Microstructural Characteristics of High-Pressure Die Casting with High Strength–Ductility Synergy Properties: A Review

Abstract

:1. Introduction

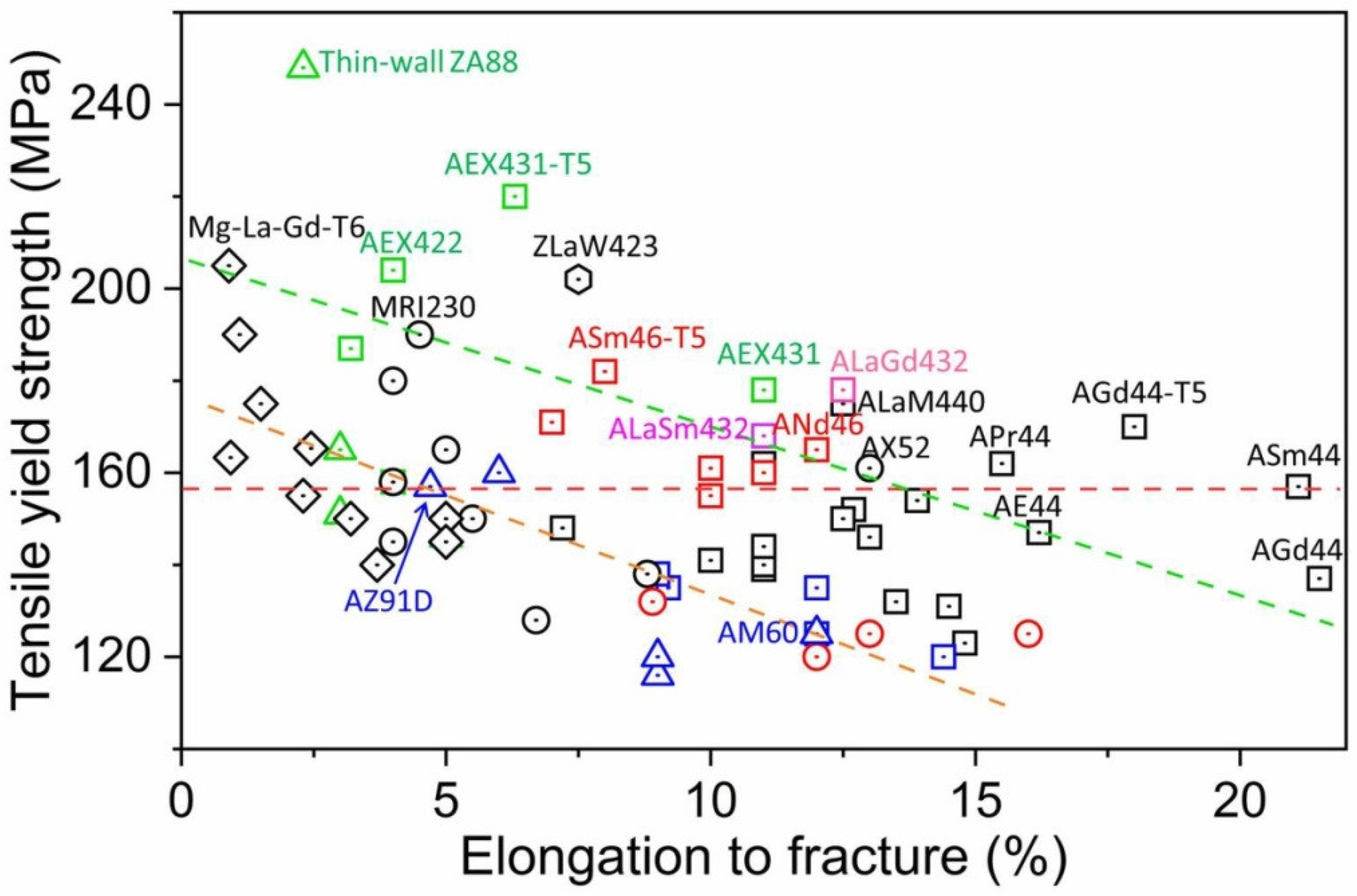

2. Strength–Ductility Properties of HPDC Mg Alloys

3. Microstructural Characteristics of AE Series Alloys

3.1. Mg-Al-MM Alloys

3.2. Influence of Other Alloying Elements on AE-Based Alloys

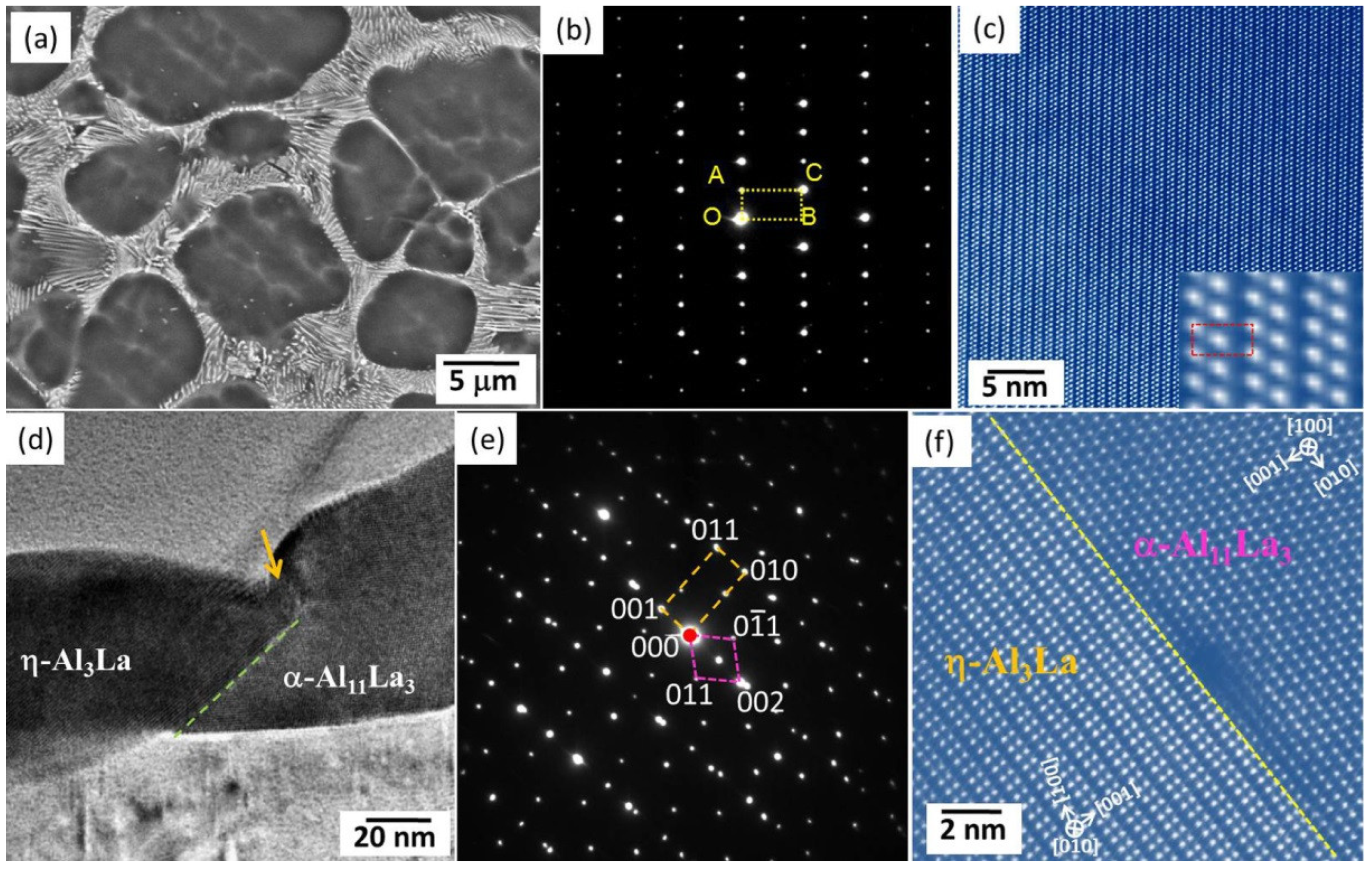

3.3. Mg-Al-La Alloys

3.4. Mg-Al-Ce Alloys

3.5. Mg-Al-Pr Alloy

3.6. Mg-Al-Nd Alloy

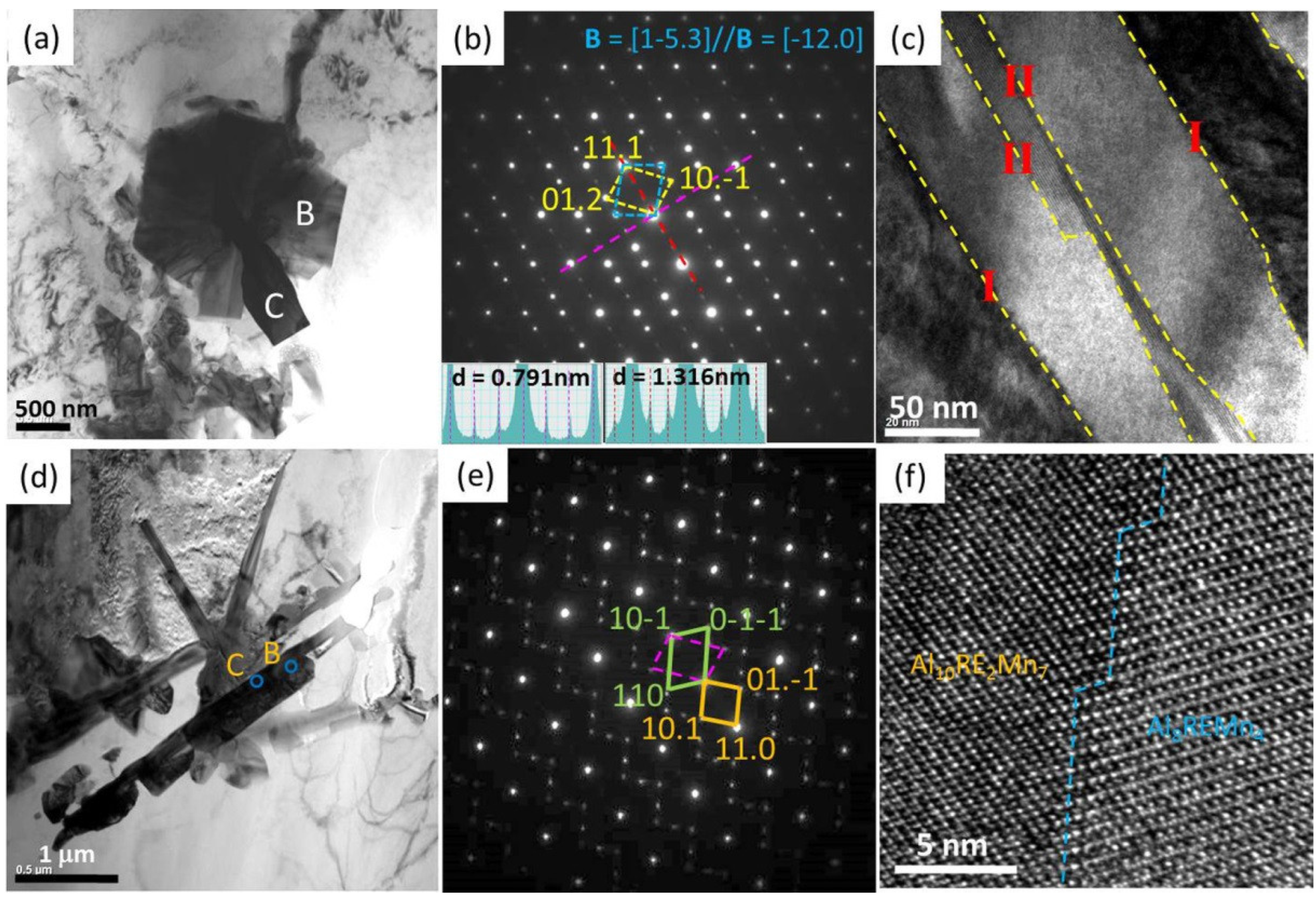

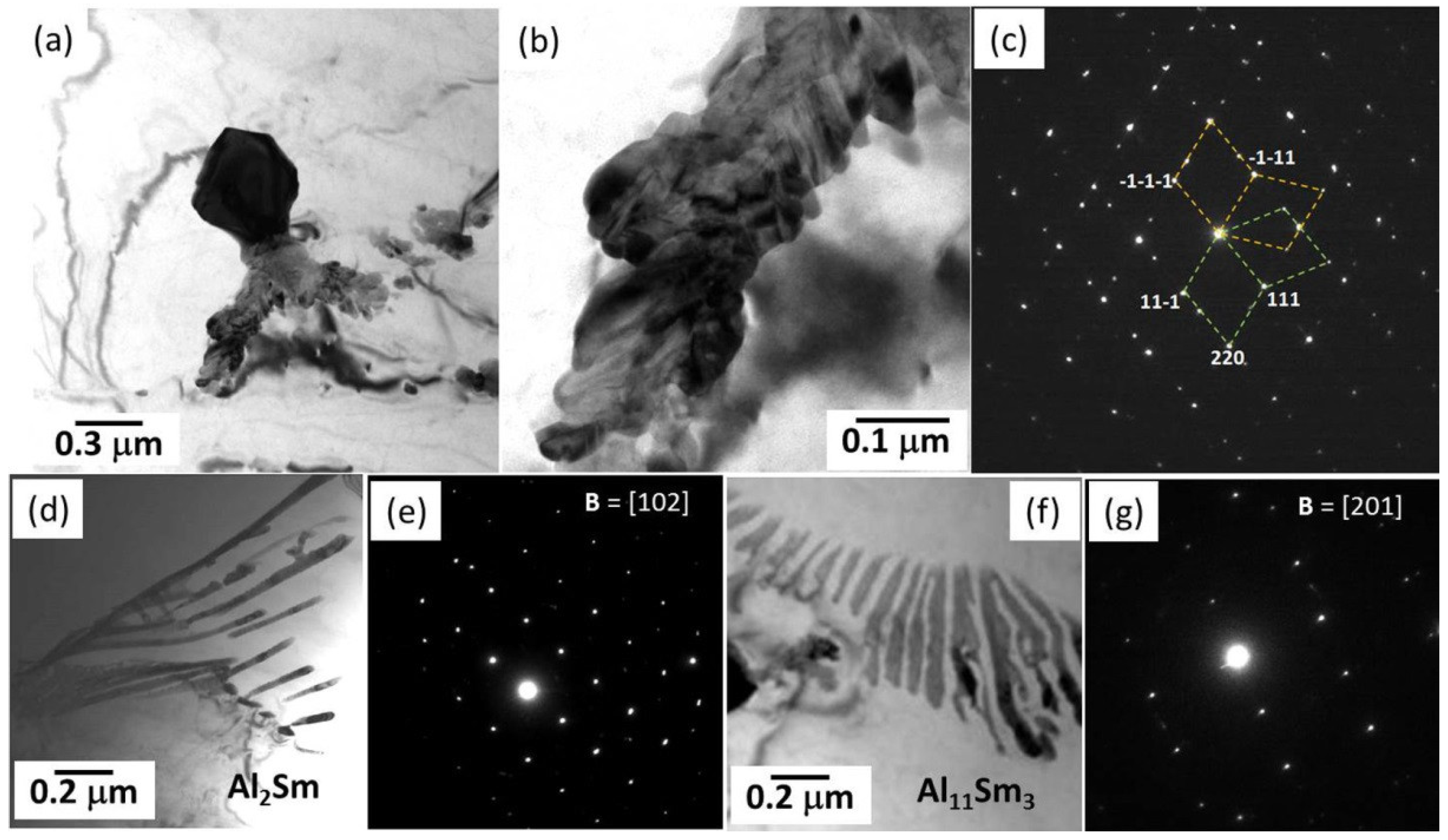

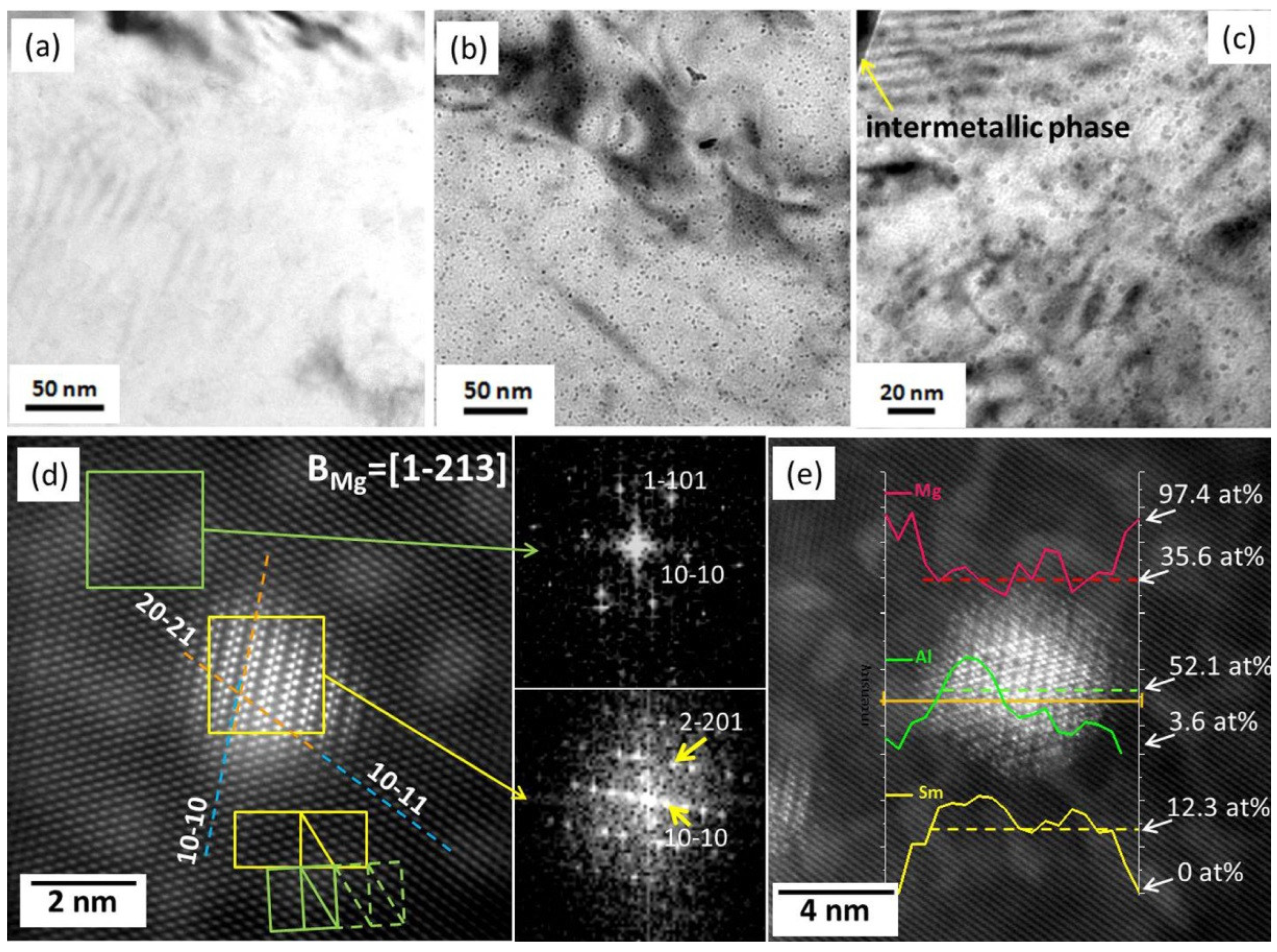

3.7. Mg-Al-Sm Alloys

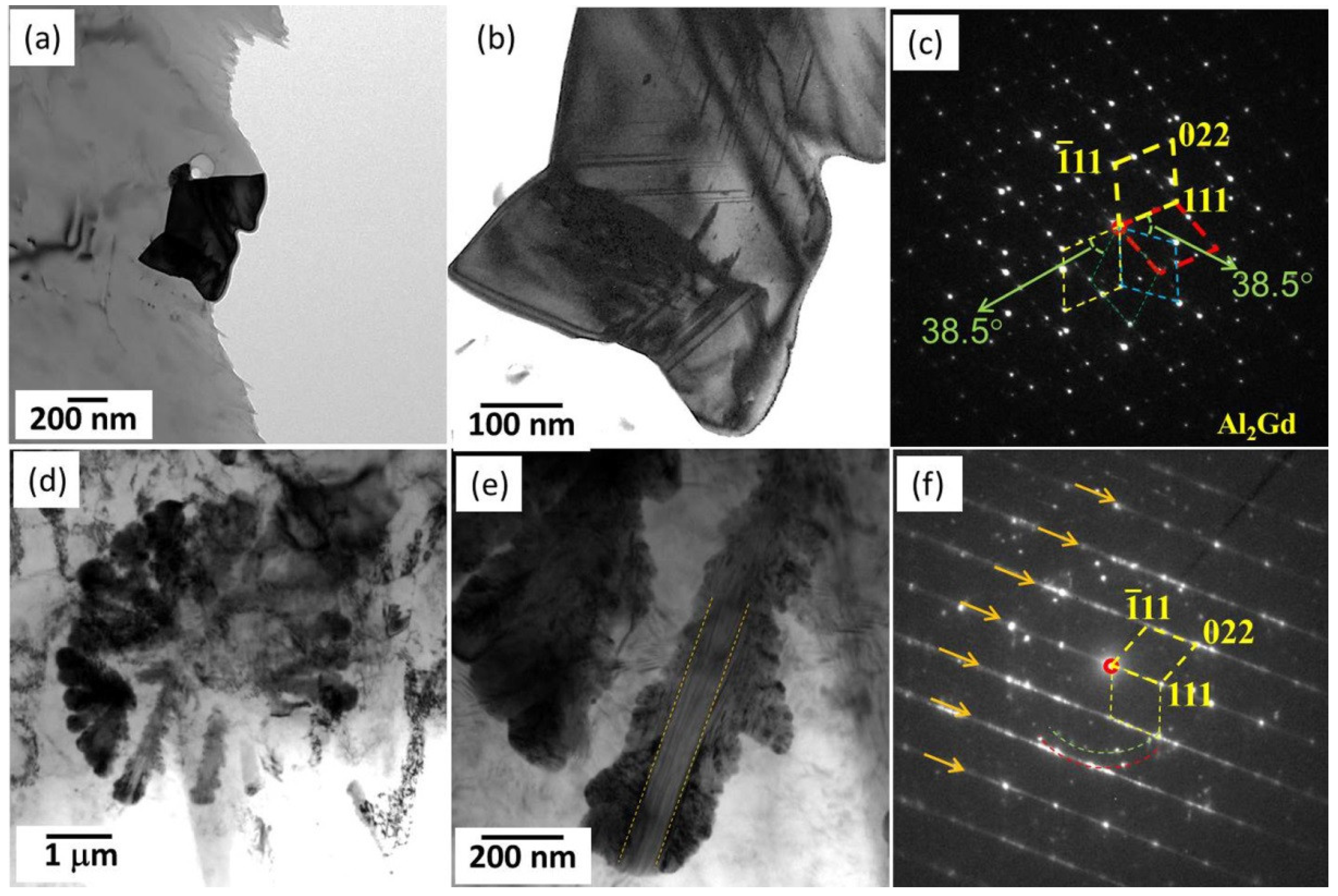

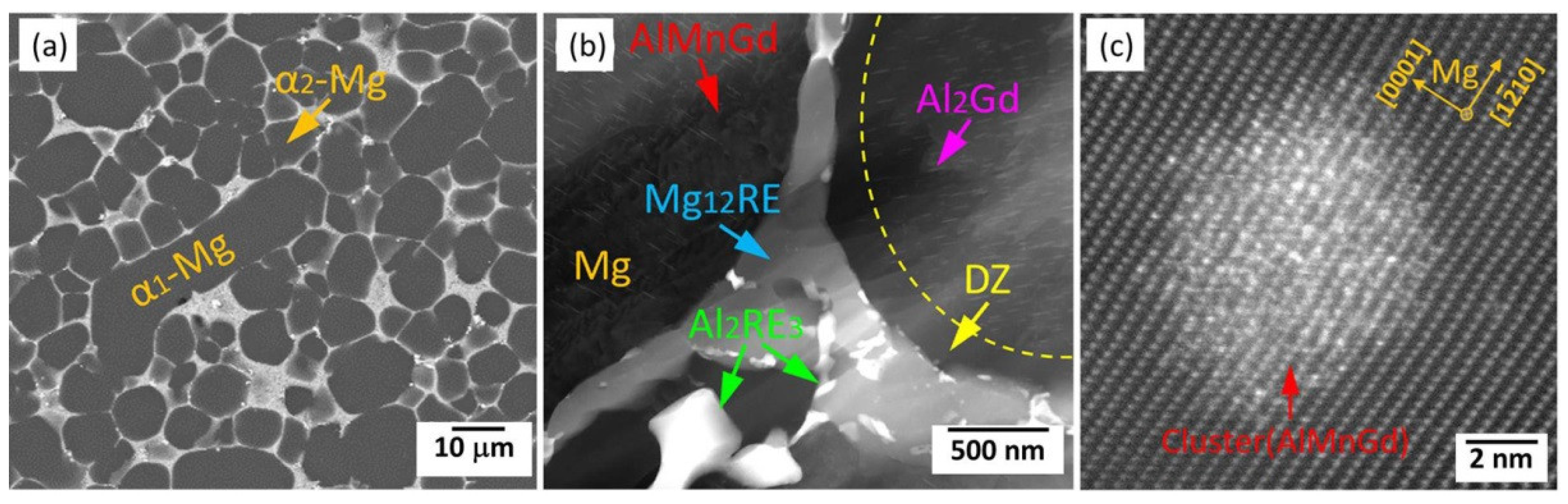

3.8. Mg-Al-Gd Alloys

3.9. Mg-Al-La-Sm/Gd Alloys

4. Microstructural Characteristics of Mg-RE-Based Alloys

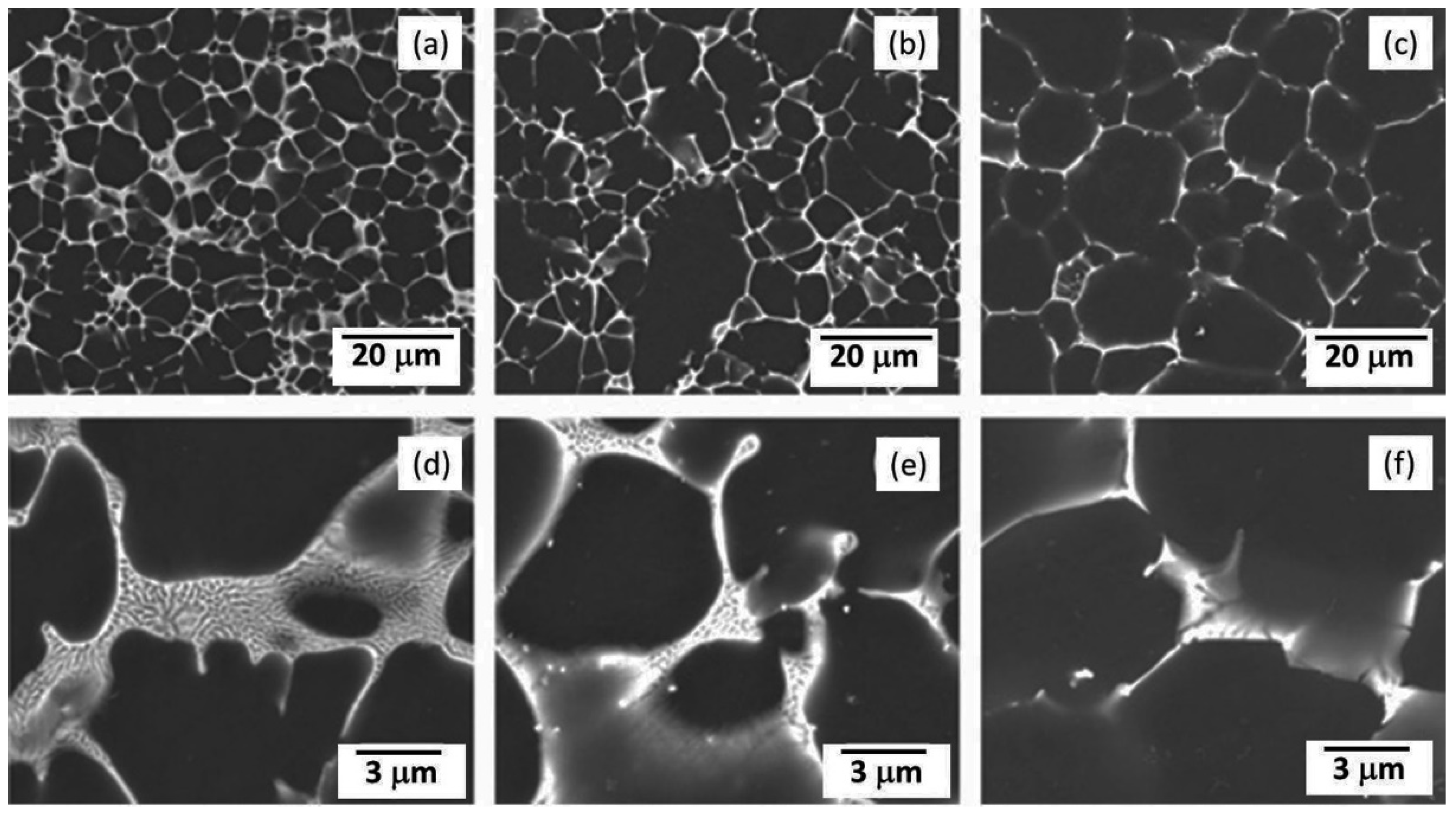

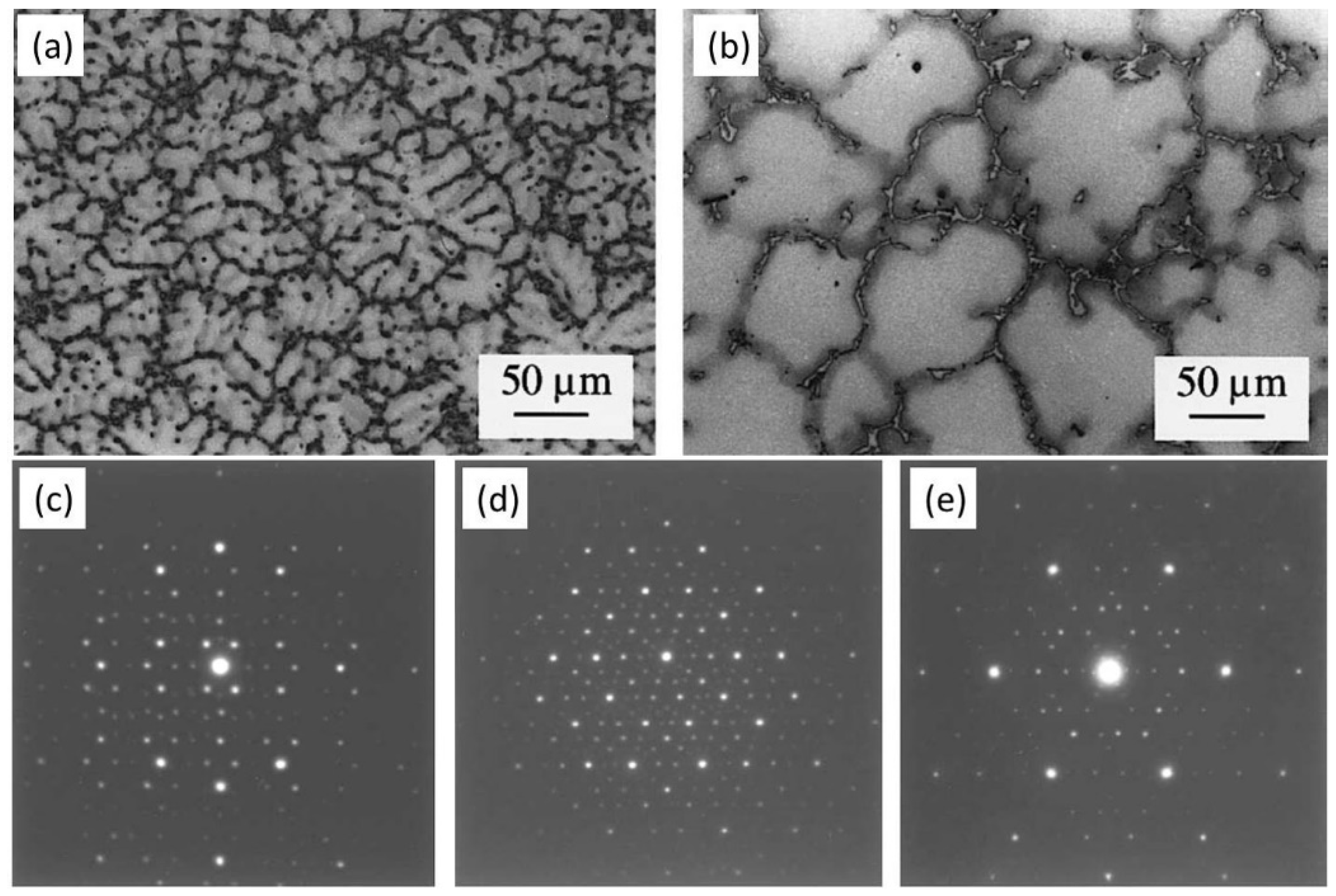

4.1. Mg-RE Binary Alloy

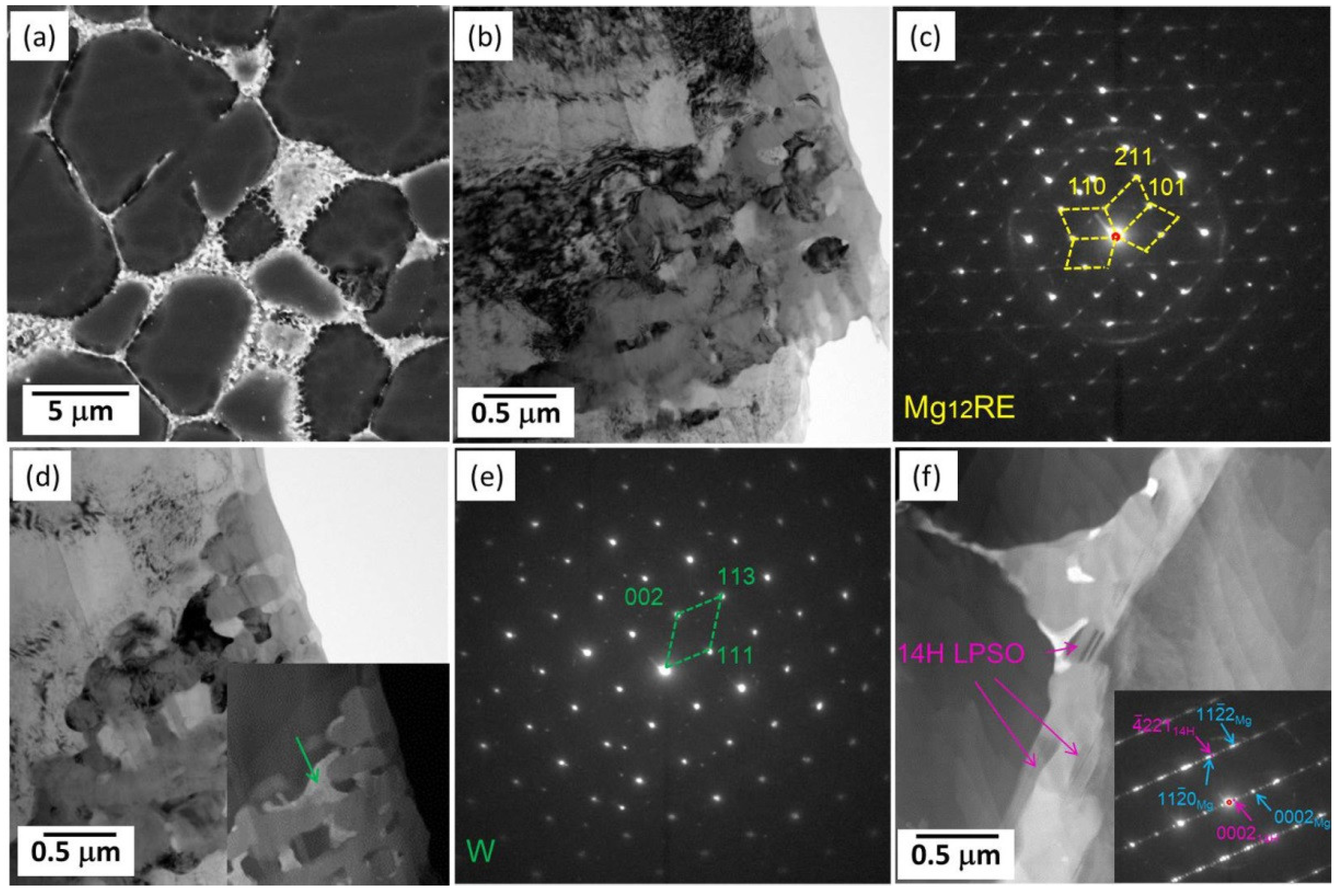

4.2. Mg-RE Ternary Alloy

4.3. Zn Addition into Mg-RE Alloy

4.4. Al Addition into Mg-RE Alloy

4.5. Zn + Al Addition into Mg-RE Alloy

5. Microstructural Characteristics of AX-Based Alloys

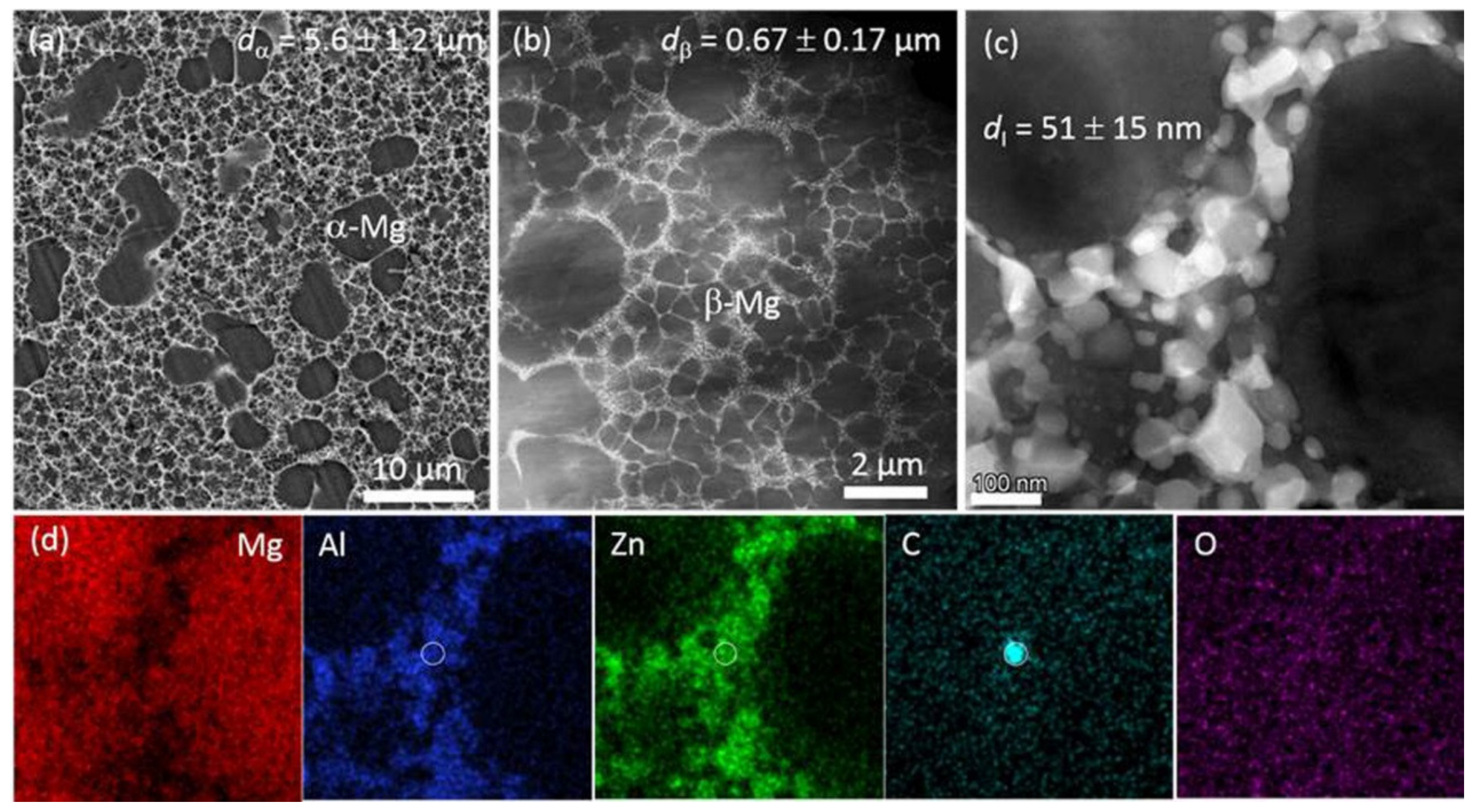

