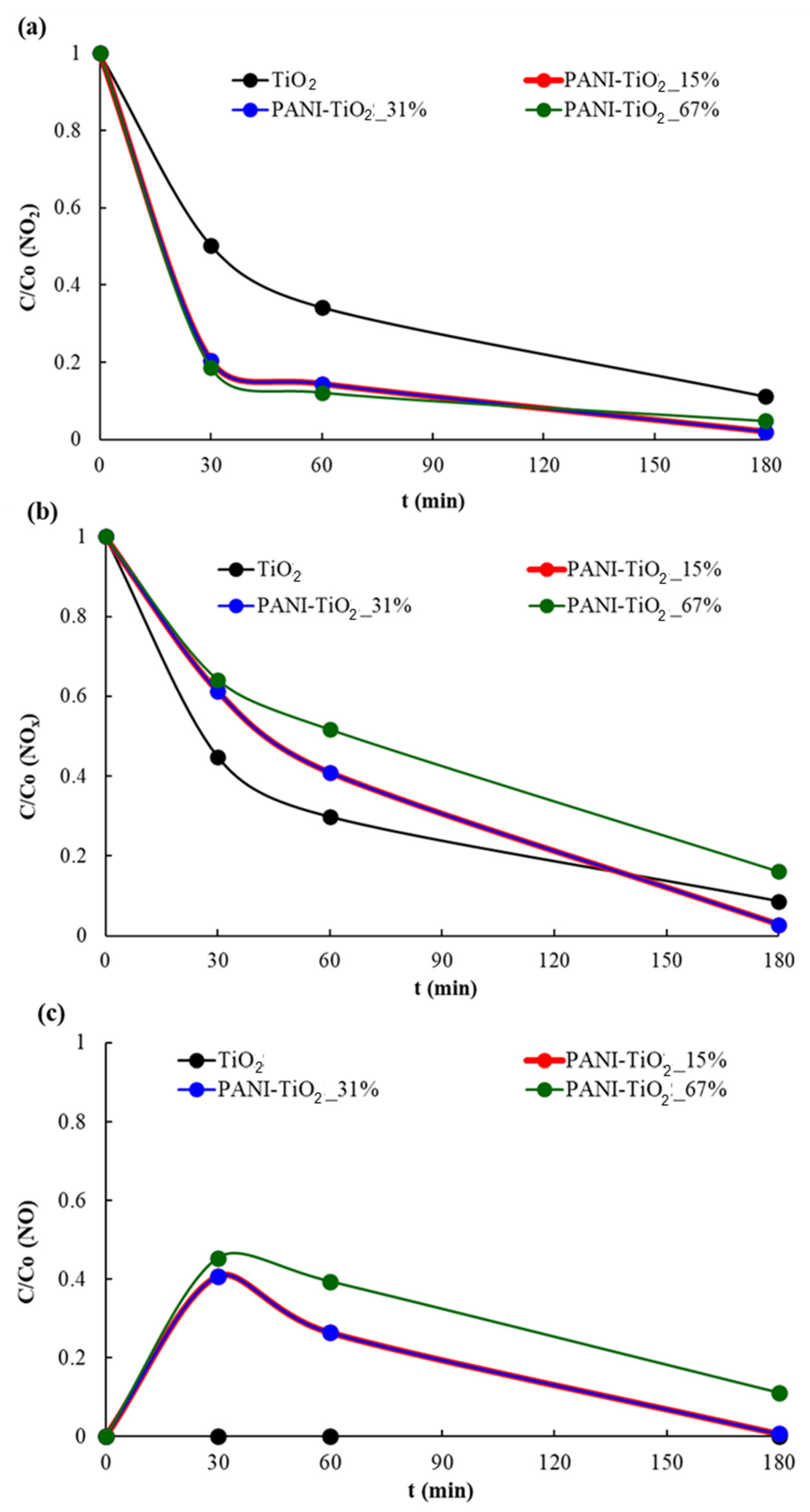

3.2. NO2 Abatement

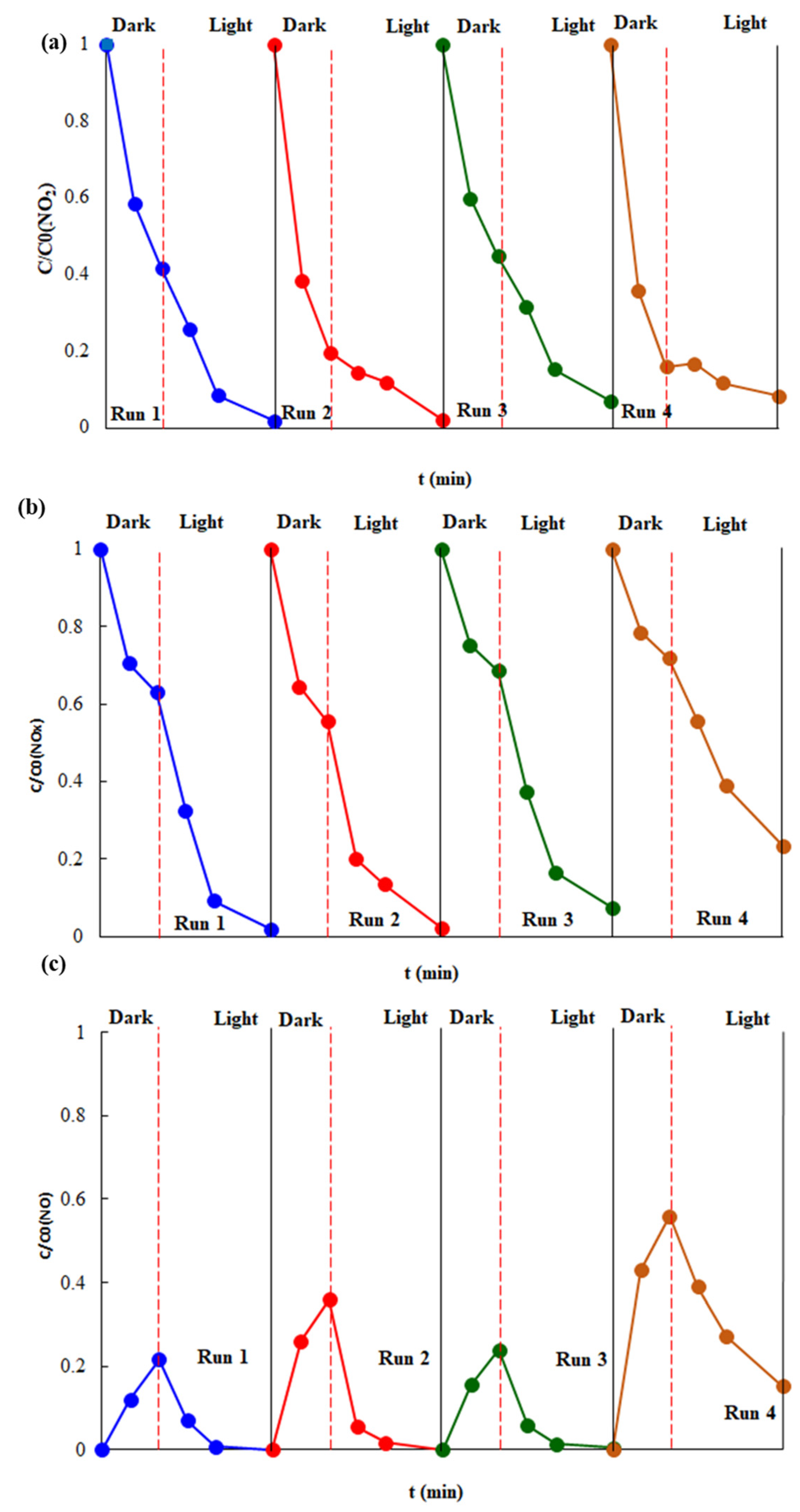

3.3. Reusability Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Air Pollution. Available online: https://www.who.int/westernpacific/health-topics/air-pollution (accessed on 20 November 2022).

- Shan, W.; Yu, Y.; Zhang, Y.; He, G.; Peng, Y.; Li, J.; He, H. Theory and practice of metal oxide catalyst design for the selective catalytic reduction of NOx with NH3. Catal. Today 2021, 376, 292–301. [Google Scholar] [CrossRef]

- Campisi, S.; Galloni, M.G.; Marchetti, S.G.; Gervasini, A. Functionalized Iron Hydroxyapatite as Eco-friendly Catalyst for NH3-SCR Reaction: Activity and Role of Iron Speciation on the Surface. ChemCatChem 2020, 12, 1676–1690. [Google Scholar] [CrossRef]

- Muzio, L.J.; Quartucy, G.C. Implementing NOx control: Research to application. Prog. Energy Combust. Sci. 1997, 23, 233–266. [Google Scholar] [CrossRef]

- Roy, S.; Hegde, M.S.; Madras, G. Catalysis for NOx abatement. Appl. Energy 2009, 86, 2283–2297. [Google Scholar] [CrossRef]

- Ângelo, J.; Andrade, L.; Madeira, L.M.; Mendes, A. An overview of photocatalysis phenomena applied to NOx abatement. J. Environ. Manag. 2013, 129, 522–539. [Google Scholar] [CrossRef]

