Selective Blocking of Graphene Defects Using Polyvinyl Alcohol through Hydrophilicity Difference

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Synthesis of Graphene

2.3. Graphene Transfer on Si Wafer

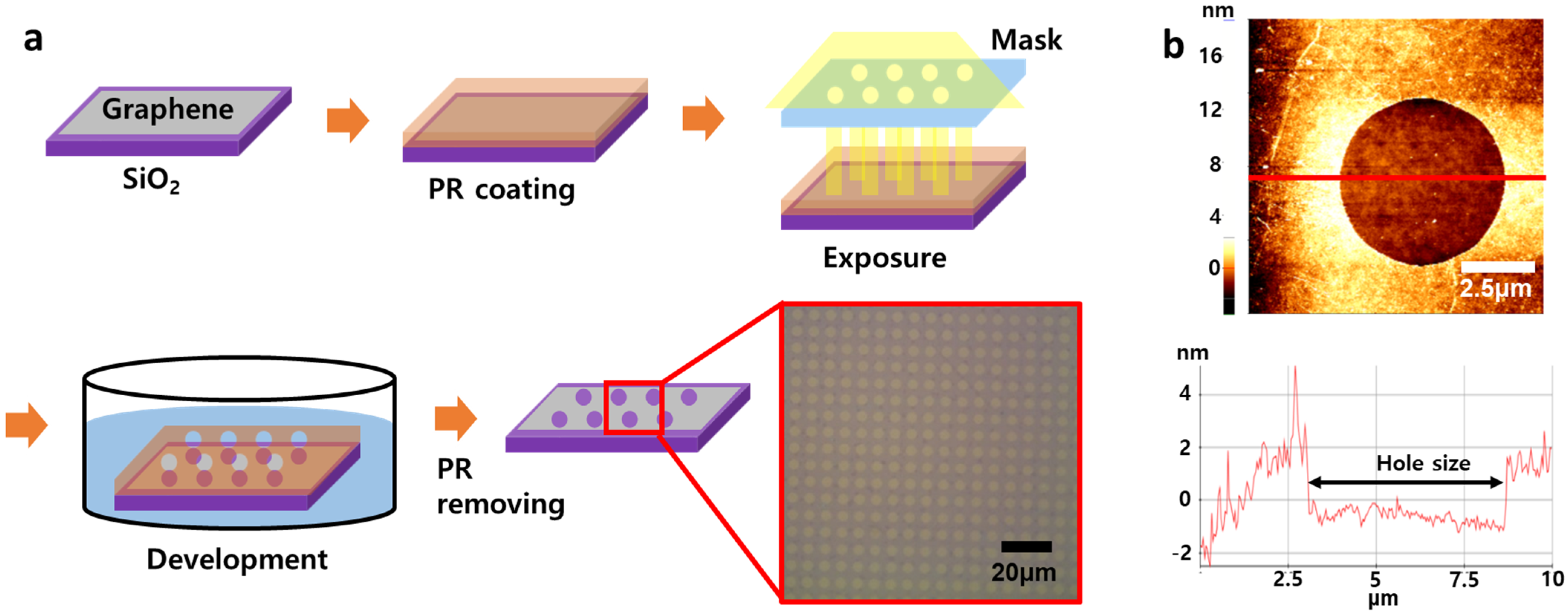

2.4. Fabrication of Graphene Defects

2.5. Preparation of HTC and PVA Solutions

2.6. Deposition of HTC and PVA

2.7. AFM Measurement

2.8. Scanning Tunneling Microscopy (STM) Study of Self–Assembled HTC on Graphene

