Manufacturing and Characterization of Dental Crowns Made of 5-mol% Yttria Stabilized Zirconia by Digital Light Processing

Abstract

:1. Introduction

2. Materials and Methods

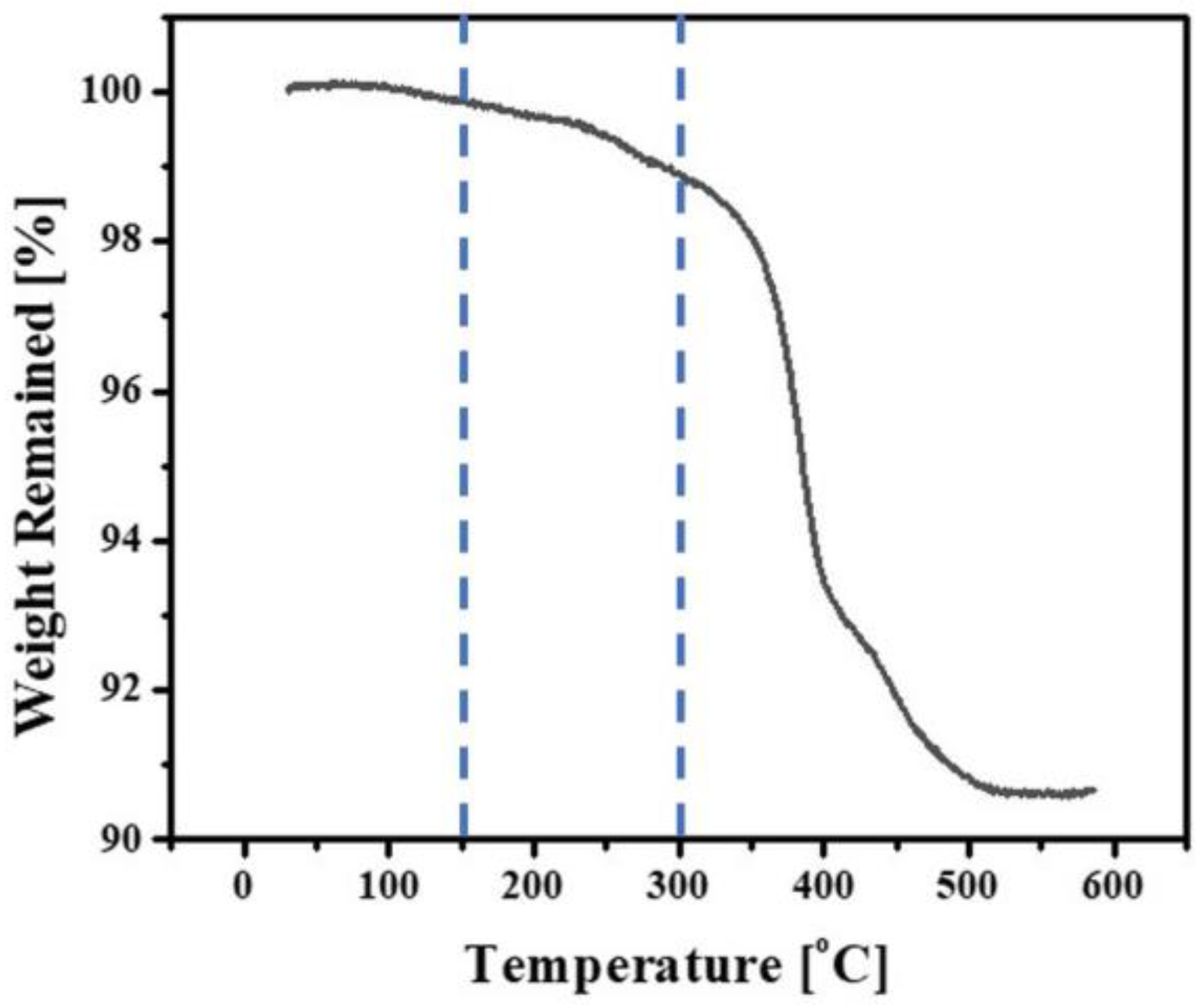

2.1. Preparation of Submicron-Sized 5Y-PSZ Particles

2.2. Constituents of Photocurable 5Y-PSZ Suspensions

2.3. Preparation of 5Y-PSZ Suspensions

2.4. Rheological Behavior Evaluations of 5Y-PSZ Suspensions

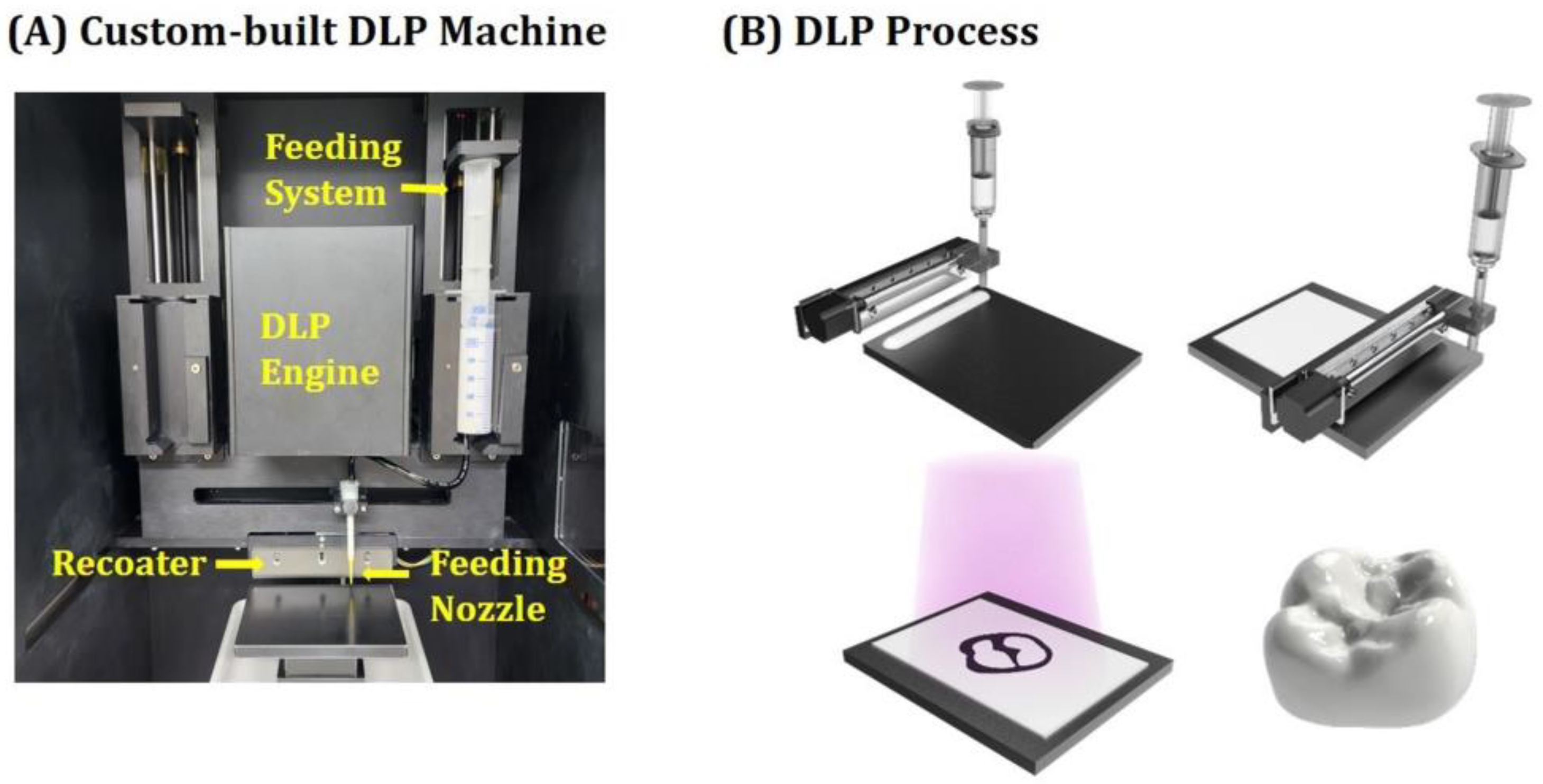

2.5. Custom-Built DLP Process

2.6. Manufacturing of 5Y-PSZ Specimens and Dental Crowns

2.7. Characterization of as-Printed and Sintered 5Y-PSZ Specimens

2.8. Mechanical Properties Evaluation

2.9. Optical Translucency Evaluation

2.10. Dimensional Accuracy Evaluation

2.11. Statistical Analysis

3. Results and Discussion

