Towards Understanding Subsurface Characteristics in Burn Process of Gear Profile Grinding

Abstract

:1. Introduction

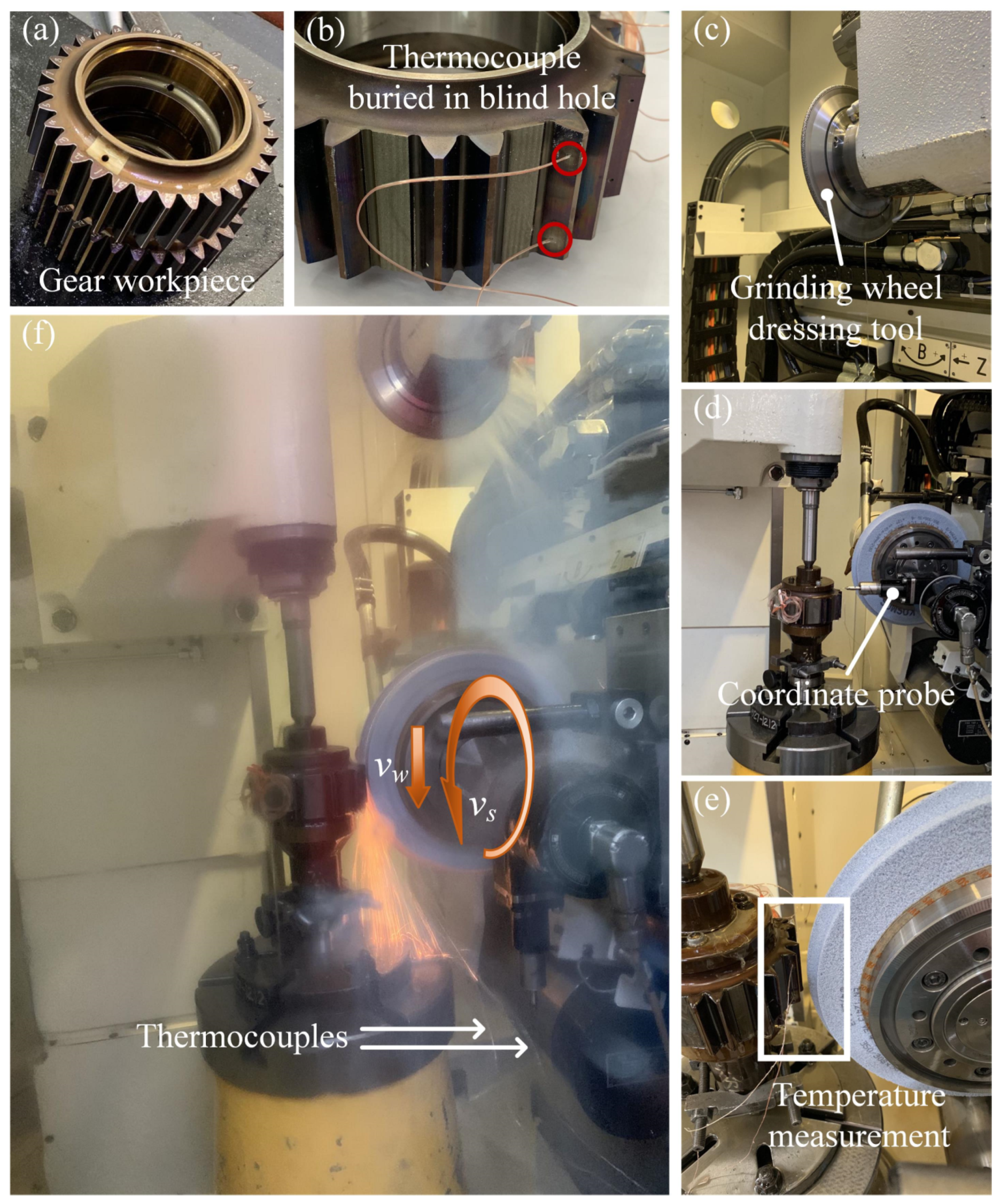

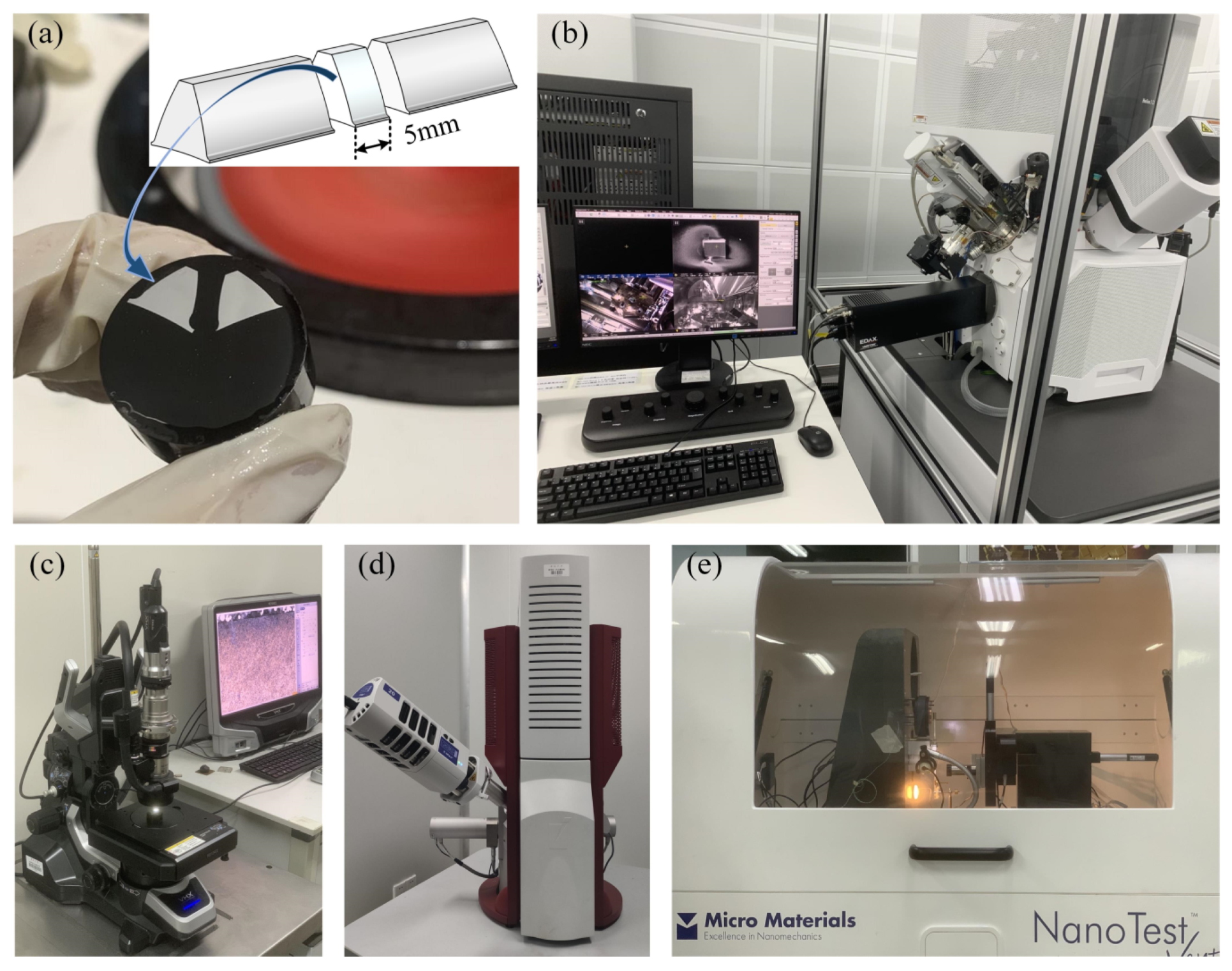

2. Experimental Details

2.1. Gear Profile Grinding Conditions

2.2. Characterization of Subsurface Layer Properties

3. Results and Discussion

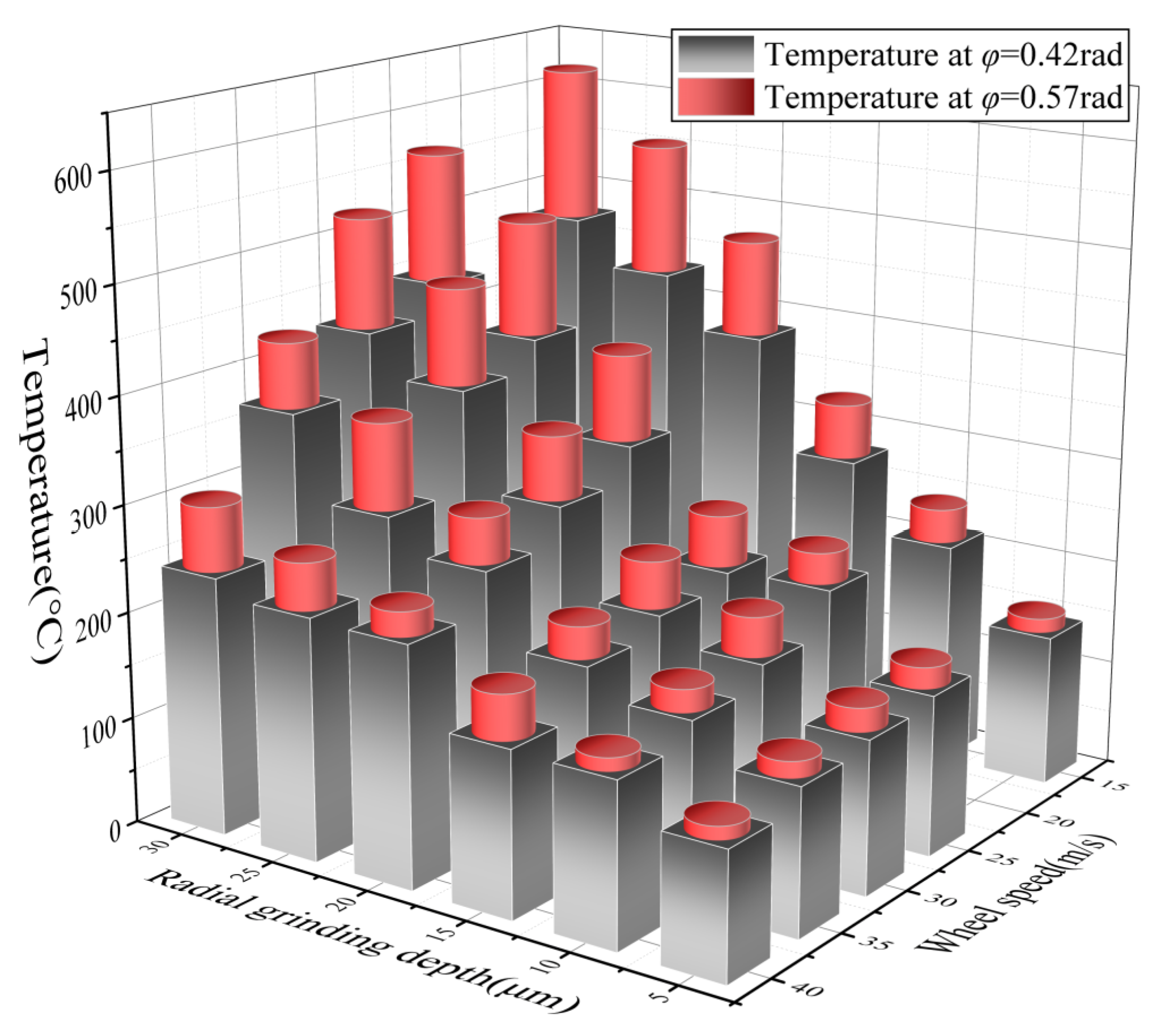

3.1. Determination of Grinding Burns

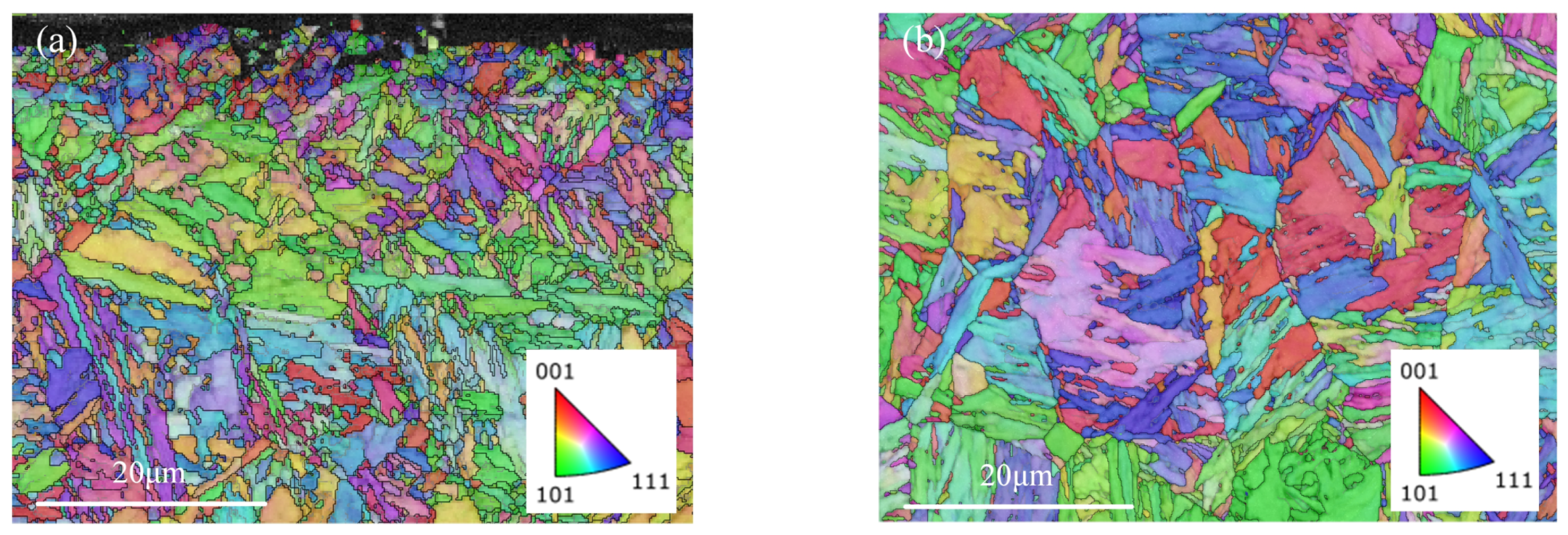

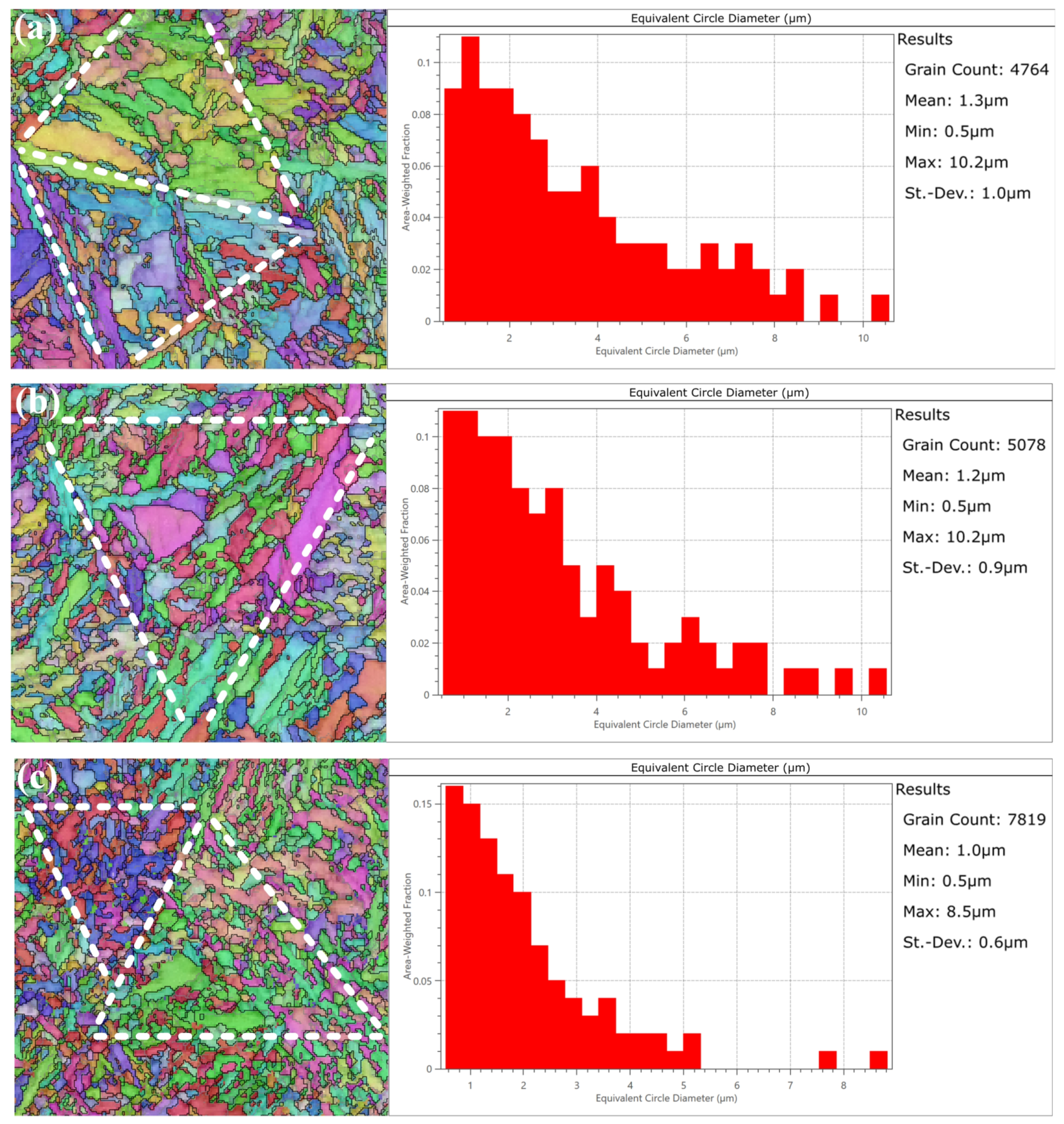

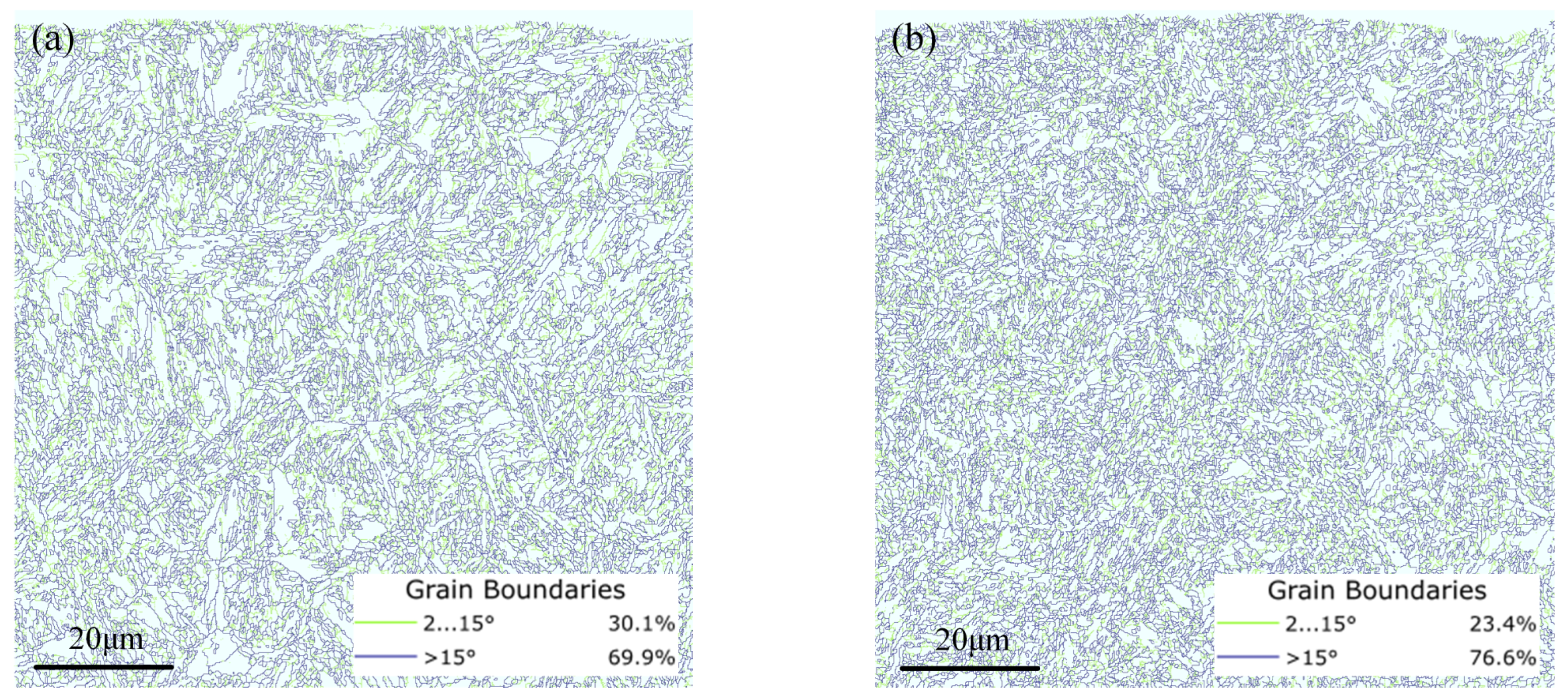

3.2. Microstructure Evolution and Burn Mechanism

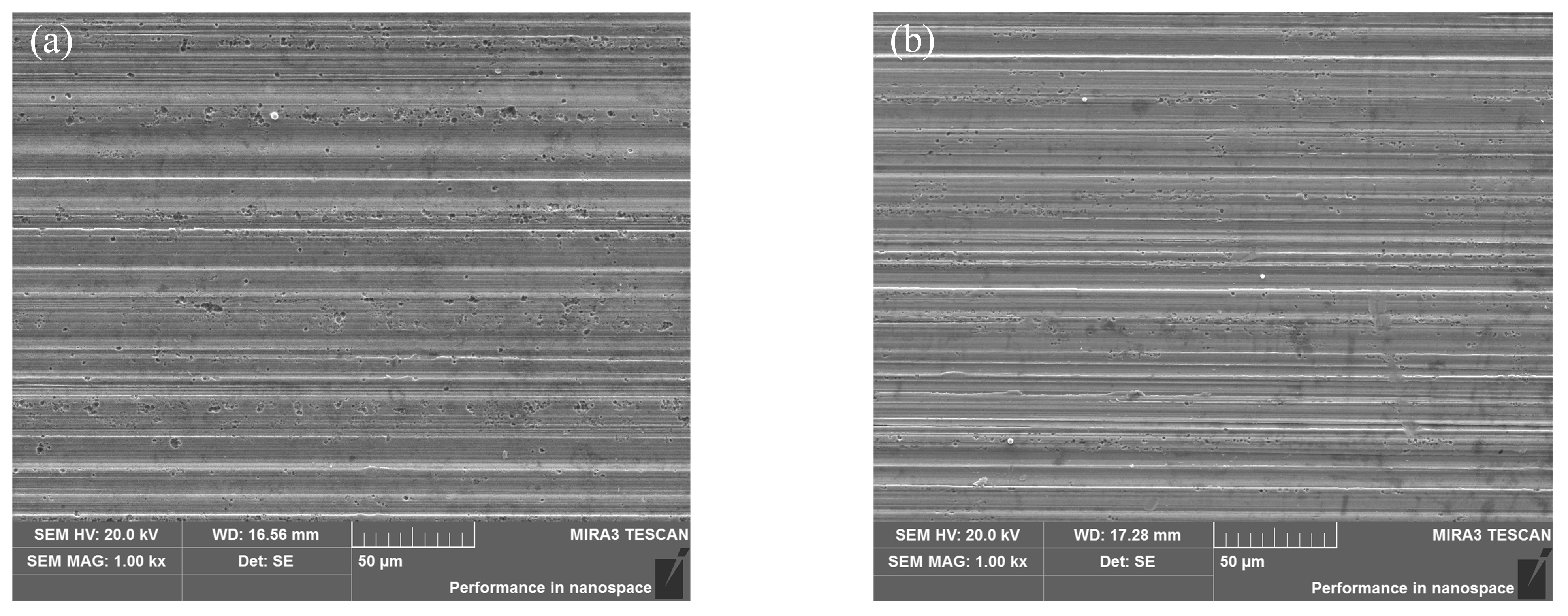

3.3. Subsurface Layer Properties Alteration in Burn Process

