Mechanical Properties under Compression and Microscopy Analysis of Basalt Fiber Reinforced Recycled Aggregate Concrete

Abstract

1. Introduction

2. Methods and Materials

2.1. Materials

2.2. Design of Mixture Proportions

2.3. Loading and Characterization of Specimens

3. Results and Discussion

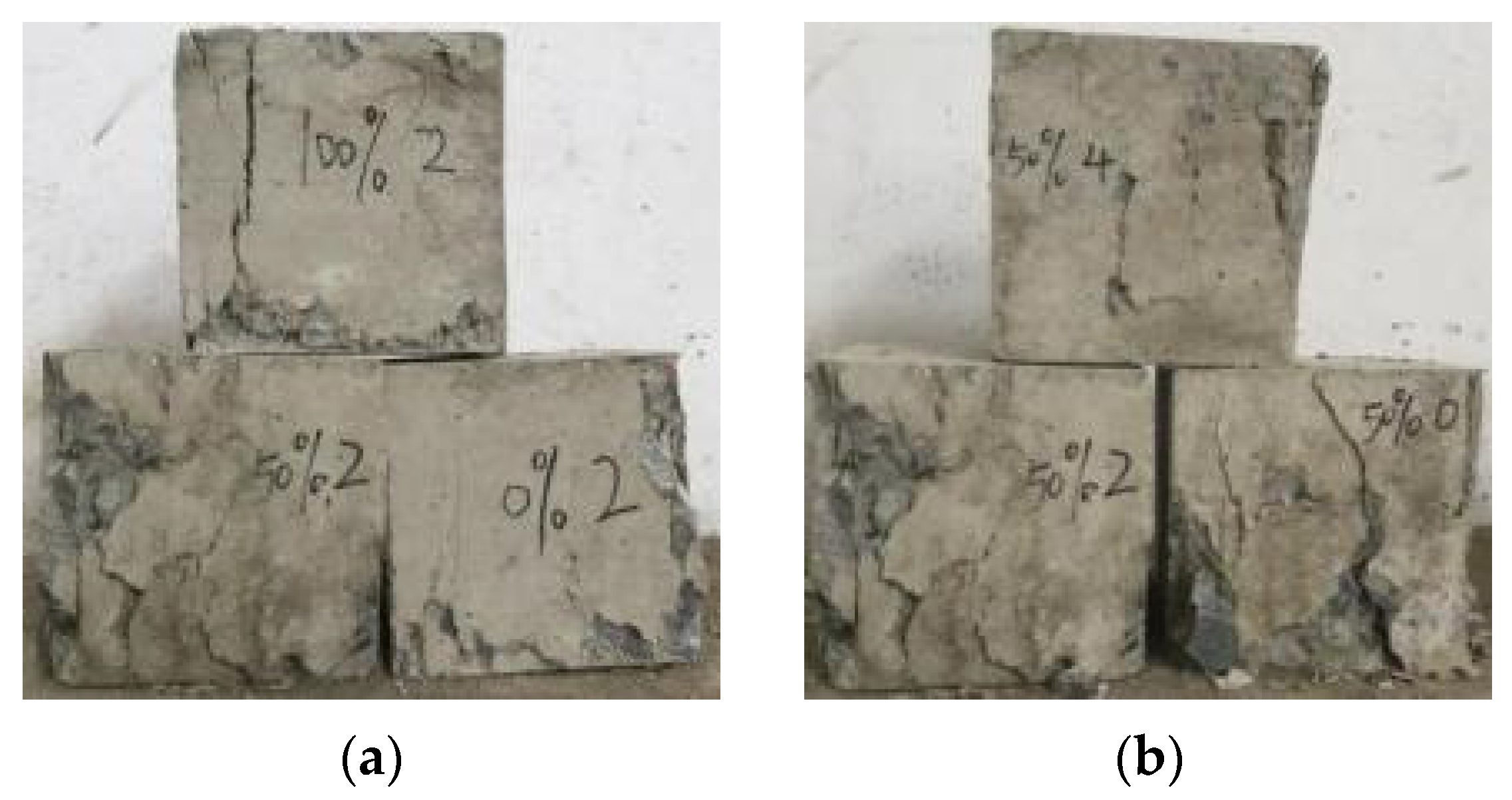

3.1. Failure Process and Morphology

3.1.1. Cubic Compression Failure

3.1.2. Axial Compression Failure

3.2. Test Result

3.3. Analysis of Influencing Factors

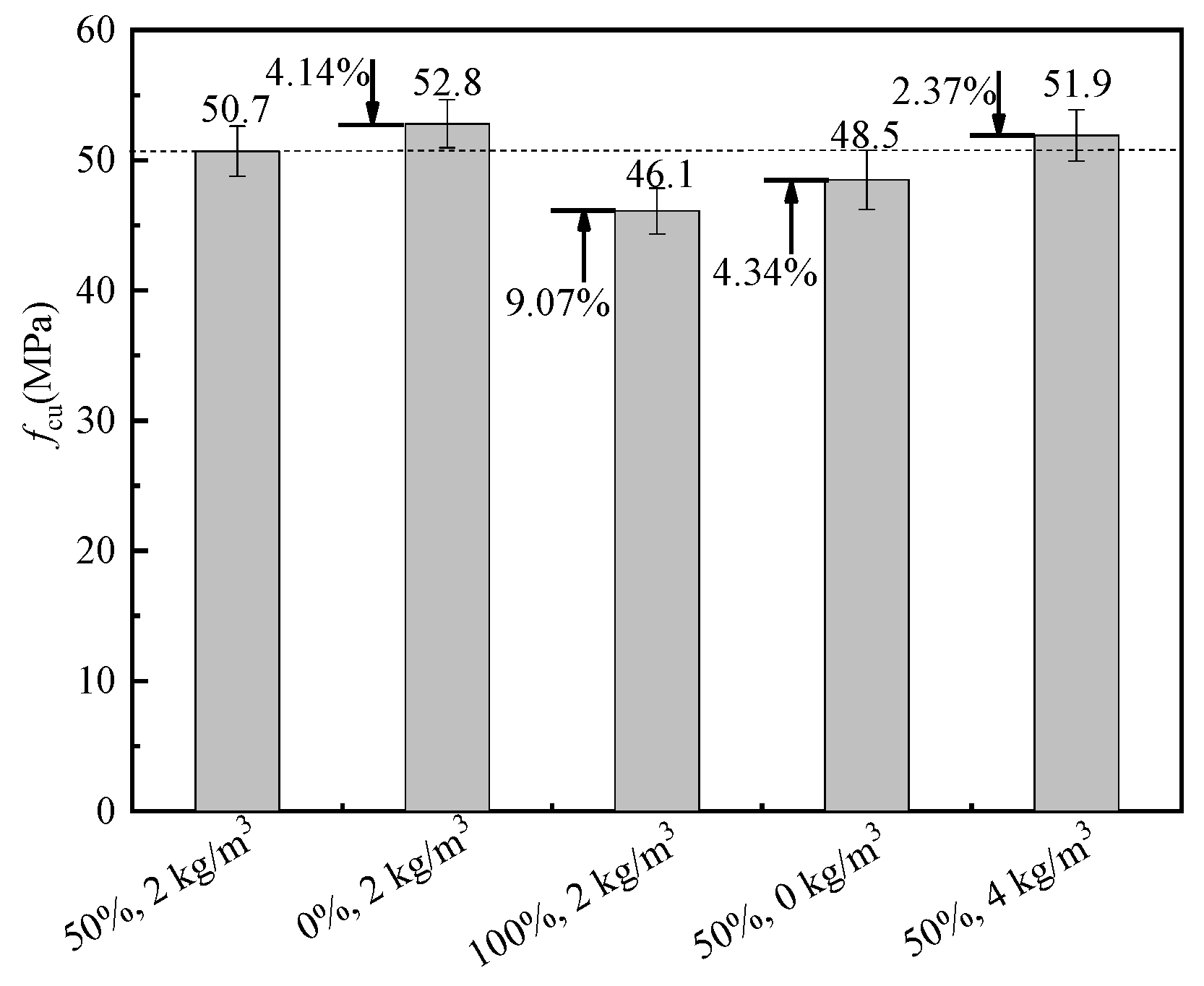

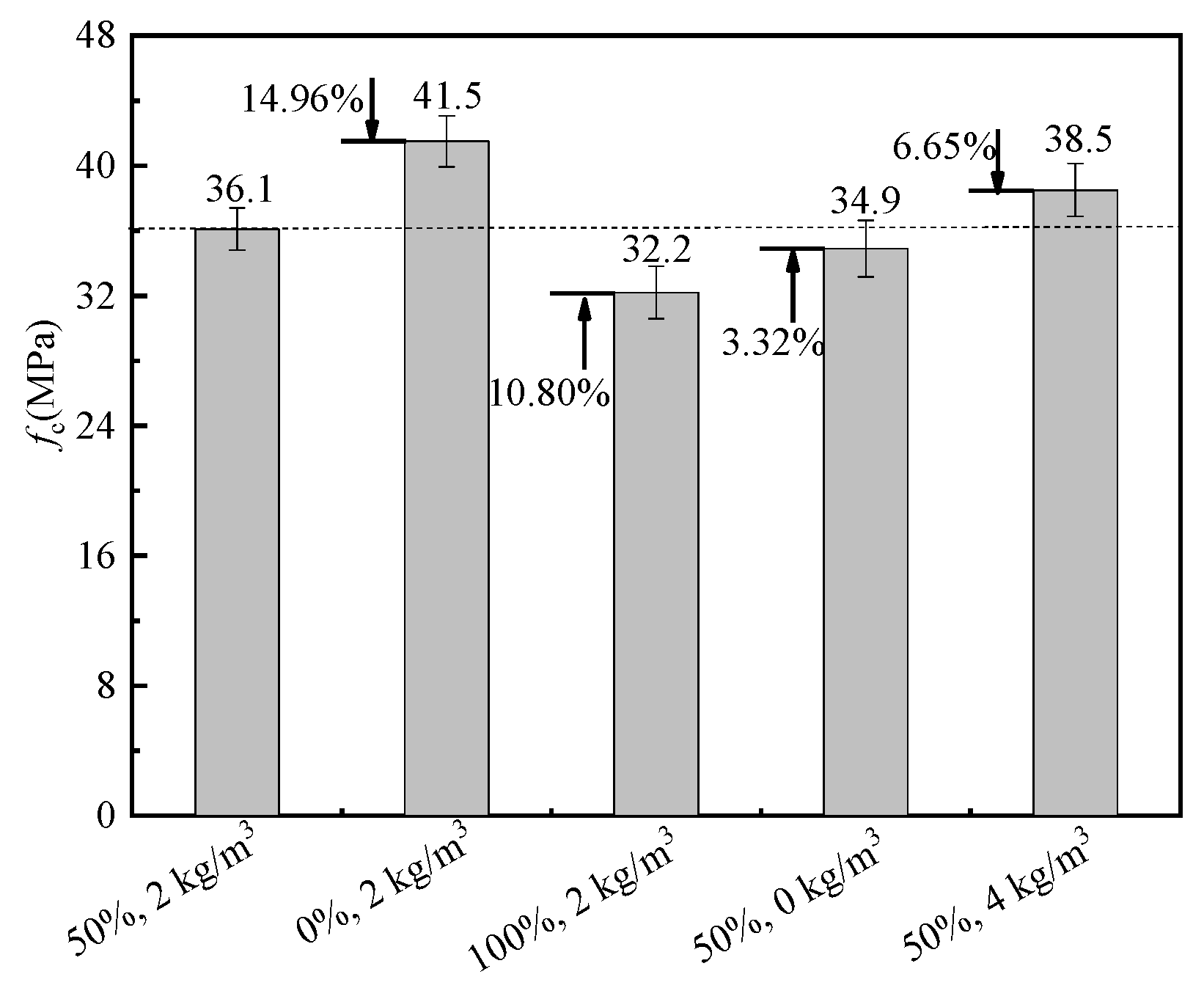

3.3.1. Compressive Strength

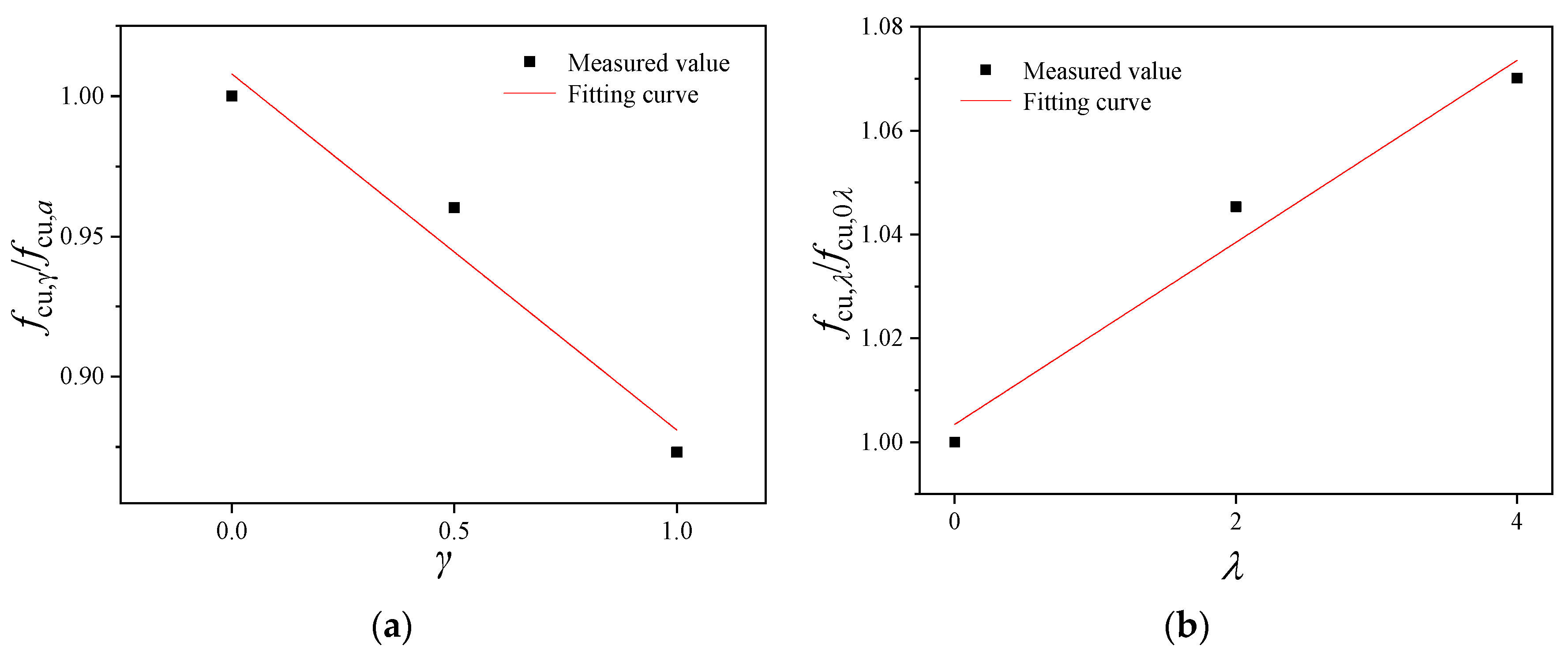

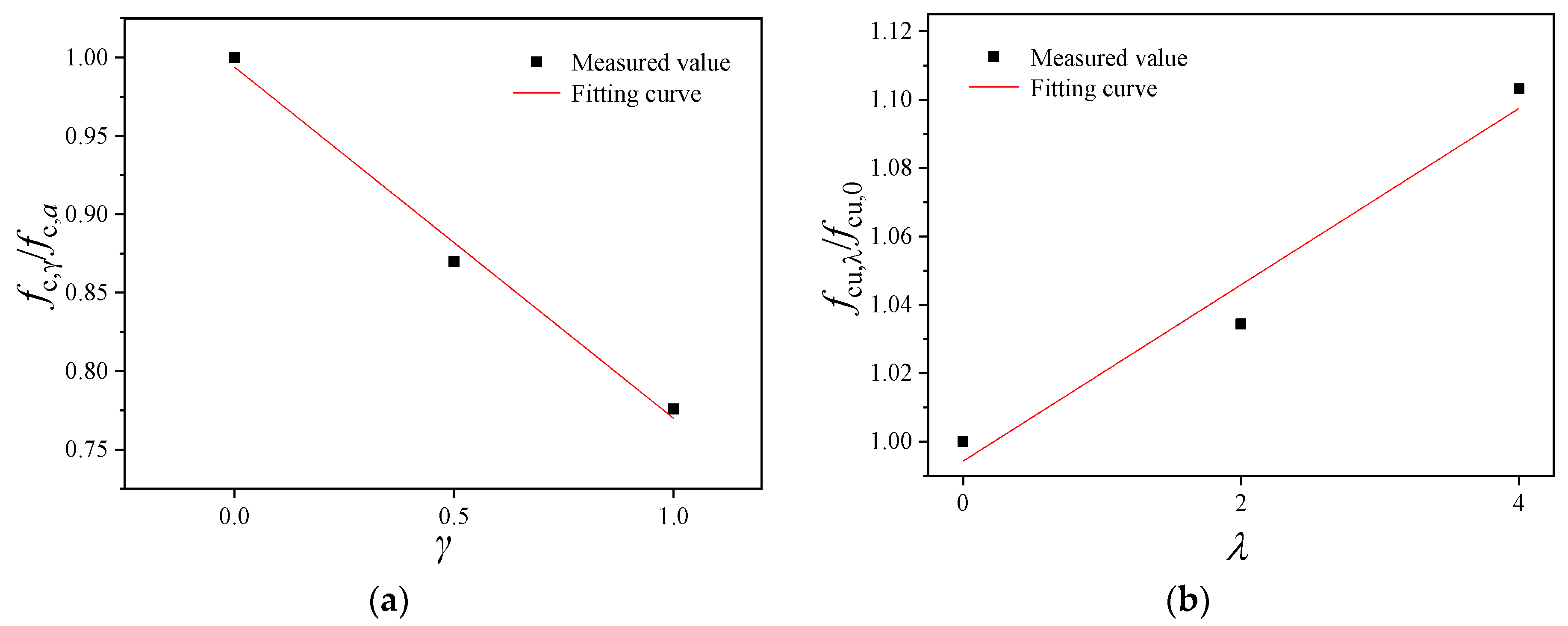

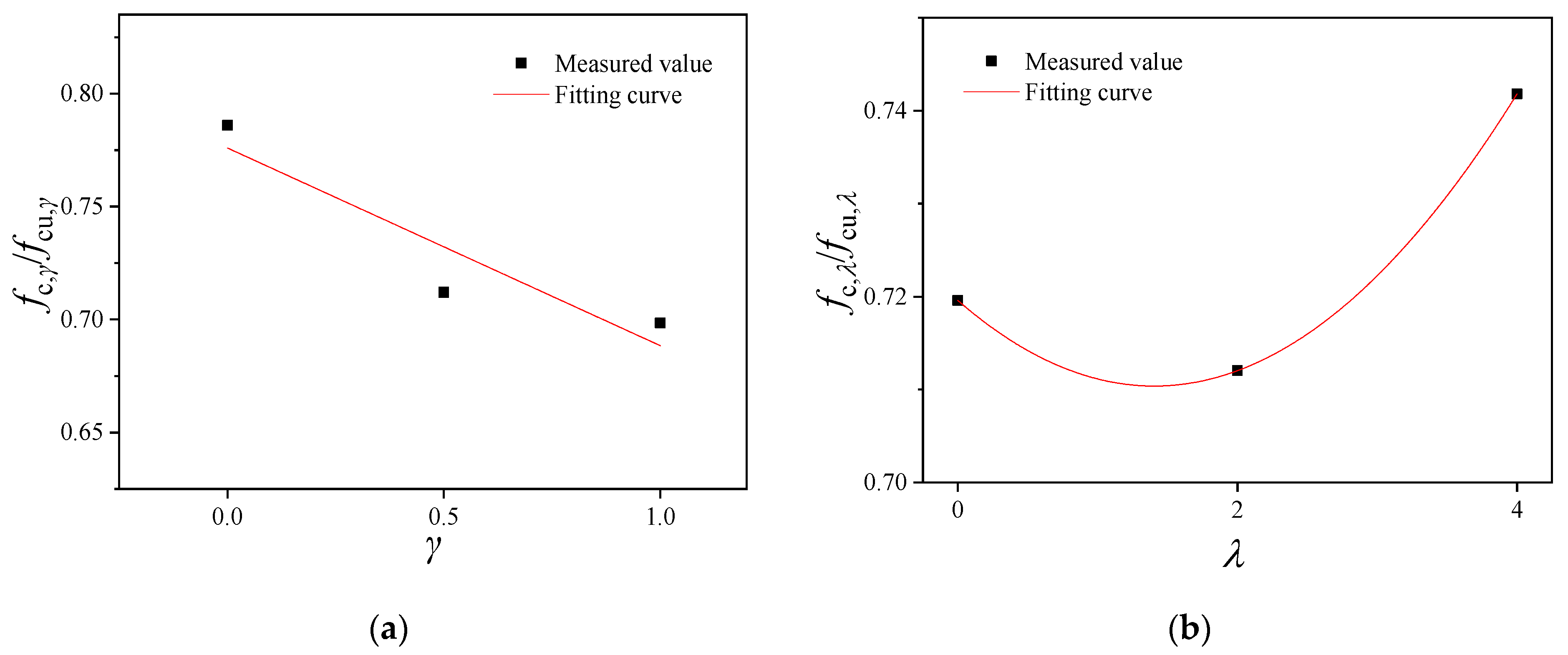

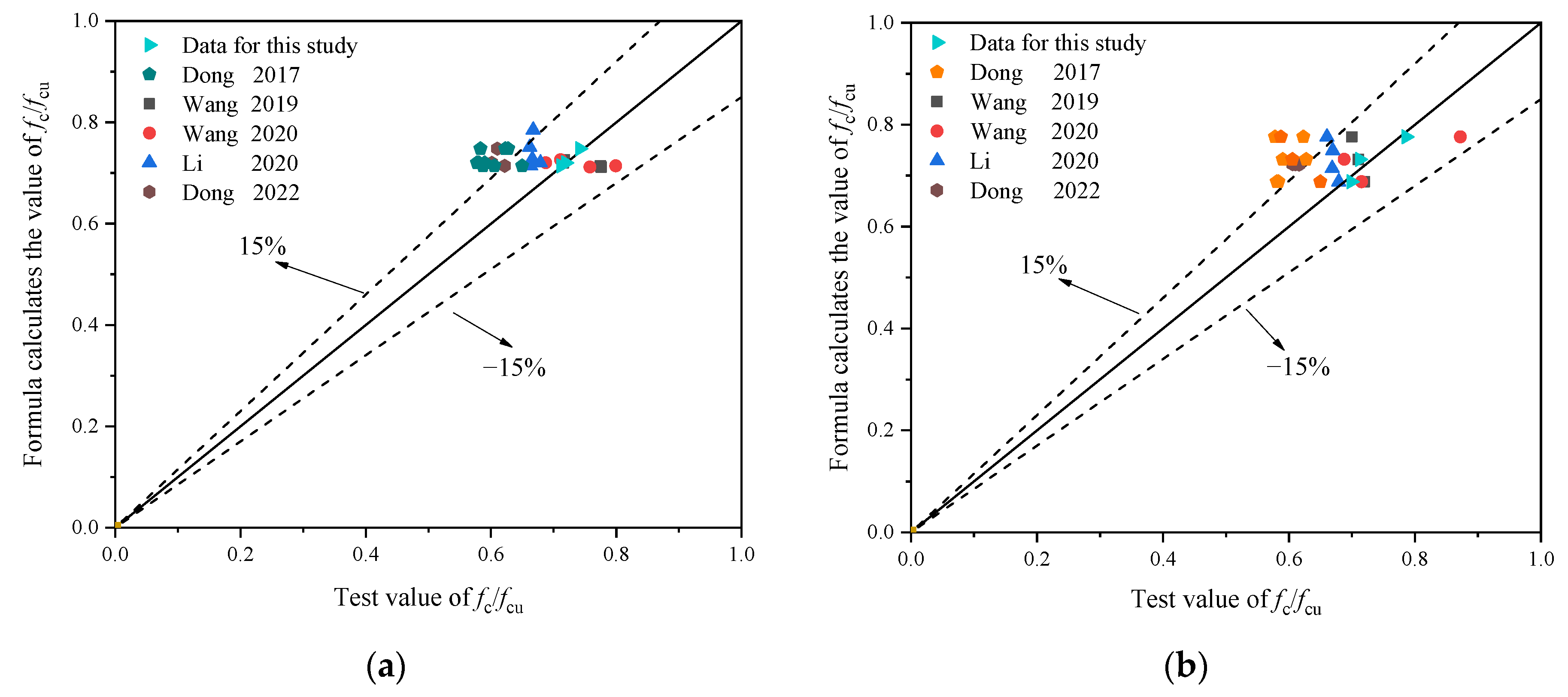

