Effect of High-Pressure Torsion and Annealing on the Structure, Phase Composition, and Microhardness of the Ti-18Zr-15Nb (at. %) Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

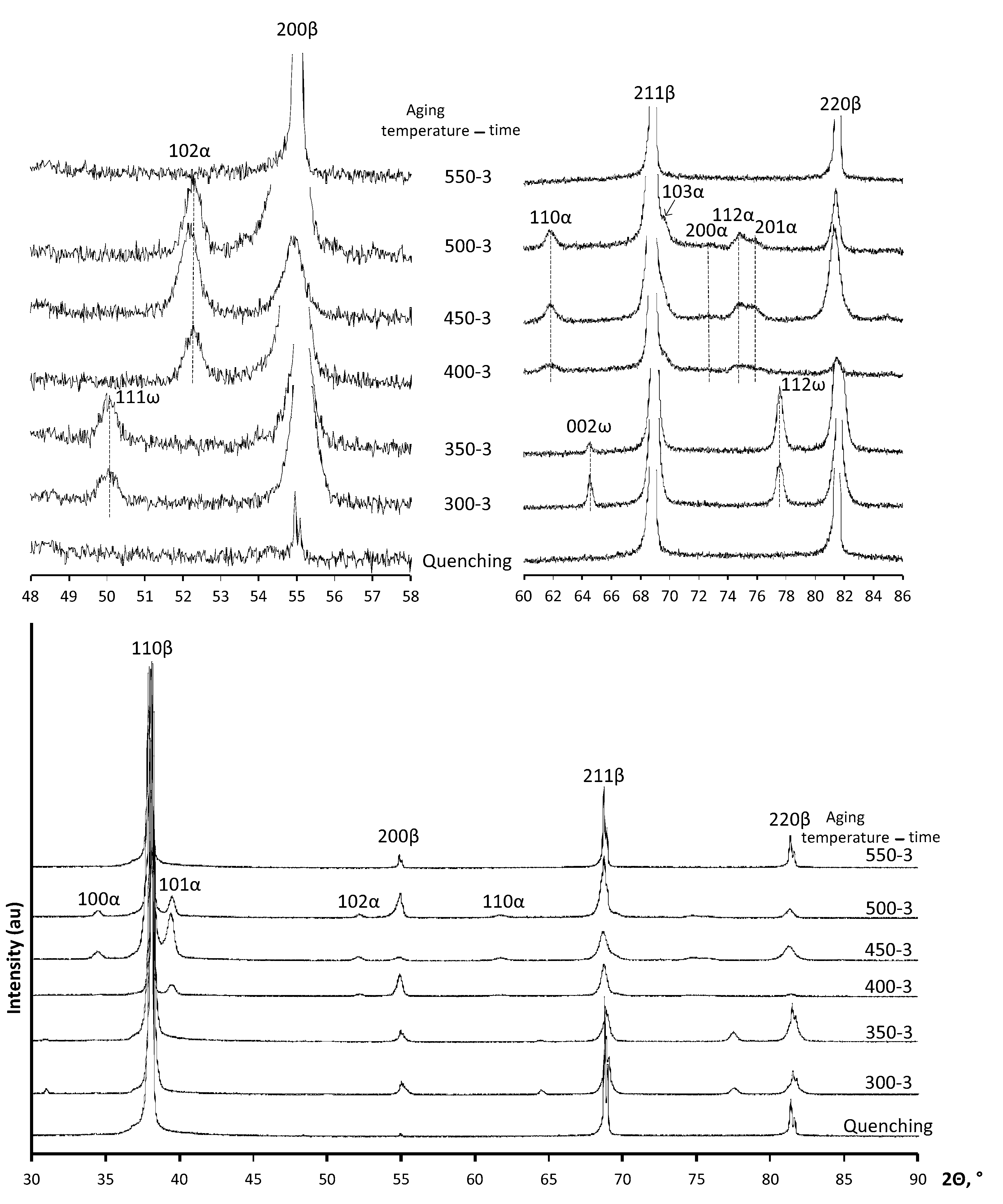

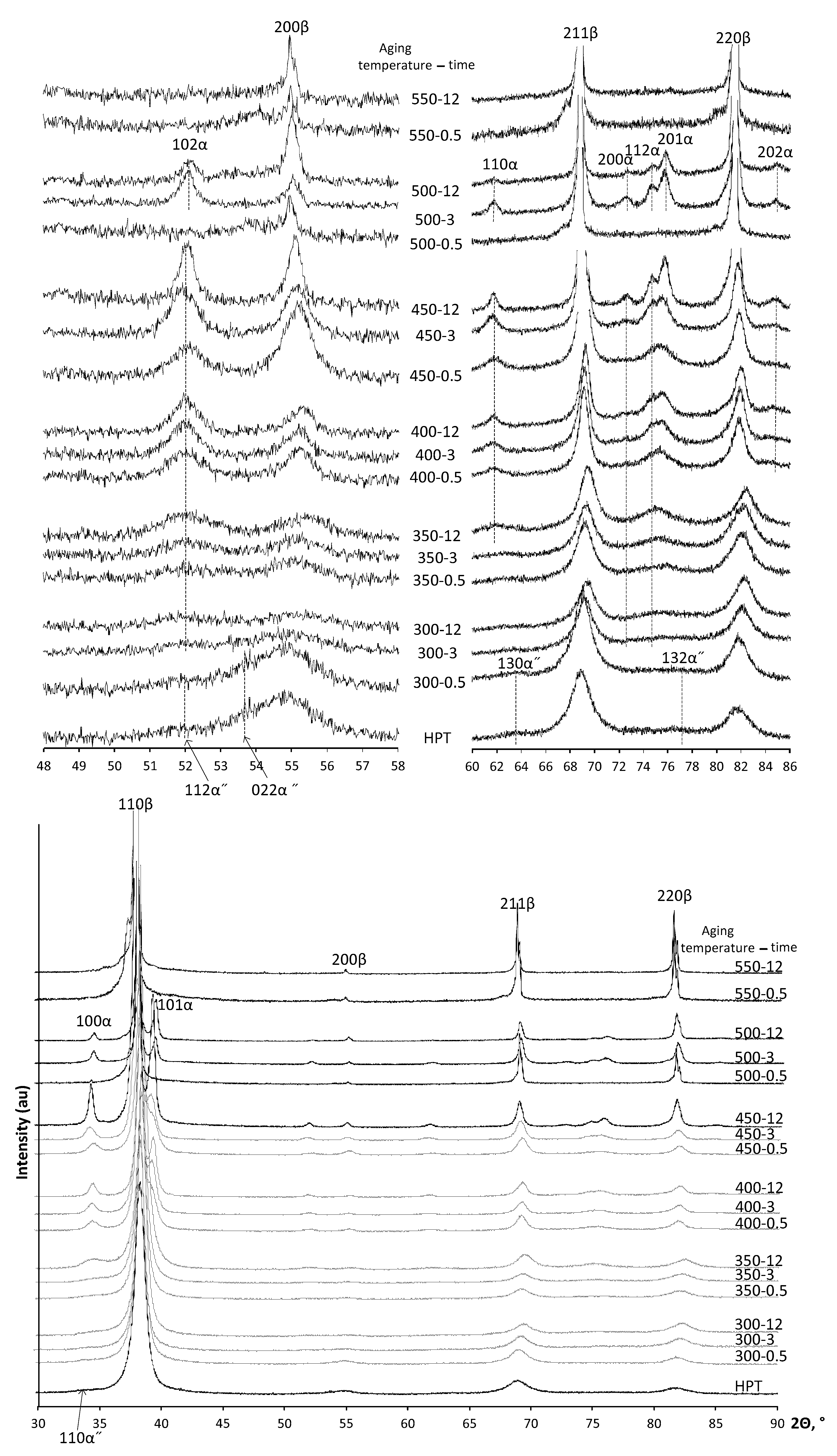

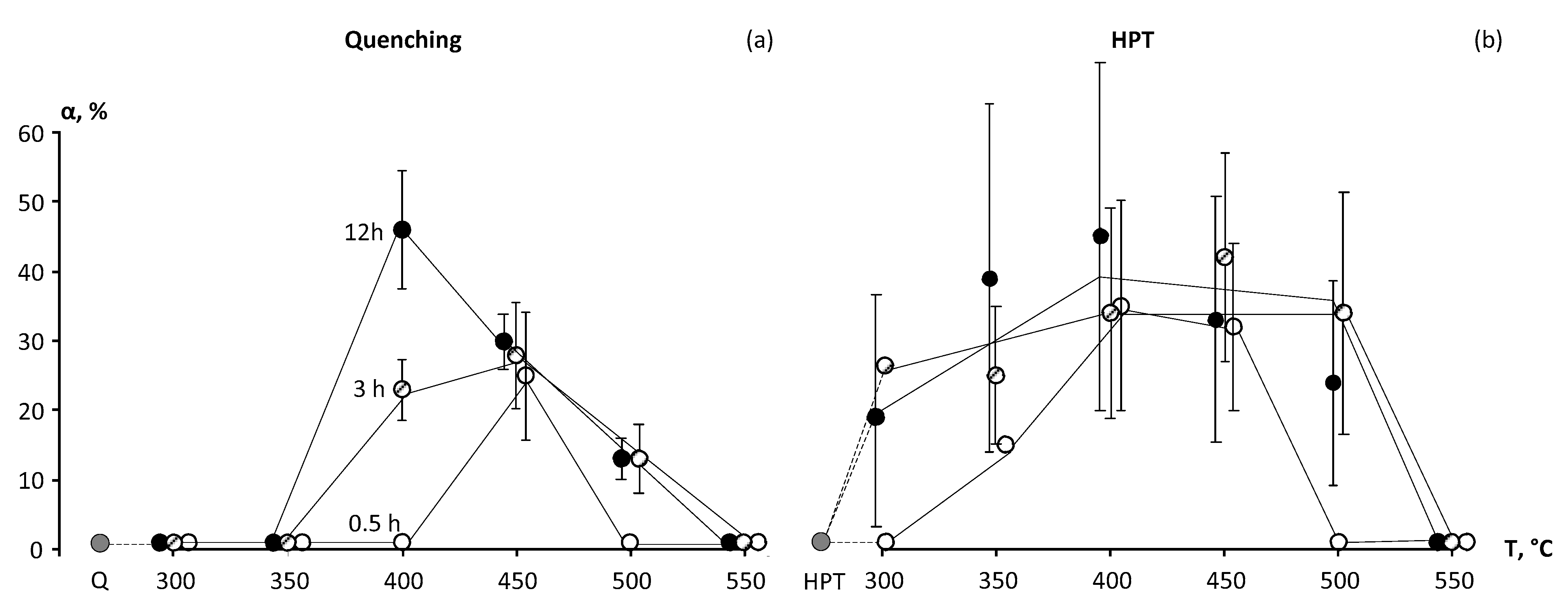

3.1. XRD Results

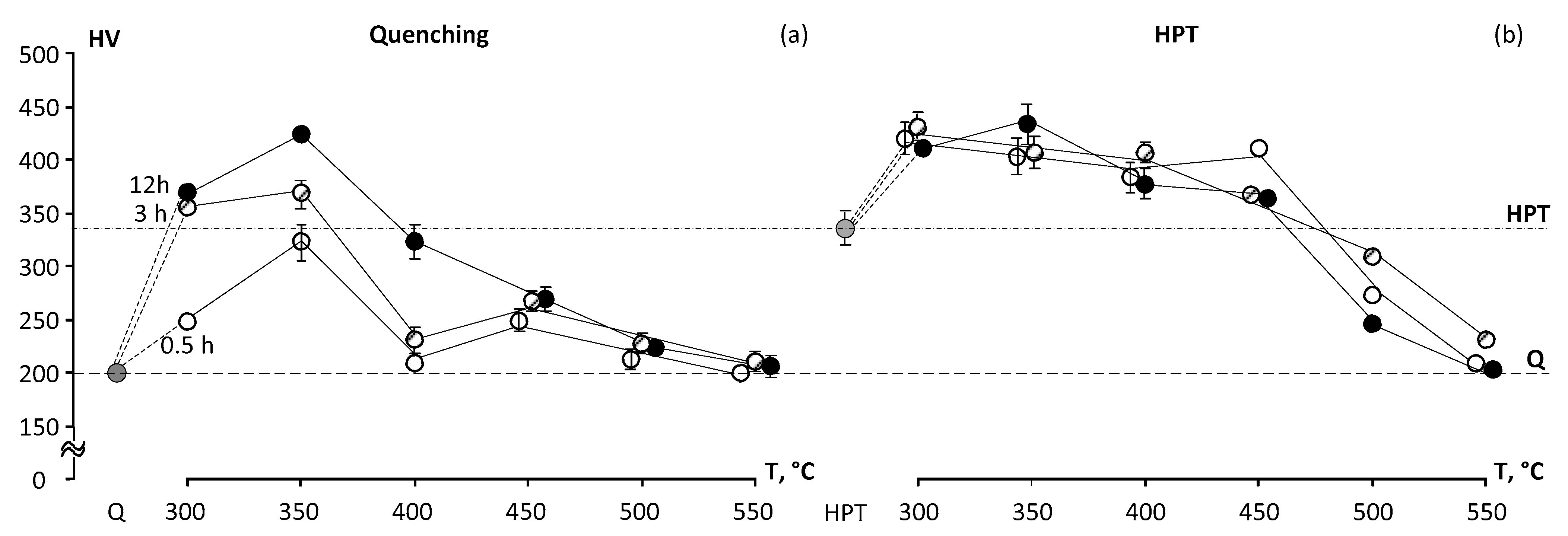

3.2. Microhardness Measurement Results

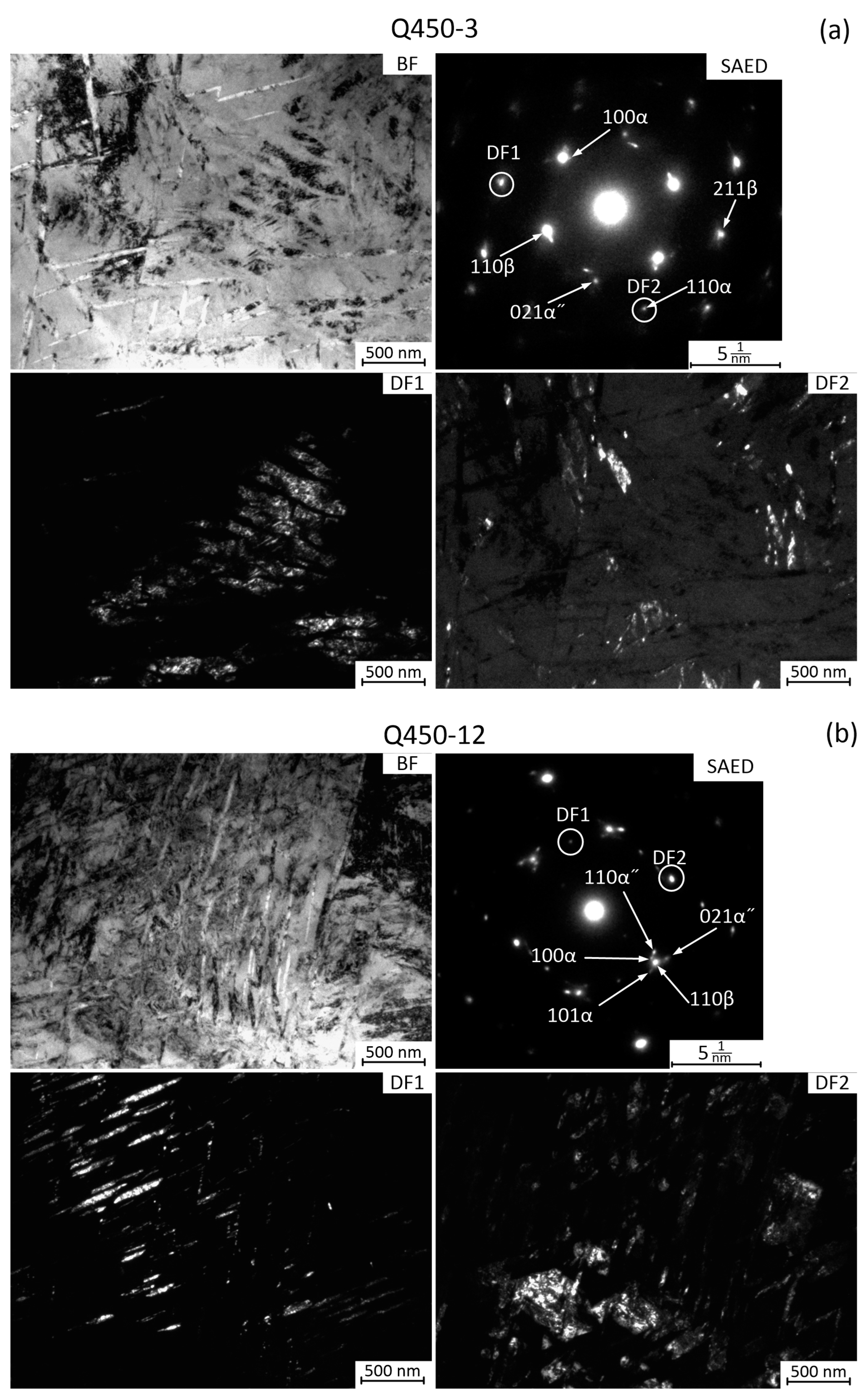

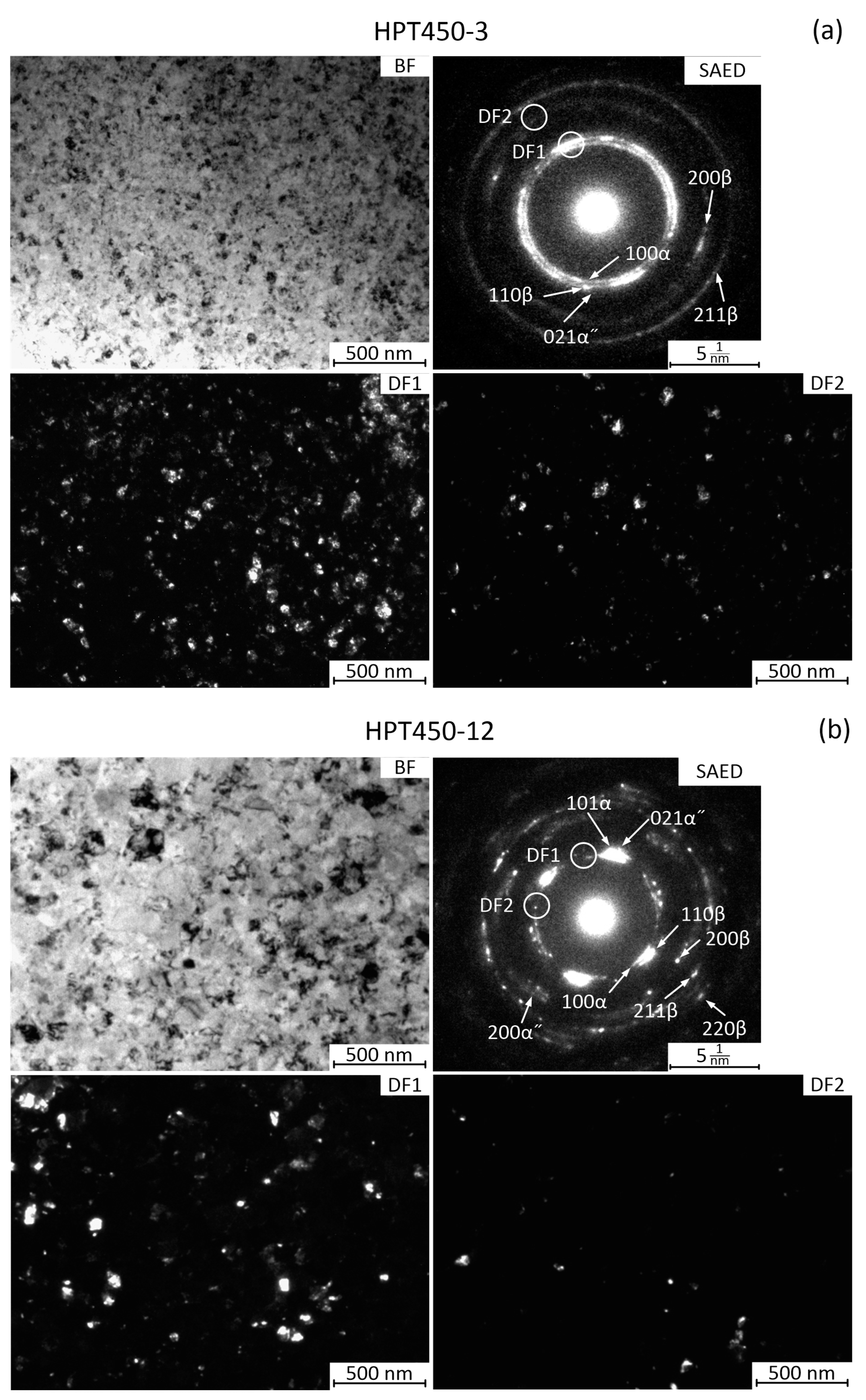

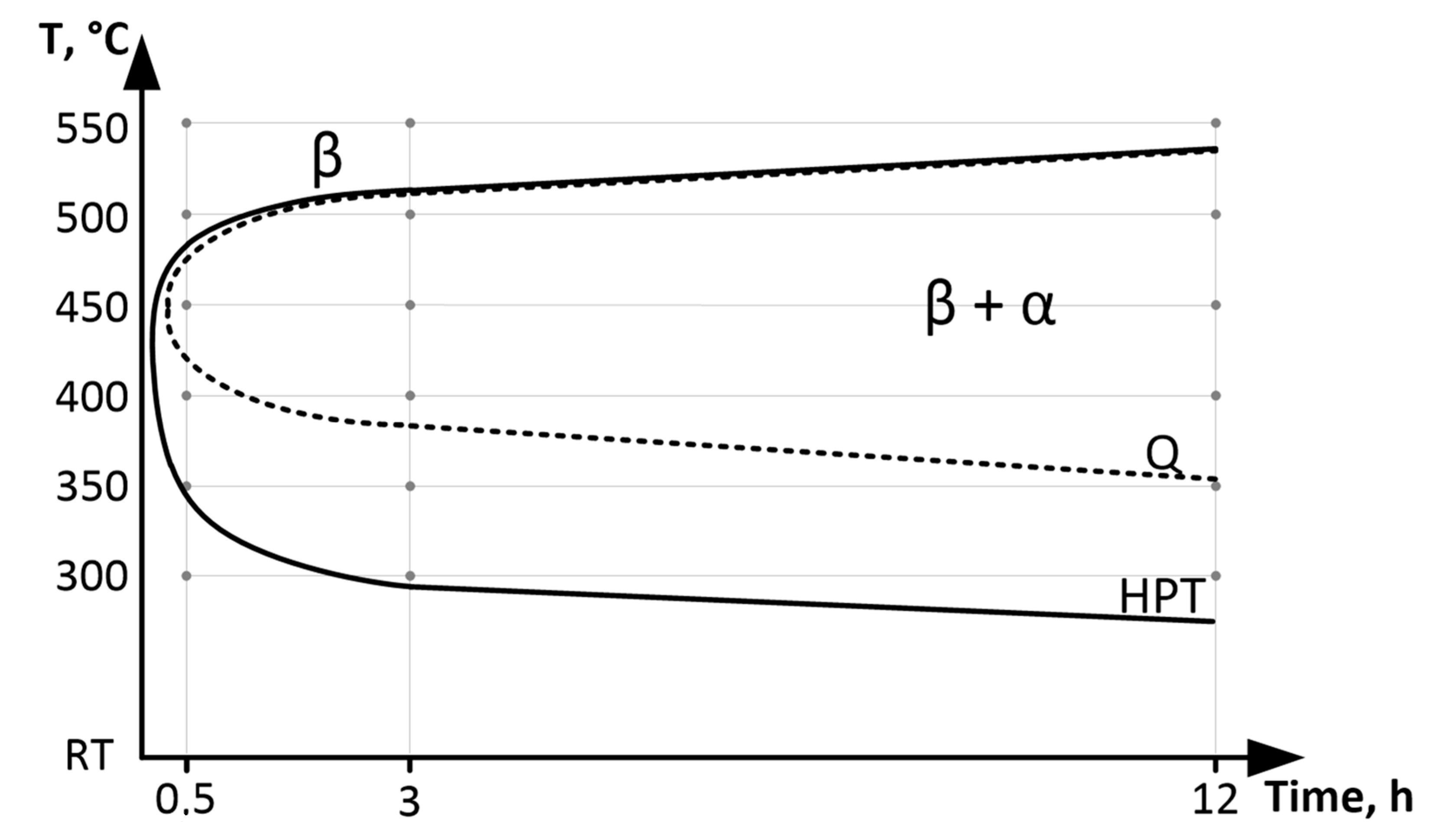

