The State of the Art in Machining Additively Manufactured Titanium Alloy Ti-6Al-4V

Abstract

:1. Introduction

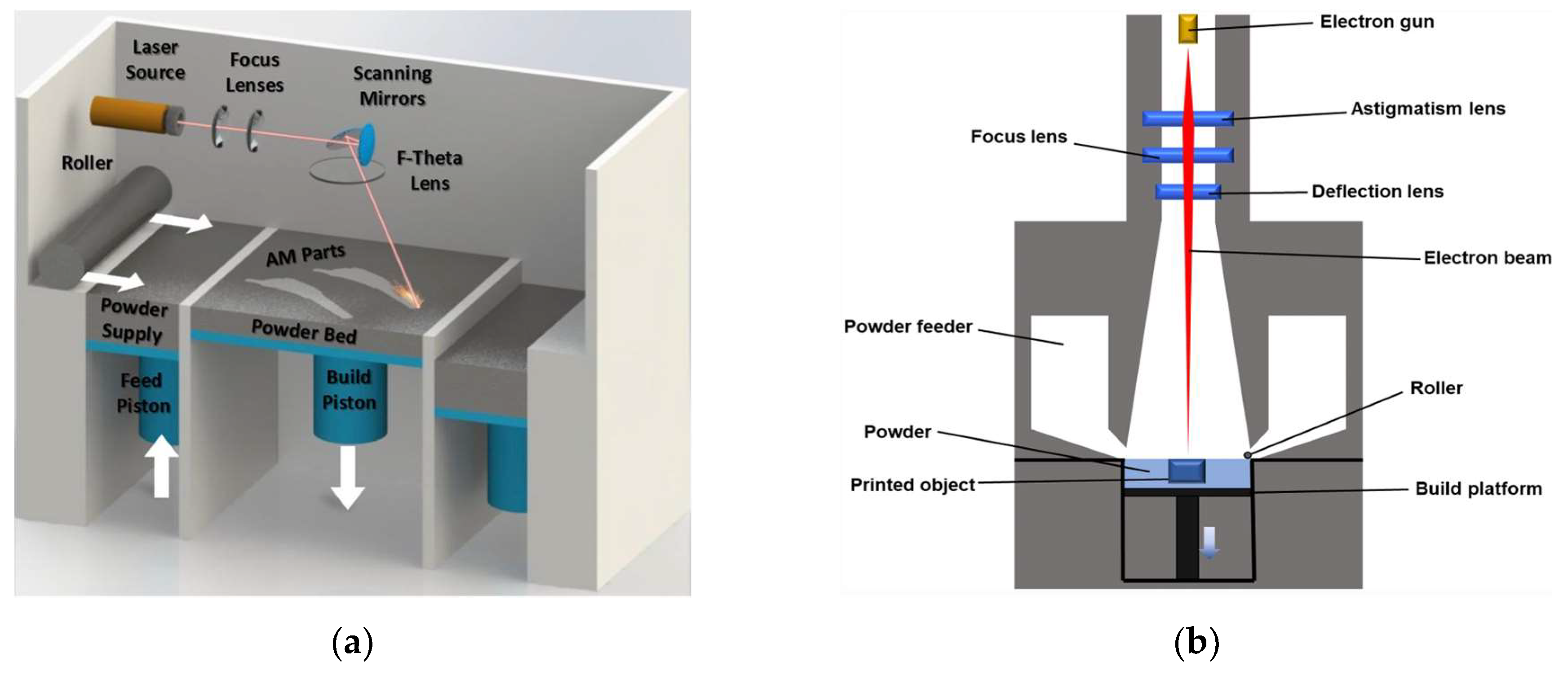

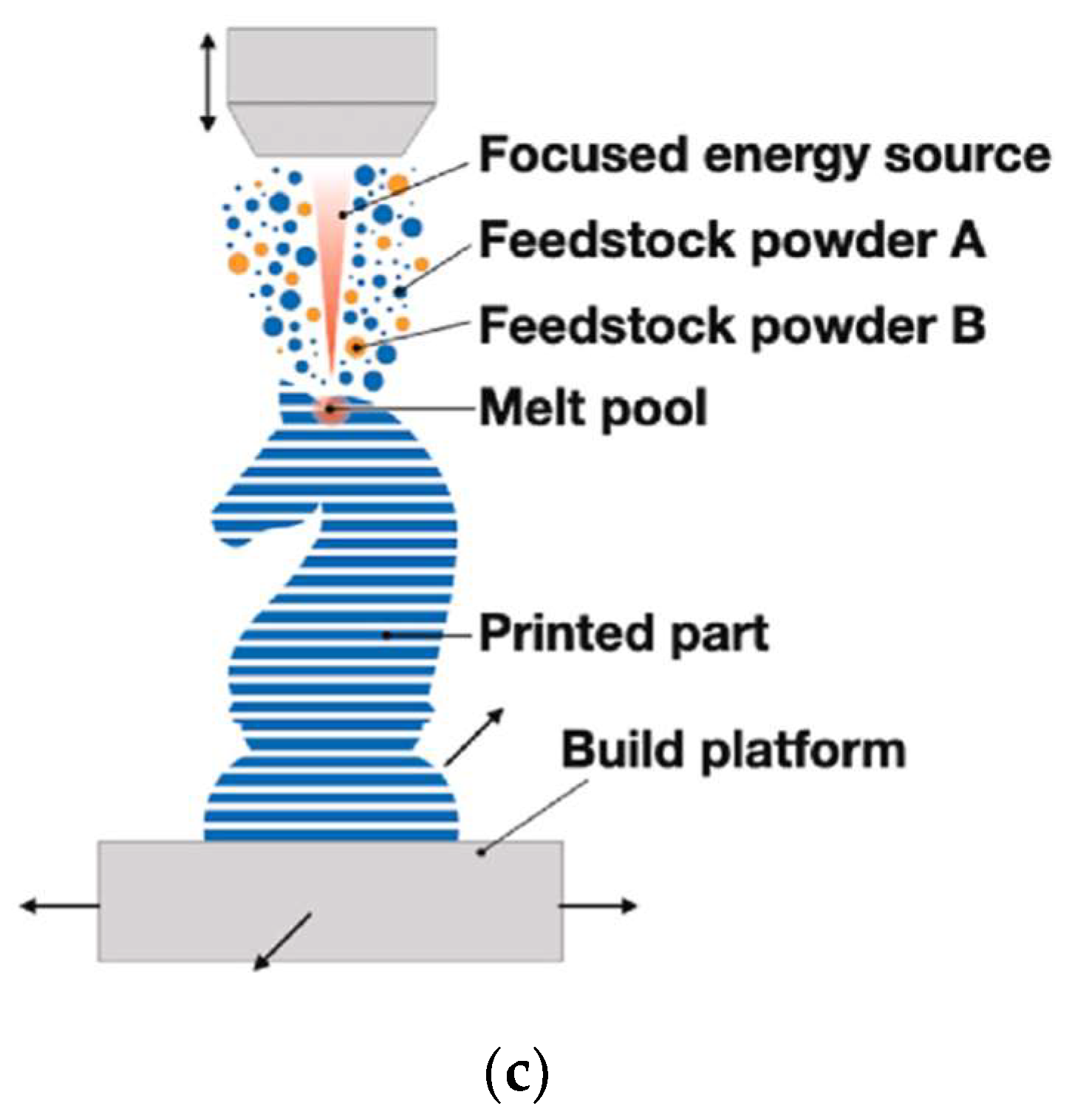

