Variation Pattern of the Compressive Strength of Concrete under Combined Heat and Moisture Conditions

Abstract

:1. Introduction

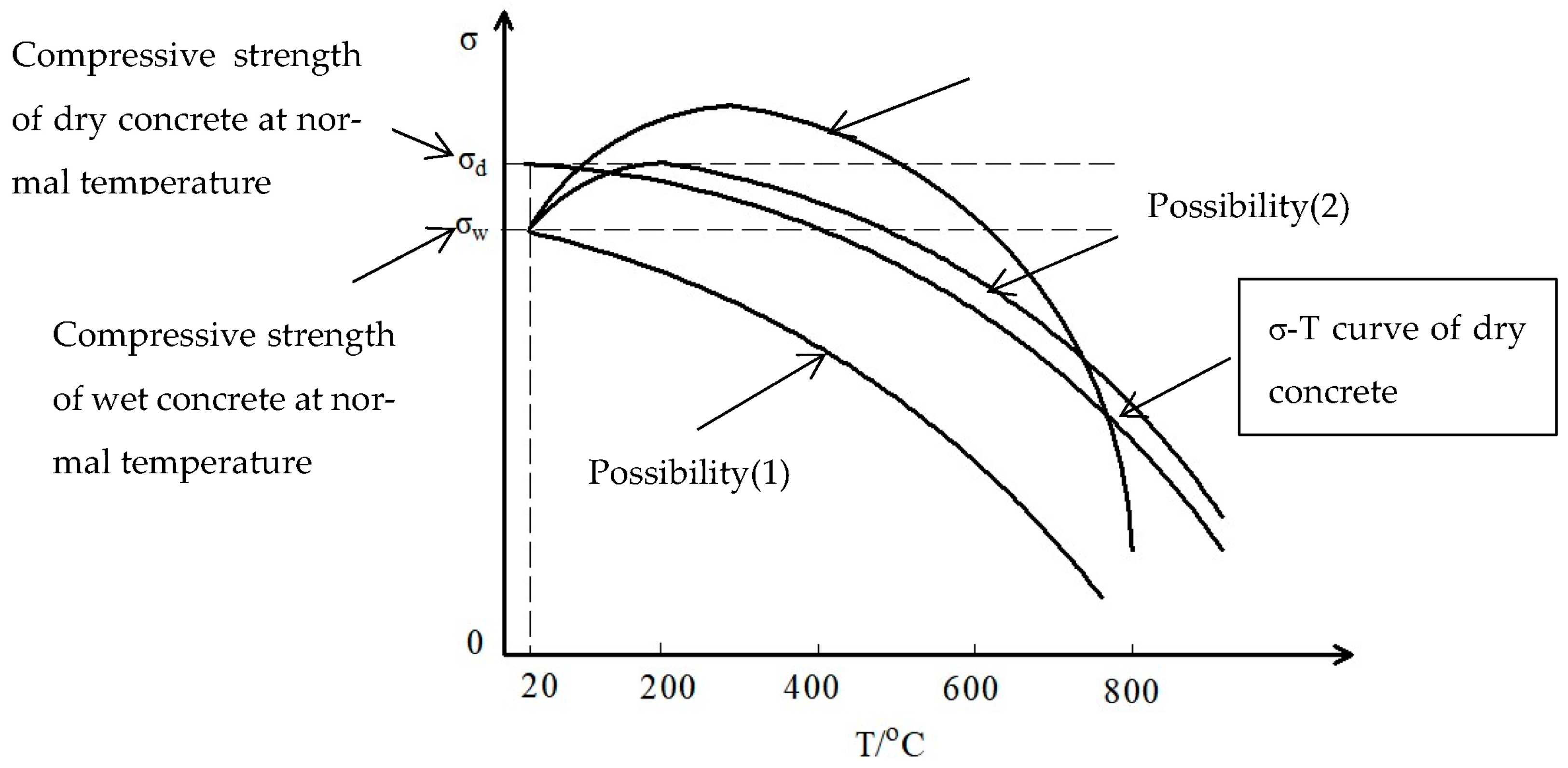

- (1)