3.3. TEM and OM Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brunette, D.M. Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses, and Medical Applications; Engineering materials; Springer: Berlin, Germany; New York, NY, USA, 2001; Volume xiii, p. 1019. [Google Scholar]

- Noyama, Y.; Miura, T.; Ishimoto, T.; Itaya, T.; Niinomi, M.; Nakano, T. Bone Loss and Reduced Bone Quality of the Human Femur after Total Hip Arthroplasty under Stress-Shielding Effects by Titanium-Based Implant. Mater. Trans. 2012, 53, 565–570. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants—A Review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Sheremetyev, V.; Petrzhik, M.; Zhukova, Y.; Kazakbiev, A.; Arkhipova, A.; Moisenovich, M.; Prokoshkin, S.; Brailovski, V. Structural, Physical, Chemical, and Biological Surface Characterization of Thermomechanically Treated Ti-Nb-Based Alloys for Bone Implants. J. Biomed. Mater. Res.—Part B Appl. Biomater. 2020, 108, 647–662. [Google Scholar] [CrossRef] [PubMed]

- Ballor, J.; Li, T.; Prima, F.; Boehlert, C.J.; Devaraj, A. A Review of the Metastable Omega Phase in Beta Titanium Alloys: The Phase Transformation Mechanisms and Its Effect on Mechanical Properties. Int. Mater. Rev. 2022. [Google Scholar] [CrossRef]

