An Investigation of Compressive Creep Aging Behavior of Al-Cu-Li Alloy Pre-Treated by Compressive Plastic Deformation and Artificial Aging

Abstract

:1. Introduction

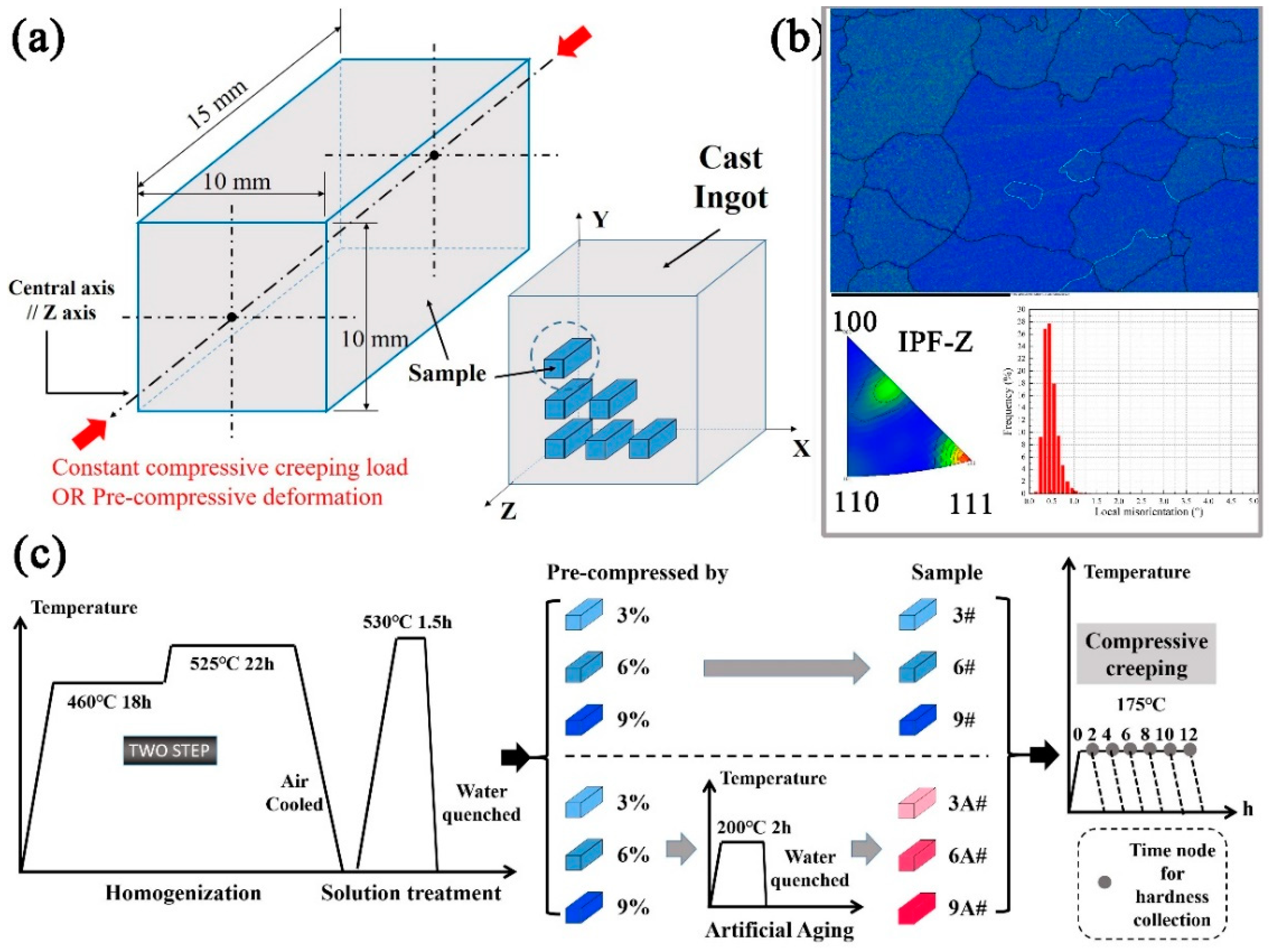

2. Experimental Procedure

3. Results

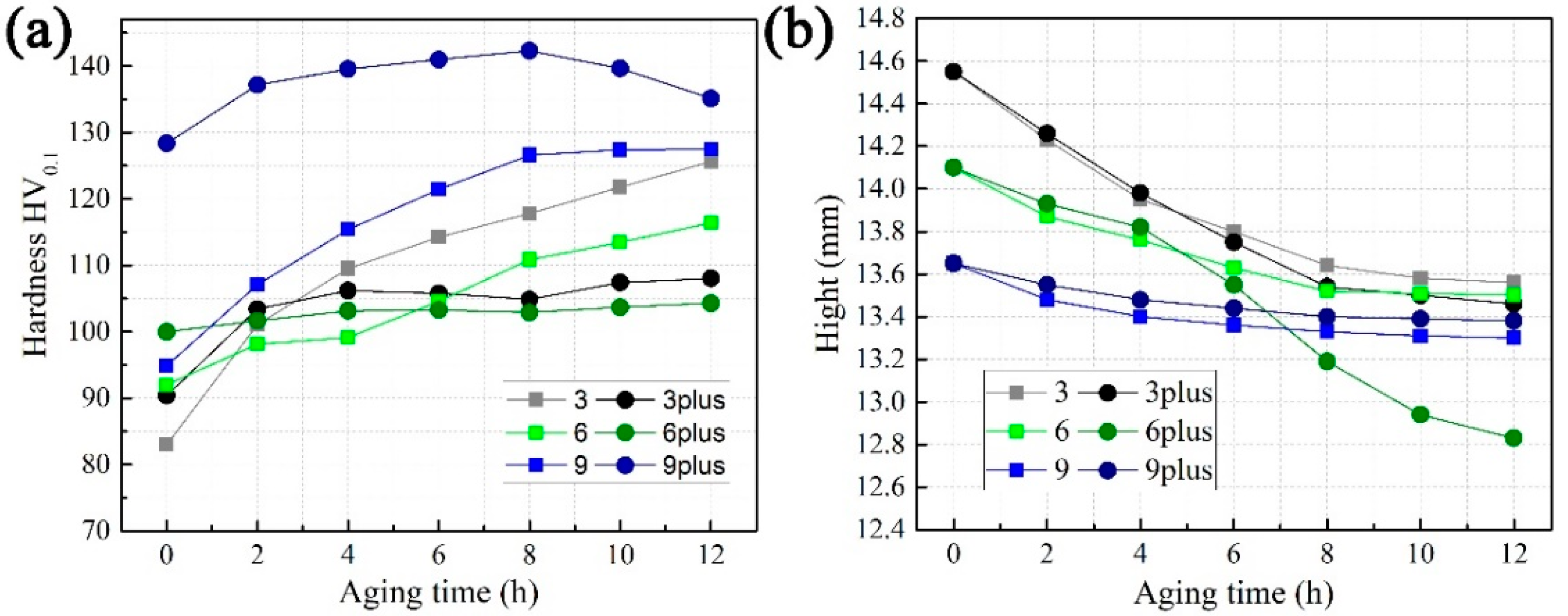

3.1. Hardness Evolution

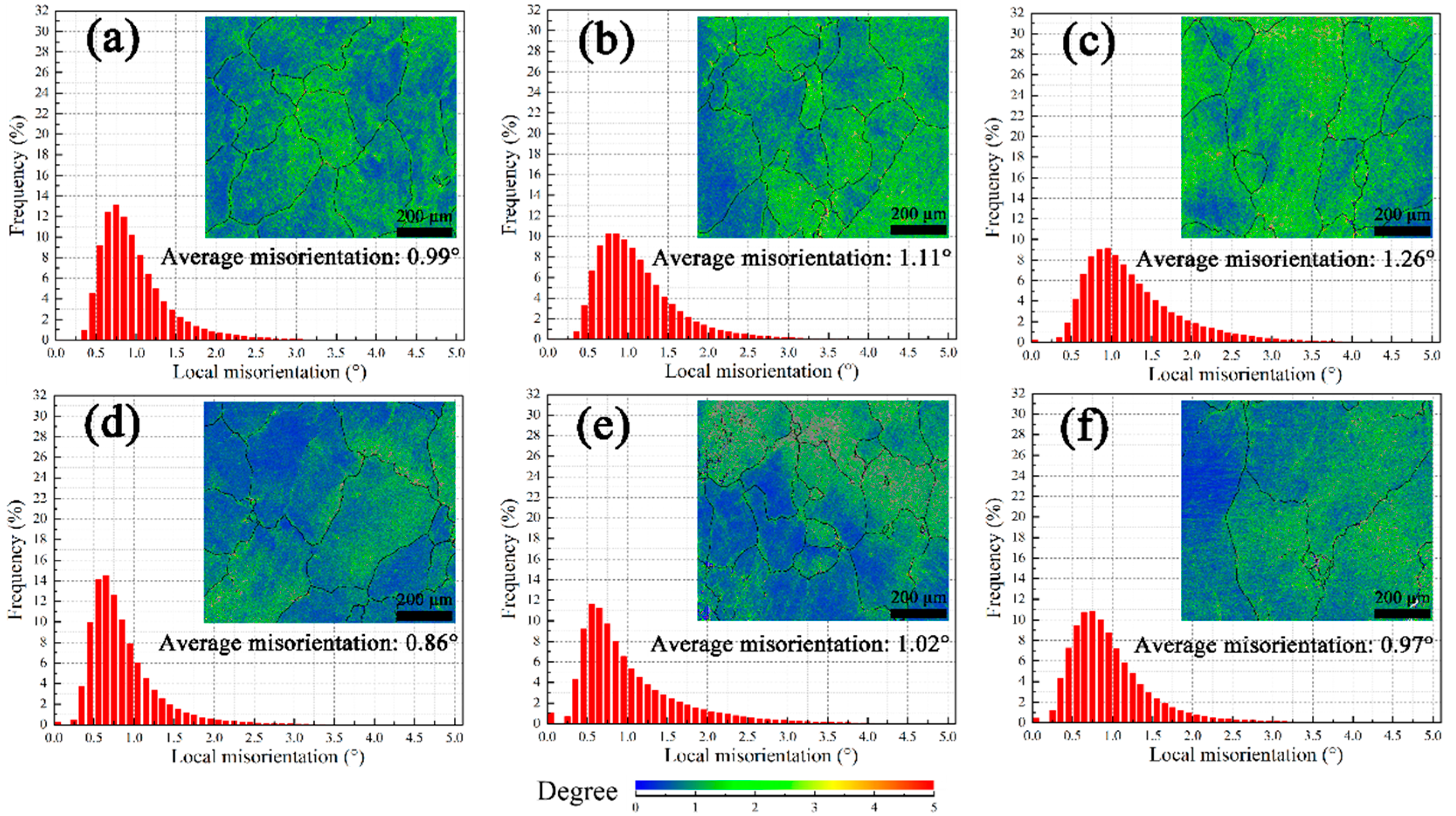

3.2. Local Misorientation

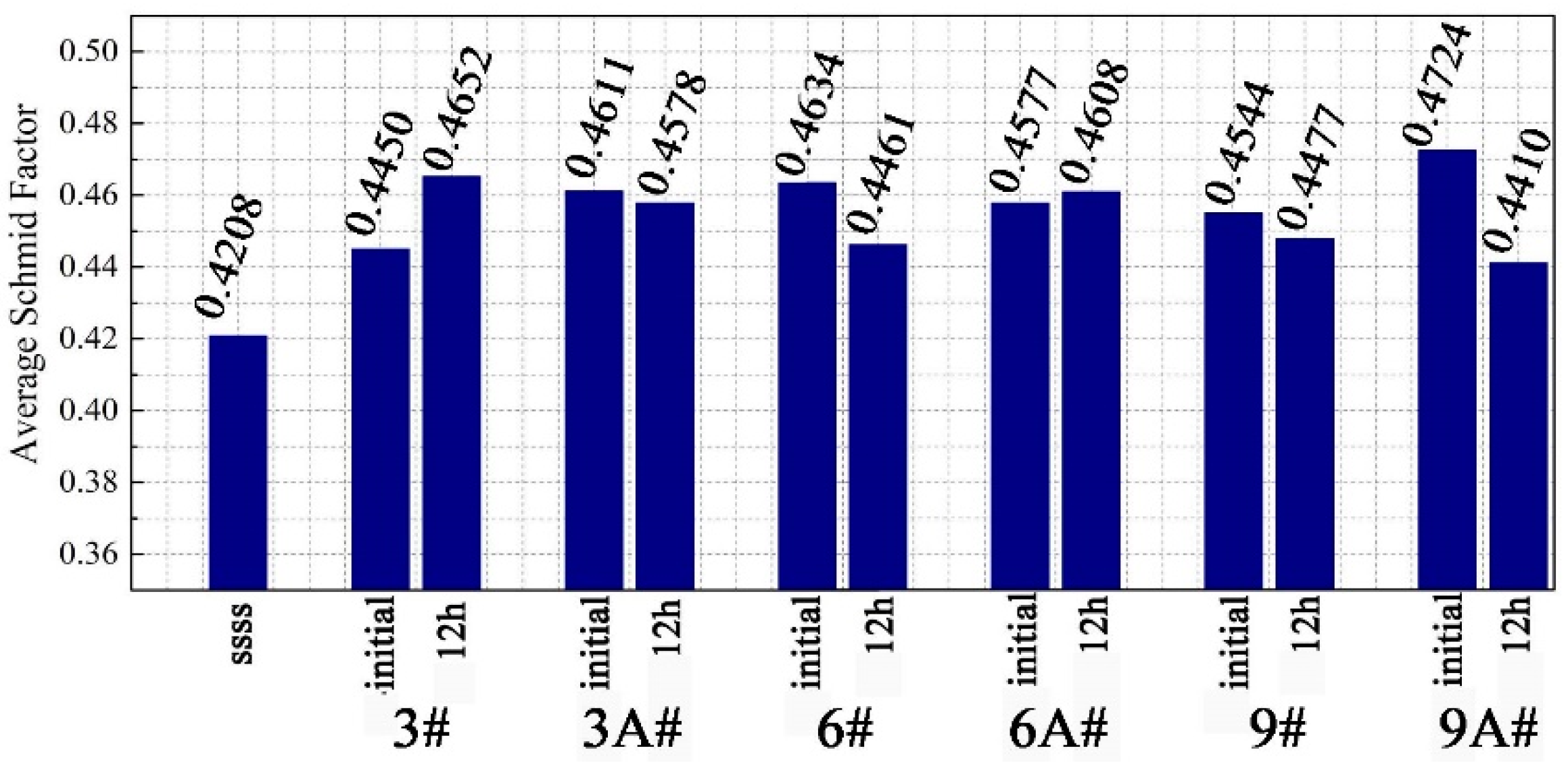

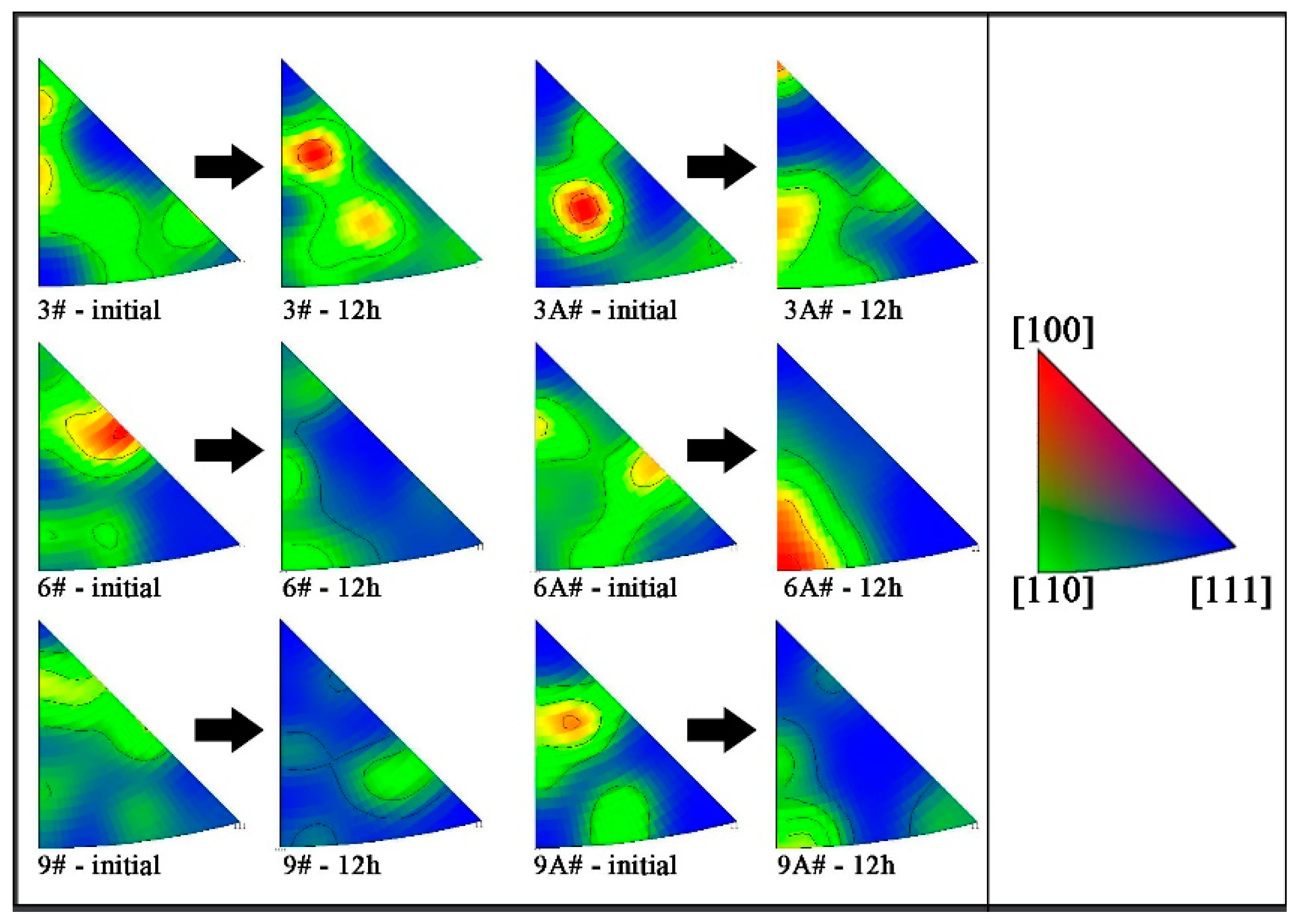

3.3. Texture and Schmidt Factor

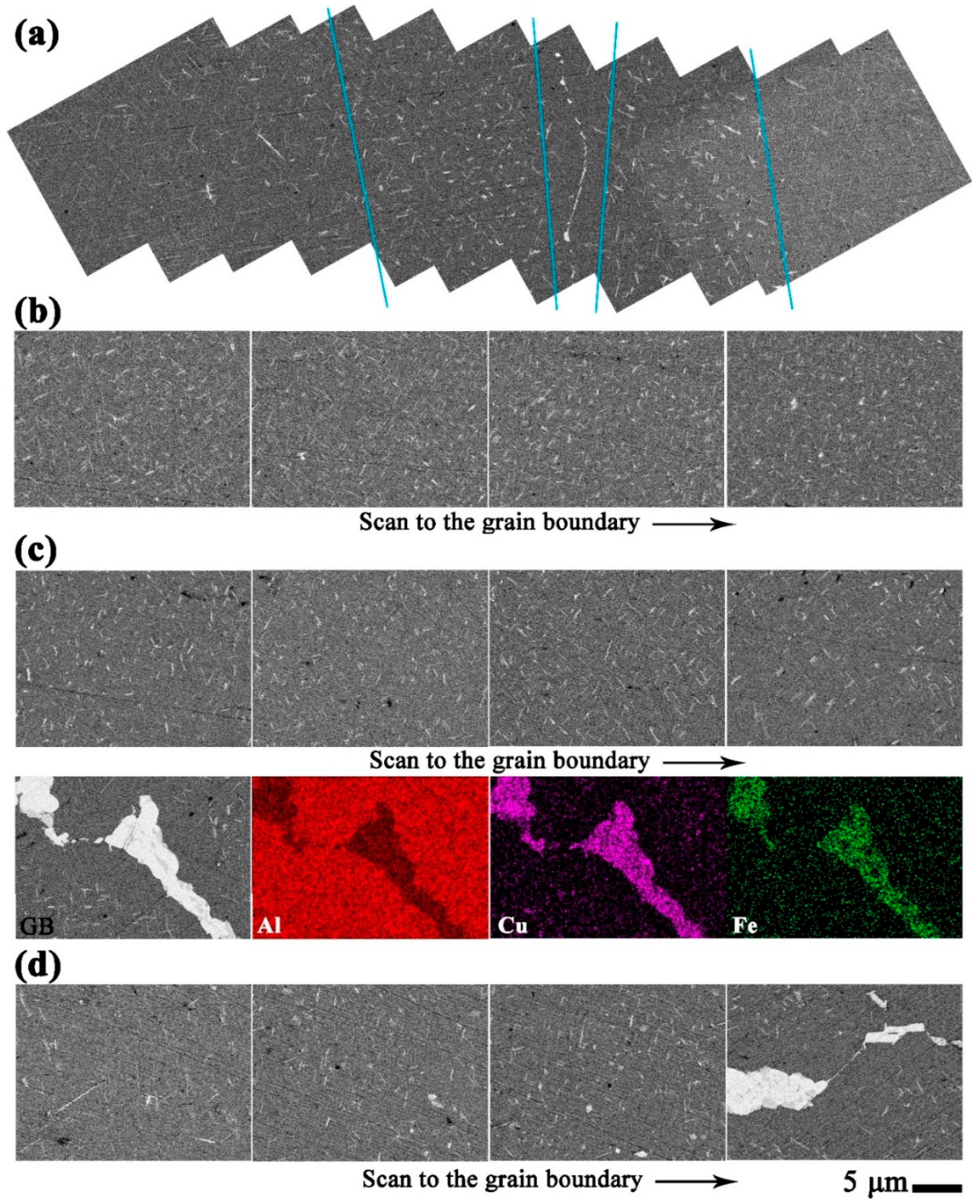

3.4. EDS and Backscatter Image of SEM

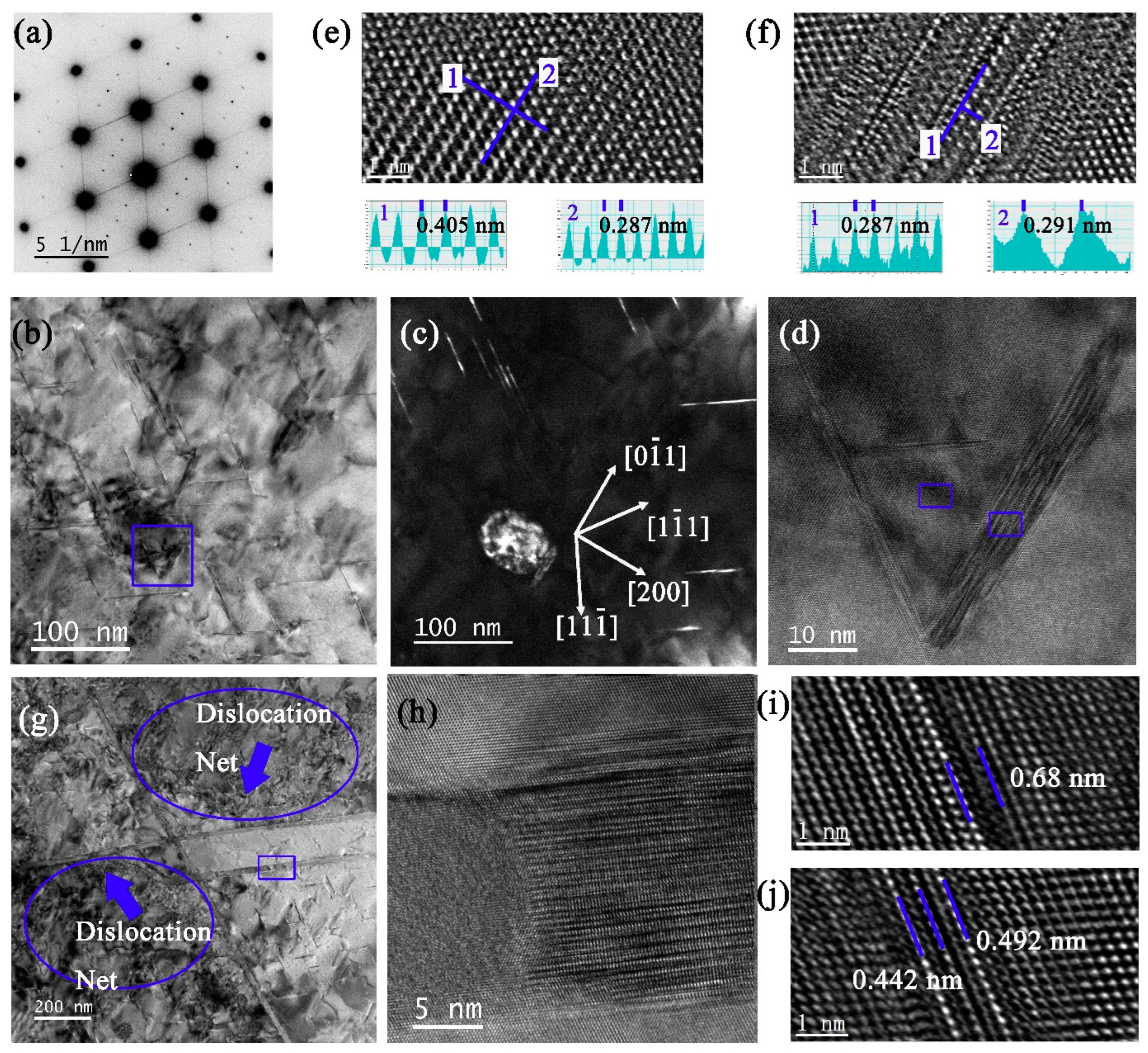