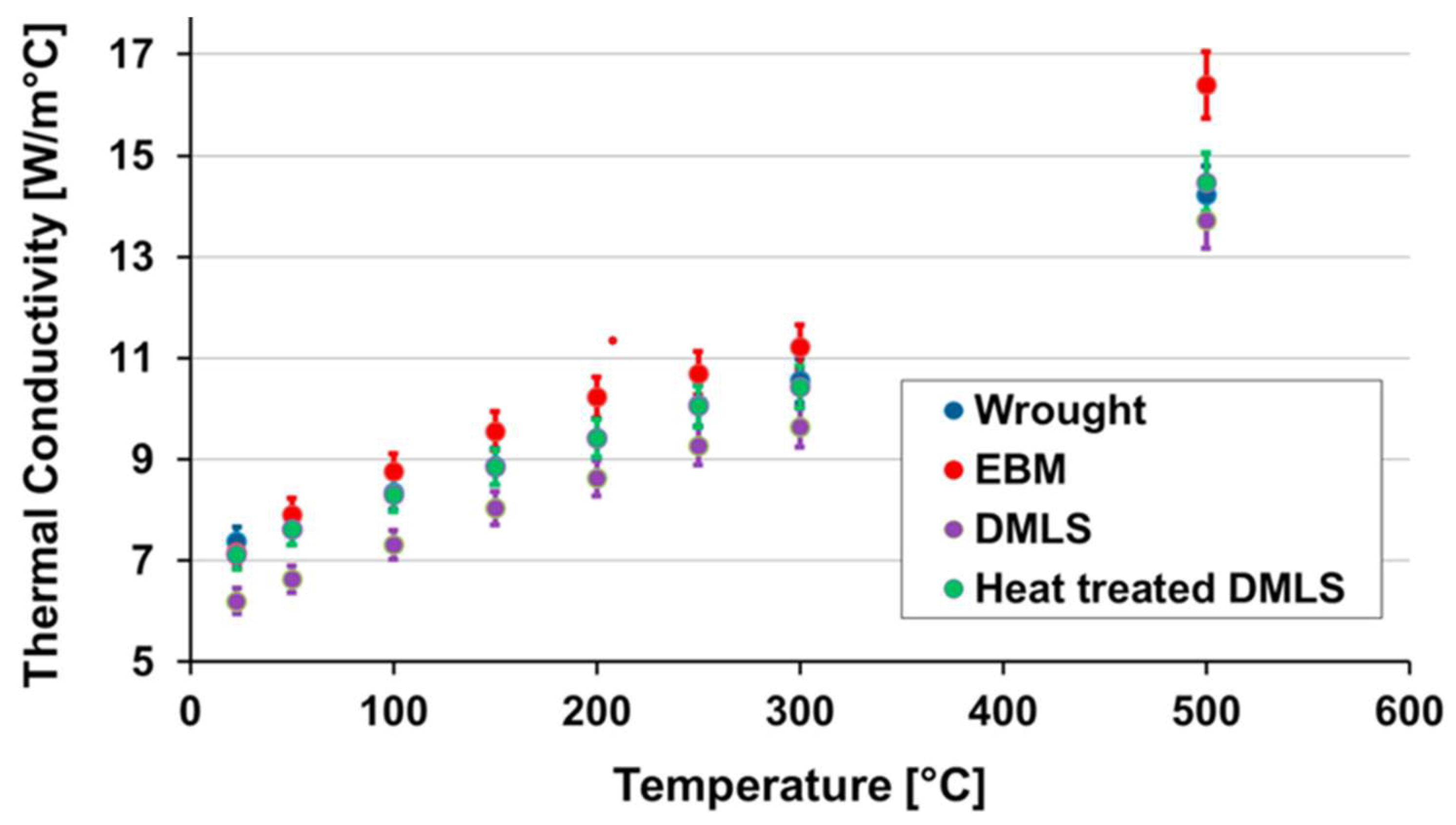

2. Additive Manufacturing Processes

