Thermal Regulation Performance of Shape-Stabilized-Phase-Change-Material-Based Prefabricated Wall for Green Grain Storage

Abstract

:1. Introduction

2. Materials and Method

2.1. Experimental Section

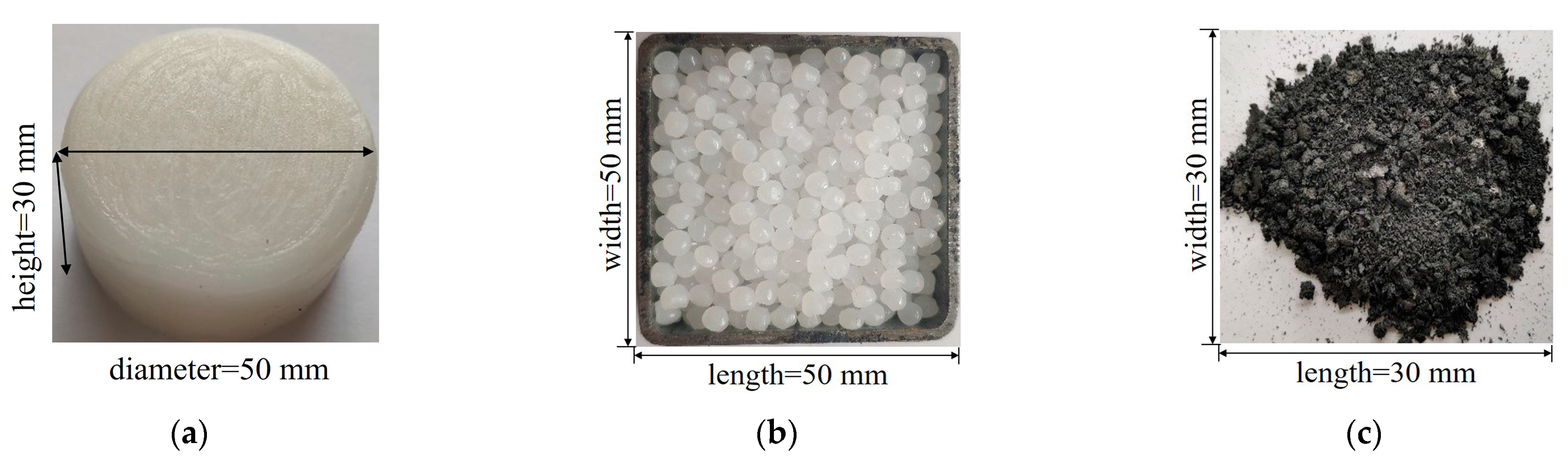

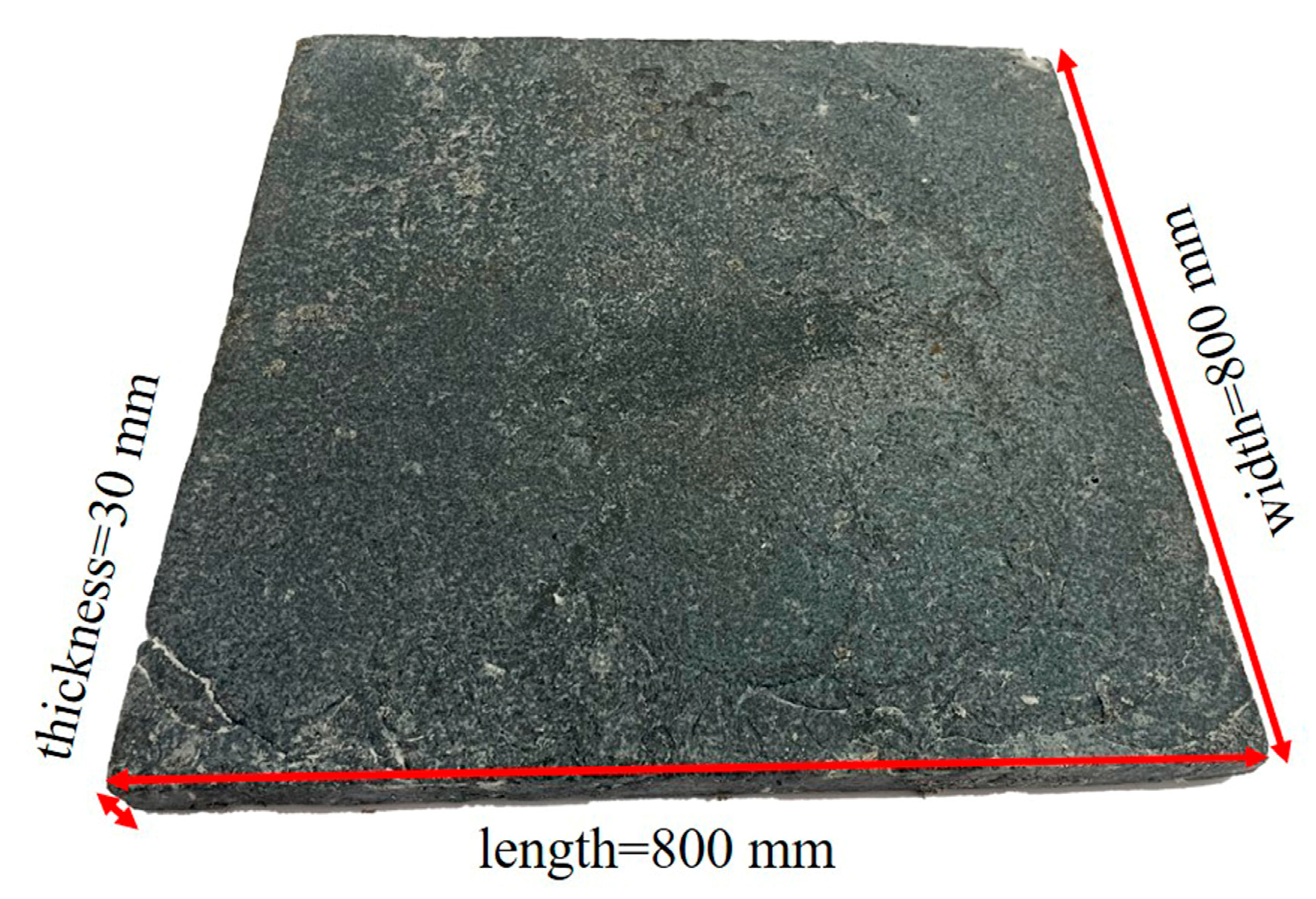

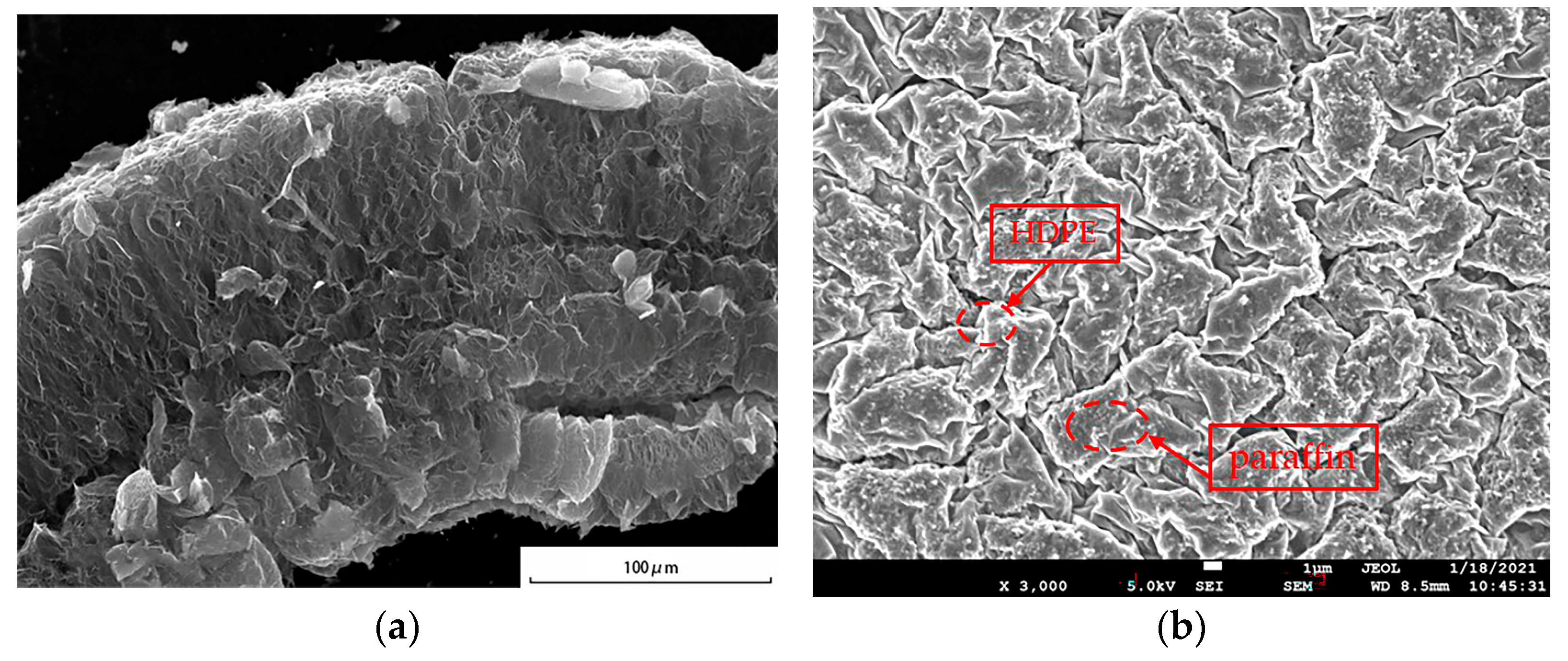

2.1.1. Preparation of SSPCM Plate

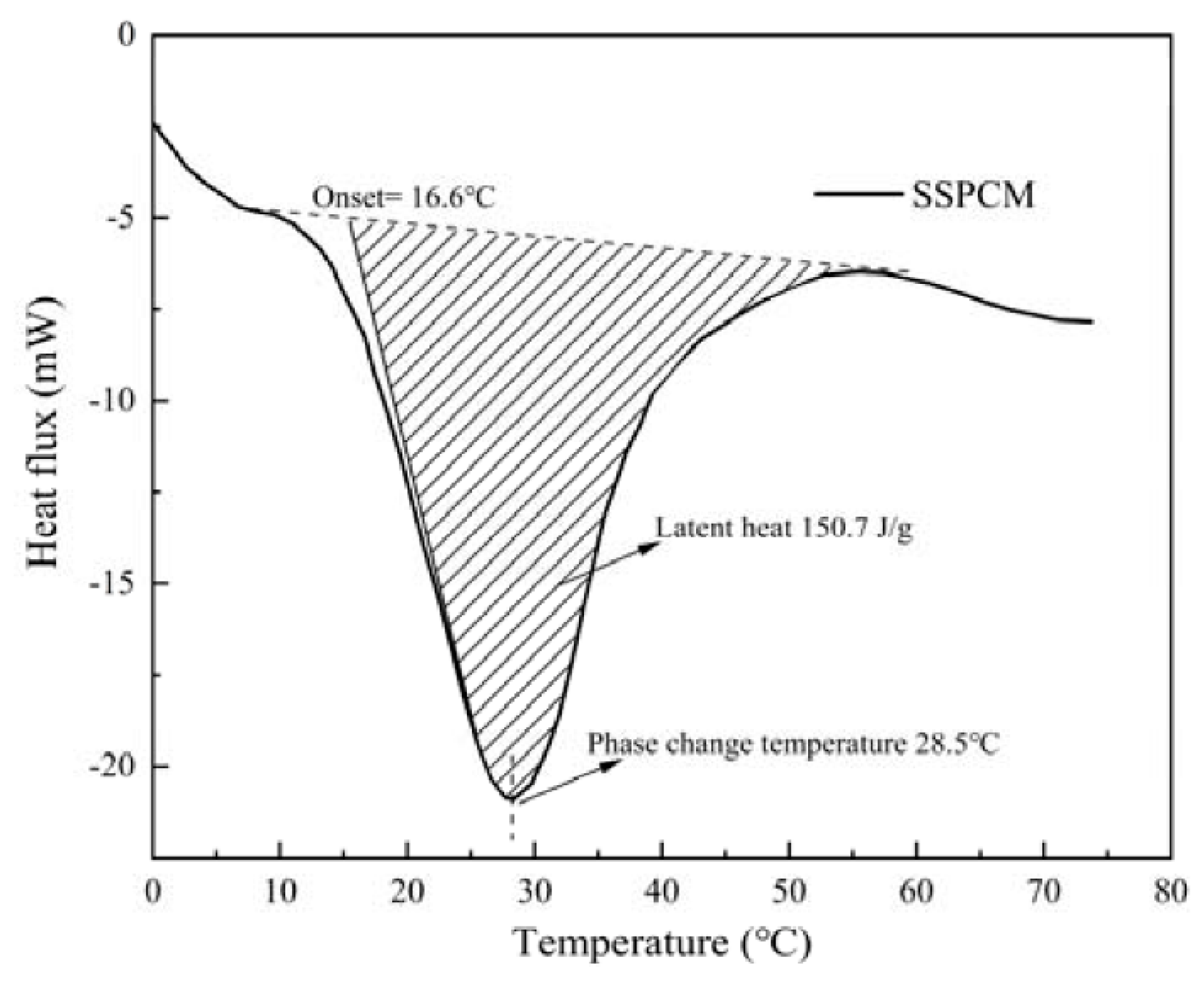

2.1.2. The Properties of SSPCM

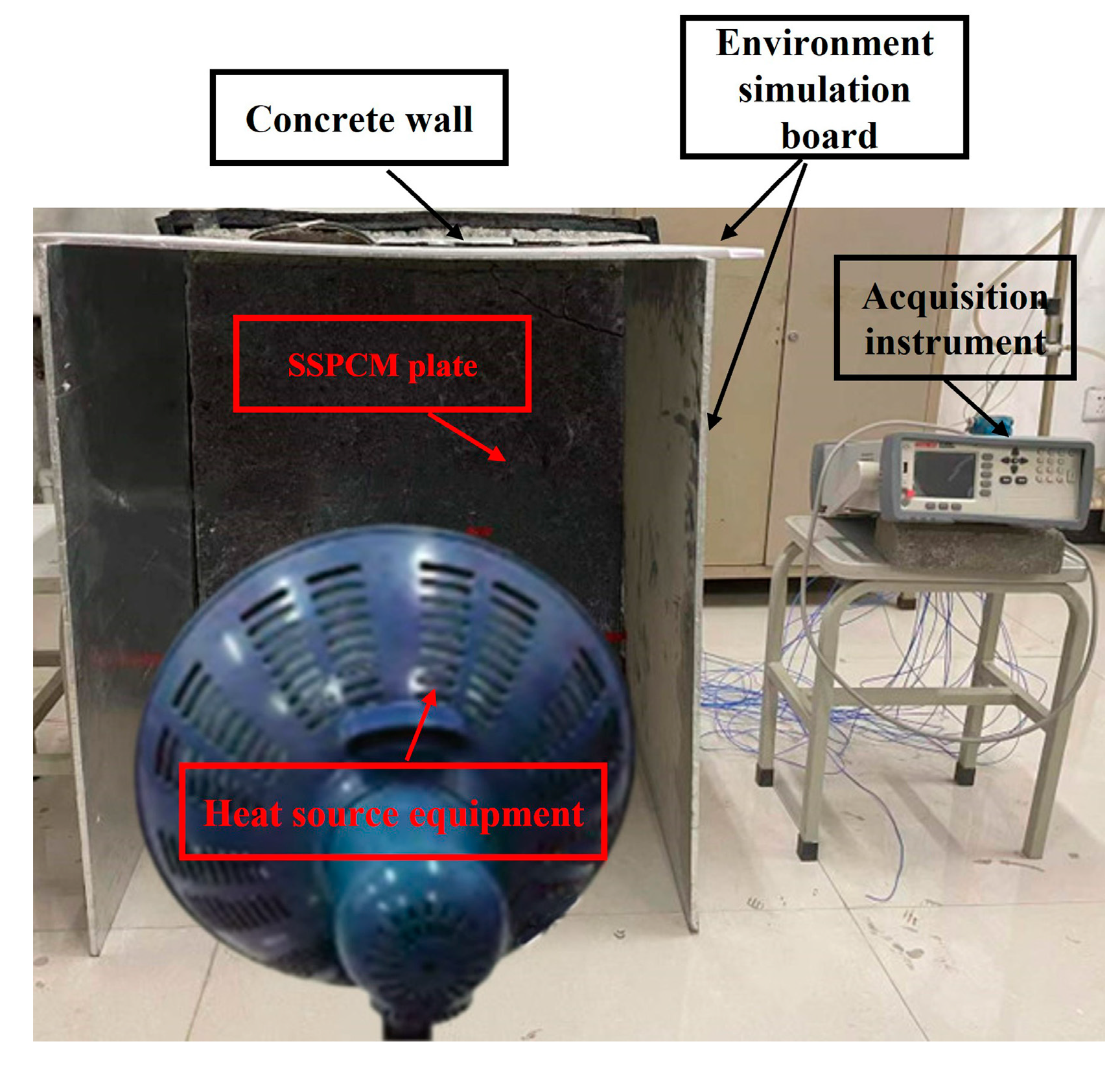

2.1.3. The Establishment of the Thermal Experimental Platform

2.2. Numerical Section

2.2.1. The Physical Model of the Granary Walls

2.2.2. Mathematical Model

- (a)

- All layers of the wall system were assumed to be homogenous and isotropic;

- (b)

- The heat transfer through the wall was one-dimensional;

- (c)

- The thermal expansion of the materials was not considered;

- (d)

- The thermophysical properties of the materials were constant, except for the change in the material properties of the SSPCM during the phase change interval;

- (e)

- For multi-layered wall systems, the contact resistance between different layers was negligible.

2.2.3. Thermal Performance Evaluation Indexes of the SSPCM Granary Wall

- (1)

- The temperature of the internal wall surface and the SSPCM layer

- (2)

- Heat flux on the internal surface of the wall

- (3)