3.3.2. The Functional Relationships between fcu, fc and Different Variables

3.3.3. fc/fcu

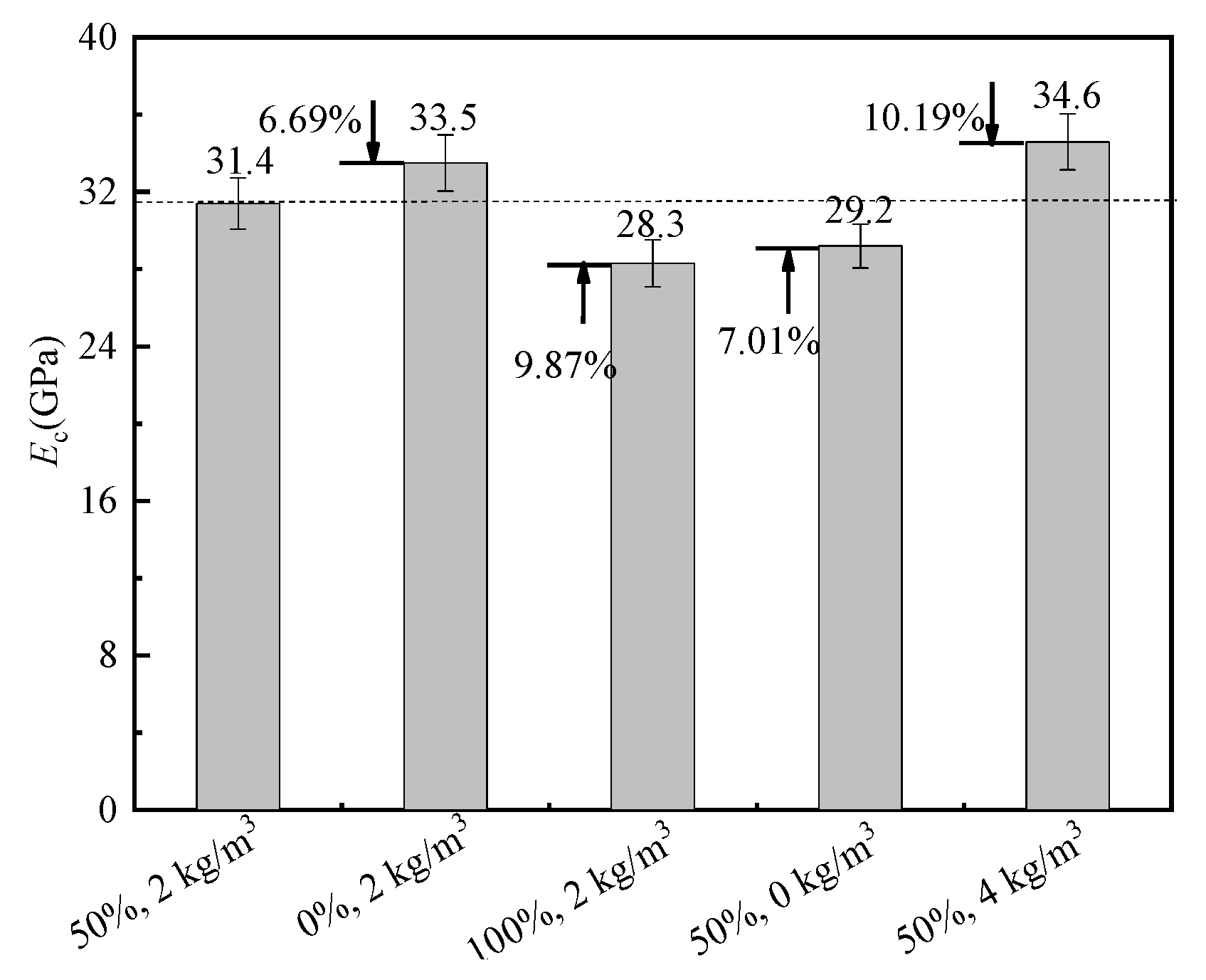

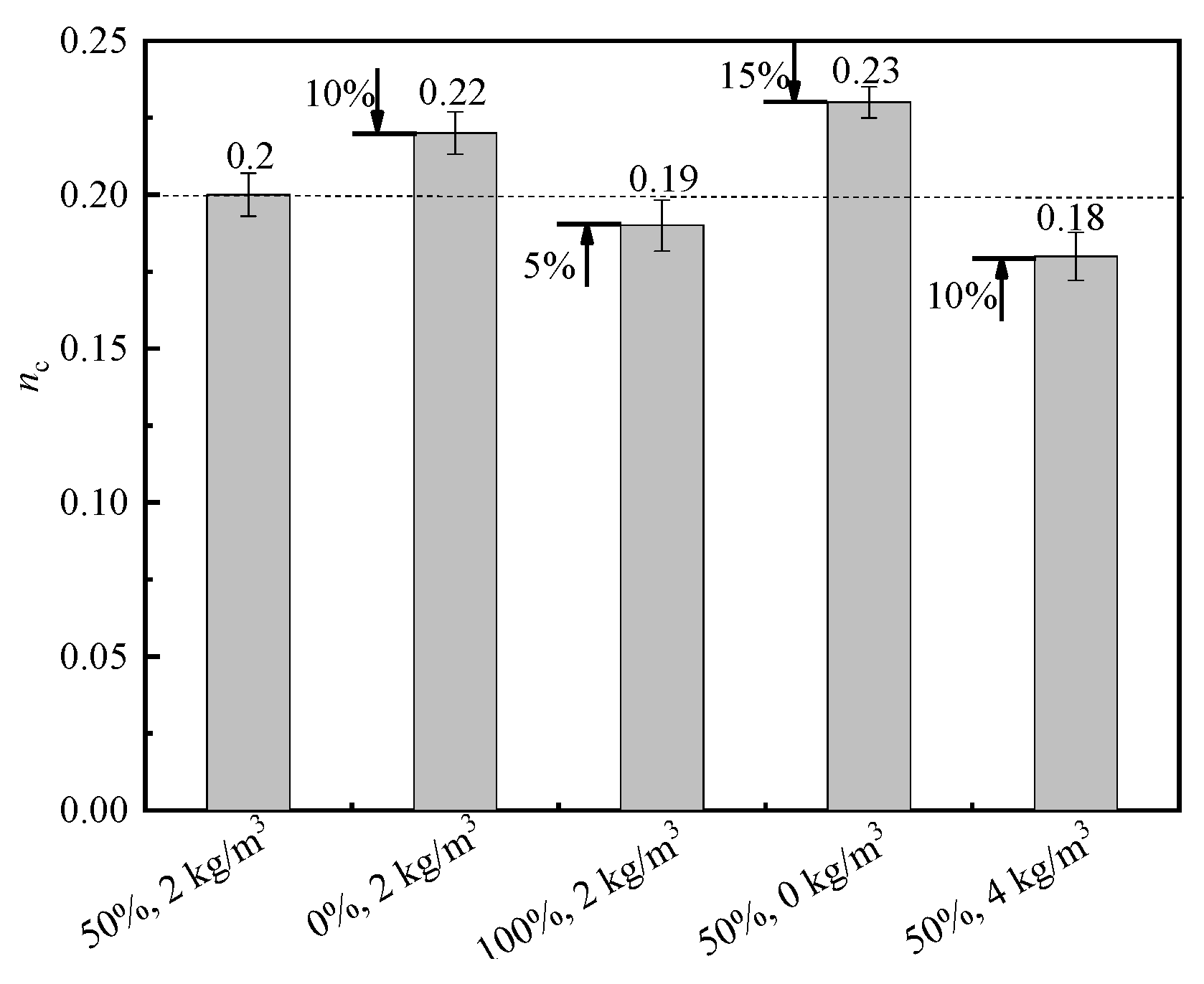

3.3.4. Elastic Modulus and Poisson’s Ratio

3.4. Analysis of Variance

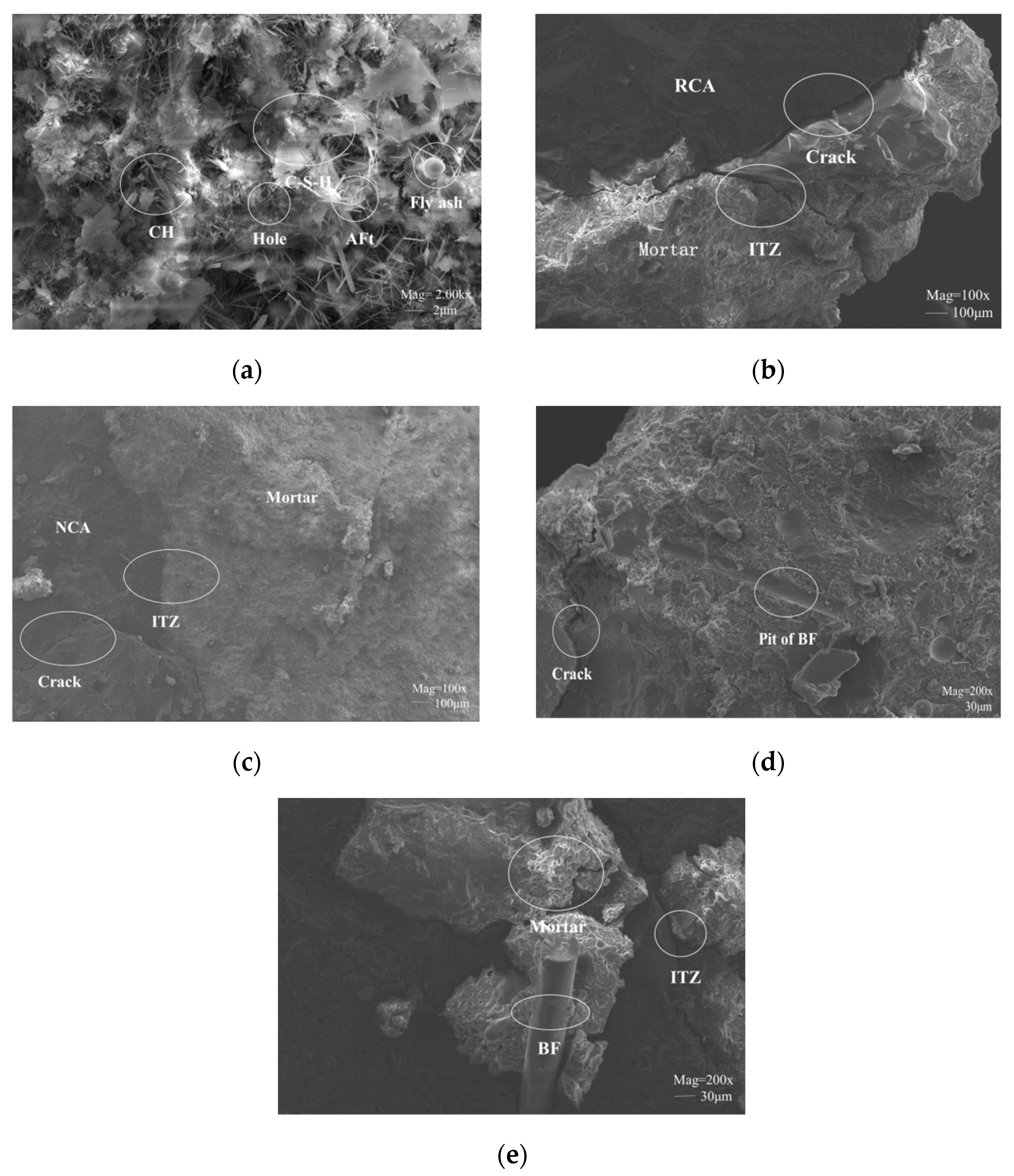

3.5. Microscopy Analysis of BFRRAC

4. Conclusions

- The morphology of the cubic specimens in each group under compression were noted to be similar, representing quadrangular pyramid failure. The BFRRAC prisms in each group represented typical oblique section shear failure, and the incorporation of BF enhanced the integrity of each specimen after failure.

- The cubic and axial compressive strength of BFRRAC decreased upon increasing the RCA replacement ratio, whereas these increased with the BF content. As the replacement