A Novel Approach to Quantifying the Failure Modes of Concrete-Epoxy Interface

Abstract

1. Introduction

2. Materials and Methods

2.1. Mechanical Testing

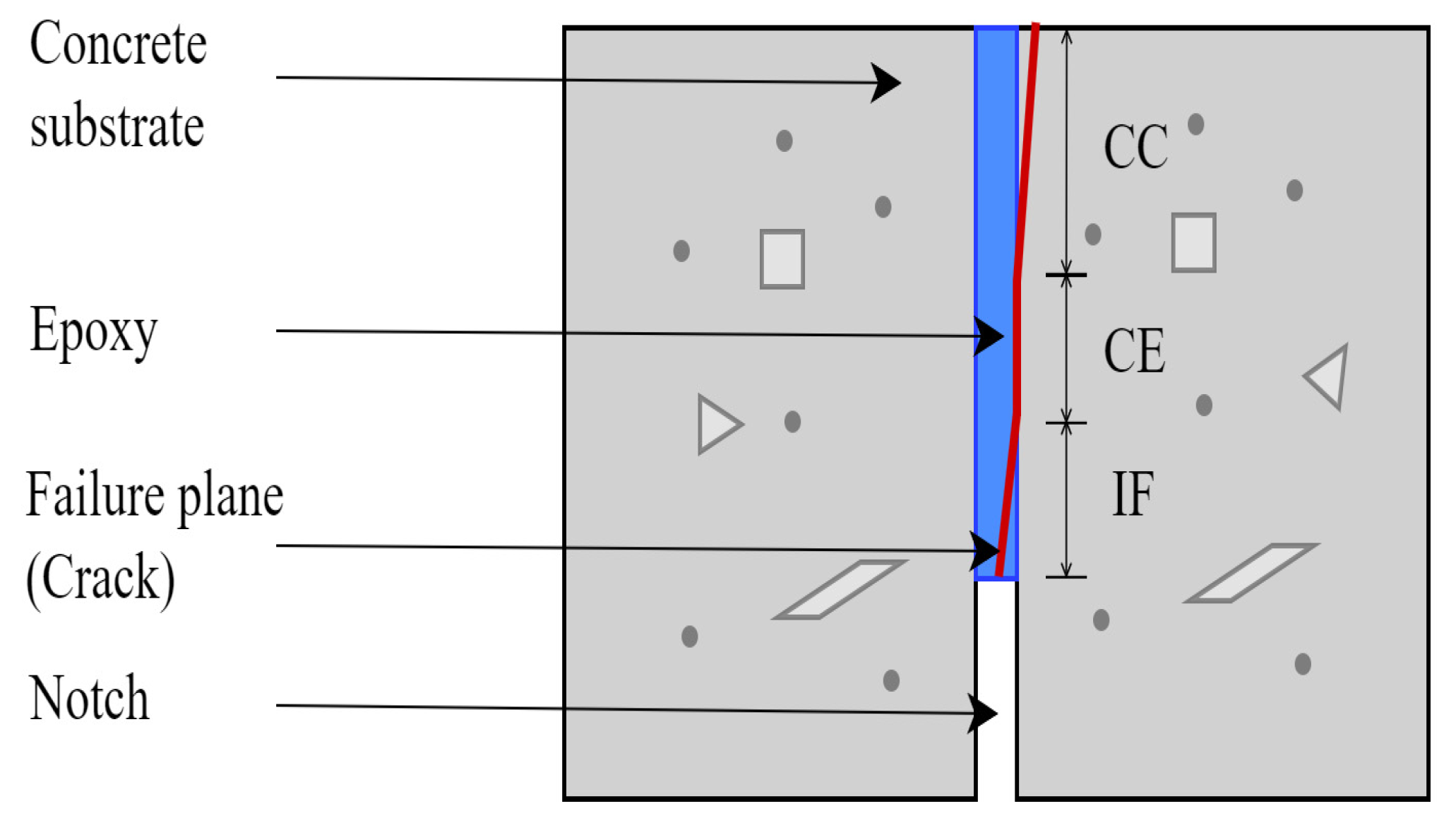

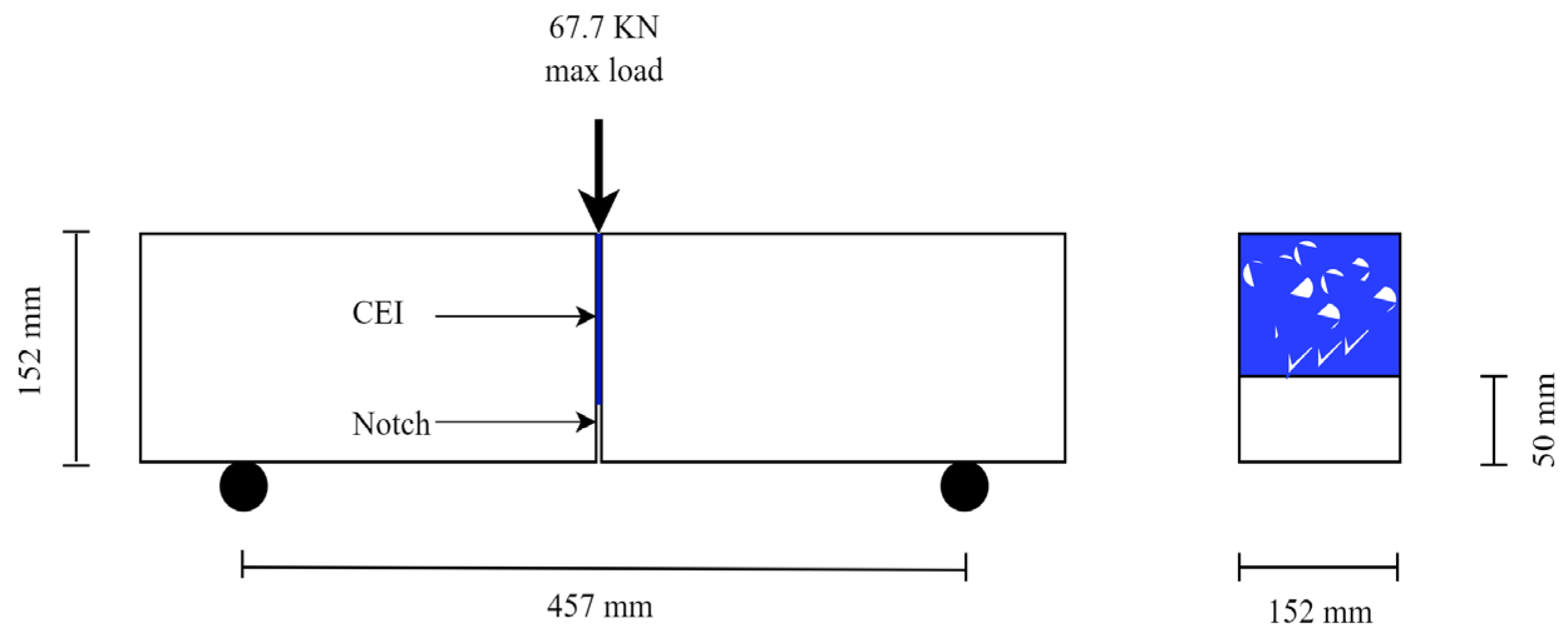

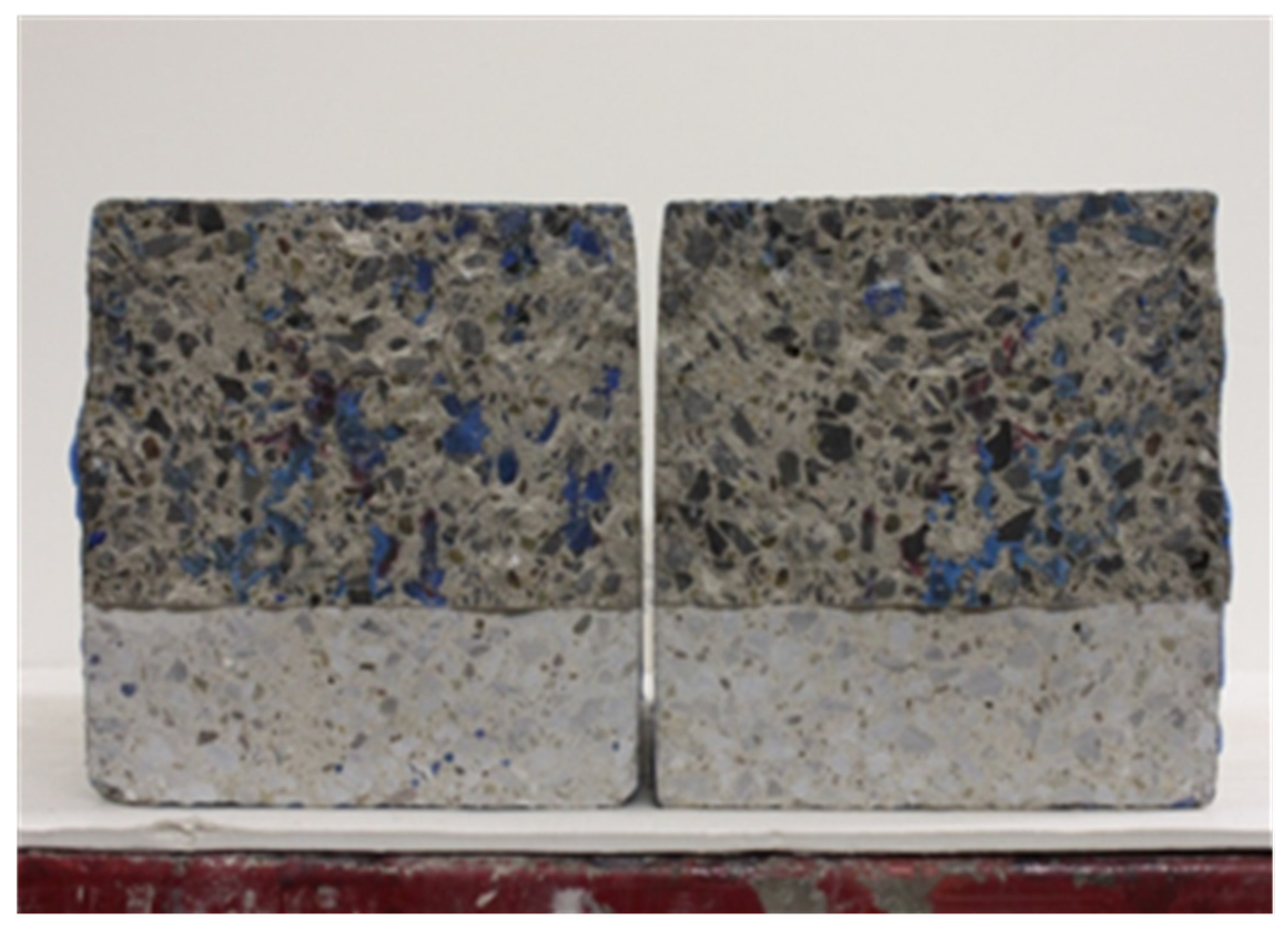

2.1.1. Test Specimen

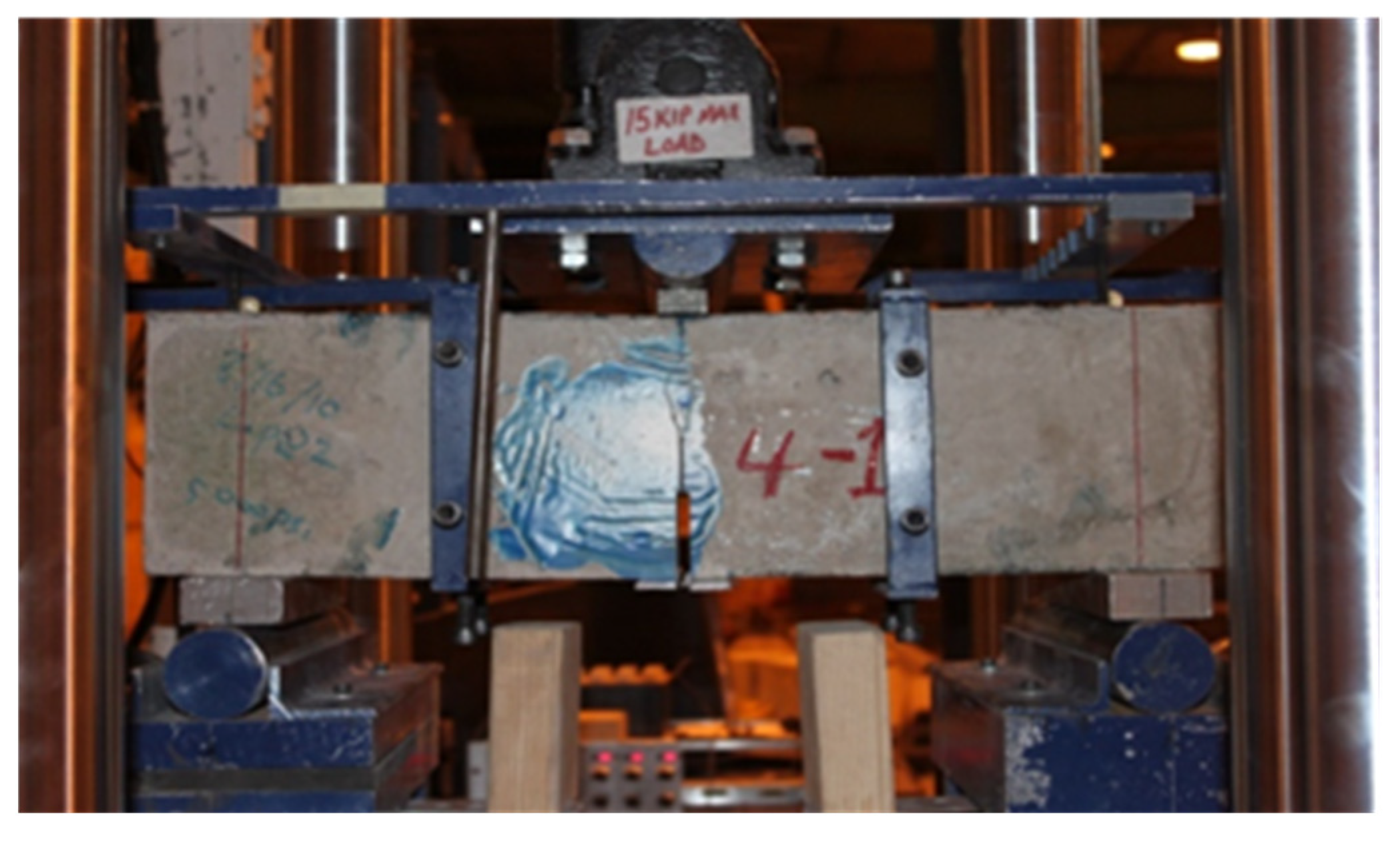

