Comparison of the Mechanical Properties and Crack Expansion Mechanism of Different Content and Shapes of Brass-Coated Steel Fiber-Reinforced Ultra-High-Performance Concrete

Abstract

:1. Introduction

2. Materials and Method

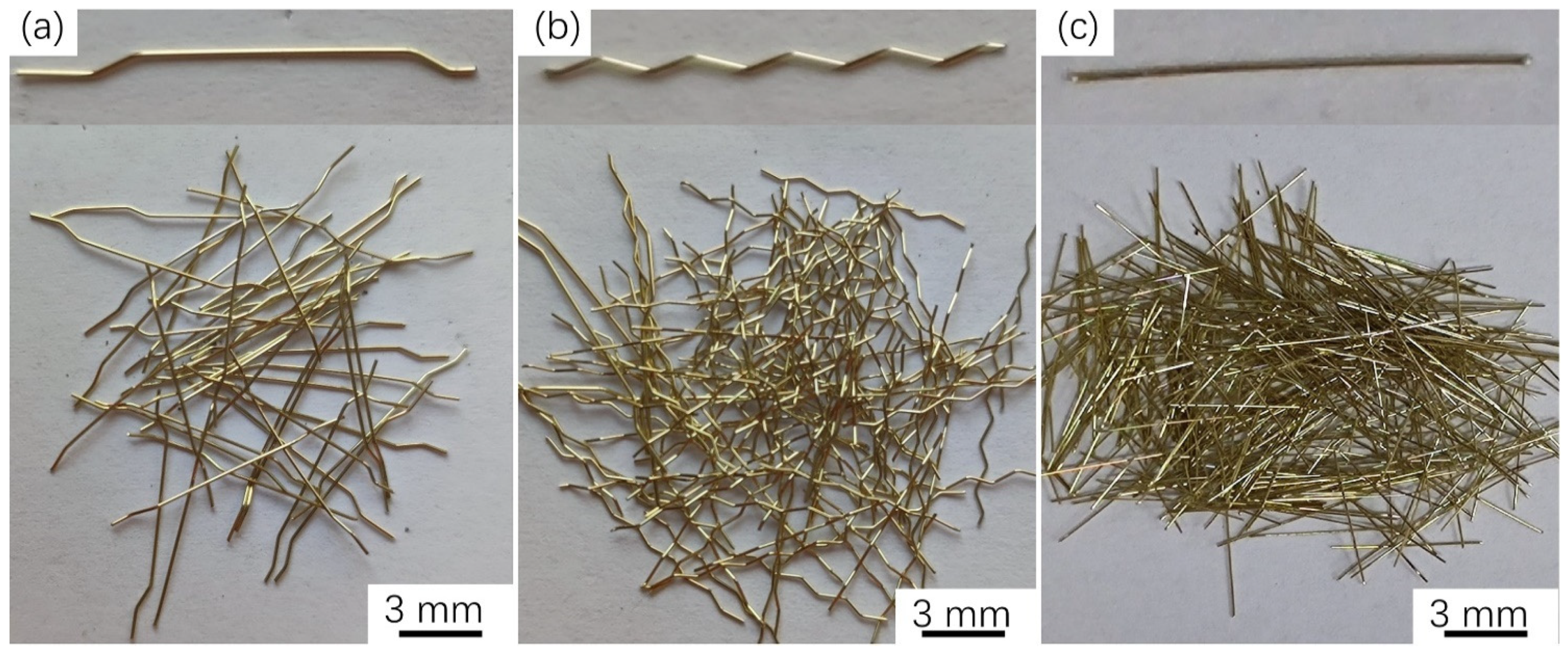

2.1. Materials

2.2. Method

2.3. Characterization

3. Results and Discussion

3.1. Effect of BCSF Content and Shapes on the Mechanical Properties of UHPC Mixtures

3.2. CT Observation of 1–6 wt.% Straight BCSF-Reinforced UHPC Mixtures

3.3. CT Observation of 6 wt.% Straight BCSF-Reinforced UHPC Mixture

3.4. Effect of Straight BCSF Contents on Crack Patterns of UHPC Mixture

3.5. BCSFs Surface

3.6. BCSFs–Matrix Interface

3.7. Crack Expansion of Straight BCSF-Reinforced UHPC

4. Conclusions

- The flexural strength and compressive strength of BCSF-reinforced UHPC mixture specimens are enhanced by increasing the weight fraction of embedded BCSF reinforcement with different shapes (straight, corrugated, and hooked).

- BCSFs play a major role in the adhesive properties and stress transfer of the interface between reinforced BCSFs and the UHPC matrix. The flexural strength of UHPC with straight BCSFs is higher than those with corrugated and hooked fibers. However, the compressive strength of UHPC with corrugated BCSFs is higher than those with straight and hooked BCSFs. The flexural strength of UHPC mixture with 6 wt.% straight BCSFs at 28 days reaches the maximum value of 26.2 MPa, and the compressive strength of UHPC with 6 wt.% corrugated BCSFs at 28 days reaches the maximum value of 142.3 MPa.

- With the increase in straight BCSF content from 1 wt.% to 6 wt.%, the porosity in the UHPC mixture reduces gradually from 18.4% to 8.3%.

- The crack propagation resistance of mix UHPC with straight BCSFs is slightly improved compared with those with corrugated and hooked BCSFs. With the increase in straight BCSF content from 1 wt.% to 6 wt.%, the crack length reduced from 34.2 mm to 12.1 mm, and average crack width reduced from 0.78 mm to less than 0.1 mm.