4. Conclusions

- (1)

- The increase in radial grinding depth is the most important factor leading to the increase in peak grinding temperature. With the increase in wheel speed, the peak grinding temperature showed a trend of a small increase and then a decrease. The temperature gradient between different rolling angle of the involute positions on the tooth flank was greatly influenced by the combination of grinding parameters. Radial grinding depths of more than 20 μm matched with wheel speeds below 30 m/s will result in severe grinding burns. The risk of burn can be significantly reduced at greater wheel speeds and lower radial grinding depth.

- (2)

- The EBSD results of grinding burn tooth show that the proportion of the large angle grain boundary is increased by 6.7% compared to the initial tooth. It suggests that the recrystallization occurs when the tempering burn happens. Tempering burn also results in the breakdown of high strength martensite and the formation of inhomogeneous secondary tempered sorbite.

- (3)

- The relationship between microstructure, grinding burn, and the mechanical properties of gear tooth is established. The substantial reduction in compressive residual stress and nano-hardness could be explained by the recovery and recrystallization of the tooth surface microstructure. Severe grinding burns can form tiny defects in the tooth surface near the tooth grinding grooves during the plowing stage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, G.; Wei, P.; Chen, K.; Liu, H.; Lu, Z. Polymer gear contact fatigue reliability evaluation with small data set based on machine learning. J. Comput. Des. Eng. 2022, 9, 583–597. [Google Scholar] [CrossRef]

- Muminovic, A.J.; Muminovic, A.; Mesic, E.; Saric, I.; Pervan, N. Spur Gear Tooth Topology Optimization: Finding Optimal Shell Thickness for Spur Gear Tooth produced using Additive Manufacturing. TEM J.-Technol. Educ. Manag. Inform. 2019, 8, 788–794. [Google Scholar]

- Hu, X.; Jiang, Y.; Luo, C.; Feng, L.; Dai, Y. Churning power losses of a gearbox with spiral bevel geared transmission. Tribol. Int. 2019, 129, 398–406. [Google Scholar] [CrossRef]