2.1.2. Test Set-Up

2.1.3. Fracture Test Results

2.2. Fracture Surface Analysis

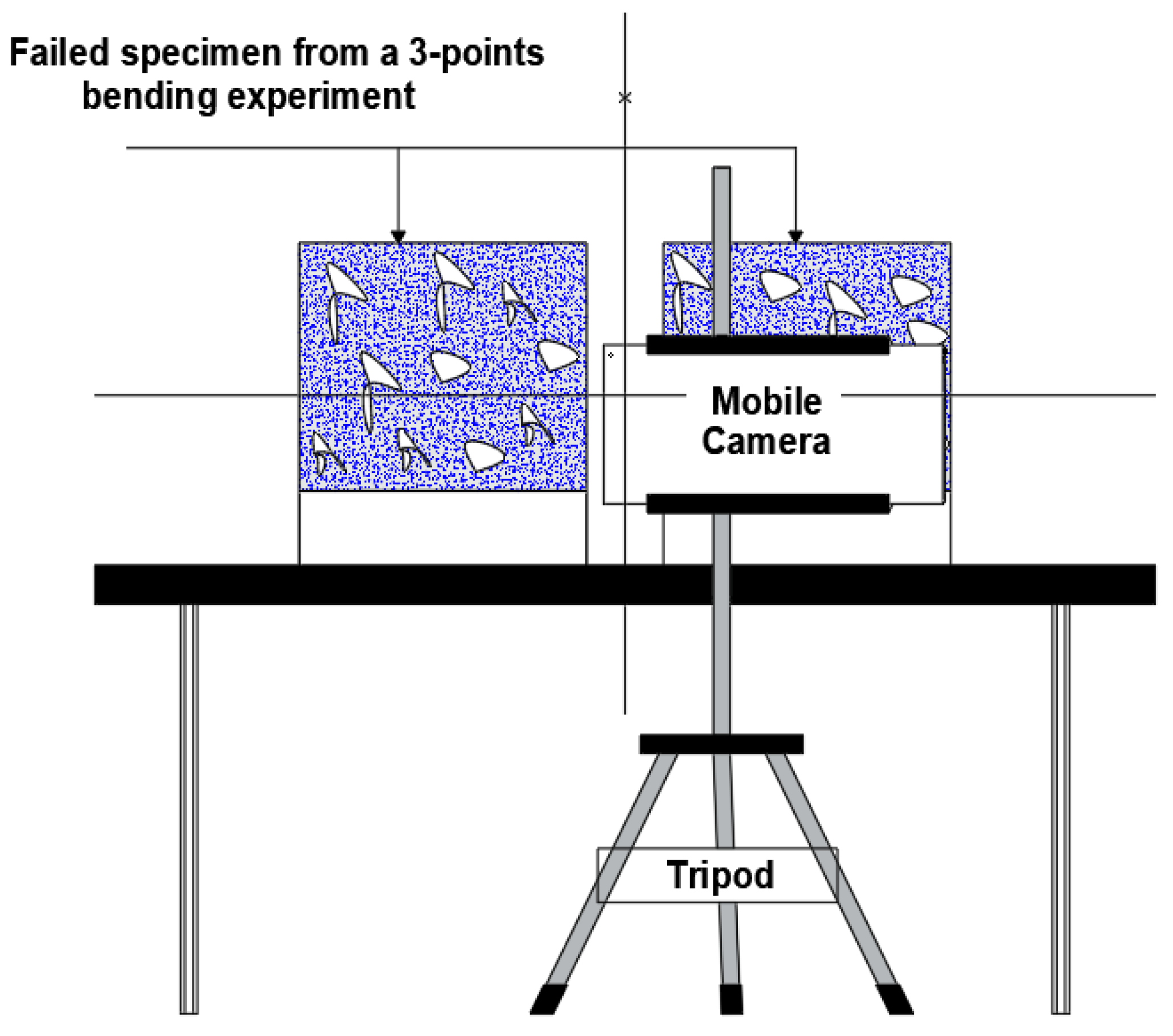

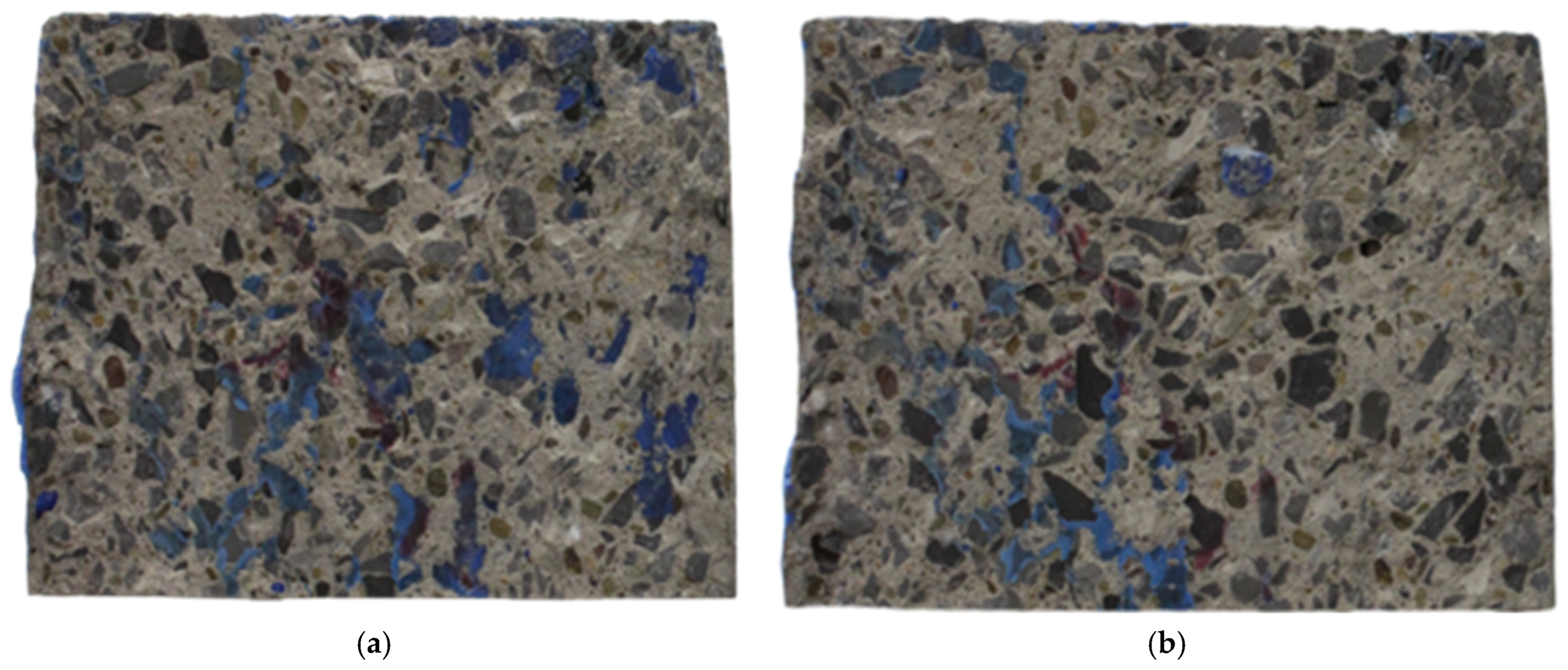

2.2.1. Fracture Surface Image Acquisition

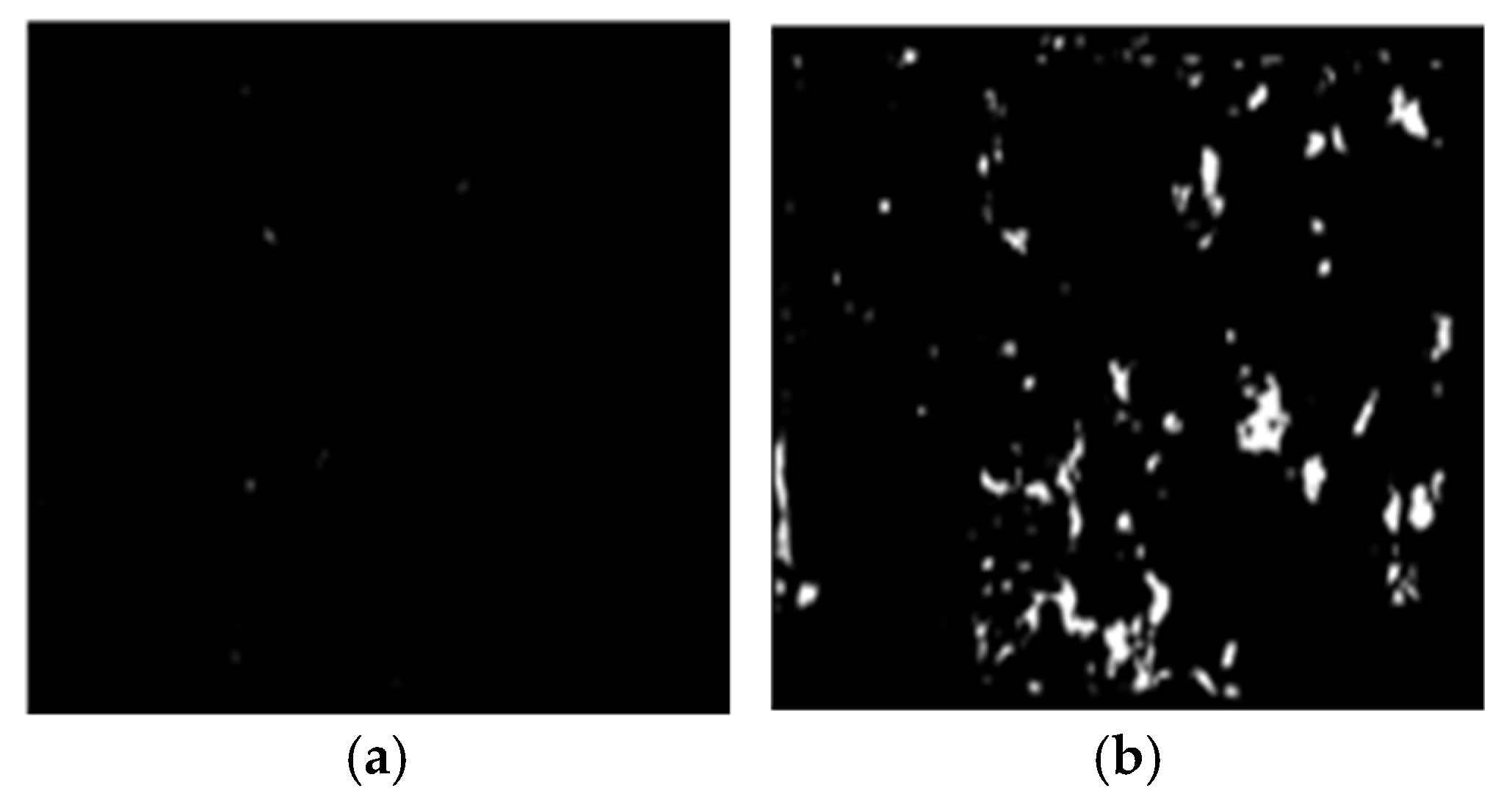

2.2.2. Fracture Surface Image Preprocessing