- Elsener, M.; Nuguid, R.J.G.; Krocher, O.; Ferri, D. HCN production from formaldehyde during the selective catalytic reduction of NOx with NH3 over V2O5/WO3-TiO2. Appl. Catal. B Environ. 2021, 281, 119462. [Google Scholar] [CrossRef]

- Galloni, M.G.; Campisi, S.; Marchetti, S.G.; Gervasini, A. Environmental Reactions of Air-Quality Protection on Eco-Friendly Iron-Based Catalysts. Catalysts 2020, 10, 1415. [Google Scholar] [CrossRef]

- Campisi, S.; Galloni, M.G.; Bossola, F.; Gervasini, A. Comparative performance of copper and iron functionalized hydroxyapatite catalysts in NH3-SCR. Catal. Commun. 2019, 123, 79–85. [Google Scholar] [CrossRef]

- Skalska, K.; Miller, J.S.; Ledakowicz, S. Trends in NOx abatement: A review. Sci. Total Environ. 2010, 408, 3976–3989. [Google Scholar] [CrossRef]

- Mok, Y.S.; Lee, H. Removal of sulfur dioxide and nitrogen oxides by using ozone injection and absorption–reduction technique. Fuel Process. Technol. 2006, 87, 591–597. [Google Scholar] [CrossRef]

- Ruggeri, M.P.; Nova, I.; Tronconi, E. Experimental and modeling study of the impact of interphase and intraphase diffusional limitations on the DeNOx efficiency of a V-based extruded catalyst for NH3–SCR of Diesel exhausts. Chem. Eng. J. 2012, 207–208, 57–65. [Google Scholar] [CrossRef]

- Nitrogen Oxides (NOx) Control Regulations. Available online: https://www3.epa.gov/region1/airquality/nox.html (accessed on 30 November 2022).

- Fiorenza, R.; Spitaleri, L.; Perricelli, F.; Nicotra, G.; Fragalà, M.E.; Sciré, S.; Gulino, A. Efficient photocatalytic oxidation of VOCs using ZnO@Au nanoparticles. J. Photochem. Photobiol. A Chem. 2023, 434, 114232. [Google Scholar] [CrossRef]

- Nguyen, V.-H.; Nguyen, B.-S.; Huang, C.-W.; Le, T.-T.; Nguyen, C.C.; Le, T.T.N.; Heo, D.; Ly, Q.V.; Trinh, Q.T.; Shokouhimehr, M.; et al. Photocatalytic NOx abatement: Recent advances and emerging trends in the development of photocatalysts. J. Clean. Prod. 2020, 270, 121912. [Google Scholar] [CrossRef]

- Galloni, M.G.; Cerrato, G.; Giordana, A.; Falletta, E.; Bianchi, C.L. Sustainable Solar Light Photodegradation of Diclofenac by Nano- and Micro-Sized SrTiO3. Catalysts 2022, 12, 804. [Google Scholar] [CrossRef]

- Galloni, M.G.; Ferrara, E.; Falletta, E.; Bianchi, C.L. Olive Mill Wastewater Remediation: From Conventional Approaches to Photocatalytic Processes by Easily Recoverable Materials. Catalysts 2022, 12, 923. [Google Scholar] [CrossRef]

- Lasek, J.; Yu, Y.H.; Wu, C.S. Removal of NOx by photocatalytic processes. Photobiol. C Photochem. Rev. 2013, 14, 29–52. [Google Scholar] [CrossRef]

- Nakata, K.; Fujishima, A. TiO2 photocatalysis: Design and applications. J. Photochem. Photobiol. C Photochem. Rev. 2012, 13, 169–189. [Google Scholar] [CrossRef]

- Scirè, S.; Fiorenza, R.; Bellardita, M.; Palmisano, L. 21—Catalytic applications of TiO2. Titan. Dioxide (TiO₂) Its Appl. 2021, 637, 679. [Google Scholar]

- Rimoldi, L.; Meroni, D.; Cappelletti, G.; Ardizzone, S. Green and low cost tetracycline degradation processes by nanometric and immobilized TiO2 systems. Catal. Today 2017, 281, 38–44. [Google Scholar] [CrossRef]

- Ge, M.; Caia, J.; Iocozzi, J.; Cao, C.; Huang, J.; Zhang, X.; Shen, J.; Wang, S.; Zhang, S.; Zhang, K.-Q. A review of TiO2 nanostructured catalysts for sustainable H2 generation. Int. J. Hydrogen Energy 2017, 42, 8418–8449. [Google Scholar] [CrossRef]

