Microstructure and Dry/Wet Tribological Behaviors of 1% Cu-Alloyed Austempered Ductile Iron

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material and Specimen Preparation

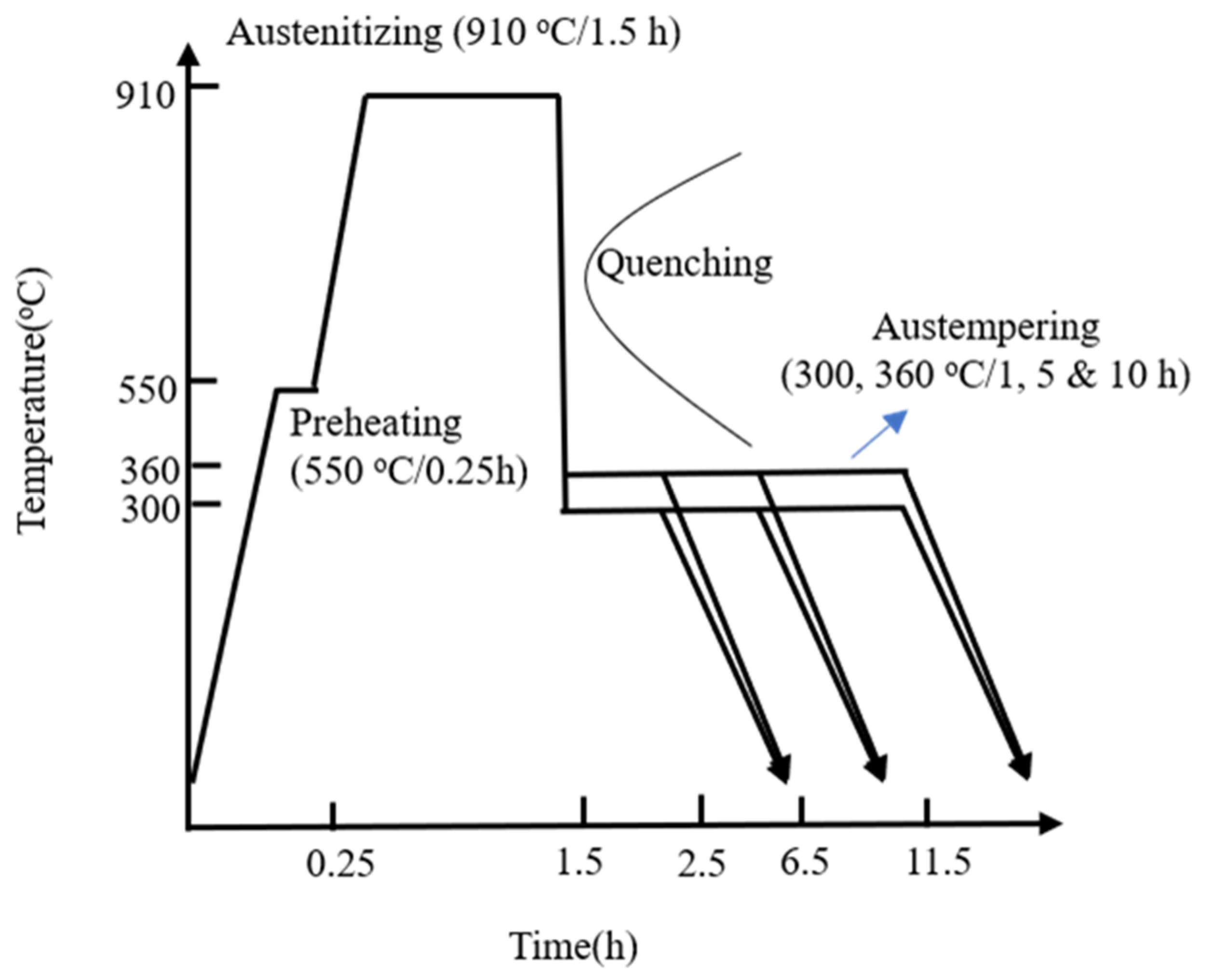

2.2. Austempering Treatment

2.3. Metallographic Test

2.4. XRD Analysis and Hardness Test

2.5. Dry and Wet Wear Tests

3. Results and Discussion

3.1. Microstructure Observation

3.2. Austempering Effect on Hardness of ADI

3.3. Wear Behavior Analysis

4. Conclusions

- The austempering temperature mainly affected ADI’s microstructure. ADI austempered at 300 °C had a dense, needle-like ausferrite structure, while ADI austempered at 360 °C had a sparse and feathery appearance;

- ADI had much higher hardness than as-cast DI (31–45 vs. 16 HRC). The hardness of ADI was affected by austempering temperature, with 300 °C–ADI being harder than 360 °C–ADI. Among all ADI specimens, the 300–10 h ADI had the highest hardness value (45 HRC).

