Influence of Nd Substitution on the Phase Constitution in (Zr,Ce)Fe10Si2 Alloys with the ThMn12 Structure

Abstract

:1. Introduction

2. Methods

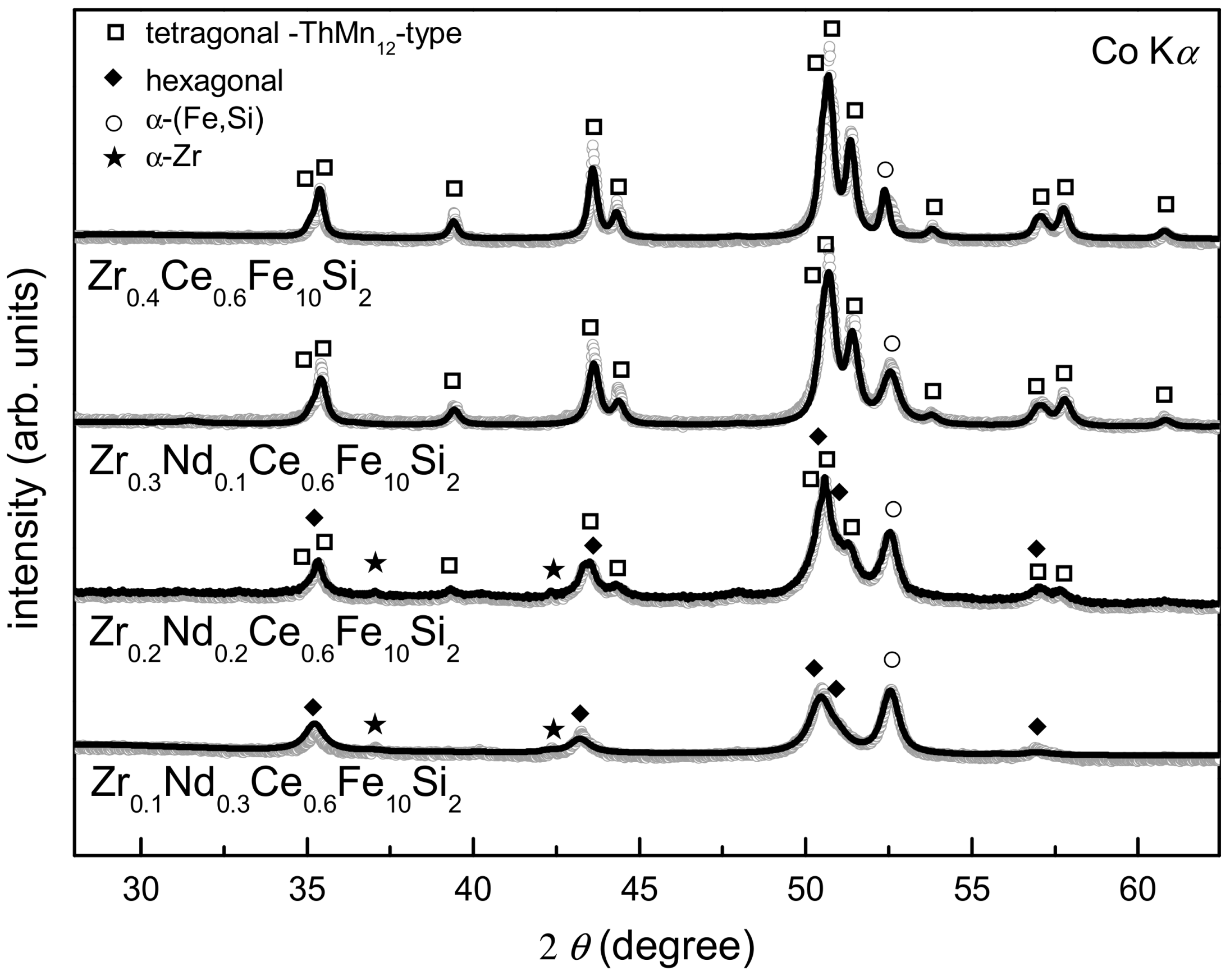

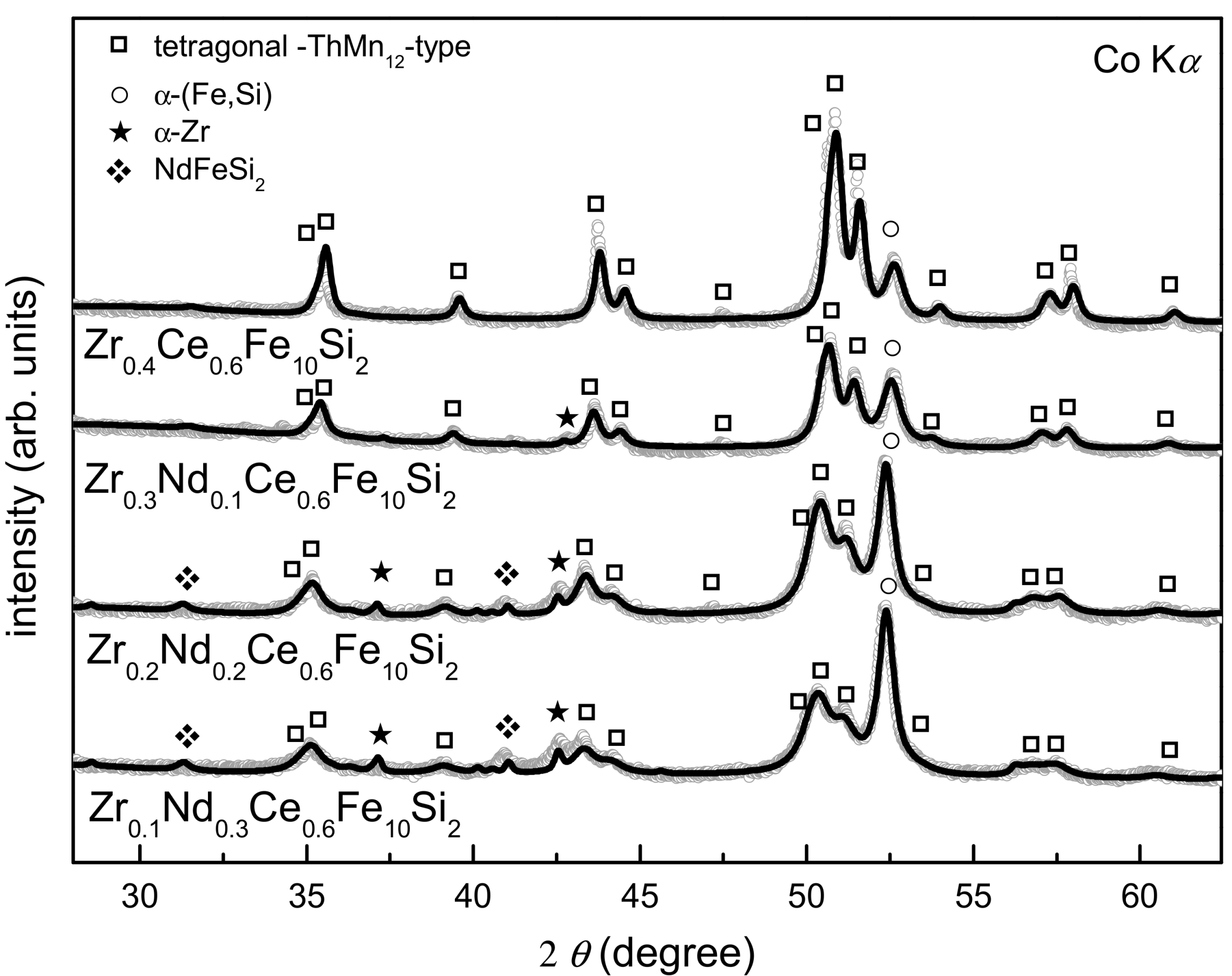

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pflüger, J.; Heinen, W.; Gudat, W. On the thermal stability of the SmCo5 magnet structure for the BESSY undulator. Nucl. Instrum. Methods Phys. Res. Sect. B Accel. Spectrom. Detect. Assoc. Equip. 1987, 262, 528–533. [Google Scholar] [CrossRef]

- Sagawa, M.; Fujimura, S.; Togawa, N.; Yamamoto, H.; Matsuura, Y. New material for permanent magnets on a base of Nd and Fe (invited). J. Appl. Phys. 1984, 55, 2083–2087. [Google Scholar] [CrossRef]

- Sagawa, M.; Fujimura, S.; Yamamoto, H.; Matsuura, Y.; Hiraga, K. Permanent magnet materials based on the rare earth-iron-boron tetragonal compounds. IEEE Trans. Magn. 1984, 20, 1584–1589. [Google Scholar] [CrossRef]

- Kumar, K. RETM5 and RE2TM17 permanent magnets development. J. Appl. Phys. 1988, 63, R13–R57. [Google Scholar] [CrossRef]

- Iriyama, T.; Kobayashi, K.; Imaoka, N.; Fukuda, T.; Kato, H.; Nakagawa, Y. Effect of nitrogen content on magnetic properties of Sm2Fe17Nx (0 < x < 6). IEEE Trans. Magn. 1992, 28, 2326–2331. [Google Scholar] [CrossRef]

- Coey, J.M.D. Permanent magnet applications. J. Magn. Magn. Mater. 2002, 248, 441–456. [Google Scholar] [CrossRef]

- Hirosawa, S.; Nishino, M.; Miyashita, S. Perspectives for high-performance permanent magnets: Applications, coercivity, and new materials. Adv. Nat. Sci. Nanosci. Nanotechnol. 2017, 8, 013002. [Google Scholar] [CrossRef]