3. Results and Discussion

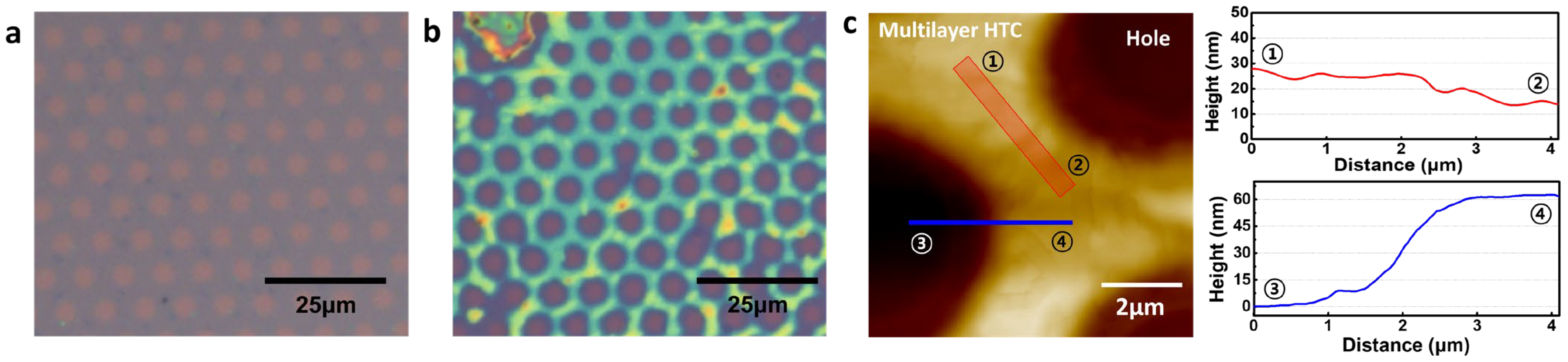

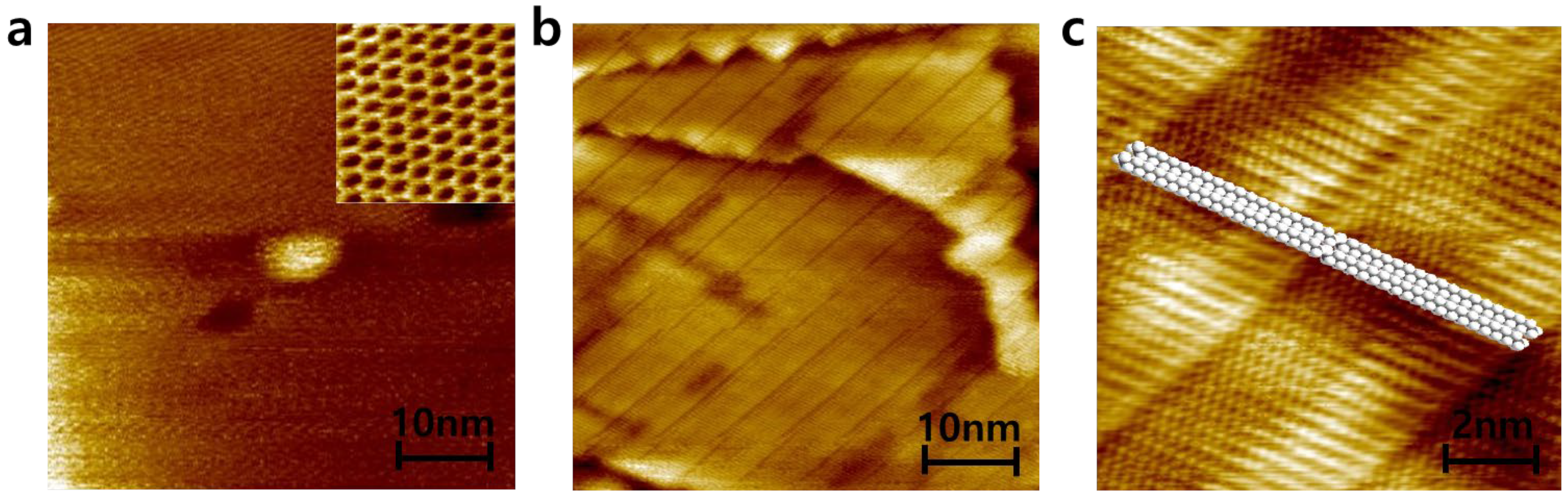

3.1. HTC Deposition on Patterned Graphene

3.2. PVA Deposition on Patterned Graphene

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, Q.; Jang, H.S.; Han, W.J.; Lee, J.H.; Choi, H.J. Stimuli-Responsive Graphene Oxide-Polymer Nanocomposites. Macromol. Res. 2019, 27, 1061–1070. [Google Scholar] [CrossRef]

