Effect of Contents on the Electrical and Piezoelectric Properties of (1 − x)(Bi, Na)TiO3–x(Ba, Sr)TiO3 Lead-Free Piezoelectric Ceramics

Abstract

:1. Introduction

2. Materials and Methods

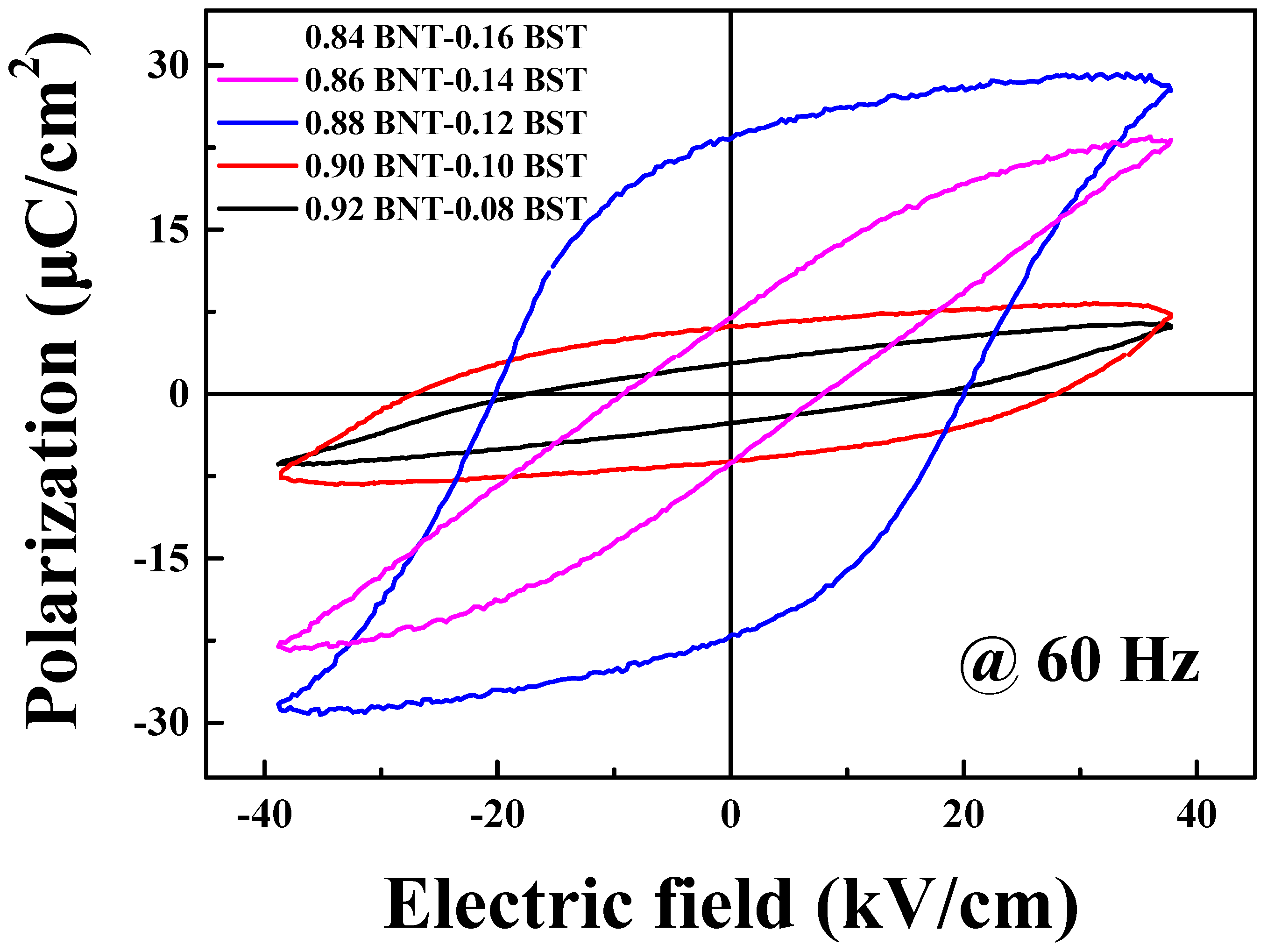

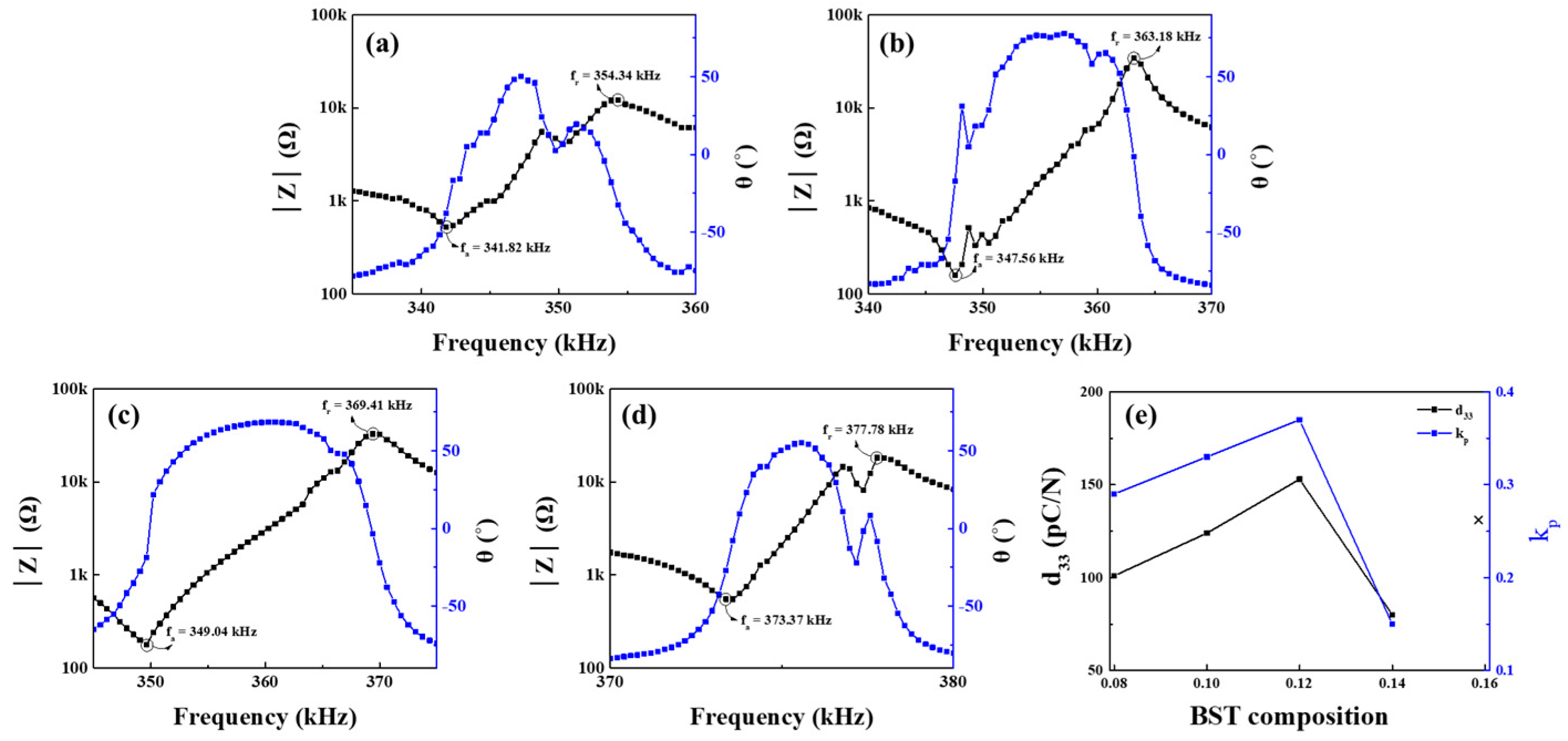

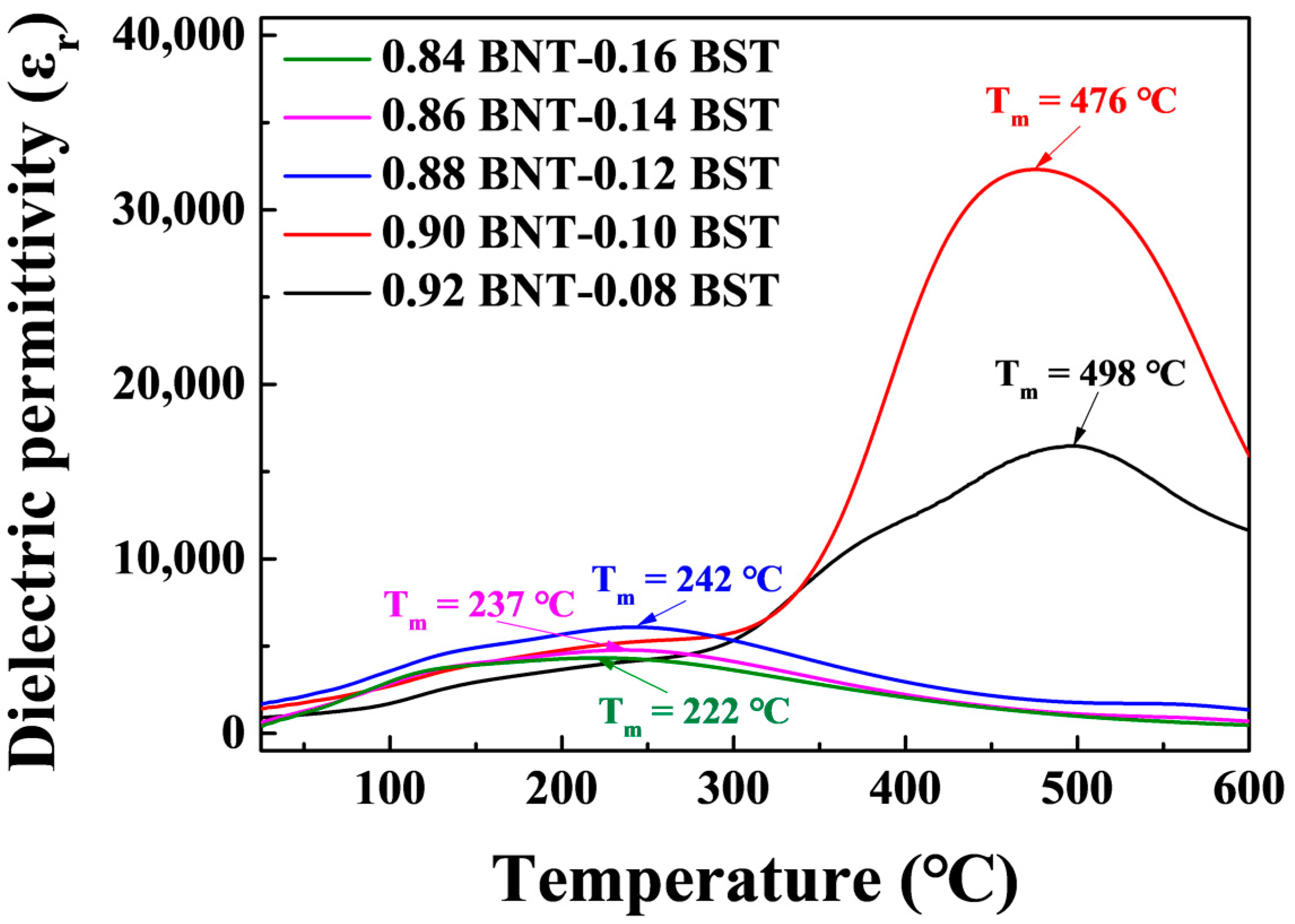

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Xia, R.; Shrout, T.R. Lead-free piezoelectric ceramics vs. PZT? J. Electroceramics 2007, 19, 251–257. [Google Scholar]

- Hooker, M.W. Properties of PZT-Based Piezoelectric Ceramics Between −150 and 250 °C. NASA 1998, 26, 208708. [Google Scholar]

- Panda, P.K.; Sahoo, B. PZT to lead free piezo ceramics: A review. Ferroelectrics 2015, 474, 128–143. [Google Scholar]

- Chu, B.J.; Chen, D.R.; Li, G.R.; Yin, Q.R. Electrical properties of Na1/2Bi1/2TiO3–BaTiO3 ceramics. J. Eur. Ceram. Soc. 2002, 22, 2115–2121. [Google Scholar]

