Behavior Under Repeated Loading of RC Beams Externally Strengthened in Flexure with SRG Systems

Abstract

:1. Introduction

2. Experimental Program

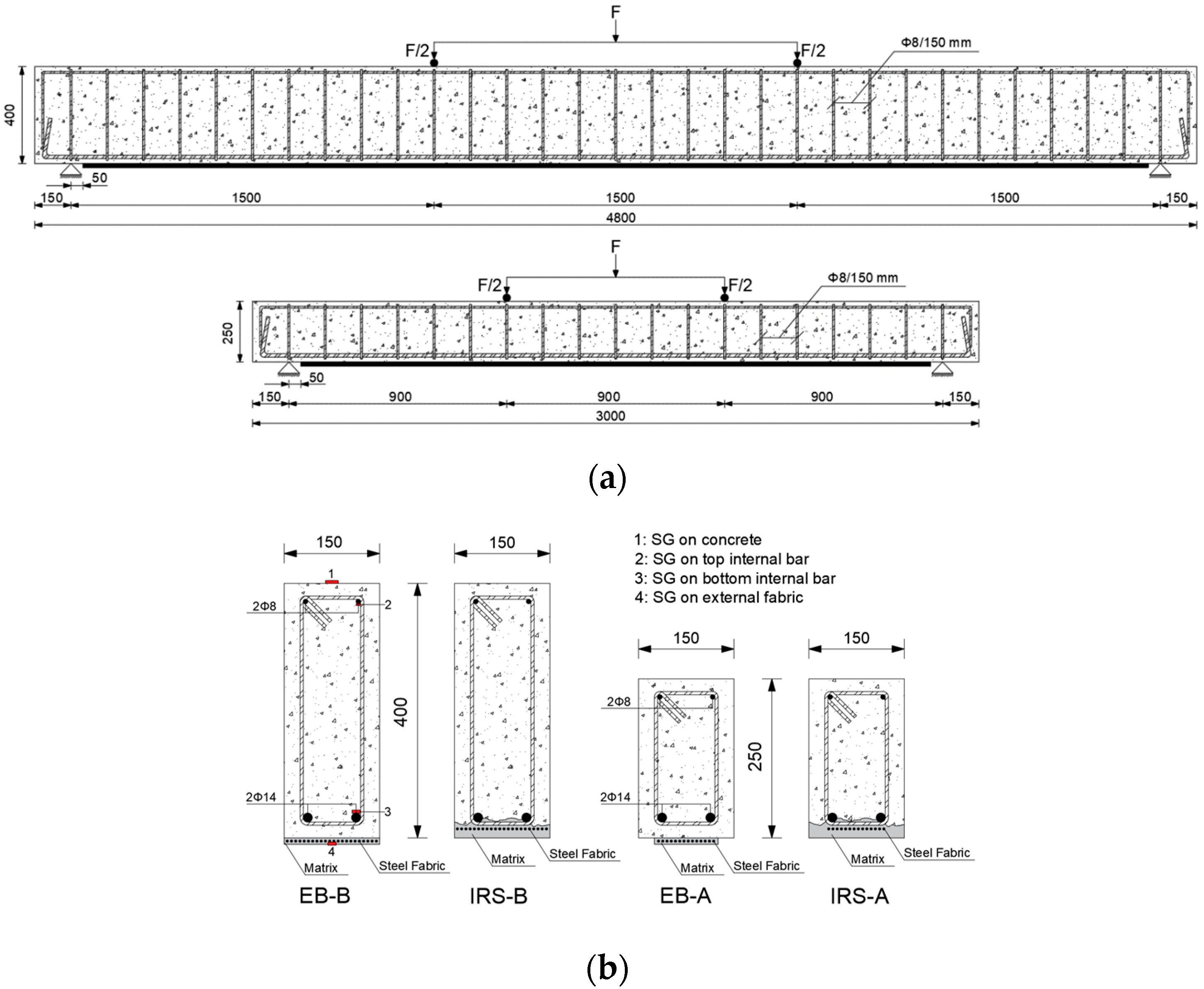

2.1. Geometries and Schedule of Tests

2.2. Concrete and Internal Steel Bars’ Properties

2.3. Steel-Reinforced Grout (SRG) Properties

2.4. Surface Preparation and Strengthening Operations

2.4.1. Traditional Externally Bonded (EB) Technique

- Preparation of the external surface (Figure 3a,b).