- The brass film promoted a physical–chemical bond and frictional resistance between the BCSFs and UHPC matrix owing to the increase in surface roughness, which contributes to increasing the flexural and compressive strength of the UHPC mixture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, S.; Tang, Z.; Zhong, W.; Wang, S.; Zhang, R.; Yao, X. Effects of steel fibers on the dynamic properties and failure process of ultra-high performance concrete. J. Build. Eng. 2022, 62, 105415. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- Zanuy, C. Special Issue: Recent Developments on High-Performance Fiber-Reinforced Concrete: Hybrid Mixes and Combinations with Other Materials. Materials 2022, 15, 3409. [Google Scholar] [CrossRef]

- Akça, K.R.; İpek, M. Effect of different fiber combinations and optimisation of an ultra-high performance concrete (UHPC) mix applicable in structural elements. Constr. Build. Mater. 2022, 315, 125777. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wang, D. Static and dynamic compressive properties of ultra-high performance concrete (UHPC) with hybrid steel fiber reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef] [Green Version]

- Bae, Y.; Pyo, S. Effect of steel fiber content on structural and electrical properties of ultra high performance concrete (UHPC) sleepers. Eng. Struct. 2020, 222, 111131. [Google Scholar] [CrossRef]

- Isa, M.N.; Pilakoutas, K.; Guadagnini, M.; Angelakopoulos, H. Mechanical performance of affordable and eco-efficient ultra-high performance concrete (UHPC) containing recycled tyre steel fibres. Constr. Build. Mater. 2020, 255, 119272. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental Tests and Reliability Analysis of the Cracking Impact Resistance of UHPFRC. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Li, Z.; Peng, Z.; Teng, J. Study of Combined Multi-Point Constraint Multi-Scale Modeling Strategy for Ultra-High-Performance Steel Fiber-Reinforced Concrete Structures. Materials 2020, 13, 5320. [Google Scholar] [CrossRef] [PubMed]

- Pokorny, P.; Kolisko, J.; Citek, D.; Kostelecka, M. Effect of Elevated Temperature on the Bond Strength of Prestressing Reinforcement in UHPC. Materials 2020, 13, 4990. [Google Scholar] [CrossRef]

