Creep Deformation and Its Effect on Mechanical Properties and Microstructure of Magnesium Phosphate Cement Concrete

Abstract

1. Introduction

2. Materials and Methods

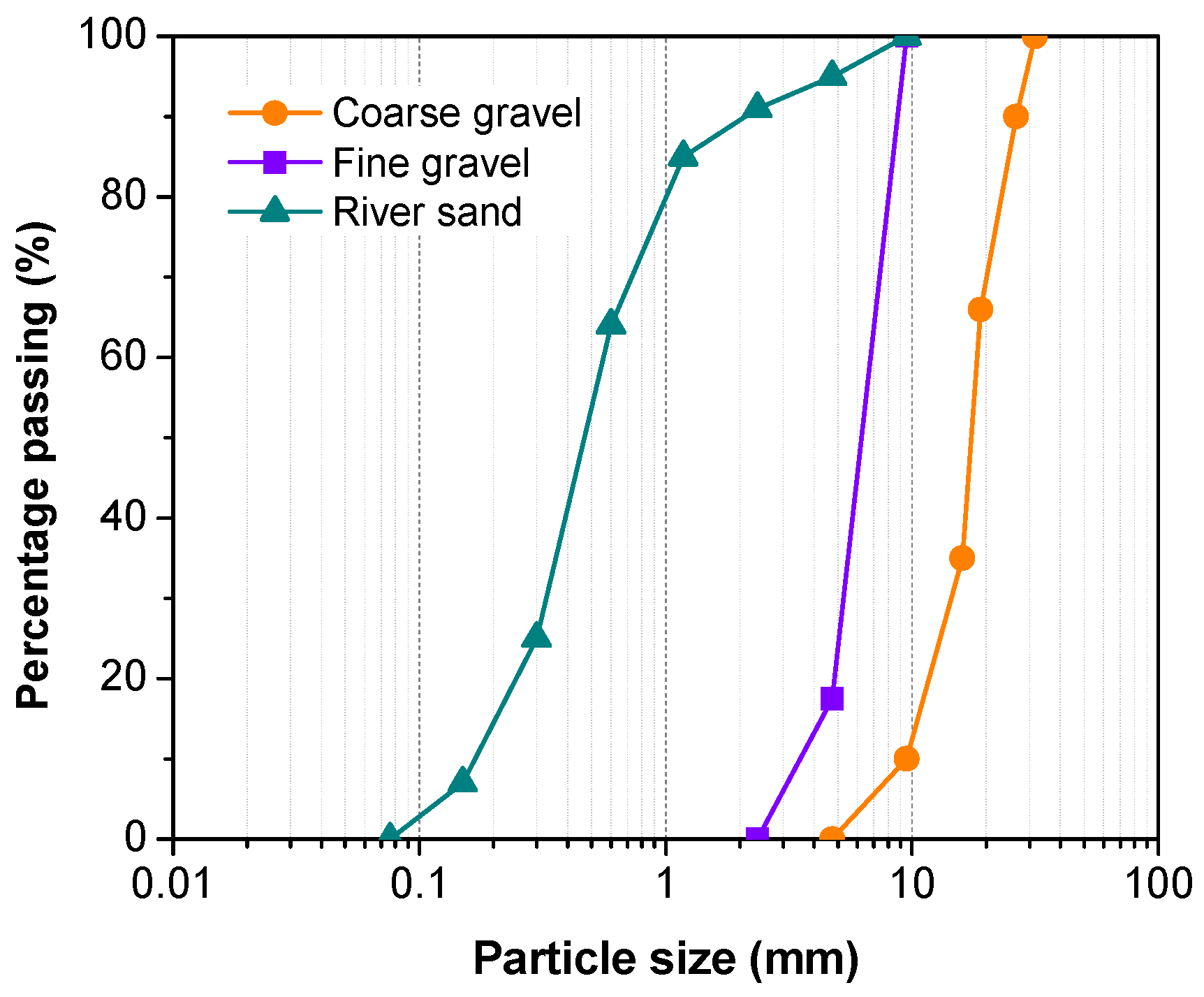

2.1. Raw Materials

2.2. Concrete Mixture and Sample Preparation

2.3. Test Methods

3. Results and Discussion

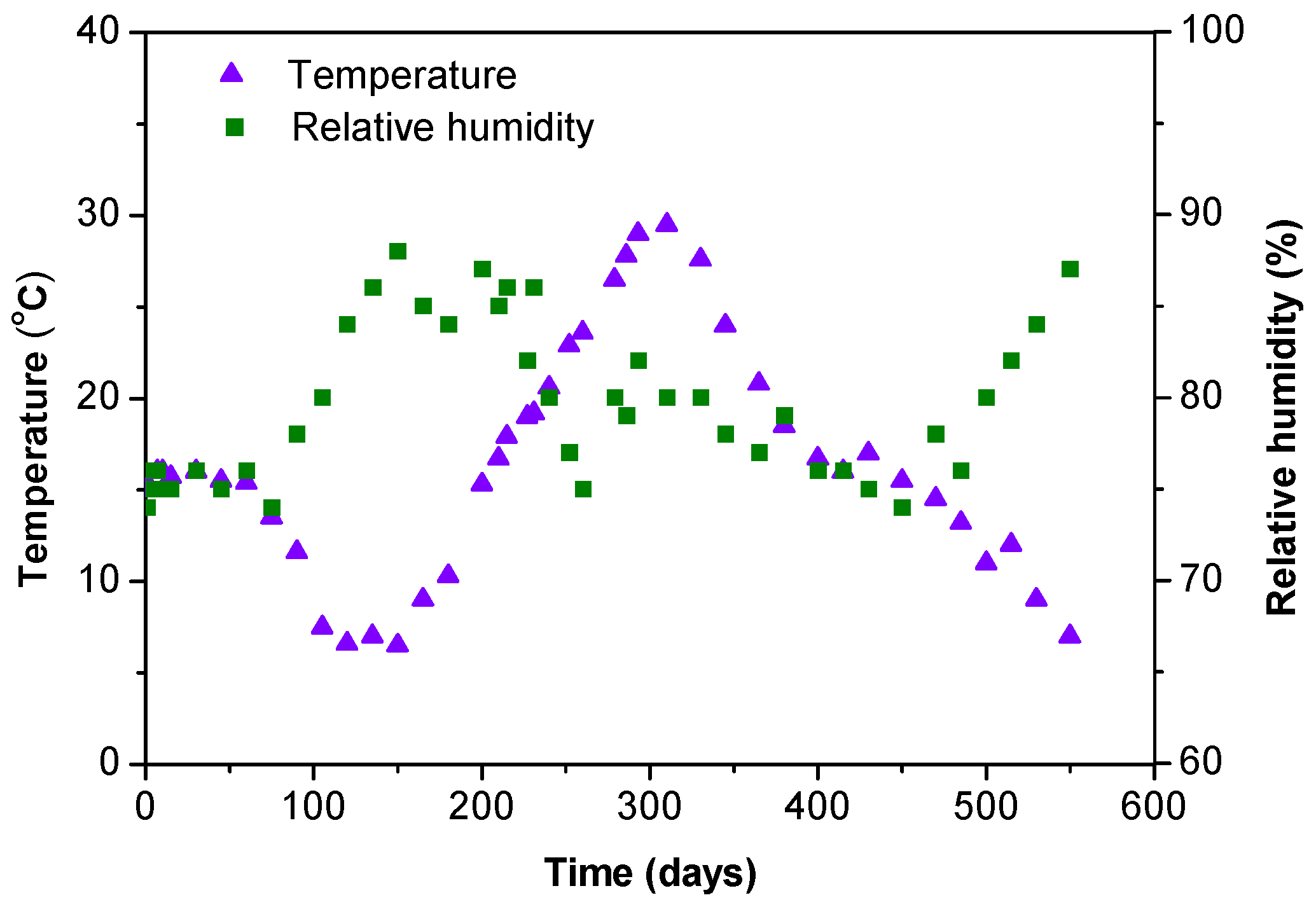

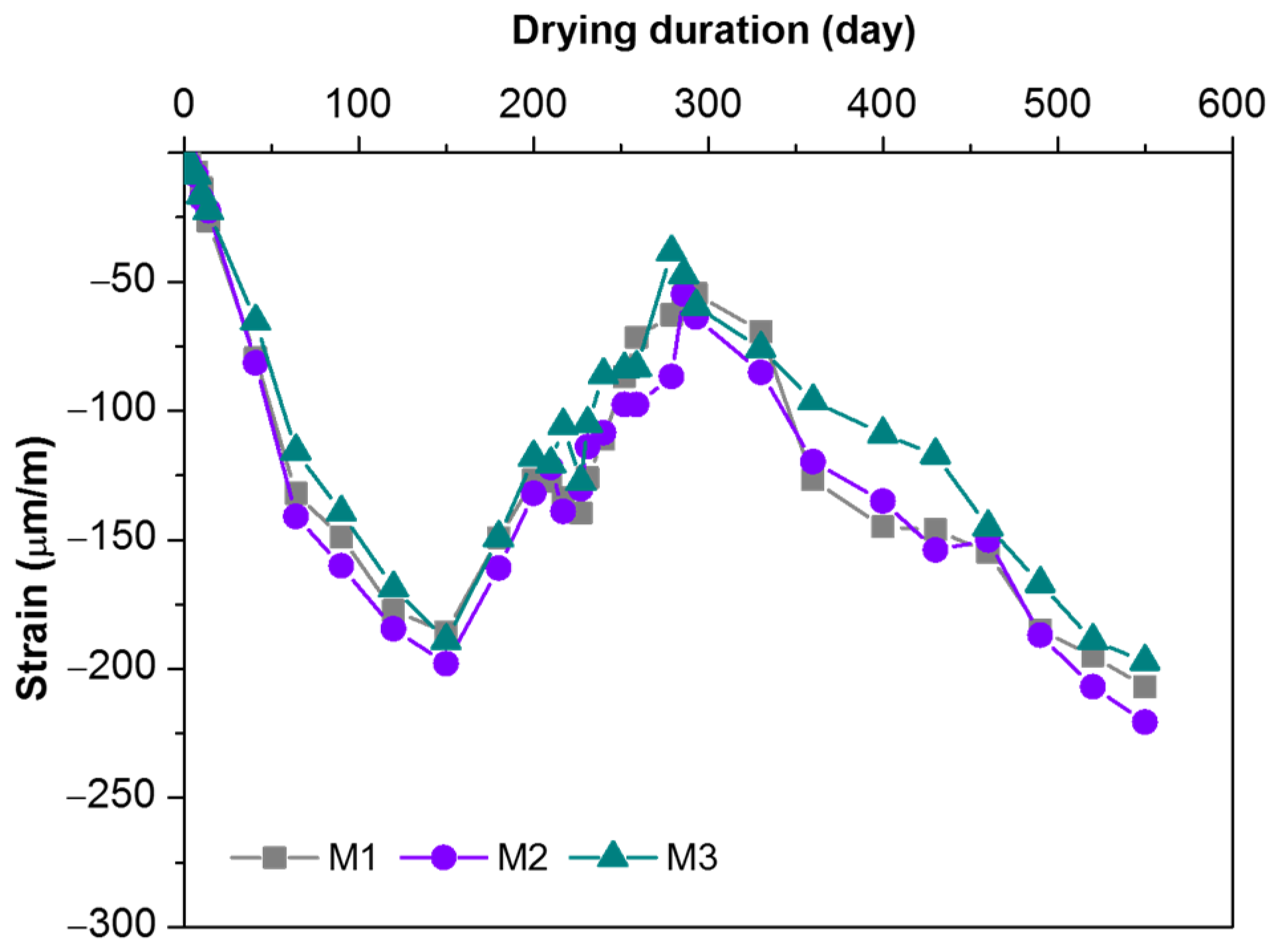

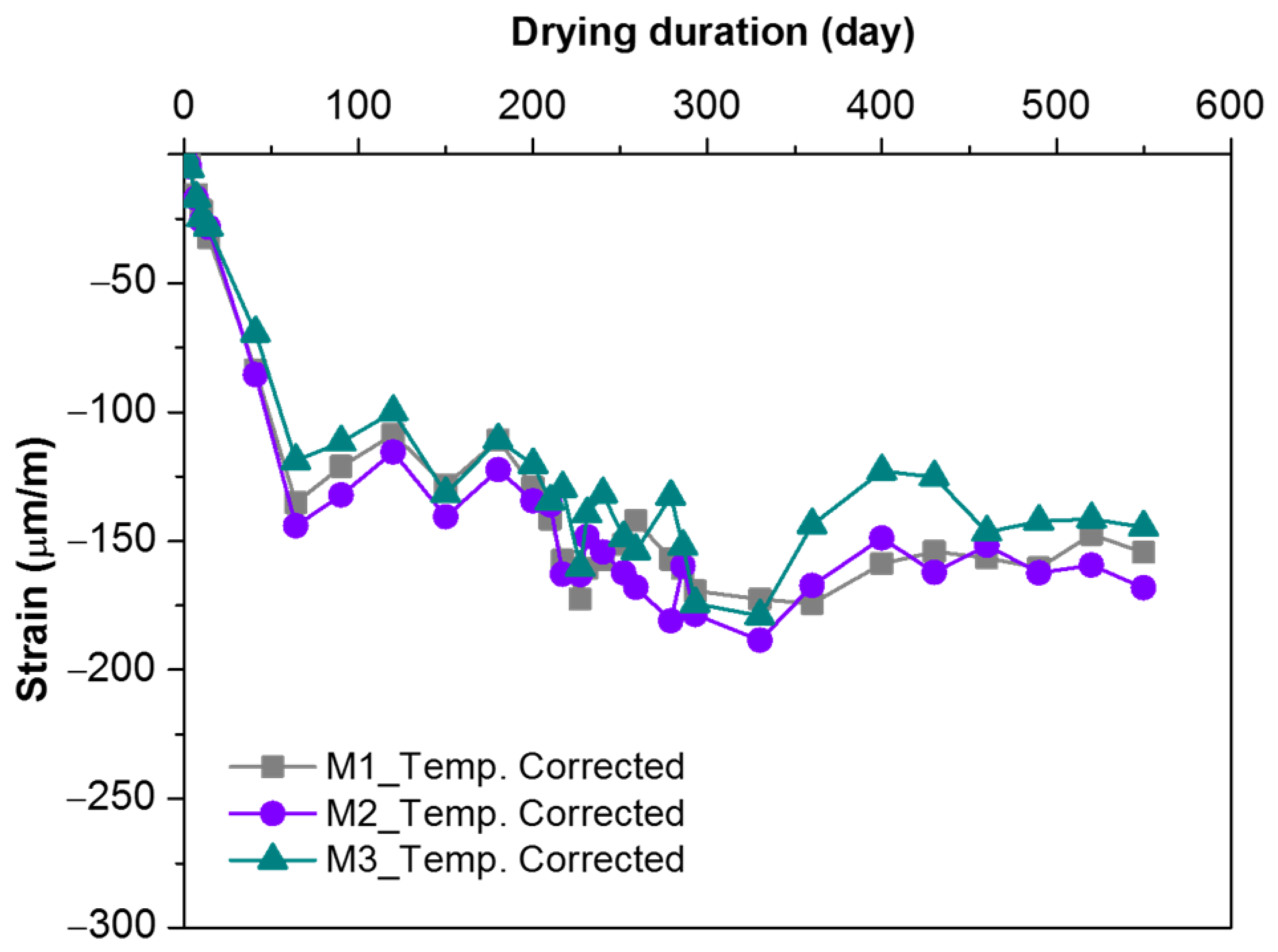

3.1. Shrinkage

