Application of Mean Modulus in Three-Point Bending and Roll Forming

Abstract

:1. Introduction

2. Calibration of Flow Stress Mathematical Model and Chord Modulus Mathematical Model

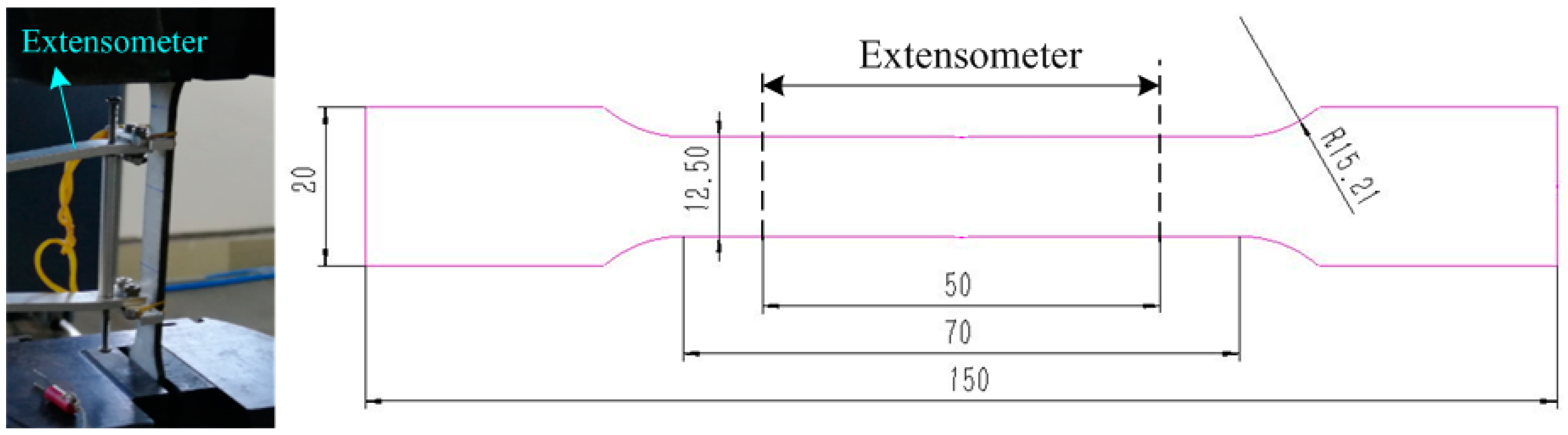

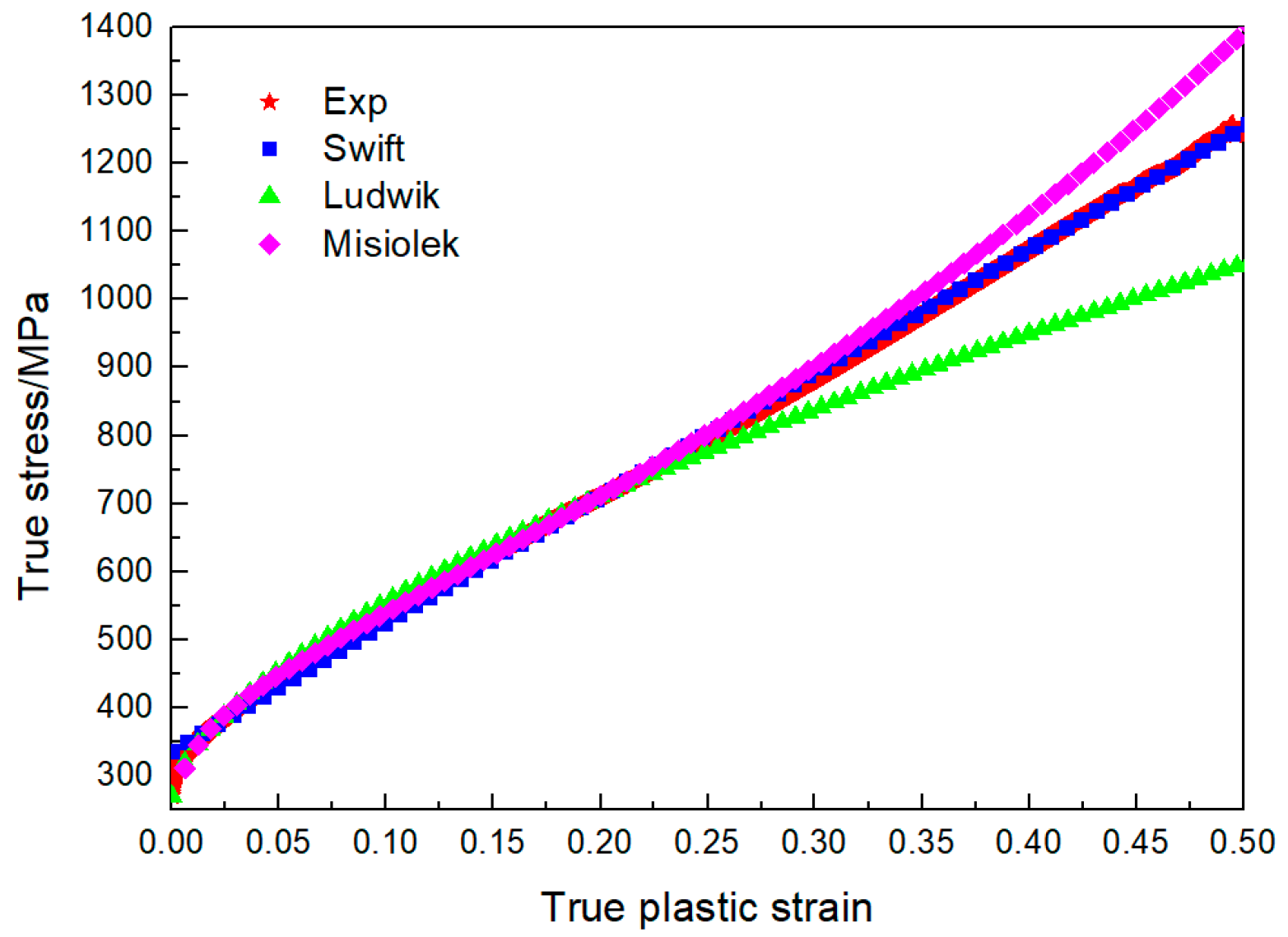

2.1. Flow Stress Mathematical Model

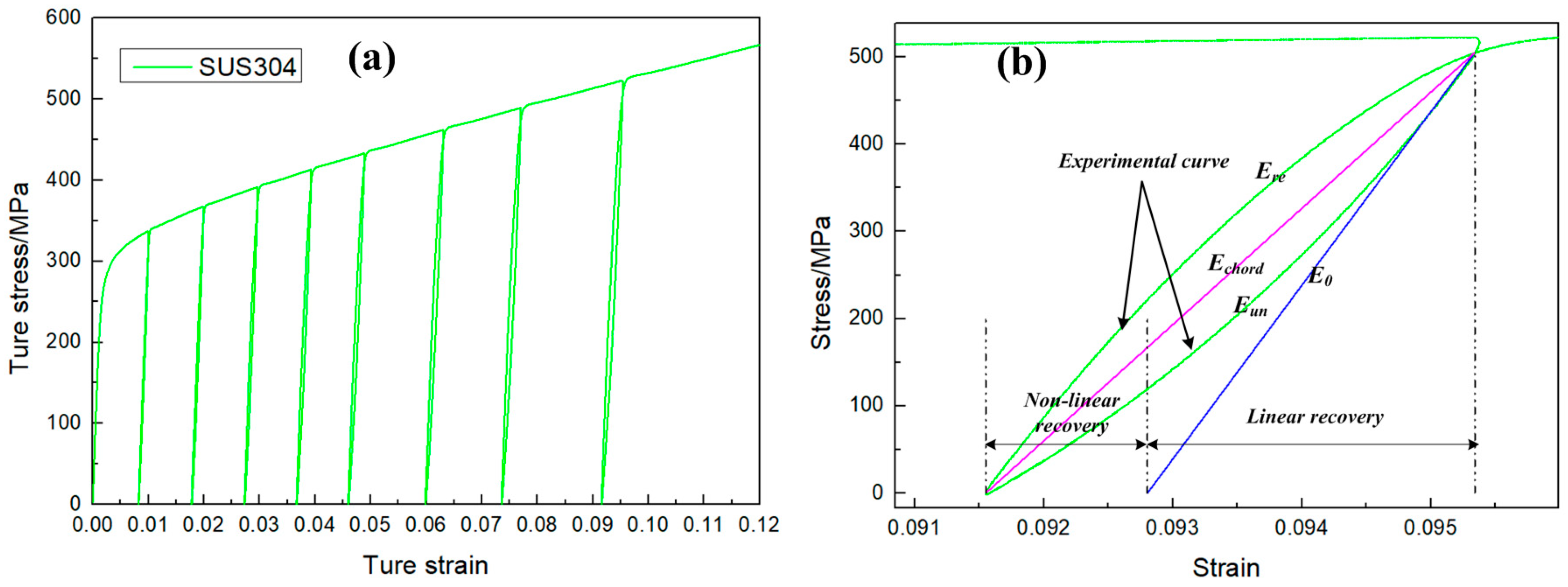