- Installation of the external strengthening:

- (a)

- Application of the first layer (upper layer) of the matrix with a suitable average thickness (thickness of 5 mm).

- (b)

- Application of steel strip reinforcement over the first layer of the wet matrix, ensuring the full impregnation of the steel fiber by pressing with a metal trowel (Figure 3g).

- (c)

- Application of the second layer (bottom layer) of the inorganic matrix (thickness of 5 mm).

2.4.2. Inhibiting-Repairing-Strengthening (IRS) Technique

- Preparation of the external surface (Figure 3c,d).

- Installation of the external strengthening:

- (a)

- Application of the first layer (upper layer) of the inorganic matrix (thickness of 20–30 mm).

- (b)

- Application of steel strip reinforcement over the first layer of the wet matrix, ensuring the full impregnation of the steel fiber by pressing with a metal trowel (Figure 3f).

- (c)

- Application of the second layer (bottom layer) of the inorganic matrix (thickness of 5–10 mm).

2.5. Test Setup and Loading Procedure

3. Test Results and Discussion

3.1. Structural Behavior

3.2. Midspan Deflection Curves and Recorded Strains

3.3. Failure Modes and Crack Patterns

4. Conclusions

- -

- The results of the experimental tests highlighted greater effectiveness of the SRG system with low mass per unit of area (GLV steel strip) in the response of the specimens under repeated loading. The high penetration capacity of the cementitious matrix produces a strong and improved bond. The quality of the bond leads to the failure mode. Both strengthening techniques (EB and IRS) provide similar structural behavior.

- -

- Using a high mass per unit of steel fiber area (SS steel strip), to prevent any damage in the strengthening composite, great attention is required in restoring the RC beams before applying the external strengthening system. In this case, the IRS technique has been confirmed to be a significantly more effective technique in strengthening, also showing greater ductility than the EB technique. The IRS technique allows a better fibers/matrix bond.

- -

- The beams strengthened with the EB/SRG system showed higher flexural capacity than the unstrengthened beams under monotonic loading. On the other hand, the experimental results point out the severe bond degradation of the beams strengthened with stainless steel fiber and subjected to repeated loading.

- -

- The IRS/SRG system response was more ductile (with a deflection ratio that ranges from 3.17 to 4.33) and more effective in terms of failure load (percentual increments range between 19.08% and 27.06%) and exploitation of all materials.

- -

- In general, for all strengthened specimens, an increase in load capacity and a decrease in ductility in terms of displacements and curvatures were found compared to the unstrengthened specimens.

- -

- The ductility index, defined as the ratio between the ultimate displacement and the displacement at the end of the elastic phase, is almost equal in the GLV-strengthened beams and in all specimens strengthened using the IRS technique.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Signorini, C.; Nobili, A. Comparing durability of steel reinforced grout (SRG) and textile reinforced mortar (TRM) for structural retrofitting. Mater. Struct. 2021, 54, 131. [Google Scholar] [CrossRef]

- Donnini, J. Durability of Glass FRCM Systems: Effects of Different Environments on Mechanical Properties. Compos. Part B 2019, 174, 107047. [Google Scholar] [CrossRef]

- Calabrese, A.; D’Antino, T.; Colombi, P.; Poggi, C. Long-Term Behavior of PBO FRCM and Comparison with Other Inorganic-Matrix Composites. Materials 2022, 15, 3281. [Google Scholar] [CrossRef] [PubMed]

- Fares, S.; Fugger, R.; De Santis, S.; de Felice, G. Strength, bond and durability of stainless steel reinforced grout. Constr. Build. Mater. 2022, 322, 126465. [Google Scholar] [CrossRef]

- Fares, S.; Fugger, R.; De Santis, S.; de Felice, G. Durability of Stainless-Steel Reinforced Grout against Salt Attack. Key Eng. Mater. 2022, 916, 43–49. [Google Scholar] [CrossRef]

- Napoli, A.; Realfonzo, R. Reinforced concrete beams strengthened with SRP/SRG systems: Experimental investigation. Constr. Build. Mater. 2015, 93, 654–677. [Google Scholar] [CrossRef]