- Li, Y.; Choi, M.C.; Jeong, K.M.; Jeong, J.H.; Lee, H.G.; Kim, G.H.; Ha, C.S. Layer-by-layer assembly of graphene on polyimide films via thermal imidization and synchronous reduction of graphene oxide. Macromol. Res. 2017, 25, 496–499. [Google Scholar] [CrossRef]

- Tan, B.; Thomas, N.L. A review of the water barrier properties of polymer/clay and polymer/graphene nanocomposites. J. Membr. Sci. 2016, 514, 595–612. [Google Scholar] [CrossRef] [Green Version]

- Manikandan, N.A.; Pakshirajan, K.; Pugazhenthi, G. Preparation and characterization of environmentally safe and highly biodegradable microbial polyhydroxybutyrate (PHB) based graphene nanocomposites for potential food packaging applications. Int. J. Biol. Macromol. 2020, 154, 866–877. [Google Scholar] [CrossRef]

- Kausar, A. Applications of polymer/graphene nanocomposite membranes: A review. Mater. Res. Innov. 2019, 23, 276–287. [Google Scholar] [CrossRef]

- Bao, C.; Guo, Y.; Song, L.; Hu, Y. Poly (vinyl alcohol) nanocomposites based on graphene and graphite oxide: A comparative investigation of property and mechanism. J. Mater. Chem. 2011, 21, 13942–13950. [Google Scholar] [CrossRef]

- Banhart, F.; Kotakoski, J.; Krasheninnikov, A.V. Structural Defects in Graphene. ACS Nano 2011, 5, 26–41. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.M.; Kim, J.H.; Ahn, J.H. Graphene as a flexible electronic material: Mechanical limitations by defect formation and efforts to overcome. Mater. Today 2015, 18, 336–344. [Google Scholar] [CrossRef]

- Zandiatashbar, A.; Lee, G.-H.; An, S.J.; Lee, S.; Mathew, N.; Terrones, M.; Hayashi, T.; Picu, C.R.; Hone, J.; Koratkar, N. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 2014, 5, 3186. [Google Scholar] [CrossRef] [Green Version]

- Bhatt, M.D.; Kim, H.; Kim, G. Various defects in graphene: A review. RSC Adv. 2022, 12, 21520–21547. [Google Scholar] [CrossRef]

- Ishikawa, R.; Findlay, S.D.; Seki, T.; Sánchez-Santolino, G.; Kohno, Y.; Ikuhara, Y.; Shibata, N. Direct electric field imaging of graphene defects. Nat. Commun. 2018, 9, 3878. [Google Scholar] [CrossRef] [Green Version]

- Carraro, G.; Savio, L.; Vattuone, L. Influence of Defects and Heteroatoms on the Chemical Properties of Supported Graphene Layers. Coatings 2022, 12, 397. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Q.; Liang, X.; Pang, X.; Zhao, Y. Defects Produced during Wet Transfer Affect the Electrical Properties of Graphene. Micromachines 2022, 13, 227. [Google Scholar] [CrossRef]

- Prusty, K.; Barik, S.; Swain, S.K. A corelation between the graphene surface area, functional groups, defects and porosity on the performance of the nanocomposites. In Functionalized Graphene Nanocomposites and their Derivatives; Elsevier: Amsterdam, The Netherlands, 2019; pp. 265–283. [Google Scholar]

- Liu, L.L.; Qing, M.Q.; Wang, Y.B.; Chen, S.M. Defects in Graphene: Generation, Healing and Their Effects on the Properties of Graphene: A Review. J. Mater. Sci. Technol. 2015, 31, 599–606. [Google Scholar] [CrossRef]

- Li, X.; Magnuson, C.W.; Venugopal, A.; Tromp, R.M.; Hannon, J.B.; Vogel, E.M.; Colombo, L.; Ruoff, R.S. Large-area graphene single crystals grown by low-pressure chemical vapor deposition of methane on copper. J. Am. Chem. Soc. 2011, 133, 2816–2819. [Google Scholar] [CrossRef]