- The effects of temperature and water on the strength of wet concrete are independent. The compressive strength of concrete is the superimposed result of the independent effects of the temperature softening effect and water softening effect. Due to the secondary hydration during water immersion, a large number of cracks occur within the concrete, which does not heal or shrink with the phase change and loss of water at high temperature. This means that the damage formed in the process of hydration is irreversible at high temperature. The compressive strength of concrete after immersion monotonically decreases with the increase in temperature.

- (2)

- When wet concrete is exposed to high temperatures, the water is evaporated and the water content decreases. With the loss of free water, the splitting effect of water at the crack tip disappears, and the hydration cracks formed in the immersion process are completely healed, and the damage is reversible. The phase transition of water does not affect the healing of cracks caused by the loss of liquid water. The compressive strength of wet concrete gradually increases with the increase in temperature until the water absorbed during the immersion process is completely lost and the compressive strength reaches the peak, which is equal to the compressive strength of dry concrete at normal temperature. Then, it shows the same decay pattern as that of the compressive strength of dry concrete at high temperature. The absorbed water delays but does not affect the temperature softening effect on the compressive strength. The effect of water on the high temperature strength of concrete materials is fully reversible such as that of the compressive strength at normal temperature, that is, the phase transition of water has no effect on the damage of concrete materials and the water content has no effect on the peak strength and the attenuation pattern of post-peak strength.

- (3)

- The effects of temperature and water on the strength of wet concrete are coupled. Under the action of high temperature, wet concrete gradually becomes dry concrete due to the evaporation of internal moisture. The compressive strength of concrete first increases to a certain peak strength and then decreases with the rise of temperature. Both the peak strength and the attenuation pattern of post-peak strength are related to the water content. The peak strength and attenuation pattern of post-peak strength are not the same as those of dry concrete under the same temperature conditions. The phase transition of water at high temperature has an irreversible effect on the evolution of cracks in concrete materials, at least on part of the crack evolution. The temperature and water effects on the compressive strength are interactive. Under the above three possibilities, the general relationship between the compressive strength and temperature is sketched as shown below (Figure 1):

2. Preparation and Testing of Specimens with Different Water Contents

3. Experimental Results

3.1. Quasi-Static Uniaxial Compression Tests on Concrete at High Temperature

3.2. Temperature Softening Effect of Compressive Strength of Dry Concrete

3.3. Water Softening Effect on the Compressive Strength of Concrete at Normal Temperature

3.4. Changes in the Compressive Strength of Concrete under Combined Heat–Moisture Conditions

- (1)

- The variation patterns of the compressive strength of immersed concrete at high temperature and normal temperature are remarkably different. At high temperature, the quasi-static compressive strength of immersed concrete shows a trend from rise to decline with the increase in relative water absorption ratio of the specimen, which is from approximately 45% to 65%. The high temperature compressive strength of concrete reaches a peak, and after that the strength decreases rapidly. Further, as the water absorption increases, the higher the temperature of concrete is, the faster the rate of strength decrease is after the peak. The relationship among the heat–moisture coupling effect factor DIF, the corresponding relative water absorption ratio, and temperature at the peak can be obtained by the fitted curve. As can be observed in Table 5, when T ≥ 200 °C, the peak of DIF decreases with the increase in temperature, and the corresponding relative water absorption ratio, , also decreases as the DIF at each temperature reaches the peak.

