Micro Nanofibrillated Cellulose as Functional Additive Supporting Processability of Surface-Active Mineral Suspensions: Exemplified by Pixel Coating of an NOx-Sorbent Layer

Abstract

:1. Introduction

2. Materials and Methods

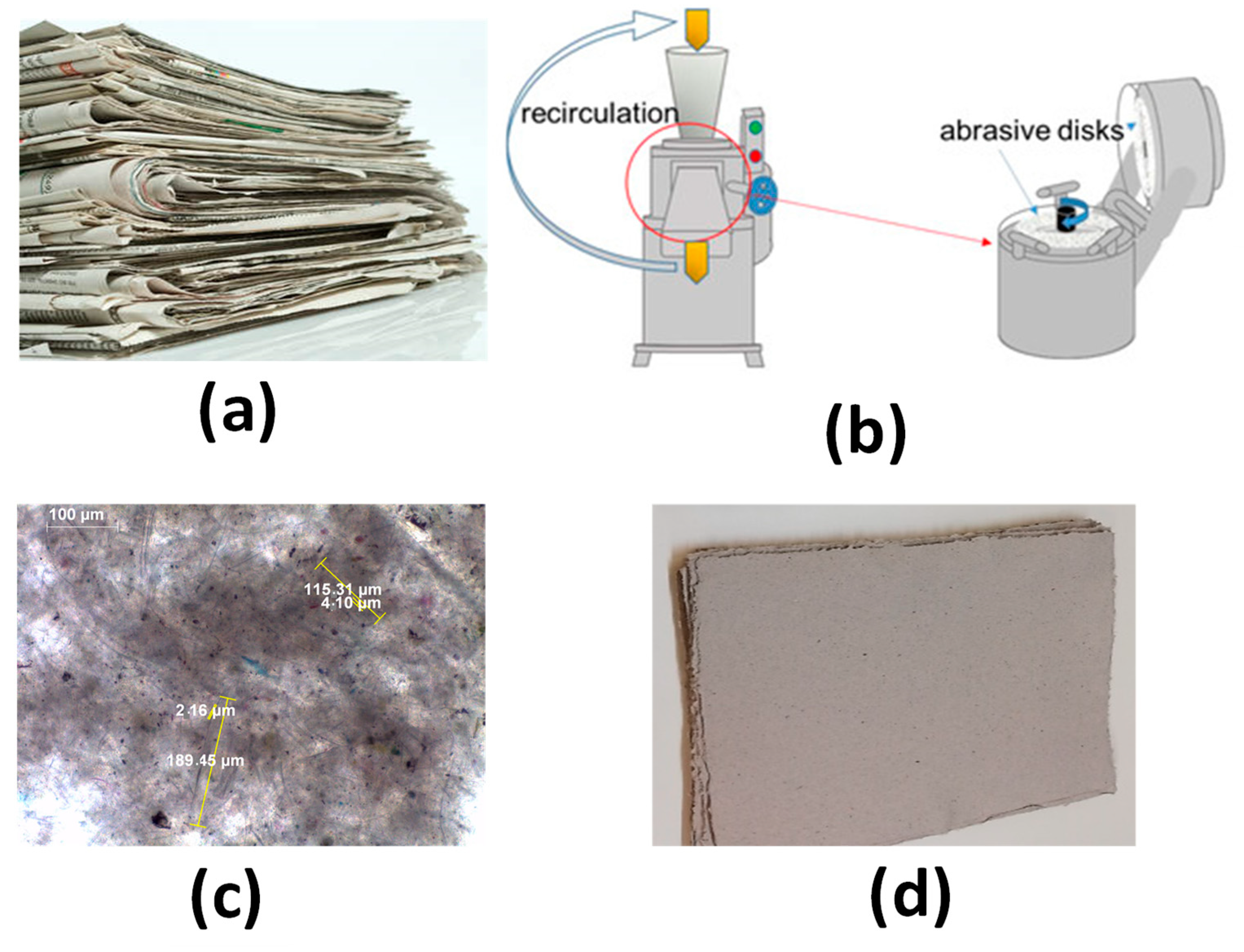

2.1. Mineral Particles

- (i).

- (ii).

2.2. Formulating the Coating Suspensions and Coating Colors

2.3. Substrate and MNFC Preparation

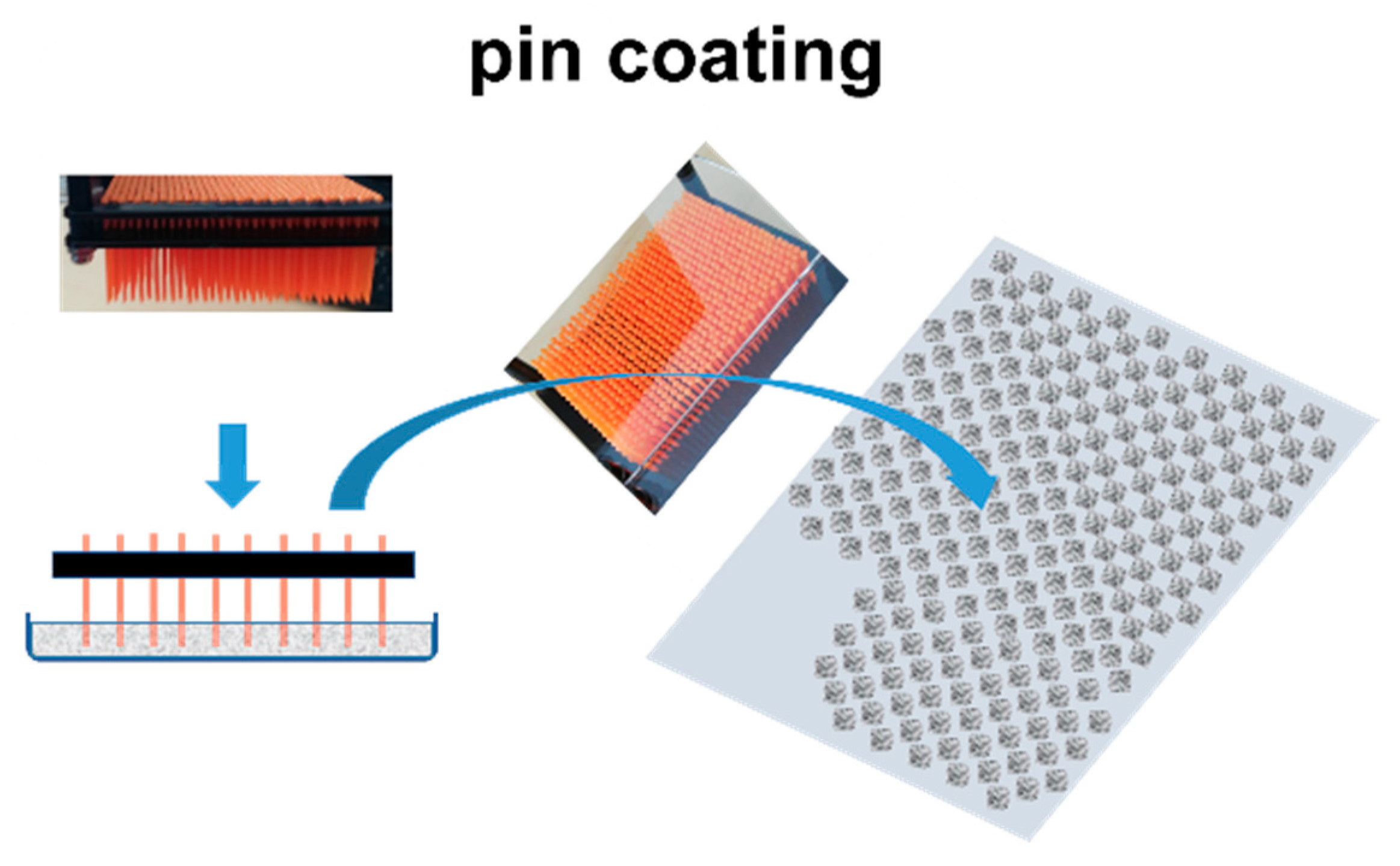

2.4. Coating Application: Pin Coating

2.5. Rheology of the Suspensions

- (a)