6. Microstructural Characteristics of ZA-Based Alloys

7. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, B.Y.; Zhang, Z.; Liu, F.; Yang, N.; Li, B.; Chen, P.; Wang, Y.; Peng, J.H.; Li, J.; Ma, E.; et al. Rejuvenation of plasticity via deformation graining in magnesium. Nat. Commun. 2022, 13, 1060. [Google Scholar] [CrossRef]

- Wu, Z.; Ahmad, R.; Yin, B.; Sandlobes, S.; Curtin, W.A. Me Mechanistic origin and prediction of enhanced ductility in magnesium alloys. Science 2018, 359, 447–452. [Google Scholar] [CrossRef] [Green Version]

- Yan, Z.; Yang, Q.; Meng, F.; Ma, R.; Bao, R.; Liu, X.; Meng, J.; Qiu, X. Interfacial precipitation in {10–12} twin boundaries of a Mg–Gd–Zn–Zr alloy. J. Mater. Sci. Technol. 2021, 93, 103–109. [Google Scholar] [CrossRef]

- Jiang, K.; Zhou, M.; Wu, H.; Liu, S.; Wu, Y.; Liu, Y. Achieving the synergistic of strength and ductility in Mg–15Gd–1Zn–0.4Zr alloy with hierarchical structure. J. Magnes. Alloys 2023, in press. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Pan, F. A review on electromagnetic shielding magnesium alloys. J. Magnes. Alloys 2021, 9, 1906–1921. [Google Scholar] [CrossRef]