- Takahashi, Y.; Sepehri-Amin, H.; Ohkubo, T. Recent advances in SmFe12-based permanent magnets. Sci. Technol. Adv. Mater. 2021, 22, 449–460. [Google Scholar] [CrossRef]

- Skomski, R.; Manchanda, P.; Kumar, P.; Balasubramanian, B.; Kashyap, A.; Sellmyer, D. Predicting the Future of Permanent-Magnet Materials. Trans. Magn. 2013, 49, 3215. [Google Scholar] [CrossRef]

- Paulevé, J.; Chamberod, A.; Krebs, K.; Bourret, A. Magnetization Curves of Fe–Ni (50–50) Single Crystals Ordered by Neutron Irradiation with an Applied Magnetic Field. J. Appl. Phys. 1968, 39, 989–990. [Google Scholar] [CrossRef]

- Lewis, L.H.; Mubarok, A.; Poirier, E.; Bordeaux, N.; Manchanda, P.; Kashyap, A.; Skomski, R.; Goldstein, J.; Pinkerton, F.E.; Mishra, R.K. Inspired by nature: Investigating tetrataenite for permanent magnet applications. J. Phys. Condens. Matter 2014, 26, 064213. [Google Scholar] [CrossRef]

- Solzi, M.; Pareti, L.; Moze, O.; David, W.I.F. Magnetic anisotropy and crystal structure of intermetallic compounds of the ThMn12 structure. J. Appl. Phys. 1988, 64, 5084–5087. [Google Scholar] [CrossRef]

- Coey, J.M.D. Permanent magnets: Plugging the gap. Scr. Mater. 2012, 67, 524–529. [Google Scholar] [CrossRef]

- Harashima, Y.; Fukazawa, T.; Kino, H.; Miyake, T. Effect of R-site substitution and the pressure on stability of RFe12: A first-principles study. J. Appl. Phys. 2018, 124, 163902. [Google Scholar] [CrossRef]

- Schultz, L.; Schnitzke, K.; Wecker, J. High coercivity in mechanically alloyed Sm-Fe-V magnets with a ThMn12 crystal structure. Appl. Phys. Lett. 1990, 56, 868–870. [Google Scholar] [CrossRef]

- Buschow, K.H.J. Permanent magnet materials based on tetragonal rare earth compounds of the type RFe12−xMx. J. Magn. Magn. Mater. 1991, 100, 79–89. [Google Scholar] [CrossRef]

- Fu, J.B.; Yu, X.; Qi, Z.Q.; Yang, W.Y.; Liu, S.Q.; Wang, C.S.; Du, H.L.; Han, J.Z.; Yang, Y.C.; Yang, J.B. Magnetic properties of Nd(Fe1-xCox)10.5M1.5 (M = Mo and V) and their nitrides. AIP Adv. 2016, 7, 056202. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C. Recent developments in RFe12-type compounds for permanent magnets. Scr. Mater. 2018, 154, 284–288. [Google Scholar] [CrossRef]

- Isnard, O.; Guillot, M.; Miraglia, S.; Fruchart, D. High field magnetization measurements of SmFe11Ti and SmFe11TiH1−δ. J. Appl. Phys. 1996, 79, 5542. [Google Scholar] [CrossRef]

- Kuno, T.; Suzuki, S.; Urushibata, K.; Kobayashi, K.; Sakuma, N.; Yano, M.; Kato, A.; Manabe, A. (Sm,Zr)(Fe,Co)11.0-11.5Ti1.0-0.5 compounds as new permanent magnet materials. AIP Adv. 2016, 6, 025221. [Google Scholar] [CrossRef] [Green Version]

- Ener, S.; Skokov, K.P.; Palanisamy, D.; Devillers, T.; Fischbacher, J.; Eslava, G.G.; Maccari, F.; Schäfer, L.; Diop, L.V.B.; Radulov, I.; et al. Twins—A weak link in the magnetic hardening of ThMn12-type permanent magnets. Acta Mater. 2021, 214, 116968. [Google Scholar] [CrossRef]

- Matsumoto, M.; Hawai, T.; Ono, K. (Sm,Zr)Fe12−xMx (M = Zr, Ti, Co) for Permanent-Magnet Applications: Ab Initio Material Design Integrated with Experimental Characterization. Phys. Rev. Appl. 2020, 13, 064028. [Google Scholar] [CrossRef]

- Landa, A.; Söderlind, P.; Moore, E.E.; Perron, A. Thermodynamics and Magnetism of SmFe12 Compound Doped with Co and Ni: An Ab Initio Study. Appl. Sci. 2022, 12, 4860. [Google Scholar] [CrossRef]

- Fukazawa, T.; Harashima, Y.; Miyake, T. First-principles study on the stability of (R, Zr)(Fe, Co, Ti)12 against 2-17 and unary phases (R = Y, Nd, Sm). Phys. Rev. Mater. 2022, 6, 054404. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C. Mechanochemical synthesis of magnetically hard anisotropic RFe10Si2 powders with R representing combinations of Sm, Ce and Zr. J. Magn. Magn. Mater. 2017, 422, 43–48. [Google Scholar] [CrossRef]