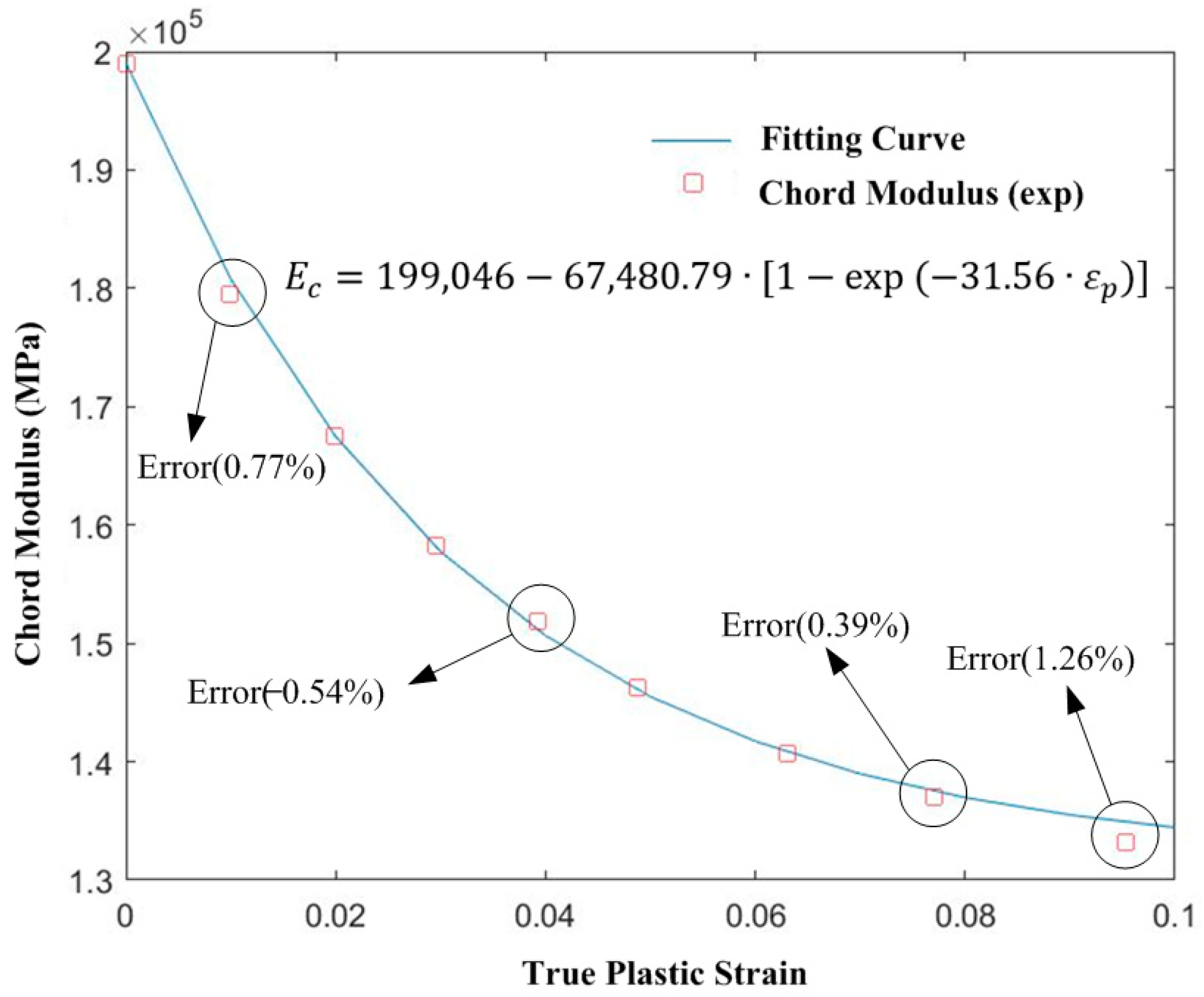

2.2. Chord Modulus Mathematical Model

3. Finite Element Model

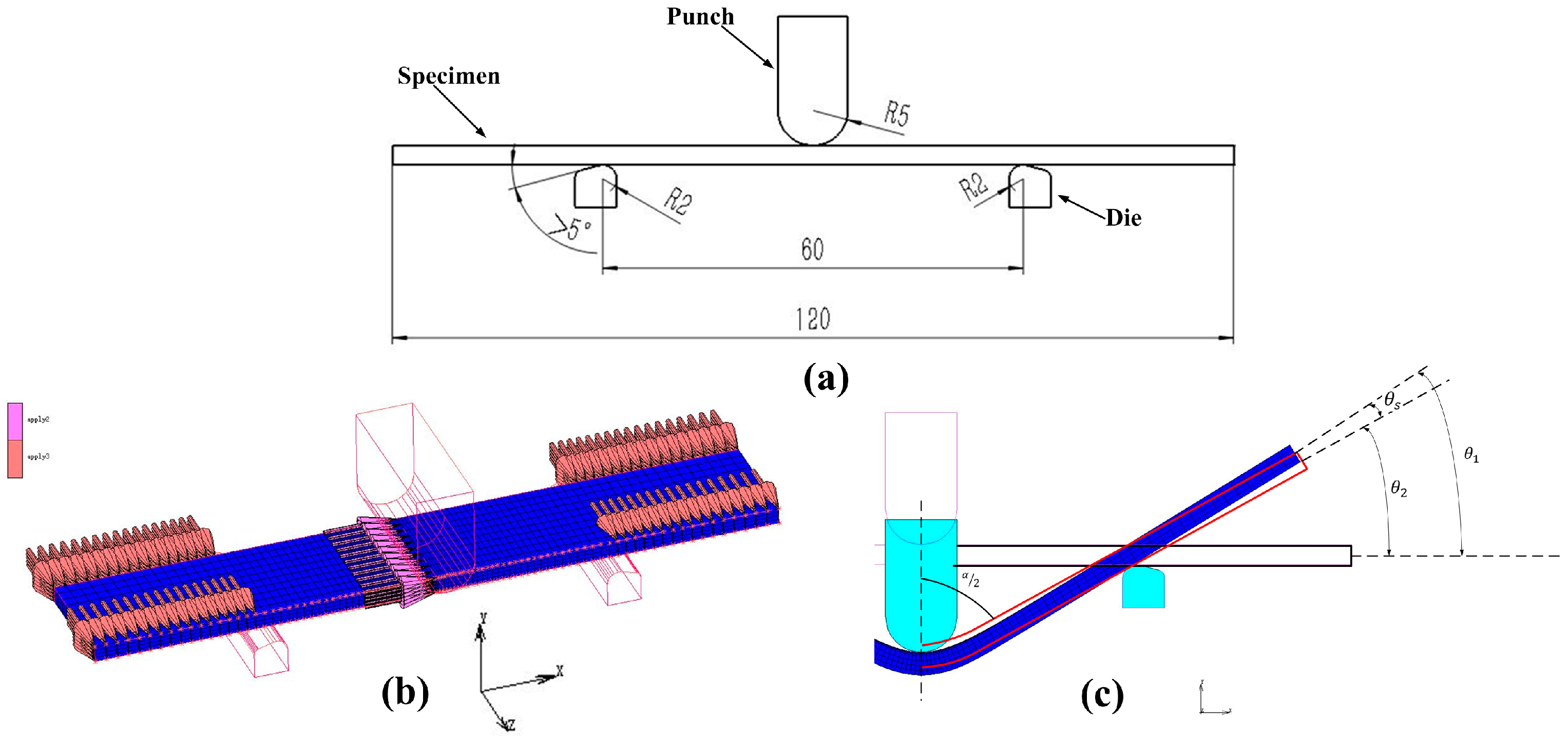

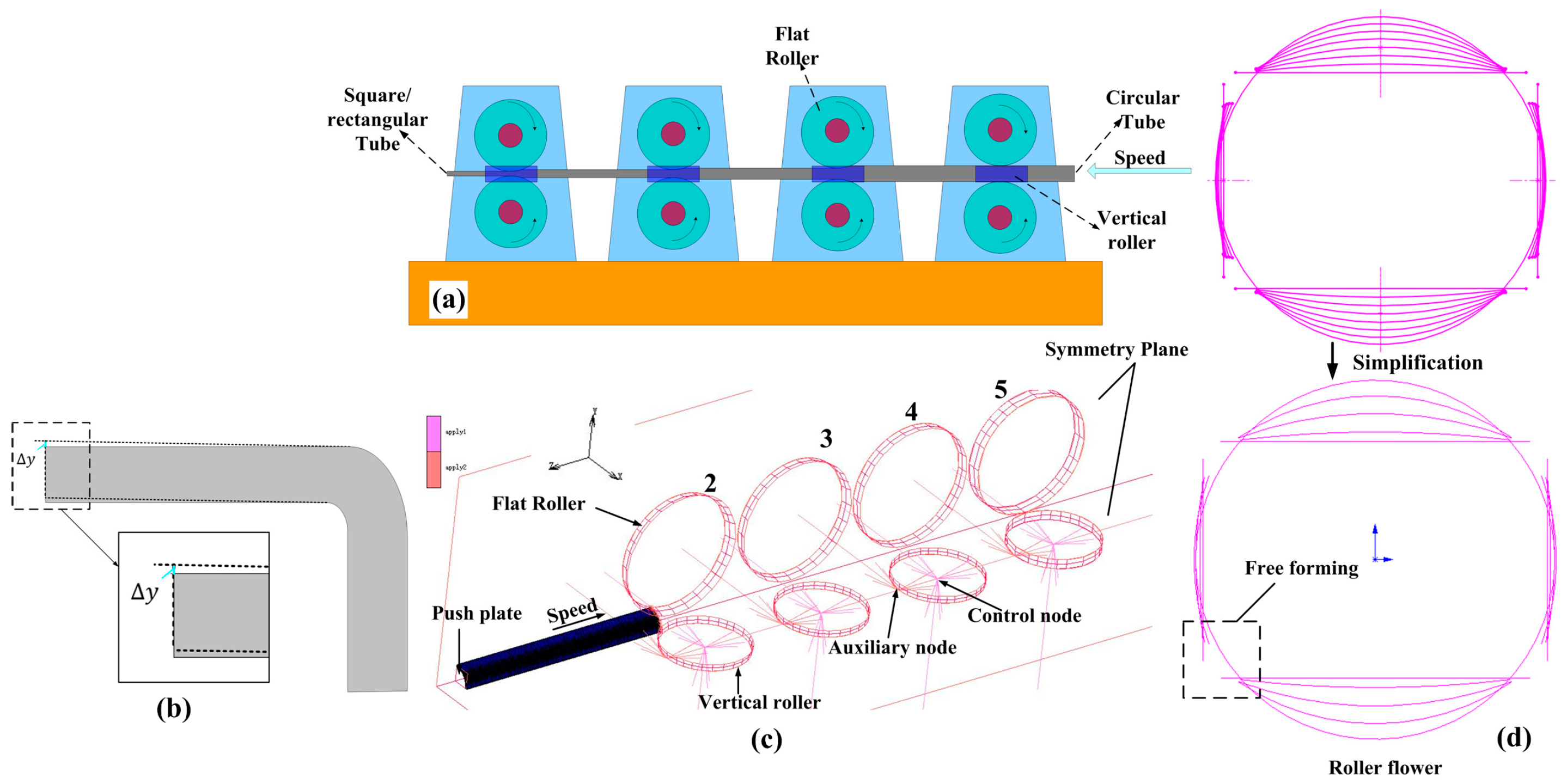

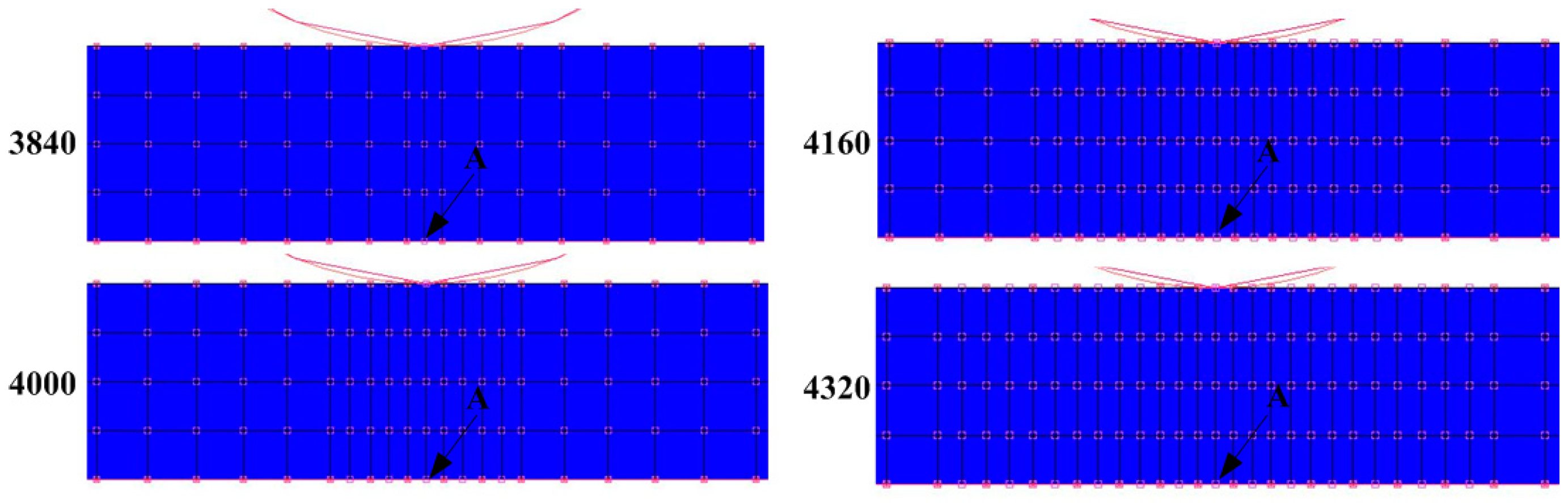

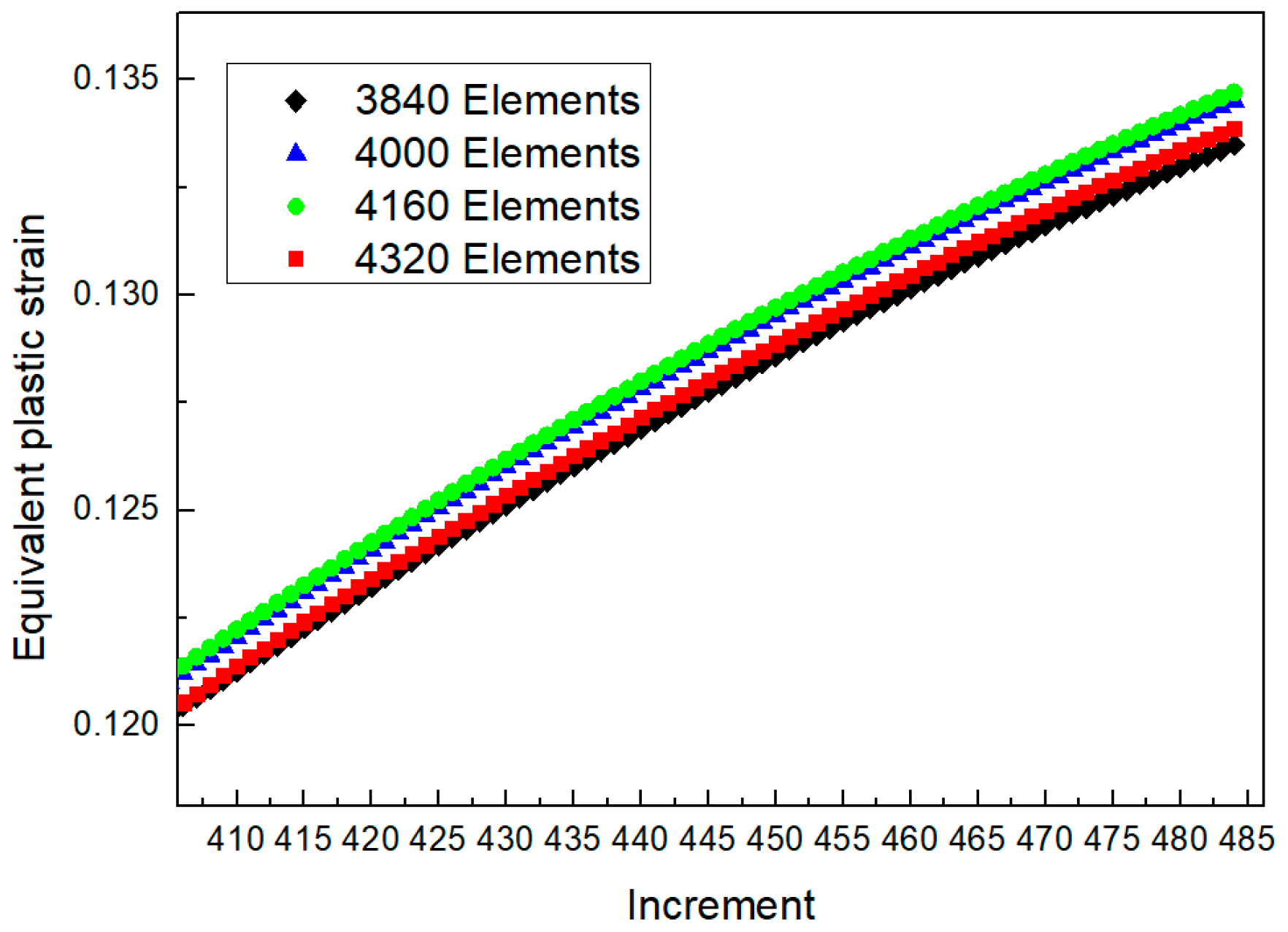

3.1. Establishment of the Finite Element Model