- Loading the pin coater array

- (b)

- Transfer to the substrate

- (c)

- Withdrawal of pins and filament separation

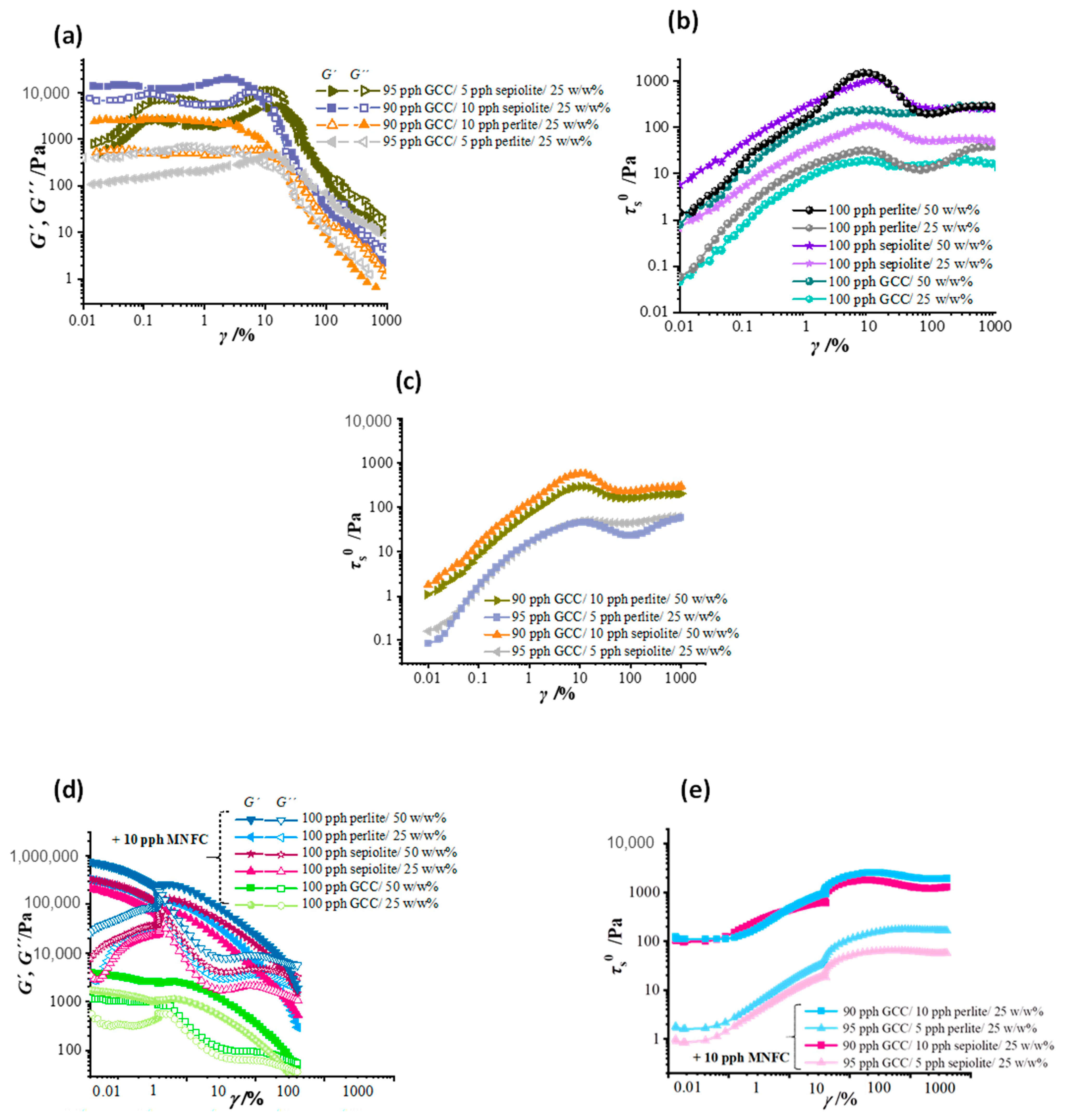

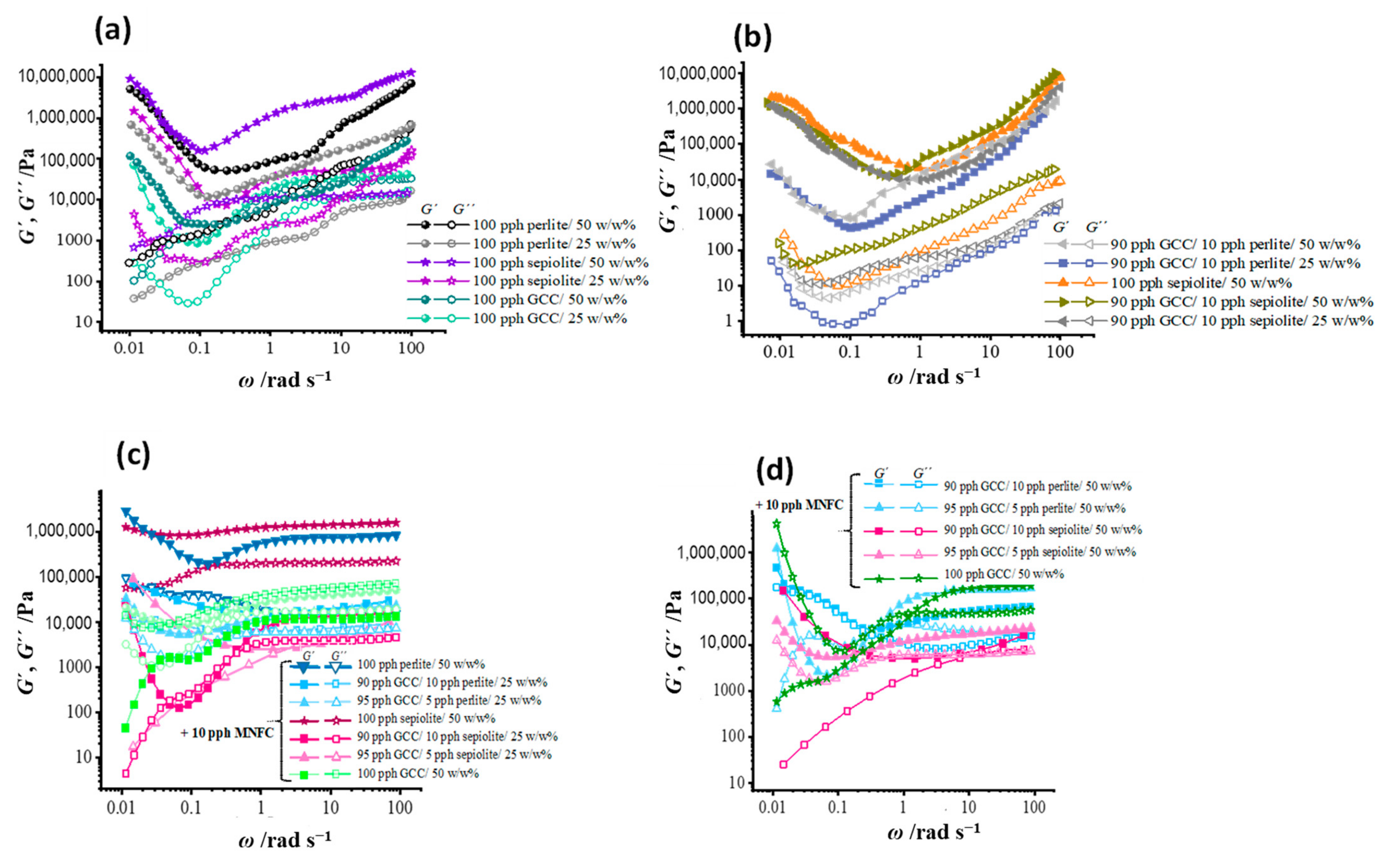

2.6. Viscoelastic Behavior

2.7. Yield Stress

2.8. Shear and Strain Response

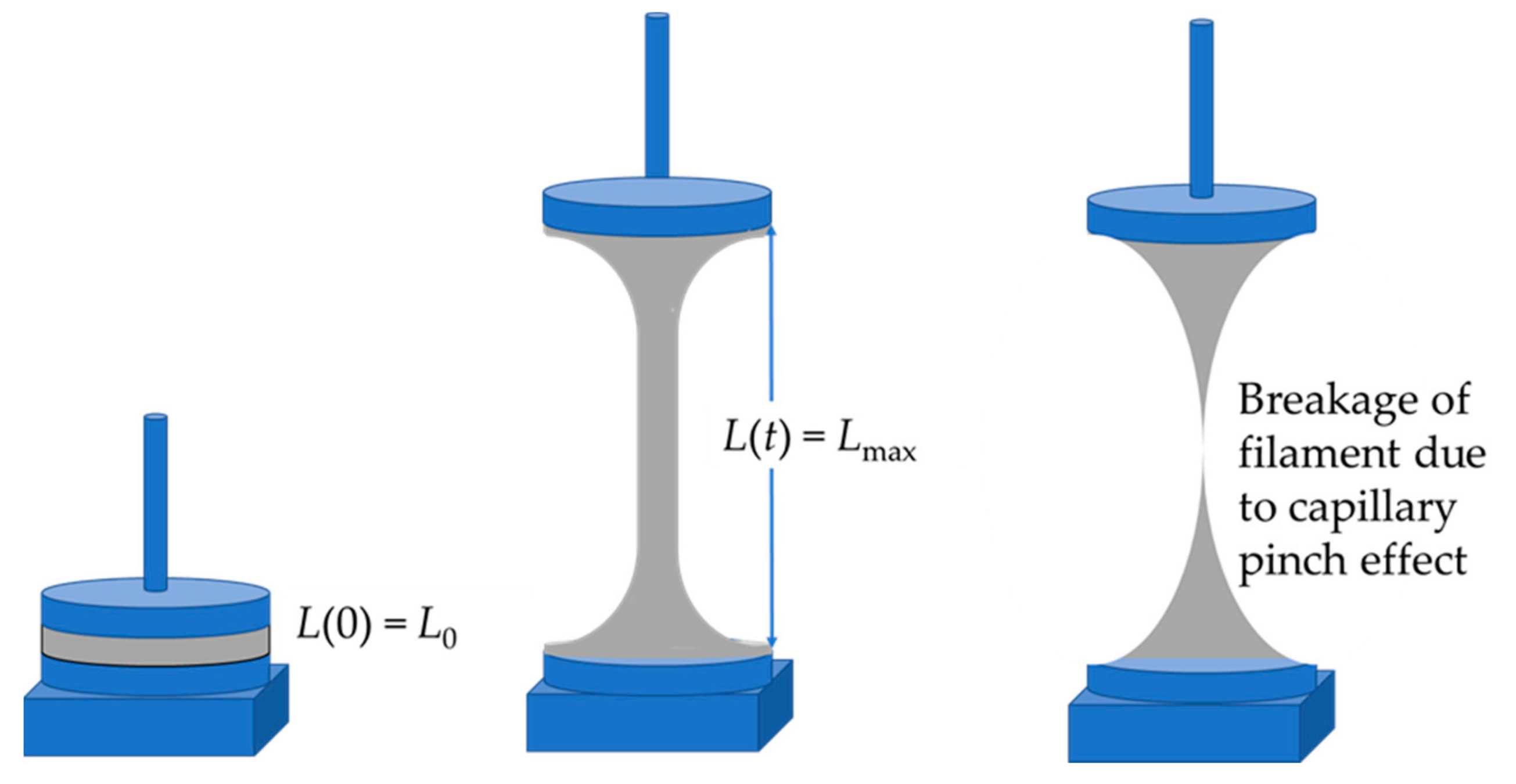

2.9. Elongation

3. Results and Discussion

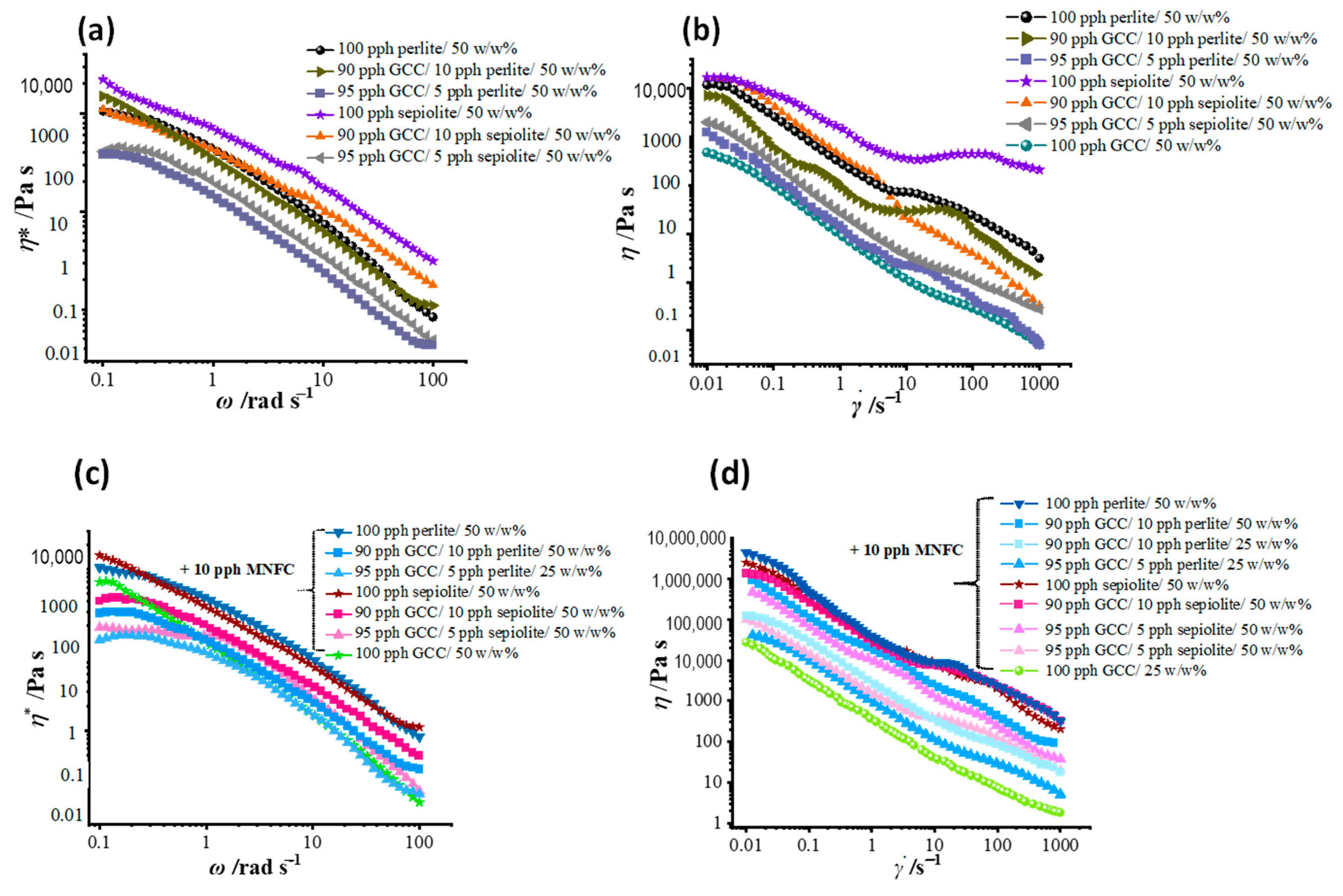

3.1. Rheological Observations

3.2. Effect of MNFC Addition

3.3. Shear Thinning Response

3.4. Model Curve Fitting (Ostwald-De Waele Parameterization)

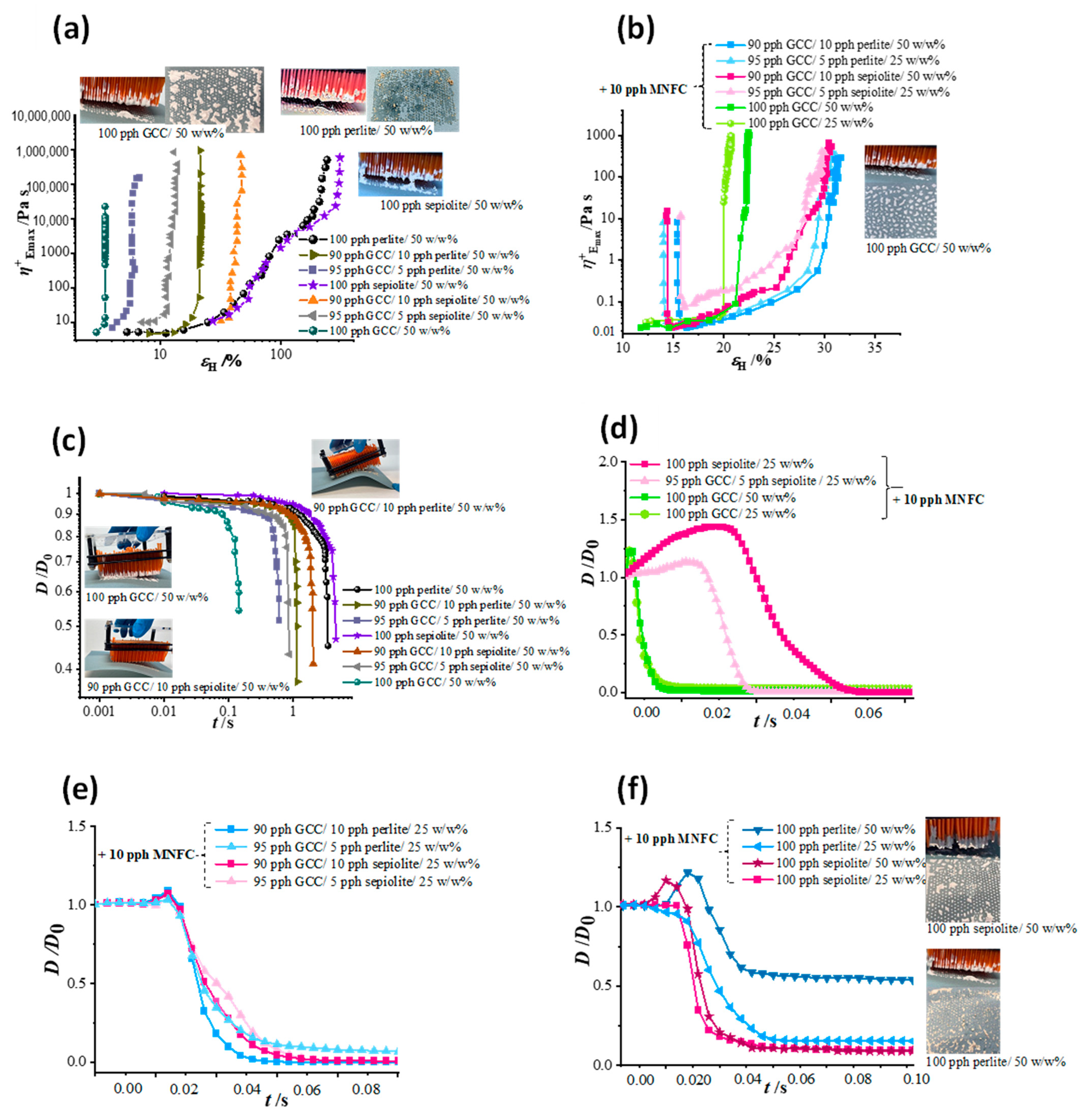

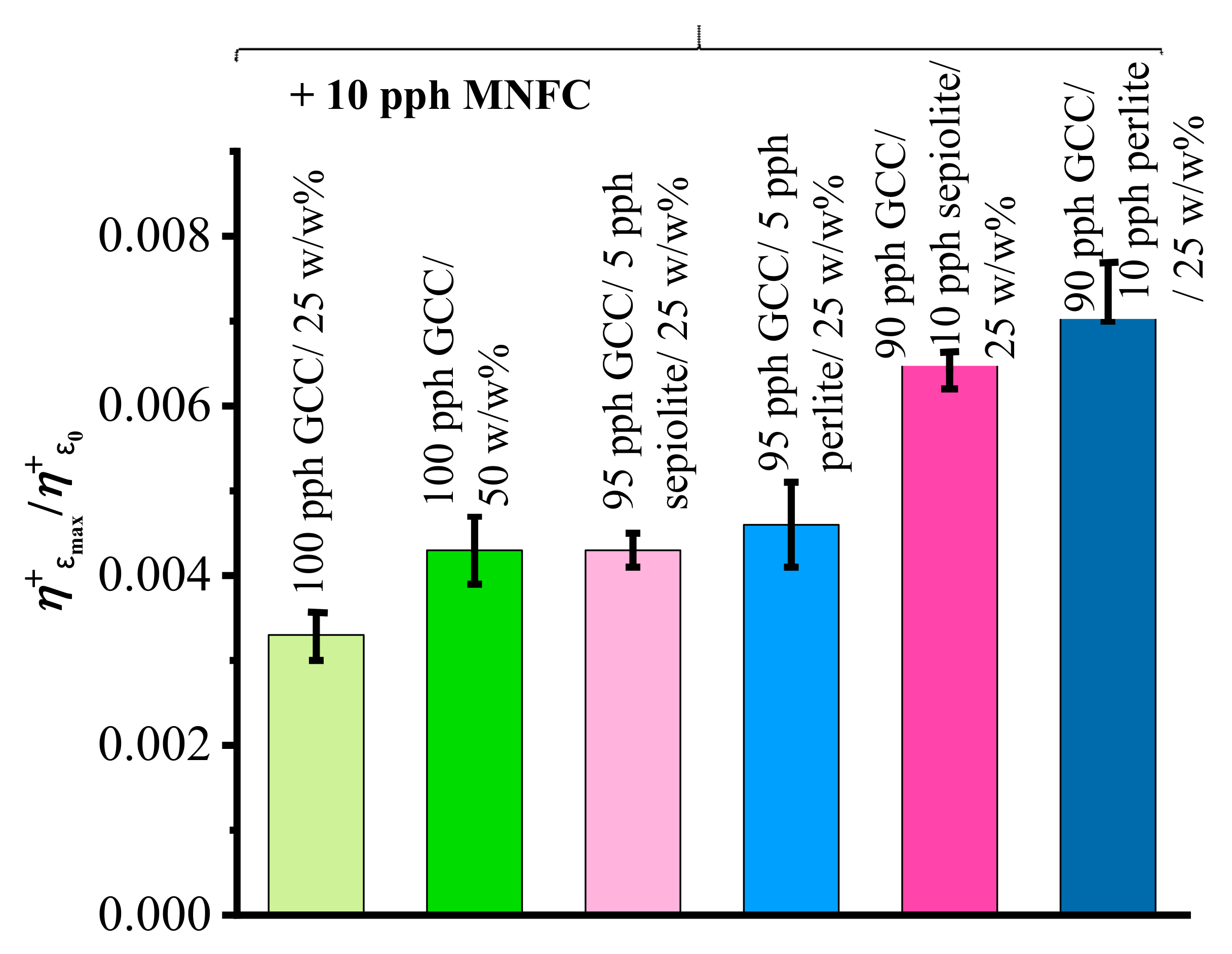

3.5. Rheological Evaluation under Extension

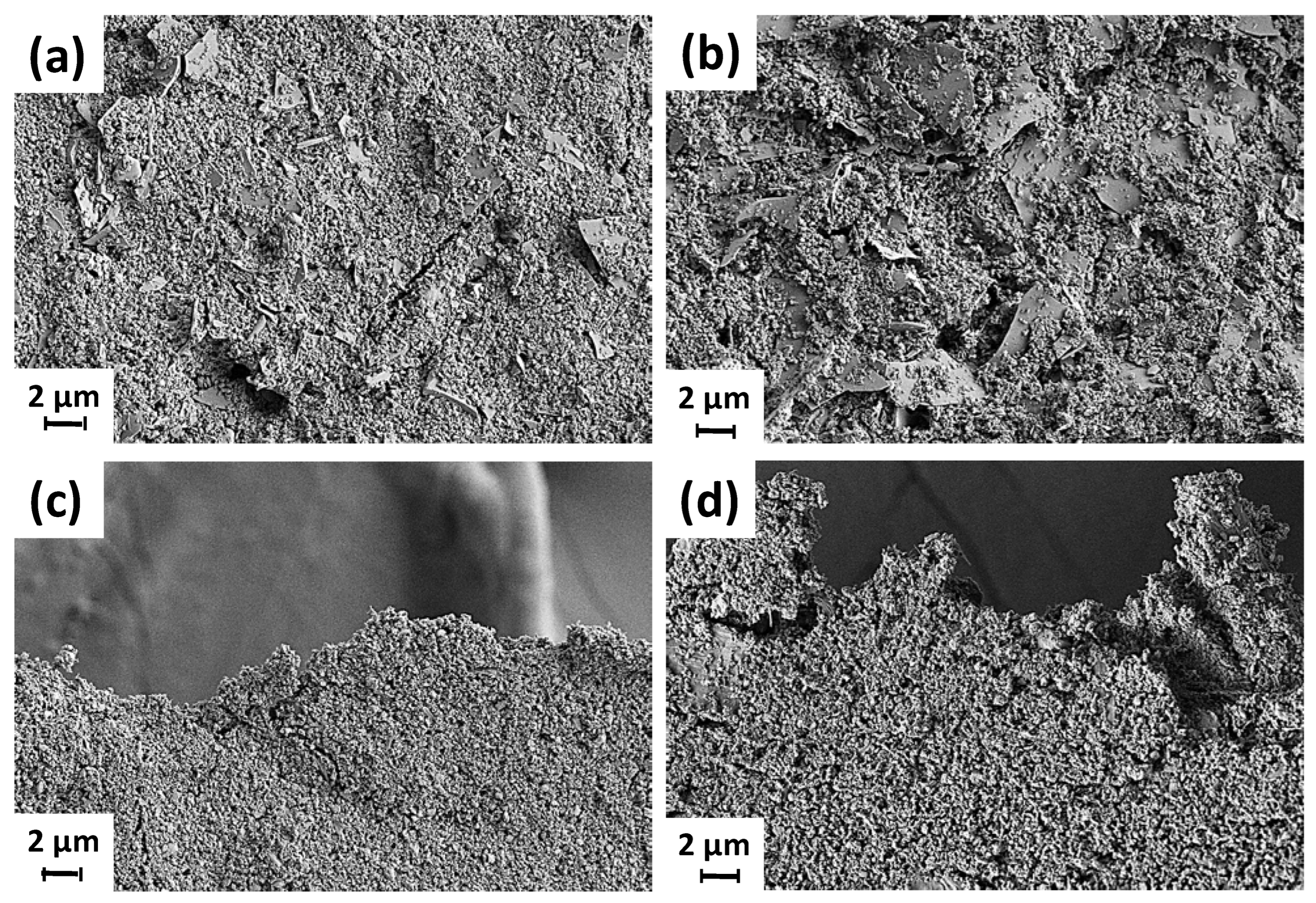

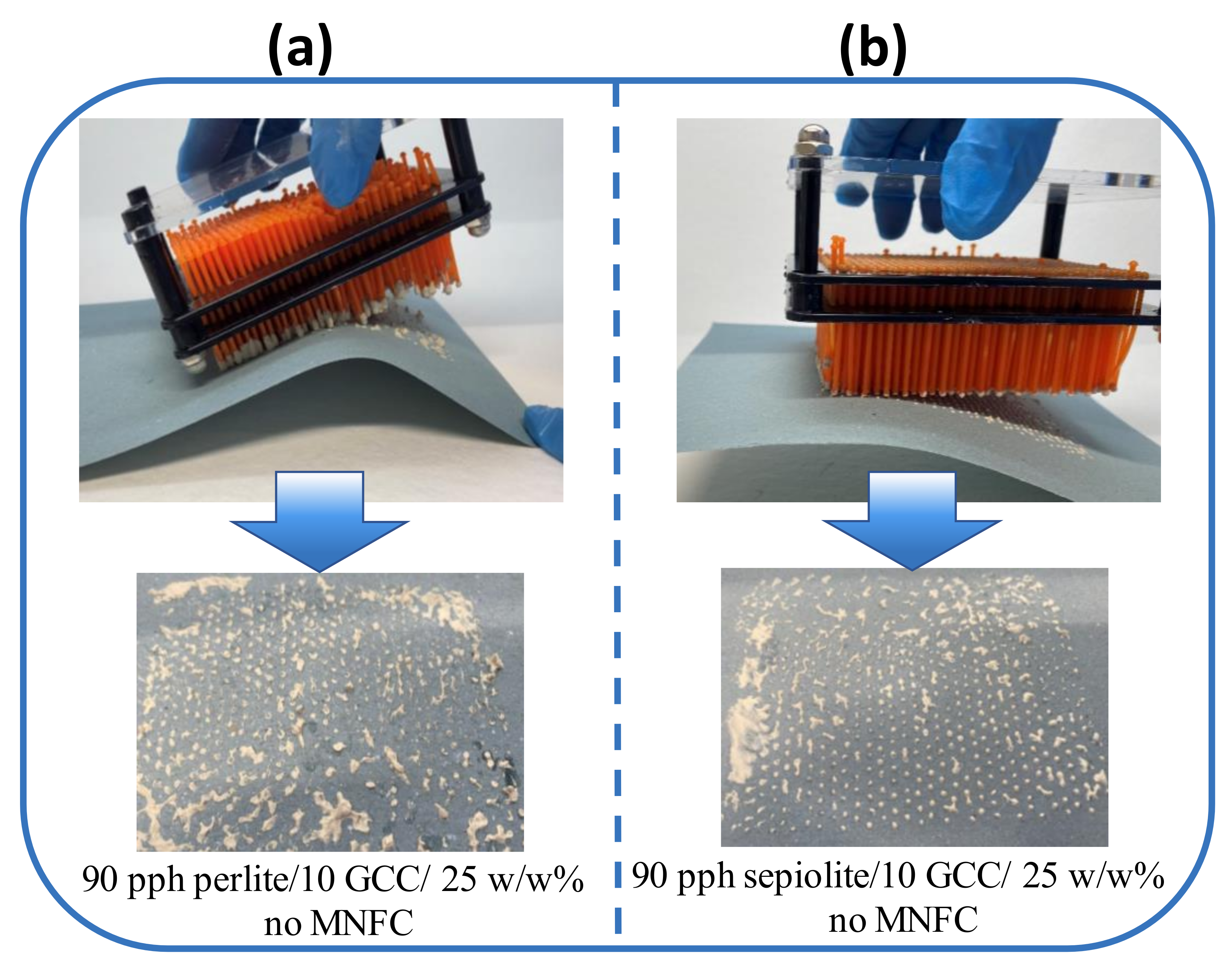

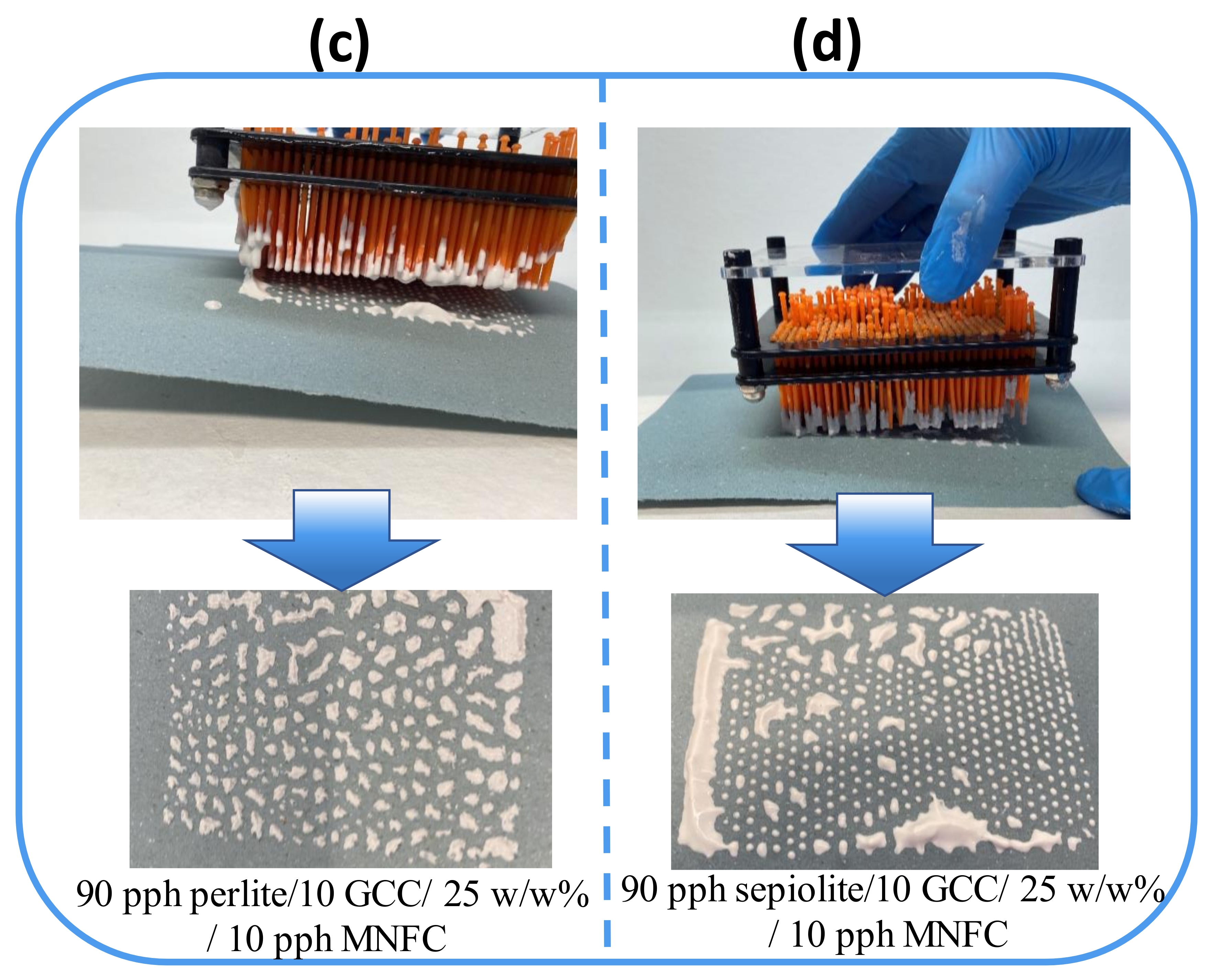