- Linsebigler, A.L.; Lu, G.; Yates, J.T. Photocatalysis on TiO2 Surfaces: Principles, Mechanisms, and Selected Results. Chem. Rev. 1995, 95, 735. [Google Scholar] [CrossRef]

- Bianchi, C.L.; Pirola, C.; Selli, E.; Biella, S. Photocatalytic NOx abatement: The role of the material supporting the TiO2 active layer. J. Hazard. Mater. 2012, 211–212, 203. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, C.L.; Cerrato, G.; Pirola, C.; Galli, F.; Capucci, V. Photocatalytic porcelain grés large slabs digitally coated with AgNPs-TiO2. Environ. Sci. Pollut. Res. 2019, 26, 36117. [Google Scholar] [CrossRef] [PubMed]

- Schieppati, D.; Galli, F.; Peyot, M.L.; Yargeau, V.; Bianchi, C.L.; Boffito, D.C. An ultrasound-assisted photocatalytic treatment to remove an herbicidal pollutant from wastewaters. Ultrason. Sonochem. 2019, 54, 302. [Google Scholar] [CrossRef]

- Yang, L.; Hakki, A.; Zheng, L.; Roderick Jones, M.; Wang, F.; Macphee, D.E. Photocatalytic concrete for NOx abatement: Supported TiO2 efficiencies and impacts. Cem. Concr. Res. 2019, 119, 57–64. [Google Scholar] [CrossRef]

- Ao, C.H.; Lee, S.C.; Zou, S.C.; Mak, C.L. Inhibition effect of SO2 on NOx and VOCs during the photodegradation of synchronous indoor air pollutants at parts per billion (ppb) level by TiO2. Appl. Catal. B Environ. 2004, 49, 187–193. [Google Scholar] [CrossRef]

- Li, L.C.; Tseng, Y.H.; Lin, H. Efficient Photodecomposition of NOx on Carbon Modified Ag/TiO2 Nanocomposites. Top. Catal. 2020, 63, 1251–1260. [Google Scholar] [CrossRef]

- Luna, M.; Gatica, J.M.; Vidal, H.; Mosquera, M.J. One-pot synthesis of Au/N-TiO2 photocatalysts for environmental applications: Enhancement of dyes and NOx photodegradation. Powder Technol. 2019, 355, 793–807. [Google Scholar] [CrossRef]

- Balayeva, N.O.; Mamiyev, Z. Chapter 5—Integrated processes involving adsorption, photolysis, and photocatalysis. In Hybrid and Combined Processes for Air Pollution Control; Elsevier: Amsterdam, The Netherlands, 2022; pp. 117–153. [Google Scholar]

- Cerrato, G.; Galli, F.; Boffito, D.C.; Operti, L.; Bianchi, C.L. Correlation preparation parameters/activity for microTiO2 decorated with SilverNPs for NOx photodegradation under LED light. Appl. Catal. B Environ. 2019, 253, 218–225. [Google Scholar] [CrossRef]

- Giannakopoulou, T.; Todorova, N.; Romanos, G.; Vaimakis, T.; Dillert, R.; Bahnemann, D.; Trapalis, C. Composite hydroxyapatite/TiO2 materials for photocatalytic oxidation of NOx. Mater. Sci. Eng. B 2012, 177, 1046–1052. [Google Scholar] [CrossRef]

- Russel, H.S.; Frederickson, L.B.; Hertel, O.; Ellermann, T.; Jensen, S.S. A Review of Photocatalytic Materials for Urban NOx Remediation. Catalysts 2021, 11, 675. [Google Scholar] [CrossRef]

- Tundo, P.; Anastas, P.; Black, D.S.; Breen, J.; Collins, T.; Memoli, S.; Miyamoto, J.; Polyakoff, M.; Tumas, W. Special Topic Issue on Green Chemistry. Pure Appl. Chem. 2000, 72, 1207–1228. [Google Scholar] [CrossRef]

- Qi, Y.; Xiang, B.; Zhang, J. Effect of titanium dioxide (TiO2) with different crystal forms and surface modifications on cooling property and surface wettability of cool roofing materials. Sol. Energy Mater. Sol. Cells 2017, 172, 34–43. [Google Scholar] [CrossRef]

- Xiang, W.; Ming, C. Implementing extended producer responsibility: Vehicle remanufacturing in China. J. Clean. Prod. 2011, 19, 680–686. [Google Scholar] [CrossRef]

- Kim, Y.K.; Hong, S.J.; Kim, H.B.; Lee, S.W. Evaluation of in-situ NOx removal efficiency of photocatalytic concrete in expressways. KSCE J. Civ. Eng. 2018, 22, 2274–2280. [Google Scholar] [CrossRef]