- Zhou, C.; Pinkerton, F.E. Magnetic hardening of CeFe12−xMox and the effect of nitrogenation. J. Alloys Compd. 2013, 583, 345–350. [Google Scholar] [CrossRef]

- Bhandari, C.; Paudyal, D. Enhancing stability and magnetism of ThMn12-type cerium-iron intermetallics by site substitution. Phys. Rev. Res. 2022, 4, 023012. [Google Scholar] [CrossRef]

- Snarski-Adamski, J.; Werwiński, M. Effect of transition metal doping on magnetic hardness of CeFe12-based compounds. J. Magn. Magn. Mater. 2022, 554, 169309. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C. ThMn12-type structure and uniaxial magnetic anisotropy in ZrFe10Si2 and Zr1−xCexFe10Si2 alloys. J. Alloys Compd. 2016, 657, 133–137. [Google Scholar] [CrossRef]

- Barandiaran, J.M.; Martin-Cid, A.; Schönhöbel, A.M.; Garitaonandia, J.S.; Gjoka, M.; Niarchos, D.; Makridis, S.; Pasko, A.; Aubert, A.; Mazaleyrat, F.; et al. Nitrogenation and sintering of (Nd-Zr)Fe10Si2 tetragonal compounds for permanent magnets applications. J. Alloys Compd. 2019, 784, 996–1002. [Google Scholar] [CrossRef] [Green Version]

- Gjoka, M.; Sarafidis, C.; Giannopoulos, G.; Niarchos, D.; Hadjipanayis, G.; Tabares, J.A.; Alcázar, G.A.P.; Zamora, L.E. Effect of cobalt substitution on structure and magnetic properties of Nd0.4Zr0.6Fe10−xCoxSi2 (x = 0–3) alloys and their ribbons. J. Rare Earths 2019, 37, 1096–1101. [Google Scholar] [CrossRef]

- Martin-Cid, A. Development of New High Anisotropy Phases for Permanent Magnet Applications. PhD Thesis, Universidad del Pais Vasco, Pais Vasco, Spain, 2018. [Google Scholar]

- Kobayashi, K.; Furusawa, D.; Suzuki, S.; Kuno, T.; Urushibata, K.; Sakuma, N.; Yano, M.; Shoji, T.; Kato, A.; Manabe, A.; et al. High-Temperature Stability of ThMn12 Magnet Materials. Mater. Trans. 2018, 59, 1845–1853. [Google Scholar] [CrossRef]

- Lutterotti, L. Total pattern fitting for the combined size–strain–stress–texture determination in thin film diffraction. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2009, 268, 334–340. [Google Scholar] [CrossRef]

- Gigla, M.; Pączkowski, P. ElDyf for Windows; Version 2.1; Institute of Materials Science, University of Silesia in Katowice: Katowice, Poland, 2005. [Google Scholar]

- Kołodziej, M.; Śniadecki, Z. Thermodynamic Modeling of Formation Enthalpies of Amorphous and Crystalline Phases in Zr, Nd, and Ce Substituted Fe-Si System. Appl. Sci. 2023, 13, 1966. [Google Scholar] [CrossRef]

- Randrianantoandro, N.; Gaffet, E.; Mira, J.; Greneche, J.-M. Magnetic hyperfine temperature dependence in Fe–Si crystalline alloys. Solid State Commun. 1999, 111, 323–327. [Google Scholar] [CrossRef]

- Varga, L.K.; Mazaleyrat, F.; Kovac, J.; Greneche, J.M. Structural and magnetic properties of metastable Fe1-xSix (0.15 < x < 0.34) alloys prepared by a rapid-quenching technique. J. Phys. Condens. Matter 2002, 14, 1985–2000. [Google Scholar] [CrossRef]

- Gjoka, M.; Psycharis, V.; Devlin, E.; Niarchos, D.; Hadjipanayis, G. Effect of Zr substitution on the structural and magnetic properties of the series Nd1−xZrxFe10Si2 with the ThMn12 type structure. J. Alloys Compd. 2016, 687, 240–245. [Google Scholar] [CrossRef]

- Zhao, L.Z.; Yu, H.Y.; Guo, W.T.; Zhang, J.S.; Zhang, Z.Y.; Hussain, M.; Liu, Z.W.; Greneche, J.M. Phase and Hyperfine Structures of Melt-spun Nanocrystalline (Ce1–xNdx)16Fe78B6 Alloys. IEEE Trans. Magn. 2017, 53, 1–5. [Google Scholar] [CrossRef]