- Yoshii, K.; Hiruma, Y.; Nagata, H.; Takenaka, T. Electrical properties and depolarization temperature of (Bi1/2Na1/2) TiO3–(Bi1/2K1/2) TiO3 lead-free piezoelectric ceramics. Jpn. J. Appl. Phys. 2006, 45, 4493. [Google Scholar]

- Zhao, S.; Li, G.; Ding, A.; Wang, T.; Yin, Q. Ferroelectric and piezoelectric properties of (Na, K)0.5Bi0.5TiO3 lead free ceramics. J. Phys. D Appl. Phys. 2006, 39, 2277. [Google Scholar]

- Takenaka, T.; Maruyama, K.I.M.K.I.; Sakata, K.S.K. (Bi1/2Na1/2)TiO3–BaTiO3 system for lead-free piezoelectric ceramics. Jpn. J. Appl. Phys. 1991, 30, 2236. [Google Scholar] [CrossRef]

- Kwon, Y.H.; Shin, D.J.; Lee, G.H.; Koh, J.H. Sintering temperature dependent piezoelectric properties of (Bi,Na)TiO3–(Ba,Sr) TiO3 ceramics. Ceram. Int. 2016, 42, 10422–10427. [Google Scholar]

- Nguyen, M.D.; Trinh, T.Q.; Dekkers, M.; Houwman, E.P.; Vu, H.N.; Rijnders, G. Effect of dopants on ferroelectric and piezoelectric properties of lead zirconate titanate thin films on Si substrates. Ceram. Int. 2014, 40, 1013–1018. [Google Scholar]

- Lin, D.; Kwok, K.W.; Chan, H.L.W. Structure and electrical properties of Bi0.5Na0.5TiO3–BaTiO3–Bi0.5Li0.5TiO3 lead-free piezoelectric ceramics. Solid State Ion. 2008, 178, 1930–1937. [Google Scholar]

- Wang, X.X.; Tang, X.G.; Chan, H.L.W. Electromechanical and ferroelectric properties of (Bi1∕2Na1∕2) TiO3–(Bi1∕2K1∕2)TiO3–BaTiO3 lead-free piezoelectric ceramics. Appl. Phys. Lett. 2004, 85, 91–93. [Google Scholar]

- Shieh, J.; Wu, K.C.; Chen, C.S. Switching characteristics of MPB compositions of (Bi0.5Na0.5)TiO3–BaTiO3–(Bi0.5K0.5)TiO3 lead-free ferroelectric ceramics. Acta Mater. 2007, 55, 3081–3087. [Google Scholar]

- Makiuchi, Y.; Aoyagi, R.; Hiruma, Y.; Nagata, H.; Takenaka, T. (Bi1/2Na1/2)TiO3–(Bi1/2K1/2)TiO3–BaTiO3-based lead-free piezoelectric ceramics. Jpn. J. Appl. Phys. 2005, 44, 4350. [Google Scholar] [CrossRef]

- Li, Y.; Chen, W.; Xu, Q.; Zhou, J.; Gu, X.; Fang, S. Electromechanical and dielectric properties of Na0.5Bi0.5TiO3–K0.5Bi0.5TiO3–BaTiO3 lead-free ceramics. Mater. Chem. Phys. 2005, 94, 328–332. [Google Scholar] [CrossRef]

- Li, Z.; Li, D.X.; Shen, Z.Y.; Zeng, X.; Song, F.; Luo, W.; Li, Y. Remarkably enhanced dielectric stability and energy storage properties in BNT—BST relaxor ceramics by A-site defect engineering for pulsed power applications. J. Adv. Ceram. 2022, 11, 283–294. [Google Scholar]

- Li, D.; Shen, Z.Y.; Li, Z.; Luo, W.; Wang, X.; Wang, Z.; Li, Y. PE hysteresis loop going slim in Ba0.3Sr0.7TiO3-modified Bi0.5Na0.5TiO3 ceramics for energy storage applications. J. Adv. Ceram. 2020, 9, 183–192. [Google Scholar]