- (2)

- Compared with the compressive strength of air-drying concrete at normal temperature, the high-temperature compressive strength of immersed concrete increases in a certain range with the increase in water absorption mass (or relative water absorption), but the increase in the value of the compressive strength and the range of the relative water absorption ratio corresponding to the increase in compressive strength are temperature dependent. When T = 200 °C, the high-temperature compressive strength of the air-drying concrete specimens is slightly lower than their normal-temperature compressive strength, and the high-temperature compressive strength of the immersed concrete specimens is higher than the normal-temperature compressive strength of the air-drying concrete specimens. Even in a larger range of relative water absorption ratio (approximately 10% to 90%), their compressive strength is higher than that of the concrete stoved in an oven at normal temperature. When T = 400 °C, the compressive strength of the immersed concrete is lower than that of the concrete stoved in an oven at normal temperature, and it is only slightly higher than the compressive strength of the air-drying concrete specimens at normal temperature near the peak. Further, the corresponding range of the relative water absorption ratio is significantly narrower than that at T = 200 °C. When T = 520 °C, the compressive strength of the immersed concrete is lower than that of the air-drying concrete specimens at normal temperature.

- (3)

- Under the same relative water absorption ratio, the compressive strength of immersed concrete at T = 200 °C is higher than that at normal temperature (it is only slightly lower than the compressive strength at normal temperature when Wab is less than 2%, approximately). At T = 400 °C, when the relative water absorption ratio, Wab, is less than 22%, the compressive strength is higher than that at normal temperature and with the same relative water absorption ratio. At T = 520 °C, when the relative water absorption ratio, Wab, is greater than 33% and less than 90%, the compressive strength is higher than that at normal temperature and with the same relative water absorption ratio. However, when Wab is greater than 90%, the compressive strength is lower than that at normal temperature with the same water absorption ratio.

- (4)

- The fitted equation of the heat–moisture coupling effect factor DIF and relative water absorption ratio, Wab, is:

- (1)

- The heat–moisture coupling effect factor DIF of quasi-static compressive strength of concrete stoved in an oven decreases linearly with increasing temperature, T. The fitted equation for the DIF–T relationship is

- (2)

- From the DIF (Wab = 0%)−T change curve of the heat–moisture coupling effect factor DIF (Wab = 0%) of the quasi-static compressive strength of the air-drying concrete (Wab = 0%) with temperature, T, it can be observed that, compared to the concrete specimens stoved in an oven, the DIF (Wab = 0%)−T curve shows an obvious non-linear decline characteristic, and its decline rate is more gentle until 350 °C. Some researchers [14,17] found that the compressive strength of the concrete specimen even increases between 200 and 400 °C, and the main reason is that the air drying of concrete specimens in the experiment is not sufficient, and the free water stored inside the specimen is excessively high. The decline gradually increases after 350 °C, especially after 400 °C, where the rate of decline exceeds that of the concrete specimens stoved in an oven.

- (3)

- The heat–moisture coupling effect factor DIF of the compressive strength of immersed concrete shows a trend from rise to decline with the increase in temperature. The DIF reaches its maximum value between 200 and 300 °C, and then decreases rapidly, and the rate of decrease is faster than that of concrete air drying or that stoved in an oven. The peak of DIF declines with the increase in water absorption, which also indicates that the moisture effect on material strength is not fully reversible. Based on the fitting curves, it is found that when the DIF reaches its peak, the corresponding peak temperatures of the concrete specimens with the relative water absorption ratio of Wab = 60% and Wab = 90% are close to each other, whereas the peak of the saturated concrete specimen (Wab = 100%) is significantly lower than that of the specimens with the above two water absorption ratios and the temperature corresponding to the peak is smaller.