- Xu, J.; Wang, J.; Zheng, C. Study on reinforcement mechanism and microscopic morphology of steel-basalt mixed fiber HPCC. Constr. Build. Mater. 2020, 256, 119480. [Google Scholar] [CrossRef]

- Biswas, R.K.; Bin Ahmed, F.; Haque, M.E.; Provasha, A.A.; Hasan, Z.; Hayat, F.; Sen, D. Effects of Steel Fiber Percentage and Aspect Ratios on Fresh and Harden Properties of Ultra-High Performance Fiber Reinforced Concrete. Appl. Mech. 2021, 2, 501–515. [Google Scholar] [CrossRef]

- Blasone, M.; Saletti, D.; Baroth, J.; Forquin, P.; Bonnet, E.; Delaplace, A. Ultra-high performance fibre-reinforced concrete under impact of an AP projectile: Parameter identification and numerical modelling using the DFHcoh-KST coupled model. Int. J. Impact Eng. 2021, 152, 103838. [Google Scholar] [CrossRef]

- Gayarre, F.L.; Suárez González, J.; Lopez Boadella, I.; López-Colina Pérez, C.; Serrano López, M. Use of Waste from Granite Gang Saws to Manufacture Ultra-High Performance Concrete Reinforced with Steel Fibers. Appl. Sci. 2021, 11, 1764. [Google Scholar] [CrossRef]

- He, J.; Chen, W.; Zhang, B.; Yu, J.; Liu, H. The Mechanical Properties and Damage Evolution of UHPC Reinforced with Glass Fibers and High-Performance Polypropylene Fibers. Materials 2021, 14, 2455. [Google Scholar] [CrossRef]

- Huang, L.; Xie, J.; Li, L.; Xu, B.; Huang, P.; Lu, Z. Compressive behaviour and modelling of CFRP-confined ultra-high performance concrete under cyclic loads. Constr. Build. Mater. 2021, 310, 124949. [Google Scholar] [CrossRef]

- Li, J.; Deng, Z. Tensile Behavior of Hybrid Fiber-Reinforced Ultra-High-Performance Concrete. Front. Mater. 2021, 8, 455. [Google Scholar] [CrossRef]

- Mala, A.A.; Sherwani, A.F.H.; Younis, K.H.; Faraj, R.H.; Mosavi, A. Mechanical and Fracture Parameters of Ultra-High Performance Fiber Reinforcement Concrete Cured via Steam and Water: Optimization of Binder Content. Materials 2021, 14, 2016. [Google Scholar] [CrossRef]

- Niu, Y.; Wei, J.; Jiao, C. Crack propagation behavior of ultra-high-performance concrete (UHPC) reinforced with hybrid steel fibers under flexural loading. Constr. Build. Mater. 2021, 294, 123510. [Google Scholar] [CrossRef]

- Bermudez, M.; Wen, K.W.; Hung, C.C. A Comparative Study on the Shear Behavior of UHPC Beams with Macro Hooked-End Steel Fibers and PVA Fibers. Materials 2022, 15, 1485. [Google Scholar] [CrossRef]

- Esmailzade, M.; Eskandarinia, M.; Aslani, F. Effect of impurities of steel fibers extracted from shredded tires on the behavior of fiber-reinforced concrete. Structures 2022, 45, 1175–1188. [Google Scholar] [CrossRef]

- Jang, Y.S.; Oh, T.; Banthia, N.; Yoo, D.-Y. Effects of nano-SiO2 coating and induced corrosion of steel fiber on the interfacial bond and tensile properties of ultra-high-performance concrete (UHPC). J. Build. Eng. 2022, 54, 104637. [Google Scholar] [CrossRef]

- Niu, Y.; Wei, J.; Jiao, C.; Miao, Q. A mesomechanics-based analysis on the flexural behavior of ultra-high-performance concrete (UHPC) with different steel fiber lengths. J. Mater. Res. Technol. 2022, 17, 3066–3079. [Google Scholar] [CrossRef]