3.6. Impact on Coating Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Verwey, E.J.; Overbeek, J.T.G.; Nes, K.V. Theory of the Stability of Lyophobic Colloids: The Interaction of Sol Particles Having an Electric Double Layer; Elsevier: New York, NY, USA, 1948. [Google Scholar]

- Derjaguin, B.; Landau, L. Theory of the stability of strongly charged lyophobic sols and of the adhesion of strongly charged particles in solutions of electrolytes. Prog. Surf. Sci. 1993, 43, 30–59. [Google Scholar] [CrossRef]

- Barac, N.; Barcelo, E.; Stojanovic, D.; Milovanovic, S.; Uskokovic, P.; Gane, P.A.C.; Dimic-Misic, K.; Imani, M.; Janackovic, D. Modification of CaCO3 and CaCO3 pin-coated cellulose paper under supercritical carbon dioxide–ethanol mixture for enhanced NO2 capture. Environ. Sci. Pollut. Res. 2021, 29, 11707–11717. [Google Scholar] [CrossRef] [PubMed]

- Gane, P.A.C.; Dimic-Misic, K.; Barac, N.; Imani, M.; Janackovic, D.; Uskokovic, P.; Barcelo, E. Unveiling a Recycling-Sourced Mineral-Biocellulose Fibre Composite for Use in Combustion-Generated NOx Mitigation Forming Plant Nutrient: Meeting Sustainability Development Goals in the Circular Economy. Appl. Sci. 2020, 10, 3927. [Google Scholar] [CrossRef]

- Gane, P.A.C.; Ridgway, C.J.; Kijevcanin, M.; Stijepovic, M.; Uskokovic, P.S.; Barac, N.; Dimic-Misic, K.; Imani, M.; Janackovic, D.; Barcelo, E. Surface Patterning Increases Fluid Sorption Efficiency in Porous Reactive Coatings: A Model for Optimised Surface-Flow Filtration. Transp. Porous Media 2021, 138, 539–576. [Google Scholar] [CrossRef]

- Dimic-Misic, K.; Gane, P.A.C.; Paltakari, J. Micro-and nanofibrillated cellulose as a rheology modifier additive in CMC-containing pigment-coating formulations. Ind. Eng. Chem. Res. 2013, 52, 16066–16083. [Google Scholar] [CrossRef]