- Xin, T.; Zhao, Y.; Mahjoub, R.; Jiang, J.; Yadav, A.; Nomoto, K.; Niu, R.; Tang, S.; Ji, F.; Quadir, Z.; et al. Ultrahigh specific strength in a magnesium alloy strengthened by spinodal decomposition. Sci. Adv. 2021, 7, eabf3039. [Google Scholar] [CrossRef] [PubMed]

- Friedrich, H.E.; Mordike, B.L. Magnesium Technology—Metallurgy, Design Data, Applications; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Kainer, K.U. Magnesium Alloys and Technologies; Wiley-VCH Verlag GmbH & Co. KG aA: Weinheim, Germany, 2003. [Google Scholar]

- Monteiro, W.A. New Features on Magnesium Alloys; IntechOpen: London, UK, 2012. [Google Scholar]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef] [Green Version]

- Qasim, M.; Bashir, M.S.; Iqbal, S.; Mahmood, Q. Recent advancements in α-diimine-nickel and -palladium catalysts for ethylene polymerization. Euro. Polym. J. 2021, 160, 110783. [Google Scholar] [CrossRef]

- Ma, C.; Yu, W.; Zhang, T.; Zhang, Z.; Ma, Y.; Xiong, S. The effect of slow shot speed and casting pressure on the 3D microstructure of high pressure die casting AE44 magnesium alloy. J. Magnes. Alloys 2021, in press. [Google Scholar] [CrossRef]

- Shakeel, A.; Rizwan, K.; Farooq, U.; Iqbal, S.; Altaf, A.A. Advanced polymeric/inorganic nanohybrids: An integrated platform for gas sensing applications. Chemosphere 2022, 294, 133772. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.G.; Weiler, J.P. Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications. J. Magnes. Alloys 2023, 11, 78–87. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Celiki, M. Creep resistance in magnesium alloys. Int. Mater. Rev. 2010, 55, 197–217. [Google Scholar] [CrossRef]

- Yu, W.; Cao, Y.; Li, X.; Guo, Z.; Xiong, S. Determination of interfacial heat transfer behavior at the metal/shot sleeve of high pressure die casting process of AZ91D alloy. J. Mater. Sci. Technol. 2017, 33, 52–58. [Google Scholar] [CrossRef]

- Xiong, S.; Li, X.; Guo, Z. Influence of melt flow on the formation of defect band in high pressure die casting of AZ91D magnesium alloy. Mater. Charact. 2017, 129, 344–352. [Google Scholar]

- Biswas, S.; Sket, F. Relationship between the 3D porosity and β-phase distributions and the mechanical properties of a high pressure die cast AZ91 Mg alloy. Metall. Mater. Trans. A 2013, 44, 4391–4403. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, W.; Ma, C.; Chen, W.; Zhang, L.; Xiong, S. The effect of different high pressure die casting parameters on 3D microstructure and mechanical properties of AE44 magnesium alloy. J. Magnes. Alloys 2022, in press. [Google Scholar] [CrossRef]