- Li, L.; Qian, C.X. Study on the removal of nitrogen oxides from automobile emissions by photocatalytic functional concrete road of Nanjing Yangtze River Third Bridge. J. Henan Univ. Sci. Technol. (Nat. Sci. Ed.) 2009, 30, 49–52. [Google Scholar]

- Zivkovic, I.; Klaser, T.; Skoko, Z.; Rokovic, M.K.; Hrnjak-Murgic, Z.; Zic, M. The Impact of In Situ Polymerization Conditions on the Structures and Properties of PANI/ZnO-Based Multiphase Composite Photocatalysts. Catalysts 2020, 10, 400. [Google Scholar]

- Gilja, V.; Novakovic, K.; Travas-Sejdic, J.; Hrnjak-Murgic, Z.; Rokovic, M.K.; Zic, M. Stability and Synergistic Effect of Polyaniline/TiO2 Photocatalysts in Degradation of Azo Dye in Wastewater. Nanomaterials 2017, 7, 412. [Google Scholar] [CrossRef] [PubMed]

- Mandic, Z.; Rokovic, M.K.; Pokupcic, T. Polyaniline as cathodic material for electrochemical energy sources: The role of morphology. Electrochim. Acta 2009, 54, 2941–2950. [Google Scholar] [CrossRef]

- Chowdhury, A.N.; Jesmeen, S.R.; Hossain, M.M. Removal of dyes from water by conducting polymeric adsorbent. Polym. Adv. Technol. 2004, 15, 633–638. [Google Scholar] [CrossRef]

- Galloni, M.G.; Bortolotto, V.; Falletta, E.; Bianchi, C.L. pH-Driven Selective Adsorption of Multi-Dyes Solutions by Loofah Sponge and Polyaniline-Modified Loofah Sponge. Polymers 2022, 14, 4897. [Google Scholar] [CrossRef]

- Sall, M.L.; Diaw, A.K.D.; Gningue-Sall, D.; Aaron, S.E.; Aaron, J.J. Toxic heavy metals: Impact on the environment and human health, and treatment with conducting organic polymers, a review. Environ. Sci. Pollut. Res. 2020, 27, 29927–29942. [Google Scholar] [CrossRef]

- Liu, Z.W.; Cao, C.X.; Han, B.H. A cationic porous organic polymer for high-capacity, fast, and selective capture of anionic pollutants. J. Hazard. Mater. 2019, 367, 348–355. [Google Scholar] [CrossRef]

- Zhang, T.; Xing, G.; Chen, W.; Chen, L. Porous organic polymers: A promising platform for efficient photocatalysis. Mater. Chem. Front. 2020, 4, 332–353. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhu, L.; Qi, L.; Yan, L.; Xue, Y.; Wang, D.; Chen, J.F.; Dai, L. Two-Dimensional Fully Conjugated Polymeric Photosensitizers for Advanced Photodynamic Therapy. Chem. Mater. 2016, 28, 8651–8658. [Google Scholar] [CrossRef]

- Lan, M.; Zhao, S.; Liu, W.; Lee, C.S.; Zhang, W.; Wang, P. Photosensitizers for Photodynamic Therapy. Adv. Healthc. Mater. 2019, 8, 1900132. [Google Scholar] [CrossRef]

- Hua, Y.; Crivello, J.V. Development of Polymeric Photosensitizers for Photoinitiated Cationic Polymerization. Macromolecules 2001, 34, 2488–2494. [Google Scholar] [CrossRef]

- Della Pina, C.; De Gregorio, M.A.; Clerici, L.; Dellavedova, P.; Falletta, E. Polyaniline (PANI): An innovative support for sampling and removal of VOCs in air matrices. J. Hazard. Mater. 2018, 344, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, H.; Saraji, M. New polymeric sorbent for the solid-phase extraction of chlorophenols from water samples followed by gas chromatography–electron-capture detection. J. Chromatogr. A 2001, 910, 87–93. [Google Scholar] [CrossRef]

- Conde-Díaz, A.; Rodríguez-Ramos, R.; Socas-Rodríguez, B.; Salazar-Carballo, P.Á.; Rodríguez-Delgado, M.Á. Application of polyaniline-based magnetic-dispersive-solid-phase microextraction combined with liquid chromatography tandem mass spectrometry for the evaluation of plastic migrants in food matrices. J. Chromatogr. A 2022, 1670, 462988. [Google Scholar] [CrossRef] [PubMed]

- Dziedzic, D.; Nawała, J.; Gordon, D.; Dawidziuk, B.; Popiel, S. Nanostructured polyaniline SPME fiber coating for chemical warfare agents analysis. Anal. Chim. Acta 2022, 1202, 339649. [Google Scholar] [CrossRef]