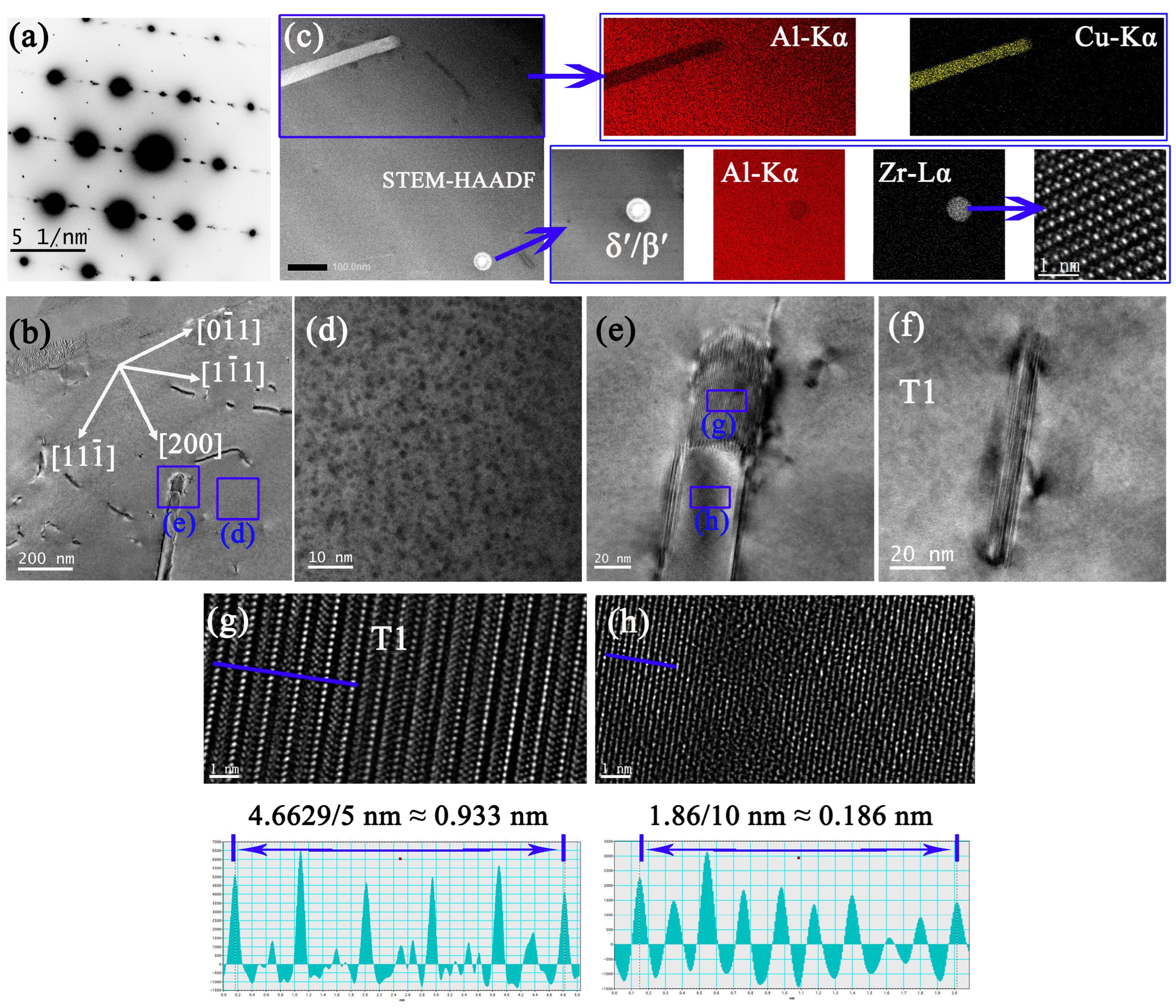

3.5. Precipitate Identification and Micro-Structure Analysis by TEM

4. Discussion

5. Conclusions

- The pre-deformed samples (3#, 6#, and 9#) after creep mainly consist of a coarse initial T1 phase, a secondary T1 phase with minor β′/δ′ and θ′ phases. The dislocation loop or Shockley incomplete dislocation induced by movable dislocation may benefit the nucleation of the secondary T1 phase, especially with moderately low plastic deformation, as was shown in sample 3#. The dislocation density contributes more to the hardness of sample 9#-12h and accelerates the aging process to reach the peak-aged state earlier.