- Zhao, L.; Li, C.; Hao, Z.; Liu, X.; Liao, X.; Zhang, J.; Su, K.; Li, L.; Yu, H.; Greneche, J.-M.; et al. Influences of element segregation on the magnetic properties in nanocrystalline Nd-Ce-Fe-B alloys. Mater. Charact. 2018, 148, 208–213. [Google Scholar] [CrossRef]

- Idzikowski, B.; Wolf, M.; Handstein, A.; Nenkov, K.; Engelmann, H.J.; Stobiecki, F.; Muller, K.-H. Inverse giant magnetoresistance in granular Nd/sub 2/Fe/sub 14/B//spl alpha/-Fe. IEEE Trans. Magn. 1997, 33, 3559–3561. [Google Scholar] [CrossRef]

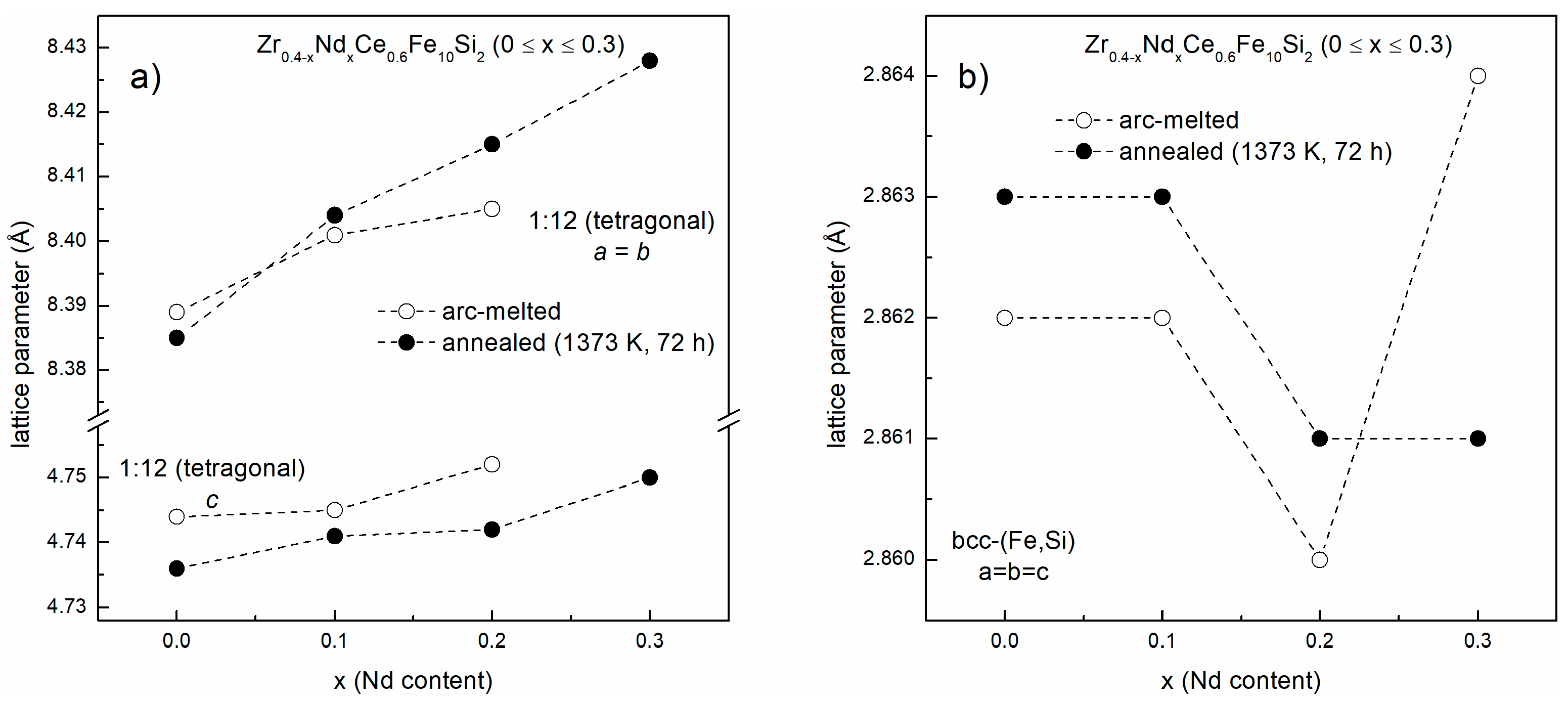

| Nd Content | x = 0 Arc-Melted | x = 0 Annealed | x = 0.1 Arc-Melted | x = 0.1 Annealed | x = 0.2 Arc-Melted | x = 0.2 Annealed | x = 0.3 Arc-Melted | x = 0.3 Annealed | |

|---|---|---|---|---|---|---|---|---|---|

| Phase | Lattice Parameter | ||||||||

| bcc-(Fe,Si) | a = b = c [±0.001] | 2.862 | 2.863 | 2.862 | 2.863 | 2.860 | 2.861 | 2.864 | 2.861 |