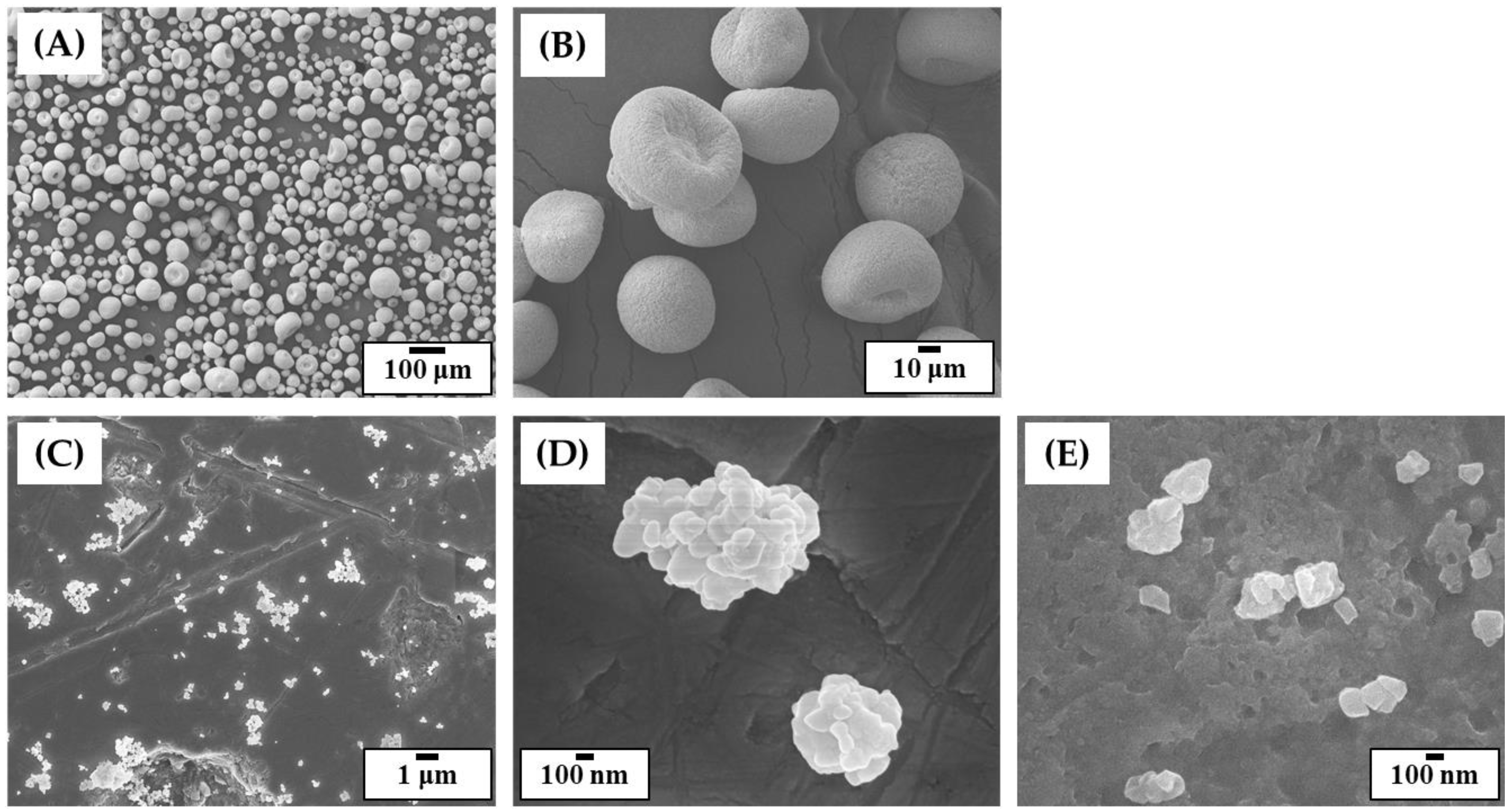

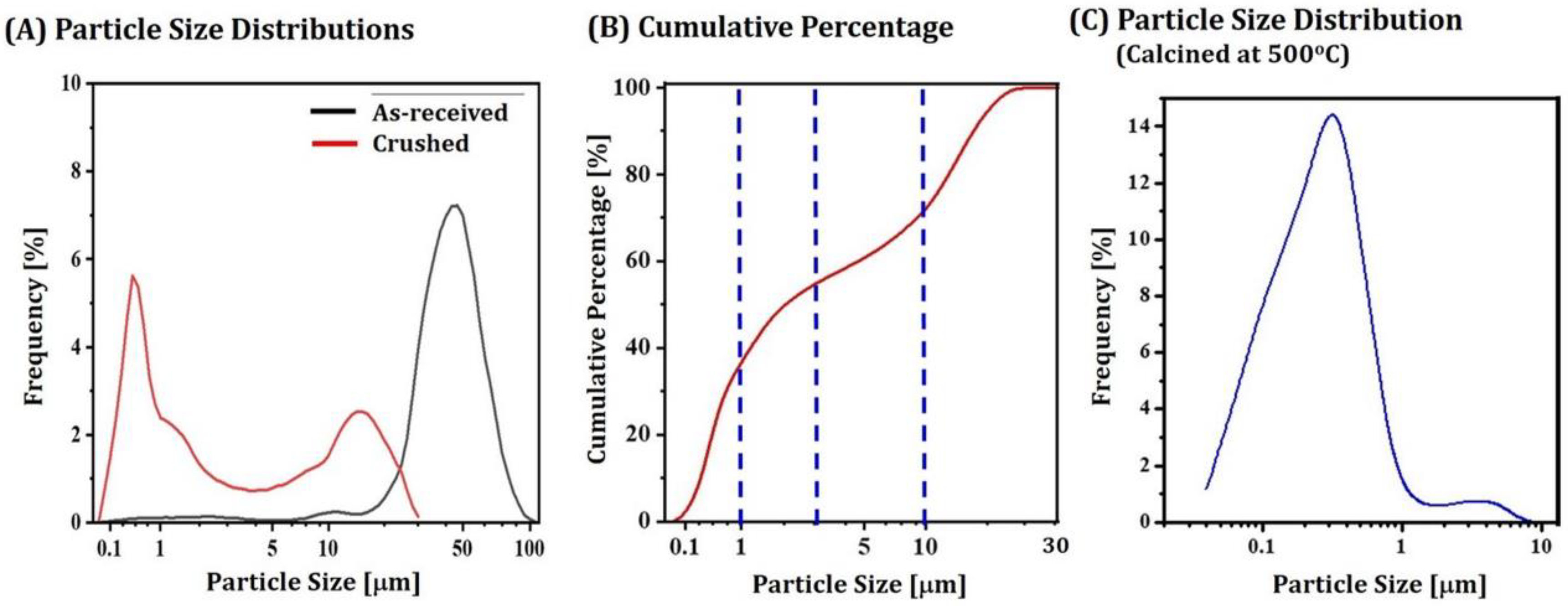

3.1. Morphologies and Size Distributions of 5Y-PSZ Granules and Particles

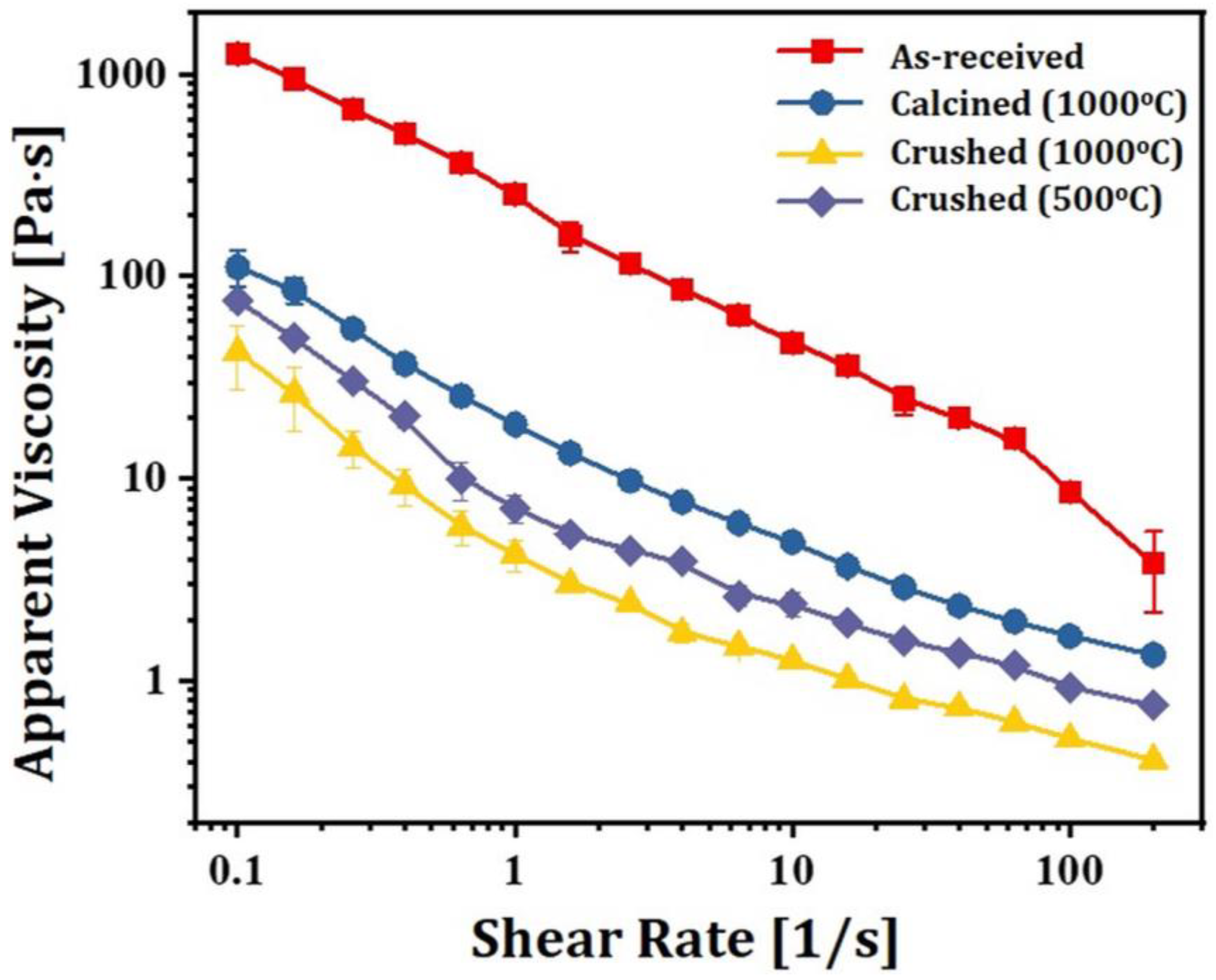

3.2. Effect of Particle Sizes on Rheological Behaviors of 5Y-PSZ Suspensions

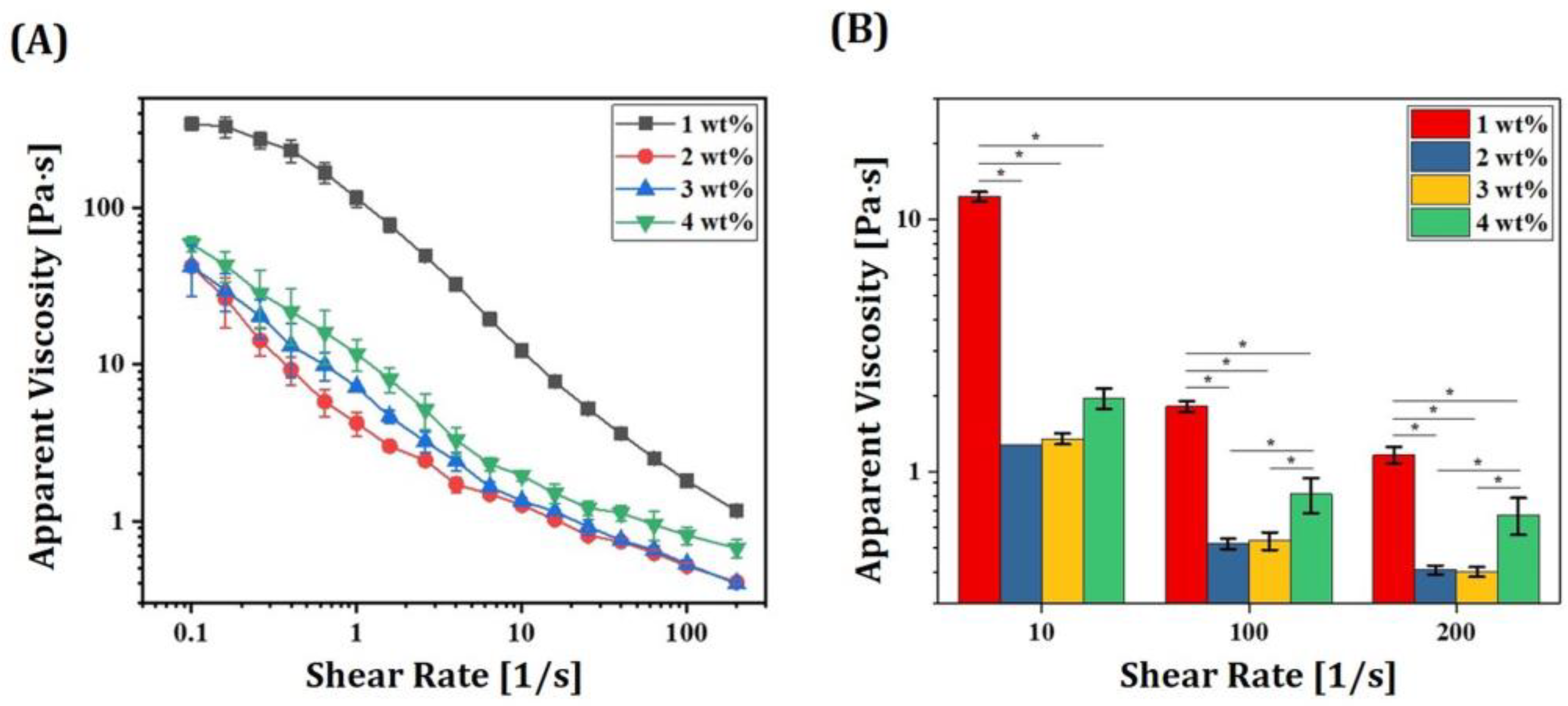

3.3. Optimization of Dispersant Content

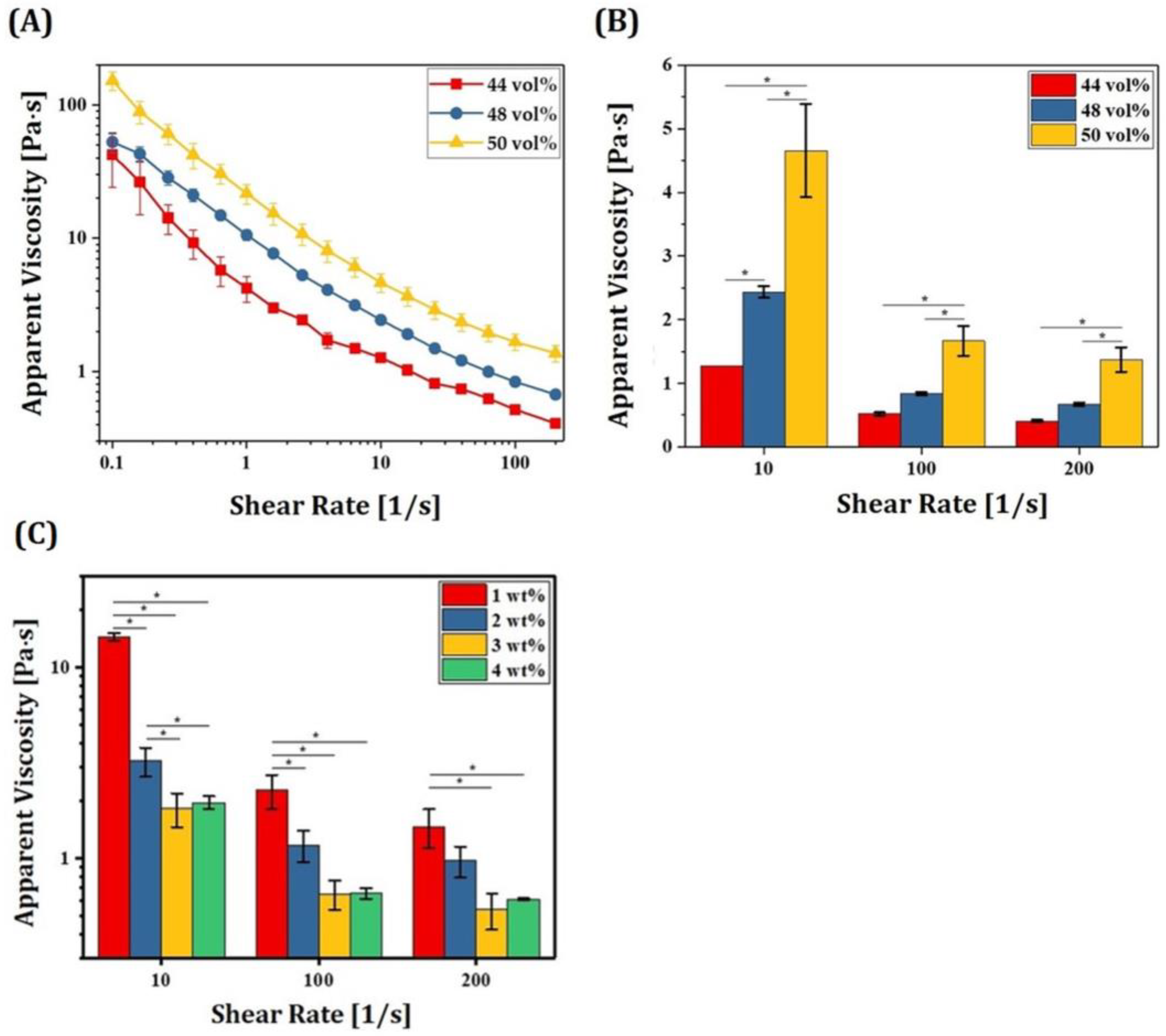

3.4. Optimization of Maximum Solid Loading

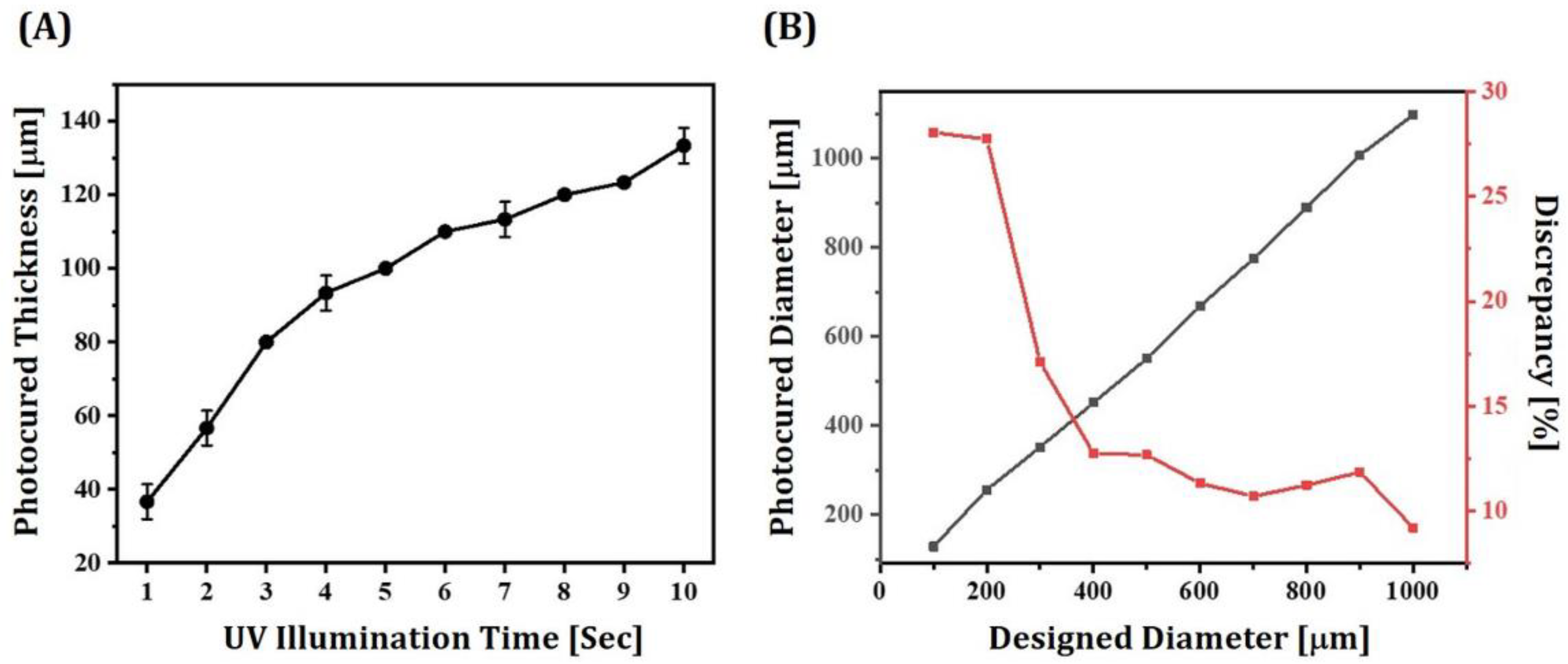

3.5. Optimization of Photocuring Process for DLP

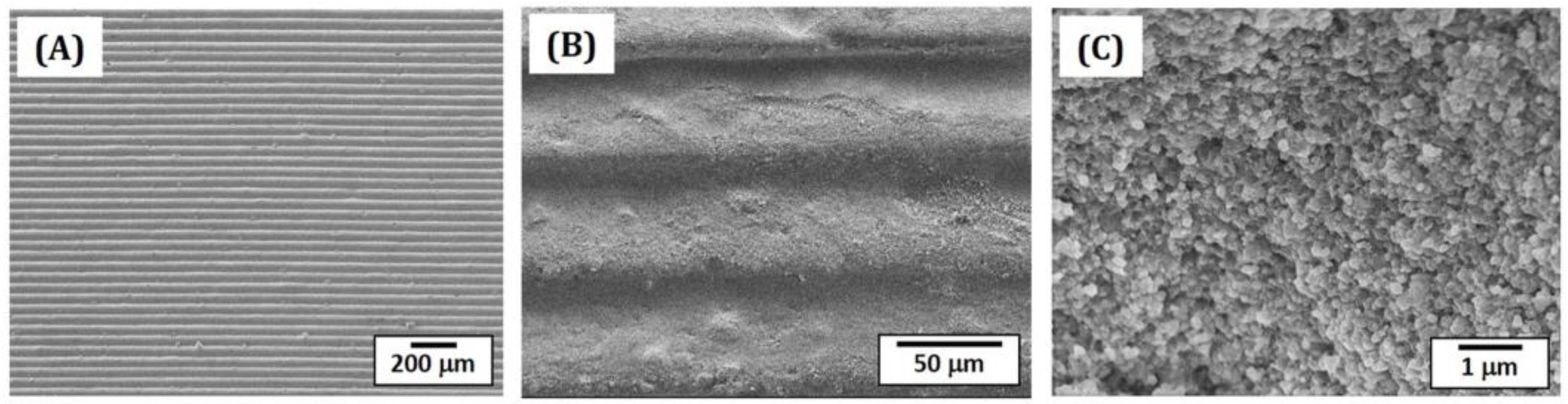

3.6. Microstructures of as-Printed 5Y-PSZ

3.7. Shrinkages and Relative Density of Sintered 5Y-PSZ

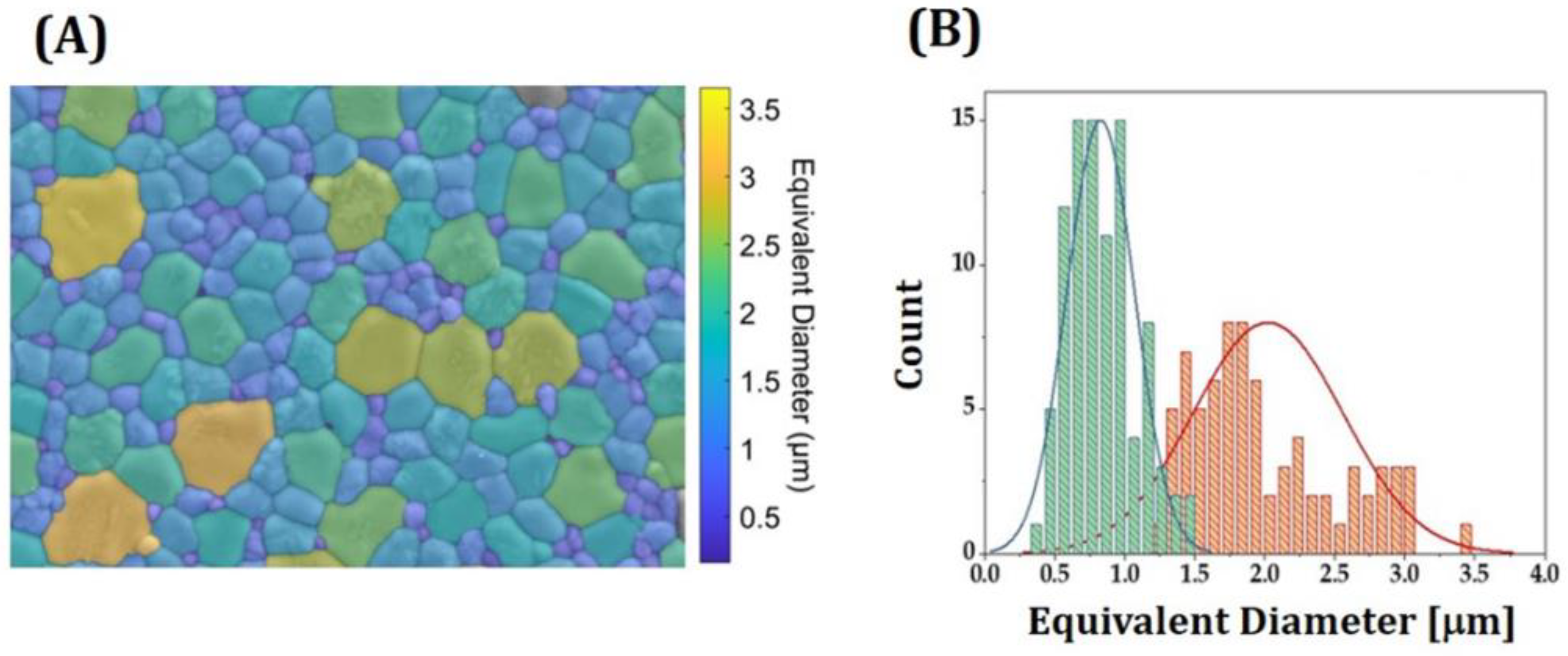

3.8. Microstructures and Grain Sizes of Sintered 5Y-PSZ

