Enhanced Filtration Efficiency of Natural Materials with the Addition of Electrospun Poly(vinylidene fluoride-co-hexafluoropropylene) Fibres

Abstract

1. Introduction

2. Materials and Methods

2.1. Filtration Efficiency

2.2. Selection of Materials

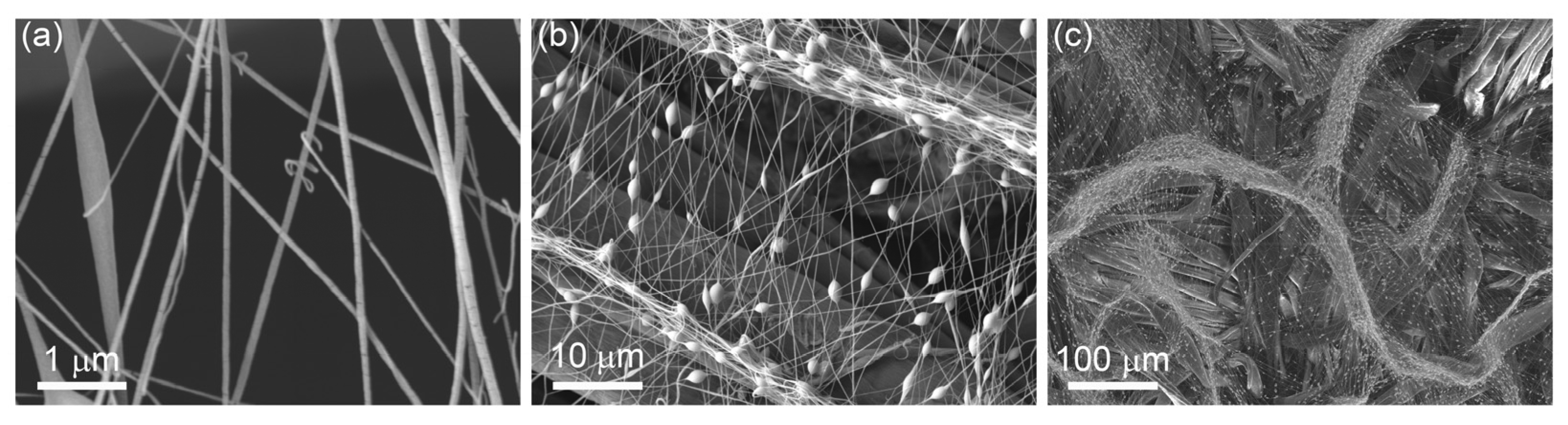

2.3. Scanning Electron Microscopy

2.4. Polymers and Electrospinning

2.5. Grammage of Electrospun Fibres

2.6. Raman Spectroscopy

2.7. Permeability Measurements

3. Results

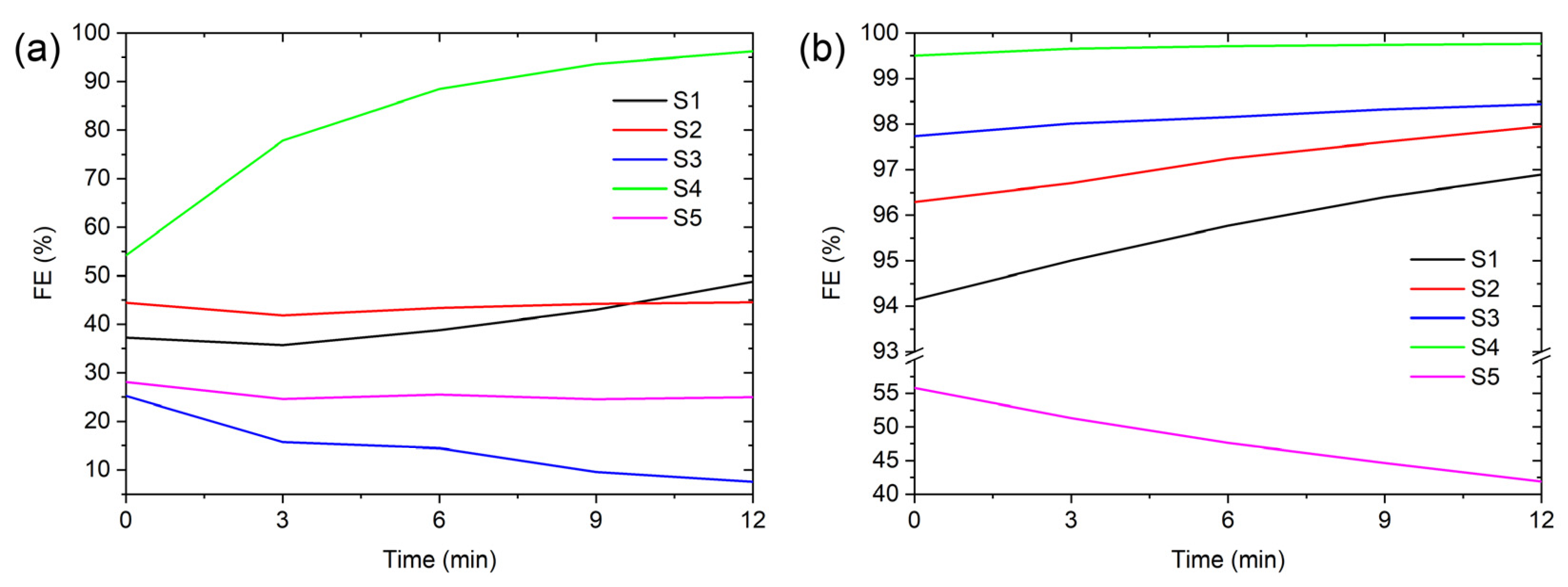

3.1. Time- and Size-Dependent Filtration Efficiency of Different Natural Materials

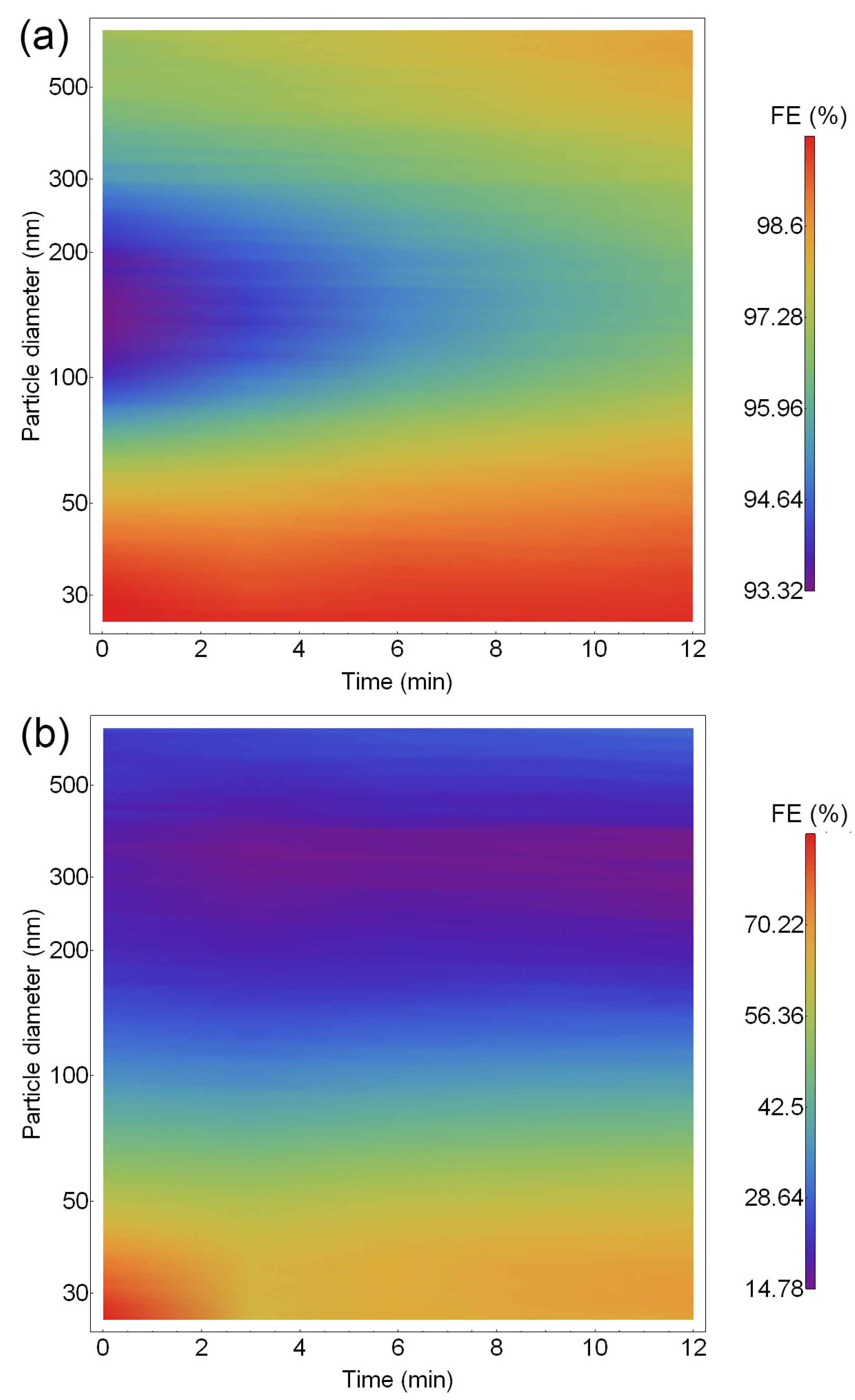

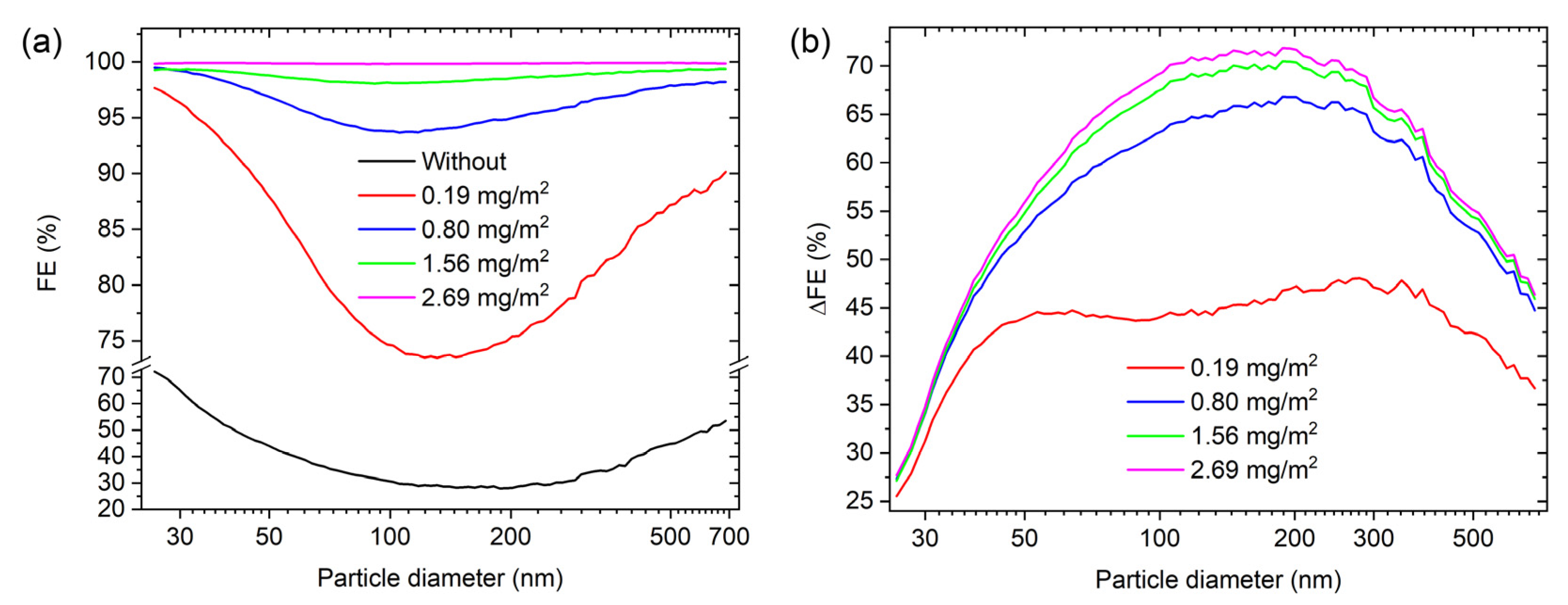