- Yan, Y.; Jiang, C.; Li, W. Simulation on coupling effects between surface wear and fatigue in spur gear. Eng. Fail. Anal. 2022, 134, 106055. [Google Scholar] [CrossRef]

- Raadnui, S. Condition monitoring of worm gear wear and wear particle analysis of industrial worm gear sets. Wear 2021, 476, 203687. [Google Scholar] [CrossRef]

- He, B.; Liu, L.; Zhang, D. Digital Twin-Driven Remaining Useful Life Prediction for Gear Performance Degradation: A Review. J. Comput. Inf. Sci. Eng. 2021, 21, 30801. [Google Scholar] [CrossRef]

- Rajinikanth, V.; Soni, M.K.; Mahato, B.; Rao, M.A. Microstructural investigation of rolling contact fatigue (RCF) on a failed planetary gear of a windmill gearbox. Eng. Fail. Anal. 2021, 121, 105167. [Google Scholar] [CrossRef]

- Zhou, W.; Tang, J.; Shao, W. Study on surface generation mechanism and roughness distribution in gear profile grinding. Int. J. Mech. Sci. 2020, 187, 105921. [Google Scholar] [CrossRef]

- Zhou, W.; Tang, J.; Shao, W.; Wen, J. Towards understanding the ploughing friction mechanism in ultrasonic assisted grinding with single grain. Int. J. Mech. Sci. 2022, 222, 107248. [Google Scholar] [CrossRef]

- Xia, C.; Wang, S.; Ma, C.; Wang, S.; Xiao, Y. Crucial geometric error compensation towards gear grinding accuracy enhancement based on simplified actual inverse kinematic model. Int. J. Mech. Sci. 2020, 169, 105319. [Google Scholar] [CrossRef]