- Energy saving rate

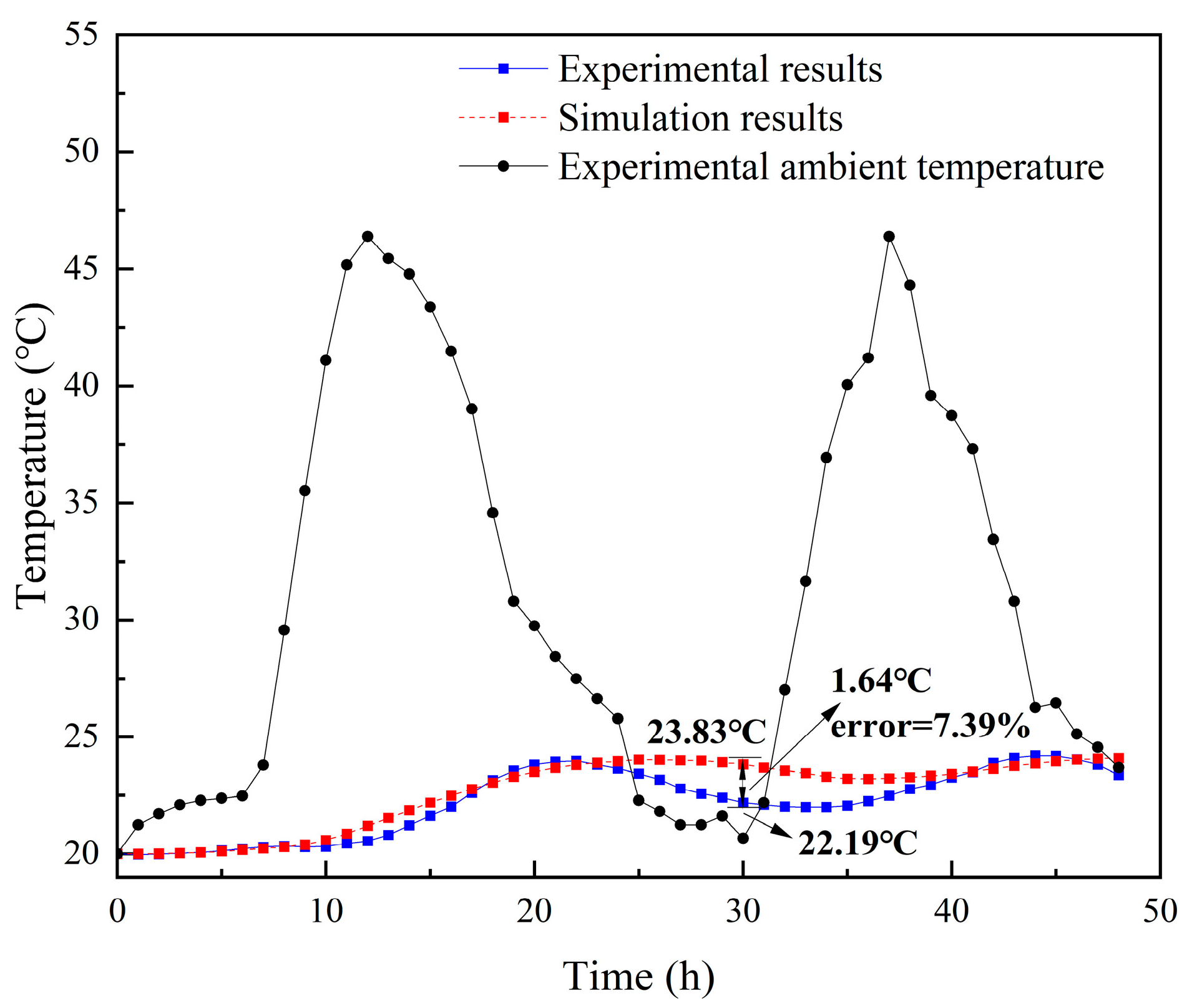

2.3. The Experiment Result and Model Validation

3. Results and Discussion

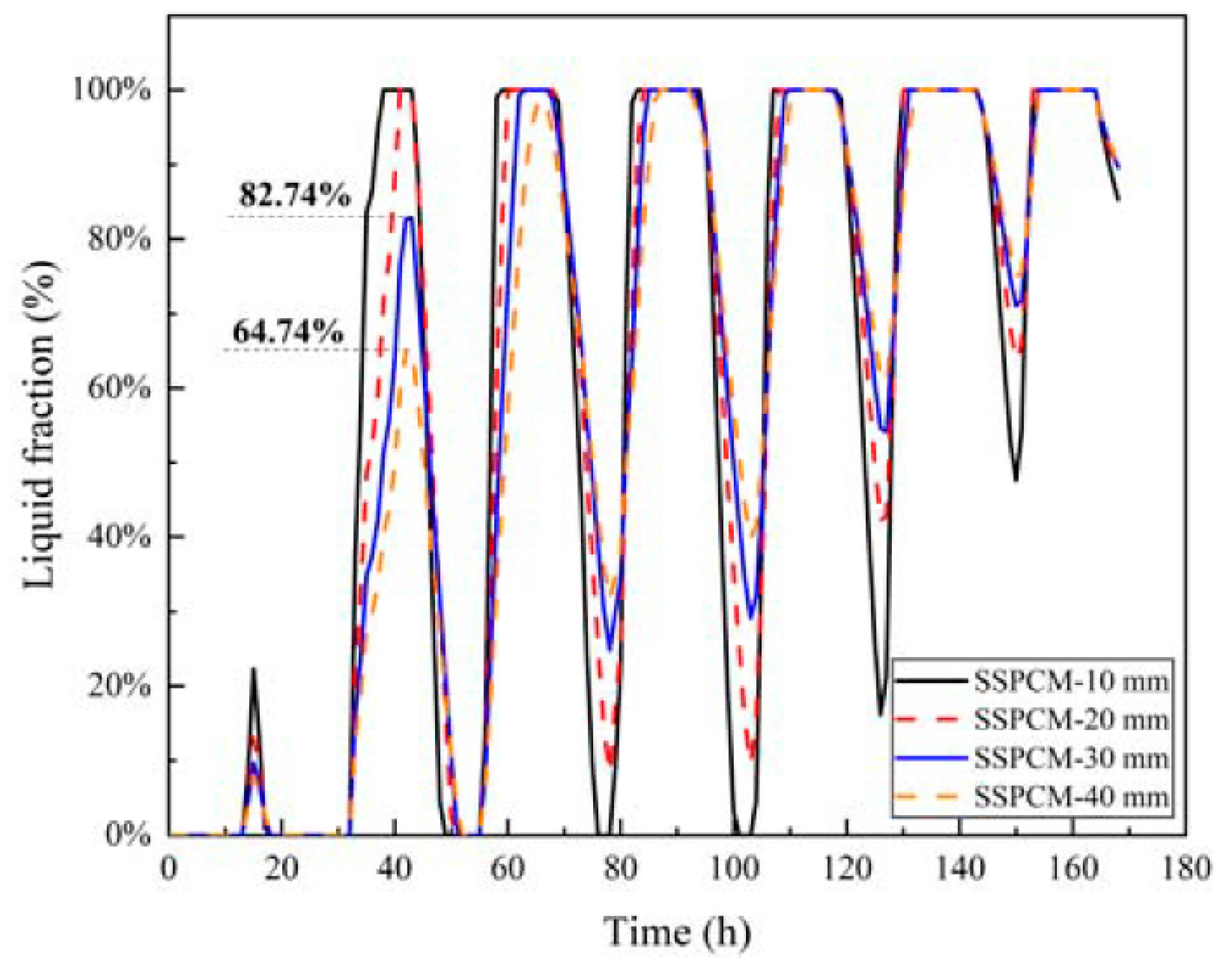

3.1. The Effect of the SSPCM Thickness on the Heat Transfer

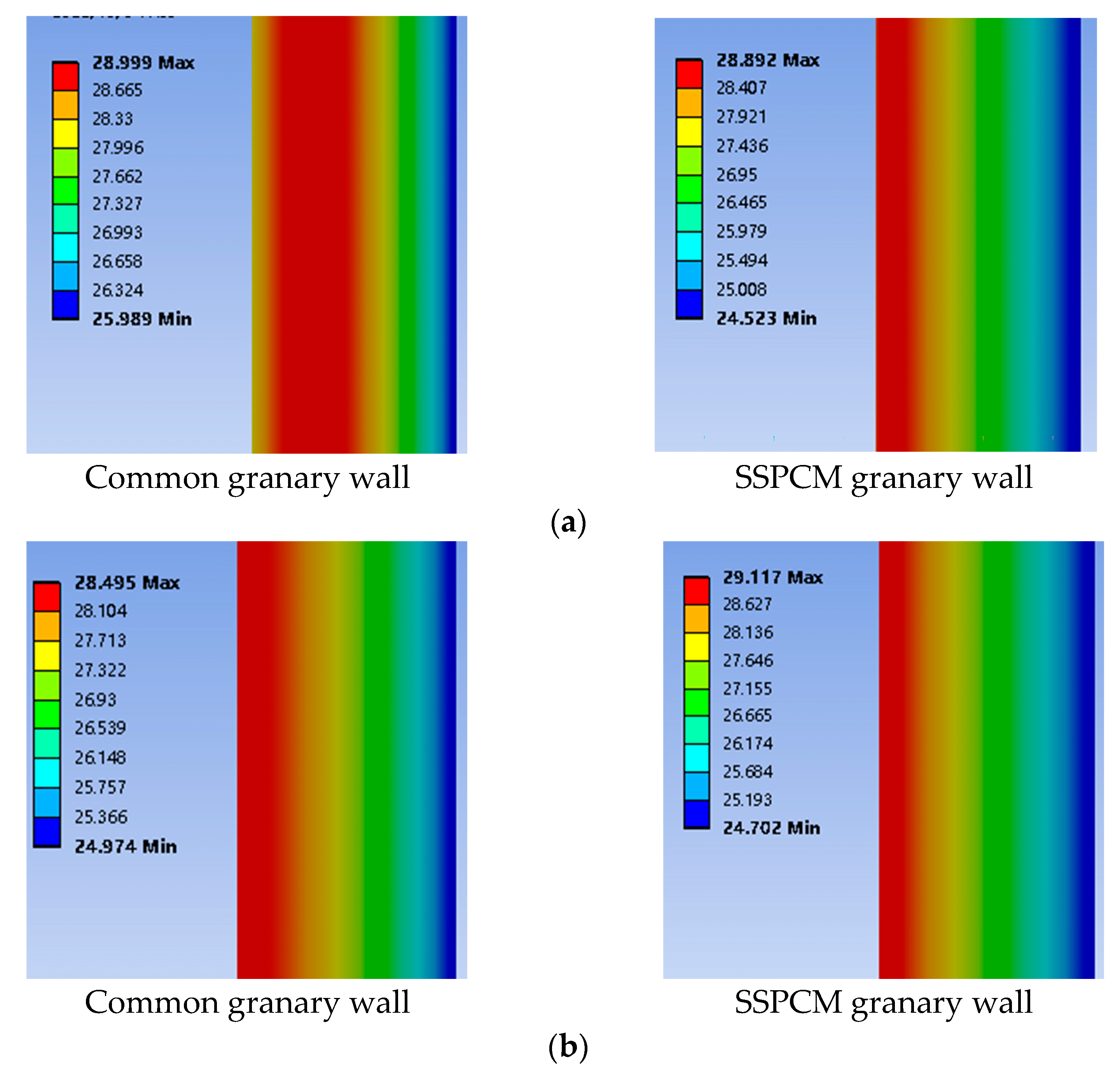

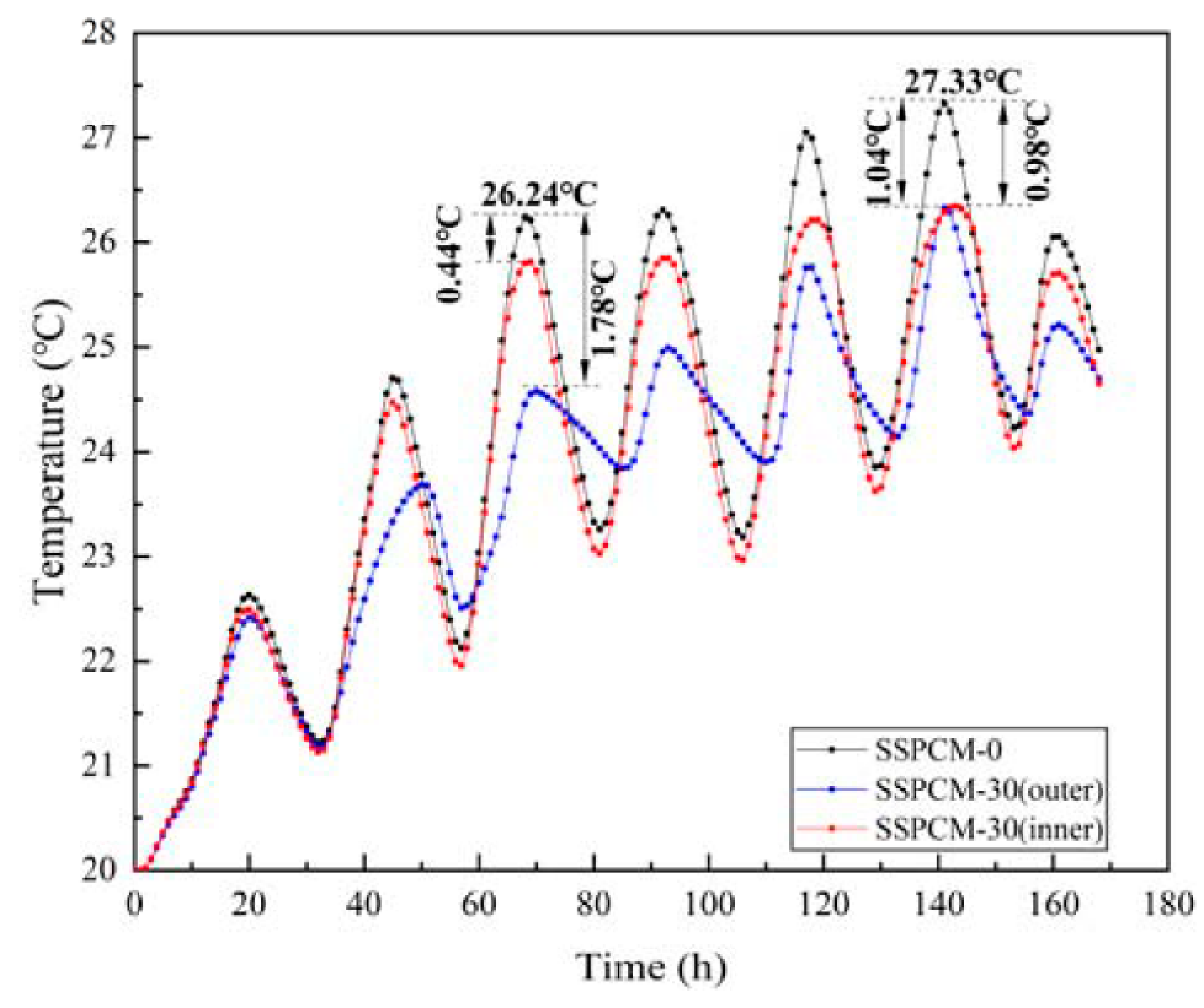

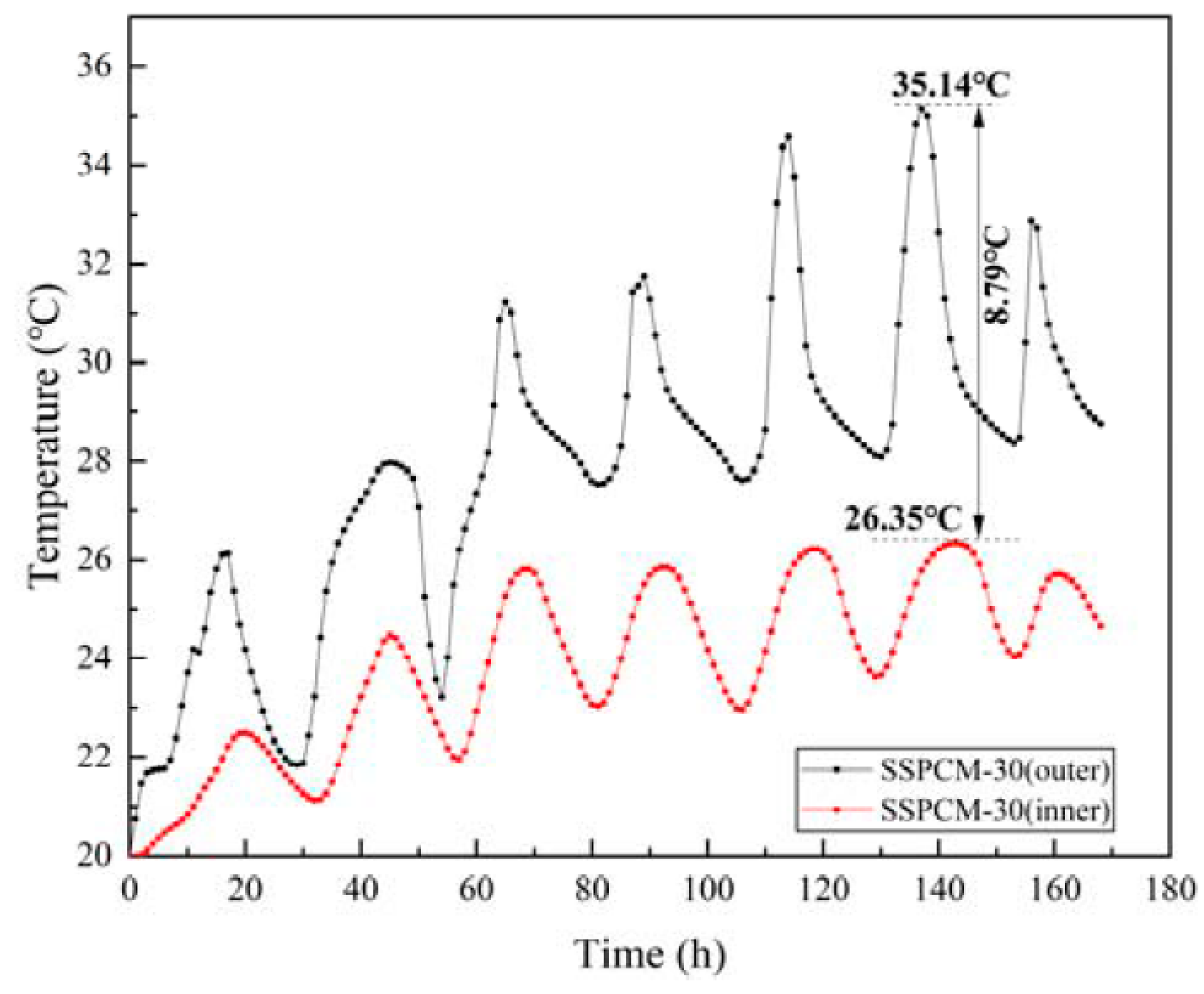

3.2. The Effects of the Prefabricated SSPCM Plate Location on the Heat Transfer

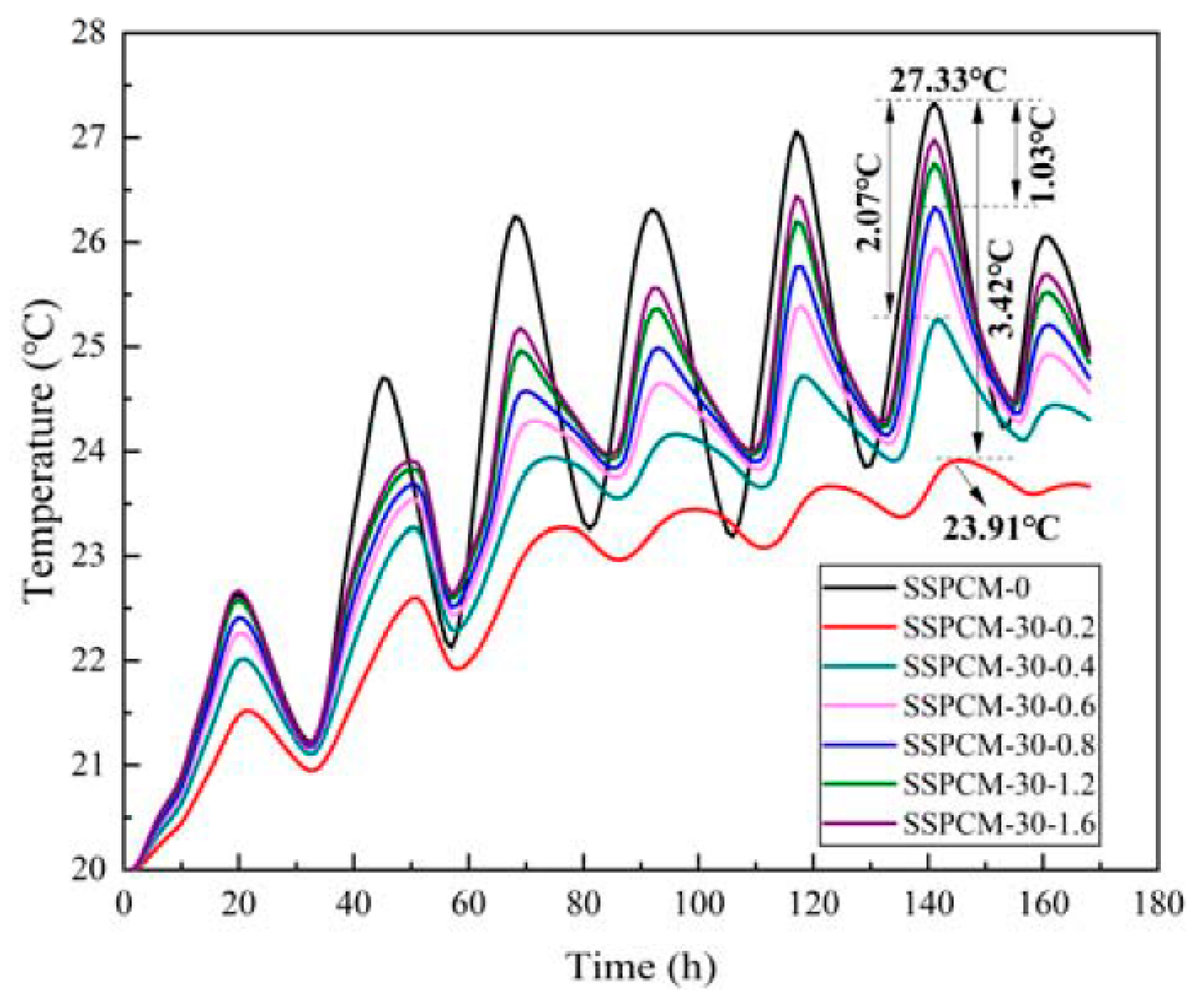

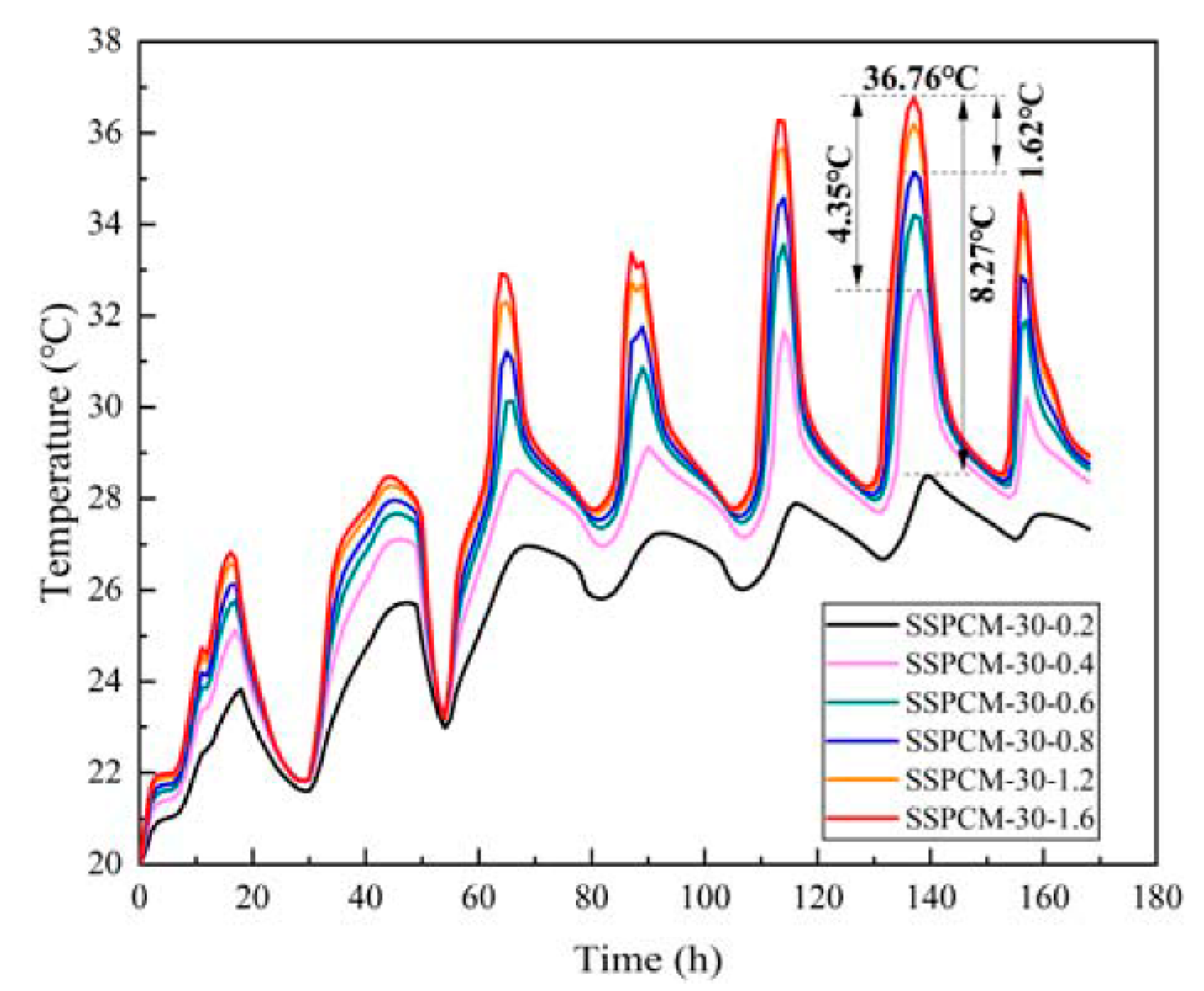

3.3. The Effects of the Thermal Conductivity

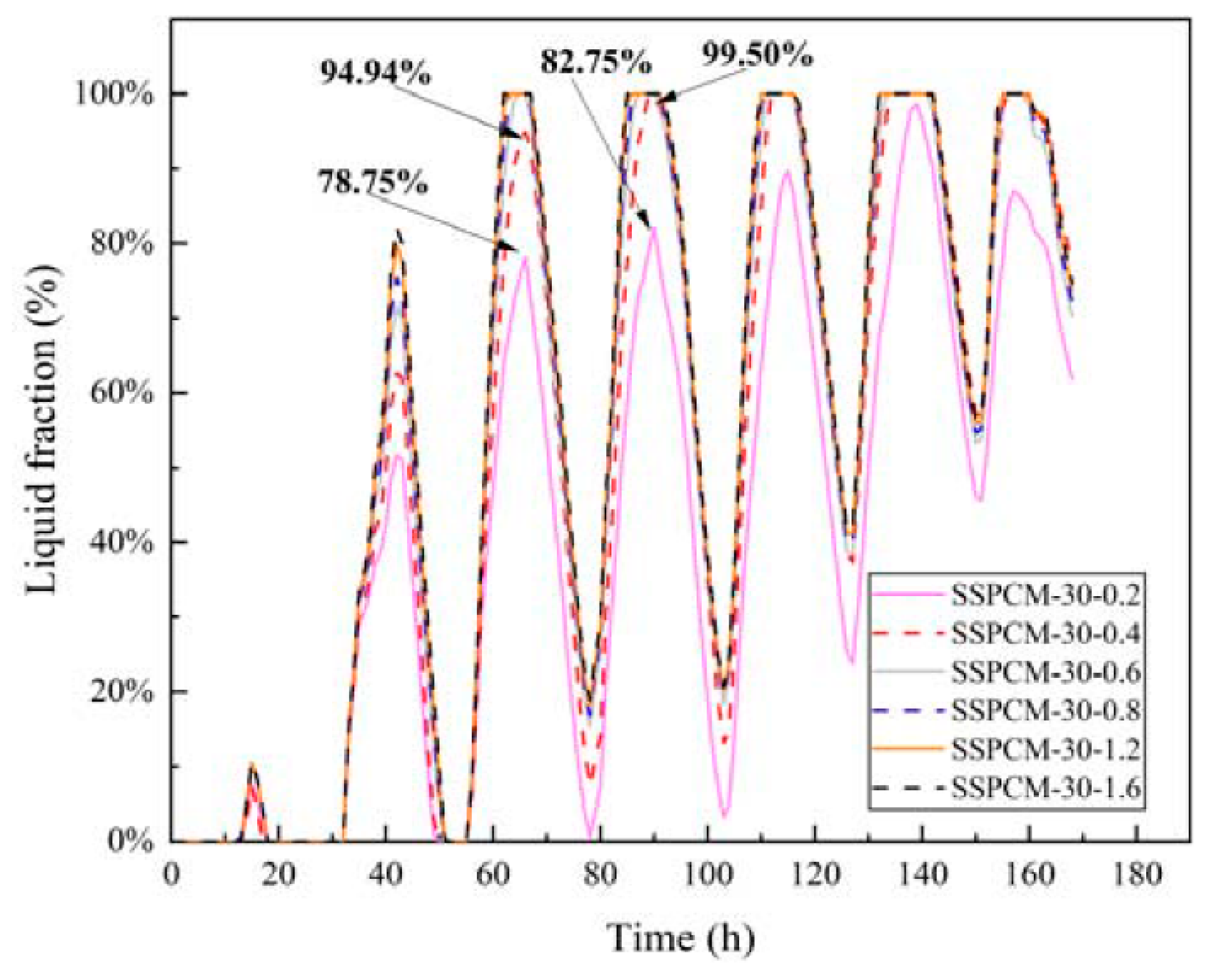

4. Conclusions

- (1)

- The SSPCM granary wall was prefabricated with the self-temperature-regulated behavior of the PCMs. The optimal parameters of the SSPCM may meet the great demand for green grain storage for large-capacity granaries in China;

- (2)