3.2. Time- and Size-Dependent FE Measurements for Different Electrospun Poylmer Thicknesses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pirker, L.; Gradišek, A.; Višić, B.; Remškar, M. Nanoparticle Exposure Due to Pyrotechnics during a Football Match. Atmos. Environ. 2020, 233, 117567. [Google Scholar] [CrossRef]

- Pirker, L.; Velkavrh, Ž.; Osīte, A.; Drinovec, L.; Močnik, G.; Remškar, M. Fireworks—A Source of Nanoparticles, PM2.5, PM10, and Carbonaceous Aerosols. Air Qual. Atmos. Health 2022, 15, 1275–1286. [Google Scholar] [CrossRef]

- Višić, B.; Kranjc, E.; Pirker, L.; Bačnik, U.; Tavčar, G.; Škapin, S.; Remškar, M. Incense Powder and Particle Emission Characteristics during and after Burning Incense in an Unventilated Room Setting. Air Qual. Atmos. Health 2018, 11, 649–663. [Google Scholar] [CrossRef]

- Pedde, M.; Kloog, I.; Szpiro, A.; Dorman, M.; Larson, T.V.; Adar, S.D. Estimating Long-Term PM10-2.5 Concentrations in Six US Cities Using Satellite-Based Aerosol Optical Depth Data. Atmos. Environ. 2022, 272, 118945. [Google Scholar] [CrossRef]

- Kumar, N.K.; Corbin, J.C.; Bruns, E.A.; Massabó, D.; Slowik, J.G.; Drinovec, L.; Močnik, G.; Prati, P.; Vlachou, A.; Baltensperger, U. Production of Particulate Brown Carbon during Atmospheric Aging of Residential Wood-Burning Emissions. Atmos. Chem. Phys. 2018, 18, 17843–17861. [Google Scholar] [CrossRef]

- Brook, R.D.; Brook, J.R.; Urch, B.; Vincent, R.; Rajagopalan, S.; Silverman, F. Inhalation of Fine Particulate Air Pollution and Ozone Causes Acute Arterial Vasoconstriction in Healthy Adults. Circulation 2002, 105, 1534–1536. [Google Scholar] [CrossRef]

- Sosa, B.S.; Porta, A.; Lerner, J.E.C.; Noriega, R.B.; Massolo, L. Human Health Risk Due to Variations in PM10-PM2.5 and Associated PAHs Levels. Atmos. Environ. 2017, 160, 27–35. [Google Scholar] [CrossRef]

- Janssen, N.A.H.; Hoek, G.; Simic-Lawson, M.; Fischer, P.; van Bree, L.; ten Brink, H.; Keuken, M.; Atkinson, R.W.; Anderson, H.R.; Brunekreef, B. Black Carbon as an Additional Indicator of the Adverse Health Effects of Airborne Particles Compared with PM10 and PM2.5. Environ. Health Perspect. 2011, 119, 1691–1699. [Google Scholar] [CrossRef]

- Rajagopalan, S.; Al-Kindi, S.G.; Brook, R.D. Air Pollution and Cardiovascular Disease: JACC State-of-the-Art Review. J. Am. Coll. Cardiol. 2018, 72, 2054–2070. [Google Scholar] [CrossRef]