- Martín-Sampedro, R.; Eugenio, M.E.; Ibarra, D.; Ruiz-Hitzky, E.; Aranda, P.; Darder, M. Tailoring the properties of nanocellulose-sepiolite hybrid nanopapers by varying the nanocellulose type and clay content. Cellulose 2022, 29, 5265–5287. [Google Scholar] [CrossRef]

- Reka, A.A.; Pavlovski, B.; Lisichkov, K.; Jashari, A.; Boev, B.; Boev, I.; Lazarova, M.; Eskizeybek, V.; Oral, A.; Makreski, P. Chemical, mineralogical and structural features of native and expanded perlite from Macedonia. Geol. Croat. 2019, 72, 215–221. [Google Scholar] [CrossRef]

- Bennett, S.M. USGS Mineral Commodity Summaries—PERLITE; Mineral Commodity Summaries; U.S. Geological Survey: Reston, VA, USA, 2019; pp. 120–121. [Google Scholar]

- Gaćina, R.; Urošević, K.; Zakonović, J. Sepiolite—A by-product of exploitation as a potential raw material in Serbian industry. Min. Eng. 2019, 35, 81–91. [Google Scholar] [CrossRef]

- Chisholm, H. (Ed.) Meerschaum. In Encyclopædia Britannica, 11th ed.; Cambridge University: Cambridge, UK, 1911. [Google Scholar]

- Pääkkönen, T.; Dimic-Misic, K.; Orelma, H.; Pönni, R.; Vuorinen, T.; Maloney, T. Effect of xylan in hardwood pulp on the reaction rate of TEMPO-mediated oxidation and the rheology of the final nanofibrillated cellulose gel. Cellulose 2016, 23, 277–293. [Google Scholar] [CrossRef]

- Dimic-Misic, K.; Nieminen, K.; Gane, P.A.C.; Maloney, T.; Sixta, H.; Paltakari, J. Deriving a Process Viscosity for Complex Particulate Nanofibrillar Cellulose Gel-containing Suspensions. Appl. Rheol. 2014, 24, 43–51. [Google Scholar] [CrossRef]

