Study on Optimization of Drilling Parameters for Laminated Composite Materials

Abstract

:1. Introduction

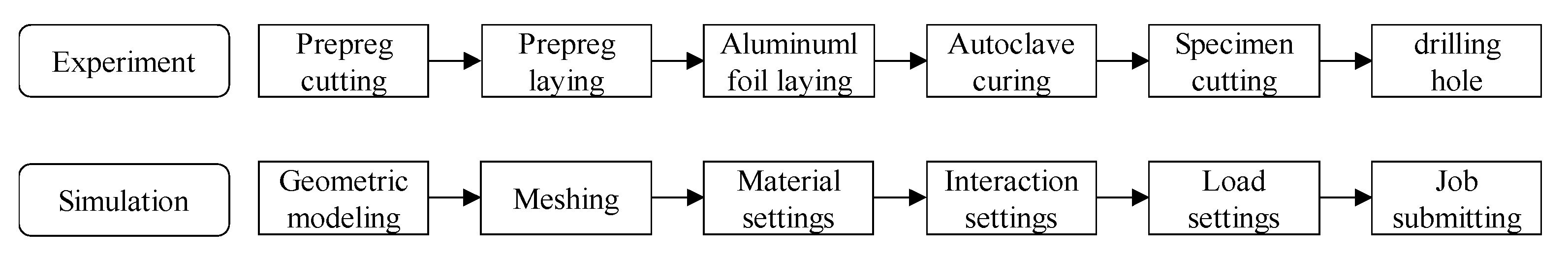

2. Experiment and Simulation

2.1. Laminate Sample

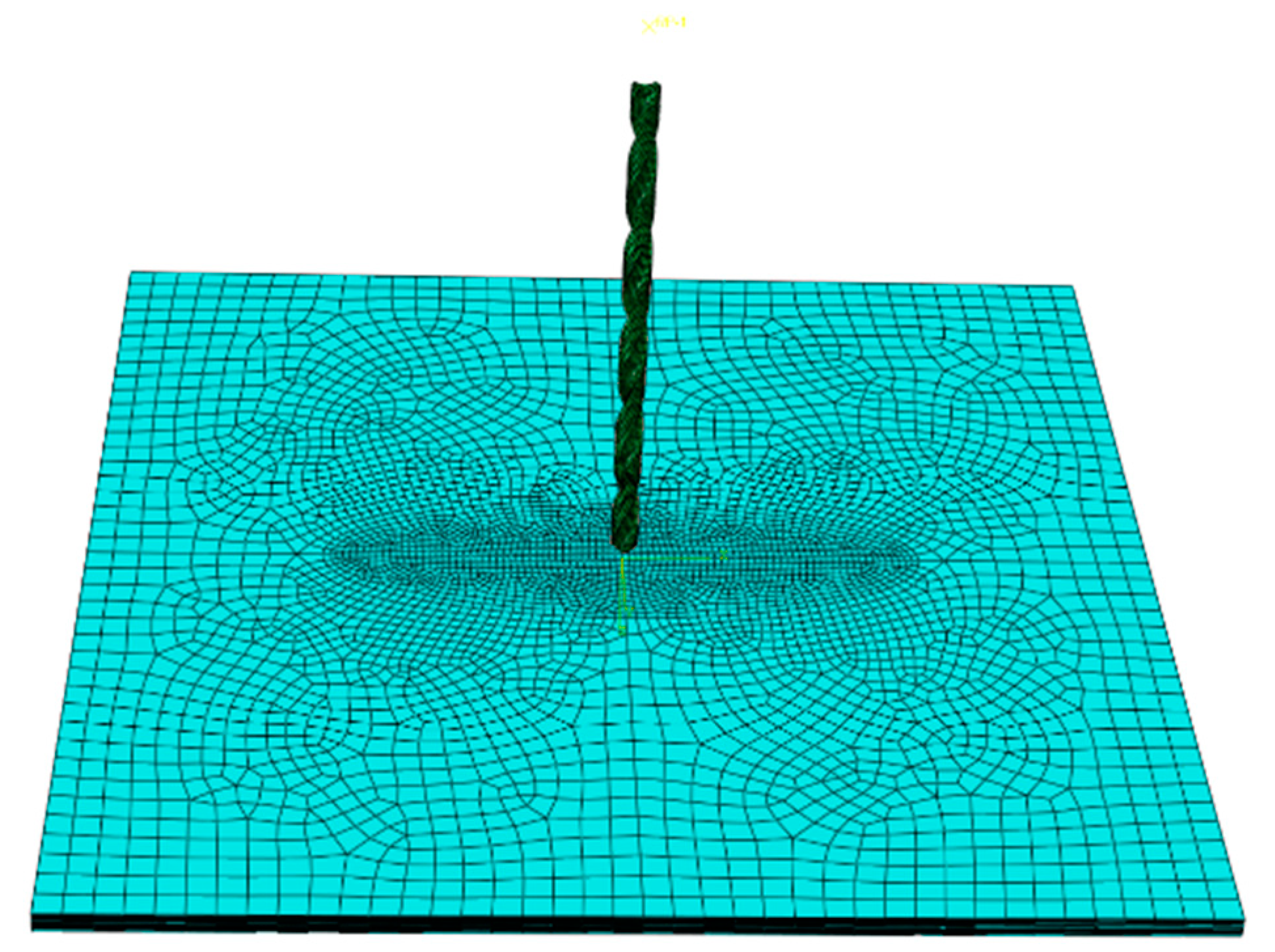

2.2. Finite Element Simulation Model