- Pirker, L.; Čebašek, M.; Serdinšek, M.; Remškar, M. Size- and Time-Dependent Aerosol Removal from a Protective Box during Simulated Intubation and Extubation Procedures. COVID 2021, 1, 315–324. [Google Scholar] [CrossRef]

- Krajnc, A.P.; Pirker, L.; Centa, U.G.; Gradišek, A.; Mekjavic, I.B.; Godnič, M.; Čebašek, M.; Bregant, T.; Remškar, M. Size-and Time-Dependent Particle Removal Efficiency of Face Masks and Improvised Respiratory Protection Equipment Used during the COVID-19 Pandemic. Sensors 2021, 21, 1567. [Google Scholar] [CrossRef]

- Pirker, L.; Krajnc, A.P.; Malec, J.; Radulović, V.; Gradišek, A.; Jelen, A.; Remškar, M.; Mekjavić, I.B.; Kovač, J.; Mozetič, M.; et al. Sterilization of Polypropylene Membranes of Facepiece Respirators by Ionizing Radiation. J. Memb. Sci. 2021, 619, 118756. [Google Scholar] [CrossRef]

- Greig, P.R.; Carvalho, C.; El-Boghdadly, K.; Ramessur, S. Safety Testing Improvised COVID-19 Personal Protective Equipment Based on a Modified Full-face Snorkel Mask. Anaesthesia 2020, 75, 970. [Google Scholar] [CrossRef]

- Rogak, S.N.; Sipkens, T.A.; Guan, M.; Nikookar, H.; Vargas Figueroa, D.; Wang, J. Properties of Materials Considered for Improvised Masks. Aerosol Sci. Technol. 2021, 55, 398–413. [Google Scholar] [CrossRef]

- Chowdhury, H.; Chowdhury, T.; Sait, S.M. Estimating Marine Plastic Pollution from COVID-19 Face Masks in Coastal Regions. Mar. Pollut. Bull. 2021, 168, 112419. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Cheela, V.R.S.; Ranjan, V.P.; Jaglan, A.K.; Dubey, B.; Goel, S.; Bhattacharya, J. Challenges, Opportunities, and Innovations for Effective Solid Waste Management during and Post COVID-19 Pandemic. Resour. Conserv. Recycl. 2020, 162, 105052. [Google Scholar] [CrossRef]

- Varghese, H.; Chandran, A. Triboelectric Nanogenerator from Used Surgical Face Mask and Waste Mylar Materials Aiding the Circular Economy. ACS Appl. Mater. Interfaces 2021, 13, 51132–51140. [Google Scholar] [CrossRef]

- Shen, M.; Zeng, Z.; Song, B.; Yi, H.; Hu, T.; Zhang, Y.; Zeng, G.; Xiao, R. Neglected Microplastics Pollution in Global COVID-19: Disposable Surgical Masks. Sci. Total Environ. 2021, 790, 148130. [Google Scholar] [CrossRef]

- Hartanto, B.W.; Mayasari, D.S. Environmentally Friendly Non-Medical Mask: An Attempt to Reduce the Environmental Impact from Used Masks during COVID-19 Pandemic. Sci. Total Environ. 2021, 760, 144143. [Google Scholar] [CrossRef]

- Sankhyan, S.; Heinselman, K.N.; Ciesielski, P.N.; Barnes, T.; Himmel, M.E.; Teed, H.; Patel, S.; Vance, M.E. Filtration Performance of Layering Masks and Face Coverings and the Reusability of Cotton Masks after Repeated Washing and Drying. Aerosol Air Qual. Res. 2021, 21, 210117. [Google Scholar] [CrossRef]

- He, R.; Li, J.; Chen, M.; Zhang, S.; Cheng, Y.; Ning, X.; Wang, N. Tailoring Moisture Electroactive Ag/Zn@ Cotton Coupled with Electrospun PVDF/PS Nanofibers for Antimicrobial Face Masks. J. Hazard. Mater. 2022, 428, 128239. [Google Scholar] [CrossRef]