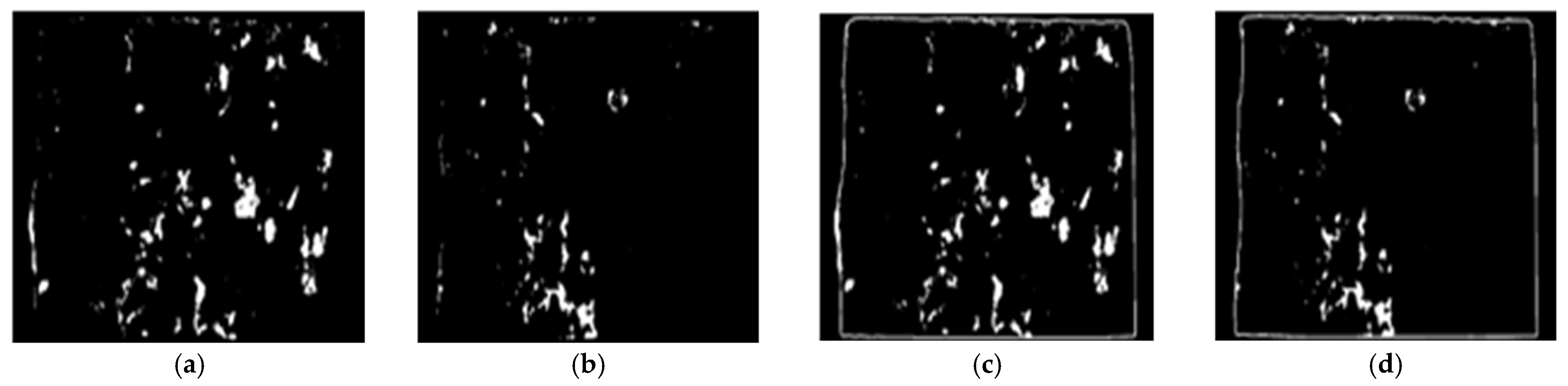

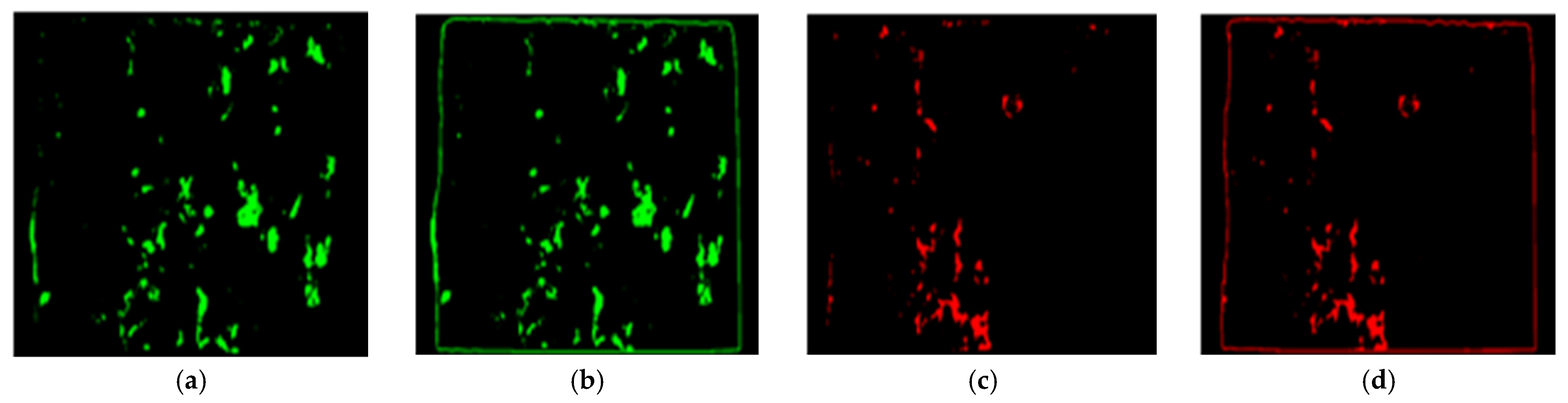

2.2.3. Failure Modes Detection and Quantification

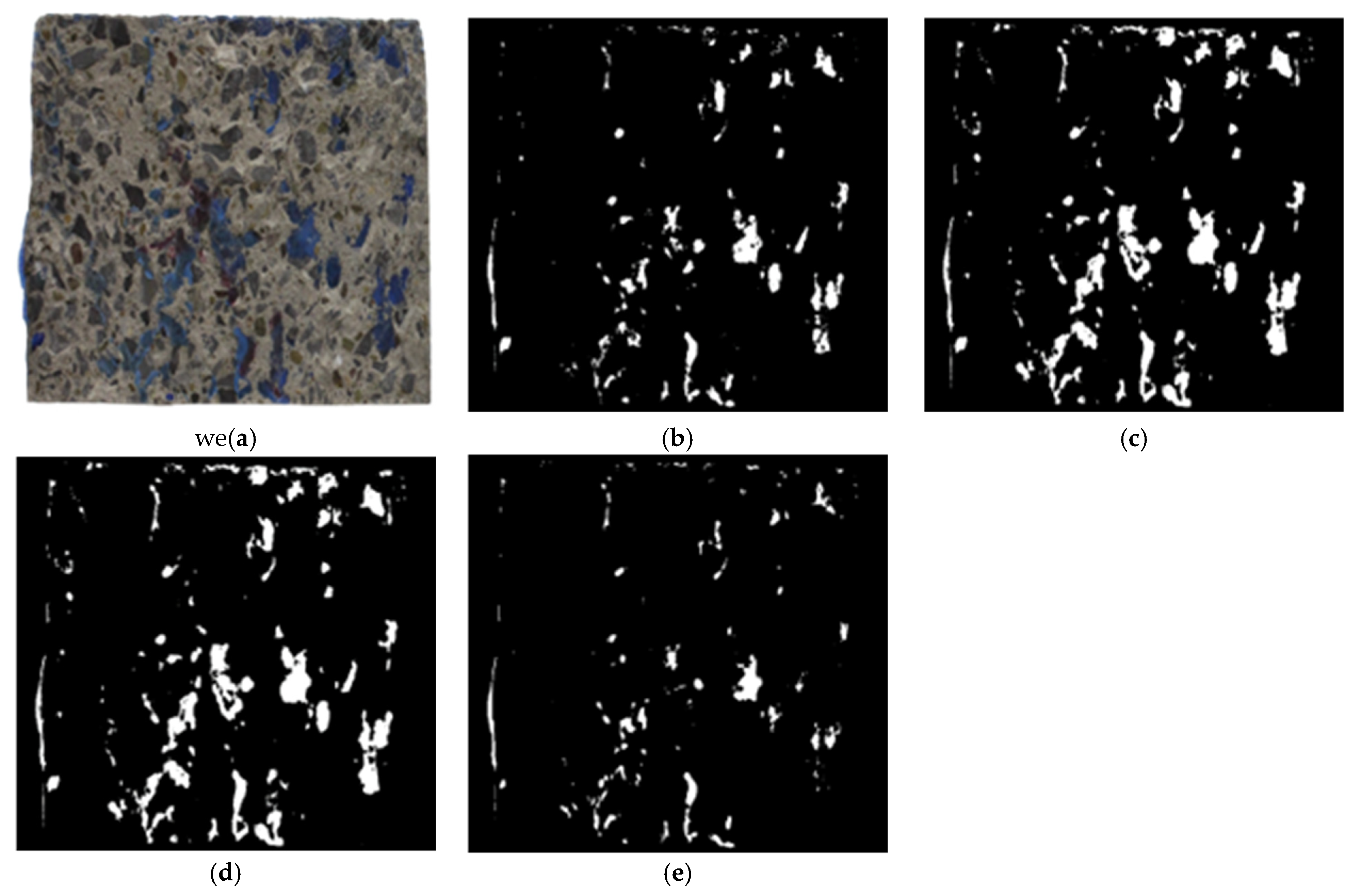

- Color space image segmentation-based image processing approach

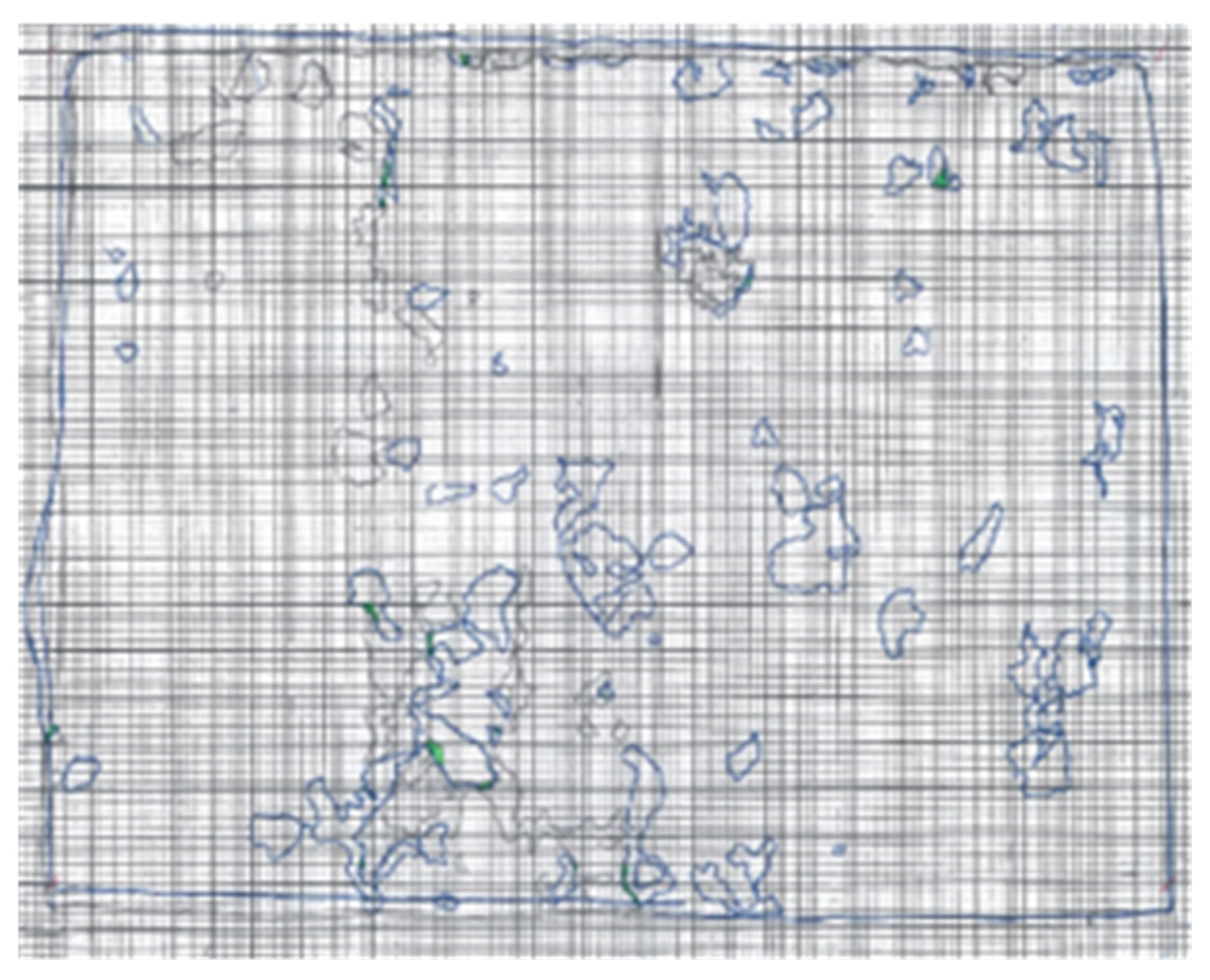

- Manual approach

- Step 1: Printing the pre-processed images of the failed CEI surfaces on 210 mm by 297 mm (A4) papers.

- Step 2: Modelling the concrete edges and epoxy areas on each CEI failure surface sides with blue and black A4-sized carbon paper, respectively. The models produced by the black and blue carbon papers were such that each represented either of the failure sides.

- Step 3: Highlighting the intersection of the epoxy area on either side. As shown in Figure 7, the overlaps of the two models were highlighted in green. The green highlights imply the region where failure within the epoxy (CE) occurred.

- Step 4: Evaluating CE. The ratio of the CE was evaluated with the aid of Equation (5).