- For pre-deformed and pre-aged samples (3A#, 6A#, and 9A#), there exist two precipitation situations. If pre-deformation is not enough to produce the stacking fault, the solute atoms Cu and Li would be consumed prematurely before creep, rather than forming the secondary T1 phase during pre-aging at 200 °C, with dispersed coherent Li-rich clusters in the matrix. Then, the alloys (samples 3A# and 6A#) no longer have the ability to form a secondary T1 phase in any quantity during subsequent creep. In other words, when the dislocation entangles seriously to some extent, a large quantity of stacking faults together with a “Suzuki atmosphere” containing Cu and Li can provide the nucleation sites for secondary T1 again, even pre-aged at 200 °C.

- The creep rate in the early creep stage is highly related to pre-deformation level rather than pre-aging. The decreasing rate of the height is higher for samples 3# and 3A# initially, due to the high density of movable dislocation. The low radius–thickness ratio of the secondary T1 phase near the GBs indicates that severe compressive creep deformation first occurs near the GBs, which extends to the grain interior steadily. An inappropriate pre-deformation and pre-aged treatment (sample 6A#) would lead to a single texture component, which results in successive slip bands and an unstable region. Sample 9A#, with proper pre-treatment, displays excellent dimensional stability during compressive creep.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dorin, T.; Deschamps, A.; Geuser, F.D.; Sigli, C. Quantification and modelling of the microstructure/strength relationship by tailoring the morphological parameters of the T1 phase in an Al−Cu−Li alloy. Acta Mater. 2014, 75, 134–146. [Google Scholar] [CrossRef]

- Huang, J.C.; Ardell, A.J. Addition rules and the contribution of δ′ precipitates to strengthening of aged Al-Li-Cu alloys. Acta Metall. 1988, 36, 2995–3006. [Google Scholar] [CrossRef]

- Decreus, B.; Deschamps, A.; De Geuser, F.; Donnadieu, P.; Sigli, C.; Weyland, M. The influence of Cu/Li ratio on precipitation in Al-Cu-Li-x alloys. Acta Mater. 2013, 61, 2207–2218. [Google Scholar] [CrossRef]

- Sidhar, H.; Mishra, R.S. Aging kinetics of friction stir welded Al-Cu-Li-Mg-Ag and Al-Cu-Li-Mg alloys. Mater. Design 2016, 110, 60–71. [Google Scholar] [CrossRef]

- Panigrahi, S.K.; Jayaganthan, R. A study on the mechanical properties of cryorolled Al−Mg−Si alloy. Mater. Sci. Eng. A 2008, 480, 299–305. [Google Scholar] [CrossRef]