- (4)

- From the fitted experimental curves, it can be observed that the strength of concrete with the relative water absorption ratios of 60% and 90% is greater than that of stoved concrete at normal temperature within a certain temperature interval corresponding to the vicinity of the DIF peak. For concrete specimens with 60% relative water absorption ratio, when the temperatures range from approximately 150 to 400 °C, their compressive strengths are greater than that of stoved concrete specimens at normal temperature, that is, DIF > 1; when the temperature is between 100 and 450 °C, their compressive strengths are greater than that of air-drying concrete specimens at normal temperature; when the temperature is between 80 and 520 °C, their compressive strengths are greater than that of air-drying concrete specimens at the same high temperature. For concrete specimens with 90% relative water absorption ratio, when the temperatures range from approximately 200 to 350 °C, their compressive strengths are greater than that of stoved concrete specimens at normal temperature, that is, DIF > 1; when the temperature is between 140 and 420 °C, their compressive strengths are greater than that of air drying concrete specimens at normal temperature; when the temperature is between 135 and 520 °C, their compressive strengths are greater than that of air-drying concrete specimens at the same high temperature. The high temperature compressive strength of fully saturated concrete specimens is lower than the normal temperature compression strength of both air-drying specimens and specimens stoved in an oven. The compressive strength of fully saturated concrete specimens is greater than that of air-drying concrete at the same temperature ranging from 200 to 400 °C.

4. Mechanism Analysis

- (1)

- Air-drying stage at normal temperature after production and curing

- (2)

- Immersion stage

- (3)

- Heating phase

5. Conclusions

- (1)

- Under combined heat and moisture conditions, the change in concrete compressive strength no longer shows a monotonic decay law, but a parabolic variation characterized by an increase followed by a decrease. When the relative water absorption ratio of the specimen is approximately 45% to 65% and the temperature is approximately 200 to 300 °C, compressive strength of the immersed concrete reaches its peak.

- (2)

- There is a significant difference in the effect of water on the compressive strength of concrete before and after immersing. That is, the free water stored during the process of production, curing, and air drying (i.e., first hydration) and the water absorbed during the process of immersing (i.e., second hydration) have different effects on the crack evolution of concrete materials, and the effect of water absorption of concrete during the second hydration is more significant on its compression strength. However, the microscopic mechanism of the effect of the two hydration processes on the evolution of microcracks needs to be further investigated in depth.

- (3)

- The expansion and closure of cracks within the concrete material are the result of the heat and moisture coupling effect. The compression strength of the concrete rises when the crack closure rate dominates, and conversely, the compression strength of the concrete material decreases when the crack expansion rate dominates. On the basis of previous studies and combined with our experimental results, we have given a reasonable explanation for the evolution process of microcracks under the combined heat and moisture conditions. However, more micro-scale experimental evidence is needed. This is also the work we are currently carrying out, and some results have been obtained, which we believe will be published in the near future. In addition, the specimen size used in the heat and moisture coupling experiment and theoretical research of concrete materials in this paper is slightly small. In the heat and mass transfer process, the internal crack evolution law caused by the temperature and moisture gradients of large-size concrete specimens under combined heat and moisture conditions may differ from that of small specimens. These are more prone to high-temperature cracking due to the more significant temperature and moisture gradients under the heat and moisture coupling conditions. The change pattern of the heat–moisture coupling effect factor of the large-size concrete specimens have to be further verified.

- (4)

- The equation for the heat–moisture coupling effect factor DIF of the compressive strength, temperature, T, and relative water absorption ratio, Wab, is:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kallel, H.; Carré, H.; La Borderie, C.; Masson, B.; Tran, N. Effect of temperature and moisture on the instantaneous behaviour of concrete. Cem. Concr. Compos. 2017, 80, 326–332. [Google Scholar] [CrossRef]

- Cho, B.; Park, D.; Kim, J.; Hamasaki, H. Study on the heat-moisture transfer in concrete under real environment. Constr. Build. Mater. 2017, 132, 124–129. [Google Scholar] [CrossRef]

- Kannangara, T.; Joseph, P.; Fragomeni, S.; Guerrieri, M. Existing theories of concrete spalling and test methods relating to moisture migration patterns upon exposure to elevated temperatures—A review. Case Stud. Constr. Mater. 2022, 16, e01111. [Google Scholar] [CrossRef]

