Preparation and Performance of Repair Materials for Surface Defects in Pavement Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of the Penetrating Repair Materials

- Preparation of the MMA-based repair materials

- A certain amount of MMA was poured into a beaker, stirred at a speed of 300/min, and distilled in a water bath at 50 °C for 10 min.

- After distillation to remove the inhibitor, 1.5% BPO, 30% DBP, and 10% PCE was added and continuously stirred for 2 min.

- The curing agent DMA was added to the prepolymer and stirred evenly until the set time of the test was reached. The three-flask was quickly put into cold water to slow down the polymerization reaction, and the MMA-based repair material was obtained.

- 2.

- Preparation of the MMA-based penetrating repair materials

- The configured prepolymer was added with a certain amount of DMA and stirred for 2 min at 300 r/min.

- After an average of 60 min, diluent was added and stirred at 300 r/min for 3 min to obtain permeable repair material.

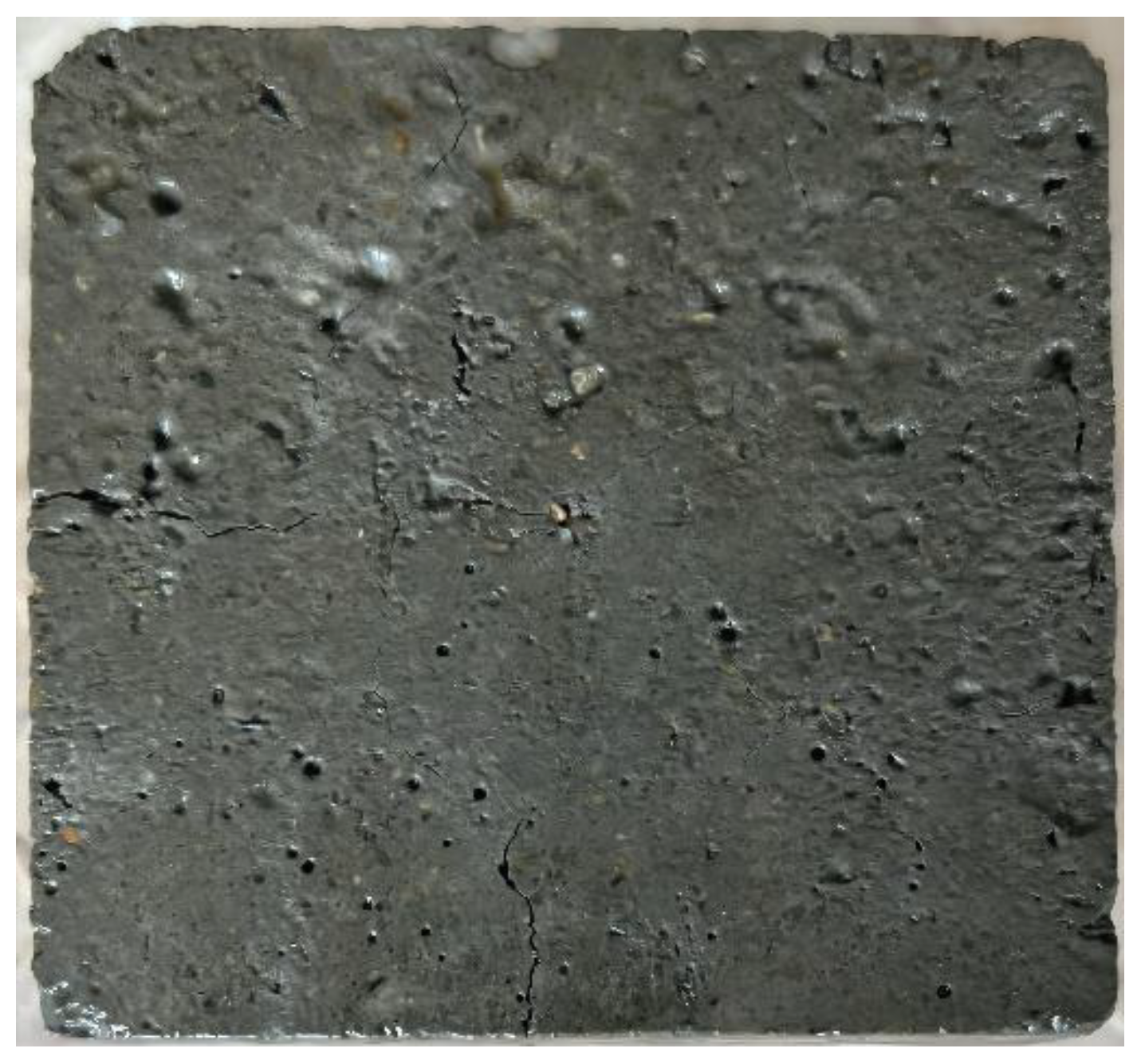

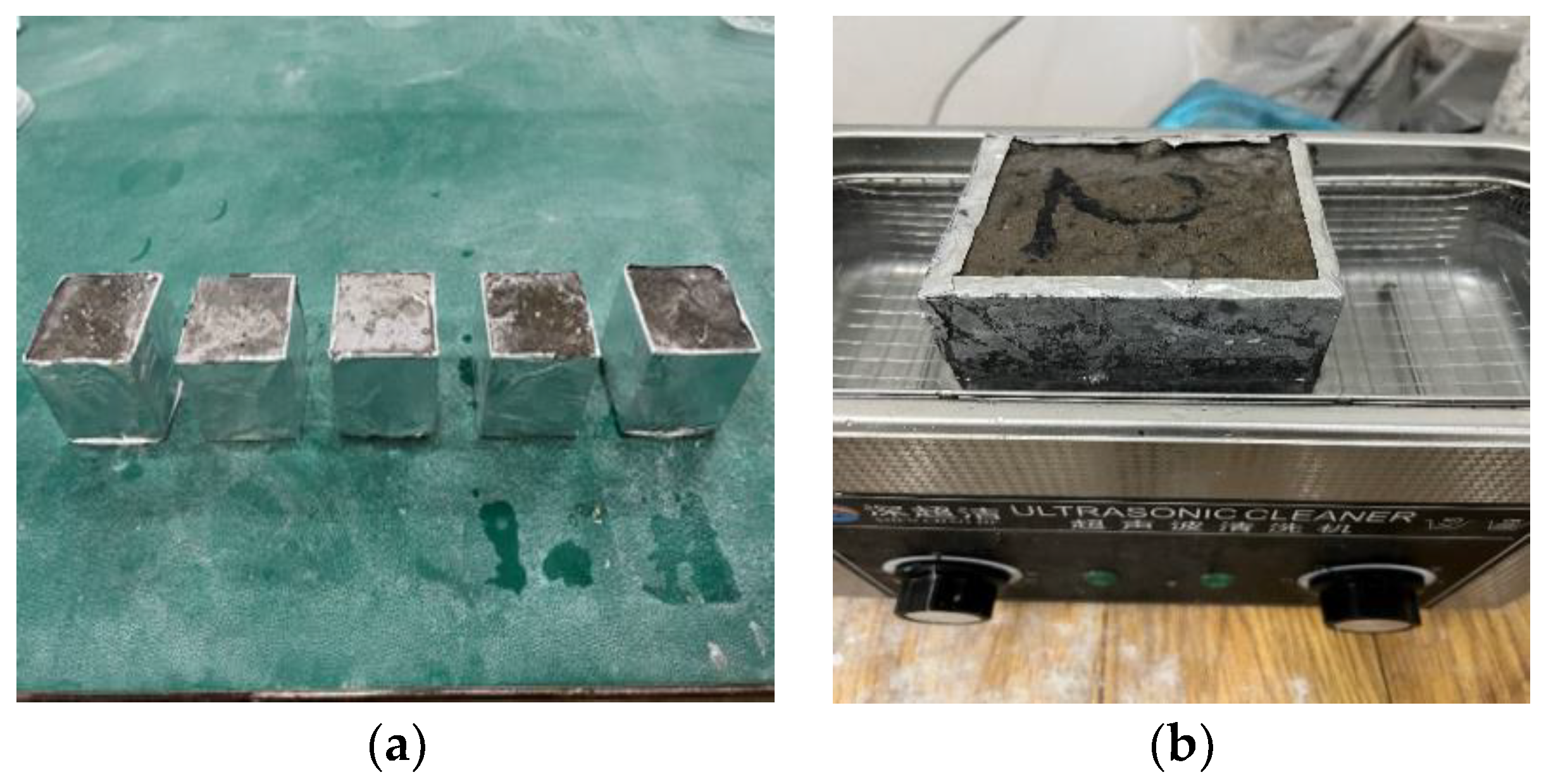

2.3. Pretreatment of the Concrete Specimen

2.4. Test Methods

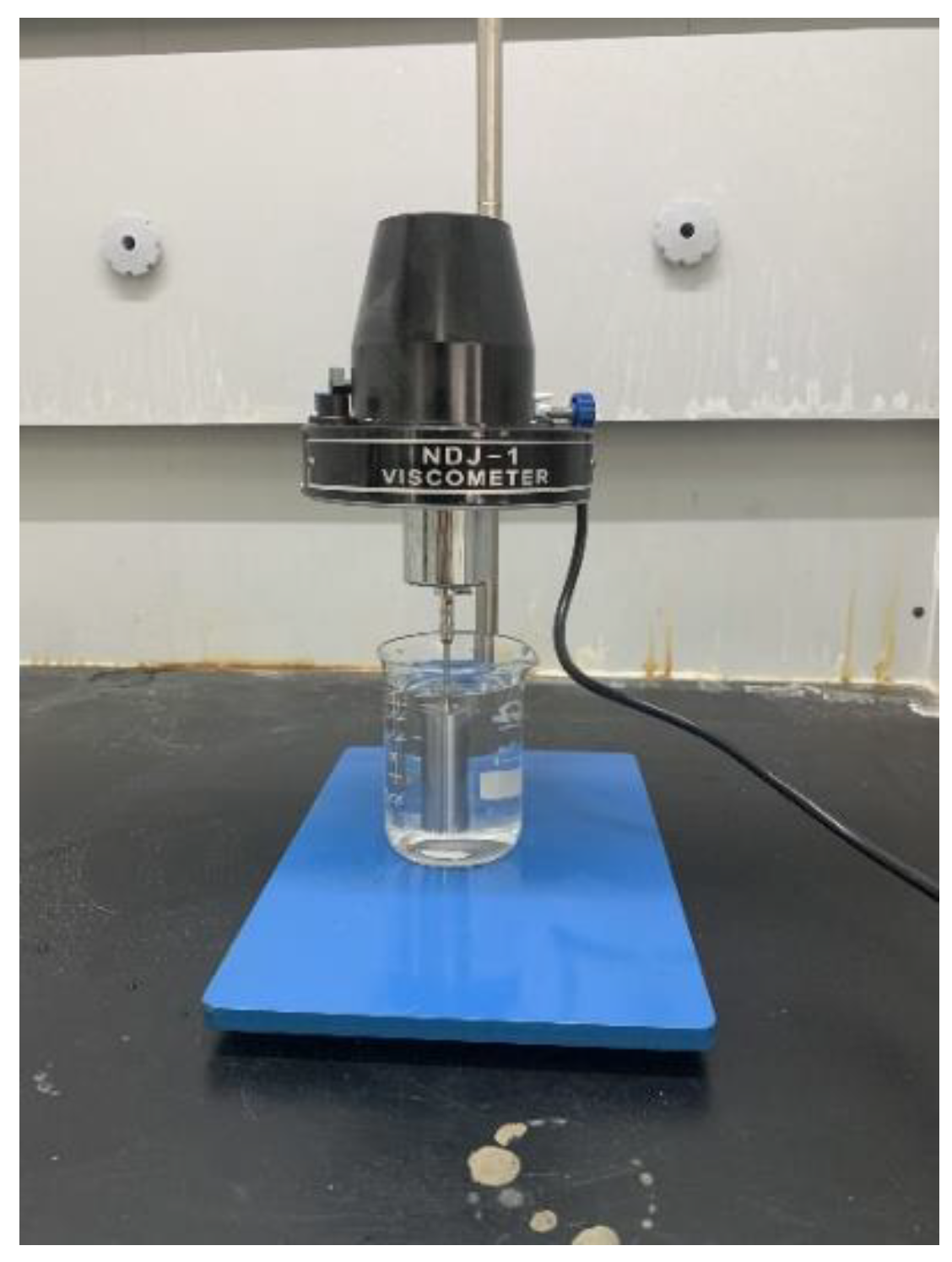

2.4.1. Viscosity Test

2.4.2. Surface-Drying Time and Through-Drying Time

2.4.3. Determination of the Film-Forming Thickness

2.4.4. Infiltration Performance

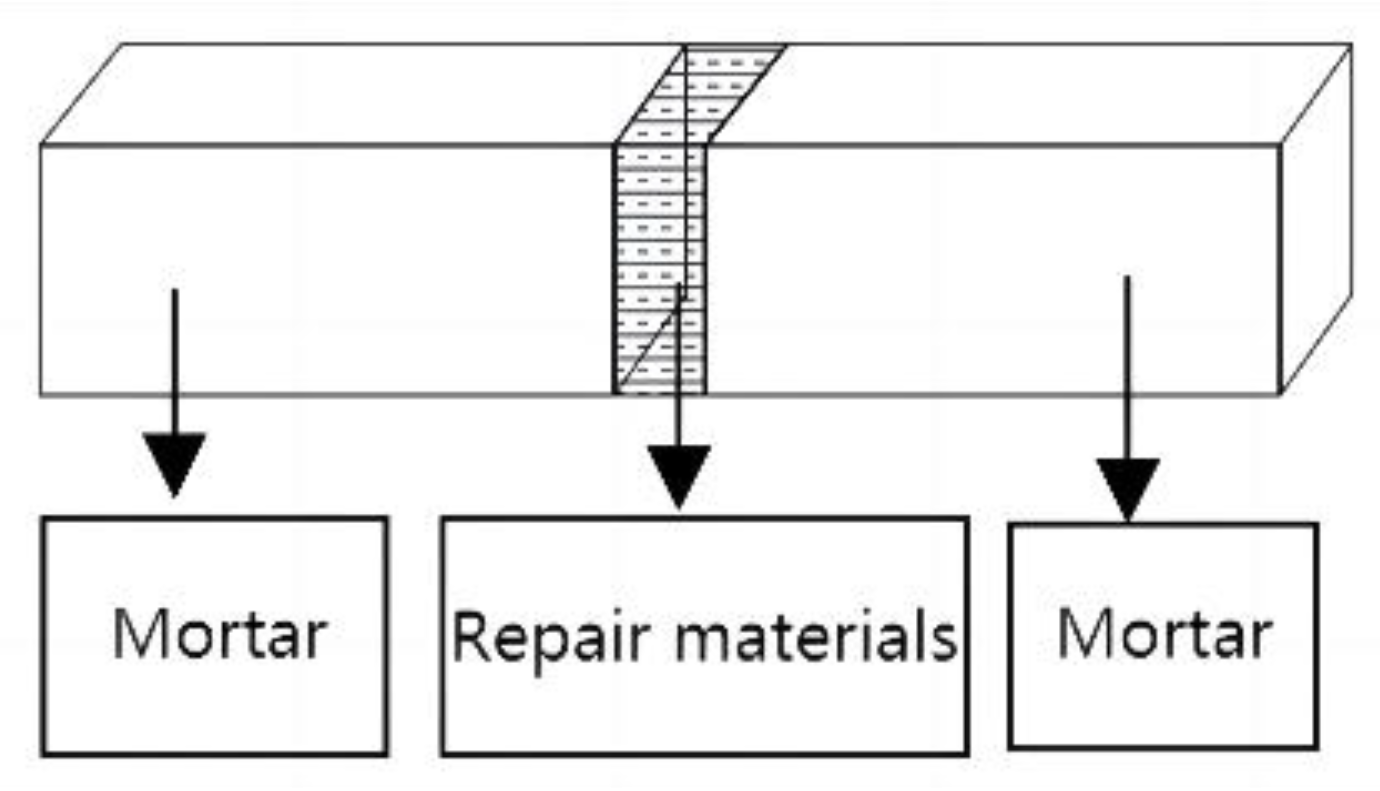

2.4.5. Bond Strength

2.4.6. Freeze–Thaw Cycle Test

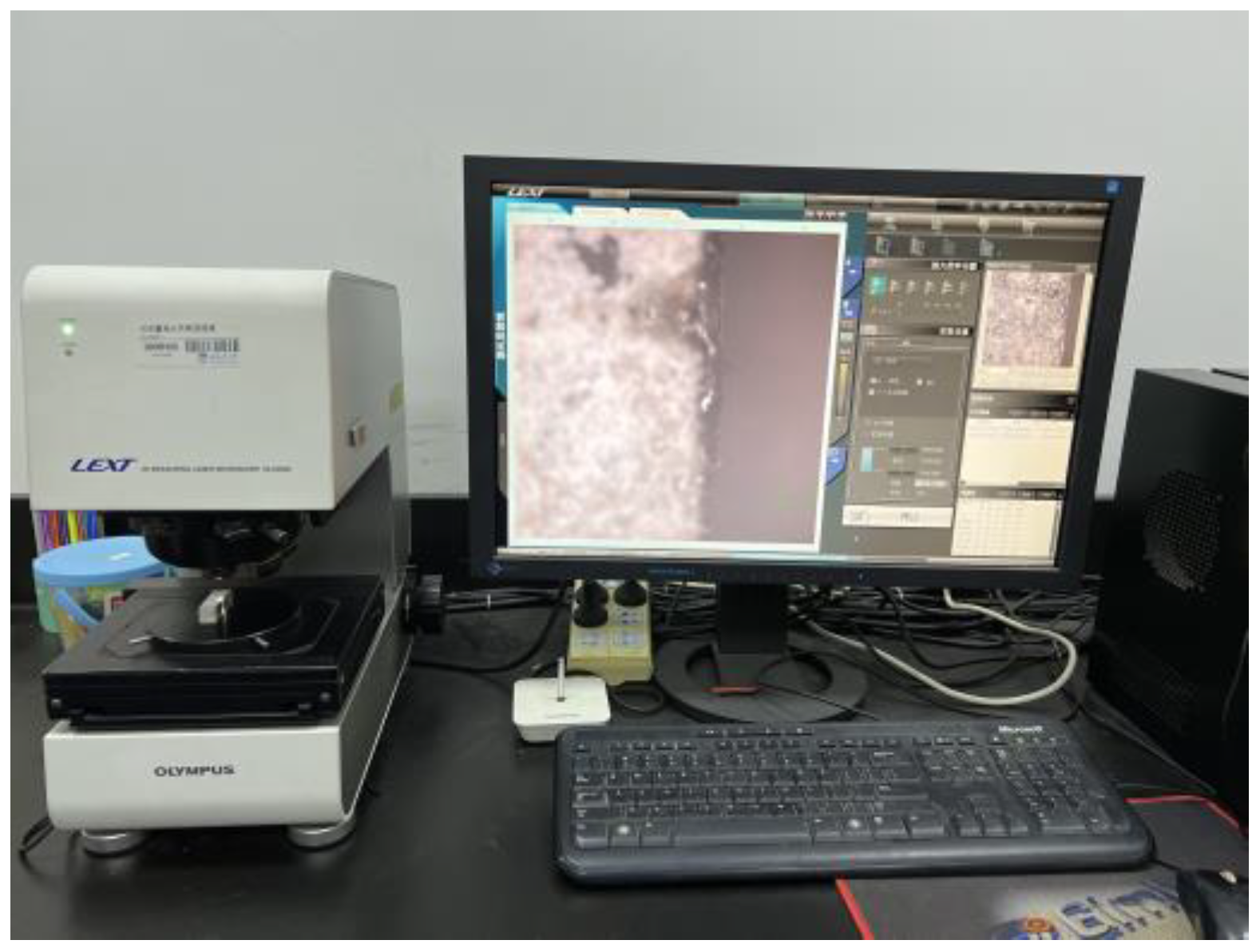

2.4.7. SEM

3. Results and Discussion

3.1. Preparation Technology of the MMA-Based Repair Materials

3.1.1. Effect of Preparation Technology on the 60-Min Average Viscosity

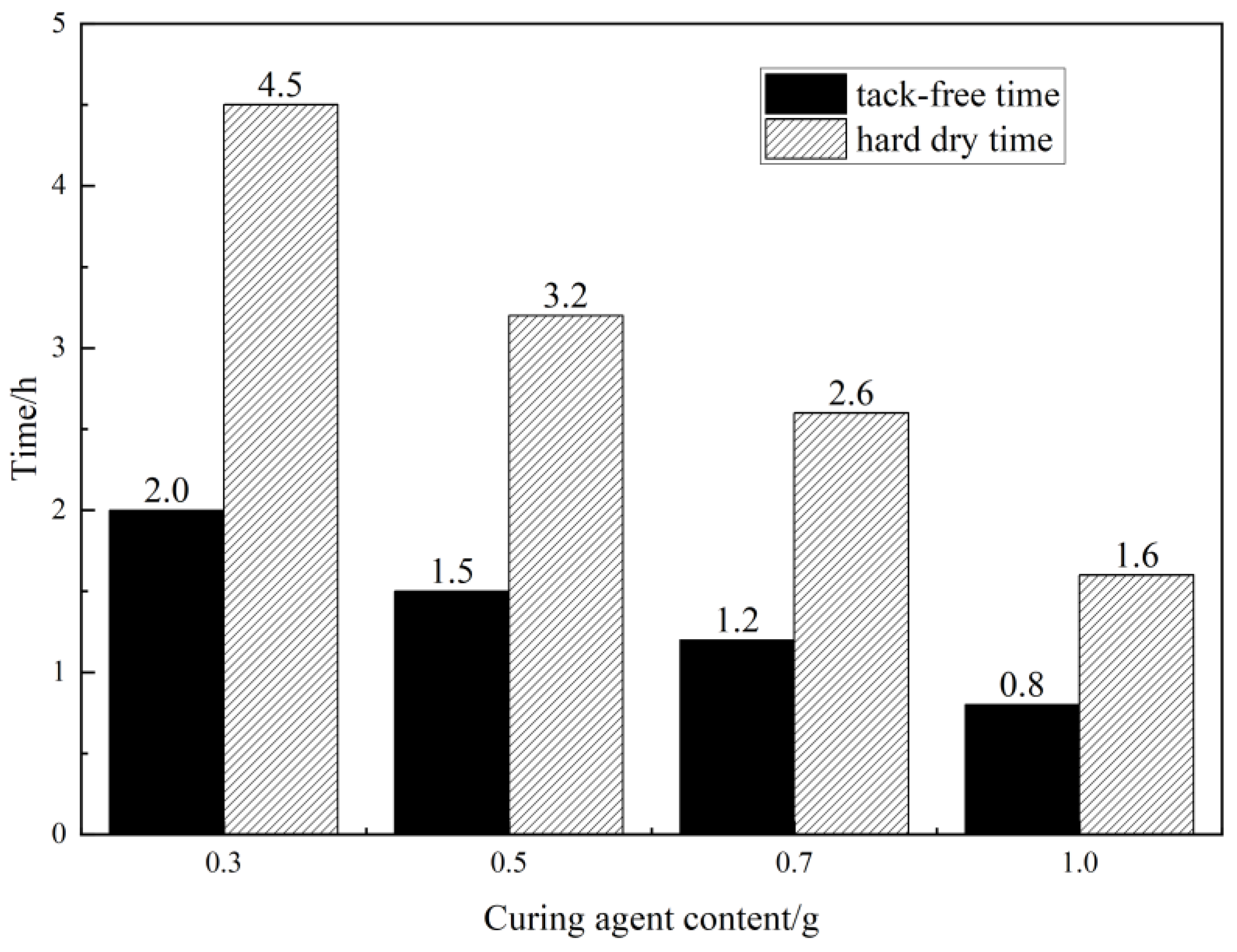

3.1.2. Effect of Preparation Technology on the 60-Min Drying Time