- Li, X.S.; Colombo, L.; Ruoff, R.S. Synthesis of Graphene Films on Copper Foils by Chemical Vapor Deposition. Adv. Mater. 2016, 28, 6247–6252. [Google Scholar] [CrossRef]

- Munoz, R.; Gomez-Aleixandre, C. Review of CVD Synthesis of Graphene. Chem. Vap. Depos. 2013, 19, 297–322. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Song, W.; Lee, S.Y.; Jeon, C.; Jung, W.; Kim, M.; Park, C.Y. Low-temperature synthesis of graphene on nickel foil by microwave plasma chemical vapor deposition. Appl. Phys. Lett. 2011, 98, 263106–2631063. [Google Scholar] [CrossRef] [Green Version]

- Juang, Z.Y.; Wu, C.Y.; Lu, A.Y.; Su, C.Y.; Leou, K.C.; Chen, F.R.; Tsai, C.H. Graphene synthesis by chemical vapor deposition and transfer by a roll-to-roll process. Carbon 2010, 48, 3169–3174. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Gong, X.L.; Gai, J.G. Progress and challenges in transfer of large-area graphene films. Adv. Sci. 2016, 3, 1500343. [Google Scholar] [CrossRef]

- Choi, K.; Nam, S.; Lee, Y.; Lee, M.; Jang, J.; Kim, S.J.; Jeong, Y.J.; Kim, H.; Bae, S.; Yoo, J.B.; et al. Reduced Water Vapor Transmission Rate of Graphene Gas Barrier Films for Flexible Organic Field-Effect Transistors. ACS Nano 2015, 9, 5818–5824. [Google Scholar] [CrossRef] [PubMed]

- Seo, T.H.; Lee, S.; Cho, H.; Chandramohan, S.; Suh, E.K.; Lee, H.S.; Bae, S.K.; Kim, S.M.; Park, M.; Lee, J.K.; et al. Tailored CVD graphene coating as a transparent and flexible gas barrier. Sci. Rep. 2016, 6, 24143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, Y.J.; Seo, T.H.; Kim, Y.H.; Suh, E.K.; Bae, S.; Hwang, J.Y.; Kim, J.; Kang, Y.; Kim, M.J.; Ahn, S. Two-Dimensional Stacked Composites of Self-Assembled Alkane Layers and Graphene for Transparent Gas Barrier Films with Low Permeability. Nano Lett. 2022, 22, 286–293. [Google Scholar] [CrossRef] [PubMed]

- Medeiros, P.V.; Gueorguiev, G.; Stafström, S. Bonding, charge rearrangement and interface dipoles of benzene, graphene and PAH molecules on Au(1 1 1) and Cu(1 1 1). Carbon 2015, 81, 620–628. [Google Scholar] [CrossRef]

- Sangiovanni, D.G.; Faccio, R.; Gueorguiev, G.K.; Kakanakova-Georgieva, A. Discovering atomistic pathways for supply of metal atoms from methyl-based precursors to graphene surface. Phys. Chem. Chem. Phys. 2023, 25, 829–837. [Google Scholar] [CrossRef]

- Page, A.; Ding, F.; Irle, S.; Morokuma, K. Insights into carbon nanotube and graphene formation mechanisms from molecular simulations: A review. Rep. Prog. Phys. 2015, 78, 036501. [Google Scholar] [CrossRef]

- Mango, F.D. The stability of hydrocarbons under the time-temperature conditions of petroleum genesis. Nature 1991, 352, 146–148. [Google Scholar] [CrossRef]

- Liu, L.; Rim, K.T.; Eom, D.; Heinz, T.F.; Flynn, G.W. Direct observation of atomic scale graphitic layer growth. Nano Lett. 2008, 8, 1872–1878. [Google Scholar] [CrossRef]

- Tsetseris, L.; Pantelides, S.T. Adsorbate-induced defect formation and annihilation on graphene and single-walled carbon nanotubes. J. Phys. Chem. B 2009, 113, 941–944. [Google Scholar] [CrossRef]