| ThMn12 | a = b [±0.001] | 8.389 | 8.385 | 8.401 | 8.404 | 8.405 | 8.415 | - | 8.428 |

| c [±0.001] | 4.744 | 4.736 | 4.745 | 4.741 | 4.752 | 4.742 | - | 4.750 | |

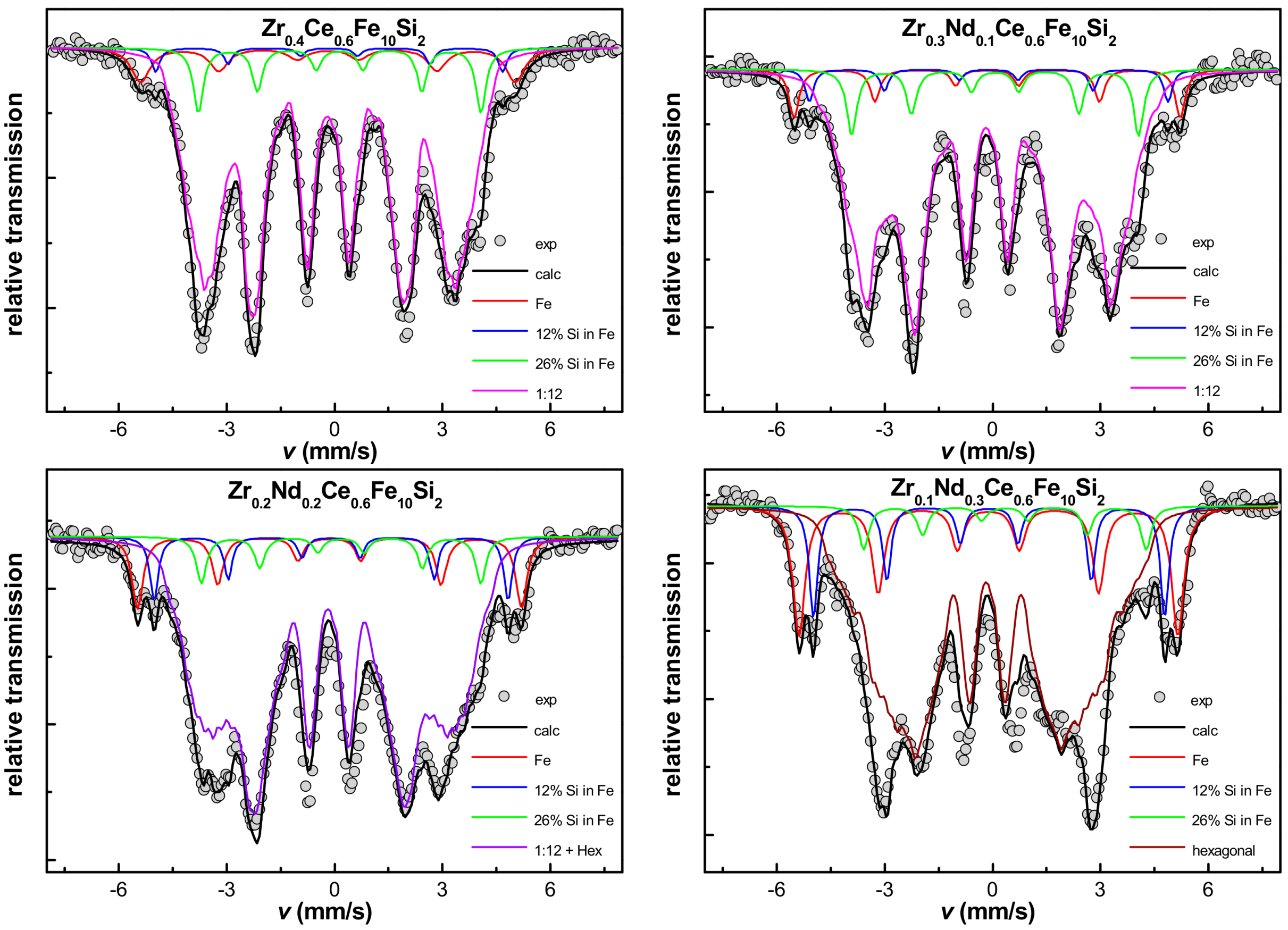

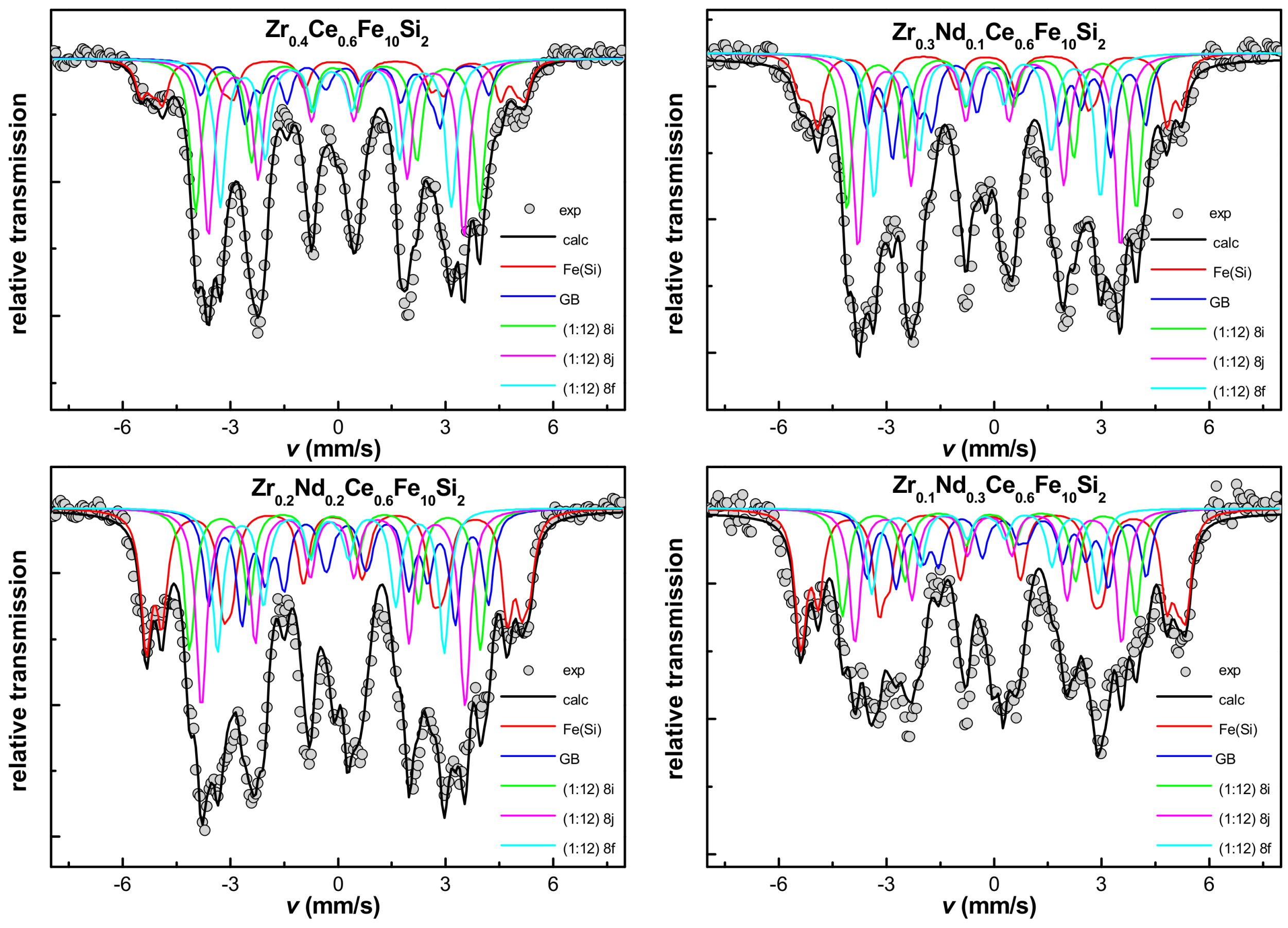

| Phase | Bhf (T) [±0.5] | δ (mm/s) [±0.01] | 2ε (mm/s) [±0.01] | Area % [±2] | ||

|---|---|---|---|---|---|---|

| Zr0.4Ce0.6Fe10Si2 | ||||||

| ThMn12 | <28.7> | <−0.13> | <0.06> | 88 | ||

| bcc-(Fe,Si) | bcc-Fe | 32.3 | −0.17 | 0 | 3 | |

| Fe—12% Si | 30.4 | −0.1 | 0 | 2 | ||

| Fe—26% Si | 24.5 | −0.1 | 0 | 7 | ||

| Zr0.3Nd0.1Ce0.6Fe10Si2 | ||||||

| ThMn12 | <28.7> | <0.05> | <0.05> | 83 | ||