- Shen, H.; Zhou, Z.; Wang, H.; Zhang, M.; Han, M.; Durkin, D.P.; Shuai, D.; Shen, Y. Development of Electrospun Nanofibrous Filters for Controlling Coronavirus Aerosols. Environ. Sci. Technol. Lett. 2021, 8, 545–550. [Google Scholar] [CrossRef]

- Kadam, V.; Truong, Y.B.; Schutz, J.; Kyratzis, I.L.; Padhye, R.; Wang, L. Gelatin/β–Cyclodextrin Bio–Nanofibers as Respiratory Filter Media for Filtration of Aerosols and Volatile Organic Compounds at Low Air Resistance. J. Hazard. Mater. 2021, 403, 123841. [Google Scholar] [CrossRef]

- Brown, R.C. Effect of Electric Charge in Filter Materials. Filtr. Sep. 1989, 26, 46–51. [Google Scholar] [CrossRef]

- Sun, Q.; Leung, W.W.-F. Charged PVDF Multi-Layer Filters with Enhanced Filtration Performance for Filtering Nano-Aerosols. Sep. Purif. Technol. 2019, 212, 854–876. [Google Scholar] [CrossRef]

- Pich, J.; Emi, H.; Kanaoka, C. Coulombic Deposition Mechanism in Electret Filters. J. Aerosol Sci. 1987, 18, 29–35. [Google Scholar] [CrossRef]

- Javidpour, L.; Božič, A.; Naji, A.; Podgornik, R. Electrostatic Interactions between the SARS-CoV-2 Virus and a Charged Electret Fibre. Soft Matter 2021, 17, 4296–4303. [Google Scholar] [CrossRef]

- Gryshkov, O.; al Halabi, F.; Kuhn, A.I.; Leal-Marin, S.; Freund, L.J.; Förthmann, M.; Meier, N.; Barker, S.-A.; Haastert-Talini, K.; Glasmacher, B. PVDF and P (VDF-TrFE) Electrospun Scaffolds for Nerve Graft Engineering: A Comparative Study on Piezoelectric and Structural Properties, and in Vitro Biocompatibility. Int. J. Mol. Sci. 2021, 22, 11373. [Google Scholar] [CrossRef]

- Laroche, G.; Marois, Y.; Guidoin, R.; King, M.W.; Martin, L.; How, T.; Douville, Y. Polyvinylidene Fluoride (PVDF) as a Biomaterial: From Polymeric Raw Material to Monofilament Vascular Suture. J. Biomed. Mater. Res. 1995, 29, 1525–1536. [Google Scholar] [CrossRef]

- Kang, D.H.; Kim, N.K.; Kang, H.W. Electrostatic Charge Retention in PVDF Nanofiber-Nylon Mesh Multilayer Structure for Effective Fine Particulate Matter Filtration for Face Masks. Polymers 2021, 13, 3235. [Google Scholar] [CrossRef]

- Peng, Z.; Shi, J.; Xiao, X.; Hong, Y.; Li, X.; Zhang, W.; Cheng, Y.; Wang, Z.; Li, W.J.; Chen, J. Self-Charging Electrostatic Face Masks Leveraging Triboelectrification for Prolonged Air Filtration. Nat. Commun. 2022, 13, 7835. [Google Scholar] [CrossRef]

- Liu, G.; Nie, J.; Han, C.; Jiang, T.; Yang, Z.; Pang, Y.; Xu, L.; Guo, T.; Bu, T.; Zhang, C. Self-Powered Electrostatic Adsorption Face Mask Based on a Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2018, 10, 7126–7133. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Hao, M.; Huang, Z.; Chen, Z.; Liu, Y. High Filterable Electrospun Nanofibrous Membrane with Charged Electret After Electrification Treatment for Air Filtration. Fibers Polym. 2023, 1–9. [Google Scholar] [CrossRef]

- Zhang, Z.; Ji, D.; He, H.; Ramakrishna, S. Electrospun Ultrafine Fibers for Advanced Face Masks. Mater. Sci. Eng. R Rep. 2021, 143, 100594. [Google Scholar] [CrossRef] [PubMed]