- Hou, Y.; Wu, M.; Tian, B.; Li, X.; Xiong, S. Characteristics and formation mechanisms of defect bands in vacuum-assisted high-pressure die casting AE44 alloy. Trans. Nonfer. Met. Soc. China 2022, 32, 1852–1865. [Google Scholar] [CrossRef]

- Berman, T.D.; Yao, Z.; Deda, E.; Godlewski, L.; Li, M.; Allison, J.E. Measuring and modeling microsegregation in high-pressure die cast Mg-Al alloys. Metall. Mater. Trans. A 2022, 53, 2730–2742. [Google Scholar] [CrossRef]

- Li, X.B.; Yu, W.B.; Wang, J.S.; Xiong, S.M. Influence of melt flow in the gating system on microstructure and mechanical properties of high pressure die casting AZ91D magnesium alloy. Mater. Sci. Eng. A 2018, 736, 219–227. [Google Scholar] [CrossRef]

- Sachdeva, D. Insights into microstructure based corrosion mechanism of high pressure die cast AM50 alloy. Corros. Sci. 2012, 60, 18–31. [Google Scholar] [CrossRef]

- Tzamtzis, S.; Zhang, H.; Xia, M.; Hari Babu, N.; Fan, Z. Recycling of high grade die casting AM series magnesium scrap with the melt conditioned high pressure die casting (MC-HPDC) process. Mater. Sci. Eng. A 2011, 528, 2664–2669. [Google Scholar] [CrossRef]

- Luo, A.A. Recent magnesium alloy development for elevated temperature applications. Int. Mater. Rev. 2004, 49, 13–30. [Google Scholar]

- Zhu, S.M.; Easton, M.A.; Gibson, M.A.; Dargusch, M.S.; Nie, J.F. Analysis of the creep behavior of die-cast Mg–3Al–1Si alloy. Mater. Sci. Eng. A 2013, 578, 377–382. [Google Scholar] [CrossRef]

- Zhang, P. Creep behavior of the die-cast Mg–Al alloy AS21. Scr. Mater. 2005, 52, 277–282. [Google Scholar] [CrossRef]

- Kondori, B.; Mahmudi, R. Effect of Ca additions on the microstructure, thermal stability and mechanical properties of a cast AM60 magnesium alloy. Mater. Sci. Eng. A 2010, 527, 2014–2021. [Google Scholar]

- Jiang, B.; Zhang, D.; Sun, C.; Li, N.; Liu, Y.; Cao, Z. Microstructure evolution and creep behavior of high-pressure die-cast Mg–9Al–1Zn–1Sr alloy. Mater. Sci. Eng. A 2019, 766, 138388. [Google Scholar] [CrossRef]

- Gjestland, H.; Nussbaum, G.; Regazzoni, G. Stress-relaxation and creep behaviour of some rapidly solidified magnesium alloys. Mater. Sci. Eng. A 1991, 134, 1197–1200. [Google Scholar] [CrossRef]

- Baril, E.; Labelle, P.; Pekguleryuz, M.O. Elevated temperature Mg–Al–Sr: Creep resistance, mechanical properties, and microstructure. JOM—J. Miner. Met. Mater. 2003, 55, 34–39. [Google Scholar]

- Mahmudi, R.; Kabirian, F.; Nematollahi, Z. Microstructural stability and high temperature mechanical properties of AZ91 and AZ91 + 2RE magnesium alloys. Mater. Des. 2011, 32, 2583–2589. [Google Scholar] [CrossRef]

- Tian, X.; Wang, L.M.; Wang, J.L.; Liu, Y.B.; An, J.; Cao, Z.Y. The microstructure and mechanical properties of Mg–3Al–3RE alloys. J. Alloys Compd. 2008, 465, 412–416. [Google Scholar] [CrossRef]

- Zhu, S.M.; Gibson, M.A.; Nie, J.F.; Easton, M.A.; Abbottc, T.B. Microstructural analysis of the creep resistance of die-cast Mg–4Al–2RE alloy. Scr. Mater. 2008, 58, 477–480. [Google Scholar] [CrossRef]

- Luo, W.; Yin, W.; Li, Y.; Dai, J.; He, H.; Li, K. Research on microstructure and mechanical properties of die casting Mg-4Al-1Si-3RE (Ce, La) and AS41 alloys. Mater. Today Commun. 2022, 33, 104625. [Google Scholar] [CrossRef]

- Xiao, W.; Zhu, S.; Easton, M.A.; Dargusch, M.S.; Gibson, M.A.; Nie, J.-F. Microstructural characterization of high pressure die cast Mg–Zn–Al–RE alloys. Mater. Charact. 2012, 65, 28–36. [Google Scholar] [CrossRef]

- Xiao, W.; Easton, M.A.; Dargusch, M.S.; Zhu, S.; Gibson, M.A. The influence of Zn additions on the microstructure and creep resistance of high pressure die cast magnesium alloy AE44. Mater. Sci. Eng. A 2012, 539, 177–184. [Google Scholar] [CrossRef]

- Xiao, W.; Easton, M.A.; Zhu, S.; Dargusch, M.S.; Gibson, M.A.; Jia, S.; Nie, J. Casting defects and mechanical properties of high pressure die cast Mg–Zn–Al–RE alloys. Adv. Eng. Mater. 2012, 14, 68–76. [Google Scholar] [CrossRef]

- Shepeleva, L.; Bamberger, M. Microstructure of high pressure die cast AZ91D modified with Ca and Ce. Mater. Sci. Eng. A 2006, 425, 312–317. [Google Scholar] [CrossRef]

- Suzuki, A.; Saddock, N.D.; Terbush, J.R.; Powell, B.R.; Jones, J.W.; Pollock, T.M. Precipitation strengthening of a Mg–Al–Ca-based AXJ530 die-cast alloy. Metall. Mater. Trans. A 2008, 39, 696–702. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Leng, Z.; Liu, X.; Niu, Z.; Zhang, M.; Wu, R. Structure stability and mechanical properties of high-pressure die-cast Mg–Al–La–Y-based alloy. Mater. Sci. Eng. A 2012, 531, 70–75. [Google Scholar] [CrossRef]

- Woo, S.K.; Blawert, C.; Yasakau, K.A.; Yi, S.; Schaenagl, N.; Suh, B.C.; Kim, B.S.; Yim, C.D. Effects of combined addition of Ca and Y on the corrosion behaviours of diecast AZ91D magnesium alloy. Corros. Sci. 2020, 166, 108451. [Google Scholar] [CrossRef]

- Suzuki, A.; Saddock, N.D.; Jones, J.W.; Pollock, T.M. Solidification paths and eutectic intermetallic phases in Mg-Al-Ca ternary alloys. Acta Mater. 2005, 53, 2823–2834. [Google Scholar] [CrossRef]

- Shi, L.L.; Xu, J.; Ma, E. Mg–Al–Ca in-situ composites with a refined eutectic structure and their compressive properties. Metall. Mater. Trans. A 2008, 39, 1225–1235. [Google Scholar] [CrossRef] [Green Version]

- Terbush, J.R.; Saddock, N.D.; Jones, J.W.; Pollock, T.M. Partitioning of solute to the primary α-Mg phase in creep-resistant Mg-Al-Ca-based cast alloys. Metall. Mater. Trans. A 2010, 41, 2435–2441. [Google Scholar] [CrossRef]

- Rong, J.; Xiao, W.; Fu, Y.; Zhao, X.; Yan, P.; Ma, C.; Chen, M.; Huang, C. A high performance Mg–Al–Ca alloy processed by high pressure die casting: Microstructure, mechanical properties and thermal conductivity. Mater. Sci. Eng. A 2022, 849, 143500. [Google Scholar] [CrossRef]

- Aljarrah, M.; Medraj, M.; Wang, X.; Essadiqi, E.; Muntasar, A.; Denes, G. Experimental investigation of the Mg-Al-Ca system. J. Alloys Compd. 2007, 436, 131–141. [Google Scholar] [CrossRef]

- Zheng, X.; Luo, A.A.; Zhang, C.; Dong, J.; Waldo, R.A. Directional solidification and micro-segregation in a magnesium–aluminum–calcium alloy. Metall. Mater. Trans. A 2012, 43, 3239–3248. [Google Scholar] [CrossRef]

- Zhu, S.M.; Mordike, B.L.; Nie, J.F. Creep and rupture properties of a squeeze-cast Mg-Al-Ca alloy. Metall. Mater. Trans. A 2006, 37, 1221–1229. [Google Scholar] [CrossRef]

- Suzuki, A.; Saddock, N.D.; Jones, J.W.; Pollock, T.M. Structure and transition of eutectic (Mg,Al)2Ca Laves phase in a die-cast Mg–Al–Ca base alloy. Scr. Mater. 2004, 51, 1005–1010. [Google Scholar] [CrossRef]

- Rzychoń, T.; Kiełbus, A.; Cwajna, J.; Mizera, J. Microstructural stability and creep properties of die casting Mg-4Al-4RE magnesium alloy. Mater. Charact. 2009, 60, 1107–1113. [Google Scholar] [CrossRef]

- Zhu, S.M.; Nie, J.F.; Gibson, M.A.; Easton, M.A.; Bakke, P. Microstructure and Creep behavior of high-pressure die-cast magnesium alloy AE44. Metall. Mater. Trans. A 2012, 43, 4137–4144. [Google Scholar] [CrossRef]

- Feng, L.; Dong, X.; Xia, M.; Zhu, X.; Ji, G.; Yang, H.; Wang, B.; Nyberg, E.A.; Ji, S. Development of high thermal conductivity, enhanced strength and cost-effective die-cast Mg alloy compared with AE44 alloy. J. Mater. Res. Technol. 2023, 22, 2955–2966. [Google Scholar]

- Zhu, S.; Easton, M.A.; Abbott, T.B.; Gibson, M.A.; Nie, J.-F. The influence of individual rare earth elements (La, Ce, or Nd) on creep resistance of die-cast magnesium alloy AE44. Adv. Eng. Mater. 2016, 18, 932–937. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, J.; He, L.; Zhang, M.; Jiang, F.; Wang, W.; Han, L.; Xu, L.; Wu, R. Al–RE intermetallic phase stability and effects on corrosion behavior in cold-chamber HPDC AE44 alloy. Adv. Eng. Mater. 2016, 18, 148–155. [Google Scholar] [CrossRef]

- Zhou, W.; Lin, J.; Dean, T.A. Microstructure and mechanical properties of curved AZ31 magnesium alloy profiles produced by differential velocity sideways extrusion. J. Magnes. Alloys 2022, in press. [Google Scholar] [CrossRef]

- Fan, M.; Zhang, Z.; Cui, Y.; Liu, L.; Liu, Y.; Liaw, P.K. Achieving strength and ductility synergy via a nanoscale superlattice precipitate in a cast Mg-Y-Zn-Er alloy. Int. J. Plast. 2023, 163, 103558. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, L.; Zhang, Y.; Feng, G.; Wang, C.; Fang, W. Improvement of strength and ductility synergy and the elimination of the yield point phenomenon of ultrafine-grained Mg–Al–Zn–Ag alloy sheet. J. Mater. Res. Technol. 2023, 23, 2900–2910. [Google Scholar] [CrossRef]