3.1.3. Effect of Preparation Technology on the 60-Min Bond Strength

3.2. Optimization of the Composition for the Penetrating Repair Material

3.2.1. Penetration Depth

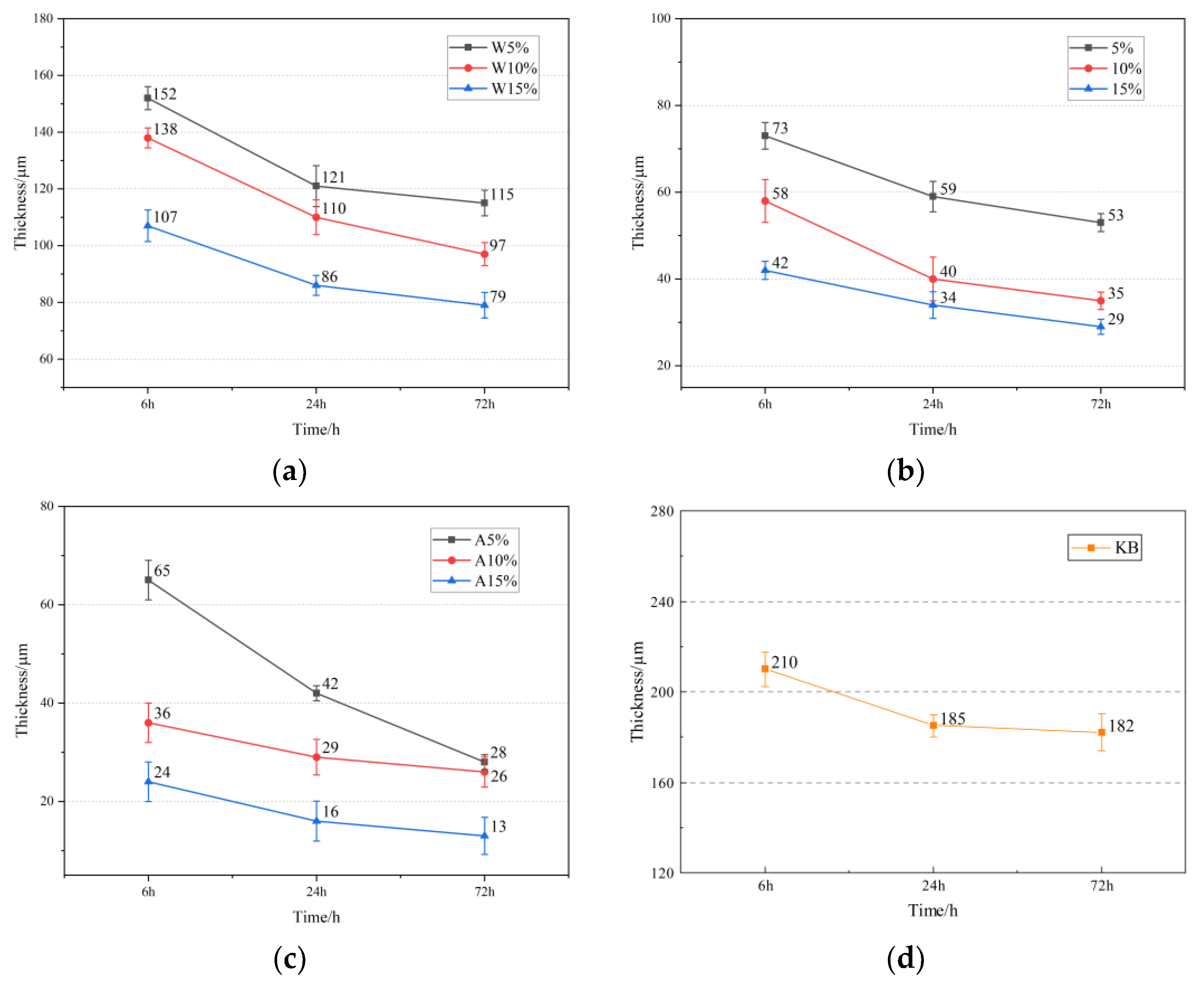

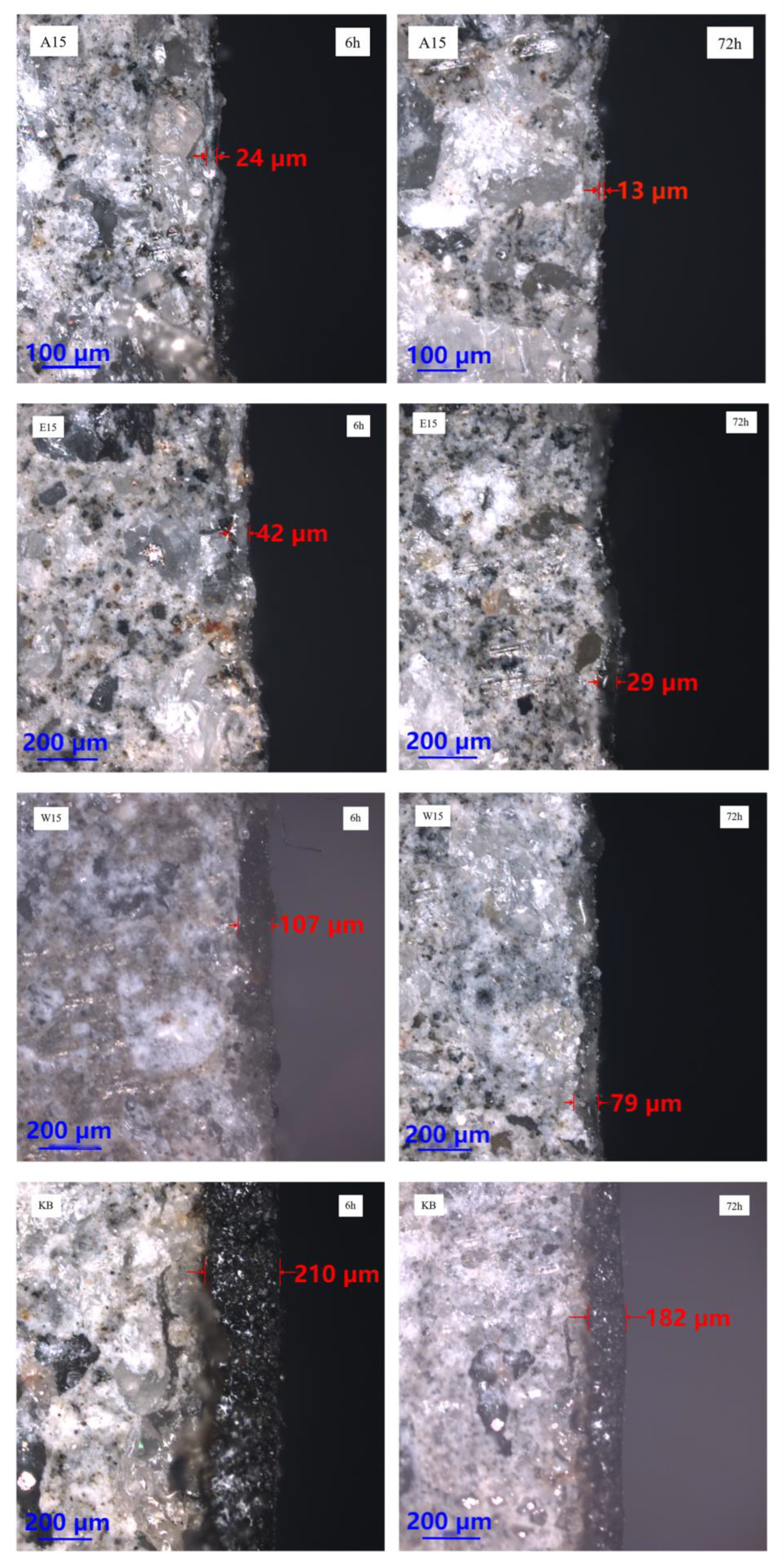

3.2.2. Surface Film Thickness

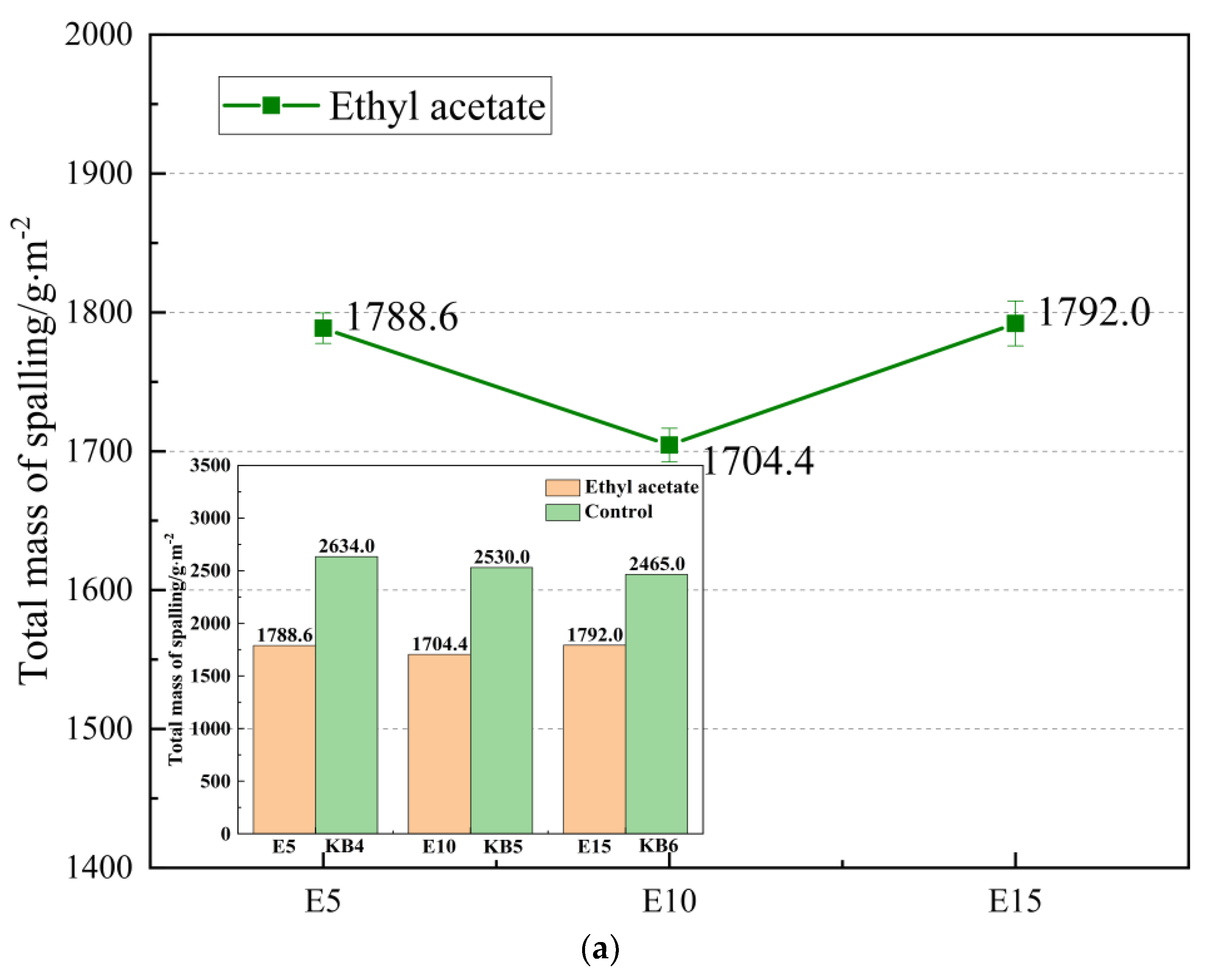

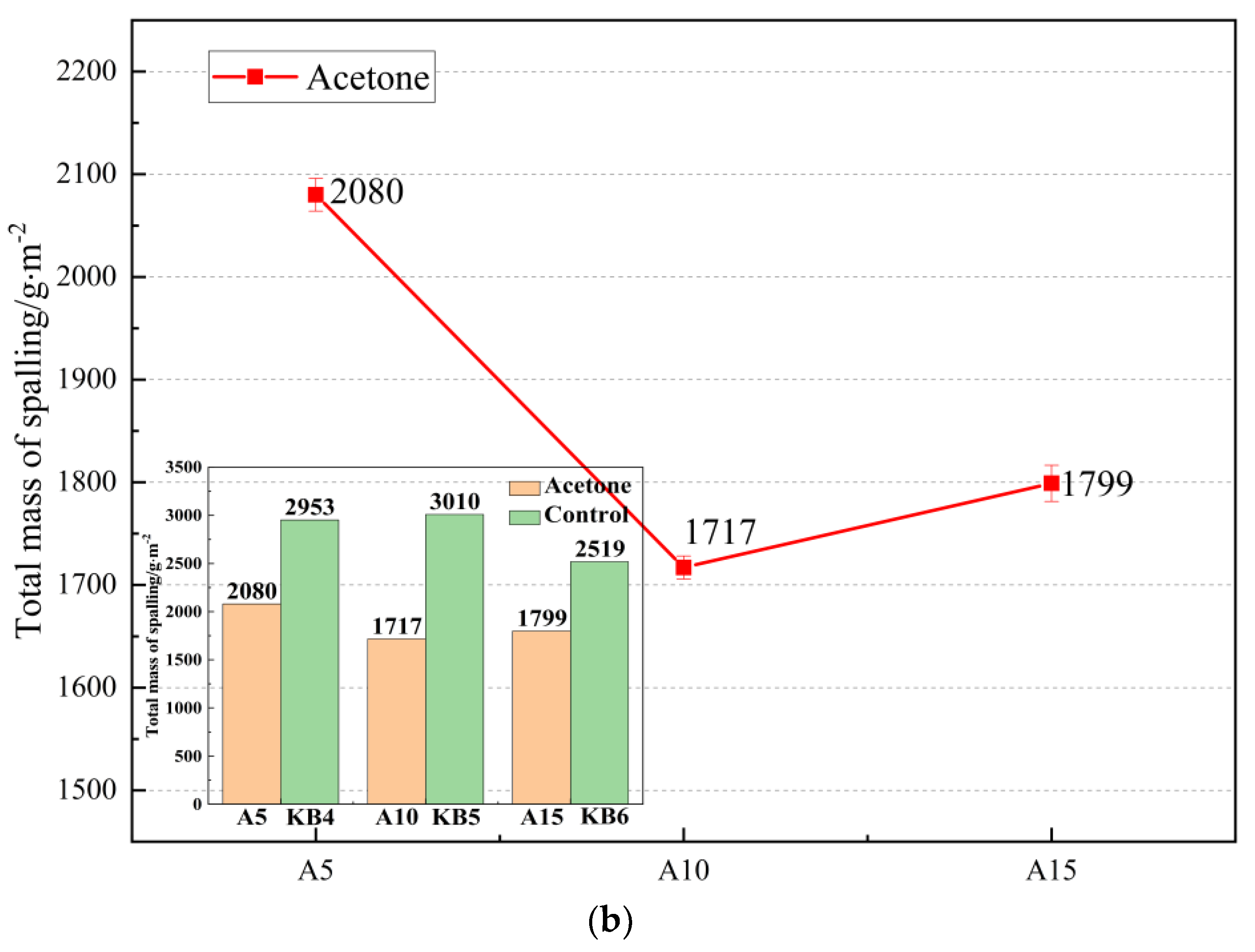

3.2.3. Freeze–Thaw Cycling Test

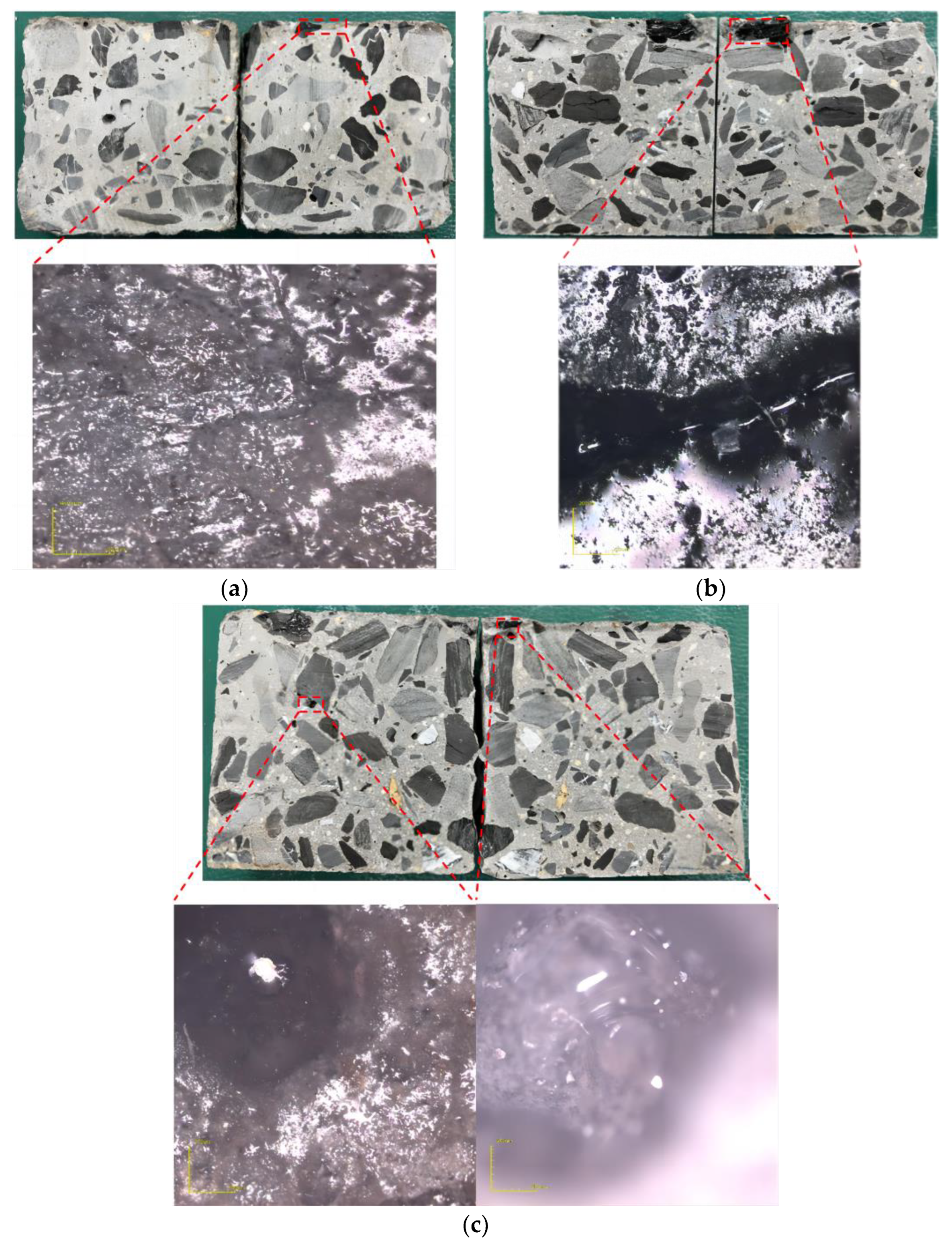

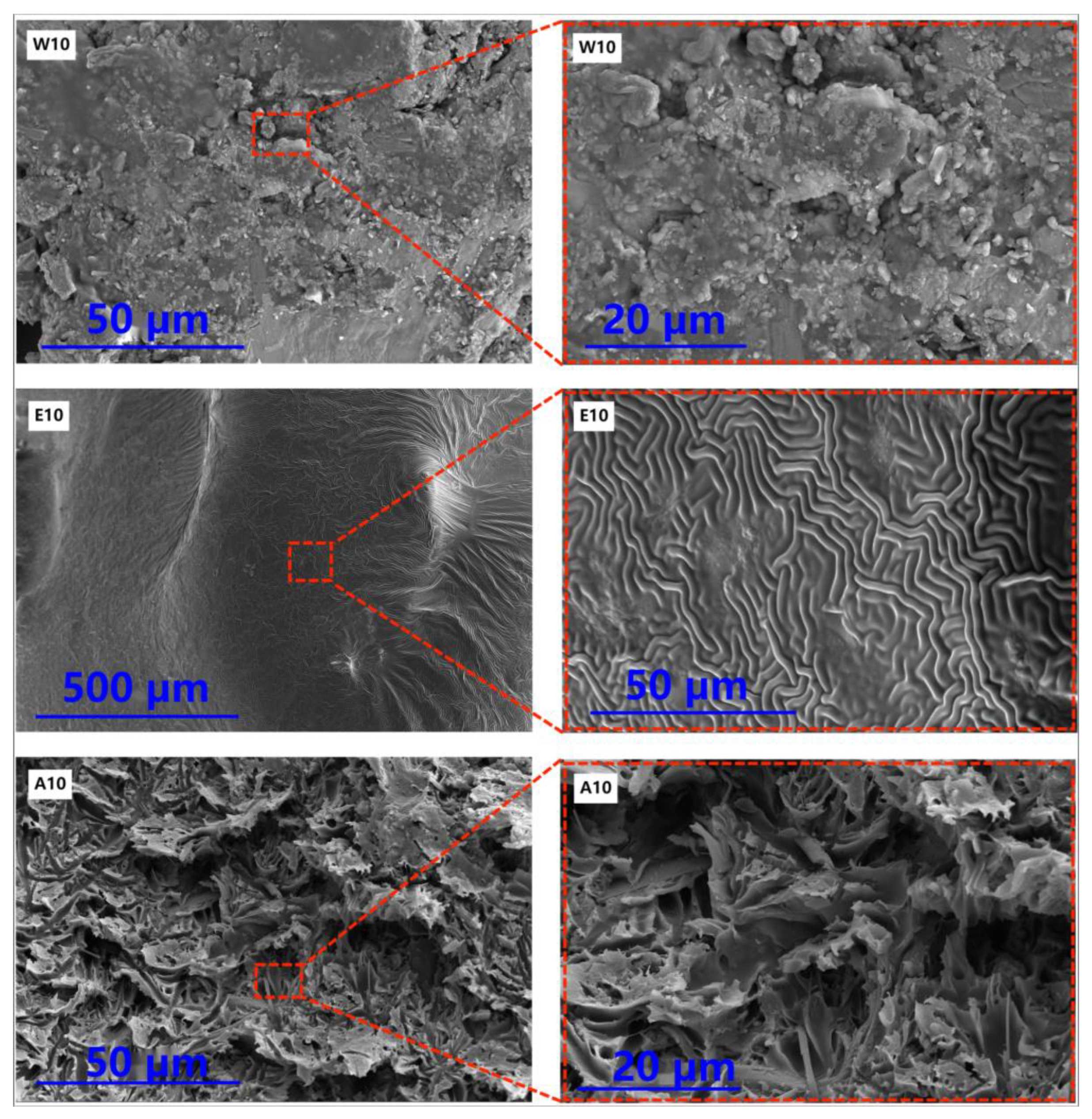

3.2.4. SEM

4. Conclusions

- In general, the optimum amount of curing agent is determined by adjusting the content of the curing agent. Then, by adding diluent, the repair material has good infiltration performance and can be consolidated in a certain depth of concrete surface, forming a “rooted type” filling so that the mechanical strength and durability of the concrete surface can be improved.