- Li, D.; Shen, Z.Y.; Li, Z.; Wang, X.; Luo, W.Q.; Song, F.; Li, Y. Structural evolution, dielectric and ferroelectric properties of (1 − x)Bi0.5Na0.5TiO3–xBa0.3Sr0.7TiO3 ceramics. J. Mater. Sci. Mater. Electron. 2019, 30, 5917–5922. [Google Scholar]

- Yoshimura, T.; Fujimura, N. Polarization Hysteresis Loops of Ferroelectric Gate Capacitors Measured by Sawyer-Tower Circuit. Jpn. J. Appl. Phys. 2003, 42, 6011–6014. [Google Scholar]

- Zhang, L.; Wang, X.; Yang, W.; Liu, H.; Yao, X. Structure and relaxor behavior of BaTiO3–CaTiO3–SrTiO3 ternary system ceramics. J. Appl. Phys. 2008, 104, 014104. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, X.; Jiang, M.; Zhao, X.; Shan, X.; Li, W.; Zhou, C. Lead-free (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3–CeO2 ceramics with high piezoelectric coefficient obtained by low-temperature sintering. Ceram. Int. 2012, 38, 4761–4764. [Google Scholar] [CrossRef]

- Li, Z.Y.; Lam, W.M.; Yang, C.; Xu, B.; Ni, G.X.; Abbah, S.A.; Cheung, K.M.C.; Luk, K.D.K.; Lu, W.W. Chemical composition, crystal size and lattice structural changes after incorporation of strontium into biomimetic apatite. Biomaterials 2007, 28, 1452–1460. [Google Scholar] [CrossRef]

- Zawrah, M.F. Investigation of lattice constant, sintering and properties of nano Mg–Al spinels. Mater. Sci. Eng. A 2004, 382, 362–370. [Google Scholar] [CrossRef]

- Lee, H.W.; Moon, S.; Choi, C.H.; Kim, D.K. Synthesis and size control of tetragonal barium titanate nanopowders by facile solvothermal method. J. Am. Ceram. Soc. 2012, 95, 2429–2434. [Google Scholar]

- Joshi, U.A.; Yoon, S.; Baik, S.; Lee, J.S. Surfactant-free hydrothermal synthesis of highly tetragonal barium titanate nanowires: A structural investigation. J. Phys. Chem. B 2006, 110, 12249–12256. [Google Scholar] [CrossRef]

- Jiang, J.; Meng, X.; Li, L.; Guo, S.; Huang, M.; Zhang, J.; Zhang, S.T. Ultrahigh energy storage density in lead-free relaxor antiferroelectric ceramics via domain engineering. Energy Storage Mater. 2021, 43, 383–390. [Google Scholar] [CrossRef]

- Boonlakhorn, J.; Thongbai, P. Dielectric properties, nonlinear electrical response and microstructural evolution of CaCu3Ti4-xSnxO12 ceramics prepared by a double ball-milling process. Ceram. Int. 2020, 46, 4952–4958. [Google Scholar]

- Thongbai, P.; Yamwong, T.; Maensiri, S.; Amornkitbamrung, V.; Chindaprasirt, P. Improved dielectric and nonlinear electrical properties of fine-grained CaCu3Ti4O12 ceramics prepared by a glycine-nitrate process. J. Am. Ceram. Soc. 2014, 97, 1785–1790. [Google Scholar]

- Jain, A.; Panwar, A.K.; Saroha, R.; Jha, A.K. Enhanced structural, dielectric, ferroelectric, and piezoelectric properties of (1 − x) Ba0.9Sr0.1TiO3–(x)Ba0.7Ca0.3TiO3 ceramics derived using mechano-chemical activation technique. J. Am. Ceram. Soc. 2017, 100, 5239–5248. [Google Scholar]

- Qi, W.; Cao, J.; Li, Z.; Wang, Y. Effect of Sr doping on the energy storage properties of BNT–BST–KNN anti-ferroelectric ceramics. Ferroelectrics 2021, 577, 229–235. [Google Scholar] [CrossRef]

- Henaish, A.M.; Mostafa, M.; Weinstein, I.; Hemeda, O.; Salem, B. Ferroelectric and Dielectric Properties of Strontium Titanate Doped with Barium. Magnetism 2021, 1, 22–36. [Google Scholar]