- Lower austempering temperature and longer austempering time can improve ADI’s wear resistance, whether in dry or wet corrosive wear tests. ADI treated with 300–10 h austempering showed excellent wear resistance performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walton, C.F.; Opar, T.J. Iron Castings Handbook; Iron Castings Society Inc.: New York, NY, USA, 1981; pp. 141–324. [Google Scholar]

- Ronchei, C. Fatigue strength estimation of ductile cast Irons containing solidification Defects. Metals 2023, 13, 83. [Google Scholar] [CrossRef]

- Sil’man, G.I.; Kamynin, V.V.; Tarasov, A.A. Effect of Copper on Structure Formation in Cast Iron. Metal Sci. Heat Treat. 2003, 45, 254–258. [Google Scholar] [CrossRef]

- Minkoff, I. The Physical Metallurgy of Cast Iron; John Wiley and Sons: New York, NY, USA, 1983; p. 201. [Google Scholar]

- Smith, W.F. Structure and Properties of Engineering Alloys; McGraw-Hill Inc.: New York, NY, USA, 1993; p. 359. [Google Scholar]

- Ramírez, A.C.; García, E.C.; Alcalá, J.F.C.; Ramírez, J.T.; Hernández, A.M. Evaluation of CADI low alloyed with chromium for camshafts application. Metals 2022, 12, 249. [Google Scholar] [CrossRef]

- Goergen, F.; Mevissen, D.; Masaggia, S.; Veneri, E.; Brecher, J.B.C. Contact fatigue strength of austempered ductile iron (ADI) in gear applications. Metals 2020, 10, 1147. [Google Scholar] [CrossRef]

- Janjatovic, P.; Cekic, O.E.; Sidjanin, L.; Balos, S.; Dramicanin, M.; Novakovic, J.G.; Rajnovic, D. The effect of water concentration in ethyl alcohol on the environmentally assisted embrittlement of austempered ductile irons. Metals 2021, 11, 94. [Google Scholar] [CrossRef]

- Owhadi, A.; Hedjazi, J.; Davami, P. Wear behavior of 1.5Mn austempered ductile iron. Mater. Sci. Technol. 1998, 14, 245–250. [Google Scholar] [CrossRef]

- Sckudlarek, W.; Krmasha, M.N.; Al-Rubaie, K.S.; Preti, O.; Milan, J.C.G.; Cesar, C.E. Effect of austempering temperature on microstructure and mechanical properties of ductile cast iron modified by niobium. J. Mater. Res. Technol. 2021, 12, 2414–2425. [Google Scholar] [CrossRef]

- Greno, G.L.; Otegui, J.L.; Boeri, R.E. Mechanism of fatigue crack growth in austempered ductile iron. Int. J. Fat 1999, 21, 35–43. [Google Scholar] [CrossRef]

- Lee, S.C.; Hsu, C.H.; Chang, C.C.; Feng, H.P. Influence of casting size and graphite nodule refinement on fracture toughness of austempered ductile iron. Metall. Mater. Trans. A 1998, 29, 2511–2521. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chuang, T.L. Influence of stepped austempering process on the fracture toughness of austempered ductile iron. Metall. Mater. Trans. A 2001, 32, 2509–2514. [Google Scholar] [CrossRef]

- Hsu, C.H.; Lin, K.T. A study on microstructure and toughness of copper alloyed and austempered ductile iron. Mater. Sci. Eng. A 2011, 528, 5706–5712. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Barber, G.C.; Pan, Y.; Cui, W.; Wang, R. Microstructure, wear behavior and surface hardening of austempered ductile iron. J. Mater. Res. Technol. 2020, 9, 9838–9855. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Guerra, F.V.; Rainforth, M.; Mejía, I.; Maldonado, C. Sliding wear behavior of austempered ductile iron microalloyed with boron. Wear 2015, 330–331, 23–31. [Google Scholar] [CrossRef]