- Della Pina, C.; De Gregorio, M.A.; Dellavedova, P.; Falletta, E. Polyanilines as New Sorbents for Hydrocarbons Removal from Aqueous Solutions. Materials 2020, 13, 2161. [Google Scholar] [CrossRef] [PubMed]

- Cionti, C.; Della Pina, C.; Meroni, D.; Falletta, E.; Ardizzone, S. Photocatalytic and Oxidative Synthetic Pathways for Highly Efficient PANI-TiO2 Nanocomposites as Organic and Inorganic Pollutant Sorbents. Nanomaterials 2020, 10, 441. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bianchi, C.L.; Djellabi, R.; Della Pina, C.; Falletta, E. Doped-polyaniline based sorbents for the simultaneous removal of heavy metals and dyes from water: Unravelling the role of synthesis method and doping agent. Chemosphere 2022, 286, 131941. [Google Scholar] [CrossRef] [PubMed]

- Lyu, W.; Yu, M.; Li, J.; Feng, J.; Yan, W. Adsorption of anionic acid red G dye on polyaniline nanofibers synthesized by FeCl3 oxidant: Unravelling the role of synthetic conditions. Colloids Surf. A Physicochem. Eng. Asp. 2022, 647, 129203. [Google Scholar] [CrossRef]

- Pandey, S. Highly sensitive and selective chemiresistor gas/vapor sensors based on polyaniline nanocomposite: A comprehensive review. J. Sci. Adv. Mater. Devices 2016, 1, 431–453. [Google Scholar] [CrossRef]

- MacDiarmid, A.G. “Synthetic Metals”: A Novel Role for Organic Polymers (Nobel Lecture). Angew. Chem. Int. Ed. 2001, 40, 2581–2590. [Google Scholar] [CrossRef]

- Liu, T.; Burger, C.; Chu, B. Nanofabrication in polymer matrices. Prog. Polym. Sci. 2003, 28, 5–26. [Google Scholar] [CrossRef]

- Adhikari, B.; Majumdar, S. Polymers in sensor applications. Prog. Polym. Sci. 2004, 29, 699–766. [Google Scholar] [CrossRef]

- Srivastava, S.; Sharma, S.S.; Agrawal, S.; Kumar, S.; Singh, M.; Vijay, Y.K. Study of chemiresistor type CNT doped polyaniline gas sensor. Synth. Met. 2010, 160, 529–534. [Google Scholar] [CrossRef]

- Lobotka, P.; Kunzo, P.; Kovacova, E.; Vavra, I.; Krizanova, Z.; Smatko, V.; Stejskal, J.; Konyushenko, E.N.; Omastova, M.; Spitalsky, Z.; et al. Thin polyaniline and polyaniline/carbon nanocomposite films for gas sensing. Thin Solid Film. 2011, 519, 4123–4127. [Google Scholar] [CrossRef]

- Yoo, K.P.; Kwon, K.H.; Min, N.K.; Lee, M.J.; Lee, C.J. Effects of O2 plasma treat-ment on NH3 sensing characteristics of multiwall carbon nanotube/polyaniline composite films. Sens. Actuators B 2009, 143, 333–340. [Google Scholar] [CrossRef]

- Geng, L.N.; Zhao, Y.Q.; Huang, X.L.; Wang, S.R.; Zhang, S.M.; Wu, S.H. Characterization and gas sensitivity study of polyaniline/SnO2 hybrid material prepared by hydrothermal route. Sens. Actuators B 2007, 120, 568–572. [Google Scholar] [CrossRef]

- Tai, H.L.; Jiang, Y.D.; Xie, G.Z.; Yu, J.S.; Chen, X. Fabrication and gas sensitivity of polyaniline–titanium dioxide nanocomposite thin film. Sens. Actuators B 2007, 125, 644–650. [Google Scholar] [CrossRef]

- Yun, J.; Jeon, S.; Kim, H. Improvement of NO gas sensing properties of polyaniline/MWCNT composite by photocatalytic effect of TiO2. J. Nanomater. 2013, 2013, 3. [Google Scholar] [CrossRef]

- Xu, H.; Chen, X.; Zhang, J.; Wang, J.; Cao, B.; Cui, D. NO2 gas sensing with SnO2–ZnO/PANI composite thick film fabricated from porous nanosolid. Sens. Actuators B Chem. 2013, 176, 166–173. [Google Scholar] [CrossRef]

- Janata, J.; Josowicz, M. Conducting polymers in electronic chemical sensors. Nat. Mater. 2003, 2, 19–24. [Google Scholar] [CrossRef]