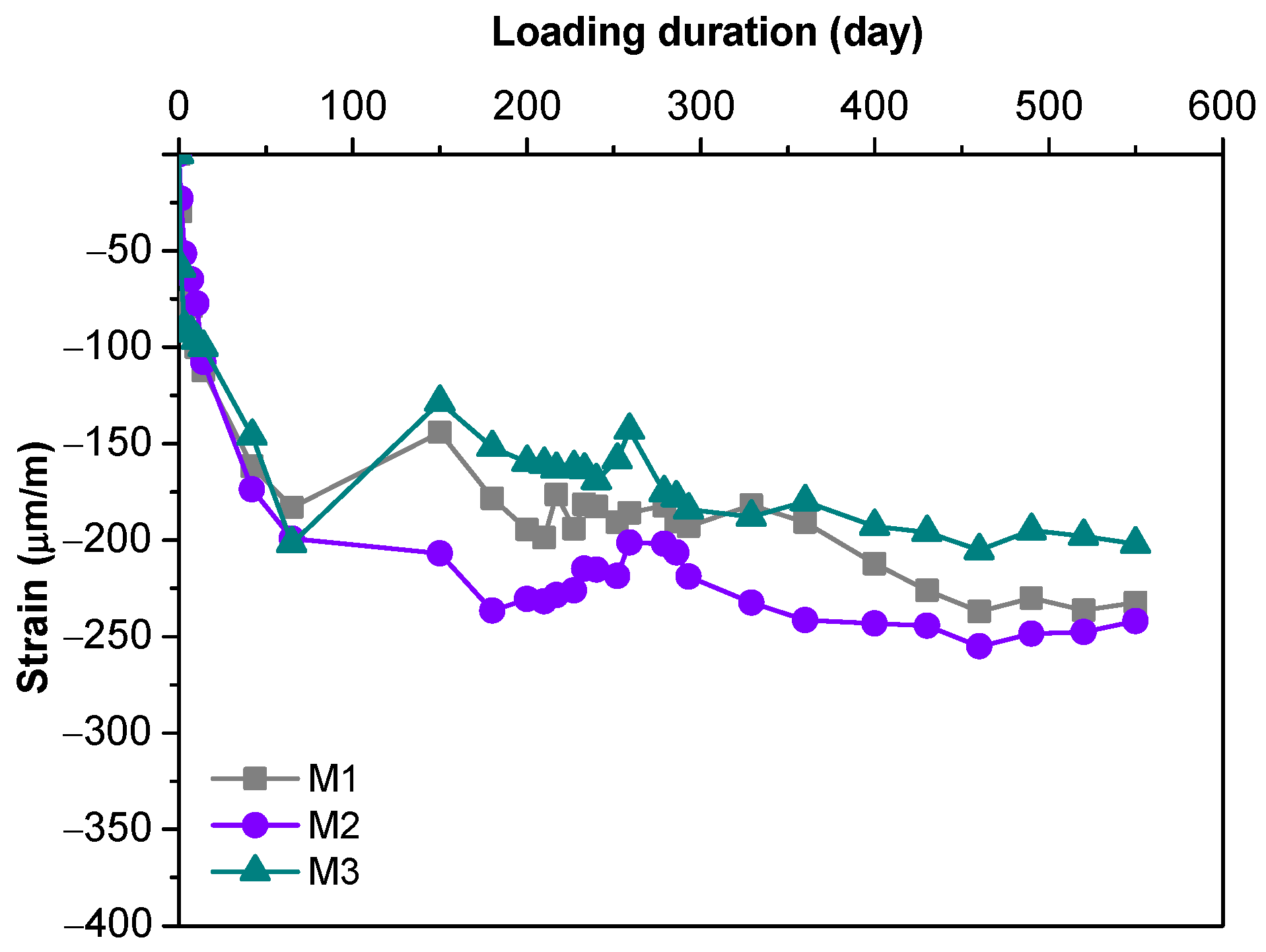

3.2. Creep

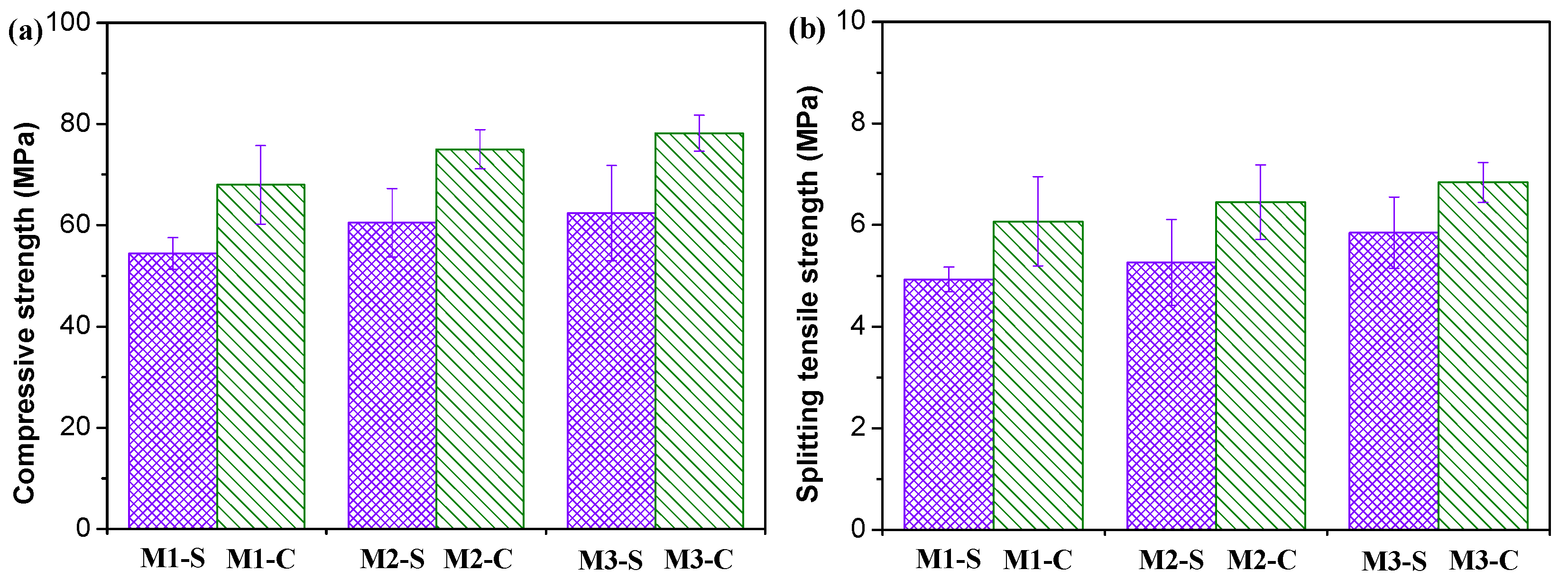

3.3. Mechanical Properties

3.4. Microstructure Analysis

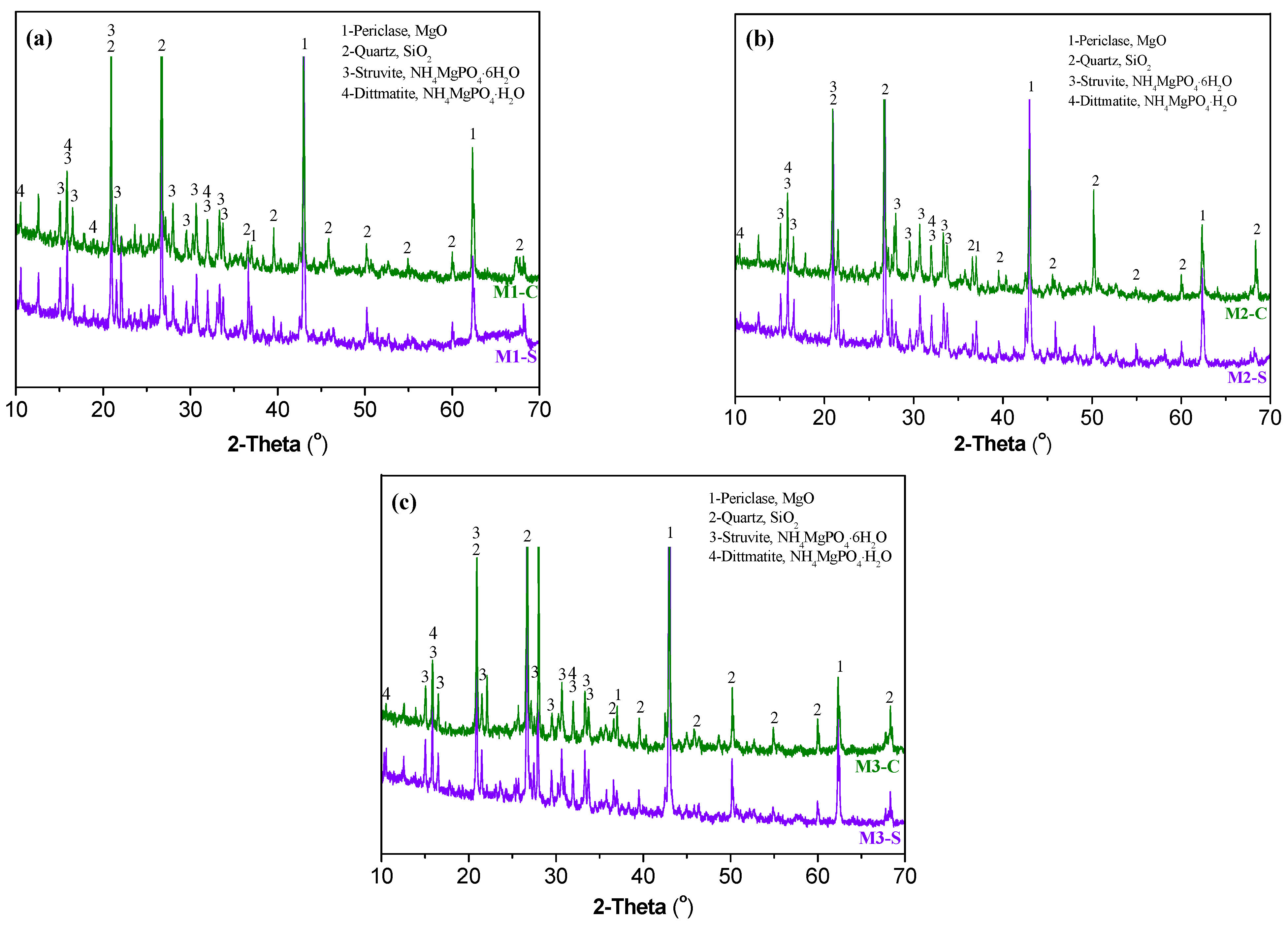

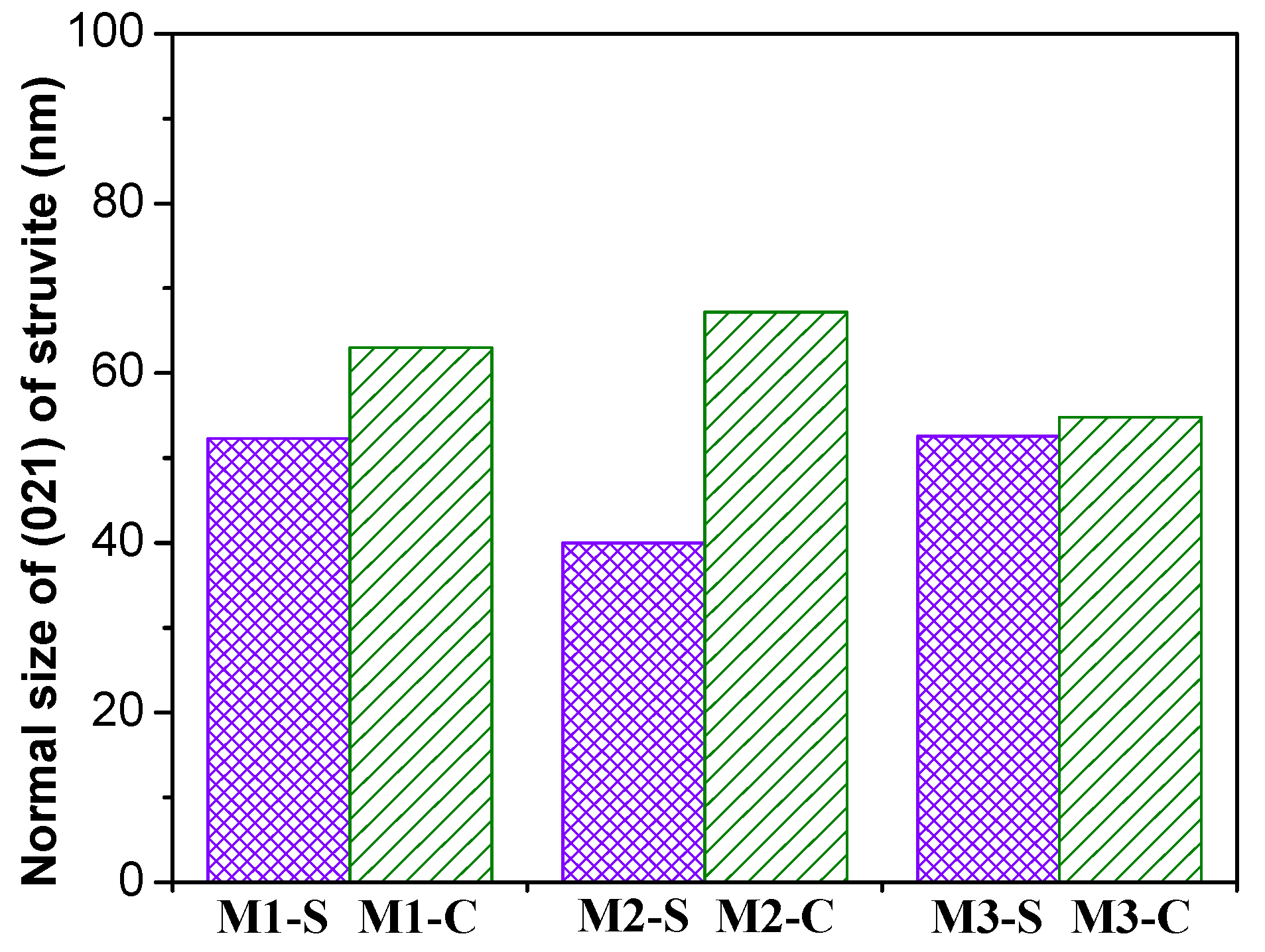

3.4.1. XRD Analysis

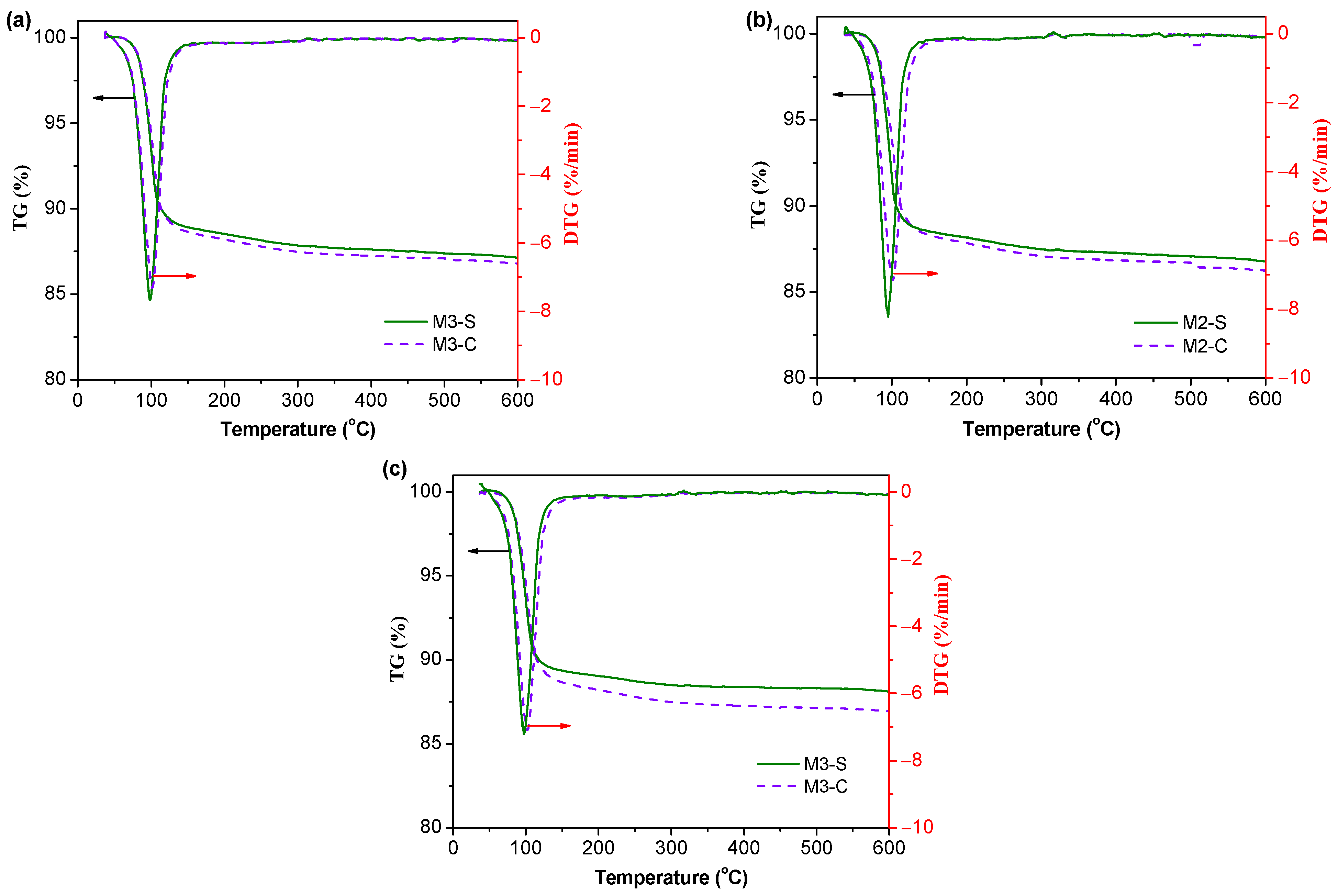

3.4.2. Thermal Analysis

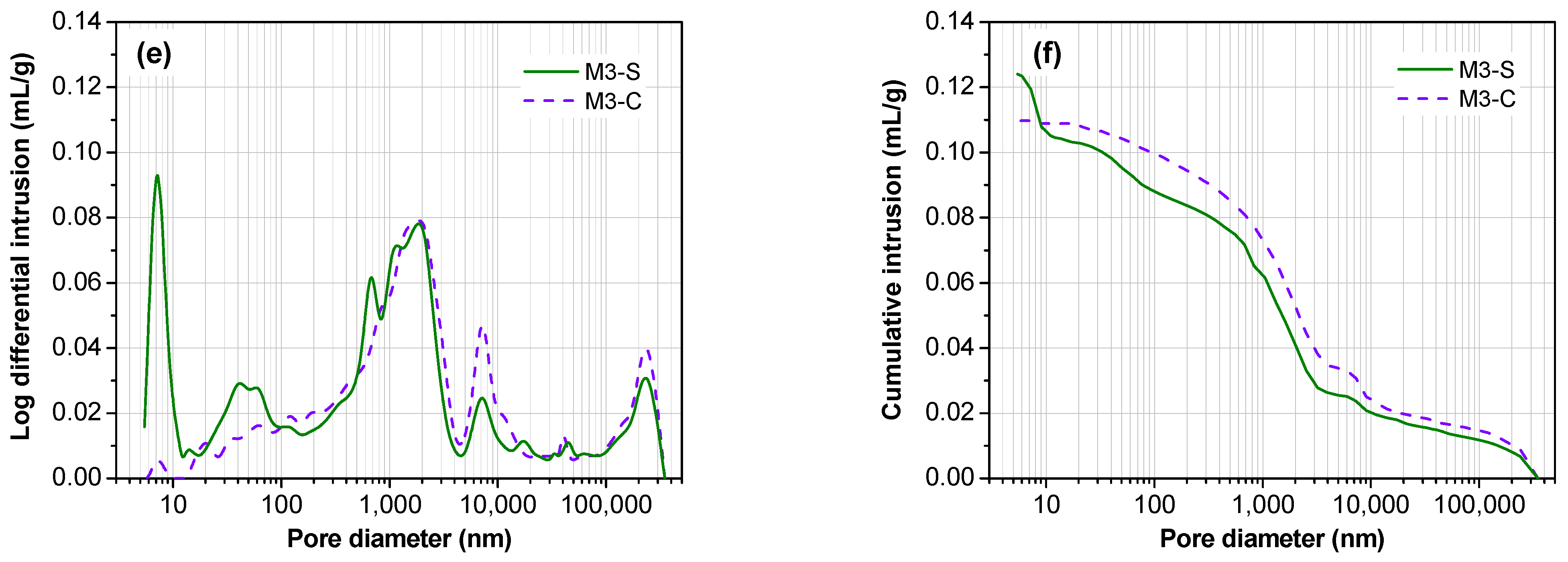

3.4.3. Analysis of Pore Structure

3.4.4. SEM Microstructure Analysis

4. Conclusions

- (1)