- Rui, Y.; Kangning, L.; Tianyi, Y.; Liwen, T.; Mengxi, D.; Zhonghe, S. Comparative study on the effect of steel and polyoxymethylene fibers on the characteristics of Ultra-High Performance Concrete (UHPC). Cem. Concr. Compos. 2022, 127, 104418. [Google Scholar] [CrossRef]

- Soares Junior, P.R.R.; Maciel, P.d.S.; Corrêa, E.C.S.; Bezerra, A.C.d.S. A multiscale investigation on the performance improvement of fiber-reinforced cementitious composites after exposure to high temperatures. Cem. Concr. Compos. 2022, 133, 104657. [Google Scholar] [CrossRef]

- Xiong, G.; Wang, C.; Zhou, S.; Zheng, Y. Study on dispersion uniformity and performance improvement of steel fibre reinforced lightweight aggregate concrete by vibrational mixing. Case Stud. Constr. Mater. 2022, 16, e01093. [Google Scholar] [CrossRef]

- Yang, T.; Xu, S.; Liu, Z.; Li, J.; Wu, P.; Yang, Y.; Wu, C. Experimental and numerical investigation of bond behavior between geopolymer based ultra-high-performance concrete and steel bars. Constr. Build. Mater. 2022, 345, 128220. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, C.; Liu, Z.; Zhang, H. 3D-printing ultra-high performance fiber-reinforced concrete under triaxial confining loads. Addit. Manuf. 2022, 50, 102568. [Google Scholar] [CrossRef]

- Yu, R.; Xu, L.L.; Li, K.K.; Leng, Y.; Wang, Z.Y. Dynamic behaviors assessment of steel fibres in fresh Ultra-High Performance Concrete (UHPC): Experiments and numerical simulations. J. Build. Eng. 2022, 59, 1–10. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, J.; Jia, W.; Fang, Z. Torsional behavior of ultra-high performance concrete (UHPC) rectangular beams without steel reinforcement: Experimental investigation and theoretical analysis. Compos. Struct. 2022, 299, 116022. [Google Scholar] [CrossRef]

- Ravichandran, D.; Prem, P.R.; Kaliyavaradhan, S.K.; Ambily, P.S. Influence of fibers on fresh and hardened properties of Ultra High Performance Concrete (UHPC)—A review. J. Build. Eng. 2022, 57, 104922. [Google Scholar] [CrossRef]

- Abdolpour, H.; Niewiadomski, P.; Sadowski, Ł. Recycling of steel fibres and spent equilibrium catalyst in ultra-high performance concrete: Literature review, research gaps, and future development. Constr. Build. Mater. 2021, 309, 125147. [Google Scholar] [CrossRef]

- Wang, W.; Shen, A.; Lyu, Z.; He, Z.; Nguyen, K.T.Q. Fresh and rheological characteristics of fiber reinforced concrete—A review. Constr. Build. Mater. 2021, 296, 123734. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Khan, M.; Yin, H.; Guan, J. Review on different testing methods and factors affecting fracture properties of fiber reinforced cementitious composites. Constr. Build. Mater. 2021, 273, 121766. [Google Scholar] [CrossRef]

- Daneshvar, K.; Moradi, M.J.; Khaleghi, M.; Rezaei, M.; Farhangi, V.; Hajiloo, H. Effects of impact loads on heated-and-cooled reinforced concrete slabs. J. Build. Eng. 2022, 61, 105328. [Google Scholar] [CrossRef]