ratio was increased from 50% to 100%, the cubic compressive strength was noted to decrease the most, by about 9.07%. As the fiber content was increased from 2 kg/m3 to 4 kg/m3, the axial compressive strength increased the most, by about 6.65%. In addition, the influence of the RAC replacement ratio on the compressive strength of the specimens was noted to be greater than that of the BF content.

- Upon increasing the RCA replacement ratio, the elastic modulus of BFRRAC decreased, whereas the Poisson’s ratio first decreased followed by an increase. As the replacement ratio was increased from 50% to 100%, the elastic modulus was noted to decrease the most, by about 9.87%. Upon increasing the BF content, the elastic modulus of BFRRAC increased, and the Poisson’s ratio decreased. As the fiber content was increased from 2 kg/m3 to 4 kg/m3, the elastic modulus increased the most by about 10.19%.

- Based on the experiment data, the functional relationships between the strength indices and different variables as well as the conversion value of each strength index and different variables were established. In addition, by comparing the test data in the literature, the formula calculation results were in good agreement with the test results and could provide guidance for future applications in engineering.

- The micromorphology of the mortar matrix and ITZ, as well as the modification mechanism of BF directly affected the macroscopic mechanical properties of RAC. The mechanical properties of RAC could be optimized by the bridging and crack resistance mechanism of BF.