3. Results and Discussion

3.1. Evaluating the Performance of the Color Spaces in Modeling

Visual Inspection of the Models of Epoxy Areas on the CEI Failure Sides

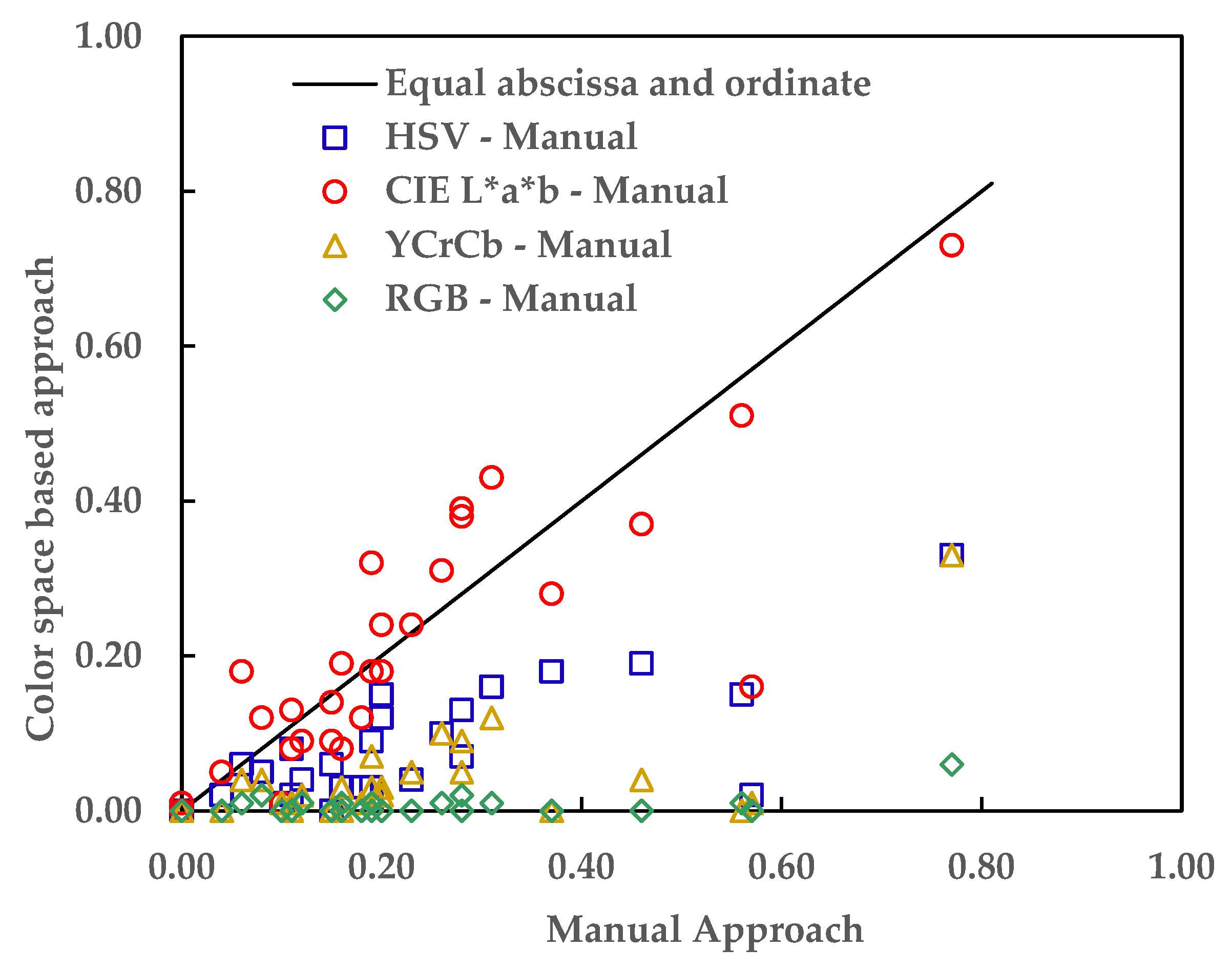

3.2. Disparity of the CE Estimated with the Image Segmentation and the Manual Approaches

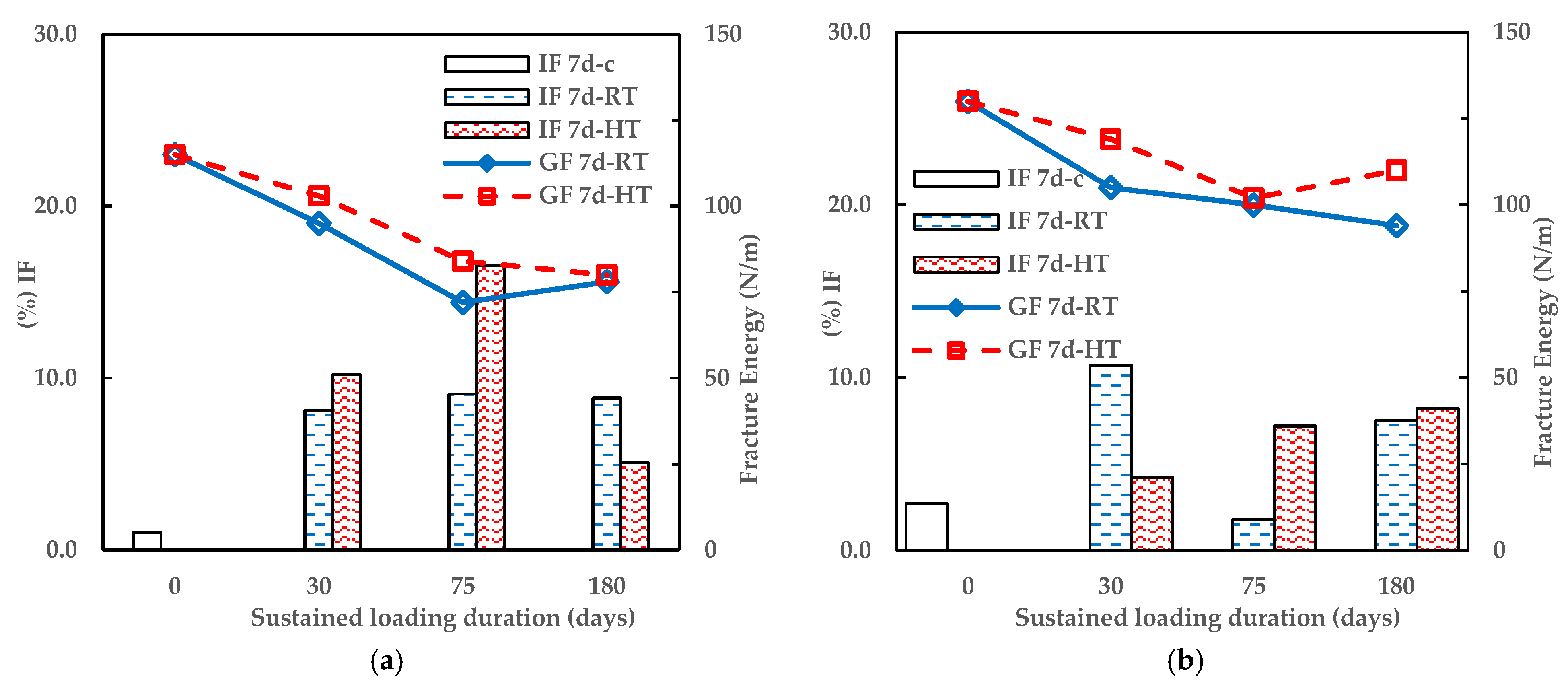

3.3. Analysis of the Correlations between the Evaluated Failure Modes and the Performance of the Epoxy Bond

4. Conclusions

- The epoxy area and the evaluated failure modes vary across the color spaces. RMSEs (Root Means Square Errors) of 0.19, 0.10, 0.23, and 0.26 was obtained when the CEs evaluated by the manual approach were compared with the CEs evaluated by the HVS, CIE L*a*b*, YCbCr, or RGB color space-based image segmentation approach, respectively.

- The CIE L*a*b* is the ideal color space for the novel approach proposed in this study, as it produced the most accurate model of the epoxy areas on the failure side and the closest evaluation of the failure mode (CE) to those made by the manual approach.

- Analysis of the evaluated failure modes shows that the failure modes have some correlations with the bond performance. The agreement of the correlations with established literature further implies the suitability of the novel approach for quantifying the failure modes of the concrete-epoxy failure surfaces.

- The epoxy matrix and the concrete substrate are the least and most susceptible to failure, respectively. The performance of the interfacial bond between the concrete and the epoxy weakens as environmental loads and sustained loading duration increase.

- The novel approach proposed in this study provides a scientific, non-subjective, and reproducible technique to quantify the failure mode on concrete-epoxy interface fracture surfaces in externally bonded FRP-repaired concrete, provided that both concrete and epoxy have distinctive colors. The novel approach proposed in this study is perfect for forensic engineering as it can give valuable insight into the probable causes of failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teng, J.G.; Smith, S.T.; Chen, J.F. Design Guidelines for Fibre-Reinforced Polymer (FRP)-Strengthened Reinforced Concrete (RC) Structures. In Strengthening and Rehabilitation of Civil Infrastructures Using Fibre-Reinforced Polymer (FRP) Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2008; pp. 195–214. ISBN 9781845694487. [Google Scholar]

- ACI Committee 440; American Concrete Institute. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2008; ISBN 9780870312854. [Google Scholar]

- Realfonzo, R. CNR-DT 200 R1/2013: Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures; Consiglio Nazionale delle Ricerche: Rome, Italy, 2014. [Google Scholar]

- Gómez, J.; Barris, C.; Baena, M.; Perera, R.; Torres, L. Sustained Loading Bond Response and Post-Sustained Loading Behaviour of NSM CFRP-Concrete Elements under Different Service Temperatures. Appl. Sci. 2021, 11, 8542. [Google Scholar] [CrossRef]

- Hollaway, L.C. A Review of the Present and Future Utilisation of FRP Composites in the Civil Infrastructure with Reference to Their Important In-Service Properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-Reinforced Polymer Composites in Strengthening Reinforced Concrete Structures: A Critical Review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Hou, D.; Yang, Q.; Wang, P.; Jin, Z.; Wang, M.; Zhang, Y.; Wang, X. Unraveling Disadhesion Mechanism of Epoxy/CSH Interface under Aggressive Conditions. Cem. Concr. Res. 2021, 146, 106489. [Google Scholar] [CrossRef]

- Jeong, Y.; Lopez, M.M.; Bakis, C.E. Effects of Temperature and Sustained Loading on the Mechanical Response of CFRP Bonded to Concrete. Constr. Build. Mater. 2016, 124, 442–452. [Google Scholar] [CrossRef]

- Wan, B.; Petrou, M.F.; Harries, K.A. The Effect of the Presence of Water on the Durability of Bond between CFRP and Concrete. J. Reinf. Plast. Compos. 2006, 25, 875–890. [Google Scholar] [CrossRef]

- Jeong, Y.; Lopez, M.M.; Bakis, C.E. Effects of Sustained Loading and Temperature on a Concrete–Epoxy Bonded Interface. J. Mater. Civ. Eng. 2020, 32, 04020016. [Google Scholar] [CrossRef]

- Coronado, C.A.; Lopez, M.M. Experimental Characterization of Concrete-Epoxy Interfaces. J. Mater. Civ. Eng. 2008, 20, 303–312. [Google Scholar] [CrossRef]

- Lau, D.; Büyüköztürk, O. Fracture Characterization of Concrete/Epoxy Interface Affected by Moisture. Mech. Mater. 2010, 42, 1031–1042. [Google Scholar] [CrossRef]

- Jeong, Y. Effects of Temperature and Sustained Loading on the Response of FRP-Strengthened Concrete Elements a Dissertation in Civil Engineering. Ph.D. Thesis, Penn State University, State College, PA, USA, 2014. [Google Scholar]