2.3. Drilling Processing Test

3. Results and Analysis

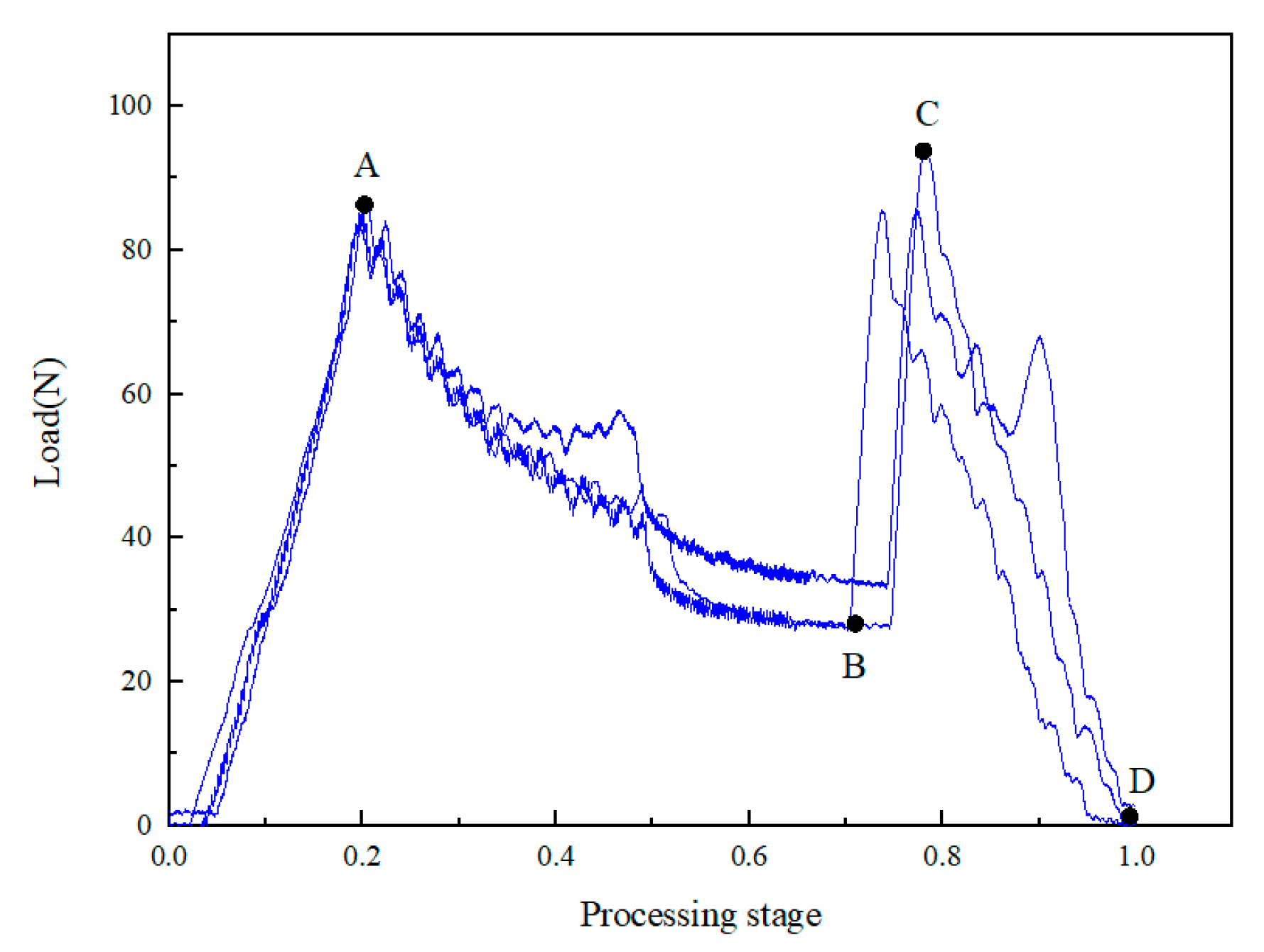

3.1. The Influence of Constant and Dynamic Feed Speed

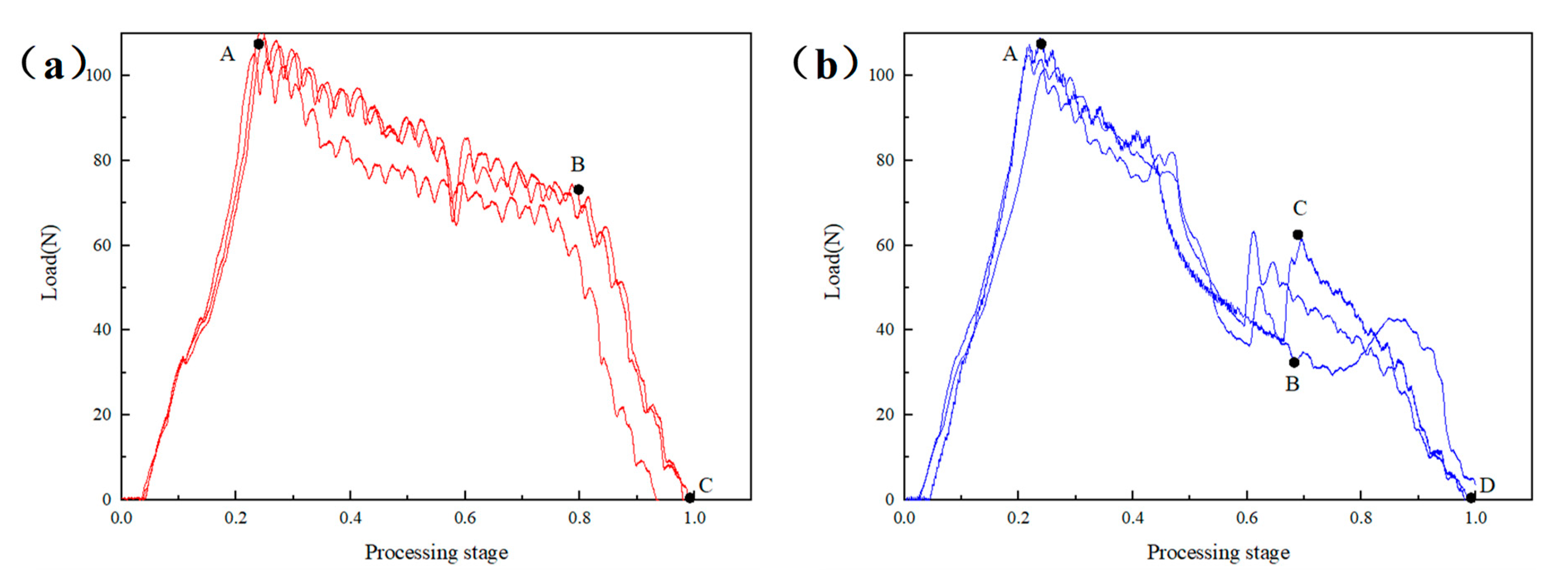

3.2. Effect of Constant and Dynamic Rotation Speed