- Overall, this study carried out the mechanical properties test and microscopy analysis of BFRRAC, and established the relationship between different parameters and BFRRAC. In the future, we can continue to carry out in-depth research on this idea: Visualization of fiber distribution and pore structure distribution of RAC is studied by numerical simulation software and the three-dimensional microscopic analysis of dynamic and static mechanical properties of BFRRAC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siempu, R.; Pancharathi, R.K. Pull-out behaviour of recycled aggregate based self compacting concrete. Comput. Concr. 2018, 21, 249–259. [Google Scholar] [CrossRef]

- Colangelo, F.; Petrillo, A.; Cioffi, R.; Borrelli, C.; Forcina, A. Life cycle assessment of recycled concretes: A case study in southern Italy. Sci. Total Environ. 2018, 615, 1506–1517. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Liang, J.F.; Wang, E.; Zhou, X.; Le, Q.L. Influence of high temperature on mechanical properties of concrete containing recycled fine aggregate. Comput. Concr. 2018, 21, 87–94. [Google Scholar] [CrossRef]

- Xu, J.; Shi, Y.; Xie, Y.; Zhao, S. A BIM-Based construction and demolition waste information management system for greenhouse gas quantification and reduction. J. Clean. Prod. 2019, 229, 308–324. [Google Scholar] [CrossRef]

- Yang, G.H.; Li, Q.Y.; Guo, Y.N.; Liu, H.B.; Zheng, S.D.; Chen, M.X. Study on the mechanical properties and durability of recycled aggregate concrete under the internal curing condition. Materials 2022, 15, 5914. [Google Scholar] [CrossRef]