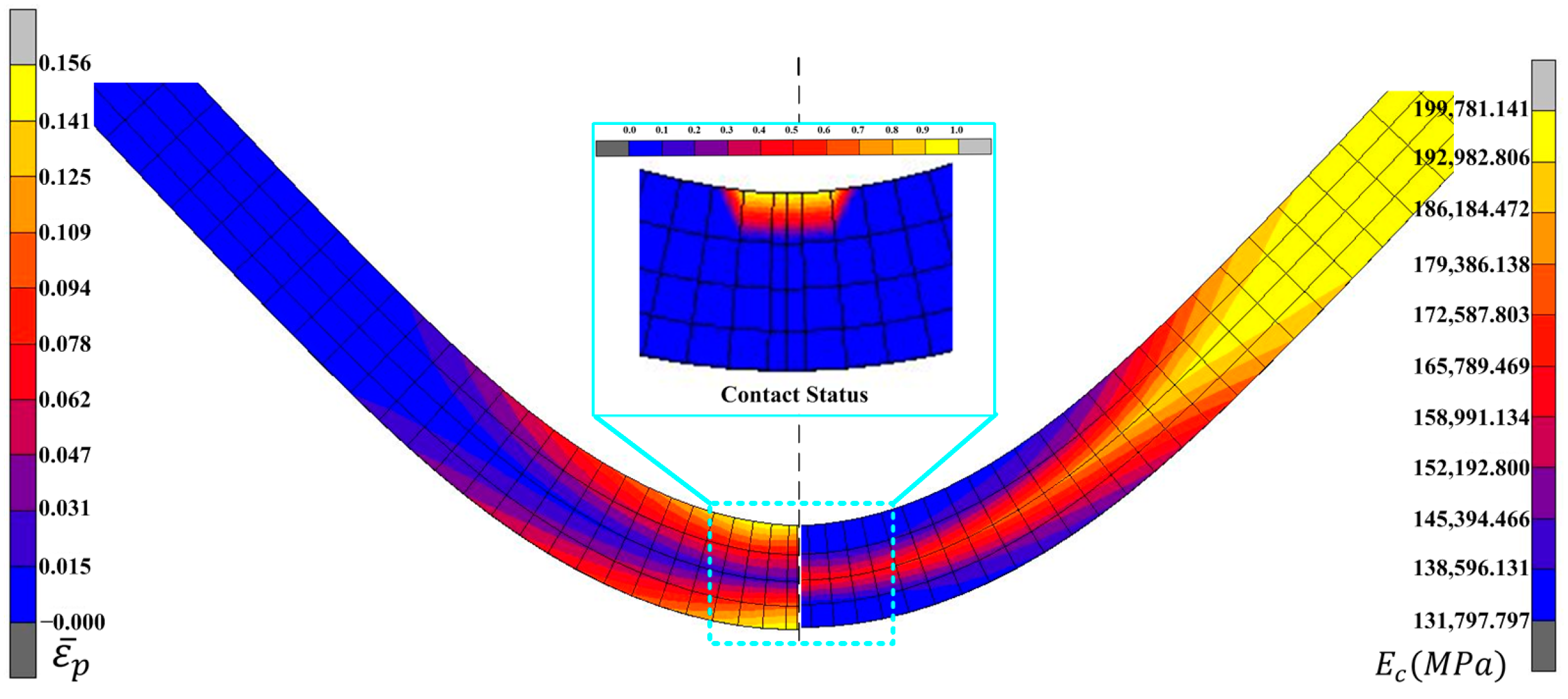

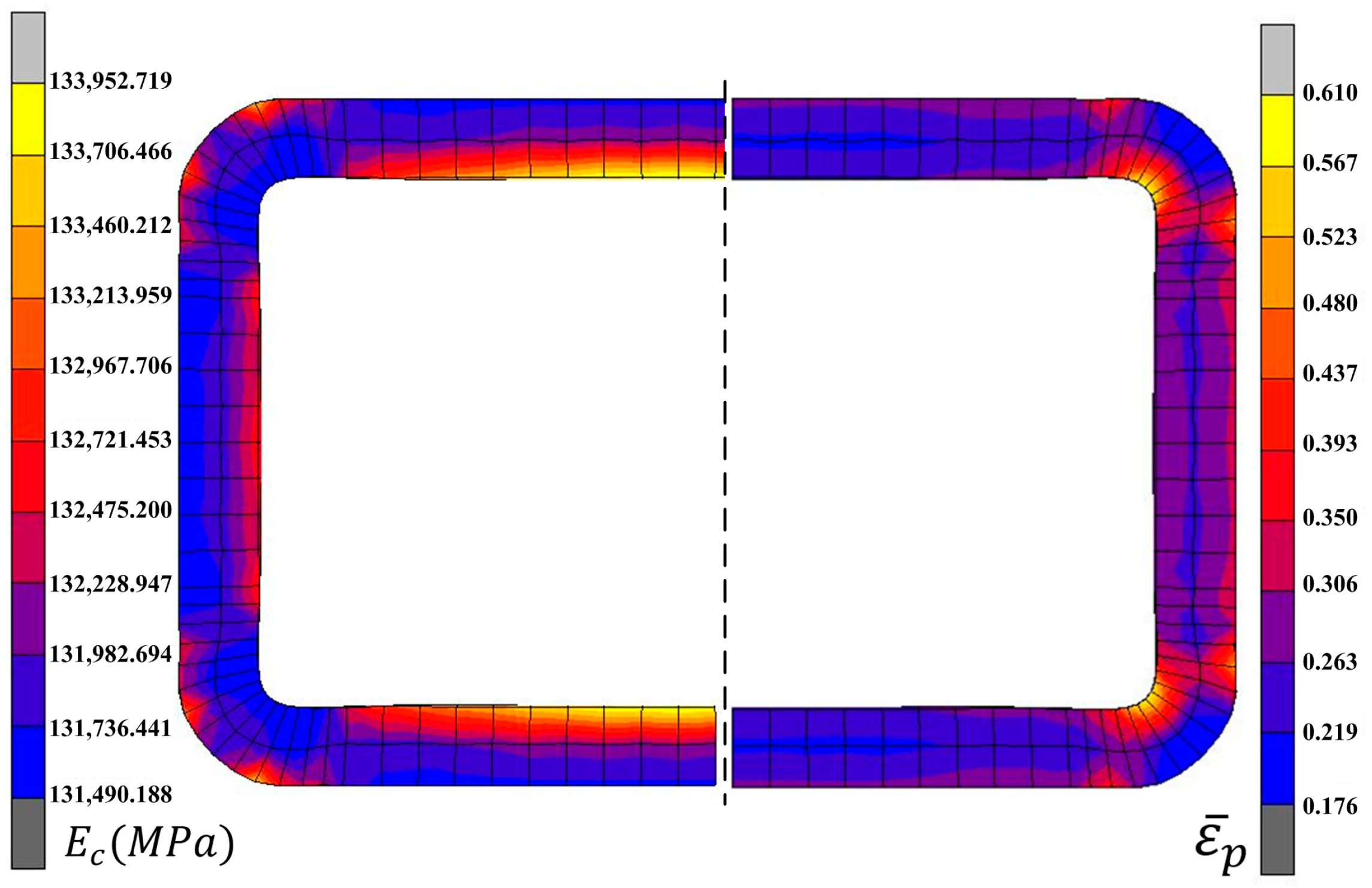

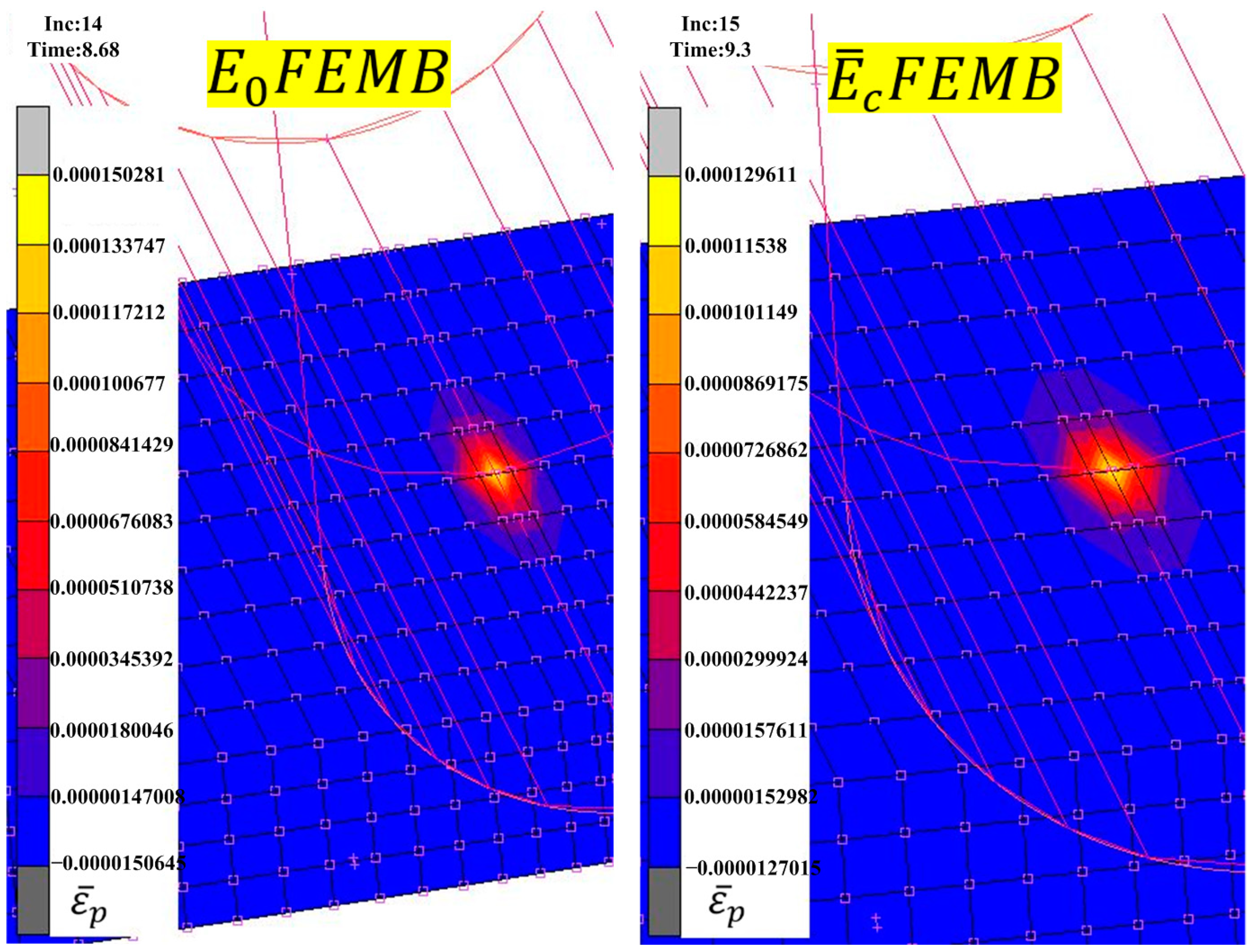

3.2. Analysis of Simulation Results

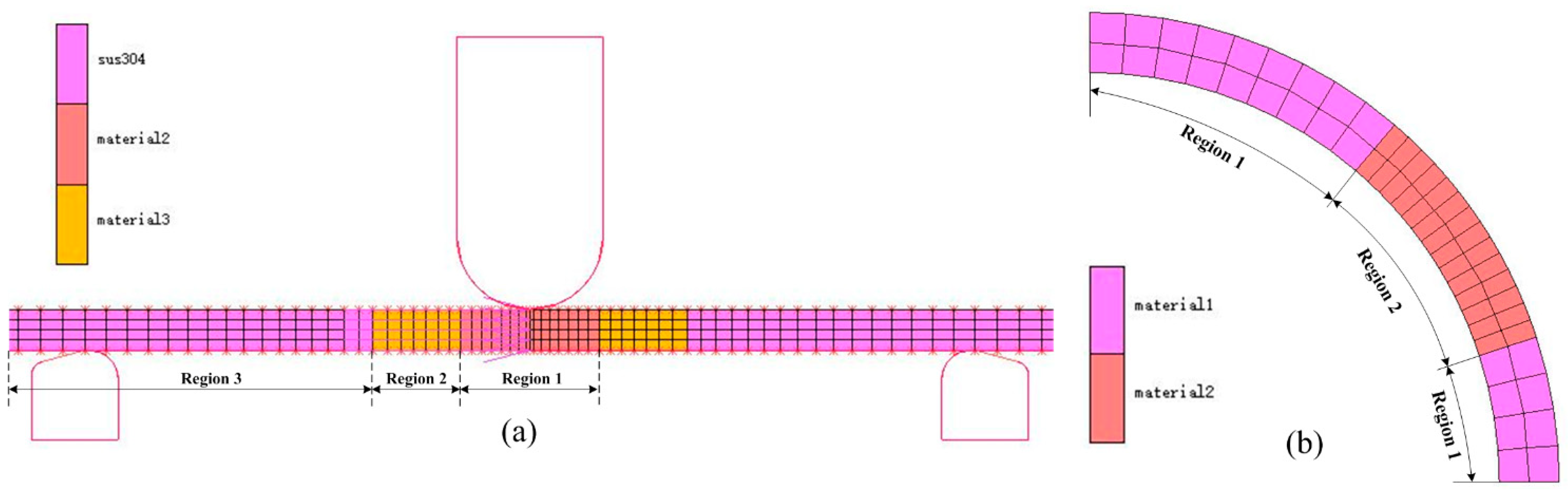

3.3. Setting of the Mean Modulus

4. Test Verification of the Mean Modulus Model

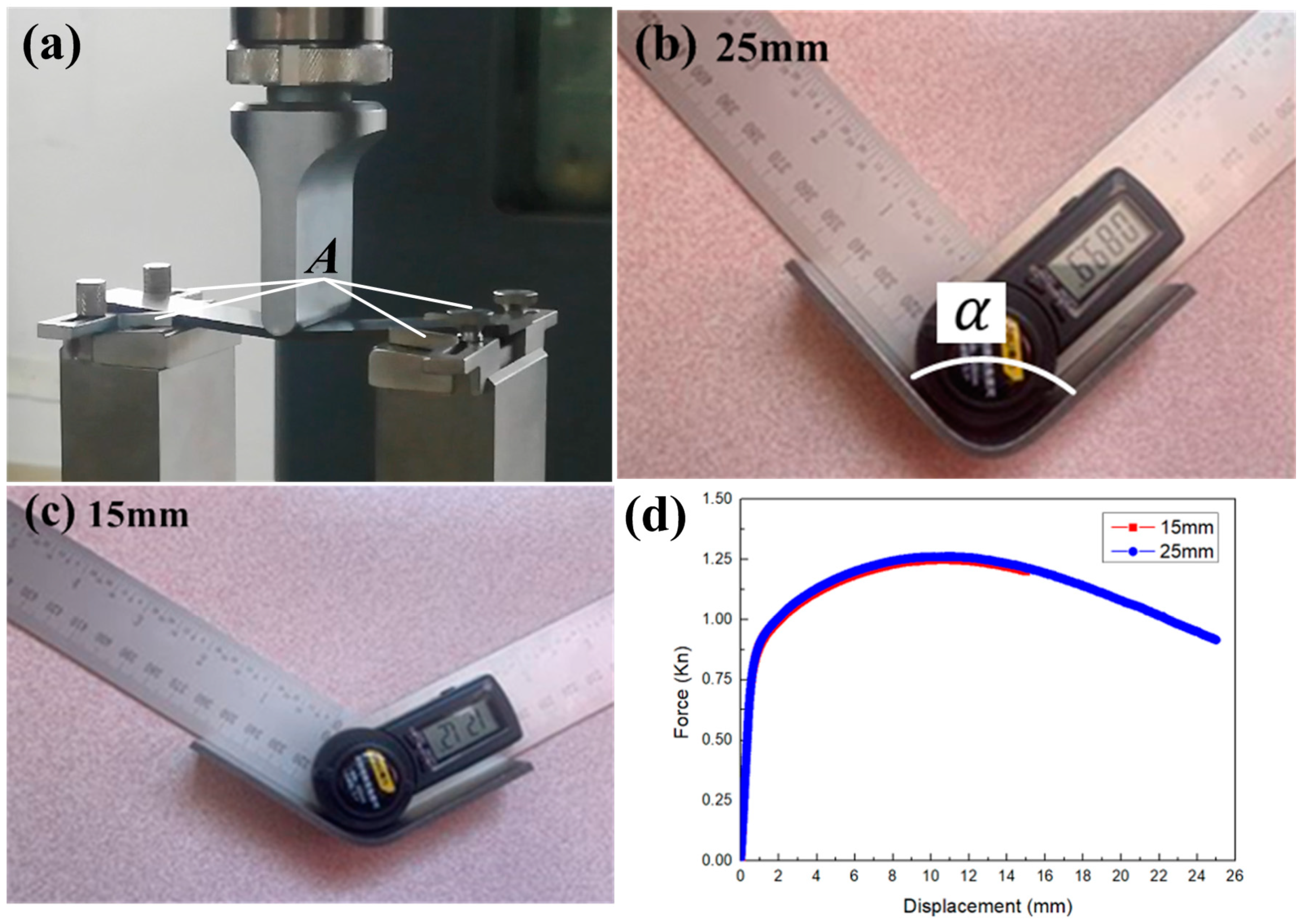

4.1. Three-Point Bending Test