3.3. The Influence of Constant and Dynamic Feed Speed

3.4. The Influence of Constant and Dynamic Rotation Speed of 1/2 Layered Sample

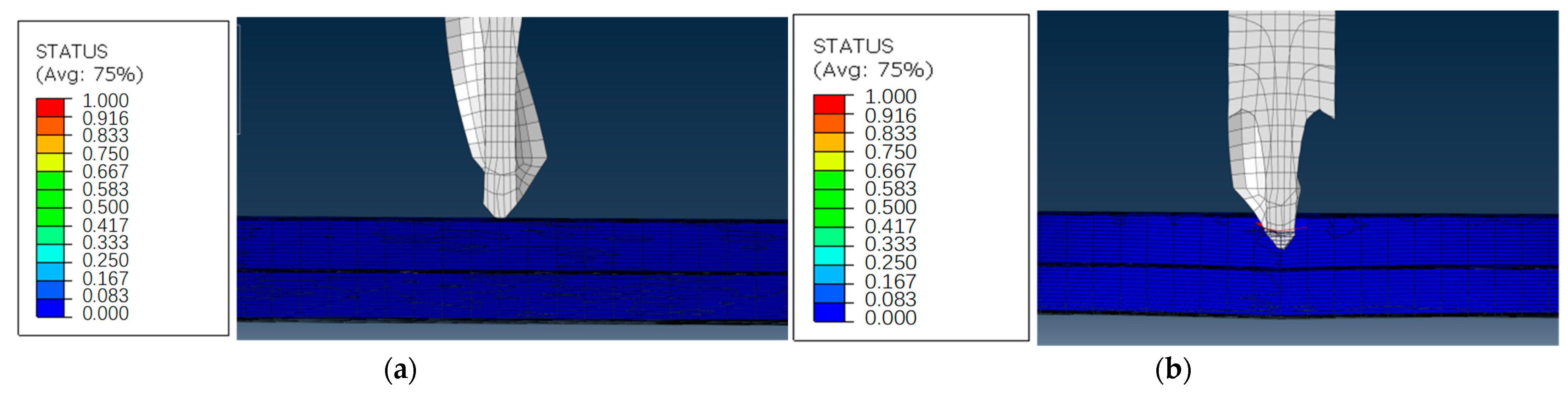

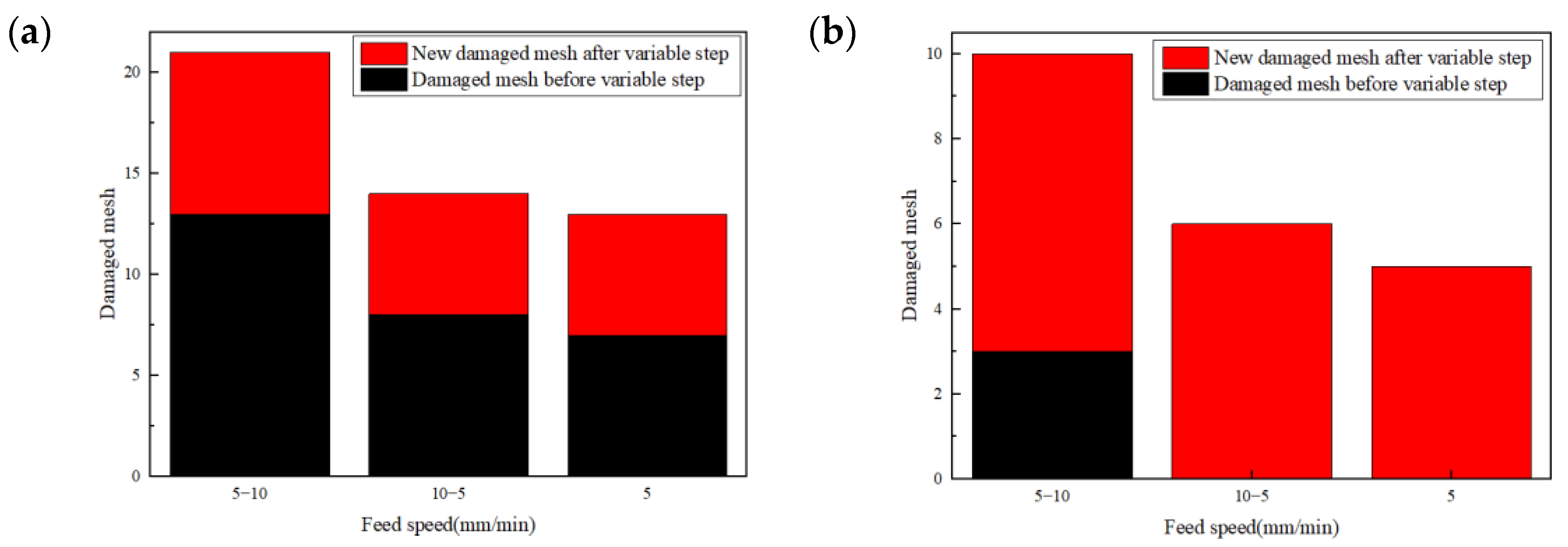

3.5. Finite Element Analysis of Mesh Damage

4. Conclusions

- (1)

- For composite laminates with delamination, when the drill bit is fed to the delamination interface, it will cause the lower laminate to bend downward, resulting in an increase in axial force and hole wall damage in the subsequent processing.