- Derakhshandeh, B.; Petekidis, G.; Shafiei Sabet, S.; Hamad, W.Y.; Hatzikiriakos, S.G. Ageing, yielding, and rheology of nanocrystalline cellulose suspensions. J. Rheol. 2013, 57, 131–148. [Google Scholar] [CrossRef]

- Schenker, M.; Schoelkopf, J.; Mangin, P.; Gane, P.A.C. Rheological investigation of complex micro nanofibrillated cellulose (MNFC) suspensions: Discussion of flow curves and gel stability. Tappi J. 2016, 15, 405–416. [Google Scholar] [CrossRef]

- Iotti, M.; Gregersen, Ø.W.; Moe, S.; Lenes, M. Rheological studies of microfibrillar cellulose water dispersions. J. Polym. Environ. 2011, 19, 137–145. [Google Scholar] [CrossRef]

- Karppinen, A.; Saarinen, T.; Salmela, J.; Laukkanen, A.; Nuopponen, M.; Seppälä, J. Flocculation of microfibrillated cellulose in shear flow. Cellulose 2012, 19, 1807–1819. [Google Scholar] [CrossRef]

- Puisto, A.; Xavier, I.; Mohtaschemi, M.; Alava, M. Modelling the rheology of nanocellulose suspensions. Nord. Pulp Pap. Res. J. 2012, 27, 277–281. [Google Scholar] [CrossRef]

- Mohtaschemi, M.; Dimic-Misic, K.; Puisto, A.; Korhonen, M.; Maloney, T.; Paltakari, J.; Alava, M.J. Rheological characterization of fibrillated cellulose suspensions via bucket vane viscometer. Cellulose 2014, 21, 1305–1312. [Google Scholar] [CrossRef]

- Eriksson, U.; Engström, G.; Rigdahl, M. Viscosity of some clay-based coating colors at high shear rates. Rheol. Acta 1990, 29, 352–359. [Google Scholar] [CrossRef]

- Niedzwiedz, K.; Buggisch, H.; Willenbacher, N. Extensional rheology of concentrated emulsions as probed by capillary breakup elongational rheometry (CaBERTM). Rheol. Acta 2010, 49, 1103–1116. [Google Scholar] [CrossRef]

- Martoïa, F.; Perge, C.; Dumont, P.J.J.; Orgéas, L.; Fardin, M.A.; Manneville, S.; Belgacem, M.N. Heterogeneous flow kinematics of cellulose nanofibril suspensions under shear. Soft Matter 2015, 11, 4742–4755. [Google Scholar] [CrossRef]

- Kumar, V.; Nazari, B.; Bousfield, D.; Toivakka, M. Rheology of microfibrillated cellulose suspensions in pressure-driven flow. Appl. Rheol. 2016, 26, 24–34. [Google Scholar] [CrossRef]

- Jäder, J.; Engström, G.; Järnström, L. Effects of Rheology, Dewatering and Consolidation on Coating Layer Structure. Prof. Papermak. 2005, 3, 56–61. [Google Scholar]

- Kugge, C.; Vanderhoek, N.; Bousfield, D.W. Oscillatory shear response of moisture barrier coatings containing clay of different shape factor. J. Colloid Interface Sci. 2011, 358, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Medina, L.; Ansari, F.; Carosio, F.; Salajkova, M.; Berglund, L.A. Nanocomposites from Clay, Cellulose Nanofibrils, and Epoxy with Improved Moisture Stability for Coatings and Semistructural Applications. ACS Appl. Nano Mater. 2019, 2, 3117–3126. [Google Scholar] [CrossRef]

- Verwey, E.J.W. Theory of the stability of lyophobic colloids. J. Phys. Colloid Chem. 1948, 51, 631–636. [Google Scholar] [CrossRef] [PubMed]

- Grenard, V.; Divoux, T.; Taberlet, N.; Manneville, S. Timescales in creep and yielding of attractive gels. Soft Matter 2014, 10, 1555–1571. [Google Scholar] [CrossRef] [PubMed]

- Barnes, H.A. The ‘yield stress myth?’ paper–21 years on. Appl. Rheol. 2007, 17, 43110–43111. [Google Scholar] [CrossRef]

- Amini, E.N.; Tajvid, M.; Bousfield, D.W.; Gardner, D.J.; Shaler, S.M. Dewatering Behavior of a Wood-Cellulose Nanofibril Particulate System. Sci. Rep. 2019, 9, 14584. [Google Scholar] [CrossRef]

- Dimic-Misic, K.; Hummel, M.; Paltakari, J.; Sixta, H.; Maloney, T.; Gane, P. From colloidal spheres to nanofibrils: Extensional flow properties of mineral pigment and mixtures with micro and nanofibrils under progressive double layer suppression. J. Colloid Interface Sci. 2015, 446, 31–43. [Google Scholar] [CrossRef]

- Salo, T.; Dimic-Misic, K.; Gane, P.A.C.; Paltakari, J. Application of pigmented coating colours containing MFC/NFC: Coating properties and link to rheology. Nord. Pulp Pap. Res. J. 2015, 30, 165–178. [Google Scholar] [CrossRef]

- Michele, J.; Pätzold, R.; Donis, R. Alignment and aggregation effects in suspensions of spheres in non-Newtonian media. Rheol. Acta 1977, 16, 317–321. [Google Scholar] [CrossRef]

- Ponche, A.; Dupuis, D. On instabilities and migration phenomena in cone and plate geometry. J. Non Newton. Fluid Mech. 2005, 127, 123–129. [Google Scholar] [CrossRef]

- Håkansson, K.M.O.; Lundell, F.; Prahl-Wittberg, L.; Söderberg, L.D. Nanofibril Alignment in Flow Focusing: Measurements and Calculations. J. Phys. Chem. B 2016, 120, 6674–6686. [Google Scholar] [CrossRef]

- Spiegelberg, S.H.; Ables, D.C.; McKinley, G.H. The role of end-effects on measurements of extensional viscosity in filament stretching rheometers. J. Non Newton. Fluid Mech. 1996, 64, 229–267. [Google Scholar] [CrossRef]

- Anna, S.L.; McKinley, G.H. Elasto-capillary thinning and breakup of model elastic liquids. J. Rheol. 2001, 45, 115–138. [Google Scholar] [CrossRef]

- Yang, A.; Salminen, P.; Vervoort, S.; Endres, I.; Bachmann, H. Role of extensional viscosity in paper coating. J. Rheol. 2011, 21, 23607. [Google Scholar] [CrossRef]

- Bischoff White, E.E.; Chellamuthu, M.; Rothstein, J.P. Extensional rheology of a shear-thickening cornstarch and water suspension. Rheol. Acta. 2010, 49, 119–129. [Google Scholar] [CrossRef]

- De Kronig, L.R. On the theory of the dispersion of X-rays. J. Opt. Soc. Am. 1926, 12, 547–557. [Google Scholar] [CrossRef]

- Kramers, H.A. La diffusion de la lumière par les atomes. Atti Cong. Intern. Fisici 1927, 2, 545–557. [Google Scholar]

- Imani, M.; Dimic-Misic, K.; Tavakoli, M.; Rojas, O.J.; Gane, P.A.C. Coupled effects of fibril width, residual and mechanically liberated lignin on the flow, viscoelasticity, and dewatering of cellulosic nanomaterials. Biomacromolecules 2020, 21, 4123–4134. [Google Scholar] [CrossRef]

- Miller, E.; Clasen, C.; Rothstein, J.P. The effect of step-stretch parameters on capillary breakup extensional rheology (CaBERTM) measurements. Rheol. Acta 2009, 48, 625–639. [Google Scholar] [CrossRef]

- Spiegelberg, S.H.; McKinley, G.H. Stress relaxation and elastic decohesion of viscoelastic polymer solutions in extensional flow. J. Non Newton. Fluid Mech. 1996, 67, 49–76. [Google Scholar] [CrossRef]