- Chen, L.Y.; Cui, Y.W.; Zhang, L.C. Recent Development in Beta Titanium Alloys for Biomedical Applications. Metals 2020, 10, 1139. [Google Scholar] [CrossRef]

- Konopatsky, A.; Sheremetyev, V.; Dubinskiy, S.; Zhukova, Y.; Firestein, K.; Golberg, D.; Filonov, M.; Prokoshkin, S.; Brailovski, V. Structure and Superelasticity of Novel Zr-Rich Ti-Zr–Nb Shape Memory Alloys. Shape Mem. Superelasticity 2021, 7, 304–313. [Google Scholar] [CrossRef]

- Kim, H.Y.; Fu, J.; Tobe, H.; Kim, J.I.; Miyazaki, S. Crystal Structure, Transformation Strain, and Superelastic Property of Ti–Nb–Zr and Ti–Nb–Ta Alloys. Shape Mem. Superelasticity 2015, 1, 107–116. [Google Scholar] [CrossRef]

- Miyazaki, S. My Experience with Ti–Ni-Based and Ti-Based Shape Memory Alloys. Shape Mem. Superelasticity 2017, 3, 279–314. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Sheremetyev, V.; Lukashevich, K.; Kreitcberg, A.; Kudryashova, A.; Tsaturyants, M.; Galkin, S.; Andreev, V.; Prokoshkin, S.; Brailovski, V. Optimization of a Thermomechanical Treatment of Superelastic Ti-Zr-Nb Alloys for the Production of Bar Stock for Orthopedic Implants. J. Alloys Compd. 2022, 928, 167143. [Google Scholar] [CrossRef]

- Lukashevich, K.; Sheremetyev, V.; Komissarov, A.; Cheverikin, V.; Andreev, V.; Prokoshkin, S.; Brailovski, V. Effect of Cooling and Annealing Conditions on the Microstructure, Mechanical and Superelastic Behavior of a Rotary Forged Ti–18Zr–15Nb (at. %) Bar Stock for Spinal Implants. J. Funct. Biomater. 2022, 13, 259. [Google Scholar] [CrossRef] [PubMed]

- Zhukova, Y.; Korobkova, A.; Dubinskiy, S.; Pustov, Y.; Konopatsky, A.; Podgorny, D.; Filonov, M.; Prokoshkin, S.; Brailovski, V. The Electrochemical and Mechanical Behavior of Bulk and Porous Superelastic Ti–Zr-Based Alloys for Biomedical Applications. Materials 2019, 12, 2395. [Google Scholar] [CrossRef] [PubMed]