- (2)

- Different advance speeds, rotational speeds and delamination thicknesses have different effects on the axial force. The location of the delamination thickness would lead to sudden changes in axial force at different times in the processing process. The decrease in rotational speed and the increase in advance speed would lead to sudden change of axial force.

- (3)

- When the drill bit is close to the original delamination position, adjust the process parameters according to the delamination situation of the component, which is helpful in reducing the longitudinal cutting force, inhibiting the hole wall damage in the delamination area, and achieving good processing results. In particular, the low speed high speed and high feed low feed processing forms can reduce secondary damage, which will greatly improve the drilling quality of the composite wallboard with delamination.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heisel, U.; Pfeifroth, T. Influence of point angle on drill hole quality and machining forces when drilling CFRP. Procedia CIRP 2012, 1, 471–476. [Google Scholar] [CrossRef] [Green Version]

- Nassiraei, H.; Rezadoost, P. SCFs in tubular X-joints retrofitted with FRP under out-of-plane bending moment. Mar. Struct. 2021, 79, 103010. [Google Scholar] [CrossRef]

- Loh, Y.R.; Rahman, M.E. Sugarcane bagasse-The future composite material: A literature review. Resour. Conserv. Recycl. 2013, 75, 14–22. [Google Scholar] [CrossRef]

- Badrnezhad, R.; Farsani, E.R. Modeling and differential evolution optimization of PAN carbon fiber production process. Fibers Polym. 2014, 15, 1182–1189. [Google Scholar] [CrossRef]

- Li, M.; Gu, Y.; Li, U. Investigation the interphase formation process of carbon fiber/epoxy composites using a multiscale simulation method. Compos. Sci. Technol. 2013, 86, 117–121. [Google Scholar] [CrossRef]

- Nakao, R.; Inoya, H.; Hamada, H. Mechanical properties of injection molded products fabricated by direct fiber feeding injection molding. Energy Procedia 2016, 89, 307–312. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.; Lee, J.; Ji, Y. Effect of filament winding methods on surface roughness and fiber volume fraction of SiCf/SiC composite tubes. J. Korean Ceram. Soc. 2013, 50, 359–363. [Google Scholar] [CrossRef] [Green Version]

- Ishida, H.; Zimmerman, D.A. RIM-pultruded prepreg for the injection molding of long-fiber epoxy composites. Int. Polym. Process. J. Polym. Process. Soc. 2013, 4, 319–327. [Google Scholar] [CrossRef]

- Koch, I.; Zscheyge, M.; Tittmann, K. Numerical fatigue analysis of CFRP components. Compos. Struct. 2017, 168, 392–401. [Google Scholar] [CrossRef]

- Singh, A.P.; Sharma, M.; Singh, I. A review of modeling and control during drilling of fiber reinforced plastic composites. Compos. Part B Eng. 2013, 47, 118–125. [Google Scholar] [CrossRef]

- Wen, Q.; Guo, D.; Gao, H. Comprehensive evaluation method for carbon/epoxy composite hole-making damages. Acta Mater. Compos. Sin. 2016, 33, 265–272. [Google Scholar]

- Durao, L.; Gonçalves, D.; Tavares, J. Drilling tool geometry evaluation for reinforced composite laminates. Compos. Struct. 2010, 92, 1545–1550. [Google Scholar] [CrossRef] [Green Version]

- Feito, N.; Lopez-puente, J.; Santiuste, C. Numerical prediction of delamination in CFRP drilling. Compos. Struct. 2014, 108, 677–683. [Google Scholar] [CrossRef] [Green Version]

- Shunmugesh, K.; Panneersel, V. Multi-response optimization in drilling of carbon fiber reinforced polymer using artificial neural network correlated to meta-heuristics algorithm. Procedia Technol. 2016, 25, 955–962. [Google Scholar] [CrossRef] [Green Version]

- Guo, D.M.; Wen, Q.; Gao, H. Prediction of the cutting forces generated in the drilling of carbon fibre reinforced plastic composites using a twist drill. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 226, 28–42. [Google Scholar] [CrossRef]