- Emara, M.; Torres, L.; Baena, M.; Barris, C.; Moawad, M. Effect of Sustained Loading and Environmental Conditions on the Creep Behavior of an Epoxy Adhesive for Concrete Structures Strengthened with CFRP Laminates. Compos. Part B Eng. 2017, 129, 88–96. [Google Scholar] [CrossRef]

- Granju, J.-L.; Sabathier, V.; Turatsinze, A.; Toumi, A. Interface Between an Old Concrete and a Bonded Overlay: Debonding Mechanism. Interface Sci. 2004, 12, 381–388. [Google Scholar] [CrossRef]

- Liang, H.; Li, S.; Lu, Y.; Yang, T. The Combined Effects of Wet–Dry Cycles and Sustained Load on the Bond Behavior of FRP–Concrete Interface. Polym. Compos. 2019, 40, 1006–1017. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Al-Osta, M.A.; Obot, I.B.; Baghabra Al-Amoudi, O.S.; Saleh, T.A.; Maslehuddin, M. Improving the Adhesion Properties of Cement/Epoxy Interface Using Graphene-Based Nanomaterials: Insights from Molecular Dynamics Simulation. Cem. Concr. Compos. 2022, 134, 104801. [Google Scholar] [CrossRef]

- Kai, M.F.; Ji, W.M.; Dai, J.G. Atomistic Insights into the Debonding of Epoxy–Concrete Interface with Water Presence. Eng. Fract. Mech. 2022, 271, 108668. [Google Scholar] [CrossRef]

- Ferrier, E.; Agbossou, A. Temperature Effects on the Shear Capacity of External Bonded Fiber Reinforced Polymer on Concrete. Constr. Build. Mater. 2017, 152, 333–344. [Google Scholar] [CrossRef]

- Gómez, J.; Barris, C.; Jahani, Y.; Baena, M.; Torres, L. The Effect of Steady and Cyclic Environmental Conditions on the Tensile Behaviour of a Structural Adhesive under Sustained Loading. Compos. Struct. 2022, 286, 115287. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Obot, I.B.; Al-Osta, M.A.; Baghabra Al-Amoudi, O.S.; Maslehuddin, M. Molecular-Level Investigation on the Effect of Surface Moisture on the Bonding Behavior of Cement-Epoxy Interface. J. Build. Eng. 2022, 61, 105299. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Al-Osta, M.A.; Baghabra Al-Amoudi, O.S.; Obot, I.B.; Adesina, A.Y.; Maslehuddin, M. A Nanoscale Adhesion Mechanism of Cement-Epoxy Interface under Varying Moisture Conditions: A Molecular Dynamics Study. Surf. Interfaces 2022, 35, 102446. [Google Scholar] [CrossRef]

- Gamage, J.C.P.H.; Al-Mahaidi, R.; Wong, B.; Ariyachandra, M.R.E.F. Bond Characteristics of CFRP-Strengthened Concrete Members Subjected to Cyclic Temperature and Mechanical Stress at Low Humidity. Compos. Struct. 2017, 160, 1051–1059. [Google Scholar] [CrossRef]

- Busin, L.; Vandenbroucke, N.; Macaire, L. Color Spaces and Image Segmentation. Adv. Imaging Electron Phys. 2009, 151, 65–168. [Google Scholar]

- International Commission on Illumination. Colorimetry; Commission Internationale de l’Eclairage: Vienna, Austria, 2004; ISBN 3901906339. [Google Scholar]

- Patra, A.K.; Ray, I.; Alein, J.S. Introduction to Fracture Failure Analysis of Fiber Reinforced Polymer Matrix Composites. In Fracture Failure Analysis of Fiber Reinforced Polymer Matrix Composites; Springer: Singapore, 2021; pp. 1–25. [Google Scholar] [CrossRef]

- William, K.P. (Ed.) Digital Image Processing, 4th ed.; John Wiley and Sons, Inc.: Los Altos, CA, USA, 2007; ISBN 978-0-471-76777-0. [Google Scholar]

- Siddiqui, F.U.; Yahya, A. Clustering Techniques for Image Segmentation; Springer International Publishing: Berlin, Germany, 2022. [Google Scholar]

- Hema, D.; Kannan, D.S. Interactive Color Image Segmentation Using HSV Color Space. Sci. Technol. J. 2019, 7, 37–41. [Google Scholar] [CrossRef]

- Shaik, K.B.; Ganesan, P.; Kalist, V.; Sathish, B.S.; Jenitha, J.M.M. Comparative Study of Skin Color Detection and Segmentation in HSV and YCbCr Color Space. Procedia Comput. Sci. 2015, 57, 41–48. [Google Scholar] [CrossRef]

- Plataniotis, K.N.; Venetsanopoulos, A.N. Color Image Processing and Applications; Digital Signal Processing; Springer: Berlin/Heidelberg, Germany, 2000; ISBN 978-3-642-08626-7. [Google Scholar]

- Zhou, H.; Torres, J.P.; Fernando, D.; Law, A.; Emberley, R. The Bond Behaviour of CFRP-to-Steel Bonded Joints with Varying Bond Properties at Elevated Temperatures. Eng. Struct. 2019, 183, 1121–1133. [Google Scholar] [CrossRef]

- Wang, S.; Stratford, T.; Reynolds, T.P.S. Linear Creep of Bonded FRP-Strengthened Metallic Structures at Warm Service Temperatures. Constr. Build. Mater. 2021, 283, 122699. [Google Scholar] [CrossRef]

| Material Properties | Values |

|---|---|

| 28 days Compressive Strength of concrete (MPa) | 34.5 |

| Tensile strength of concrete (MPa) | 2.85 |

| Elastic modulus of concrete (GPa) | 27.7 |

| Elastic modulus of epoxy (GPa) | 3.10 |

| Yield strain of epoxy (%) | 0.4 |

| Tensile strength of epoxy (GPa) | 55.2 |

| Specimen ID | Sustained Loading Duration (Days) | Average Fracture Energy (N/m) |

|---|---|---|

| 7d-C | - | 115 |

| 7d-HT-SL30d | 32 | 103 |

| 7d-RT-SL30d | 31 | 95 |

| 7d-HT-SL75d | 77 | 84 |

| 7d-RT-SL75d | 77 | 72 |

| 7d-HT-SL180d | 181 | 80 |

| 7d-RT-SL180d | 180 | 78 |

| 90d-C | - | 130 |

| 90d-HT-SL30d | 32 | 119 |

| 90d-RT-SL30d | 31 | 105 |

| 90d-HT-SL75d | 75 | 102 |

| 90d-RT-SL75d | 76 | 100 |

| 90d-HT-SL180d | 182 | 110 |

| Specimen | HSV | CIE L*a*b* | YCbCr | RGB | Manual |

|---|---|---|---|---|---|

| 7d-C-1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 7d-C-2 | 0.04 | 0.09 | 0.02 | 0.01 | 0.12 |