- Lv, S.; Lv, X.; Meng, F.; Li, Y.; Duan, Q.; Yang, Q. Microstructures and mechanical properties of a hot-extruded Mg–8Ho–0.6Zn–0.5Zr alloy. J. Alloys Compd. 2019, 774, 926–938. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, J.; You, Z.; Liu, S.; Guan, K.; Wu, R.; Wang, J.; Feng, J. Towards developing Mg alloys with simultaneously improved strength and corrosion resistance via RE alloying. J. Magnes. Alloys 2021, 9, 41–56. [Google Scholar] [CrossRef]

- Tu, T.; Chen, X.; Chen, T.; Yuan, Y.; Pan, F. New high-modulus and high-strength Mg–Gd–Ag–Mn–Ge alloys. Mater. Sci. Eng. A. 2021, 805, 140559. [Google Scholar] [CrossRef]

- Cao, F.; Shang, H.; Guo, N.; Kong, S.; Liu, R. High Strain Rate Quasi-Superplasticity Behavior in an Ultralight Mg-9.55Li-2.92Al-0.027Y-0.026Mn Alloy Fabricated by Multidirectional Forging and Asymmetrical Rolling. Materials 2022, 15, 7539. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Huan, B.; Xin, Y.; Huang, G.; Wu, O.; Liu, Q. Revealing the role of pyramidal <c + a> slip in the high ductility of Mg-Li alloy. J. Magnes. Alloys 2021, in press. [Google Scholar] [CrossRef]

- Lv, S.; Yang, Q.; Lv, X.; Meng, F.; Qiu, X. Effects of reduced extrusion temperature on microstructure and mechanical properties of Mg–6Zn–0.5Zr alloy. Mater. Des. 2023, 225, 111568. [Google Scholar] [CrossRef]

- Chen, M.; Ma, C.; Liu, Q.; Cheng, M.; Wang, H.; Hu, X. Plastic deformation mechanism of high strength and toughness ZK61 magnesium alloy plate by multipass horizontal continuous rolling. Materials 2023, 16, 1320. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Wu, X.; Zhang, W.; Yan, Z.; Tong, G.; Chen, X.; Lv, S.; Xu, T.; Li, J.; Qiu, X. Microstructures and mechanical properties of an ultrathin wall high-pressure die casting Mg–8Zn–8Al (wt%) alloy. J. Alloys Compd. 2023, 936, 168200. [Google Scholar] [CrossRef]

- Meng, F.; Lv, S.; Yang, Q.; Qin, P.; Zhang, J.; Guan, K.; Huang, Y.; Hort, N.; Li, B.; Liu, X.; et al. Developing a die casting magnesium alloy with excellent mechanical performance by controlling intermetallic phase. J. Alloys Compd. 2019, 795, 436–445. [Google Scholar] [CrossRef]

- Amberger, D.; Eisenlohr, P.; Goken, M. On the importance of a connected hard-phase skeleton for the creep resistance of Mg alloys. Acta Mater. 2012, 60, 2277–2289. [Google Scholar] [CrossRef]

- Yang, Q.; Guan, K.; Bu, F.; Zhang, Y.; Qiu, X.; Zheng, T.; Liu, X.; Meng, J. Microstructures and tensile properties of a high-strength die-cast Mg–4Al–2RE–2Ca–0.3Mn alloy. Mater. Charact. 2016, 113, 180–188. [Google Scholar] [CrossRef]

- Yang, Q.; Bu, F.; Meng, F.; Qiu, X.; Zhang, D.; Zheng, T.; Liu, X.; Meng, J. The improved effects by the combinative addition of lanthanum and samarium on the microstructures and the tensile properties of high-pressure die-cast Mg–4Al-based alloy. Mater. Sci. Eng. A 2015, 628, 319–326. [Google Scholar] [CrossRef]

- Dong, X.; Feng, L.; Wang, S.; Nyberg, E.A.; Ji, S. A new die-cast magnesium alloy for applications at higher elevated temperatures of 200–300 °C. J. Magnes. Alloys 2021, 9, 90–101. [Google Scholar] [CrossRef]

- Rong, J.; Xiao, W.; Zhao, X.; Fu, Y.; Liao, H.; Ma, C.; Chen, M.; Huang, C. Effects of Al addition on the microstructure, mechanical properties and thermal conductivity of high pressure die cast Mg–3RE–0.5Zn alloy ultrathin–walled component. J. Alloys Compd. 2022, 896, 162943. [Google Scholar] [CrossRef]

- Easton, M.; Zhu, S.; Gibson, M.; Abbott, T.; Ang, H.Q.; Chen, X.; Birbilis, N.; Savage, G. Performance evaluation of high-pressure die-cast magnesium alloys. In Magnesium Technology, the Minerals; Solanki, K.N., Orlov, D., Singh, A., Neelameggham, N.R., Eds.; Metals & Materials Series; Springer: Berlin/Heidelberg, Germany, 2017; pp. 123–128. [Google Scholar]

- Zhu, S.M.; Easton, M.A.; Abbott, T.B.; Nie, J.F.; Dargusch, M.S.; Hort, N.; Gibson, M.A. Evaluation of magnesium die-casting alloys for elevated temperature applications: Microstructure, tensile properties, and creep resistance. Metall. Mater. Trans. A 2015, 46, 3543–3554. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.; Hou, Y.; Hua, L.; Ma, H.; Li, X.; Xiong, S. On the deformation behavior of heterogeneous microstructure and its effect on the mechanical properties of die cast AZ91D magnesium alloy. J. Magnes. Alloys 2022, 10, 1981–1993. [Google Scholar] [CrossRef]

- Ang, H.Q.; Abbott, T.B.; Zhu, S.; Gu, C.; Easton, M.A. Proof stress measurement of die-cast magnesium alloys. Mater. Des. 2016, 112, 402–409. [Google Scholar] [CrossRef]

- Easton, M.; Gibson, M.A.; Zhu, S.; Abbott, T.; Nie, J.F.; Bettles, C.J.; Savage, G. Development of magnesium-rare earth die-casting alloys. In Magnesium Technology, the Minerals; Orlov, D., Joshi, V., Solanki, K., Neelameggham, N.R., Eds.; Metals & Materials Series; Springer: Berlin/Heidelberg, Germany, 2018; pp. 329–336. [Google Scholar]

- Dargusch, M.S.; Pettersen, K.; Bakke, P.; Nogita, K.; Bowles, A.L.; Dunlop, G.L. Microstructure and mechanical properties of high pressure die cast magnesium alloy AE42 with 1% strontium. Int. J. Cast Met. Res. 2004, 17, 170–173. [Google Scholar] [CrossRef]

- Zhu, S.M.; Abbott, T.B.; Gibson, M.A.; Nie, J.F.; Easton, M.A. The influence of minor Mn additions on creep resistance of die-cast Mg–Al–RE alloys. Mater. Sci. Eng. A 2017, 682, 535–541. [Google Scholar] [CrossRef]

- Zhu, S.M.; Abbott, T.B.; Gibson, M.A.; Nie, J.F.; Easton, M.A. Age hardening in die-cast Mg–Al–RE alloys due to minor Mn additions. Mater. Sci. Eng. A 2016, 656, 34–38. [Google Scholar] [CrossRef]

- Yang, Q.; Bu, F.; Zheng, T.; Meng, F.; Liu, X.; Zhang, D.; Qiu, X.; Meng, J. Influence of trace Sr additionson the microstructures and the mechanical properties of Mg–Al–La-based alloy. Mater. Sci. Eng. A 2014, 619, 256–264. [Google Scholar] [CrossRef]

- Qin, P.-F.; Yang, Q.; He, Y.-Y.; Zhang, J.-H.; Xie, J.-S.; Hua, X.-R.; Guan, K.; Meng, J. Microstructure and mechanical properties of high-strength high pressure die-cast Mg–4Al–3La–1Ca–0.3Mn alloy. Rare Met. 2021, 40, 2956–2963. [Google Scholar] [CrossRef]

- Yang, Q.; Zheng, T.; Zhang, D.; Liu, X.; Fan, J.; Qiu, X.; Niu, X.; Meng, J. Microstructures and tensile properties of Mg–4Al–4La–0.4Mn–xB (x = 0, 0.01, 0.02, 0.03) alloy. J. Alloys Compd. 2013, 572, 129–136. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Meng, J.; Wu, R.; Tang, D. Microstructures and mechanical properties of heat-resistant high-pressure die-cast Mg–4Al–xLa–0.3Mn (x = 1, 2, 4, 6) alloys. Mater. Sci. Eng. A 2010, 527, 2527–2537. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, K.; Fang, D.; Qiu, X.; Tang, D.; Meng, J. Microstructure, tensile properties, and creep behavior of high-pressure die-cast Mg–4Al–4RE–0.4Mn (RE = La, Ce) alloys. J. Mater. Sci. 2009, 44, 2046–2054. [Google Scholar] [CrossRef]

- Su, M.; Zhang, J.; Feng, Y.; Bai, Y.; Wang, W.; Zhang, Z.; Jiang, F. Al–Nd intermetallic phase stability and its effects on mechanical properties and corrosion resistance of HPDC Mg–4Al–4Nd–0.2Mn alloy. J. Alloys Compd. 2017, 691, 634–643. [Google Scholar] [CrossRef]

- Yang, Q.; Guan, K.; Qiu, X.; Zhang, D.; Lv, S.; Bu, F.; Zhang, Y.; Liu, X.; Meng, J. Structures of Al2Sm phase in a high-pressure die-cast Mg–4Al–4Sm–0.3Mn alloy. Mater. Sci. Eng. A 2016, 675, 396–402. [Google Scholar] [CrossRef]

- Yang, Q.; Bu, F.; Qiu, X.; Li, Y.; Li, W.; Sun, W.; Liu, X.; Meng, J. Strengthening effect of nano-scale precipitates in a die-cast Mg-4Al–5.6Sm–0.3Mn alloy. J. Alloys Compd. 2016, 665, 240–250. [Google Scholar] [CrossRef]

- Qin, P.; Yang, Q.; Guan, K.; Meng, F.; Lv, S.; Li, B.; Zhang, D.; Wang, N.; Zhang, J.; Meng, J. Microstructures and mechanical properties of a high pressure die-cast Mg–4Al−4Gd−0.3Mn alloy. Mater. Sci. Eng. A 2019, 764, 138254. [Google Scholar] [CrossRef]

- Lv, S.; Lü, X.; Meng, F.; Yang, Q.; Qiu, X.; Qin, P.; Duan, Q.; Meng, J. Microstructures and mechanical properties in a Gd-modified high-pressure die casting Mg–4Al–3La–0.3Mn alloy. Mater. Sci. Eng. A 2020, 773, 138725. [Google Scholar] [CrossRef]

- Suzuki, A.; Saddock, N.D.; Riester, L.; Lara-Curzio, E.; Jones, J.W.; Pollock, T.M. Effect of Sr additions on the microstructure and strength of a Mg–Al–Ca ternary alloy. Metall. Mater. Trans. A 2007, 38, 420–427. [Google Scholar] [CrossRef]

- Gavras, S.; Zhu, S.M.; Nie, J.F.; Gibson, M.A.; Easton, M.A. On the microstructural factors affecting creep resistance of die-cast Mg–La-rare earth (Nd, Y or Gd) alloys. Mater. Sci. Eng. A 2016, 675, 65–75. [Google Scholar] [CrossRef]

- Hua, X.; Yang, Q.; Zhang, D.; Meng, F.; Chen, C.; You, Z.; Zhang, J.; Lv, S.; Meng, J. Microstructures and mechanical properties of a newly developed high-pressure die casting Mg–Zn–RE alloy. J. Mater. Sci. Technol. 2020, 53, 174–184. [Google Scholar] [CrossRef]