- Baranova, A.; Dubinskiy, S.; Tabachkova, N.; Prokoshkin, S.; Brailovski, V. Kinetic Features of the Isothermal ω-Phase Formation in Superelastic Ti-Nb-Zr Alloys. Mater. Lett. 2022, 325, 132820. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; Wiley: New York, NY, USA, 2013; pp. 1–440. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Semenova, I.P.; Latysh, V.V.; Rack, H.; Lowe, T.C.; Petruzelka, J.; Dluhos, L.; Hrusak, D.; Sochova, J. Nanostructured Titanium for Biomedical Applications. Adv. Eng. Mater. 2008, 10, B15–B17. [Google Scholar] [CrossRef]

- Waitz, T.; Antretterb, T.; Fischerb, F.D.; Simhad, N.K.; Karnthale, H.P. Size effects on the martensitic phase transformation of NiTi nanograins. J. Mech. Phys. Solids 2007, 55, 419–444. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Gunderov, D.V.; Lukyanov, A.V.; Pushin, V.G. Mechanical Behavior of Nanocrystalline TiNi Alloy Produced by Severe Plastic Deformation. J. Mater. Sci. 2012, 47, 7848–7853. [Google Scholar] [CrossRef]

- Prokoshkin, S.; Dubinskiy, S.; Brailovski, V. Features of a Nanosubgrained Structure in Deformed and Annealed Ti–Ni SMA: A Brief Review. Shape Mem. Superelasticity 2019, 5, 336–345. [Google Scholar] [CrossRef]

- Gunderov, D.; Prokoshkin, S.; Churakova, A.; Sheremetyev, V.; Ramazanov, I. Effect of HPT and Accumulative HPT on Structure Formation and Microhardness of the Novel Ti18Zr15Nb Alloy. Mater. Lett. 2021, 283, 128819. [Google Scholar] [CrossRef]

- Sheremetyev, V.; Churakova, A.; Derkach, M.; Gunderov, D.; Raab, G.; Prokoshkin, S. Effect of ECAP and Annealing on Structure and Mechanical Properties of Metastable Beta Ti-18Zr-15Nb (at.%) Alloy. Mater. Lett. 2021, 305, 130760. [Google Scholar] [CrossRef]

- Churakova, A.A.; Gunderov, D.V.; Raab, G.I.; Prokoshkin, S.D.; Sheremetyev, V.A.; Filho, P.N.L.; Pedro, J.; Claro, A.P.R.A. Influence of ECAP on the Structure and Properties of Ti18Zr15Nb and Ti10Mo8Nb6Zr Alloys for Medical Application. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1014, 012006. [Google Scholar] [CrossRef]

- Kilmametov, A.R.; Khristoforov, A.V.; Wilde, G.; Valiev, R.Z. X-ray Studies of Nanostructured Metals Processed by Severe Plastic Deformation. Z. Fur Krist 2007, 2 (Suppl. 26), 339–344. [Google Scholar] [CrossRef]

- Edalati, K.; Matsubara, E.; Horita, Z. Processing Pure Ti by High-Pressure Torsion in Wide Ranges of Pressures and Strain. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 2079–2086. [Google Scholar] [CrossRef]

- Shirooyeh, M.; Xu, J.; Langdon, T.G. Microhardness Evolution and Mechanical Characteristics of Commercial Purity Titanium Processed by High-Pressure Torsion. Mater. Sci. Eng. A 2014, 614, 223–231. [Google Scholar] [CrossRef]

- Gatina, S.; Semenova, I.; Janecek, M.; Strasky, J. Effect of High Pressure Torsion on the Aging Kinetics of β-Titanium Ti-15Mo Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012068. [Google Scholar] [CrossRef]

- Janeček, M.; Čížek, J.; Stráský, J.; Václavová, K.; Hruška, P.; Polyakova, V.; Gatina, S.; Semenova, I. Microstructure Evolution in Solution Treated Ti15Mo Alloy Processed by High Pressure Torsion. Mater. Charact. 2014, 98, 233–240. [Google Scholar] [CrossRef]

- Gatina, S.; Semenova, I.; Leuthold, J.; Valiev, R. Nanostructuring and Phase Transformations in the β-Alloy Ti-15Mo during High-Pressure Torsion. Adv. Eng. Mater. 2015, 17, 1742–1747. [Google Scholar] [CrossRef]

- Brailovski, V.; Prokoshkin, S.; Inaekyan, K.; Demers, V. Functional Properties of Nanocrystalline, Submicrocrystalline and Polygonized Ti–Ni Alloys Processed by Cold Rolling and Post-Deformation Annealing. J. Alloys Compd. 2011, 509, 2066–2075. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Prokoshkin, S.D.; Chernavina, A.A. Peculiarities of Implementation of Abnormally High Shape Memory Effects in Thermomechanically Treated Ti-Ni Alloys. Inorg. Mater. Appl. Res. 2013, 4, 348–355. [Google Scholar] [CrossRef]