- Csontos, A.A.; Starke, E.A. The effect of inhomogeneous plastic deformation on the ductility and fracture behavior of age hardenable aluminum alloys. Int. J. Plast. 2005, 21, 1097–1118. [Google Scholar] [CrossRef]

- Duan, S.W.; Guo, F.Q.; Wu, D.T.; Wang, T.; Tsuchiya, T.; Matsuda, K.; Zou, Y. Influences of pre-rolling deformation on aging precipitates and mechanical properties for a novel Al-Cu-Li alloy. J. Mater. Res. Technol. 2021, 15, 2379–2392. [Google Scholar] [CrossRef]

- Kim, J.D.; Park, J.K. Effect of stretching on the precipitation kinetics of an Al-2.0Li-2.8Cu-0.5Mg(-0.13Zr) alloy. Metall. Mater. Trans. A 1993, 24, 2613–2621. [Google Scholar] [CrossRef]

- Gable, B.M.; Zhu, A.W.; Csontos, A.A.; Starke, E.A. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al–Li–Cu–X alloy. J. Light Met. 2001, 1, 1–14. [Google Scholar] [CrossRef]

- Zhan, L.; Lin, J.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tools Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

- Ribeiro, F.C.; Marinho, E.P.; Inforzat, D.J.; Costa, P.R. Creep age forming: A short review of fundaments and applications. J. Achiev. Mater. Manuf. Eng. 2010, 43, 353–361. [Google Scholar]

- Watcham, K. Airbus A380 takes creep age-forming to new heights. Mater. World 2004, 12, 10–11. [Google Scholar]

- Zhang, J.; Wang, C.; Zhang, Y.; Deng, Y. Effects of creep aging upon Al-Cu-Li alloy: Strength, toughness and microstructure. J. Alloys Compd. 2018, 764, 452–459. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Deng, Y.; Zhang, X. Effect of deformation degree on the creep age forming of 7475 aluminum alloy: The feasibility of the extended deformation range. Mater. Sci. Eng. A 2016, 664, 126–134. [Google Scholar] [CrossRef]

- Jia, T.; Jin, Z.; Yunlai, D.; Xinming, Z. Properties evolution and microstructure analysis of creep aging process in Al-Cu-Li alloy. Chin. J. Nonferr. Metals. 2019, 29, 1341–1347. [Google Scholar]

- Jin, Z.; Zhide, L.; Fushun, X.; Cheng, H. Regulating effect of pre-stretching degree on the creep aging process of Al-Cu-Li alloy. Mater. Sci. Eng. A 2019, 763, 138157. [Google Scholar]

- Guo, X.B.; Deng, Y.L.; Zhang, J.; Zhang, X.M. The inhibiting effect of dislocation helices on the stress-induced orientation of S’ precipitates in Al–Cu–Mg alloy. Mater. Char. 2015, 107, 197–201. [Google Scholar] [CrossRef]

- Guo, X.B.; Deng, Y.L.; Zhang, J.; Zhang, X.M. A crystallographic orientation based model for describing the precipitation strengthening of stress-aged Al–Cu alloy. Mater. Sci. Eng. A 2015, 644, 358–364. [Google Scholar] [CrossRef]

- Guo, X.B.; Zhang, Y.; Zhang, J.; Deng, Y.L.; Zhang, X.M. A precipitate-strengthening model based on crystallographic anisotropy, stress-induced orientation, and dislocation of stress-aged Al-Cu-Mg single crystals. Metall. Mater. Trans. A 2017, 10, 4857–4870. [Google Scholar] [CrossRef]

- Xu, F.S.; Zhang, J.; Deng, Y.L.; Zhang, X.M. Precipitation orientation effect of 2124 aluminum alloy in creep aging. T. Nonferr. Metal. Soc. 2014, 7, 2067–2071. [Google Scholar] [CrossRef]

- Zhu, A.W.; Starke, E.A. Stress aging of Al–xCu alloys: Experiments. Acta Mater. 2001, 49, 2285–2295. [Google Scholar] [CrossRef]

- Jiang, D.D.; Yang, R.B.; Wang, D.F.; Liu, Z.X. Effect of external stress on the microstructure and mechanical properties of creep-aged Al-Cu-Li-Ag alloy. Micron 2021, 143, 103011. [Google Scholar] [CrossRef]

- Ma, P.P.; Zhan, L.H.; Liu, C.H.; Yang, J.S.; Chen, K.L.; Huang, Z.B. Strong stress-level dependence of creep-ageing behavior in Al–Cu–Li alloy. Mater. Sci. Eng. A 2021, 802, 140381. [Google Scholar] [CrossRef]

- Rodgers, B.I.; Prangnell, P.B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al-Cu-Li alloy AA2195. Acta Mater. 2016, 108, 55–67. [Google Scholar] [CrossRef]

- Mishra, S.; Beura, V.K.; Singh, A.; Yadava, M.; Nayan, N. Deformation behaviour of Al-Cu-Li alloy containing T-1 precipitates. Mater. Sci. Technol. 2018, 34, 2105–2113. [Google Scholar] [CrossRef]

- Jin, Z.; Zhen, J.; Fushun, X.; Mingan, C. Effects of Pre-Stretching on Creep Behavior, Mechanical Property and Microstructure in Creep Aging of Al-Cu-Li Alloy. Materials 2019, 12, 333. [Google Scholar]

- Ya, T.; Daihong, X.; Lanping, H.; Renxuan, Y.; Xinyue, Z.; Nan, L.; Yunzhu, M.; Wensheng, L. Dynamic microstructural evolution of Al-Cu-Li alloys during hot deformation. Mater. Char. 2022, 191, 112135. [Google Scholar]