- Under natural conditions, temperature changes affected significantly the free shrinkage strain but had less effect on the compressive creep strain. The shrinkage and creep strains of MPC concretes stabilized in the ranges of −140 to −170 με and −200 to −240 με after 550 days, respectively, highlighting the good volume stability of MPC concrete. This can be attributed to the low water-to-cement ratio and the formation of crystalline struvite;

- (2)

- The creep strain had almost no effect on the type of hydration products but increased the crystal size and the quantity of hydration product struvite. The microstructure of MPC concrete can be densified under sustained loading, characterized by reduced porosity, particularly in the volume of pores smaller than 20 nm and larger than 200 nm;

- (3)

- Compared to shrinkage specimens, the compressive strength and splitting tensile strength of creep specimens were increased by 24.0–25.3% and 16.9–23.1%, respectively. The positive effect of creep on the mechanical strengths of MPC concrete could be due to the modification of the hydration products and densification of the microstructure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wagh, A.S. Chemically Bonded Phosphate Ceramics, 2nd ed.; Matthew Deans: Naperville, IL, USA, 2016. [Google Scholar]

- Walling, S.A.; Provis, J.L. Magnesia-based cements: A journey of 150 years, and cements for the future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef]

- Qin, J.; Dai, F.; Ma, H.; Dai, X.; Li, Z.; Jia, X.; Qian, J. Development and characterization of magnesium phosphate cement based ultra-high performance concrete. Compos. Part B Eng. 2022, 234, 109694. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; Dai, X.; You, C.; Ma, H.; Li, Z. Effect of water content on microstructure and properties of magnesium potassium phosphate cement pastes with different magnesia-to-phosphate ratios. J. Am. Ceram. Soc. 2021, 104, 2799–2819. [Google Scholar] [CrossRef]