- It was found that the 60-min average viscosity of the repair material increased first and then decreased as the content of DMA added was 0.3%, 0.5%, 0.7%, and 1%. When the reaction time reached 40–60 min, the viscosity of the system increased significantly. The viscosity of the repair material with 1% DMA content reached 284 mPa·s at 60 min, which was 46.12% higher than that of 0.3% DMA on average. Considering the controllability of viscosity and the prevention of explosion, DMA content in the range of 0.3–0.5% is more suitable.

- After conducting surface-drying time, through-drying time, and bonding strength tests, it was found that the surface-drying time and through-drying time of the repair material with 1% DMA content were 0.8 h and 1.5 h, respectively, which were 60% and 67% shorter than those of the repair material with 0.3% DMA content. However, excessive addition of the curing agent can lead to a sharp increase in the reaction of the repair material, resulting in the formation of tiny bubbles. When the curing agent content was 0.5%, the bonding strength reached its peak, with values of 10.99 MPa and 9.24 MPa at the dry interface and wet interface, respectively. Therefore, the optimal curing agent content was determined to be 0.5%.

- A comparison study of three different diluents showed that sample E10 had a penetration depth of 24 mm and a film thickness of only 35 µm after 72 h. After the freeze–thaw cycling test, E10 showed the best protective performance for concrete, with an average peeling strength of only 1704.4 g/m². SEM showed that the polymer formed a tightly interwoven protective film on the surface of the cement paste, effectively preventing the ingress of corrosive substances.