- Sha, G.; Wang, Y.B.; Liao, X.Z.; Duan, Z.C.; Ringer, S.P.; Langdon, T.G. Influence of equeal-channel angular pressing on precipitation in an Al-Zn-Mg-Cu alloy. Acta Mater. 2009, 57, 3123–3132. [Google Scholar] [CrossRef]

- Jiang, J.; Jiang, F.; Huang, H.; Zhang, M.; Tang, Z.; Tong, M. Hot deformation analysis and microstructure evolution of Al-Mg-Mn-Sc-Zr alloy by isothermal compression. J. Alloys Compd. 2020, 858, 157655. [Google Scholar] [CrossRef]

- Qian, Z.; Quanan, L.; Xiaoya, C.; Jiaxin, Z.; Jian, B.; Ziyi, C. Dynamic precipitation and recrystallization mechanism during hot compression of Mg-Gd-Y-Zr alloy. J. Mat Res. Technol. 2021, 15, 37–51. [Google Scholar]

- Kang, S.J.; Kim, T.H.; Yang, C.W.; Lee, J.I.; Park, E.S.; Noh, T.W.; Kim, M. Atomic structure and growth mechanism of T1 precipitate in Al–Cu–Li–Mg–Ag alloy. Scr. Mater. 2015, 109, 68–71. [Google Scholar] [CrossRef]

- Ovri, H.; Jagele, A.; Stark, A. Microstructural influenceson strengthening in a naturally aged and overaged Al-Cu-Li-Mg based alloy. Mater. Sci. Eng. A 2015, 637, 162–169. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.W.; Zhao, K.; Fan, L. Combinative hardening effects of precipitation in a commercial aged Al-Cu-Li-X alloy. Mater. Sci. Eng. A 2013, 588, 59–64. [Google Scholar]

- Yuan, Z.S.; Lu, Z.; Wu, X.L.; Xie, Y.H.; Dai, S.L.; Liu, C.S. Retrogression characteristics of a novel Al-Cu-Li-X alloy. Int. J. Min. Met. Mater. 2010, 17, 624–628. [Google Scholar] [CrossRef]

- Juan, M.; Xiaochun, L.; Desheng, Y.; Lijian, R. A novel GP-Li precursor and the correlated precipitation behaviors in Al-Cu-Li alloys with different Cu/Li ratio. Acta Mater. 2023, 243, 118442. [Google Scholar]

- Gao, Z.; Liu, J.Z.; Chen, J.H.; Duan, S.Y.; Liu, Z.R.; Ming, W.Q.; Wu, C.L. Formation mechanism of precipitate T1 in AlCuLi alloys. J. Alloys Compd. 2015, 624, 22–26. [Google Scholar] [CrossRef]

- Deng, Y.; Bai, J.; Wu, X.; Huang, G.; Cao, L.; Huang, L. Investigation on formation mechanism of T1 precipitate in an Al-Cu-Li alloys. J. Alloys Compd. 2017, 723, 661–666. [Google Scholar] [CrossRef]

- Balducci, E.; Ceschini, L.; Messieri, S.; Wenner, S.; Holmestad, R. Thermal stability of the lightweight 2099 Al-Cu-Li alloy: Tensile tests and microstructural investigations after overaging. Mater. Design 2017, 119, 54–64. [Google Scholar] [CrossRef] [Green Version]

| Cu | Li | Mn | Zr | Mg | Ti | Fe | Si | Co | Ce | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 2.66 | 1.31 | 0.27 | 0.11 | 0.09 | 0.03 | 0.04 | 0.01 | 0.005 | 0.002 | Bal. |

| Sample No. | Pre- Deformation | Pre- Artificial Aging | Compressive Creep Aging |

|---|---|---|---|

| 3# | Strain: ε = −3% | - | 170 °C/200 MPa |

| 3A# | Strain: ε = −3% | 200 °C/2 h | 170 °C/200 MPa |

| 6# | Strain: ε = −6% | - | 170 °C/200 MPa |

| 6A# | Strain: ε = −6% | 200 °C/2 h | 170 °C/200 MPa |

| 9# | Strain: ε = −9% | - | 170 °C/200 MPa |

| 9A# | Strain: ε = −9% | 200 °C/2 h | 170 °C/200 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Guo, F.; Matsuda, K.; Wang, T.; Zou, Y. An Investigation of Compressive Creep Aging Behavior of Al-Cu-Li Alloy Pre-Treated by Compressive Plastic Deformation and Artificial Aging. Materials 2023, 16, 2054. https://doi.org/10.3390/ma16052054

Liu J, Guo F, Matsuda K, Wang T, Zou Y. An Investigation of Compressive Creep Aging Behavior of Al-Cu-Li Alloy Pre-Treated by Compressive Plastic Deformation and Artificial Aging. Materials. 2023; 16(5):2054. https://doi.org/10.3390/ma16052054

Chicago/Turabian StyleLiu, Jinqiu, Fuqiang Guo, Kenji Matsuda, Tao Wang, and Yong Zou. 2023. "An Investigation of Compressive Creep Aging Behavior of Al-Cu-Li Alloy Pre-Treated by Compressive Plastic Deformation and Artificial Aging" Materials 16, no. 5: 2054. https://doi.org/10.3390/ma16052054

APA StyleLiu, J., Guo, F., Matsuda, K., Wang, T., & Zou, Y. (2023). An Investigation of Compressive Creep Aging Behavior of Al-Cu-Li Alloy Pre-Treated by Compressive Plastic Deformation and Artificial Aging. Materials, 16(5), 2054. https://doi.org/10.3390/ma16052054