- Abhishek, K.; Datta, S.; Mahapatra, S.S. Optimization of thrust, torque, entry, and exist delamination factor during drilling of CFRP composites. Int. J. Adv. Manuf. Technol. 2015, 76, 401–416. [Google Scholar] [CrossRef]

- Eneyew, E.D.; Ramulu, M. Experimental study of surface quality and damage when drilling unidirectional CFRP composites. J. Mater. Res. Technol. 2014, 3, 354–362. [Google Scholar] [CrossRef] [Green Version]

- Luo, H.; Hanagud, S. Delamination Modes in Composite Plates. J. Aerosp. Eng. 1996, 9, 106–113. [Google Scholar] [CrossRef]

- Phadnis, V.A.; Makhdum, F.; Roy, A. Drilling in carbon/epoxy composites: Experimental investigations and finite element implementation. Compos. Part A Appl. Sci. Manuf. 2013, 47, 41–51. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J. Delamination formation and delamination propagation of composite laminates under compressive fatigue loading. Chin. J. Aeronaut. 2000, 13, 8–13. [Google Scholar]

- Freitas, M.D.; Carvalho, R.D. Residual strength of a damaged laminated CFRP under compressive fatigue stresses. Compos. Sci. Technol. 2006, 66, 373–378. [Google Scholar] [CrossRef]

- Aslan, Z.; Şahin, M. Buckling behavior and compressive failure of composite laminates containing multiple large delamination. Compos. Struct. 2009, 89, 382–390. [Google Scholar] [CrossRef]

- Sorrentino, L.; Turchetta, S.; Bellini, C. A new method to reduce delaminations during drilling of FRP laminates by feed rate control. Compos. Struct. 2018, 186, 154–164. [Google Scholar] [CrossRef]

- Tsao Chen, C. Effects of Passive Backup Force on Delamination in Drilling Composite Materials Using Twist Drill. Adv. Mater. Res. 2012, 479, 213–216. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C.C.; Liu, C.S.; Chen, H.A. Reducing drilling-induced delamination in composite tube by magnetic colloid back-up. CIRP Ann.—Manuf. Technol. 2014, 63, 85–88. [Google Scholar] [CrossRef]

- Khashaba, U.A. Delamination in drilling GFR-thermoset composites. Compos. Struct. 2004, 63, 313–327. [Google Scholar] [CrossRef]

- Jain, S.; Yang, D.C.H. Effects of feed rate and chisel edge on delamination in composites drilling. J. Eng. Ind. 1993, 115, 398–405. [Google Scholar]

- Li, M.; Soo, S.L.; Aspinwall, D.K.; Pearson, D.; Leahy, W. Study on tool wear and workpiece surface integrity following drilling of CFRP laminates with variable feed rate strategy. Procedia CIRP 2018, 71, 407–412. [Google Scholar] [CrossRef]

| E1 (GPa) | E2 (GPa) | G12 (GPa) | G13 (GPa) | XT (MPa) |

| 135 | 8.8 | 4.47 | 4.47 | 1548 |

| XC (MPa) | YT (MPa) | YC (MPa) | S12 (MPa) | S23 (MPa) |

| 1426 | 55.2 | 218 | 80 | 68 |

| Serial | Rotation Speed (r/min) | Feed Speed (mm/min) |

|---|---|---|

| 1 | 4000 | 10 |

| 2 | 4000 | 5–10 |

| 3 | 4000 | 10–5 |

| 4 | 4000–2000 | 10 |

| 5 | 2000–4000 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Chen, T.; Zhao, Y. Study on Optimization of Drilling Parameters for Laminated Composite Materials. Materials 2023, 16, 1796. https://doi.org/10.3390/ma16051796

Yu J, Chen T, Zhao Y. Study on Optimization of Drilling Parameters for Laminated Composite Materials. Materials. 2023; 16(5):1796. https://doi.org/10.3390/ma16051796

Chicago/Turabian StyleYu, Jiali, Tao Chen, and Yiming Zhao. 2023. "Study on Optimization of Drilling Parameters for Laminated Composite Materials" Materials 16, no. 5: 1796. https://doi.org/10.3390/ma16051796

APA StyleYu, J., Chen, T., & Zhao, Y. (2023). Study on Optimization of Drilling Parameters for Laminated Composite Materials. Materials, 16(5), 1796. https://doi.org/10.3390/ma16051796