- Cionti, C.; Della Pina, C.; Meroni, D.; Falletta, E. Triply green polyaniline: UV irradiation-induced synthesis of a highly porous PANI/TiO2 composite and its application in dye removal. Chem. Commun. 2018, 54, 10702–10705. [Google Scholar] [CrossRef]

- Chiang, J.C.; MacDiarmid, A.G. ‘Polyaniline’: Protonic acid doping of the emeraldine form to the metallic regime. Synth. Met. 1986, 13, 193–205. [Google Scholar] [CrossRef]

- Chen, Z.; Della Pina, C.; Falletta, E.; Rossi, M. A green route to conducting polyaniline by copper catalysis. J. Catal. 2009, 267, 93–96. [Google Scholar] [CrossRef]

- Falletta, E.; Costa, P.; Della Pina, C.; Lanceros-Mendez, S. Development of high sensitive polyaniline based piezoresistive films by conventional and green chemistry approaches. Sens. Actuators A: Phys. 2014, 220, 13–21. [Google Scholar] [CrossRef]

- Mingxi, L.; Yizhu, H.; Guoxiong, S. Microstructure and wear resistance of laser clad cobalt-based alloy multi-layer coatings. Appl. Surf. Sci. 2004, 230, 201–206. [Google Scholar] [CrossRef]

- Pouget, J.P.; Jozefowicz, M.E.; Epstein, A.J.; Tang, X.; MacDiarmid, A.G. X-ray structure of polyaniline. Macromolecules 1991, 24, 779–789. [Google Scholar] [CrossRef]

- De Albuquerque, J.E.; Mattoso, L.H.C.; Faria, R.M.; Masters, J.G.; MacDiarmid, A.G. Study of the interconversion of polyaniline oxidation states by optical absorption spectroscopy. Synth. Met. 2004, 146, 1–10. [Google Scholar] [CrossRef]

- Elizalde-Torres, J.; Hub, H.; Guadarrama-Santana, A.; García-Valenzuela, A.; Saniger, J. Thermally assisted NO2 and NH3 gas desorption process in a polyaniline thin film based optochemical sensor. Rev. Mex. FíSica 2008, 54, 358–363. [Google Scholar]

- Recommendation from the Scientific Committee on Occupational Exposure Limits for Nitrogen Monoxide, SCOEL/SUM/89, June 2014. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwjn6PXM5_X8AhXHOnAKHekjACsQFnoECA4QAQ&url=https%3A%2F%2Fec.europa.eu%2Fsocial%2FBlobServlet%3FdocId%3D12432%26langId%3Den&usg=AOvVaw0y20qAEUGwy3UlBw_lZgAz (accessed on 15 November 2022).

- Mercer, R.R. Morphometric Analysis of Alveolar Responses of F344 Rats to Sub-Chronic Inhalation of Nitric Oxide; Health Effects Institute Research Report No. 88; Health Effects Institute: Cambridge, MA, USA, 1999. [Google Scholar]

- Falletta, E.; Bruni, A.; Sartirana, M.; Boffito, D.C.; Cerrato, G.; Giordana, A.; Djellabi, R.; Khatibi, E.S.; Bianchi, C.L. Solar Light Photoactive Floating Polyaniline/TiO2 Composites for Water Remediation. Nanomaterials 2021, 11, 3071. [Google Scholar] [CrossRef]

- Zouzelka, R.; Rathousky, J. Photocatalytic abatement of NOx pollutants in the air using commercial functional coating with porous morphology. Appl. Catal. B Environ. 2017, 217, 466–476. [Google Scholar] [CrossRef]

- Ahmad, R.; Mondal, P.K. Adsorption and Photodegradation of Methylene Blue by Using PANI/TiO2 Nanocomposite. J. Dispers. Sci. Technol. 2012, 33, 380–386. [Google Scholar] [CrossRef]