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Si-pei, L.I. Some Common Quality Defects on Cement Concrete Pavement and Precautions. Sci-Tech Inf. Dev. Econ. 2009, 9, 230–232. [Google Scholar]

- Berrocal, C.G.; Löfgren, I.; Lundgren, K.; Tang, L. Corrosion initiation in cracked fibre reinforced concrete: Influence of crack width, fibre type and loading conditions. Corros. Sci. 2015, 98, 128–139. [Google Scholar] [CrossRef]

- Basheer, L.; Kropp, J.; Cleland, D.J. Assessment of the durability of concrete from its permeation properties: A review. Constr. Build. Mater. 2001, 15, 93–103. [Google Scholar] [CrossRef]

- Flores-Vivian, I.; Hejazi, V.; Kozhukhova, M.I.; Nosonovsky, M.; Sobolev, K. Self-Assembling Particle-Siloxane Coatings for Superhydrophobic Concrete. ACS Appl. Mater. Inter. 2013, 5, 13284–13294. [Google Scholar] [CrossRef]

- Fardin, H.E.; Santos, A.G.D. Predicted responses of fatigue cracking and rutting on Roller Compacted Concrete base composite pavements. Constr. Build. Mater. 2021, 272, 121847. [Google Scholar] [CrossRef]

- Xiao, Y.; Erkens, S.; Li, M.; Ma, T.; Liu, X. Sustainable Designed Pavement Materials. Materials 2020, 13, 1575. [Google Scholar] [CrossRef]

- Litina, C.; Al-Tabbaa, A. First generation microcapsule-based self-healing cementitious construction repair materials. Constr. Build. Mater. 2020, 255, 119389. [Google Scholar] [CrossRef]

- Cabrera, J.G.; Al-Hasan, A.S. Performance Properties of Concrete Repair Materials. Constr. Build. Mater. 1997, 11, 283–290. [Google Scholar] [CrossRef]

- Venkiteela, G.; Klein, M.; Najm, H.; Balaguru, P.N. Evaluation of the Compatibility of Repair Materials for Concrete Structures. Int. J. Concr. Struct. Mater. 2017, 11, 435–445. [Google Scholar] [CrossRef]