- Liu, L.; Gao, J.; Zhang, X.; Yan, T.; Ding, F. Vacancy inter-layer migration in multi-layered graphene. Nanoscale 2014, 6, 5729–5734. [Google Scholar] [CrossRef]

- Wang, B.; Pantelides, S. Controllable healing of defects and nitrogen doping of graphene by CO and NO molecules. Phys. Rev. B 2011, 83, 245403. [Google Scholar] [CrossRef]

- Karoui, S.; Amara, H.; Bichara, C.; Ducastelle, F. Nickel-assisted healing of defective graphene. ACS Nano 2010, 4, 6114–6120. [Google Scholar] [CrossRef] [Green Version]

- Yoon, T.; Kim, J.H.; Choi, J.H.; Jung, D.Y.; Park, I.J.; Choi, S.Y.; Cho, N.S.; Lee, J.I.; Kwon, Y.D.; Cho, S.; et al. Healing Graphene Defects Using Selective Electrochemical Deposition: Toward Flexible and Stretchable Devices. ACS Nano 2016, 10, 1539–1545. [Google Scholar] [CrossRef]

- Ye, J.Q.; Zhao, H.Q.; Kang, M.M.; Song, W.; Kong, Q.Q.; Chen, C.M.; Wu, R.; Mi, J.; Li, Z. Defect formation-induced tunable evolution of oxygen functional groups for sodium storage in porous graphene. Chem. Commun. 2020, 56, 1089–1092. [Google Scholar] [CrossRef]

- Luo, D.; Xu, J.; Guo, Q.; Fang, L.; Zhu, X.; Xia, Q.; Xia, H. Surface-dominated sodium storage towards high capacity and ultrastable anode material for sodium-ion batteries. Adv. Funct. Mater. 2018, 28, 1805371. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, L.L.; Sheng, L.Z.; Zhou, Q.H.; Wei, T.; Zhang, B.S.; Fan, Z.J. Oxygen Clusters Distributed in Graphene with “Paddy Land” Structure: Ultrahigh Capacitance and Rate Performance for Supercapacitors. Adv. Funct. Mater. 2018, 28, 1705258. [Google Scholar] [CrossRef]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.F.; Park, J.S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Kim, H.R.; Song, Y.I.; et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef] [Green Version]

- An, C.J.; Kim, S.J.; Choi, H.O.; Kim, D.W.; Jang, S.W.; Jin, M.L.; Park, J.M.; Choi, J.K.; Jung, H.T. Ultraclean transfer of CVD-grown graphene and its application to flexible organic photovoltaic cells. J. Mater. Chem. A 2014, 2, 20474–20480. [Google Scholar] [CrossRef]

- Shi, R.B.; Xu, H.L.; Chen, B.Y.; Zhang, Z.Y.; Peng, L.M. Scalable fabrication of graphene devices through photolithography. Appl. Phys. Lett. 2013, 102, 113102. [Google Scholar] [CrossRef]

- Shukla, S.; Kang, S.Y.; Saxena, S. Synthesis and patterning of graphene: Strategies and prospects. Appl. Phys. Rev. 2019, 6, 021311. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.-j.; Kim, Y.H.; Ahn, S. Selective Blocking of Graphene Defects Using Polyvinyl Alcohol through Hydrophilicity Difference. Materials 2023, 16, 2001. https://doi.org/10.3390/ma16052001

Kim Y-j, Kim YH, Ahn S. Selective Blocking of Graphene Defects Using Polyvinyl Alcohol through Hydrophilicity Difference. Materials. 2023; 16(5):2001. https://doi.org/10.3390/ma16052001

Chicago/Turabian StyleKim, Yoon-jeong, Yang Hui Kim, and Seokhoon Ahn. 2023. "Selective Blocking of Graphene Defects Using Polyvinyl Alcohol through Hydrophilicity Difference" Materials 16, no. 5: 2001. https://doi.org/10.3390/ma16052001

APA StyleKim, Y.-j., Kim, Y. H., & Ahn, S. (2023). Selective Blocking of Graphene Defects Using Polyvinyl Alcohol through Hydrophilicity Difference. Materials, 16(5), 2001. https://doi.org/10.3390/ma16052001