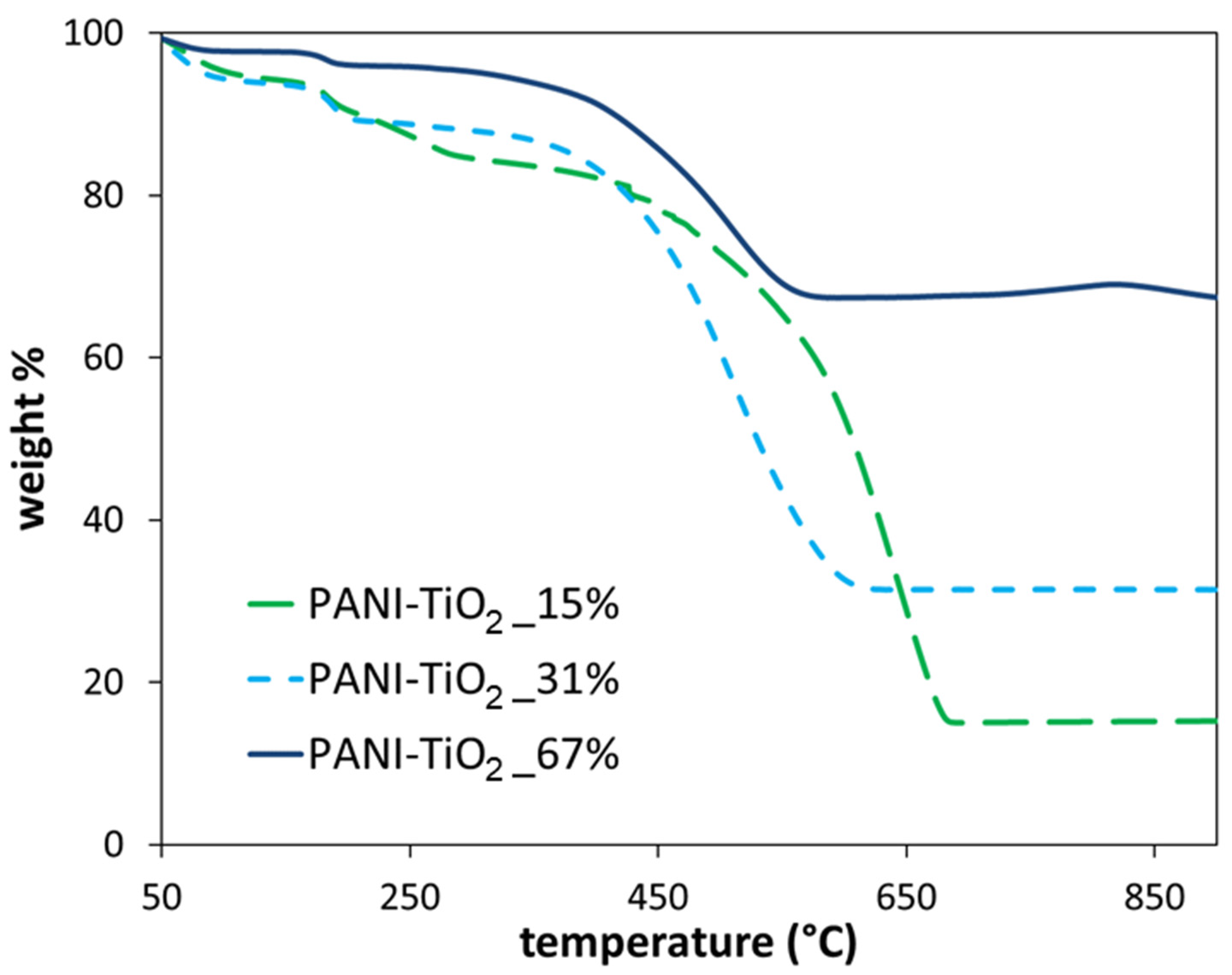

| Sample | Sample Composition (TGA) | SBET (m2/g) | |||

|---|---|---|---|---|---|

| % PANI | % TiO2 | % H2O | % HCl | ||

| PANI-TiO2_15% | 70 | 15 | 5 | 10 | 6 |

| PANI-TiO2_31% | 58 | 31 | 6 | 5 | 48 |

| PANI-TiO2_67% | 29 | 67 | 3 | 1 | 47 |

| PANI_ref1 | 82 | - | 8 | 10 | 20 |

| PANI_ref2 | 85 | - | 5 | 10 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meroni, D.; Galloni, M.G.; Cionti, C.; Cerrato, G.; Falletta, E.; Bianchi, C.L. Efficient Day-and-Night NO2 Abatement by Polyaniline/TiO2 Nanocomposites. Materials 2023, 16, 1304. https://doi.org/10.3390/ma16031304

Meroni D, Galloni MG, Cionti C, Cerrato G, Falletta E, Bianchi CL. Efficient Day-and-Night NO2 Abatement by Polyaniline/TiO2 Nanocomposites. Materials. 2023; 16(3):1304. https://doi.org/10.3390/ma16031304

Chicago/Turabian StyleMeroni, Daniela, Melissa G. Galloni, Carolina Cionti, Giuseppina Cerrato, Ermelinda Falletta, and Claudia L. Bianchi. 2023. "Efficient Day-and-Night NO2 Abatement by Polyaniline/TiO2 Nanocomposites" Materials 16, no. 3: 1304. https://doi.org/10.3390/ma16031304