- Increasing the thickness of the SSPCM layer can reduce the temperature and heat flux of the internal wall surface to achieve the energy-saving effect. In Zhengzhou city, the SSPCM layer located on the outer wall surface can enhance the temperature-regulation effect of the SSPCM granary wall;

- (3)

- With the increasing thickness of the SSPCM, the internal surface temperature decreased. However, in comparison to the maximum thickness of 40 mm, both the maximum latent heat utilization rate and the energy-storage effect are obtained when the SSPCM layer thickness is 30 mm;

- (4)

- Thermal conductivity has a controversial effect on the temperature regulation of the walls. A smaller thermal conductivity dominates in the thermal regulation of walls by restraining the heat flux conducted to the indoors. The maximum energy-saving rate was up to 35.83% for the outer SSPCM layer with a thickness of 30 mm and a thermal conductivity of 0.2 W/m·K. The optimal utilization of the SSPCM layer was present when the thermal conductivity was 0.4 W/m·K.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ziegler, V.; Paraginski, R.T.; Ferreira, C.D. Grain storage systems and effects of moisture, temperature and time on grain quality-A review. J. Stored Prod. Res. 2021, 91, 101770. [Google Scholar] [CrossRef]

- Zhang, X.X.; Zhang, H.; Wang, Z.Q.; Chen, X.; Chen, Y. Research on temperature field of grain piles in underground grain silos lined with plastic. J. Food Process Eng. 2022, 45, e13971. [Google Scholar] [CrossRef]

- Derradji, L.; Imessad, K.; Amara, M.; Boudali, E.F. A study on residential energy requirement and the effect of the glazing on the optimum insulation thickness. Appl. Therm. Eng. 2017, 112, 975–985. [Google Scholar] [CrossRef]

- Wang, H.T.; Hang, Y.G.; Liu, Y. Integrated economic and environmental assessment-based optimization design method of building roof thermal insulation. Buildings 2022, 12, 916. [Google Scholar] [CrossRef]

- Rinawa, M.L.; Pitchandi, P.; Vigneshkumar, N.; Sharma, R.; Singh, M.K.; Subbiah, R.; Kumar, P.M. Experimental analysis of the metal roofed industrial building using nano-silica disbanded crude wax (NDCW). Mater. Today Proc. 2022, 62, 1746–1751. [Google Scholar] [CrossRef]