- Shen, L.; Monte, F.L.; Di Luzio, G.; Cusatis, G.; Li, W.; Felicetti, R.; Lombardi, F.; Lualdi, M.; Cao, M.; Ren, Q. On the moisture migration of concrete subject to high temperature with different heating rates. Cem. Concr. Res. 2021, 146, 106492. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, Y.; Xi, Y. Modeling the effect of temperature gradient on moisture and ionic transport in concrete. Cem. Concr. Compos. 2020, 106, 103454. [Google Scholar] [CrossRef]

- Ali, M.A.; Tomann, C.; Aldakheel, F.; Mahlbacher, M.; Noii, N.; Oneschkow, N.; Drake, K.-H.; Lohaus, L.; Wriggers, P.; Haist, M. Influence of Moisture Content and Wet Environment on the Fatigue Behaviour of High-Strength Concrete. Materials 2022, 15, 1025. [Google Scholar] [CrossRef]

- Zhao, X.; Zou, B.; Wang, M.; Li, H.; Lou, Z. Influence of free water on dynamic tensile behavior of ultra-high toughness cementitious composites. Constr. Build. Mater. 2021, 269, 121295. [Google Scholar] [CrossRef]

- Liu, B.D.; Lv, W.J.; Li, L.; Li, P.F. Effect of moisture content on static compressive elasticity modulus of concrete. Constr. Build. Mater. 2014, 69, 133–142. [Google Scholar] [CrossRef]

- Gorzelaczyk, T. Moisture influence on the failure of self-compacting concrete under compression. Arch. Civ. Mech. Eng. 2011, 11, 45–60. [Google Scholar] [CrossRef]

- Pham, D.T.; Vu, M.N.; Trieu, H.T.; Bui, T.S.; Nguyen-Thoi, T. A thermo-mechanical meso-scale lattice model to describe the transient thermal strain and to predict the attenuation of thermo-mechanical properties at elevated temperature up to 800 °C of concrete. Fire Saf. J. 2020, 114, 103011. [Google Scholar] [CrossRef]

- ANSI/AISC 360-10; Specification for Structural Steel Buildings. American Institute of Steel Construction, Inc.: Chicago, IL, USA, 2010.

- European Committee for Standardization (CEN). EN 1992-1-2 Eurocode 2: Design of Concrete Structures-Part 1–2: General Rules—Structural Fire Design (Brussels); European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Xing, Z.; Beaucour, A.-L.; Hebert, R.; Noumowe, A.; Ledesert, B. Influence of the nature of aggregates on the behaviour of concrete subjected to elevated temperature. Cem. Concr. Res. 2011, 41, 392–402. [Google Scholar] [CrossRef]

- Chan, Y.; Peng, G.; Anson, M. Residual strength and pore structure of high-strength concrete and normal strength concrete after exposure to high temperatures. Cem. Concr. Compos. 1999, 21, 23–27. [Google Scholar] [CrossRef]

- Novak, J.; Kohoutkova, A. Mechanical properties of concrete composites subject to elevated temperature. Fire Saf. J. 2018, 95, 66–76. [Google Scholar] [CrossRef]

- Zhai, Y.; Deng, Z.; Li, N.; Xu, R. Study on compressive mechanical capabilities of concrete after high temperature exposure and thermo-damage constitutive model. Constr. Build. Mater. 2014, 68, 777–782. [Google Scholar] [CrossRef]

- Seshu, D.R.; Pratusha, A. Study on compressive strength behaviour of normal concrete and self-compacting concrete subjected to elevated temperatures. Mag. Concr. Res. 2013, 65, 415–421. [Google Scholar] [CrossRef]

- Sideris, K.K. Mechanical characteristics of self-consolidating concrete exposed to elevated temeperatures. ASCE J. Mater. Civ. Eng. 2007, 19, 648–654. [Google Scholar] [CrossRef]

- Persson, B. Fire resistance of self-compacting concrete. SCC Mater. Struct. 2004, 37, 575–584. [Google Scholar] [CrossRef]

- Eurocode 4: Design of Composite Steel and Concrete Structures, Manager Structural Systems; Heavy Engineering Research Association: Auckland, New Zealand, 1994.