| bcc-(Fe,Si) | bcc-Fe | 33.1 | −0.15 | 0 | 6 | |

| Fe—12% Si | 30.8 | −0.11 | 0 | 3 | ||

| Fe—26% Si | 24.6 | 0.07 | 0 | 8 | ||

| Zr0.2Nd0.2Ce0.6Fe10Si2 | ||||||

| ThMn12 + hex | <29.9> | <−0.14> | <0.0> | 76 | ||

| bcc-(Fe,Si) | bcc-Fe | 32.8 | −0.14 | 0 | 11 | |

| Fe—12% Si | 30.3 | −0.09 | 0 | 7 | ||

| Fe—26% Si | 24.1 | 0.18 | 0 | 6 | ||

| Zr0.1Nd0.3Ce0.6Fe10Si2 | ||||||

| Nd(Zr, Ce)Fe hex | <30.6> | <−0.14> | <0.02> | 66 | ||

| bcc-(Fe,Si) | bcc-Fe | 32.6 | −0.12 | 0 | 17 | |

| Fe—12% Si | 30.1 | −0.1 | 0 | 11 | ||

| Fe—26% Si | 24.2 | 0.3 | 0 | 6 |

| Phase | Bhf (T) [±0.5] | δ (mm/s) [±0.01] | 2ε (mm/s) [±0.01] | Area % [±2] | ||