- Lee, J.S.; Yoon, S.; Lim, J.H.; Park, C.K.; Ryu, J.; Jeong, D.Y. Improvement of Energy Storage Characteristics of (Ba0.7Ca0.3)TiO3 Thick Films by the Increase of Electric Breakdown Strength from Nano-Sized Grains. Korean J. Mater. Res. 2019, 29, 73–78. [Google Scholar] [CrossRef]

- Erhart, J.; Sebastian, T. Effective electromechanical coupling for the partially electroded ceramic resonators different geometries. Ann. “Dunarea Jos” Univ. Fascicle IX Metall. Mater. Sci. 2015, 38, 7–16. [Google Scholar]

- Yamashita, Y.; Harada, K.; Hosono, Y.; Natsume, S.; Ichinose, N. Effects of B-site ions on the electromechanical coupling factors of Pb(B’B”)O3–PbTiO3 piezoelectric materials. Jpn. J. Appl. Phys. 1998, 37, 5288. [Google Scholar]

- Chen, F.; Kong, L.; Song, W.; Jiang, C.; Tian, S.; Yu, F.; Zhao, X. The electromechanical features of LiNbO3 crystal for potential high temperature piezoelectric applications. J. Mater. 2019, 5, 73–80. [Google Scholar] [CrossRef]

- Meng, X.; Chen, Q.; Fu, H.; Liu, H.; Zhu, J. Influence of PNN on the structure and electronic properties of BSPT ceramics. J. Mater. Sci. Mater. Electron. 2018, 29, 12785–12794. [Google Scholar]

- Wang, Y.; Cao, J.; Li, Z. Effects of co-doping of Sr element and KNN group on the dielectric properties of BNT-BT ceramics. Ferroelectrics 2021, 573, 166–172. [Google Scholar] [CrossRef]

- Wu, R.; Huang, L.; Jin, L.; Gao, R.; Bai, L.; Xu, Z. Microstructure, dielectric and ferroelectric properties of (1 − x)Bi0.5Na0.5TiO3–x (0.8Ba0.9Sr0.1TiO3–0.2BiFeO3) lead-free ceramics. J. Mater. Sci. Mater. Electron. 2022, 33, 25404–25418. [Google Scholar] [CrossRef]