- Liang, C.; Ma, H.; Pan, Y.; Ma, Z.; Duan, Z.; He, Z. Chloride permeability and the caused steel corrosion in the concrete with carbonated recycled aggregate. Constr. Build. Mater. 2019, 218, 506–518. [Google Scholar] [CrossRef]

- Elhakam, A.A.; Mohamed, A.E.; Awad, E. Influence of self-healing, mixing method and adding silica fume on mechanical properties of recycled aggregates concrete. Constr. Build. Mater. 2012, 35, 421–427. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Wang, R.; Yu, N.; Li, Y. Methods for improving the microstructure of recycled concrete aggregate: A review. Constr. Build. Mater. 2020, 242, 118164. [Google Scholar] [CrossRef]

- Engelsen, C.J.; van der Sloot, H.A.; Petkovic, G. Long-term leaching from recycled concrete aggregates applied as sub-base material in road construction. Sci. Total Environ. 2017, 587, 94–101. [Google Scholar] [CrossRef] [PubMed]

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Anike, E.E.; Saidani, M.; Ganjian, E.; Tyrer, M.; Olubanwo, A.O. Evaluation of conventional and equivalent mortar volume mix design methods for recycled aggregate concrete. Mater. Struct. 2020, 53, 22. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Adesina, A. Performance of cementitious composites reinforced with chopped basalt fibres—An overview. Constr. Build. Mater. 2020, 266, 120970. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Filho, R.D.T. Compressive stress–strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Zhang, J.-H.; Chen, G.-M.; Xie, Z.-H. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fiber—A review. J. Text. Inst. 2016, 107, 923–937. [Google Scholar] [CrossRef]

- Azevedo, A.R.; Marvila, M.T.; Zanelato, E.B.; Alexandre, J.; Xavier, G.C.; Cecchin, D. Development of mortar for laying and coating with pineapple fibers. Rev. Bras. Eng. Agric. Ambient. 2020, 24, 187–193. [Google Scholar] [CrossRef]

- Fayed, S.; Mansour, W. Evaluate the effect of steel, polypropylene and recycled plastic fibers on concrete properties. Adv. Concr. Constr. 2020, 10, 319–332. [Google Scholar]

- Skarżyński, L. Mechanical and radiation shielding properties of concrete reinforced with boron-basalt fibers using Digital Image Correlation and X-ray micro-computed tomography. Constr. Build. Mater. 2020, 255, 119252. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C. Production of sustainable and structural fiber reinforced recycled aggregate concrete with improved fracture properties: A review. J. Clean. Prod. 2020, 279, 123832. [Google Scholar] [CrossRef]

- Liang, C.F.; Ma, H.W.; Pan, Y.Q.; Ma, Z.M.; Duan, Z.H.; He, Z.H. The evaluation of calcium carbonate added and basalt fiber reinforced roller compacted high performance concrete for pavement. Case Stud. Constr. Mater. 2022, 17, e01293. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, F.; Cao, P.; Liu, K. The fracture toughness analysis on the basalt fiber reinforced asphalt concrete with prenotched three-point bending beam test. Case Stud. Constr. Mater. 2022, 16, e01079. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.; Qi, Y. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical properties of the concrete containing recycled fibers and aggregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Sun, X.; Gao, Z.; Cao, P.; Zhou, C. Mechanical properties tests and multiscale numerical simulations for basalt fiber reinforced concrete. Constr. Build. Mater. 2019, 202, 58–72. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.; Guan, Z. Material properties of basalt fibre reinforced concrete made with recycled earthquake waste. Constr. Build. Mater. 2017, 130, 241–251. [Google Scholar] [CrossRef]

- Wang, Y.; Hughes, P.; Niu, H.; Fan, Y. A new method to improve the properties of recycled aggregate concrete: Composite addition of basalt fiber and nano-silica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar] [CrossRef]

- Fang, S.-E.; Hong, H.-S.; Zhang, P.-H. Mechanical Property Tests and Strength Formulas of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials 2018, 11, 1851. [Google Scholar] [CrossRef] [PubMed]

- Dilbas, H.; Çakır, O. Influence of basalt fiber on physical and mechanical properties of treated recycled aggregate concrete. Constr. Build. Mater. 2020, 254, 119216. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture and Building Press: Beijing, China, 2019. (In Chinese)

- Chen, A.; Han, X.; Chen, M.; Wang, X.; Wang, Z.; Guo, T. Mechanical and stress-strain behavior of basalt fiber reinforced rubberized recycled coarse aggregate concrete. Constr. Build. Mater. 2020, 260, 119888. [Google Scholar] [CrossRef]

- Wang, Y.G.; Li, S.P.; Hughes, P.; Fan, Y.H. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Zheng, Y.X.; Zhuo, J.B.; Zhang, P. Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete. Nanotechnol. Rev. 2022, 11, 2169–2189. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Chen, W. Bending performance of unbonded prestressed basalt fiber recycled concrete beams. Eng. Struct. 2020, 221, 110937. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.Y.; Guan, Z.; Chai, H. High-temperature behaviour of basalt fibre reinforced concrete made with recycled aggregates from earthquake waste. J. Build. Eng. 2022, 48, 103895. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- Dilbas, H.; Çakır, Ö.; Yıldırım, H. An experimental investigation on fracture parameters of recycled aggregate concrete with optimized ball milling method. Constr. Build. Mater. 2020, 252, 119118. [Google Scholar] [CrossRef]

| Fineness (%) | Ignition Loss (%) | SO3 (%) | MgO (%) | fcu (MPa) | fcf (MPa) | Initial Setting Time (min) | Final Setting Time (min) |