- Abrams, M.S. Compressive Strength of Concreteat Temperatures to 1600F; ACI Special Publication: Farmington Hills, MI, USA, 1971; Volume 25, pp. 33–58. [Google Scholar]

- Lie, T.T. Structural Fire Protection; American Society of Civil Engineers: New York, NY, USA, 1992. [Google Scholar]

- Malhotra, H.L. The effect of temperature on the compressive strength of concrete. Mag. Concr. Res. 1956, 8, 85–94. [Google Scholar] [CrossRef]

- Chen, L.; Fang, Q.; Jiang, X.; Ruan, Z.; Hong, J. Combined effects of high temperature and high strain rate on normal weight concrete. Int. J. Impact Eng. 2015, 86, 40–56. [Google Scholar] [CrossRef]

- Liu, C.X.; Li, Y.L. Effects of Temperature and Strain-Rate on the Compressive Strength of Concrete. Adv. Mater. Res. 2011, 168, 2619–2624. [Google Scholar] [CrossRef]

- Zhai, C.; Chen, L.; Fang, Q.; Chen, W.; Jiang, X. Experimental study of strain rate effects on normal weight concrete after exposure to elevated temperature. Mater. Struct. 2017, 50, 40. [Google Scholar] [CrossRef]

- Huo, J.S.; He, Y.M.; Xiao, L.P.; Chen, B.S. Experimental study on dynamic behaviours of concrete after exposure to high temperatures up to 700 °C. Mater. Struct. 2013, 46, 255–265. [Google Scholar] [CrossRef]

- Jin, L.; Hao, H.; Zhang, R.; Du, X. Mesoscale simulation on the effect of elevated temperature on dynamic compressive behavior of steel fiber reinforced concrete. Fire Technol. 2020, 56, 1801–1823. [Google Scholar] [CrossRef]

- Li, Z.; Xu, J.; Bai, E. Static and dynamic mechanical properties of concrete after high temperature exposure. Mater. Sci. Eng. A 2012, 544, 27–32. [Google Scholar] [CrossRef]

- Li, P.; Sun, C.; Huang, R.; Duan, S. The Law of Combined Effect of Rate and Temperature on Compressive Strength of Concrete Materials. Chin. J. High Press. Phys. 2022, 36, 94–104. [Google Scholar]

- Du, H.; Zhang, M. Experimental investigation of thermal pore pressure in reinforced C80 high performance concrete slabs at elevated temperatures. Constr. Build. Mater. 2020, 260, 120451. [Google Scholar] [CrossRef]

- Li, Y.; Yang, E.-H.; Zhou, A.; Liu, T. Pore pressure build-up and explosive spalling in concrete at elevated temperature: A review. Constr. Build. Mater. 2021, 284, 122818. [Google Scholar] [CrossRef]

- Mindeguia, J.-C.; Pimienta, P.; Noumowé, A.; Kanema, M. Temperature, pore pressure and mass variation of concrete subjected to high temperature—Experimental and numerical discussion on spalling risk. Cem. Concr. Res. 2010, 40, 477–487. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Prog. Struct. Eng. Mater. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Lau, D.; Büyüköztürk, O. Fracture characterization of concrete/epoxy interface affected by moisture. Mech. Mater. 2010, 42, 1031–1042. [Google Scholar] [CrossRef]

- Pyszniak, J.; Hoła, J. Application of acoustic method to the assessment of concrete humidity influence on the process of concrete destruction. Arch. Acoust. 1991, 16, 343–353. [Google Scholar]

- Ranjith, P.; Jasinge, D.; Song, J.; Choi, S. A study of the effect of displacement rate and moisture content on the mechanical properties of concrete: Use of acoustic emission. Mech. Mater. 2008, 40, 453–469. [Google Scholar] [CrossRef]