- Dong, X.; Feng, L.; Wang, S.; Ji, G.; Addad, A.; Yang, H.; Nyberg, E.A.; Ji, S. On the exceptional creep resistance in a die-cast Gd-containing Mg alloy with Al addition. Acta Mater. 2022, 232, 117957. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Qiu, X.; Zhang, D.; Tian, Z.; Niu, X.; Tang, D.; Meng, J. Effect of Nd on the microstructure, mechanical properties and corrosion behavior of die-cast Mg–4Al-based alloy. J. Alloys Compd. 2008, 464, 556–564. [Google Scholar] [CrossRef]

- Zhang, J.; Leng, Z.; Zhang, M.; Meng, J.; Wu, R. Effect of Ce on microstructure, mechanical properties and corrosion behavior of high-pressure die-cast Mg–4Al-based alloy. J. Alloys Compd. 2011, 509, 1069–1078. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, K.; Fang, D.; Qiu, X.; Yu, P.; Tang, D.; Meng, J. Microstructures, mechanical properties and corrosion behavior of high-pressure die-cast Mg–4Al–0.4Mn–xPr (x = 1, 2, 4, 6) alloys. J. Alloys Compd. 2009, 480, 810–819. [Google Scholar] [CrossRef]

- Zhang, J.; Niu, X.; Qiu, X.; Liu, K.; Nan, C.; Tang, D.; Meng, J. Effect of yttrium-rich misch metal on the microstructures, mechanical properties and corrosion behavior of die cast AZ91 alloy. J. Alloys Compd. 2009, 471, 322–330. [Google Scholar] [CrossRef]

- Wong, C.; Styles, M.J.; Zhu, S.; Qiu, D.; McDonald, S.D.; Zhu, Y.; Gibson, M.A.; Abbott, T.B. (Al,Mg)3La: A new phase in the Mg-Al-La system. Acta Crystall. 2018, 74, 370–375. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.-C.; Li, M.-X.; Yu, Z.-Y.; Meng, Z.-Y.; Wang, C.; Yang, Z.-Z.; Wang, H.-Y. Simultaneous refinement of α-Mg grains and β-Mg17Al12 in Mg-Al based alloys via heterogeneous nucleation on Al8Mn4Sm. J. Magnes. Alloys 2023, 11, 348–360. [Google Scholar] [CrossRef]

- Saddock, N.D.; Suzuki, A.; Jones, J.W.; Pollock, T.M. Grain-scale creep processes in Mg–Al–Ca base alloys: Implications for alloy design. Scr. Mater. 2010, 63, 692–697. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Shi, Z.; Zhu, H.; Atrens, A.; Song, G.-L. Microstructure modification and corrosion resistance enhancement of die-cast Mg-Al-RE alloy by Sr alloying. J. Magnes. Alloys 2021, 9, 950–963. [Google Scholar] [CrossRef]

- Li, J.H.; Sha, G.; Jie, W.Q.; Ringera, S.P. Precipitation microstructure and their strengthening effects of an Mg-2.8Nd-0.6Zn-0.4Zr alloy with a 0.2 wt.% Y addition. Mater. Sci. Eng. A 2012, 538, 272–280. [Google Scholar] [CrossRef]

- Bai, Y.; Yu, X.; Wang, L.; Zhang, N.; Ye, B.; Cheng, W.; Kong, X. New HPDC Mg-RE based alloy with exceptional strength and creep resistance at elevated temperature. Mater. Sci. Eng. A 2022, 840, 142921. [Google Scholar] [CrossRef]

- TerBush, J.R.; Suzuki, A.; Saddock, N.D.; Jones, J.W.; Pollock, T.M. Dislocation substructures of three die-cast Mg–Al–Ca-based alloys. Scr. Mater. 2008, 58, 914–917. [Google Scholar] [CrossRef]

- Weiler, J.P. Exploring the concept of castability in magnesium die-casting alloys. J. Magnes. Alloys 2021, 9, 102–111. [Google Scholar] [CrossRef]

- Zhu, S.; Abbott, T.B.; Nie, J.-F.; Ang, H.Q.; Qiu, D.; Nogita, K.; Easton, M.A. Re-evaluation of the mechanical properties and creep resistance of commercial magnesium die-casting alloy AE44. J. Magnes. Alloys 2021, 9, 1537–1545. [Google Scholar] [CrossRef]

- Bu, F.; Yang, Q.; Guan, K.; Qiu, X.; Zhang, D.; Sun, W.; Zheng, T.; Cui, X.; Sun, S.; Tang, Z.; et al. Study on the mutual effect of La and Gd on microstructure and mechanical properties of Mg–Al–Zn extruded alloy. J. Alloys Compd. 2016, 688, 1241–1250. [Google Scholar] [CrossRef]

- Yang, L.; He, S.; Yang, C.; Zhou, X.; Lu, X.; Huang, Y.; Qin, G.; Zhang, E. Mechanism of Mn on inhibiting Fe-caused magnesium corrosion. J. Magnes. Alloys 2021, 9, 676–685. [Google Scholar] [CrossRef]

- Zeng, G.; Xian, J.; Gourlay, C. Nucleation and growth crystallography of Al8Mn5 on B2-Al(Mn,Fe) in AZ91 magnesium alloys. Acta Mater. 2018, 153, 364–376. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Lv, S.-H.; Meng, F.-Z.; Guan, K.; Li, B.-S.; Zhang, X.-H.; Zhang, J.-Q.; Liu, X.-J.; Meng, J. Detailed Structures and Formation Mechanisms of Well-Known Al10RE2Mn7 Phase in Die-Cast Mg–4Al–4RE–0.3Mn Alloy. Acta Metall. Sin. 2019, 32, 178–186. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Guan, K.; Li, B.; Lv, S.; Meng, F.; Sun, W.; Zhang, Y.; Liu, X.; Meng, J. Microstructural characterizations on Mn-containing intermetallic phases in a high-pressure die-casting Mg–4Al–4RE–0.3Mn alloy. Mater. Charact. 2017, 132, 381–387. [Google Scholar] [CrossRef]

- Braszczynska-Malik, K.N. Effect of high-pressure die casting on structure and properties of Mg-5Al-0.4Mn-xRE (x = 1, 3 and 5 wt%) experimental alloys. J. Alloys Compd. 2017, 694, 841–847. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Zhu, S.M.; Nie, J.F.; Dunlop, G.L. Microstructural analysis of the improved creep resistance of a die-cast magnesium–aluminium–rare earth alloy by strontium additions. Scr. Mater. 2009, 60, 116–119. [Google Scholar] [CrossRef]

- Bai, J.; Sun, Y.; Xue, F.; Xue, S.; Qiang, J.; Zhu, T. Influence of annealing on microstructures, mechanical and creep properties of Mg–4Al–2Sr alloy. Mater. Sci. Technol. 2006, 22, 1208–1212. [Google Scholar] [CrossRef]

- Luo, A.A.; Balogh, M.P.; Powell, B.R. Creep and microstructure of magnesium–aluminum–calcium based alloys. Metall. Mater. Trans. A 2002, 33, 567–574. [Google Scholar] [CrossRef]

- Xu, S.W.; Oh-Ishi, K.; Kamado, S.; Uchida, F.; Homma, T.; Hono, K. High-strength extruded Mg–Al–Ca–Mn alloy. Scr. Mater. 2011, 65, 269–272. [Google Scholar] [CrossRef]

- Yang, Q.; Lv, S.; Qin, P.; Meng, F.; Qiu, X.; Hua, X.; Guan, K.; Sun, W.; Liu, X.; Meng, J. Interphase boundary segregation induced phase transformation in a high-pressure die casting Mg-Al-La-Ca-Mn alloy. Mater. Des 2020, 190, 108566. [Google Scholar] [CrossRef]

- Yang, Q.; Qiu, X.; Lv, S.; Meng, F.; Guan, K.; Li, B.; Zhang, D.; Zhang, Y.; Liu, X.; Meng, J. Deteriorated tensile creep resistance of a high-pressure die-cast Mg–4Al–4RE–0.3Mn alloy induced by substituting part RE with Ca. Mater. Sci. Eng. A 2018, 716, 120–128. [Google Scholar] [CrossRef]

- Games de Mesuita, A.H.; Buschow, K.H.J. The crystal structure of so-called α-LaAl4 (La3Al11). Acta Cryst. 1967, 22, 497–501. [Google Scholar] [CrossRef]

- Dill, B.; Li, Y.; Alkhafaji, M.; Rainforth, W.M.; Buckley, R.A.; Jones, H. Structure, properties and response to heat treatment of melt-spun AI-Y and AI-La alloys. J. Mater. Sci. 1994, 29, 3913–3918. [Google Scholar] [CrossRef]

- Lv, S.; Lu, X.; Li, Y.; Meng, F.; Hua, X.; Yang, Q.; Qiu, X.; Meng, J.; Duan, Q. Crystallographic orientation relationships between the aggregated intermetallic phases in a casting Mg–Ag–Al alloy. Mater. Des. 2020, 190, 108561. [Google Scholar] [CrossRef]

- Yang, Q.; Zheng, T.; Zhang, D.; Bu, F.; Qiu, X.; Liu, X.; Meng, J. Creep behavior of high-pressure die-cast Mg–4Al–4La–0.4Mn alloy under medium stresses and at intermediate temperatures. Mater. Sci. Eng. A 2016, 650, 190–196. [Google Scholar] [CrossRef]

- Meng, F.; Lv, S.; Qiu, X.; Yang, Q.; Meng, J.; Duan, Q. Interphase precipitation in an Ag-modified Mg-Al-La casting alloy. Mater. Charact. 2020, 161, 110144. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, X.; Bu, F.; Meng, F.; Zheng, T.; Zhang, D.; Meng, J. First-principles phase stability and elastic properties of Al-La binary system intermetallic compounds. Intermetallics 2015, 60, 92–97. [Google Scholar] [CrossRef]

- Lv, S.; Li, Y.; Meng, F.; Duan, Q.; Yang, Q.; Liu, X.; Meng, J. Thermodynamic stability of Al11RE3 intermetallic compounds from first-principles calculations. Comput. Mater. Sci. 2017, 131, 28–34. [Google Scholar] [CrossRef]

- Lv, S.; Meng, F.; Yang, Q.; Guan, K.; Meng, J. Atomic study on phase transformation of the strengthening phase in a die-casting Mg–Al–La alloy via an intermediate phase. Mater. Des. 2021, 208, 109904. [Google Scholar] [CrossRef]

- Sommer, F.; Keita, M. Determination of the enthalpies of formation of intermetallic compounds of aluminium with cerium, erbium and gadolinium. J. Less-Common Met. 1987, 136, 95–99. [Google Scholar] [CrossRef]

- She, J.; Zhan, Y.; Li, C.; Du, Y.; Xu, H.; He, Y. Phase equilibria of the Al–Pr–Zr ternary system at 773 K. J. Alloys Compd. 2010, 503, 57–60. [Google Scholar] [CrossRef]

- Buschow, K.H.J. Phase Relations and intermetallic compounds in the systems neodymium-aluminum and gadolinium-aluminum. J. Less-Common Met. 1965, 9, 452–456. [Google Scholar] [CrossRef]

- Li, K.; Li, Q.; Jing, X.; Chen, J.; Zhang, X.; Zhang, Q. Effects of Sm addition on microstructure and mechanical properties of Mg–6Al–0.6Zn alloy. Scr. Mater. 2009, 60, 1101–1104. [Google Scholar]