| 7d-HT-SL30d-1 | 0.00 | 0.09 | 0.00 | 0.00 | 0.15 |

| 7d-HT-SL30d-2 | 0.13 | 0.38 | 0.09 | 0.02 | 0.28 |

| 7d-RT-SL30d-1 | 0.03 | 0.19 | 0.03 | 0.01 | 0.16 |

| 7d-RT-SL30d-2 | 0.15 | 0.51 | 0.00 | 0.01 | 0.56 |

| 7d-HT-SL75d-1 | 0.04 | 0.24 | 0.05 | 0.00 | 0.23 |

| 7d-HT-SL75d-2 | 0.01 | 0.01 | 0.01 | 0.00 | 0.10 |

| 7d-RT-SL75d-1 | 0.07 | 0.39 | 0.05 | 0.00 | 0.28 |

| 7d-RT-SL75d-2 | 0.06 | 0.18 | 0.04 | 0.01 | 0.06 |

| 7d-HT-SL180d-1 | 0.19 | 0.37 | 0.04 | 0.00 | 0.46 |

| 7d-HT-SL180d-2 | 0.08 | 0.13 | 0.01 | 0.00 | 0.11 |

| 7d-RT-SL180d-1 | 0.03 | 0.08 | 0.00 | 0.00 | 0.16 |

| 7d-RT-SL180d-2 | 0.15 | 0.24 | 0.03 | 0.00 | 0.20 |

| 90d-C-1 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 |

| 90d-C-2 | 0.06 | 0.14 | 0.00 | 0.00 | 0.15 |

| 90d-HT-SL30d-1 | 0.33 | 0.73 | 0.33 | 0.06 | 0.77 |

| 90d-HT-SL30d-2 | 0.09 | 0.32 | 0.07 | 0.01 | 0.19 |

| 90d-RT-SL30d-1 | 0.02 | 0.05 | 0.00 | 0.00 | 0.04 |

| 90d-RT-SL30d-2 | 0.05 | 0.12 | 0.04 | 0.02 | 0.08 |

| 90d-HT-SL75d-1 | 0.12 | 0.18 | 0.02 | 0.00 | 0.20 |

| 90d-HT-SL75d-2 | 0.18 | 0.28 | 0.00 | 0.00 | 0.37 |

| 90d-RT-SL75d-1 | 0.16 | 0.43 | 0.12 | 0.01 | 0.31 |

| 90d-RT-SL75d-2 | 0.10 | 0.31 | 0.10 | 0.01 | 0.26 |

| 90d-HT-SL180d -1 | 0.02 | 0.08 | 0.00 | 0.00 | 0.11 |

| 90d-HT-SL180d -2 | 0.03 | 0.18 | 0.03 | 0.00 | 0.19 |

| 90d-RT-SL180d -1 | 0.03 | 0.12 | 0.01 | 0.00 | 0.18 |

| 90d-RT-SL180d -2 | 0.02 | 0.16 | 0.01 | 0.00 | 0.57 |

| Specimen | HSV (%) | CIE L*a*b (%) | YCbCr (%) | RGB (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CE | IF | CC | CE | IF | CC | CE | IF | CC | CE | IF | CC | |

| 7d-C-1 | 0 | 0.31 | 99.69 | 0 | 0.74 | 99.26 | 0 | 0.06 | 99.94 | 0 | 0.01 | 99.99 |

| 7d-C-2 | 0.04 | 1.19 | 98.77 | 0.09 | 2.21 | 97.7 | 0.02 | 0.61 | 99.37 | 0.01 | 0.26 | 99.73 |

| 7d-HT-SL30d-1 | 0 | 2.07 | 97.93 | 0.09 | 5.07 | 94.03 | 0 | 1.05 | 98.95 | 0 | 0.29 | 99.71 |

| 7d-HT-SL30d-2 | 0.13 | 6.3 | 93.57 | 0.38 | 10.74 | 88.88 | 0.09 | 3.97 | 95.94 | 0.02 | 1.85 | 98.13 |

| 7d-RT-SL30d-1 | 0.03 | 6.58 | 93.39 | 0.19 | 10.06 | 89.75 | 0.03 | 2.93 | 97.04 | 0.01 | 1.16 | 98.83 |

| 7d-RT-SL30d-2 | 0.15 | 5.98 | 93.86 | 0.51 | 10.32 | 89.16 | 0 | 2.89 | 97.11 | 0.01 | 1.67 | 98.32 |

| 7d-HT-SL75d-1 | 0.04 | 6.78 | 93.18 | 0.24 | 12.93 | 86.83 | 0.05 | 4.88 | 95.07 | 0 | 1.53 | 98.47 |

| 7d-HT-SL75d-2 | 0.01 | 1.57 | 98.43 | 0.01 | 5.3 | 94.68 | 0.01 | 1.1 | 98.89 | 0 | 0.25 | 99.75 |

| 7d-RT-SL75d-1 | 0.07 | 9.86 | 90.07 | 0.39 | 17.74 | 81.87 | 0.05 | 4.78 | 95.17 | 0 | 2.38 | 97.62 |

| 7d-RT-SL75d-2 | 0.06 | 11.07 | 88.87 | 0.18 | 15.37 | 84.45 | 0.04 | 7.86 | 92.09 | 0.01 | 5.29 | 94.7 |

| 7d-HT-SL180d-1 | 0.19 | 10.69 | 89.12 | 0.37 | 13.89 | 85.74 | 0.04 | 3.34 | 96.62 | 0 | 0.25 | 99.75 |

| 7d-HT-SL180d-2 | 0.08 | 3.33 | 96.59 | 0.13 | 3.79 | 96.08 | 0.01 | 0.56 | 99.43 | 0 | 0 | 100 |

| 7d-RT-SL180d-1 | 0.03 | 4.51 | 95.46 | 0.08 | 5.49 | 94.43 | 0 | 1.32 | 98.68 | 0 | 0.04 | 99.96 |

| 7d-RT-SL180d-2 | 0.15 | 3.88 | 95.97 | 0.24 | 4.64 | 95.12 | 0.03 | 1.49 | 98.48 | 0 | 0.06 | 99.94 |

| 90d-C-1 | 0 | 0.44 | 99.56 | 0.01 | 1.43 | 98.56 | 0 | 0.44 | 99.56 | 0 | 0.26 | 99.74 |

| 90d-C-2 | 0.06 | 1.9 | 98.04 | 0.14 | 2.73 | 97.13 | 0 | 0.44 | 99.56 | 0 | 0.11 | 99.89 |

| 90d-HT-SL30d-1 | 0.33 | 8.95 | 90.71 | 0.73 | 12.82 | 86.45 | 0.33 | 7.96 | 91.71 | 0.06 | 4.15 | 95.79 |

| 90d-HT-SL30d-2 | 0.09 | 3.89 | 96.02 | 0.32 | 8.51 | 91.17 | 0.07 | 3.02 | 96.91 | 0.01 | 0.87 | 99.11 |

| 90d-RT-SL30d-1 | 0.02 | 2.88 | 97.1 | 0.05 | 3.5 | 96.44 | 0 | 1.44 | 98.56 | 0 | 0.43 | 99.57 |

| 90d-RT-SL30d-2 | 0.05 | 3.83 | 96.11 | 0.12 | 4.81 | 95.07 | 0.04 | 2.98 | 96.98 | 0.02 | 1.81 | 98.17 |

| 90d-HT-SL75d-1 | 0.12 | 2.11 | 97.76 | 0.18 | 2.87 | 96.95 | 0.02 | 0.61 | 99.38 | 0 | 0.15 | 99.85 |

| 90d-HT-SL75d-2 | 0.18 | 0.61 | 99.2 | 0.28 | 0.69 | 99.03 | 0 | 0.05 | 99.95 | 0 | 0 | 100 |

| 90d-RT-SL75d-1 | 0.16 | 8.6 | 91.24 | 0.43 | 11.93 | 87.64 | 0.12 | 6.08 | 93.81 | 0.01 | 2.96 | 97.02 |

| 90d-RT-SL75d-2 | 0.1 | 1.69 | 98.22 | 0.31 | 2.51 | 97.18 | 0.1 | 0.79 | 99.12 | 0.01 | 0.32 | 99.67 |

| 90d-HT-SL180d -1 | 0.02 | 4.02 | 95.95 | 0.08 | 5.45 | 94.47 | 0 | 1.84 | 98.16 | 0 | 0.57 | 99.43 |

| 90d-HT-SL180d -2 | 0.03 | 6.75 | 93.22 | 0.18 | 9.62 | 90.2 | 0.03 | 5.39 | 94.58 | 0 | 2.39 | 97.61 |

| 90d-RT-SL180d -1 | 0.03 | 5.72 | 94.25 | 0.12 | 8.09 | 91.79 | 0.01 | 2.76 | 97.23 | 0 | 0.92 | 99.08 |

| 90d-RT-SL180d -2 | 0.02 | 5.04 | 94.93 | 0.16 | 8.3 | 91.54 | 0.01 | 4.6 | 95.39 | 0 | 2.37 | 97.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishaq, A.S.; Jang, Y.; An, D.; Jeong, Y.; Youn, I. A Novel Approach to Quantifying the Failure Modes of Concrete-Epoxy Interface. Materials 2023, 16, 2376. https://doi.org/10.3390/ma16062376

Ishaq AS, Jang Y, An D, Jeong Y, Youn I. A Novel Approach to Quantifying the Failure Modes of Concrete-Epoxy Interface. Materials. 2023; 16(6):2376. https://doi.org/10.3390/ma16062376

Chicago/Turabian StyleIshaq, Abubakar Sodiq, Yoonju Jang, Donghyeok An, Yoseok Jeong, and Ilro Youn. 2023. "A Novel Approach to Quantifying the Failure Modes of Concrete-Epoxy Interface" Materials 16, no. 6: 2376. https://doi.org/10.3390/ma16062376

APA StyleIshaq, A. S., Jang, Y., An, D., Jeong, Y., & Youn, I. (2023). A Novel Approach to Quantifying the Failure Modes of Concrete-Epoxy Interface. Materials, 16(6), 2376. https://doi.org/10.3390/ma16062376