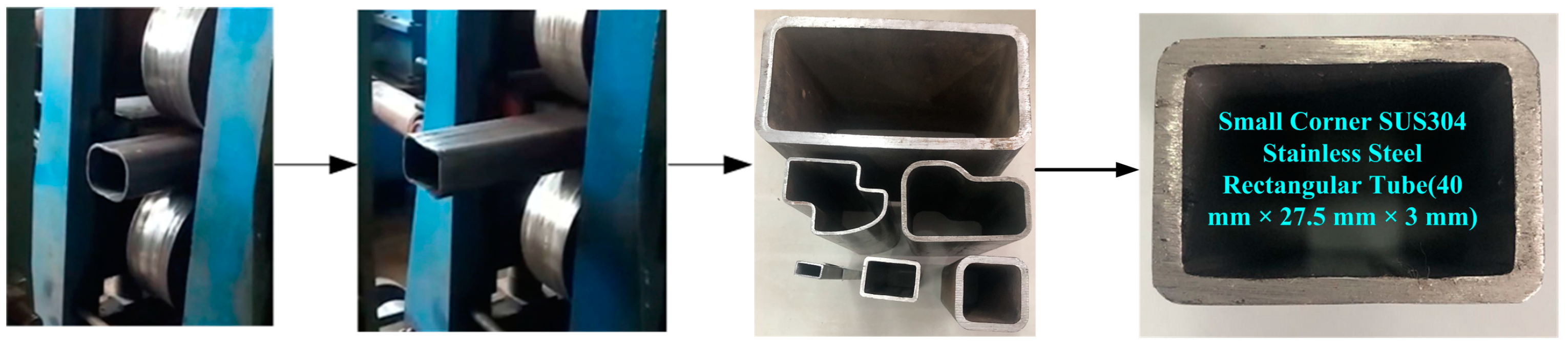

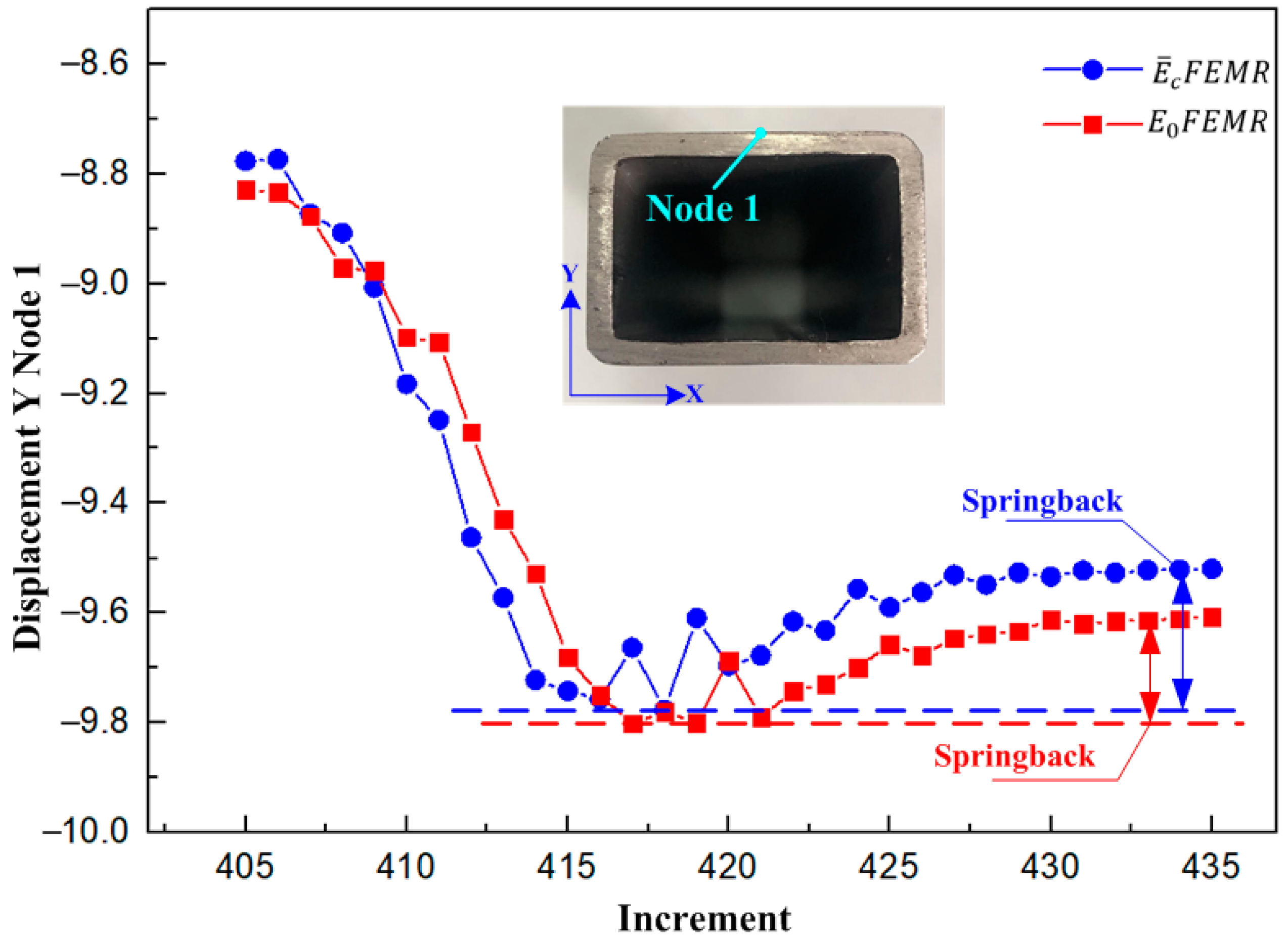

4.2. Roll Forming Test

5. Conclusions

- (1)

- For SUS304 stainless steel, the flow stress mathematical model and chord modulus mathematical model were calibrated by uniaxial tensile tests and loading–unloading–loading tensile tests. The two mathematical models fitted well with the test results and could be used for finite element simulation.

- (2)

- Constant modulus finite element models for three-point bending and roll forming were established. The chord modulus distribution was output by the PLOTV subroutine in MSC.MARC, and the mean modulus was calculated based on this. The mean modulus was set for different forming regions, and the based on the mean modulus was established.

- (3)

- Combined with the three-point bending tests and the roll forming tests, the simulation results of and were compared with the test results. In three-point bending forming, when the displacement was 15 mm, the error between the -calculated results and the test results was 0.84%. When the displacement was 25 mm, the error between the -calculated results and the test results was 1.16%. In roll forming, the error between the -calculated results and the test results was 15%, which was within an acceptable range (less than 20%) and verified the validity of the .