- Sun, X.; Wang, H.; Cheng, X.; Sheng, Y. Effect of pore liquid viscosity on the dynamic compressive properties of concrete. Constr. Build. Mater. 2020, 231, 117143. [Google Scholar] [CrossRef]

- Feldman, R.F.; Sereda, P.J. A new model for hydrated portland cement and its practical implications. Eng. J. 1970, 53, 53–59. [Google Scholar]

| Cement (kg/m3) | Sand (kg/m3) | Aggregate (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|

| 425 | 600 | 1132 | 184 | 8 |

| Immersion Time/h | Specimen Mass/g | Water Absorption Mass/g | Water Absorption Ratio/% | 1 Relative Water Absorption Ratio/% | Water Content Mass/g | Water Content Ratio/% | 2 Relative Saturation Ratio/% |

|---|---|---|---|---|---|---|---|

| 0 | 434.82 | 0 | 0 | 0 | 7.99 | 1.87 | 50.03 |

| 2 | 436.53 | 1.71 | 0.39 | 21.43 | 9.7 | 2.27 | 60.74 |

| 6 | 439.69 | 4.87 | 1.12 | 61.03 | 12.86 | 3.01 | 80.53 |

| 12 | 440.33 | 5.51 | 1.28 | 69.05 | 13.5 | 3.16 | 84.53 |

| 18 | 440.77 | 5.95 | 1.38 | 74.56 | 13.94 | 3.27 | 87.29 |

| 24 | 441.03 | 6.21 | 1.43 | 77.82 | 14.2 | 3.33 | 88.92 |

| 30 | 441.31 | 6.49 | 1.49 | 81.33 | 14.48 | 3.39 | 90.67 |

| 36 | 441.44 | 6.62 | 1.52 | 82.96 | 14.61 | 3.42 | 91.48 |

| 48 | 441.79 | 6.97 | 1.60 | 87.34 | 14.96 | 3.50 | 93.68 |

| 60 | 441.93 | 7.11 | 1.64 | 89.10 | 15.10 | 3.54 | 94.55 |

| 72 | 442.29 | 7.47 | 1.72 | 93.61 | 15.46 | 3.62 | 96.81 |

| 100 | 442.73 | 7.91 | 1.82 | 99.12 | 15.90 | 3.73 | 99.56 |

| 120 | 442.80 | 7.98 | 1.84 | 100 | 15.97 | 3.74 | 100 |

| 140 | 442.80 | 7.98 | 1.84 | 100 | 15.97 | 3.74 | 100 |

| 160 | 442.80 | 7.98 | 1.84 | 100 | 15.97 | 3.74 | 100 |

| Immersion Time/h | Specimen Mass/g | Water Absorption Mass/g | Water Absorption Ratio/% | 1 Relative Water Absorption Ratio/% | Water Content Mass/g | Water Content Ratio/% | 2 Relative Saturation Ratio/% |