|---|---|---|---|---|---|---|

| Zr0.4Ce0.6Fe10Si2 | ||||||

| ThMn12 | 8i | 24.4 | −0.06 | 0.09 | 23 | |

| 8j | 21.9 | −0.1 | 0.09 | 26 | ||

| 8f | 19.8 | −0.1 | 0.09 | 22 | ||

| bcc-(Fe,Si) | bcc-Fe | 33.1 | −0.12 | −0.03 | 5 | |

| Fe—4.5% Si | 31.3 | −0.08 | −0.03 | 3 | ||

| Fe—12% Si | 29.1 | −0.16 | −0.03 | 6 | ||

| Fe—26% Si | 24.7 | 0.2 | −0.03 | 5 | ||

| Zr0.3Nd0.1Ce0.6Fe10Si2 | ||||||

| ThMn12 | 8i | 24.9 | −0.1 | 0.06 | 20 | |

| 8j | 22.5 | −0.16 | 0.06 | 24 | ||

| 8f | 19.4 | −0.22 | 0.06 | 18 | ||

| bcc-(Fe,Si) | bcc-Fe | 33 | −0.18 | 0.17 | 4 | |

| Fe—4.5% Si | 32.3 | −0.08 | 0.17 | 2 | ||

| Fe—12% Si | 30 | −0.13 | 0.17 | 9 | ||

| Fe—26% Si | 24 | 0.25 | 0.17 | 9 | ||

| Zr0.2Nd0.2Ce0.6Fe10Si2 | ||||||

| ThMn12 | 8i | 25 | −0.1 | 0.04 | 15 | |

| 8j | 22.7 | −0.15 | 0.04 | 21 | ||

| 8f | 19.5 | −0.21 | 0.04 | 15 | ||

| bcc-(Fe,Si) | bcc-Fe | 33 | −0.03 | 0.06 | 6 | |

| Fe—4.5% Si | 32.3 | −0.15 | 0.06 | 8 | ||

| Fe—12% Si | 29.7 | −0.12 | 0.06 | 10 | ||

| Fe—26% Si | 24 | 0.27 | 0.06 | 10 | ||

| Zr0.1Nd0.3Ce0.6Fe10Si2 | ||||||

| ThMn12 | 8i | 25.2 | −0.12 | −0.03 | 15 | |

| 8j | 22.9 | −0.14 | −0.03 | 18 | ||

| 8f | 19.4 | −0.24 | −0.03 | 12 | ||

| bcc-(Fe,Si) | bcc-Fe | 33.3 | −0.06 | −0.03 | 12 | |

| Fe—4.5% Si | 32.3 | −0.13 | −0.03 | 7 | ||

| Fe—12% Si | 30 | −0.07 | −0.03 | 12 | ||

| Fe—26% Si | 24 | 0.32 | −0.03 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kołodziej, M.; Grenèche, J.-M.; Auguste, S.; Idzikowski, B.; Zubko, M.; Bessais, L.; Śniadecki, Z. Influence of Nd Substitution on the Phase Constitution in (Zr,Ce)Fe10Si2 Alloys with the ThMn12 Structure. Materials 2023, 16, 1522. https://doi.org/10.3390/ma16041522

Kołodziej M, Grenèche J-M, Auguste S, Idzikowski B, Zubko M, Bessais L, Śniadecki Z. Influence of Nd Substitution on the Phase Constitution in (Zr,Ce)Fe10Si2 Alloys with the ThMn12 Structure. Materials. 2023; 16(4):1522. https://doi.org/10.3390/ma16041522

Chicago/Turabian StyleKołodziej, Mieszko, Jean-Marc Grenèche, Sandy Auguste, Bogdan Idzikowski, Maciej Zubko, Lotfi Bessais, and Zbigniew Śniadecki. 2023. "Influence of Nd Substitution on the Phase Constitution in (Zr,Ce)Fe10Si2 Alloys with the ThMn12 Structure" Materials 16, no. 4: 1522. https://doi.org/10.3390/ma16041522

APA StyleKołodziej, M., Grenèche, J.-M., Auguste, S., Idzikowski, B., Zubko, M., Bessais, L., & Śniadecki, Z. (2023). Influence of Nd Substitution on the Phase Constitution in (Zr,Ce)Fe10Si2 Alloys with the ThMn12 Structure. Materials, 16(4), 1522. https://doi.org/10.3390/ma16041522