- Zhou, S.H.; Napolitano, R.E. The stability of Al11Sm3 (Al4Sm) phases in the Al-Sm binary system. Metall. Mater. Trans. A 2007, 38, 1145–1151. [Google Scholar] [CrossRef] [Green Version]

- Harris, I.R.; Mansey, R.C.; Raynor, G.V. Rare earth intermediate phases: III. The cubic laves phases formed with aluminium and cobalt. J. Less Common Met. 1965, 9, 270–280. [Google Scholar] [CrossRef]

- van Vucht, J.H.N.; Buschow, K.H.J. The structures of the rare-earth trialuminides. J. Less Common Met. 1965, 10, 98–107. [Google Scholar] [CrossRef]

- Lv, S.; Xie, Z.; Yang, Q.; Meng, F.; Qiu, X. Microstructures and mechanical properties of a hot-extruded Mg−8Zn−6Al−1Gd (wt%) alloy. J. Alloys Compd. 2022, 904, 164040. [Google Scholar] [CrossRef]

- Stanford, N.; Atwell, D.; Barnett, M.R. The effect of Gd on the recrystallisation, texture and deformation behaviour of magnesium-based alloys. Acta Mater. 2010, 58, 6773–6783. [Google Scholar] [CrossRef]

- Lv, S.; Li, Y.; Lu, X.; Meng, F.; Yang, Q.; Han, D.; Duan, Q.; Meng, J. The types and structures of the intermetallic phases in a cast Mg-4Al-15Gd-4Y-1Zn alloy. J. Alloys Compd. 2018, 731, 612–619. [Google Scholar] [CrossRef]

- Wang, X.D.; Du, W.B.; Liu, K.; Wang, Z.H.; Li, S.B. Microstructure, tensile properties and creep behaviors of as-cast Mg–2Al–1Zn–xGd (x = 1, 2, 3, and 4 wt.%) alloys. J. Alloys. Comp. 2012, 522, 78–84. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, J.; Zhao, D.; Tang, S. Investigation of the crystallographic orientations of the β-Mg17Al12 precipitates in an Mg–Al–Zn–Sn alloy. Mater. Charact. 2016, 118, 481–485. [Google Scholar] [CrossRef]

- Wei, J.; Wang, Q.; Cao, H.; Ebrahimi, M.; Lei, C. Microstructure and impact behavior of Mg-4Al-5RE-xGd cast magnesium alloys. J. Magnes. Alloys 2022, in press. [Google Scholar] [CrossRef]

- Pettersen, G.; Westengen, H.; Hoier, R.; Lohne, O. Microstructure of a pressure die cast magnesium-4wt.% aluminium alloy modified with rare earth additions. Mater. Sci. Eng. A 1996, 207, 115–120. [Google Scholar] [CrossRef]

- Gavras, S.; Easton, M.A.; Gibson, M.A.; Zhu, S.; Nie, J.-F. Microstructure and property evaluation of high-pressure die-cast Mg–La–rare earth (Nd, Y or Gd) alloys. J. Alloy. Compd. 2014, 597, 21. [Google Scholar] [CrossRef]

- Easton, M.; Gibson, M.; Zhu, S.M.; Abbott, T. An a priori hot-tearing indicator applied to die-cast magnesium-rare earth alloys. Metall. Mater. Trans. A 2014, 45, 3586–3595. [Google Scholar] [CrossRef]

- Paliwal, M.; Das, S.K.; Kim, J.; Jung, I.-H. Diffusion of Nd in hcp Mg and interdiffusion coefficients in Mg–Nd system. Scr. Mater. 2015, 108, 11–14. [Google Scholar] [CrossRef]

- Mo, N.; Tan, Q.Y.; Bermingham, M.; Huang, Y.D.; Dieringa, H.; Hort, N.; Zhang, M.X. Current development of creep-resistant magnesium cast alloys: A review. Mater. Des. 2018, 155, 422–442. [Google Scholar] [CrossRef]

- Moreno, I.P.; Nandy, T.K.; Jones, J.W.; Allison, J.E.; Pollock, T.M. Microstructural stability and creep of rare-earth containing magnesium alloys. Scr. Mater. 2003, 48, 1029–1034. [Google Scholar] [CrossRef]

- Moreno, I.P.; Nandy, T.K.; Jones, J.W.; Allison, J.E.; Pollock, T.M. Microstructural characterization of a die-cast magnesium-rare earth alloy. Scr. Mater. 2001, 45, 1423–1429. [Google Scholar] [CrossRef]

- Zhu, S.M.; Gibson, M.A.; Eastona, M.A.; Nie, J.F. The relationship between microstructure and creep resistance in die-cast magnesium–rare earth alloys. Scr. Mater. 2010, 63, 698–703. [Google Scholar] [CrossRef]

- Choudhuri, D.; Srinivasan, S.G.; Gibson, M.A.; Zheng, Y.; Jaeger, D.L.; Fraser, H.L.; Banerjee, R. Exceptional increase in the creep life of magnesium rare-earth alloys due to localized bond stiffening. Nat. Commun. 2017, 8, 2000. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Guan, K.; Yang, Q.; Niu, X.; Zhang, D.; Yu, Z.; Zhang, X.; Tang, Z.; Meng, J. Effects of 0.5 wt% Ce addition on microstructures and mechanical properties of a wrought Mg–8Gd–1.2Zn–0.5Zr alloy. J. Alloys Compd. 2018, 763, 120–133. [Google Scholar] [CrossRef]

- Meng, F.; Lv, S.; Yang, Q.; Yan, Z.; Duan, Q.; Meng, J. Multiplex intermetallic phases in a gravity die-cast Mg–6.0Zn–1.5Nd–0.5Zr (wt%) alloy. J. Magnes. Alloys 2022, 10, 209–223. [Google Scholar] [CrossRef]

- Grobner, J.; Kozlov, A.; Fang, X.Y.; Zhu, S.M.; Nie, J.F.; Gibson, M.A.; Schmid-Fetzer, R. Phase equilibria and transformations in ternary Mg–Gd–Zn alloys. Acta Mater. 2015, 90, 400–416. [Google Scholar] [CrossRef]

- Baenziger, N.C.; Hegenbarth, J.J. Gadolinium and dysprosium intermetallic phases. III. The structures of Gd3Al2, Dy3Al2, Gd5Ge3, Dy5Ge3 and DyAl3. Acta Crystallogr. 1964, 17, 620–621. [Google Scholar] [CrossRef] [Green Version]

- Yu, X.; Bai, Y.; Ye, B.; Wang, L.; Zhao, B.; Kong, X. A Mg–6Y–3Zn–1Al Mg HPDC alloy having high thermal stability: Study of grain growth kinetics. J. Alloys Compd. 2022, 925, 166503. [Google Scholar] [CrossRef]

- Ozturk, K.; Zhong, Y.; Luo, A.A.; Liu, Z.-K. Creep resistant Mg-Al-Ca alloys: Computational thermodynamics and experimental investigation. JOM 2003, 55, 40–44. [Google Scholar] [CrossRef]

- Singh, A.; Hiroto, T.; Ode, M.; Takakura, H.; Tesar, K.; Somekawa, H.; Hara, T. Precipitation of stable icosahedral quasicrystal phase in a Mg–Zn–Al alloy. Acta Mater. 2022, 225, 117563. [Google Scholar] [CrossRef]

- Wang, Y.; Guan, S.; Zeng, X.; Ding, W. Effects of RE on the microstructure and mechanical properties of Mg–8Zn–4Al magnesium alloy. Mater. Sci. Eng. A 2006, 416, 109–118. [Google Scholar] [CrossRef]

- Vogel, M.; Kraft, O.; Dehm, G.; Arzt, E. Quasi-crystalline grain-boundary phase in the magnesium die-cast alloy ZA85. Scr. Mater. 2001, 45, 517–524. [Google Scholar] [CrossRef]

- Somekawa, H.; Osawa, Y.; Singh, A.; Mukai, T. Rare-earth free wrought-processed magnesium alloy with dispersion of quasicrystal phase. Scr. Mater. 2009, 61, 705–708. [Google Scholar] [CrossRef]

- Garces, G.; Medina, J.; Perez, P.; Mathis, K.; Horvath, K.; Stark, A.; Schell, N.; Adeva, P. Influence of quasicrystal I-phase on twinning of extruded Mg–Zn–Y alloys under compression. Acta Mater. 2018, 151, 271–281. [Google Scholar] [CrossRef]

| Alloy | Grain Size (μm) | Dominant Intermetallic Phases | Reference |

|---|---|---|---|

| AE44 | ~14 | Acicular/needle-like Al11RE3, blocky Al2RE | [44,45] |

| ALa44 | 7–16 | Acicular/needle-like Al11La3 | [83,84] |

| ALaM440 | ~15.6 | Acicular η-Al3La (or (Mg,Al)3La) | [66,99] |

| ACe44 | ~14 | Acicular/needle-like Al11Ce3, blocky Al2Ce | [95] |

| APr44 | ~8.5 | Quadrangle/polygon Al2Pr, acicular/petal-like Al11Pr3 | [96] |

| ANd44 | ~10.5 | Quadrangle Al2Nd, dendritic/coarse-surface Al11Nd3 | [85,94] |

| ASm44 | ~9.6 | Petaloid Al2Sm | [86] |

| ASm46 | ~6.3 | Petaloid/blocky/short-rod-like Al2Sm, dendritic Al11Sm3 | [87] |

| AGd44 | ~5.9 | Petaloid/blocky Al2Gd | [88] |

| AE432 | ~6.1 | Acicular/flaky η-Al3RE, blocky/spindle-shapedAl2RE, claviform Al7RE3 | [69,89] |

| AEX series | ~7 | Lamellae (Mg,Al)2Ca, lath-like Al11RE3, rod-like η-Al3RE, blocky Al2.12RE0.88 | [68,81,100] |

| AEJ series | ~13.6 | Blocky Al4Sr or Mg8Al4Sr, lamellae Mg17Sr2 | [80,100,101,102] |

| ALa44+B | 10.7 | Acicular Al11RE3, blocky Al2RE | [82] |

| Mg-RE series | ~5.1 | Net-work Mg12RE, lamellae Mg3RE, plate-like β-series precipitates | [91,103] |

| ZLaW423 | ~6.1 | Aggregated lamellae Mg12RE and blocky W phase, lath-like LPSO | [46] |

| Mg-RE-Al | α1 = 10–30, α2 = 2–10 | Lamellae Mg12RE, blocky Al2RE3, precipitated AlMnRE cluster/Al2RE | [71,93] |

| AX/J series | ~6.1 | Lamellae (Mg,Al)2Ca/Mg17Sr2, net-work Mg2Ca/Al4Sr, precipitated Al2Ca | [31,49,90,91,92,104,105] |

| ZA88 | α1 = ~5.6, α2 = ~0.67 | Nanosized icosahedral quasicrystal phase | [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Wu, X.; Qiu, X. Microstructural Characteristics of High-Pressure Die Casting with High Strength–Ductility Synergy Properties: A Review. Materials 2023, 16, 1954. https://doi.org/10.3390/ma16051954

Yang Q, Wu X, Qiu X. Microstructural Characteristics of High-Pressure Die Casting with High Strength–Ductility Synergy Properties: A Review. Materials. 2023; 16(5):1954. https://doi.org/10.3390/ma16051954

Chicago/Turabian StyleYang, Qiang, Xiaohan Wu, and Xin Qiu. 2023. "Microstructural Characteristics of High-Pressure Die Casting with High Strength–Ductility Synergy Properties: A Review" Materials 16, no. 5: 1954. https://doi.org/10.3390/ma16051954