- Batra, U.; Batra, N.; Sharma, J.D. Wear performance of Cu-alloyed austempered ductile iron. J. Mater. Eng. Perf. 2013, 22, 1136–1142. [Google Scholar] [CrossRef]

- Batra, U.; Ray, S.; Prabhakar, S.R. Tensile properties of copper alloyed austempered ductile iron: Effect of austempering parameters. J. Mater. Eng. Perf. 2004, 13, 537–541. [Google Scholar] [CrossRef]

- Boulifa, M.I.; Hadji, A. Effect of alloying elements on the mechanical behavior and wear of austempered ductile iron. Mech. Ind. 2015, 16, 304. [Google Scholar] [CrossRef]

- Khazaei, B.A. Wear mechanism of ADI. Adv. Mater. Res. 2012, 445, 673–678. [Google Scholar] [CrossRef]

- Sahin, Y.; Erdogan, M.; Kilicli, V. Wear behavior of austempered ductile irons with dual matrix structures. Mater. Sci. Eng. A 2007, 444, 31–38. [Google Scholar] [CrossRef]

- Wieczorek, A.N.; Wójcicki, M.; Drwięga, A.; Tuszyński, W.; Nuckowski, P.M.; Nędza, J. Abrasive wear of mining chain drums made of austempered ductile iron in different operating modes. Materials 2022, 15, 2709. [Google Scholar] [CrossRef]

- ASTM E975-13; Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation. ASTM International: West Conshohocken, PA, USA, 2013. Available online: https://standards.globalspec.com/std/3850104/astm-e975-13 (accessed on 1 January 2020).

- Aranzabal, J.; Gutierrez, I.; Urcola, J.J. Influence of heat treatments on microstructure of austempered ductile iron. Mater. Sci. Technol. 1994, 10, 728–737. [Google Scholar] [CrossRef]

- ASTM A897/897M-16; Standard Specification for Austempered Ductile Iron Castings. ASTM International: West Conshohocken, PA, USA, 2016. Available online: https://www.scribd.com/document/553733016/ASTM-A897-A897M-2016 (accessed on 1 January 2020).

- Hsu, C.H.; Lee, S.C.; Feng, H.P.; Shy, Y.H. The effect of testing temperature on fracture toughness of austempered ductile iron. Metall. Mater. Trans. A 2001, 32, 295–303. [Google Scholar] [CrossRef]

- Azdani, S.; Elliott, R. Influence of molybdenum on austempering behaviour of ductile iron Part 3-Austempering kinetics, mechanical properties, and hardenability of ductile iron containing 0·25%Mo. Mater. Sci. Technol. 1999, 15, 885–895. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chen, M.L. Corrosion behavior of nickel alloyed and austempered ductile irons in 3.5% sodium chloride. Corr. Sci. 2010, 52, 2945–2949. [Google Scholar] [CrossRef]

- Mussa, A.; Krakhmalev, P.; Bergstrom, J. Wear mechanisms and wear resistance of austempered ductile iron in reciprocal sliding contact. Wear 2022, 498–499, 204305. [Google Scholar] [CrossRef]

- Prado, J.M.; Pujol, A.; Tartera, J. Dry sliding wear of austempered ductile iron. Mater. Sci. Technol. 1995, 11, 294–298. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cu | Fe. |

|---|---|---|---|---|---|---|

| 3.42 | 1.93 | 0.24 | 0.05 | 0.02 | 1.01 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, C.-H.; Lin, C.-Y.; You, W.-S. Microstructure and Dry/Wet Tribological Behaviors of 1% Cu-Alloyed Austempered Ductile Iron. Materials 2023, 16, 2284. https://doi.org/10.3390/ma16062284

Hsu C-H, Lin C-Y, You W-S. Microstructure and Dry/Wet Tribological Behaviors of 1% Cu-Alloyed Austempered Ductile Iron. Materials. 2023; 16(6):2284. https://doi.org/10.3390/ma16062284

Chicago/Turabian StyleHsu, Cheng-Hsun, Chun-Yin Lin, and Wei-Shih You. 2023. "Microstructure and Dry/Wet Tribological Behaviors of 1% Cu-Alloyed Austempered Ductile Iron" Materials 16, no. 6: 2284. https://doi.org/10.3390/ma16062284