- Gade, H.; Bokka, S.; Chase, G.G. Polarization Treatments of Electrospun PVDF Fiber Mats. Polymer 2021, 212, 123152. [Google Scholar] [CrossRef]

- Xu, C.; Liu, W.; Luo, X.; Huang, X.; Nielsen, P.V. Prediction and Control of Aerosol Transmission of SARS-CoV-2 in Ventilated Context: From Source to Receptor. Sustain. Cities Soc. 2022, 76, 103416. [Google Scholar] [CrossRef] [PubMed]

- Hinds, W.C. Aerosol Technology: Properties, Behaviour, and Measurement of Airborne Particles; John Wiley & Sons: Hoboken, NJ, USA, 1982; ISBN 0471087262. [Google Scholar]

- Kobayashi, M.; Tashiro, K.; Tadokoro, H. Molecular Vibrations of Three Crystal Forms of Poly (Vinylidene Fluoride). Macromolecules 1975, 8, 158–171. [Google Scholar] [CrossRef]

- Sanyal, A.; Sinha-Ray, S. Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review. Polymers 2021, 13, 1864. [Google Scholar] [CrossRef]

| Sample Name | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Material | Cotton | Wool | Linen | Silk | Muslin |

| Grammage (g/m2) | 140 | 150 | 190 | 90 | 130 |

| Nbr. of fibres in weft/warp | 90/80 | 50/40 | 280/220 | 140/40 | 60/60 |

| Wefts/Warps per length (mm−1) | 2.4/4.1 | 3.4/3.4 | 1.4/1.7 | 3.6/4.8 | 2.1/2.1 |

| Grammage of electrospun PVDF (mg/m2) | 0.19, 0.46, 0.80, 1.56, 2.69 | 0.80 | 0.80 | 0.80 | 0.80 |

| Sample | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| FE (%)—without | 38.8 | 43.3 | 19.5 | 88.5 | 25.5 |

| FE (%)—with | 95.8 | 97.3 | 98.2 | 99.7 | 47.6 |

| ΔFE (%) | 57.0 | 54.0 | 83.7 | 11.2 | 22.1 |

| Grammage (mg/m2) | Without | 0.19 | 0.80 | 1.56 | 2.69 |

|---|---|---|---|---|---|

| FE (%) | 38.8 | 82.6 | 95.8 | 98.6 | 99.9 |

| Pressure difference (Pa) | 500 | 455 | 407 | 485 | 613 |

| Quality factor (kPa−1) | 1 | 3.8 | 7.8 | 8.8 | 11.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filipič, G.; Pirker, L.; Krajnc, A.P.; Ješelnik, M.; Remškar, M. Enhanced Filtration Efficiency of Natural Materials with the Addition of Electrospun Poly(vinylidene fluoride-co-hexafluoropropylene) Fibres. Materials 2023, 16, 2314. https://doi.org/10.3390/ma16062314

Filipič G, Pirker L, Krajnc AP, Ješelnik M, Remškar M. Enhanced Filtration Efficiency of Natural Materials with the Addition of Electrospun Poly(vinylidene fluoride-co-hexafluoropropylene) Fibres. Materials. 2023; 16(6):2314. https://doi.org/10.3390/ma16062314

Chicago/Turabian StyleFilipič, Gregor, Luka Pirker, Anja Pogačnik Krajnc, Marjan Ješelnik, and Maja Remškar. 2023. "Enhanced Filtration Efficiency of Natural Materials with the Addition of Electrospun Poly(vinylidene fluoride-co-hexafluoropropylene) Fibres" Materials 16, no. 6: 2314. https://doi.org/10.3390/ma16062314

APA StyleFilipič, G., Pirker, L., Krajnc, A. P., Ješelnik, M., & Remškar, M. (2023). Enhanced Filtration Efficiency of Natural Materials with the Addition of Electrospun Poly(vinylidene fluoride-co-hexafluoropropylene) Fibres. Materials, 16(6), 2314. https://doi.org/10.3390/ma16062314