- Poletika, T.M.; Girsova, S.L.; Lotkov, A.I. Ti3Ni4 Precipitation Features in Heat-Treated Grain/Subgrain Nanostructure in Ni-Rich TiNi Alloy. Intermetallics 2020, 127, 106966. [Google Scholar] [CrossRef]

- Gorelik, S.S.; Skakov, Y.A.; Rastorguev, L.N. X-ray and Electron-Optical Analysis, 4th ed.; Revised and Additional; MISIS: Moscow, Russia, 2002; p. 357. [Google Scholar]

- Shmueli, U. (Ed.) International Tables for X-ray Crystallography; IDC: Birmingam, UK, 1980; Volume 1. [Google Scholar]

- Devaraj, A.; Williams, R.E.A.; Nag, S.; Srinivasan, R.; Fraser, H.L.; Banerjee, R. Three-dimensional morphology and composition of omega precipitates in a binary titanium–molybdenum alloy. Scr. Mater. 2009, 61, 701–704. [Google Scholar] [CrossRef]

- Ankem, S.; Seagle, S.R. Heat treatment of metastable beta titanium alloys. In Beta Titanium Alloys in the 1980’s; IntechOpen: London, UK, 1983; pp. 107–126. [Google Scholar]

- Wang, Y.B.; Wang, Y.B.; Zhao, Y.H.; Lian, Q.; Liao, X.Z.; Valiev, R.Z.; Ringer, S.P.; Zhu, Y.T.; Lavernia, E.J. Grain size and reversible beta to omega phase transformation in a Ti alloy. Scr. Mater. 2010, 63, 613–616. [Google Scholar] [CrossRef]

| Type | {hkl} | ||

|---|---|---|---|

| BCC | 110 | 12 | |

| 200 | 6 | ||

| 211 | 24 | ||

| 220 | 12 | ||

| 310 | 24 | ||

| 222 | 8 | ||

| HCP | 100 | 6 | |

| 002 | 2 | ||

| 101 | 12 | ||

| 102 | 12 | ||

| 110 | 6 | ||

| 103 | 12 | ||

| 200 | 6 | ||

| 112 | 12 | ||

| 201 | 12 | ||

| 004 | 2 | ||

| 022 | 12 |

| State | Annealing Temperature, °C | Annealing Time | ||

|---|---|---|---|---|

| 0.5 h | 3 h | 12 h | ||

| Q | 300 | ω* | ω* | ω* |

| Q | 350 | ω* | ω* | ω* |

| α phase content, % | ||||

| Q | 400 | - | 23 ± 4 | 46 ± 9 |

| Q | 450 | 26 ± 9 | 29 ± 8 | 30 ± 4 |

| Q | 500 | - | 11 ± 4 | 13 ± 3 |

| Q | 550 | - | - | - |

| HPT | 300 | - | 26 ** | 19 ** |

| HPT | 350 | 15 ** | 25 ± 11 | 39 ± 27 |

| HPT | 400 | 35 ± 16 | 34 ± 17 | 46 ± 28 |

| HPT | 450 | 32 ± 12 | 42 ± 16 | 33 ± 17 |

| HPT | 500 | 0 | 34 ± 18 | 25 ± 15 |

| HPT | 550 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gunderov, D.; Kim, K.; Gunderova, S.; Churakova, A.; Lebedev, Y.; Nafikov, R.; Derkach, M.; Lukashevich, K.; Sheremetyev, V.; Prokoshkin, S. Effect of High-Pressure Torsion and Annealing on the Structure, Phase Composition, and Microhardness of the Ti-18Zr-15Nb (at. %) Alloy. Materials 2023, 16, 1754. https://doi.org/10.3390/ma16041754

Gunderov D, Kim K, Gunderova S, Churakova A, Lebedev Y, Nafikov R, Derkach M, Lukashevich K, Sheremetyev V, Prokoshkin S. Effect of High-Pressure Torsion and Annealing on the Structure, Phase Composition, and Microhardness of the Ti-18Zr-15Nb (at. %) Alloy. Materials. 2023; 16(4):1754. https://doi.org/10.3390/ma16041754

Chicago/Turabian StyleGunderov, Dmitry, Karina Kim, Sofia Gunderova, Anna Churakova, Yuri Lebedev, Ruslan Nafikov, Mikhail Derkach, Konstantin Lukashevich, Vadim Sheremetyev, and Sergey Prokoshkin. 2023. "Effect of High-Pressure Torsion and Annealing on the Structure, Phase Composition, and Microhardness of the Ti-18Zr-15Nb (at. %) Alloy" Materials 16, no. 4: 1754. https://doi.org/10.3390/ma16041754

APA StyleGunderov, D., Kim, K., Gunderova, S., Churakova, A., Lebedev, Y., Nafikov, R., Derkach, M., Lukashevich, K., Sheremetyev, V., & Prokoshkin, S. (2023). Effect of High-Pressure Torsion and Annealing on the Structure, Phase Composition, and Microhardness of the Ti-18Zr-15Nb (at. %) Alloy. Materials, 16(4), 1754. https://doi.org/10.3390/ma16041754