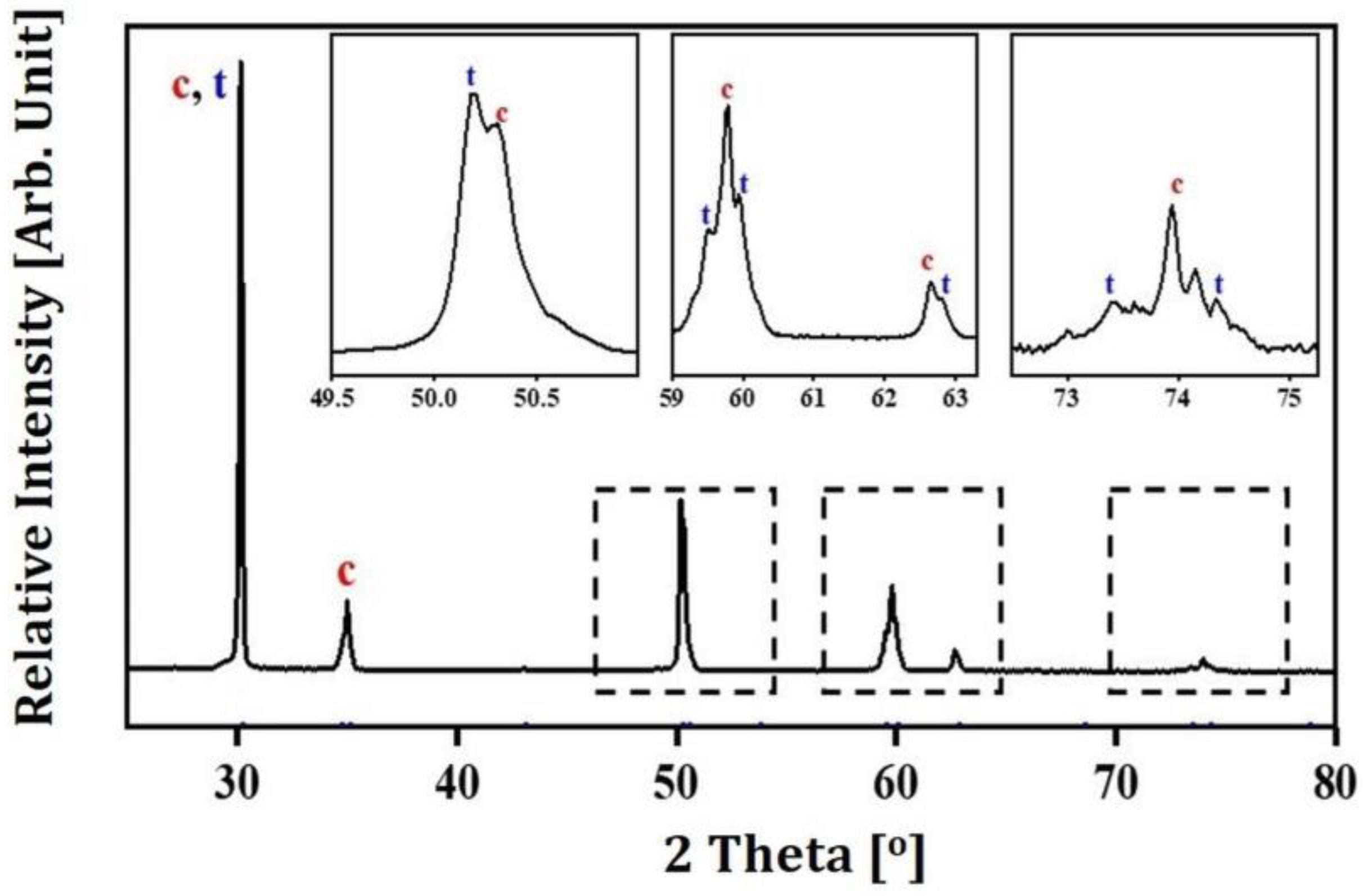

3.9. Crystalline Phases of Sintered 5Y-PSZ

3.10. Chemical Compositions of Tetragonal and Cubic Grains

3.11. Mechanical Properties of Sintered 5Y-PSZ

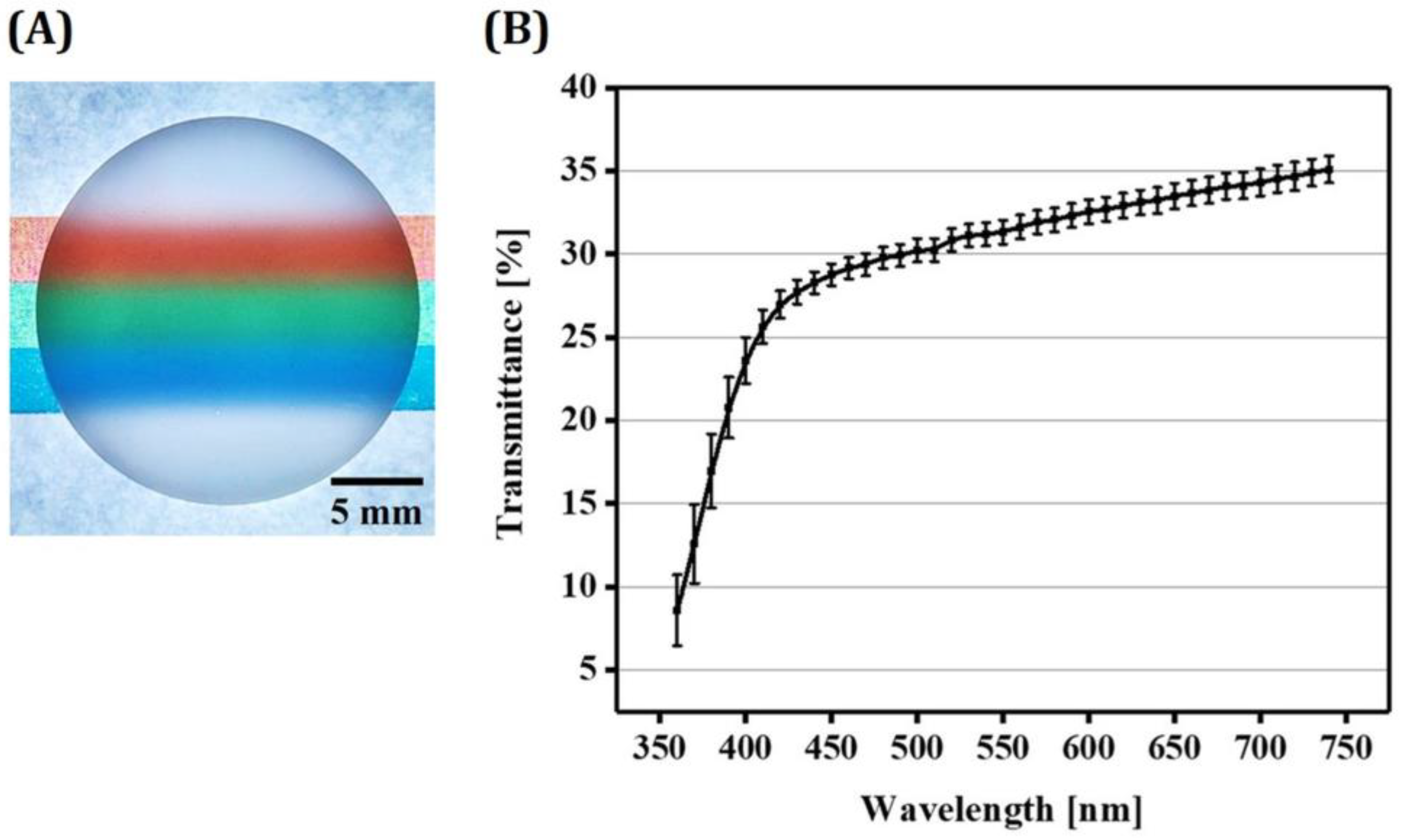

3.12. Optical Translucency of 5Y-PSZ Disks

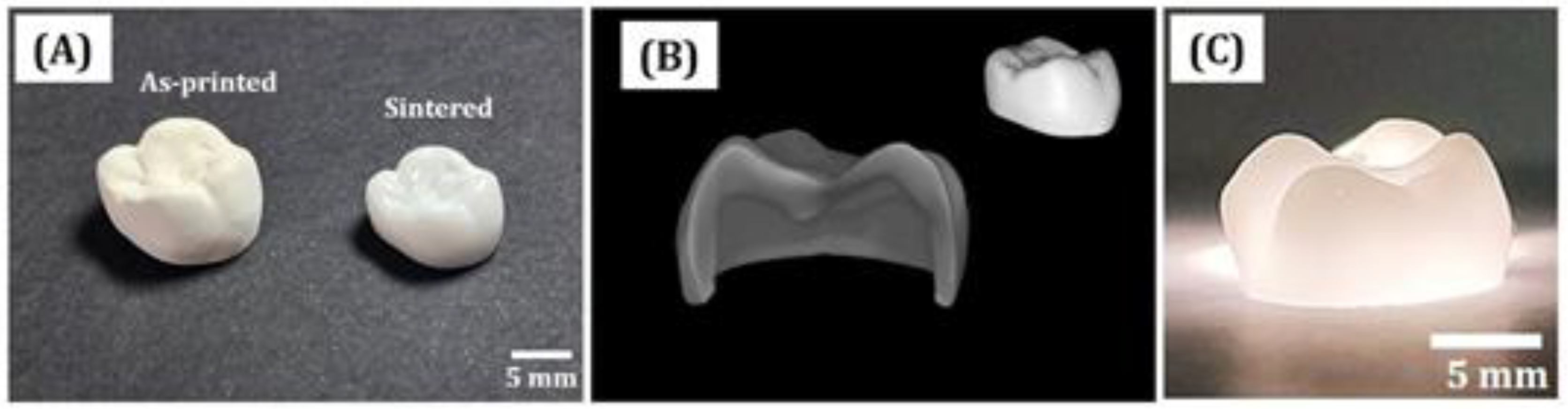

3.13. Dimensional Accuracy of 5Y-PSZ Dental Crowns

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miyazaki, T.; Hotta, Y.; Kunii, J.; Kuriyama, S.; Tamaki, Y. A review of dental CAD/CAM: Current status and future perspectives from 20 years of experience. Dent. Mater. J. 2009, 28, 44–56. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Nakamura, T.; Matsumura, H.; Ban, S.J.; Kobayashi, T. Current status of zirconia restoration. J. Prosthodont. Res. 2013, 57, 236–261. [Google Scholar] [CrossRef] [PubMed]