- Qudama, A.Y.; Márta, S. Influential aspects on melting and solidification of PCM energy storage containers in building envelope applications. Int. J. Green Energy. 2021, 18, 966–986. [Google Scholar]

- Austin, M.C.; Araúz, J.; Mora, D. Numerical assessment of different phase change materials as a passive strategy to reduce energy consumption in buildings under tropical climates. Buildings 2022, 12, 906. [Google Scholar] [CrossRef]

- Boobalakrishnan, P.; Kumar, P.M.; Balaji, G.; Jenaris, D.S.; Kaarthik, S.; Babu, M.J.P.; Karthhik, K. Thermal management of metal roof building using phase change material (PCM). Mater. Today: Proc. 2022, 47, 5052–5058. [Google Scholar] [CrossRef]

- Guo, J.W.; Jiang, Y.Q.; Wang, Y.; Zou, B. Thermal storage and thermal management properties of a novel ventilated mortar block integrated with phase change material for floor heating: An experimental study. Energy Convers. Manag. 2020, 205, 112288. [Google Scholar] [CrossRef]

- Jin, W.Z.; Jiang, L.H.; Chen, L.; Yin, T.J.; Gu, Y.; Guo, Z.M.; Yan, X.C.; Ben, X.Q. Enhancement of thermal conductivity by graphene as additive in lauric/stearic acid/treated diatomite composite phase change materials for heat storage in building envelope. Energy Build. 2021, 246, 111087. [Google Scholar] [CrossRef]

- Yuan, X.W.; Wang, B.M.; Chen, P.; Luo, T. Study on the Frost Resistance of Concrete Modified with Steel Balls Containing Phase Change Material (PCM). Materials. 2021, 14, 4497. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.; Rai, A.C. Performance assessment of residential building envelopes enhanced with phase change materials. Energy Build. 2020, 208, 109664. [Google Scholar] [CrossRef]

- GB/T229890; Technical Criterion for Grain and Oil-Seeds Storage. China Standards Press: Beijing, China, 2013.

- GB/55015; General Code for Energy Efficiency and Renewable Energy Application in Buildings. China Building Industry Press: Beijing, China, 2021.