- Al-kahtani, M.S.M.; Zhu, H.; Ibrahim, Y.E.; Haruna, S.I. Experimental study on the strength and durability-related properties of ordinary Portland and rapid hardening Portland cement mortar containing polyurethane binder. Case Stud. Constr. Mater. 2022, 17, e1530. [Google Scholar] [CrossRef]

- Feng, H.; Lu, L.; Chen, J.; Wang, G.; Zhang, Y. Influence of fly ash/silica fume composite admixtureson the performance of cement paste. Appl. Chem. Ind. 2014, 43, 389–391, 394. [Google Scholar]

- Wu, R.; Wang, X. Progress in Polyurethane Based Road Repair Materials. J. Mater. Sci. Eng. 2021, 39, 163, 164–166. [Google Scholar]

- Lee, S. Mechanical Properties and Durability of Mortars Made with Organic-Inorganic Repair Material. J. Test. Eval. 2021, 49, 4378–4389. [Google Scholar] [CrossRef]

- Zhang, G.; Zhu, Z.; Ma, C.; Zhang, G. Organic/inorganic dual network formed by epoxy and cement. Polym. Compos. 2018, 39, E2490–E2496. [Google Scholar] [CrossRef]

- Kim, T.K.; Park, J.S. Experimental Evaluation of the Durability of Concrete Repair Materials. Appl. Sci. 2021, 11, 2303. [Google Scholar] [CrossRef]

- Hassan, K.E.; Brooks, J.J.; Al-Alawi, L. Compatibility of repair mortars with concrete in a hot-dry environment. Cem. Concr. Compos. 2001, 23, 93–101. [Google Scholar] [CrossRef]

- Khalina, M.; Beheshty, M.H.; Salimi, A. The effect of reactive diluent on mechanical properties and microstructure of epoxy resins. Polym. Bull. 2019, 76, 3905–3927. [Google Scholar] [CrossRef]

- Pang, B.; Jin, Z.; Zhang, Y.; Xu, L.; Li, M.; Wang, C.; Zhang, Y.; Yang, Y.; Zhao, P.; Bi, J.; et al. Ultraductile waterborne epoxy-concrete composite repair material: Epoxy-fiber synergistic effect on flexural and tensile performance. Cem. Concr. Compos. 2022, 129, 104463. [Google Scholar] [CrossRef]

- Li, X.; Hao, M.; Zhong, Y.; Zhang, B.; Wang, F.; Wang, L. Experimental study on the diffusion characteristics of polyurethane grout in a fracture. Constr. Build. Mater. 2021, 273, 121711. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wei, T.; Li, Z.; Jiang, S.Z.; Xue, X.L. Study and Application of CW Epoxy Resin Chemical Grouting Materials. J. Yangtze River Sci. Res. Inst. 2011, 28, 167–170. [Google Scholar]

- Issa, C.A.; Debs, P. Experimental study of epoxy repairing of cracks in concrete. Constr. Build. Mater. 2007, 21, 157–163. [Google Scholar] [CrossRef]

- Safan, M.A.; Etman, Z.A.; Konswa, A. Evaluation of polyurethane resin injection for concrete leak repair. Case Stud. Constr. Mater. 2019, 11, e307. [Google Scholar] [CrossRef]

- Han, J.; Xu, L.; Feng, T.; Shi, X.; Zhang, P. Effect of PCE on Properties of MMA-Based Repair Material for Concrete. Materials 2021, 14, 859. [Google Scholar] [CrossRef] [PubMed]

- Sabah, S.A.; Hassan, M.H.; Bunnori, N.M.; Johari, M.M. Bond strength of the interface between normal concrete substrate and GUSMRC repair material overlay. Constr. Build. Mater. 2019, 216, 261–271. [Google Scholar] [CrossRef]

- Besheli, A.E.; Samimi, K.; Nejad, F.M.; Darvishan, E. Improving concrete pavement performance in relation to combined effects of freeze–thaw cycles and de-icing salt. Constr. Build. Mater. 2021, 277, 122273. [Google Scholar] [CrossRef]

- Pojman, J.A. Cure-on-Demand Composites by Frontal Polymerization. In Encyclopedia of Materials: Plastics and Polymers; Hashmi, M.S.J., Ed.; Elsevier: Oxford, UK, 2022; pp. 85–100. ISBN 978-0-12-823291-0. [Google Scholar]

- Cui, Y.; Tan, Z.; An, C. Research and application of multi-functional acrylic resin grouting material. Constr. Build. Mater. 2022, 359, 129381. [Google Scholar] [CrossRef]

- Looney, T.; Leggs, M.; Volz, J.; Floyd, R. Durability and corrosion resistance of ultra-high performance concretes for repair. Constr. Build. Mater. 2022, 345, 128238. [Google Scholar] [CrossRef]

- Krainer, S.; Hirn, U. Contact angle measurement on porous substrates: Effect of liquid absorption and drop size. Colloids Surf. A Physicochem. Eng. Asp. 2021, 619, 126503. [Google Scholar] [CrossRef]

- Fitzsimons, B.; Parry, T. Paint and Coating Failures and Defects. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-12-803581-8. [Google Scholar]

| Water | Cement | Sand | Coarse Aggregate |

|---|---|---|---|

| 205 kg/ | 340 kg/ | 705 kg/ | 1150 kg/ |

| NO. | MMA /g | BPO /% | DBP /% | DMA /% | PCE /% | Anhydrous Ethanol /% | Ethyl Acetate /% | Acetone /% |

|---|---|---|---|---|---|---|---|---|

| KB | 80 | 1.5 | 30 | 0.5 | 10 | 0 | 0 | 0 |

| W5 | 80 | 1.5 | 30 | 0.5 | 10 | 5 | 0 | 0 |

| W10 | 80 | 1.5 | 30 | 0.5 | 10 | 10 | 0 | 0 |

| W15 | 80 | 1.5 | 30 | 0.5 | 10 | 15 | 0 | 0 |

| E5 | 80 | 1.5 | 30 | 0.5 | 10 | 0 | 5 | 0 |

| E10 | 80 | 1.5 | 30 | 0.5 | 10 | 0 | 10 | 0 |

| E15 | 80 | 1.5 | 30 | 0.5 | 10 | 0 | 15 | 0 |

| A5 | 80 | 1.5 | 30 | 0.5 | 10 | 0 | 0 | 5 |

| A10 | 80 | 1.5 | 30 | 0.5 | 10 | 0 | 0 | 10 |

| A15 | 80 | 1.5 | 30 | 0.5 | 10 | 0 | 0 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Mao, Z.; Huang, X.; Deng, M. Preparation and Performance of Repair Materials for Surface Defects in Pavement Concrete. Materials 2023, 16, 2439. https://doi.org/10.3390/ma16062439

Li P, Mao Z, Huang X, Deng M. Preparation and Performance of Repair Materials for Surface Defects in Pavement Concrete. Materials. 2023; 16(6):2439. https://doi.org/10.3390/ma16062439

Chicago/Turabian StyleLi, Pengfei, Zhongyang Mao, Xiaojun Huang, and Min Deng. 2023. "Preparation and Performance of Repair Materials for Surface Defects in Pavement Concrete" Materials 16, no. 6: 2439. https://doi.org/10.3390/ma16062439

APA StyleLi, P., Mao, Z., Huang, X., & Deng, M. (2023). Preparation and Performance of Repair Materials for Surface Defects in Pavement Concrete. Materials, 16(6), 2439. https://doi.org/10.3390/ma16062439