- Khanlar, L.N.; Rios, A.S.; Tahmaseb, A.; Zandinejad, A. Additive manufacturing of zirconia ceramic and its application in clinical dentistry: A review. Dent. J. 2021, 9, 104. [Google Scholar] [CrossRef] [PubMed]

- Galante, R.; Figueiredo-Pina, C.G.; Serro, A.P. Additive manufacturing of ceramics for dental applications: A review. Dent. Mater. 2019, 35, 825–846. [Google Scholar] [CrossRef]

- Borlaf, M.; Serra-Capdevila, A.; Colominas, C.; Graule, T. Development of UV-curable ZrO2 slurries for additive manufacturing (LCMDLP) technology. J. Eur. Ceram. Soc. 2019, 39, 3797–3803. [Google Scholar] [CrossRef]

- Kim, J.H.; Maeng, W.Y.; Koh, Y.H.; Kim, H.E. Digital light processing of zirconia prostheses with high strength and translucency for dental applications. Ceram. Int. 2020, 46, 28211–28218. [Google Scholar] [CrossRef]

- Chen, F.; Zhuc, H.; Wu, J.M.; Chen, S.; Cheng, L.J.; Shia, Y.S.; Mo, Y.C.; Li, C.H.; Xiao, J. Preparation and biological evaluation of ZrO2 all-ceramic teeth by DLP technology. Ceram. Int. 2020, 46, 11268–11274. [Google Scholar] [CrossRef]

- Sun, J.; Chen, X.; Wade-Zhu, J.; Binner, J.; Bai, J. A comprehensive study of dense zirconia components fabricated by additive manufacturing. Addit. Manuf. 2021, 43, 101994. [Google Scholar] [CrossRef]

- Li, W.; Liu, M.; Liu, W.; Zhou, H.; Li, M.; Chen, Y.; Xing, Z. High-performance integrated manufacturing of a 3Y-TZP ceramic crown through viscoelastic paste-based vat photopolymerization with a conformal contactless support. Addit. Manuf. 2022, 59, 103143. [Google Scholar] [CrossRef]

- Revilla-León, M.; Methani, M.M.; Morton, D.; Zandinejad, A. Internal and marginal discrepancies associated with stereolithography (SLA) additively manufactured zirconia crowns. J. Prosthet. Dent. 2020, 124, 730–737. [Google Scholar] [CrossRef]

- Abualsaud, R.; Alalawi, H. Fit, precision, and trueness of 3D-printed zirconia crowns compared to milled counterparts. Dent. J. 2022, 10, 215. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.M.; Jeong, C.S.; Lee, H.J.; Bae, J.M.; Choi, E.J.; Kim, S.T.; Park, Y.B.; Oh, S.H. A comparative study of additive and subtractive manufacturing techniques for a zirconia dental product: An analysis of the manufacturing accuracy and the bond strength of porcelain to zirconia. Materials 2022, 15, 5398. [Google Scholar] [CrossRef] [PubMed]