- Larbi, A.S.; Agbossou, A.; Hamelin, P. Experimental and numerical investigations about textile-reinforced concrete and hybrid solutions for repairing and/or strengthening reinforced concrete beams. Compos. Struct. 2013, 99, 152–162. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Flexural strengthening of RC beams using textile reinforced mortar—Experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- Petrou, M.F.; Perdikaris, P.C.; Wang, A. Fatigue behavior of noncomposite reinforced concrete bridge deck models. In Transportation Research Record; Transportation Research Board: Washington, DC, USA, 1994; pp. 73–80. [Google Scholar]

- Rezansoff, T.; Zacaruk, J.A.; Afseth, J.G. High cycle (fatigue) resistance of reinforced concrete beams with lap splices. Can. J. Civ. Eng. 1993, 20, 642–649. [Google Scholar] [CrossRef]

- Katakalos, K.; Papakonstantinou, C.G. Fatigue of Reinforced Concrete Beams Strengthened with Steel-Reinforced Inorganic Polymers. J. Compos. Constr. 2009, 13, 103–112. [Google Scholar] [CrossRef]

- Barnes, R.A.; Mays, G.C. Fatigue performance of concrete beams strengthened with CFRP plates. J. Compos. Constr. 1999, 3, 63–72. [Google Scholar] [CrossRef]

- Brena, S.F.; Benouaich, M.A.; Kreger, M.E.; Wood, S.L. Fatigue tests of reinforced concrete beams strengthened using carbon fiber-reinforced polymer composites. ACI Struct. J. 2005, 102, 305–313. [Google Scholar]

- Ekenel, M.; Rizzo, A.; Myers, J.J.; Nanni, A. Flexural fatigue behavior of reinforced concrete beams strengthened with FRP fabric and precured laminate systems. J. Compos. Constr. 2006, 10, 433–442. [Google Scholar] [CrossRef]

- Shahawy, M.; Beitelman, T.E. Static and fatigue performance of RC beams strengthened with CFRP laminates. J. Struct. Eng. 1999, 125, 613–621. [Google Scholar] [CrossRef]

- Quattlebaum, J.B.; Harries, K.A.; Petrou, M.F. Comparison of three flexural retrofit systems under monotonic and fatigue loads. J. Bridge Eng. 2005, 10, 731–740. [Google Scholar] [CrossRef]

- Reboul, N.; Mesticou, Z.; Larbi, A.S.; Ferrier, E. Experimental study of the in-plane cyclic behaviour of masonry walls strengthened by composite materials. Constr. Build. Mater. 2018, 164, 70–83. [Google Scholar] [CrossRef]

- Yacila, J.; Salsavilca, J.; Tarque, N.; Camata, G. Experimental assessment of confined masonry walls retrofitted with SRG under lateral cyclic loads. Eng. Struct. 2019, 199, 109555. [Google Scholar] [CrossRef]

- Capani, F.; D’Ambrisi, A.; De Stefano, M.; Focacci, F.; Luciano, R.; Nudo, R.; Penna, R. Experimental investigation on cyclic response of RC elements repaired by CFRP external reinforcing systems. Compos. Part B Eng. 2017, 112, 290–299. [Google Scholar] [CrossRef]

- Golias, E.; Zapris, A.G.; Kytinou, V.K.; Osman, M.; Koumtzis, M.; Siapera, D.; Chalioris, C.E.; Karayannis, C.G. Application of X-Shaped CFRP Ropes for Structural Upgrading of Reinforced Concrete Beam–Column Joints under Cyclic Loading–Experimental Study. Fibers 2021, 9, 42. [Google Scholar] [CrossRef]

- Faleschini, F.; Gonzalez-Libreros, J.; Zanini, M.A.; Hofer, L.; Sneed, L.; Pellegrino, C. Repair of severely-damaged RC exterior beam-column joints with FRP and FRCM composites. Compos. Struct. 2019, 207, 352–363. [Google Scholar] [CrossRef]

- Messori, M.; Nobili, A.; Signorini, C.; Sola, A. Effect of high temperature exposure on epoxy-coated glass textile reinforced mortar (GTRM) composites. Constr Build Mater. 2019, 212, 765–774. [Google Scholar] [CrossRef]