- Wen, J.; Tang, J.; Zhou, W. Study on formation mechanism and regularity of residual stress in ultrasonic vibration grinding of high strength alloy steel. J. Manuf. Process. 2021, 66, 608–622. [Google Scholar] [CrossRef]

- Wen, J.; Zhou, W.; Tang, J.; Shao, W. Residual stress evolution for tooth double-flank by gear form grinding. J. Manuf. Process. 2022, 77, 754–769. [Google Scholar] [CrossRef]

- Su, J.; Ke, Q.; Deng, X.; Ren, X. Numerical simulation and experimental analysis of temperature field of gear form grinding. Int. J. Adv. Manuf. Technol. 2018, 97, 2351–2367. [Google Scholar] [CrossRef]

- Heinzel, C.; Heinzel, J.; Guba, N.; Huesemann, T. Comprehensive analysis of the thermal impact and its depth effect in grinding. CIRP Ann.-Manuf. Technol. 2021, 70, 289–292. [Google Scholar] [CrossRef]

- Huesemann, T.; Saddei, P.; Karpuschewski, B. Discontinuous profile grinding of multi-phase, case-hardened gears with improved load-carrying capacity. CIRP Ann.-Manuf. Technol. 2019, 68, 333–336. [Google Scholar] [CrossRef]

- Guerrini, G.; Landi, E.; Peiffer, K.; Fortunato, A. Dry grinding of gears for sustainable automotive transmission production. J. Clean. Prod. 2018, 176, 76–88. [Google Scholar] [CrossRef]

- Dychton, K.; Gradzik, A.; Kolek, L.; Raga, K. Evaluation of Thermal Damage Impact on Microstructure and Properties of Carburized AISI 9310 Gear Steel Grade by Destructive and Non-Destructive Testing Methods. Materials 2021, 14, 5276. [Google Scholar] [CrossRef]

- Wang, L.; Tang, X.; Wang, L.; Yang, N.; Chen, X.; Li, P.; Liu, G.; Liu, G. Mechanism of grinding-induced burns and cracks in 20CrMnTi steel gear. Mater. Manuf. Process. 2019, 34, 1143–1150. [Google Scholar] [CrossRef]

- Kang, B.; Ma, H.; Li, J.; Xu, B. Effect of grinding parameters on surface quality, microstructure and rolling contact fatigue behaviors of gear steel for vacuum pump. Vacuum 2020, 180, 109637. [Google Scholar] [CrossRef]

- Sun, C.; Liu, Z.; Lan, D.; Duan, J.; Xiu, S. Study on the influence of the grinding chatter on the workpiece’s microstructure transformation. Int. J. Adv. Manuf. Technol. 2018, 96, 3861–3879. [Google Scholar] [CrossRef]

- Sun, C.; Hong, Y.; Xiu, S.; Yao, Y. Grain refinement mechanism of metamorphic layers by abrasive grinding hardening. J. Manuf. Process. 2021, 69, 125–141. [Google Scholar] [CrossRef]

- Hong, Y.; Sun, C.; Xiu, S.; Deng, Y.; Yao, Y.; Kong, X. Phase evolution and strengthening mechanism induced by grinding hardening. Int. J. Adv. Manuf. Technol. 2022, 120, 5605–5622. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Y.; Xiu, S. Study on the dynamic recrystallization mechanism during pre-stress dry grinding. J. Manuf. Process. 2018, 32, 100–109. [Google Scholar] [CrossRef]

- Sun, C.; Xiu, S.; Hong, Y.; Kong, X.; Lu, Y. Prediction on residual stress with mechanical-thermal and transformation coupled in DGH. Int. J. Mech. Sci. 2020, 179, 105629. [Google Scholar] [CrossRef]

- Sackmann, D.; Karpuschewski, B.; Epp, J.; Jedamski, R. Detection of surface damages in ground spur gears by non-destructive micromagnetic methods. Forsch. Im Ing.-Eng. Res. 2019, 83, 563–570. [Google Scholar] [CrossRef]

- Teixeira, P.H.O.; Rego, R.R.; Pinto, F.W.; de Oliveira Gomes, J.; Loepenhaus, C. Application of Hall effect for assessing grinding thermal damage. J. Mater. Process. Technol. 2019, 270, 356–364. [Google Scholar] [CrossRef]

- Guba, N.; Heinzel, J.; Heinzel, C.; Karpuschewski, B. Grinding burn limits: Generation of surface layer modification charts for discontinuous profile grinding with analogy trials. CIRP J. Manuf. Sci. Technol. 2020, 31, 99–107. [Google Scholar] [CrossRef]

- Gao, Z.; Lin, J.; Wang, X.; Liao, Y. Grinding Burn Detection Based on Cross Wavelet and Wavelet Coherence Analysis by Acoustic Emission Signal. Chin. J. Mech. Eng. 2019, 32, 68. [Google Scholar] [CrossRef] [Green Version]