- Xu, B.; Lothenbach, B.; Leemann, A.; Winnefeld, F. Reaction mechanism of magnesium potassium phosphate cement with high magnesium-to-phosphate ratio. Cem. Concr. Res. 2018, 108, 140–151. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Yan, C.; Ma, H.; Luo, Z.; Zhou, X.; Wang, L. Influence of phosphorus sources on the compressive strength and microstructure of ferronickel slag-based magnesium phosphate cement. Materials 2022, 15, 1965. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B.; Li, Z. Magnesium potassium phosphate cement paste: Degree of reaction, porosity and pore structure. Cem. Concr. Res. 2014, 65, 96–104. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B.; Liu, J.; Pei, H.; Li, Z. Effects of water content, magnesia-to-phosphate molar ratio and age on pore structure, strength and permeability of magnesium potassium phosphate cement paste. Mater. Des. 2014, 64, 497–502. [Google Scholar] [CrossRef]

- Xu, B.; Winnefeld, F.; Kaufmann, J.; Lothenbach, B. Influence of magnesium-to-phosphate ratio and water-to-cement ratio on hydration and properties of magnesium potassium phosphate cements. Cem. Concr. Res. 2019, 123, 105781. [Google Scholar] [CrossRef]

- Le Rouzic, M.; Chaussadent, T.; Stefan, L.; Saillio, M. On the influence of Mg/P ratio on the properties and durability of magnesium potassium phosphate cement pastes. Cem. Concr. Res. 2017, 96, 27–41. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B. Potential to design magnesium potassium phosphate cement paste based on an optimal magnesia-to-phosphate ratio. Mater. Des. 2017, 118, 81–88. [Google Scholar] [CrossRef]

- You, C.; Qian, J.S.; Qin, J.H.; Wang, H.T. Effect of early hydration temperature on hydration product and strength development of magnesium phosphate cement (MPC). Cem. Concr. Res. 2015, 78, 179–189. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, B.; Zhang, S.; Wu, X. Properties and applications of magnesia–phosphate cement mortar for rapid repair of concrete. Cem. Concr. Res. 2000, 30, 1807–1813. [Google Scholar] [CrossRef]

- Le Rouzic, M.; Chaussadent, T.; Platret, G.; Stefan, L. Mechanisms of k-struvite formation in magnesium phosphate cements. Cem. Concr. Res. 2017, 91, 117–122. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, B.; Wu, X. Characteristics and durability test of magnesium phosphate cement-based material for rapid repair of concrete. Mater. Struct. 2000, 33, 229–234. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; You, C.; Fan, Y.; Li, Z.; Wang, H. Bond behavior and interfacial micro-characteristics of magnesium phosphate cement onto old concrete substrate. Constr. Build. Mater. 2018, 167, 166–176. [Google Scholar] [CrossRef]

- Li, Y.; Shi, T.; Li, J. Effects of fly ash and quartz sand on water-resistance and salt-resistance of magnesium phosphate cement. Constr. Build. Mater. 2016, 105, 384–390. [Google Scholar] [CrossRef]

- Dai, X.; Qian, J.; Qin, J.; Yue, Y.; Zhao, Y.; Jia, X. Preparation and Properties of Magnesium Phosphate Cement-Based Fire Retardant Coating for Steel. Materials 2022, 15, 4134. [Google Scholar] [CrossRef]

- Wagh, A.S. Recent Progress in Chemically Bonded Phosphate Ceramics. ISRN Ceram. 2013, 2013, 983731. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; Song, Q.; Ren, W.; Jia, X. Research Progress on Magnesium Phosphate Cement. J. Chin. Ceram. Soc. 2022, 50, 1592–1606. [Google Scholar]

- Liao, W.; Ma, H.; Sun, H.; Huang, Y.; Wang, Y. Potential large-volume beneficial use of low-grade fly ash in magnesia-phosphate cement based materials. Fuel 2017, 209, 490–497. [Google Scholar] [CrossRef]

- Gardner, L.J.; Corkhill, C.L.; Walling, S.A.; Vigor, J.E.; Murray, C.A.; Tang, C.C.; Provis, J.L.; Hyatt, N.C. Early age hydration and application of blended magnesium potassium phosphate cements for reduced corrosion of reactive metals. Cem. Concr. Res. 2021, 143, 106375. [Google Scholar] [CrossRef]

- Yu, L.; Xia, K.; Gong, C.; Chen, J.; Dai, H. An injectable bioactive magnesium phosphate cement incorporating carboxymethyl chitosan for bone regeneration. Int. J. Biol. Macromol. 2020, 160, 101–111. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, W.; Cao, Y. Laboratory evaluation of magnesium phosphate cement paste and mortar for rapid repair of cement concrete pavement. Constr. Build. Mater. 2014, 58, 122–128. [Google Scholar] [CrossRef]

- Gayarre, F.L.; González, J.S.; Pérez, C.L.; López, M.A.S.; Ros, P.S.; Martínez-Barrera, G. Shrinkage and creep in structural concrete with recycled brick aggregates. Constr. Build. Mater. 2019, 228, 116750. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, X.; Ma, H.; Hou, D. Advanced Concrete Technology, 2nd ed.; Hoboken: Wiley, NJ, USA, 2022. [Google Scholar]

- Zhou, X.; Zheng, W.; Zeng, Y.; Xu, C.; Chen, P. Effect of fiber content and stress–strength ratio on the creep of basalt fiber–reinforced alkali-activated slag concrete. Struct. Concr. 2022, 23, 382–394. [Google Scholar] [CrossRef]

- Kammouna, Z.; Briffaut, M.; Malecot, Y. Experimental study of the creep effect on the mechanical properties of concrete. Adv. Civ. Eng. 2019, 2019, 5907923. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete. Standards Press of China: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standards Press of China: Beijing, China, 2019.