- Calabrese, A.; D’Antino, T.; Poggi, C.; Colombi, P.; Fava, G.; Pisani, M. Application of Externally Bonded Inorganic-Matrix Composites to Existing Masonry Structures. In Buildings for Education: A Multidisciplinary Overview of The Design of School Buildings; Della Torre, S., Bocciarelli, M., Daglio, L., Neri, R., Eds.; Research for Development; Springer International Publishing: Cham, Switzerland, 2020; pp. 283–292. [Google Scholar]

- Huang, X.; Birman, V.; Nanni, A.; Tunis, G. Properties and potential for application of steel reinforced polymer and steel reinforced grout composites. Compos B Eng. 2005, 36, 73–82. [Google Scholar] [CrossRef]

- Wobbe, E.; Silva, P.; Barton, B.L.; Dharani, L.R.; Birman, V.; Nanni, A.; Alkhrdaji, T.; Thomas, J.; Tunis, T. Flexural capacity of RC beams externally bonded with SRP and SRG. In Proceedings of the International SAMPE Technical Conference, Long Beach, CA, USA, 16–20 May 2004; pp. 3009–3016. [Google Scholar]

- Da Porto, F.; Stivanin, E.; Gabim, E.; Valluzzi, M.R. SRG applications for structural strengthening of R beams. ACI Spec. Pub. 2012, 286, 119–132. [Google Scholar]

- Thermou, G.E.; Hajirasouliha, I. Compressive behavior of concrete columns confined with steel reinforced grout jackets. Compos. Part B Eng. 2018, 184, 56–65. [Google Scholar]

- Ombres, L.; Verre, S. Shear strengthening of reinforced concrete beams with SRG (Steel Reinforced Grout) composites: Experimental investigation and modelling. J. Build. Eng. 2021, 42, 103047. [Google Scholar] [CrossRef]

- ST5-0218. Kimia S.p.A. Available online: www.kimia.it (accessed on 20 June 2020).

- ST6-0820. Kimia S.p.A. Available online: www.kimia.it (accessed on 20 June 2020).

- ST6-0319. Kimia S.p.A. Available online: www.kimia.it (accessed on 20 June 2020).

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. Part B Eng. 2013, 45, 1667–1676. [Google Scholar] [CrossRef]

- Bencardino, F.; Condello, A. Eco-friendly external strengthening system for existing reinforced concrete beams. Compos. Part B: Eng. 2016, 93, 163–173. [Google Scholar] [CrossRef]

- UNI EN 12190:2000; Product and System for the Protection and Repair Concrete Structures—Test Methods—Determination of Compressive Strength of Repair Mortar. Comite Europeen de Normalisation: Brussels, Belgium, 2000.

- Bencardino, F.; Condello, A. Innovative solution to retrofit RC members: Inhibiting-Repairing-Strengthening (IRS). Constr. Build. Mater. 2016, 117, 171–181. [Google Scholar] [CrossRef]

- EN 1992-1-1:2004:E; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Union: Maastricht, The Netherlands, 1992.

- ACI 549.4R-20; Guide to Design and Construction of Externally Bonded Fabric-Reinforced and Steel-Reinforced Grout Systems 583 for Repair and Strengthening of Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2013.

| Group ID | L (mm) | l (mm) | h (mm) | d (mm) | l/h | a (mm) | a/d |

|---|---|---|---|---|---|---|---|

| A | 3000 | 2700 | 250 | 218 | 12 | 900 | 4.1 |

| B | 4800 | 4500 | 400 | 368 | 1500 |

| fcm (MPa) | fctm (MPa) | fym (MPa) | ftm (MPa) | ||

|---|---|---|---|---|---|

| Concrete | 28 days | 33.45 (0.108) | 3.76 (0.119) | - | - |

| day of tests | 34.81 (0.095) | 2.54 (0.107) | - | - | |

| Internal steel bars | Φ8 | - | - | 510.57 (0.013) | 595.57 (0.006) |

| Φ14 | - | - | 501.20 (0.005) | 606.60 (0.005) | |

| Steel Fiber | Af,str (mm2) | s (cords/cm) | ωf (g/m2) | tf (mm) |

|---|---|---|---|---|

| Stainless steel (SS) | 0.470 | 1.57 | 2200 | 0.235 |

| Galvanized steel (GLV) | 0.519 | 5.20 | 650 | 0.083 |

| fcmm (MPa) | ftmm (MPa) | Em (MPa) |

|---|---|---|

| 43.67 | 5.77 | 13,607.84 |

| Trave | ρf | Fcr (kN) | Fsy (kN) | Fu (kN) | δcr (mm) | δsy (mm) | δu (mm) | ΔF | μδ | Δμ | Failure Mode |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CB_A | - | 16.71 | 68.38 | 70.20 | 1.22 | 14.30 | 98.11 | - | 6.86 | - | CC |