- Nikiforov, A. Rational organizational and technological decisions on the grain storages construction or renovation sites. Acad. J. Ser. Ind. Mach. Build. Civ. Eng. 2018, 1, 290–297. [Google Scholar] [CrossRef]

- Wang, C.X.; Deng, S.M.; Niu, J.L.; Long, E. A numerical study on optimizing the designs of applying PCMs to a disaster-relief prefabricated temporary-house (PTH) to improve its summer daytime indoor thermal environment. Energy 2019, 181, 239–249. [Google Scholar] [CrossRef]

- Jia, J.J.; Liu, B.; Ma, L.Y.; Wang, H.; Li, D.; Wang, Y.R. Energy saving performance optimization and regional adaptability of prefabricated buildings with PCM in different climates. Case Stud. Therm. Eng. 2021, 26, 101164. [Google Scholar] [CrossRef]

- Li, W.W.; Cheng, W.L.; Xie, B.; Liu, N.; Zhang, L.S. Thermal sensitive flexible phase change materials with high thermal conductivity for thermal energy storage. Energy Convers. Manag. 2017, 149, 1–12. [Google Scholar] [CrossRef]

- Qu, Y.; Wang, S.; Tian, Y.; Zhou, D. Comprehensive evaluation of Paraffin-HDPE shape stabilized PCM with hybrid carbon nano-additives. Appl. Therm. Eng. 2019, 163, 114404. [Google Scholar] [CrossRef]

- Mu, M.L.; Basheer, P.A.M.; Sha, W.; Bai, Y.; McNally, T. Shape stabilised phase change materials based on a high melt viscosity HDPE and paraffin waxes. Appl. Energy 2016, 162, 68–82. [Google Scholar] [CrossRef] [Green Version]

- Frac, M.; Pichór, W.; Szołdra, P.; Szudek, W. Cement composites with expanded graphite/paraffin as storage heater. Constr. Build. Mater. 2021, 275, 122126. [Google Scholar] [CrossRef]

- Xu, N. Study on New Phase Change Energy Storage Wall of the Granary and Its Heat Transfer Characteristics. Master’s Thesis, Henan Technology and University, Zhengzhou, China, 2022. [Google Scholar]

- Li, W.W.; Wang, F.; Cheng, W.L.; Chen, X.; Zhao, Q. Study of using enhanced heat-transfer flexible phase change material film in thermal management of compact electronic device. Energy Convers. Manag. 2020, 210, 122680. [Google Scholar] [CrossRef]

- Betancourt-Jimenez, D.; Montoya, M.; Haddock, J.; Youngblood, J.P.; Martinez, C.J. Regulating asphalt pavement temperature using microencapsulated phase change materials (PCMs). Constr. Build. Mater. 2022, 350, 128924. [Google Scholar] [CrossRef]

- Cheng, W.L.; Zhang, R.M.; Xie, K.; Liu, N.; Wang, J. Heat conduction enhanced shape-stabilized paraffin/HDPE composite PCMs by graphite addition: Preparation and thermal properties. Sol. Energy Mater. Sol. Cells. 2010, 94, 1636–1642. [Google Scholar] [CrossRef]

- Qiu, L.; Ouyang, Y.X.; Feng, Y.H.; Zhang, X.X. Review on micro/nano phase change materials for solar thermal applications. Renew. Energy 2019, 140, 513–538. [Google Scholar] [CrossRef]

- Lawag, R.A.; Ali, H.M. Phase change materials for thermal management and energy storage: A review. J. Energy Storage 2022, 55, 105602. [Google Scholar] [CrossRef]

- Yuan, S.; Li, C.E.; Yu, H.; Tang, Y.; Xia, Z.G. Optimization of the phase-change wallboard test method: Experimental and numerical investigation. J. Energy Storage 2020, 30, 101559. [Google Scholar]

- Yan, Q.S.; Zhao, Q.Z. Building Thermal Process; China Architecture & Building Press: Beijing, China, 1986; pp. 86–87. [Google Scholar]

- Energy Plus. Available online: https://energyplus.net/weather (accessed on 5 August 2022).

- Lei, J.; Yang, J.; Yang, E.H. Energy performance of building envelopes integrated with phase change materials for cooling load reduction in tropical Singapore. Appl. Energy. 2016, 162, 207–217. [Google Scholar] [CrossRef]

- Li, M.L.; Cao, Q.; Pan, H.; Wang, X.Y. Effect of melting point on thermodynamics of thin PCM reinforced residential frame walls in different climate zones. Appl. Therm. Eng. 2021, 188, 116615. [Google Scholar] [CrossRef]

- Li, Z.X.; Abdullah, A.A.A.A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavar, A.; Afrand, M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: Effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]

- Yu, J.H.; Yang, Q.C.; Ye, H.; Huang, J.C.; Liu, Y.X.; Tao, J.W. The optimum phase transition temperature for building roof with outer layer pcm in different climate regions of China. Energy Procedia 2019, 158, 3045–3051. [Google Scholar] [CrossRef]

- Arıcı, M.; Bilgin, F.; Nižetić, S.; Karabei, H. PCM integrated to external building walls: An optimization study on maximum activation of latent heat. Appl. Therm. Eng. 2019, 165, 114560. [Google Scholar] [CrossRef]

- Mechouet, A.; Oualim, E.M.; Mouhib, T. Effect of mechanical ventilation on the improvement of the thermal performance of PCM-incorporated double external walls: A numerical investigation under different climatic conditions in Morocco. J. Energy Storage 2021, 38, 102495. [Google Scholar] [CrossRef]

- Liu, Z.A.; Hou, J.W.; Meng, X.; Dewancker, B.J. A numerical study on the effect of phase-change material (PCM) parameters on the thermal performance of lightweight building walls. Case Stud. Constr. Mater. 2021, 15, e00758. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Specific Heat Capacity (J/kg·K) | Phase Change Temperature (°C) | Latent Heat (J/g) | Thermal Conductivity (W/m·K) | PCM Thickness (mm) |

|---|---|---|---|---|---|---|

| Concrete | 2400 | 1030 | N/A | N/A | 1.74 | N/A |

| SSPCM | 790 | 1500 | 28.5 | 150 | 0.8 | 10, 20, 30, 40 |

| 0.2, 0.4, 0.6, 0.8, 1.2, 1.6 | 30 |

| Parameters | Common Granary Wall | PCM Granary Wall Thermal Conductivity of PCM (W/m·K) | |||||

|---|---|---|---|---|---|---|---|

| 0.2 | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | ||

| Q (W·h·m−2) | 5996.43 | 3848.16 | 4729.11 | 5139.63 | 5375.09 | 5634.28 | 5774.07 |

| ΔQ (W·h·m−2) | / | 2148.27 | 1267.32 | 856.8 | 621.34 | 326.15 | 222.36 |

| Esaving (%) | / | 35.83 | 21.13 | 14.29 | 10.36 | 6.04 | 3.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, C.; Hu, C.; Li, W. Thermal Regulation Performance of Shape-Stabilized-Phase-Change-Material-Based Prefabricated Wall for Green Grain Storage. Materials 2023, 16, 964. https://doi.org/10.3390/ma16030964

Zeng C, Hu C, Li W. Thermal Regulation Performance of Shape-Stabilized-Phase-Change-Material-Based Prefabricated Wall for Green Grain Storage. Materials. 2023; 16(3):964. https://doi.org/10.3390/ma16030964

Chicago/Turabian StyleZeng, Changnv, Chaoxin Hu, and Wanwan Li. 2023. "Thermal Regulation Performance of Shape-Stabilized-Phase-Change-Material-Based Prefabricated Wall for Green Grain Storage" Materials 16, no. 3: 964. https://doi.org/10.3390/ma16030964

APA StyleZeng, C., Hu, C., & Li, W. (2023). Thermal Regulation Performance of Shape-Stabilized-Phase-Change-Material-Based Prefabricated Wall for Green Grain Storage. Materials, 16(3), 964. https://doi.org/10.3390/ma16030964