- Jasiczak, J.; Szymański, P.; Nowotarski, P. Impact of Moisture Conditions on Early Shrinkage of Ordinary Concrete with Changing Water-Binder Ratio. Arch. Civ. Eng. 2014, 60, 241–256. [Google Scholar] [CrossRef]

- Wang, G.; Yun, K.; Tao, S.; Shui, Z. Effect of water-binder ratio and fly ash on the homogeneity of concrete. Constr. Build. Mater. 2013, 38, 1129–1134. [Google Scholar] [CrossRef]

- Thilagavathi, S.; Dhinakaran, G.; Ramana, J.V. Effects of mineral admixtures, water binder ratio and curing on compressive strength of concrete. J. Civ. Eng. Res. Pract. 2007, 4, 15. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Li, Y.; Wang, R. Evaluation of concrete creep properties based on indentation test and multiscale homogenization method. Cem. Concr. Compos. 2021, 123, 104135. [Google Scholar] [CrossRef]

- Garrault-Gauffinet, S.; Nonat, A. Experimental investigation of calcium silicate hydrate (C-S-H) nucleation. J. Cryst. Growth 1999, 200, 565–574. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Monteiro, P.J. Preferred orientation of calcium aluminosilicate hydrate compacts: Implications for creep and indentation. Cem. Concr. Res. 2020, 143, 106371. [Google Scholar] [CrossRef]

- Viani, A.; Lanzafame, G.; Chateigner, D.; El Mendili, Y.; Sotiriadis, K.; Mancini, L.; Zucali, M.; Ouladdiaf, B. Microstructural evolution and texture analysis of magnesium phosphate cement. J. Am. Ceram. Soc. 2020, 103, 1414–1424. [Google Scholar] [CrossRef]

- Benboudjema, F.; Meftah, F.; Torrenti, J.M. Interaction between drying, shrinkage, creep and cracking phenomena in concrete. Eng. Struct. 2005, 27, 239–250. [Google Scholar] [CrossRef]

- Zhao, Q.; Sun, W.; Zheng, K.; Chen, H.; Qin, H.; Liu, J. Influence of fly ash proportion on creep characteristics of high-performance concrete and its mechanism. J. Chin. Ceram. Soc. 2006, 34, 446–451. [Google Scholar]

- Asamoto, S.; Kato, K.; Maki, T. Effect of creep induction at an early age on subsequent prestress loss and structural response of prestressed concrete beam. Constr. Build. Mater. 2014, 70, 158–164. [Google Scholar] [CrossRef]

- Ma, J.; Dehn, F. Shrinkage and creep behavior of an alkali-activated slag concrete. Struct. Concr. 2017, 18, 801–810. [Google Scholar] [CrossRef]

- Liniers, A.D. Microcracking of concrete under compression and its influence on tensile strength. Mater. Struct. 1987, 20, 111–116. [Google Scholar] [CrossRef]

- Hayhurst, D.R.; Henderson, J.T. Creep stress redistribution in notched bars. Int. J. Mech. Sci. 1977, 19, 133–146. [Google Scholar] [CrossRef]

- Patterson, A.L. The Scherrer formula for X-ray particle size determination. Phys. Rev. 1939, 56, 978. [Google Scholar] [CrossRef]

- Yu, J.; Qian, J.; Wang, F.; Li, Z.; Jia, X. Preparation and properties of a magnesium phosphate cement with dolomite. Cem. Concr. Res. 2020, 138, 106235. [Google Scholar] [CrossRef]

- Liu, G.T.; Gao, H.; Chen, F.Q. Microstudy on creep of concrete at early age under biaxial compression. Cem. Concr. Res. 2002, 32, 1865–1870. [Google Scholar] [CrossRef]

- Wu, Z. Discussion on the recent development direction of concrete science and technology. J. Chin. Ceram. Soc. 1979, 3, 82–90. [Google Scholar]

- Yu, B.; Zhou, J.; Cheng, B.; Yang, W. Compressive strength development and microstructure of magnesium phosphate cement concrete. Constr. Build. Mater. 2021, 283, 122585. [Google Scholar] [CrossRef]

| Compound | MgO | P2O5 | SiO2 | Al2O3 | Fe2O3 | CaO | TiO2 | Na2O | SO3 | K2O | MnO |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MPC | 57.85 | 17.01 | 11.80 | 6.36 | 2.20 | 1.26 | 1.04 | 0.78 | 0.45 | 0.26 | 0.18 |

| FA | 1.32 | - | 50.30 | 27.78 | 6.08 | 5.01 | 1.99 | - | 1.05 | - | - |

| Sample | MPC | FA | Sand | Coarse Gravel | Fine Gravel | Water |

|---|---|---|---|---|---|---|

| M1 | 585 | 65 | 600 | 1200 | 0 | 110 |

| M2 | 630 | 70 | 580 | 1160 | 0 | 119 |

| M3 | 630 | 70 | 580 | 780 | 380 | 119 |

| Sample | Total Porosity (%) | Pore Size Distribution (%) | Average Pore Diameter (nm) | Median Pore Diameter (nm) | Tortuosity | |||

|---|---|---|---|---|---|---|---|---|

| Harmless Pores (<20 nm) | Less Harmful Pores (20–100 nm) | Harmful Pores (100–200 nm) | More Harmful Pores (>200 nm) | |||||

| M1-S | 18.77 | 0.28 | 2.68 | 1.03 | 14.79 | 133.9 | 8.9 | 67.78 |

| M1-C | 17.06 | 0.91 | 1.85 | 0.77 | 13.53 | 179.4 | 35.7 | 88.10 |

| M2-S | 21.23 | 4.80 | 1.06 | 0.74 | 14.63 | 38.1 | 8.3 | 9.70 |

| M2-C | 20.35 | 1.30 | 2.45 | 0.86 | 15.73 | 128.4 | 16.5 | 14.81 |

| M3-S | 24.53 | 0.69 | 3.69 | 0.95 | 19.20 | 41.5 | 8.1 | 15.95 |

| M3-C | 20.94 | 0.13 | 1.84 | 1.05 | 17.92 | 251.3 | 34.5 | 26.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Qin, J.; Li, Z.; Jia, X.; Qian, J. Creep Deformation and Its Effect on Mechanical Properties and Microstructure of Magnesium Phosphate Cement Concrete. Materials 2023, 16, 1760. https://doi.org/10.3390/ma16051760

Gao Y, Qin J, Li Z, Jia X, Qian J. Creep Deformation and Its Effect on Mechanical Properties and Microstructure of Magnesium Phosphate Cement Concrete. Materials. 2023; 16(5):1760. https://doi.org/10.3390/ma16051760

Chicago/Turabian StyleGao, Yuxin, Jihui Qin, Zhen Li, Xingwen Jia, and Jueshi Qian. 2023. "Creep Deformation and Its Effect on Mechanical Properties and Microstructure of Magnesium Phosphate Cement Concrete" Materials 16, no. 5: 1760. https://doi.org/10.3390/ma16051760

APA StyleGao, Y., Qin, J., Li, Z., Jia, X., & Qian, J. (2023). Creep Deformation and Its Effect on Mechanical Properties and Microstructure of Magnesium Phosphate Cement Concrete. Materials, 16(5), 1760. https://doi.org/10.3390/ma16051760