| M/EB_SS_A | 0.00076 | 13.40 | 70.20 | 83.70 | 0.99 | 13.38 | 25.85 | 1.19 | 1.93 | 0.28 | ID |

| IRS_SS_A | 0.00076 | - | 56.70 | 83.60 | - | 10.24 | 44.37 | 1.19 | 4.33 | 0.63 | ID |

| EB_GLV_A | 0.00026 | - | 51.70 | 75.70 | - | 8.49 | 26.89 | 1.08 | 3.17 | 0.46 | SR |

| IRS_GLV_A | 0.00026 | - | 56.20 | 75.50 | - | 10.85 | 35.21 | 1.08 | 3.24 | 0.47 | SR |

| CB_B | - | 24.95 | 67.18 | 70.83 | 1.91 | 19.62 | 123.75 | - | 6.31 | - | CC |

| M/EB_SS_B | 0.00067 | 16.80 | 77.20 | 93.00 | 1.94 | 25.22 | 68.76 | 1.31 | 2.73 | 0.43 | ID |

| EB_SS_B | 0.00067 | - | 50.70 | 77.40 | - | 11.92 | 22.98 | 1.09 | 1.93 | 0.31 | ID |

| IRS_SS_B | 0.00067 | - | 64.10 | 90.00 | - | 15.83 | 62.18 | 1.27 | 3.93 | 0.62 | ID |

| EB_GLV_B | 0.00023 | - | 63.20 | 78.30 | - | 16.35 | 37.10 | 1.11 | 2.27 | 0.36 | SR |

| IRS_GLV_B | 0.00023 | - | 59.80 | 77.70 | - | 16.63 | 55.68 | 1.10 | 3.35 | 0.53 | SR |

| Beam ID | εc | ε′s | εs | εf |

|---|---|---|---|---|

| M/EB_SS_A | 0.00255 | 0.00108 | 0.00724 | 0.00621 |

| IRS_SS_A | 0.00218 | 0.00110 | 0.00724 | 0.00855 |

| EB_GLV_A | 0.00234 | 0.00115 | 0.00773 | 0.00701 |

| IRS_GLV_A | 0.00324 | 0.00198 | 0.0133 | 0.0113 |

| M/EB_SS_B | 0.00181 | 0.000791 | 0.00531 | 0.00833 |

| EB_SS_B | 0.000798 | 0.000520 | 0.00246 | 0.00286 |

| IRS_SS_B | 0.00130 | 0.000740 | 0.00806 | 0.00775 |

| EB_GLV_B | 0.00135 | 0.00069 | 0.00392 | 0.00710 |

| IRS_GLV_B | 0.00209 | 0.00106 | 0.0100 | 0.0107 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bencardino, F.; Nisticò, M. Behavior Under Repeated Loading of RC Beams Externally Strengthened in Flexure with SRG Systems. Materials 2023, 16, 1510. https://doi.org/10.3390/ma16041510

Bencardino F, Nisticò M. Behavior Under Repeated Loading of RC Beams Externally Strengthened in Flexure with SRG Systems. Materials. 2023; 16(4):1510. https://doi.org/10.3390/ma16041510

Chicago/Turabian StyleBencardino, Francesco, and Mattia Nisticò. 2023. "Behavior Under Repeated Loading of RC Beams Externally Strengthened in Flexure with SRG Systems" Materials 16, no. 4: 1510. https://doi.org/10.3390/ma16041510

APA StyleBencardino, F., & Nisticò, M. (2023). Behavior Under Repeated Loading of RC Beams Externally Strengthened in Flexure with SRG Systems. Materials, 16(4), 1510. https://doi.org/10.3390/ma16041510