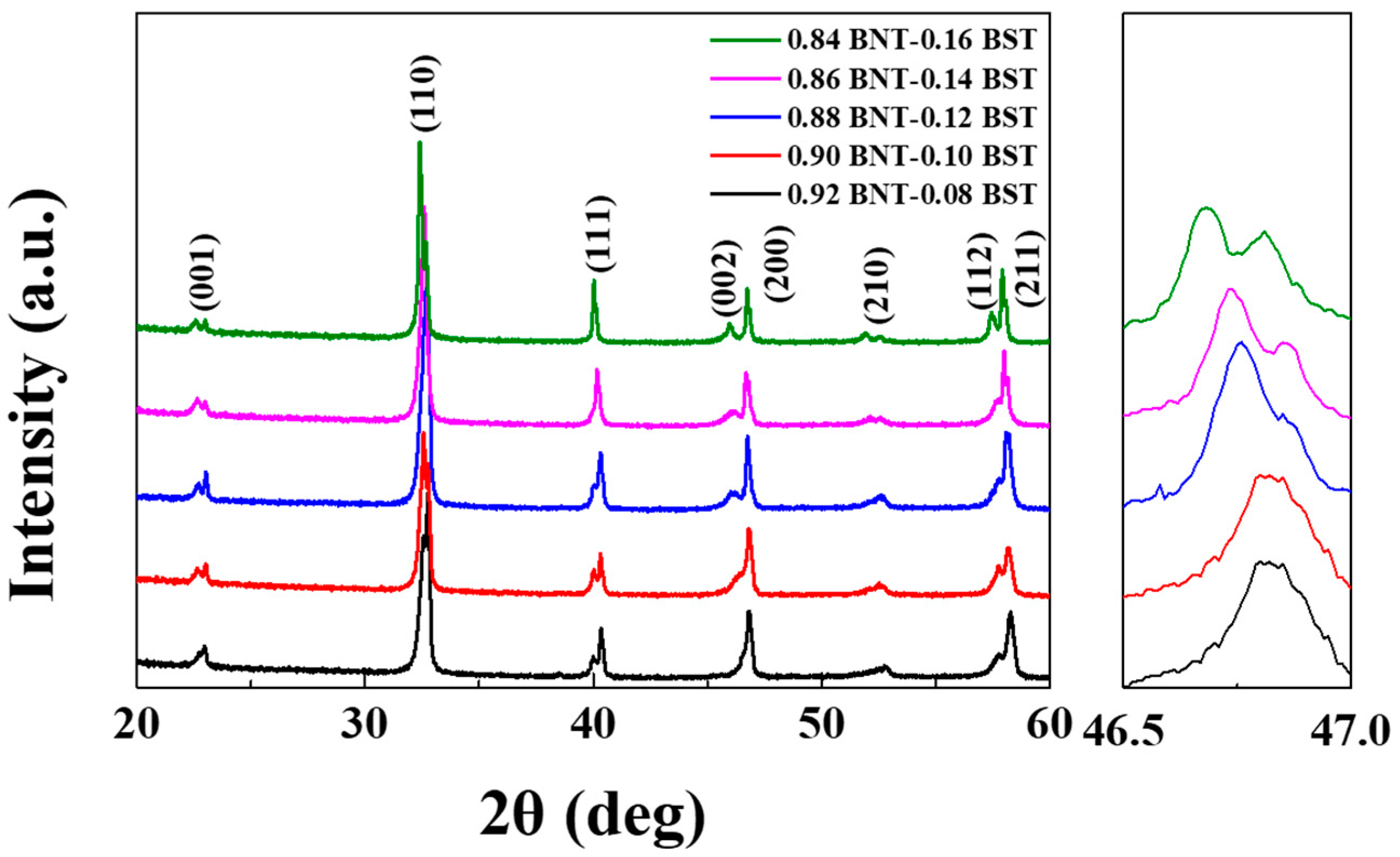

| 0.08 BST | 0.10 BST | 0.12 BST | 0.14 BST | 0.16 BST | ||

|---|---|---|---|---|---|---|

| Crystal Structure | Rhombohedral | Rhombohedral | Tetragonal | Tetragonal | Tetragonal | |

| length | a | 3.879 Å | 3.879 Å | 3.875 Å | 3.880 Å | 3.886 Å |

| c | 3.882 Å | 3.8789 Å | 3.8758 Å | |||

| Angle | α | 90.2543° | 90.067° | 90° | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.-M.; Kim, T.W.; Kim, N.-H.; Kim, S.-J.; Koh, J.-H. Effect of Contents on the Electrical and Piezoelectric Properties of (1 − x)(Bi, Na)TiO3–x(Ba, Sr)TiO3 Lead-Free Piezoelectric Ceramics. Materials 2023, 16, 1469. https://doi.org/10.3390/ma16041469

Kang S-M, Kim TW, Kim N-H, Kim S-J, Koh J-H. Effect of Contents on the Electrical and Piezoelectric Properties of (1 − x)(Bi, Na)TiO3–x(Ba, Sr)TiO3 Lead-Free Piezoelectric Ceramics. Materials. 2023; 16(4):1469. https://doi.org/10.3390/ma16041469

Chicago/Turabian StyleKang, Seok-Mo, Tae Wan Kim, Nam-Hoon Kim, Sung-Jin Kim, and Jung-Hyuk Koh. 2023. "Effect of Contents on the Electrical and Piezoelectric Properties of (1 − x)(Bi, Na)TiO3–x(Ba, Sr)TiO3 Lead-Free Piezoelectric Ceramics" Materials 16, no. 4: 1469. https://doi.org/10.3390/ma16041469

APA StyleKang, S.-M., Kim, T. W., Kim, N.-H., Kim, S.-J., & Koh, J.-H. (2023). Effect of Contents on the Electrical and Piezoelectric Properties of (1 − x)(Bi, Na)TiO3–x(Ba, Sr)TiO3 Lead-Free Piezoelectric Ceramics. Materials, 16(4), 1469. https://doi.org/10.3390/ma16041469