- Meng, J.; Lian, Q.; Xi, S.; Yi, Y.; Lu, Y.; Wu, G. Crown fit and dimensional accuracy of zirconia fixed crowns based on the digital light processing technology. Ceram. Int. 2022, 48, 17852–17863. [Google Scholar] [CrossRef]

- Lüchtenborga, J.; Willems, E.; Zhang, F.; Wesemann, C.; Weiss, F.; Nold, J.; Sun, J.; Sandra, F.; Bai, J.; Reveron, H.; et al. Accuracy of additively manufactured zirconia four-unit fixed dental prostheses fabricated by stereolithography, digital light processing and material jetting compared with subtractive manufacturing. Dent. Mater. 2022, 38, 1459–1469. [Google Scholar] [CrossRef]

- Kim, Y.K.; Han, J.S.; Yoon, H.I. Evaluation of intaglio surface trueness, wear, and fracture resistance of zirconia crown under simulated mastication: A comparative analysis between subtractive and additive manufacturing. J. Adv. Prosthodont. 2022, 14, 122–132. [Google Scholar] [CrossRef] [PubMed]

- Su, C.Y.; Wang, J.C.; Chen, D.S.; Chuang, C.C.; Lin, C.K. Additive manufacturing of dental prosthesis using pristine and recycled zirconia solvent-based slurry stereolithography. Ceram. Int. 2020, 46, 28701–28709. [Google Scholar] [CrossRef]

- Li, X.; Zhong, H.; Zhang, J.; Duan, Y.; Li, J.; Jiang, D. Fabrication of zirconia all-ceramic crown via DLP-based stereolithography. Int. J. Appl. Ceram. Technol. 2020, 17, 844–853. [Google Scholar] [CrossRef]

- Marsico, C.; Øilo, M.; Kutsch, J.; Kauf, M.; Arola, D. Vat polymerization-printed partially stabilized zirconia: Mechanical properties, reliability and structural defects. Addit. Manuf. 2020, 36, 101450. [Google Scholar] [CrossRef] [PubMed]

- Harrer, W.; Schwentenwein, M.; Lube, T.; Danzer, R. Fractography of zirconia-specimens made using additive manufacturing (LCM) technology. J. Eur. Ceram. Soc. 2017, 37, 4331–4338. [Google Scholar] [CrossRef]

- Jang, K.J.; Kang, J.H.; Fisher, J.G.; Parka, S.W. Effect of the volume fraction of zirconia suspensions on the microstructure and physical properties of products produced by additive manufacturing. Dent. Mater. 2019, 35, e91–e106. [Google Scholar] [CrossRef]

- Zhang, K.; He, R.; Ding, G.; Feng, C.; Song, W.; Fang, D. Digital light processing of 3YTZP strengthened ZrO2 ceramics. Mater. Sci. Eng. A 2020, 774, 138768. [Google Scholar] [CrossRef]

- Xiang, D.; Xu, Y.; Bai, W.; Lin, H. Dental zirconia fabricated by stereolithography: Accuracy, translucency and mechanical properties in different build orientations. Ceram. Int. 2021, 47, 28837–28847. [Google Scholar] [CrossRef]

- Shen, M.; Zhao, W.; Xing, B.; Sing, Y.; Gao, S.; Wang, C.; Zhao, C. Effects of exposure time and printing angle on the curing characteristics and flexural strength of ceramic samples fabricated via digital light processing. Ceram. Int. 2020, 46, 24379–24384. [Google Scholar] [CrossRef]

- Jang, J.G.; Kang, J.H.; Joe, K.B.; Sakthiabirami, K.; Jang, K.J.; Jun, M.J.; Oh, G.J.; Park, C.; Park, S.W. Evaluation of Physical Properties of Zirconia Suspension with Added Silane Coupling Agent for Additive Manufacturing Processes. Materials 2022, 15, 1337. [Google Scholar] [CrossRef]

- Coppola, B.; Schmitt, J.; Lacondemine, T.; Tardivat, C.; Montanaro, L.; Palmero, P. Digital light processing stereolithography of zirconia ceramics: Slurry elaboration and orientation-reliant mechanical properties. J. Eur. Ceram. Soc. 2022, 42, 2974–2982. [Google Scholar] [CrossRef]

- de Camargo, I.L.; Morais, M.N.; Fortulan, C.A.; Branciforti, M.C. A review on the rheological behavior and formulations of ceramic suspensions for vat photopolymerization. Ceram. Int. 2021, 47, 11906–11921. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Li, X.; Zhong, H.; Zhang, J.; Duan, Y.; Bai, H.; Li, J.; Jiang, D. Dispersion and properties of zirconia suspensions for stereolithography. Int. J. Appl. Ceram. Technol. 2020, 17, 239–247. [Google Scholar] [CrossRef]

- Lee, S.Y.; Jiang, C.P. Printing system using dynamic mask projection for fabricating zirconia dental implants. Mater. Manuf. Process. 2015, 30, 1498–1504. [Google Scholar] [CrossRef]

- Jiang, C.P.; Hsu, H.J.; Lee, S.Y. Development of mask-less projection slurry stereolithography for the fabrication of zirconia dental coping. Int. J. Precis. Eng. Manuf. 2014, 15, 2413–2419. [Google Scholar] [CrossRef]

- Komissarenko, D.A.; Sokolov, P.S.; Evstigneeva, A.D.; Shmeleva, I.A.; Dosovitsky, A.E. Rheological and curing behavior of acrylate-based suspensions for the DLP 3D printing of complex zirconia parts. Materials 2018, 11, E2350. [Google Scholar] [CrossRef] [PubMed]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; He, R.; Wu, Z.; Jiang, Q.; Song, X.; Chen, Y.; Cheng, L.; Wu, S. Fabrication of dense zirconia-toughened alumina ceramics through a stereolithography-based additive manufacturing. Ceram. Int. 2017, 43, 968–972. [Google Scholar] [CrossRef]

- Lee, Y.H.; Lee, J.B.; Maeng, W.Y.; Koh, Y.H.; Kim, H.E. Photocurable ceramic slurry using solid camphor as novel diluent for conventional digital light processing (DLP) process. J. Eur. Ceram. Soc. 2019, 39, 4358–4365. [Google Scholar] [CrossRef]

- Manicone, P.F.; Iommetti, P.R.; Raffaelli, L. An overview of zirconia ceramics: Basic properties and clinical applications. J. Dent. 2007, 35, 819–826. [Google Scholar] [CrossRef]

- Zhang, Y.; Lawn, B.R. Novel zirconia materials in dentistry. J. Dent. Res. 2018, 97, 140–147. [Google Scholar] [CrossRef]

- Zhang, F.; Reveron, H.; Spies, B.C.; Van Meerbeek, B.; Chevalier, J. Trade-off between fracture resistance and translucency of zirconia and lithium-disilicate glass ceramics for monolithic restorations. Acta Biomater. 2019, 91, 24–34. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Scattering of ultraviolet radiation in turbid suspensions. J. Appl. Phys. 1997, 81, 2538–2546. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic stereolithography: Additive manufacturing for ceramics by photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Rasaki, S.A.; Xiong, D.; Xiong, S.; Su, F.; Idrees, M.; Chen, Z. Photopolymerization-based additive manufacturing of ceramics: A systematic review. J. Adv. Ceram. 2021, 10, 442–471. [Google Scholar] [CrossRef]

- Ingel, R.P.; Lewis, D., III. Lattice parameters and density for Y2O3-Stabilized ZrO2. J. Am. Cerarn. Soc. 1986, 69, 325–332. [Google Scholar] [CrossRef]

- ISO 6872; Dentistry-Ceramic Materials. International Organization of Standardization: Geneva, Switzerland, 2008.