|---|---|---|---|---|---|---|---|

| 0 | 430.09 | 0 | 0 | 0 | 3.26 | 0.76 | 20.39 |

| 1 | 433.23 | 3.14 | 0.73 | 24.67 | 6.4 | 1.50 | 40.03 |

| 3 | 438.53 | 8.44 | 1.96 | 66.30 | 11.7 | 2.74 | 73.17 |

| 8 | 440.29 | 10.2 | 2.37 | 80.13 | 13.46 | 3.15 | 84.18 |

| 18 | 441.09 | 11 | 2.56 | 86.41 | 14.26 | 3.34 | 89.18 |

| 25 | 441.31 | 11.22 | 2.61 | 88.14 | 14.48 | 3.39 | 90.56 |

| 31 | 441.46 | 11.37 | 2.64 | 89.32 | 14.63 | 3.43 | 91.49 |

| 55 | 441.55 | 11.46 | 2.66 | 90.02 | 14.72 | 3.45 | 92.058 |

| 79 | 441.85 | 11.76 | 2.73 | 92.38 | 15.02 | 3.52 | 93.93 |

| 103 | 442.14 | 12.05 | 2.81 | 94.66 | 15.31 | 3.59 | 95.75 |

| 151 | 442.45 | 12.36 | 2.87 | 97.09 | 15.62 | 3.66 | 97.69 |

| 199 | 442.82 | 12.73 | 2.96 | 100 | 15.99 | 3.75 | 100 |

| 247 | 442.82 | 12.73 | 2.96 | 100 | 15.99 | 3.75 | 100 |

| Immersion Time/h | Specimen Mass/g | Water Absorption Mass/g | Water Absorption Ratio/% | 1 Relative Water Absorption Ratio/% | Water Content Mass/g | Water Content Ratio/% | 2 Relative Saturation Ratio/% |

|---|---|---|---|---|---|---|---|

| 0 | 274.52 | 0 | 0 | 0 | 2.10 | 0.76 | 20.58 |

| 3 | 278.06 | 3.54 | 1.29 | 43.28 | 5.64 | 2.06 | 54.95 |

| 5 | 280.42 | 5.90 | 2.15 | 72.13 | 8.00 | 2.93 | 77.86 |

| 7 | 280.69 | 6.17 | 2.25 | 75.43 | 8.27 | 3.03 | 80.49 |

| 22 | 281.78 | 7.26 | 2.65 | 88.75 | 9.36 | 3.43 | 91.07 |

| 34 | 282.31 | 7.79 | 2.84 | 95.23 | 9.89 | 3.62 | 96.21 |

| 46 | 282.39 | 7.87 | 2.87 | 96.21 | 9.97 | 3.65 | 96.99 |

| 70 | 282.51 | 7.99 | 2.91 | 97.68 | 10.09 | 3.70 | 98.16 |

| 94 | 282.57 | 8.05 | 2.93 | 98.41 | 10.15 | 3.72 | 98.74 |

| 118 | 282.63 | 8.11 | 2.96 | 99.14 | 10.21 | 3.74 | 99.32 |

| 142 | 282.70 | 8.18 | 2.98 | 100 | 10.28 | 3.77 | 100 |

| 166 | 282.70 | 8.18 | 2.98 | 100 | 10.28 | 3.77 | 100 |

| Peak of DIF | Temperature T/°C | |

|---|---|---|

| 1.10 | 200 | 58% |

| 0.96 | 400 | 52% |

| 0.90 | 520 | 47% |

| T/°C | A | B (×102) | C (×104) |

|---|---|---|---|

| 20 | 0.92 | −0.14 | −0.12 |

| 200 | 0.91 | 0.62 | −0.6 |

| 400 | 0.76 | 0.80 | −0.78 |

| 520 | 0.63 | 1.14 | −1.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Liu, J.; Duan, S.; Huang, R. Variation Pattern of the Compressive Strength of Concrete under Combined Heat and Moisture Conditions. Materials 2023, 16, 1548. https://doi.org/10.3390/ma16041548

Li P, Liu J, Duan S, Huang R. Variation Pattern of the Compressive Strength of Concrete under Combined Heat and Moisture Conditions. Materials. 2023; 16(4):1548. https://doi.org/10.3390/ma16041548

Chicago/Turabian StyleLi, Ping, Ji Liu, Shiwei Duan, and Ruiyuan Huang. 2023. "Variation Pattern of the Compressive Strength of Concrete under Combined Heat and Moisture Conditions" Materials 16, no. 4: 1548. https://doi.org/10.3390/ma16041548

APA StyleLi, P., Liu, J., Duan, S., & Huang, R. (2023). Variation Pattern of the Compressive Strength of Concrete under Combined Heat and Moisture Conditions. Materials, 16(4), 1548. https://doi.org/10.3390/ma16041548