- Tavora, C.G.; Aguiar, P.R.; Castro, B.A.; Alexandre, F.A.; Andreoli, A.L.; Bianchi, E.C. Hinkley criterion applied to detection and location of burn in grinding process. Int. J. Adv. Manuf. Technol. 2021, 113, 3177–3188. [Google Scholar] [CrossRef]

- Gu, B.-P.; Yang, Z.-S.; Pan, L.; Wei, W. Evolution of the microstructure, mechanical properties, and high-order modal characteristics of AISI 1045 steel subjected to a simulative environment of surface grinding burn. Int. J. Adv. Manuf. Technol. 2016, 82, 253–263. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, X.; Gindy, N. Fuzzy pattern recognition of AE signals for grinding burn. Int. J. Mach. Tools Manuf. 2005, 45, 811–818. [Google Scholar] [CrossRef]

- Zhou, K.; Ding, H.; Wang, W.; Guo, J.; Liu, Q. Surface integrity during rail grinding under wet conditions: Full-scale experiment and multi-grain grinding simulation. Tribol. Int. 2022, 165, 107327. [Google Scholar] [CrossRef]

- Xiao, G.X.; Stevenson, R.; Hanna, I.M.; Hucker, S.A. Modeling of residual stress in grinding of nodular cast iron. J. Manuf. Sci. Eng.-Trans. ASME 2002, 124, 833–839. [Google Scholar] [CrossRef]

- Yang, Z.; Wu, H.; Yu, Z.; Huang, Y. A non-destructive surface burn detection method for ferrous metals based on acoustic emission and ensemble empirical mode decomposition: From laser simulation to grinding process. Meas. Sci. Technol. 2014, 25, 35602. [Google Scholar] [CrossRef]

- Lin, B.; Zhou, K.; Guo, J.; Liu, Q.Y.; Wang, W.J. Influence of grinding parameters on surface temperature and burn behaviors of grinding rail. Tribol. Int. 2018, 122, 151–162. [Google Scholar] [CrossRef]

- Jamshidi, H.; Budak, E. On the prediction of surface burn and its thickness in grinding processes. CIRP Ann.-Manuf. Technol. 2021, 70, 285–288. [Google Scholar] [CrossRef]

- Neslusan, M.; Cizek, J.; Kolarik, K.; Minarik, P.; Cillikova, M.; Melikhova, O. Monitoring of grinding burn via Barkhausen noise emission in case-hardened steel in large-bearing production. J. Mater. Process. Technol. 2017, 240, 104–117. [Google Scholar] [CrossRef]

- Zheng, G.; Mao, X.; Li, L.; Dang, R. The variation of microstructures, textures and mechanical properties from edge to center in cross section of Ti6242s titanium alloy. Vacuum 2019, 160, 81–88. [Google Scholar] [CrossRef]

| Gear Parameter | Value |

|---|---|

| Modulus (mm) | 3.8788 |

| Number of teeth | 31 |

| Pressure angle (°) | 28 |

| Flank width (mm) | 45 |

| Element | C | Mn | Si | S | P | Cr | Ni |

|---|---|---|---|---|---|---|---|

| Composition (%) | 0.1~0.15 | 0.3~0.6 | 0.17~0.37 | ≤0.015 | ≤0.025 | 1.25~1.75 | 3.25~3.75 |

| Material | k (W/(m·K)) | c (J/(kg·K)) | ρ (kg/m3) | α (1/K) |

|---|---|---|---|---|

| 12Cr2Ni4A | 28 | 547 | 7840 | 1.3 × 10−5 |

| Processing Parameter | Value |

|---|---|

| Feed speed (mm/min) | 1200 |

| Maximum diameter of wheel (mm) | 286 |

| Abrasive type | Ceramic grain (30% Cubitron 321) |

| Abrasive size | 80 |

| Radial grinding depth (μm) | 5 10 15 20 25 30 |

| Wheel speed (m/s) | 15 25 30 35 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, J.; Tang, J.; Shao, W.; Zhou, W.; Huang, W. Towards Understanding Subsurface Characteristics in Burn Process of Gear Profile Grinding. Materials 2023, 16, 2493. https://doi.org/10.3390/ma16062493

Wen J, Tang J, Shao W, Zhou W, Huang W. Towards Understanding Subsurface Characteristics in Burn Process of Gear Profile Grinding. Materials. 2023; 16(6):2493. https://doi.org/10.3390/ma16062493

Chicago/Turabian StyleWen, Jun, Jinyuan Tang, Wen Shao, Weihua Zhou, and Weiwei Huang. 2023. "Towards Understanding Subsurface Characteristics in Burn Process of Gear Profile Grinding" Materials 16, no. 6: 2493. https://doi.org/10.3390/ma16062493