- Rothstein, J.P. Transient extensional rheology of wormlike micelle solutions. J. Rheol. 2003, 47, 1227–1247. [Google Scholar] [CrossRef]

- Alves, L.; Ferraz, E.; Santarén, J.; Rasteiro, M.G.; Gamelas, J.A.F. Improving Colloidal Stability of Sepiolite Suspensions: Effect of the Mechanical Disperser and Chemical Dispersant. Minerals 2020, 10, 779. [Google Scholar] [CrossRef]

| Volume Defined Particle Size Distribution Measured by Light Scattering | ||

|---|---|---|

| Particle Size | Before Sonication/μm | After Sonication/μm |

| d10 (vol) | 3.33 | 1.12 |

| d50 (vol) | 4.61 | 1.41 |

| d90 (vol) | 6.05 | 1.77 |

| Mineral Component/pph * (+ 10 pph MNFC) | Solid Content/w/w% | Formulation Nomenclature |

|---|---|---|

| 100 GCC | 25 | 100 pph GCC/25 w/w% |

| 50 | 100 pph GCC/50 w/w% | |

| 100 perlite | 25 | 100 pph perlite/25 w/w% |

| 50 | 100 pph perlite/50 w/w%% | |

| 100 sepiolite | 25 | 100 pph sepiolite/25 w/w% |

| 50 | 100 pph sepiolite/50 w/w% | |

| 95:5 GCC:perlite | 25 | 95 pph GCC/5 pph perlite/25 w/w% |

| 50 | 95 pph GCC/5 pph perlite/50 w/w% | |

| 95:5 GCC:sepiolite | 25 | 95 pph GCC/5 pph sepiolite/25 w/w% |

| 50 | 95 pph GCC/5 pph sepiolite/50 w/w% | |

| 90:10 GCC:perlite | 25 | 90 pph GCC/10 pph perlite/25 w/w% |

| 50 | 90 pph GCC/10 pph perlite/50 w/w% | |

| 90:10 GCC:sepiolite | 25 | 90 pph GCC/10 pph sepiolite/25 w/w% |

| 50 | 90 pph GCC/10 pph sepiolite/50 w/w% |

| Sample | Flow Modifier MNFC /pph | nc | n | kc /Pa snc | k /Pa sn | τs0 /Pa | τd0 /Pa |

|---|---|---|---|---|---|---|---|

| 100 pph GCC/25 w/w% | 10 | 0.89 | 0.86 | 21.4 | 19.5 | 164 | 148 |

| 95 pph GCC/5 pph perlite/25 w/w% | 10 | 0.89 | 0.84 | 51.4 | 46.8 | 255 | 251 |

| 95 pph GCC/5 pph sepiolite/25 w/w% | 10 | 0.87 | 0.84 | 96.1 | 87.4 | 270 | 257 |

| 90 pph GCC/10 pph perlite/25 w/w% | 10 | 0.77 | 0.75 | 101.6 | 92.4 | 312 | 285 |

| 90 pph GCC/10 pph sepiolite/25 w/w% | 10 | 0.70 | 0.68 | 106.9 | 97.2 | 334 | 321 |

| 100 pph perlite/25 w/w% | 10 | 0.66 | 0.65 | 127.7 | 116.1 | 423 | 387 |

| 100 pph sepiolite/25 w/w% | 10 | 0.64 | 0.63 | 148.1 | 134.6 | 467 | 432 |

| 100 pph GCC/50 w/w% | 10 | 0.64 | 0.62 | 160.6 | 146.2 | 537 | 485 |

| 95 pph GCC/5 pph perlite/50 w/w% | 10 | 0.63 | 0.61 | 201.7 | 182.8 | 579 | 527 |

| 95 pph GCC/5 pph sepiolite/50 w/w% | 10 | 0.79 | 0.79 | 219.1 | 199.1 | 601 | 548 |

| 90 pph GCC/10 pph perlite/50 w/w% | 10 | 0.76 | 0.76 | 269.1 | 244.6 | 622 | 569 |

| 90 pph GCC/10 pph sepiolite/50 w/w% | 10 | 0.72 | 0.72 | 295.5 | 268.6 | 687 | 638 |

| 100 pph perlite/50 w/w% | 10 | 0.71 | 0.70 | 307.2 | 279.3 | 1334 | 1248 |

| 100 pph sepiolite/50 w/w% | 10 | 0.70 | 0.69 | 322.3 | 293.2 | 2234 | 2178 |

| 100 pph GCC/25 w/w% | 0 | 0.69 | 0.67 | 43.4 | 39.5 | 867 | 739 |

| 95 pph GCC/5 pph perlite/25 w/w% | 0 | 0.66 | 0.66 | 117.4 | 106.8 | 1210 | 943 |

| 95 pph GCC/5 pph sepiolite/25 w/w% | 0 | 0.65 | 0.63 | 162.1 | 147.4 | 1264 | 1195 |

| 90 pph GCC/10 pph perlite/25 w/w% | 0 | 0.61 | 0.59 | 189.6 | 172.4 | 1365 | 1375 |

| 90 pph GCC/10 pph sepiolite/25 w/w% | 0 | 0.58 | 0.56 | 216.9 | 197.2 | 1421 | 1494 |

| 100 pph perlite/25 w/w% | 0 | 0.67 | 0.66 | 259.7 | 236.1 | 1576 | 1468 |

| 100 pph sepiolite/25 w/w% | 0 | 0.66 | 0.62 | 291.1 | 264.6 | 1584 | 1543 |

| 100 pph GCC/50 w/w% | 0 | 0.64 | 0.62 | 325.7 | 296.1 | 2290 | 1724 |

| 95 pph GCC/5 pph perlite/50 w/w% | 0 | 0.61 | 0.59 | 353.4 | 321.3 | 2344 | 1892 |

| 95 pph GCC/5 pph sepiolite/50 w/w% | 0 | 0.73 | 0.72 | 426.1 | 387.4 | 2568 | 2034 |

| 90 pph GCC/10 pph perlite/50 w/w% | 0 | 0.67 | 0.66 | 535.9 | 487.2 | 2816 | 2132 |

| 90 pph GCC/10 pph sepiolite/50 w/w% | 0 | 0.68 | 0.64 | 588.1 | 534.6 | 3131 | 2633 |

| 100 pph perlite/50 w/w% | 0 | 0.64 | 0.62 | 845.1 | 768.2 | 3598 | 2882 |

| 100 pph sepiolite/50 w/w% | 0 | 0.57 | 0.55 | 1092.3 | 993.4 | 4175 | 3552 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dimic-Misic, K.; Imani, M.; Barac, N.; Janackovic, D.; Uskokovic, P.; Barcelo, E.; Gane, P. Micro Nanofibrillated Cellulose as Functional Additive Supporting Processability of Surface-Active Mineral Suspensions: Exemplified by Pixel Coating of an NOx-Sorbent Layer. Materials 2023, 16, 1598. https://doi.org/10.3390/ma16041598

Dimic-Misic K, Imani M, Barac N, Janackovic D, Uskokovic P, Barcelo E, Gane P. Micro Nanofibrillated Cellulose as Functional Additive Supporting Processability of Surface-Active Mineral Suspensions: Exemplified by Pixel Coating of an NOx-Sorbent Layer. Materials. 2023; 16(4):1598. https://doi.org/10.3390/ma16041598

Chicago/Turabian StyleDimic-Misic, Katarina, Monireh Imani, Nemanja Barac, Djordje Janackovic, Petar Uskokovic, Ernest Barcelo, and Patrick Gane. 2023. "Micro Nanofibrillated Cellulose as Functional Additive Supporting Processability of Surface-Active Mineral Suspensions: Exemplified by Pixel Coating of an NOx-Sorbent Layer" Materials 16, no. 4: 1598. https://doi.org/10.3390/ma16041598