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moneke, M.; Groche, P. The origin of end flare in roll formed profiles. Int. J. Mater. Form. 2021, 14, 1439–1461. [Google Scholar] [CrossRef]

- Liu, X.L.; Cao, J.G.; Chai, X.T.; Liu, J.; Zhao, R.G.; Kong, N. Investigation of forming parameters on springback for ultra high strength steel considering young’s modulus variation in cold roll forming. J Manuf. Process 2017, 29, 289–297. [Google Scholar] [CrossRef]

- Krinninger, M.; Opritescu, D.; Golle, R.; Volk, W. Experimental Investigation of the Influence of Punch Velocity on the Springback Behavior and the Flat Length in Free Bending. Procedia CIRP 2016, 41, 1066–1071. [Google Scholar] [CrossRef] [Green Version]

- Ben-Elechi, S.; Bahloul, R.; Chatti, S. Investigation on the effect of friction and material behavior models on the springback simulation precision: Application to automotive part B-Pillar and material TRIP800 steel. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 380. [Google Scholar] [CrossRef]

- Komgrit, L.; Hamasaki, H.; Hino, R.; Yoshida, F. Elimination of springback of high-strength steel sheet by using additional bending with counter punch. J. Mater. Process. Technol. 2016, 229, 199–206. [Google Scholar] [CrossRef]

- Kim, H.; Nargundkar, N.; Altan, T. Prediction of bend allowance and springback in air bending. J. Manuf. Sci. Eng. 2007, 129, 342–351. [Google Scholar] [CrossRef]

- Tian, K.V.; Festa, G.; Basoli, F.; Laganà, G.; Scherillo, A.; Andreani, C.; Bollero, P.; Licoccia, S.; Senesi, R.; Cozza, P. Orthodontic archwire composition and phase analyses by neutron spectroscopy. Dent. Mater. J. 2017, 36, 282–288. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, L.; Wagoner, R. Complex unloading behavior: Nature of the deformation and its consistent constitutive representation. Int. J. Plast. 2011, 27, 1126–1144. [Google Scholar] [CrossRef]

- Yoshida, F.; Amaishi, T. Model for description of nonlinear unloading-reloading stress-strain response with special reference to plastic-strain dependent chord modulus. Int. J. Plast. 2020, 130, 102708. [Google Scholar] [CrossRef]

- Yu, H.; Chen, S.J. A mixed hardening model combined with the transformation-induced plasticity effect. J. Manuf. Process. 2017, 28, 390–398. [Google Scholar] [CrossRef]

- Chang, Y.; Wang, N.; Wang, B.; Li, X.; Wang, C.; Zhao, K.; Dong, H. Prediction of bending springback of the medium-Mn steel considering elastic modulus attenuation. J. Manuf. Process. 2021, 67, 345–355. [Google Scholar] [CrossRef]

- Badr, O.M.; Rolfe, B.; Zhang, P.; Weiss, M. Applying a new constitutive model to analyse the springback behaviour of titanium in bending and roll forming. Int. J. Mech. Sci. 2017, 128–129, 389–400. [Google Scholar] [CrossRef]

- Chongthairungruang, B.; Uthaisangsuk, V.; Suranuntchai, S.; Jirathearanat, S. Experimental and numerical investigation of springback effect for advanced high strength dual phase steel. Mater. Des. 2012, 39, 318–328. [Google Scholar] [CrossRef]

- Yang, X.; Choi, C.; Sever, N.K.; Altan, T. Prediction of Springback in Air-Bending of Advanced High Strength steel (DP780) Considering Young’s Modulus Variation and with a Piecewise Hardening Function. Int. J. Mech. Sci. 2016, 105, 266–272. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Probabilistic analysis of the SCFs in tubular T/Y-joints reinforced with FRP under axial, in-plane bending, and out-of-plane bending loads. Structures 2022, 35, 1078–1097. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. SCFs in tubular X-joints retrofitted with FRP under out-of-plane bending moment. Mar. Struct. 2021, 79, 103010. [Google Scholar] [CrossRef]

- Liu, J.; Meng, L.; Liu, Y.; Özdemir, E.D.; Aksel, M.H. Signal-to-noise ratio analysis on saw-tooth vortex generator in vehicle radiators. Trans. Can. Soc. Mech. Eng. 2022, 47, 1–14. [Google Scholar] [CrossRef]

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Ludwik, P. Elemente der Technologischen Mechanik; Springer: Berlin/Heidelberg, Germany, 1909. [Google Scholar] [CrossRef]

- Misiolek, Z.; Kowalczyk, J.; Kastner, P. Investigation of plastic flow stresses of Zn and its alloys. Arch. Hut. 1977, 22, 71–88. [Google Scholar]

- Mendiguren, J.; Cortés, F.; Gómez, X.; Galdos, L. Elastic behaviour characterisation of TRIP 700 steel by means of loading–unloading tests. Mater. Sci. Eng. A 2015, 634, 147–152. [Google Scholar] [CrossRef]

- Yoshida, F.; Uemori, T.; Fujiwara, K. Elastic–plastic behavior of steel sheets under in-plane cyclic tension–compression at large strain. Int. J. Plast. 2002, 18, 633–659. [Google Scholar] [CrossRef]

- Du, F.S.; Xing, M.L.; Wang, H.J.; Fu, Y.T.; Pei, X.Y. Influence of pass parameters and pass configuration on rectangular tube forming. J. Plast. Eng. 2022, 29, 65–71. (In Chinese) [Google Scholar]

- Han, F.; Niu, L.L.; Wang, Y.; Yang, Y.H. Research on Springback Mechanism and Control of Ultra High Strength Steel in Roll Forming Process. J. Mech. Eng. 2018, 54, 131–137. (In Chinese) [Google Scholar] [CrossRef] [Green Version]

| C | Si | Mn | P | S | Ni | Cr | Fe |

|---|---|---|---|---|---|---|---|

| ≤0.08 | ≤1 | ≤2 | ≤0.045 | ≤0.03 | 8~10.5 | 18~20 | Remaining |

| Model | Material Parameters | Correlation Coefficient |

|---|---|---|

| Swift [18]: | 0.99996 | |

| Ludwik [19]: | 0.98873 | |

| Misiolek [20]: | 0.99204 |

| Parameters | Friction Coefficient of Flat Roller | Friction Coefficient of Vertical Roller | Speed of Flat Roller (rad/s) | Diameter of the Circular Tube (mm) | Thickness of the Circular Tube (mm) | Diameter of the Second Pass at the Top of the Roller (mm) | Roller Diameter of the 5th Pass (mm) |

|---|---|---|---|---|---|---|---|

| values | 0.2 | 0.001 | 2 | 47 | 3 | 158 | 164 |

| Different Regions | Region 1 (MPa) | Region 2 (MPa) | Region 3 (MPa) |

|---|---|---|---|

| 177,772 | 182,634 | 199,046 | |

| 177,595 | 181,212 | 199,046 | |

| 165,000 | 150,000 | - |

| Test Results | The Error Between and Test Results | The Error Between and Test Results | |||

|---|---|---|---|---|---|

| 15 mm | 122.26 | 122.22 | 121.2 | 0.87% | 0.84% |

| 25 mm | 92.04 | 90.94 | 89.9 | 2.38% | 1.16% |

| Test Results | Error Between and Test Results | Error Between and Test Results | |||

|---|---|---|---|---|---|

| 0.14 | 0.23 | 0.2 | −30% | 15% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, M.; Wang, H.; Liu, J.; Fu, Y.; Du, F. Application of Mean Modulus in Three-Point Bending and Roll Forming. Materials 2023, 16, 2571. https://doi.org/10.3390/ma16072571

Xing M, Wang H, Liu J, Fu Y, Du F. Application of Mean Modulus in Three-Point Bending and Roll Forming. Materials. 2023; 16(7):2571. https://doi.org/10.3390/ma16072571

Chicago/Turabian StyleXing, Menglong, Haijun Wang, Jiyan Liu, Yutao Fu, and Fengshan Du. 2023. "Application of Mean Modulus in Three-Point Bending and Roll Forming" Materials 16, no. 7: 2571. https://doi.org/10.3390/ma16072571

APA StyleXing, M., Wang, H., Liu, J., Fu, Y., & Du, F. (2023). Application of Mean Modulus in Three-Point Bending and Roll Forming. Materials, 16(7), 2571. https://doi.org/10.3390/ma16072571