- Zhang, F.; Meerbeek, B.V.; Vleugels, J. Importance of tetragonal phase in high-translucent partially stabilized zirconia for dental restorations. Dent. Mater. 2020, 36, 491–500. [Google Scholar] [CrossRef] [PubMed]

- Miura, D.; Ishida, Y.; Miyasaka, T.; Aoki, H.; Shinya, A. Reliability of different bending test methods for dental press ceramics. Materials 2020, 13, 5162. [Google Scholar] [CrossRef] [PubMed]

- Souza, R.C.; dos Santos, C.; Barboza, M.J.R.; Bicalho, L.D.A.; Baptista, C.A.R.P.; Elias, C.N. Fatigue behavior of 3%Y2O3-doped ZrO2 ceramics. J. Mater. Res. Technol. 2014, 3, 48–54. [Google Scholar] [CrossRef]

- ISO 11664; Colorimetry−Part 2: CIE Standard Illuminants. International Organization of Standardization: Geneva, Switzerland, 2007.

- Yang, M.S.; Kim, S.K.; Heo, S.J.; Koak, J.Y.; Park, J.M. Investigation of the marginal fit of a 3D-printed three-unit resin prosthesis with different build orientations and layer thicknesses. J. Adv. Prosthodont. 2022, 14, 250–261. [Google Scholar] [CrossRef]

- Jang, Y.; Sim, J.Y.; Park, J.K.; Kim, W.C.; Kim, H.Y.; Kim, J.H. Evaluation of the marginal and internal fit of a single crown fabricated based on a three-dimensional printed model. J. Adv. Prosthodont. 2018, 10, 367–373. [Google Scholar] [CrossRef]

- ISO 12836; Digitizing Devices for CAD/CAM Systems for Indirect Dental Restorations—Test Methods for Assessing. International Organization of Standardization: Geneva, Switzerland, 2015.

- Çakmak, G.; Cuellar, A.R.; Donmez, M.B.; Schimmel, M.; Abou-Ayash, S.; Lu, W.E.; Yilmaz, B. Effect of printing layer thickness on the trueness and margin quality of 3D-printed interim dental crowns. Appl. Sci. 2021, 11, 9246. [Google Scholar] [CrossRef]

- Santoliquido, O.; Colombo, P.; Ortona, A. Additive manufacturing of ceramic components by digital light processing: A comparison between the “bottom-up” and the “top-down” approaches. J. Eur. Ceram. Soc. 2019, 39, 2140–2148. [Google Scholar] [CrossRef]

- Bae, C.J.; Halloran, J.W. Concentrated suspension-based additive manufacturing—Viscosity, packing density, and segregation. J. Eur. Ceram. Soc. 2019, 39, 4299–4306. [Google Scholar] [CrossRef]

- Franks, G.V.; Tallon, C.; Studart, A.R.; Sesso, M.L.; Leo, S. Colloidal processing: Enabling complex shaped ceramics with unique multiscale structures. J. Am. Ceram. Soc. 2017, 100, 458–490. [Google Scholar] [CrossRef]

- ASTM E112-13; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 13383-1; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)−Microstructural Characterization−Part 1: Determination of Grain Size and Size Distribution. International Organization of Standardization: Geneva, Switzerland, 2012.

- Kulyk, V.V.; Duriagina, Z.A.; Vasyliv, B.D.; Vavrukh, V.; Kovbasiuk, T.M.; Holovchuk, M. Effects of yttria content and sintering temperature on the microstructure and tendency to brittle fracture of yttria-stabilized zirconia. Arch. Mater. Sci. Eng. 2021, 109, 65–79. [Google Scholar] [CrossRef]

- Kulyk, V.; Duriagina, Z.; Kostryzhev, A.; Vasyliv, B.; Vavrukh, V.; Marenych, O. The effect of yttria content on microstructure, strength, and fracture behavior of yttria-stabilized zirconia. Materials 2022, 15, 5212. [Google Scholar] [CrossRef] [PubMed]

- Too, T.D.C.; Inokoshi, M.; Nozaki, K.; Shimizubata, M.; Nakai, H.; Liu, H.; Minakuchi, S. Influence of sintering conditions on translucency, biaxial flexural strength, microstructure, and low-temperature degradation of highly translucent dental zirconia. Dent. Mater. J. 2021, 40, 1321–1328. [Google Scholar]

- Lim, C.H.; Vardhaman, S.; Reddy, N.; Zhang, Y. Composition, processing, and properties of biphasic zirconia bioceramics: Relationship to competing strength and optical properties. Ceram. Int. 2022, 48, 17095–17103. [Google Scholar] [CrossRef]

- Lee, Y.K. Criteria for clinical translucency evaluation of direct esthetic restorative materials. Restor. Dent. Endod. 2016, 41, 159–166. [Google Scholar] [CrossRef]

- Miyagawa, Y.; Powers, J.M.; O’Brien, W.J. Optical properties of direct restorative materials. J. Dent. Res. 1981, 60, 890–894. [Google Scholar] [CrossRef]

- Tan, X.; Lu, Y.; Gao, J.; Wang, Z.; Xie, C.; Yu, H. Effect of high-speed sintering on the microstructure, mechanical properties and ageing resistance of stereolithographic additive-manufactured zirconia. Ceram. Int. 2022, 48, 9797–9804. [Google Scholar] [CrossRef]

- Magnani, G.; Fabbri, P.; Leoni, E.; Salernitano, E.; Mazzanti, F. New perspectives on zirconia composites as biomaterials. J. Compos. Sci. 2021, 5, 244. [Google Scholar] [CrossRef]

- McLean, J.W.; von Fraunhofer, J.A. The estimation of cement film thickness by an in vivo technique. Br. Dent. J. 1971, 131, 107–111. [Google Scholar] [CrossRef]

| Role | Material | Weight [g] | Volume Percent (%) |

|---|---|---|---|

| Zirconia Particle | 5 mol% yttria-partially stabilized zirconia (Zpex Smile) | 70.75 | 50.00 |

| Photocurable Monomer | 1,6-hexanediol diacrylate (HDDA) | 6.50 | 27.18 |

| Diluent | Decalin | 3.50 | 16.70 |

| Dispersant | Solution of a structured acrylate copolymer with pigment-affinic groups (DISPERBYK-180) | 1.42 | 5.60 |

| Photo initiator | Diphenyl(2,4,6-trimethylbenzoyl) phosphine oxide (TPO) | 0.13 | 0.49 |

| Step | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Heating Rate (°C/min) | 2 | 0.8 | 0.8 | 1 | 5 |

| Temperature (°C) | 310 | 380 | 430 | 470 | 1500 |

| Dwelling Time (min] | 180 | 180 | 60 | 60 | 120 |

| Linear Sintering Shrinkage (%) | Measured Density (g/cm3) | Relative Density (%) | |

|---|---|---|---|

| Diameter | Thickness | ||

| 19.12 ± 0.18 | 19.65 ± 0.27 | 5.976 ± 0.023 | 99.03 ± 0.39 |

| Elements (wt%) | Compositions (mol %) | ||||

|---|---|---|---|---|---|

| Zr | Y | O | ZrO2 | Y2O3 | |

| Large Grain | 64.3 ± 0.9 | 9.5 ± 0.3 | 26.2 ± 1.0 | 93.0 ± 0.7 | 7.0 ± 0.3 |

| Small Grain | 66.8 ± 3.3 | 5.2 ± 0.8 | 28.0 ± 3.5 | 96.2 ± 0.7 | 3.8 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, J.-M.; Kim, G.-N.; Koh, Y.-H.; Kim, H.-E. Manufacturing and Characterization of Dental Crowns Made of 5-mol% Yttria Stabilized Zirconia by Digital Light Processing. Materials 2023, 16, 1447. https://doi.org/10.3390/ma16041447

Jung J-M, Kim G-N, Koh Y-H, Kim H-E. Manufacturing and Characterization of Dental Crowns Made of 5-mol% Yttria Stabilized Zirconia by Digital Light Processing. Materials. 2023; 16(4):1447. https://doi.org/10.3390/ma16041447

Chicago/Turabian StyleJung, Jae-Min, Gyu-Nam Kim, Young-Hag Koh, and Hyoun-Ee Kim. 2023. "Manufacturing and Characterization of Dental Crowns Made of 5-mol% Yttria Stabilized Zirconia by Digital Light Processing" Materials 16, no. 4: 1447. https://doi.org/10.3390/ma16041447

APA StyleJung, J.-M., Kim, G.-N., Koh, Y.-H., & Kim, H.-E. (2023). Manufacturing and Characterization of Dental Crowns Made of 5-mol% Yttria Stabilized Zirconia by Digital Light Processing. Materials, 16(4), 1447. https://doi.org/10.3390/ma16041447