|---|---|---|---|---|---|---|---|

| 1.30 | 2.41 | 2.45 | 2.11 | 51 | 8.5 | 180 | 265 |

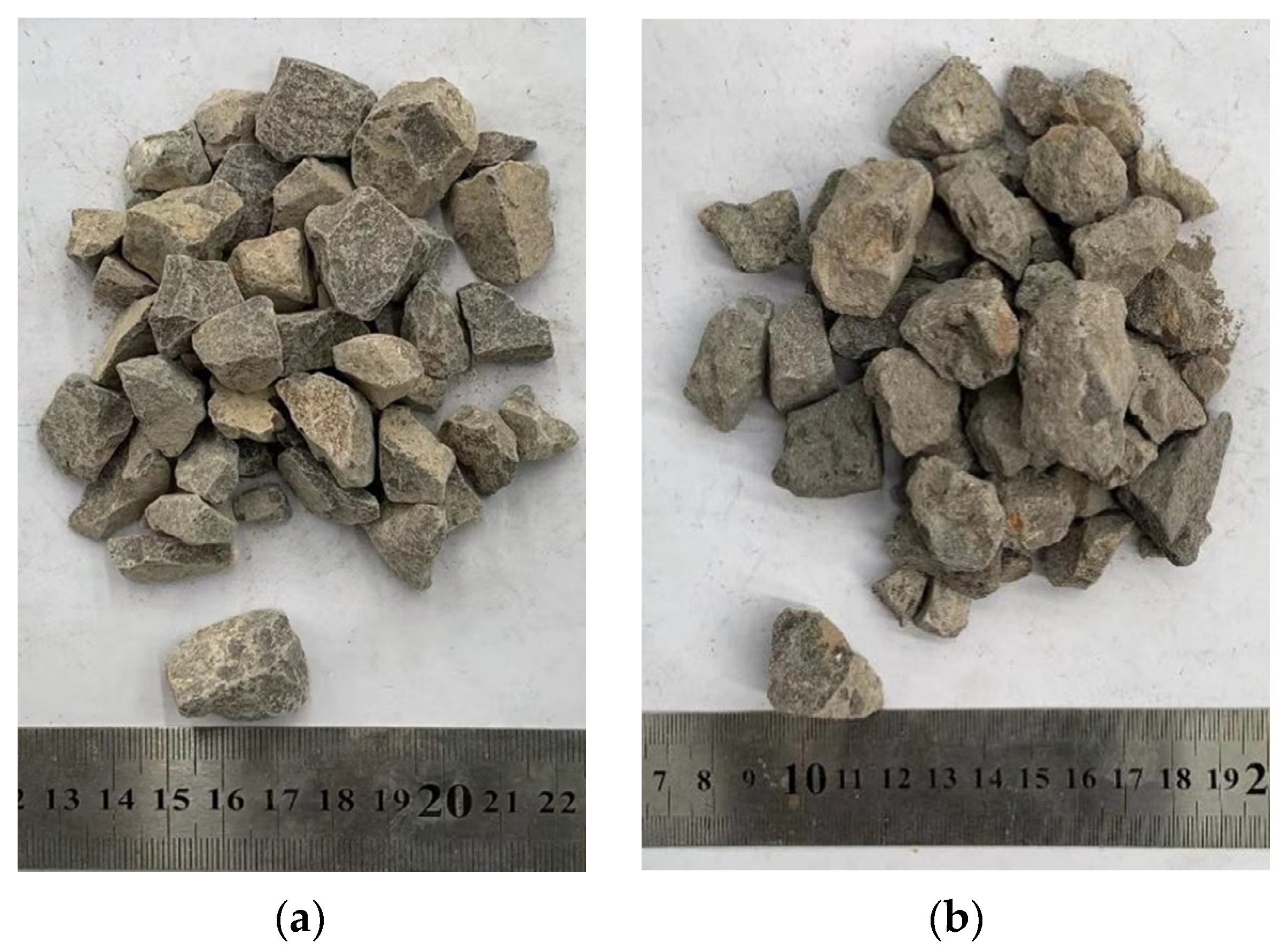

| Aggregate Type | Particle Size (mm) | Bulk Density (kg/m3) | Apparent Density (kg/m3) | Water Content (%) | Water Absorption (%) | Water Content (%) |

|---|---|---|---|---|---|---|

| Natural | 5~31.5 | 1681 | 2498 | 0.0 | 0.1 | 0.0 |

| Recycled | 5~31.5 | 1274 | 2196 | 2.0 | 5.6 | 0.0 |

| Diameter (μm) | Length (mm) | Density (kg/m3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| 15 | 18 | 2650 | 4150~4850 | 93~115 | 3.0~3.2 |

| γ (%) | W/B | Sand Ratio (%) | Net Water | Aditional Water | Cement | Fly Ash | Recycled Coarse Aggregate | Natural Coarse Aggregate | Sand | Water Reducer |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.40 | 31 | 205 | 0.0 | 427.1 | 85.4 | 0.0 | 1115.2 | 501 | 2.56 |

| 50 | 0.40 | 31 | 205 | 31.2 | 427.1 | 85.4 | 557.6 | 557.6 | 501 | 2.56 |

| 100 | 0.40 | 31 | 205 | 62.5 | 427.1 | 85.4 | 1115.2 | 0.0 | 501 | 2.56 |

| γ (%) | λ (kg/m3) | fcu (MPa) | fc (MPa) | Ec (GPa) | νc |

|---|---|---|---|---|---|

| 0 | 2 | 52.8 | 41.5 | 33.5 | 0.22 |

| 50 | 0 | 48.5 | 34.9 | 29.2 | 0.23 |

| 2 | 50.7 | 36.1 | 31.4 | 0.20 | |

| 4 | 51.9 | 38.5 | 34.6 | 0.18 | |

| 100 | 2 | 46.1 | 32.2 | 28.3 | 0.23 |

| Dependent Variable | Independent Variable | Degrees of Freedom | Sum of Squares | Variance | F | p | Contribution (%) |

|---|---|---|---|---|---|---|---|

| fcu | BF content | 2 | 17.009 | 8.505 | 3.788 | 0.060 | 11.44 |

| γ | 2 | 69.946 | 34.973 | 15.579 | 0.001 | 59.83 | |

| Error | 10 | 22.449 | 2.245 | 28.73 | |||

| Total | 14 | 109.404 | 100 | ||||

| fc | BF content | 2 | 19.265 | 9.633 | 6.172 | 0.018 | 9.76 |

| γ | 2 | 130.485 | 65.242 | 41.806 | 0.000 | 77.03 | |

| Error | 10 | 15.606 | 1.561 | 13.21 | |||

| Total | 14 | 165.356 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhou, G.; Xu, P.; Fu, L.; Deng, D.; Kuang, X.; Fan, Y. Mechanical Properties under Compression and Microscopy Analysis of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials 2023, 16, 2520. https://doi.org/10.3390/ma16062520

Zhang X, Zhou G, Xu P, Fu L, Deng D, Kuang X, Fan Y. Mechanical Properties under Compression and Microscopy Analysis of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials. 2023; 16(6):2520. https://doi.org/10.3390/ma16062520

Chicago/Turabian StyleZhang, Xianggang, Gaoqiang Zhou, Ping Xu, Lei Fu, Dapeng Deng, Xiaomei Kuang, and Yuhui Fan. 2023. "Mechanical Properties under Compression and Microscopy Analysis of Basalt Fiber Reinforced Recycled Aggregate Concrete" Materials 16, no. 6: 2520. https://doi.org/10.3390/ma16062520

APA StyleZhang, X., Zhou, G., Xu, P., Fu, L., Deng, D., Kuang, X., & Fan, Y. (2023). Mechanical Properties under Compression and Microscopy Analysis of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials, 16(6), 2520. https://doi.org/10.3390/ma16062520