- Moradi, N.; Tavana, M.H.; Habibi, M.R.; Amiri, M.; Moradi, M.J.; Farhangi, V. Predicting the compressive strength of concretecontaining binary supplementary cementitious material using machine learning approach. Materials 2022, 15, 5336. [Google Scholar] [CrossRef]

| Number | Brass-Coated Steel Fibers Content /wt.% | 20-Grain Quartz Sand /g | 40-Grain Quartz Sand /g | 80-Grain Quartz Sand /g | Cement /g | Silica Fume /g | Active Superplasticizer /g | Defoamer /g |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 330 | 330 | 330 | 880 | 220 | 6.4 | 0.32 |

| 2 | 2 | 330 | 330 | 330 | 880 | 220 | 6.4 | 0.32 |

| 3 | 3 | 330 | 330 | 330 | 880 | 220 | 6.4 | 0.32 |

| 4 | 4 | 330 | 330 | 330 | 880 | 220 | 6.4 | 0.32 |

| 5 | 5 | 330 | 330 | 330 | 880 | 220 | 6.4 | 0.32 |

| 6 | 6 | 330 | 330 | 330 | 880 | 220 | 6.4 | 0.32 |

| Type | Length (mm) | Diameter (mm) | Aspect Ratio | Density | Tensile Strength (MPa) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|---|

| Corrugated | 13 | 0.2 | 65 | 7.8 | >2000 | 200 |

| hooked | 13 | 0.2 | 65 | 7.8 | >2000 | 200 |

| Straight | 13 | 0.2 | 65 | 7.8 | >2000 | 200 |

| Content of BCSFs | 1 wt.% | 2 wt.% | 3 wt.% | 4 wt.% | 5 wt.% | 6 wt.% |

|---|---|---|---|---|---|---|

| Porosity of UHPC mixture | 18.4% | 15.2% | 13.6% | 11.7% | 9.6% | 8.3% |

| Average pore diameter | 0.8 | 0.7 | 0.5 | 0.4 | 0.3 | <0.1 |

| Slice Location | a | b | c | d | e | f |

|---|---|---|---|---|---|---|

| Porosity of UHPC mixture | 12.3% | 11.2% | 11.6% | 10.4% | 9.6% | 8.2% |

| Average pore diameter, mm | 0.5 | 0.4 | 0.3 | 0.2 | <0.1 | <0.1 |

| Content of BCSFs | 1 wt.% | 2 wt.% | 3 wt.% | 4 wt.% | 5 wt.% | 6 wt.% |

|---|---|---|---|---|---|---|

| Max crack length, mm | 34.2 | 28.8 | 24.8 | 19.3 | 18.1 | 12.1 |

| Average crack width, mm | 0.78 | 0.52 | 0.36 | <0.2 | <0.2 | <0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Yan, Y.; Li, T.; Cao, X.; Yu, L.; Qi, H. Comparison of the Mechanical Properties and Crack Expansion Mechanism of Different Content and Shapes of Brass-Coated Steel Fiber-Reinforced Ultra-High-Performance Concrete. Materials 2023, 16, 2257. https://doi.org/10.3390/ma16062257

Jiang Y, Yan Y, Li T, Cao X, Yu L, Qi H. Comparison of the Mechanical Properties and Crack Expansion Mechanism of Different Content and Shapes of Brass-Coated Steel Fiber-Reinforced Ultra-High-Performance Concrete. Materials. 2023; 16(6):2257. https://doi.org/10.3390/ma16062257

Chicago/Turabian StyleJiang, Yanli, Yulong Yan, Tianran Li, Xiuling Cao, Liang Yu, and Haiquan Qi. 2023. "Comparison of the Mechanical Properties and Crack Expansion Mechanism of Different Content and Shapes of Brass-Coated Steel Fiber-Reinforced Ultra-High-Performance Concrete" Materials 16, no. 6: 2257. https://doi.org/10.3390/ma16062257

APA StyleJiang, Y., Yan, Y., Li, T., Cao, X., Yu, L., & Qi, H. (2023). Comparison of the Mechanical Properties and Crack Expansion Mechanism of Different Content and Shapes of Brass-Coated Steel Fiber-Reinforced Ultra-High-Performance Concrete. Materials, 16(6), 2257. https://doi.org/10.3390/ma16062257