3. Machinability of Additively Manufactured Ti-6Al-4V

3.1. Cutting Forces in Machining Additively Manufactured Ti-6Al-4V

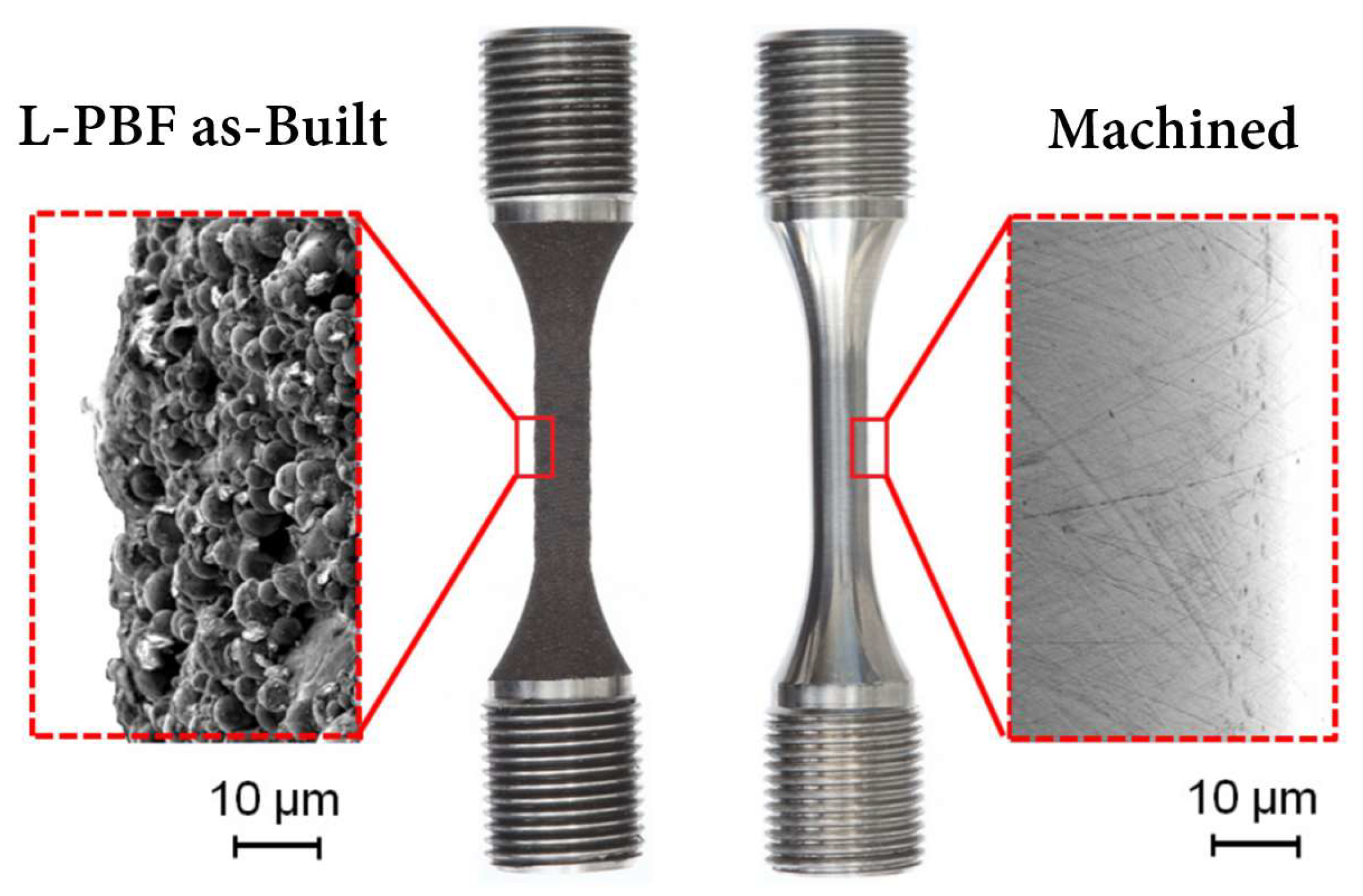

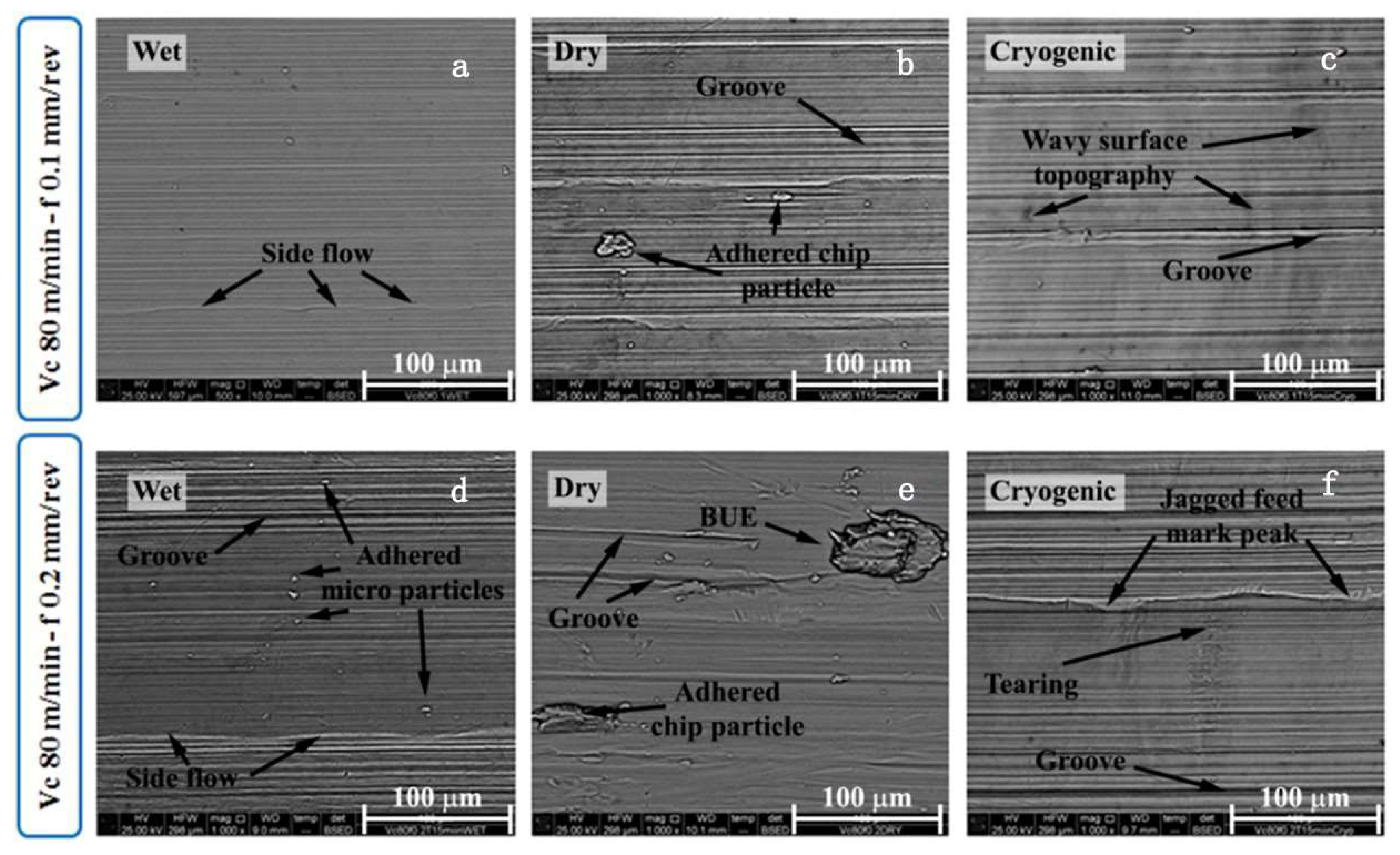

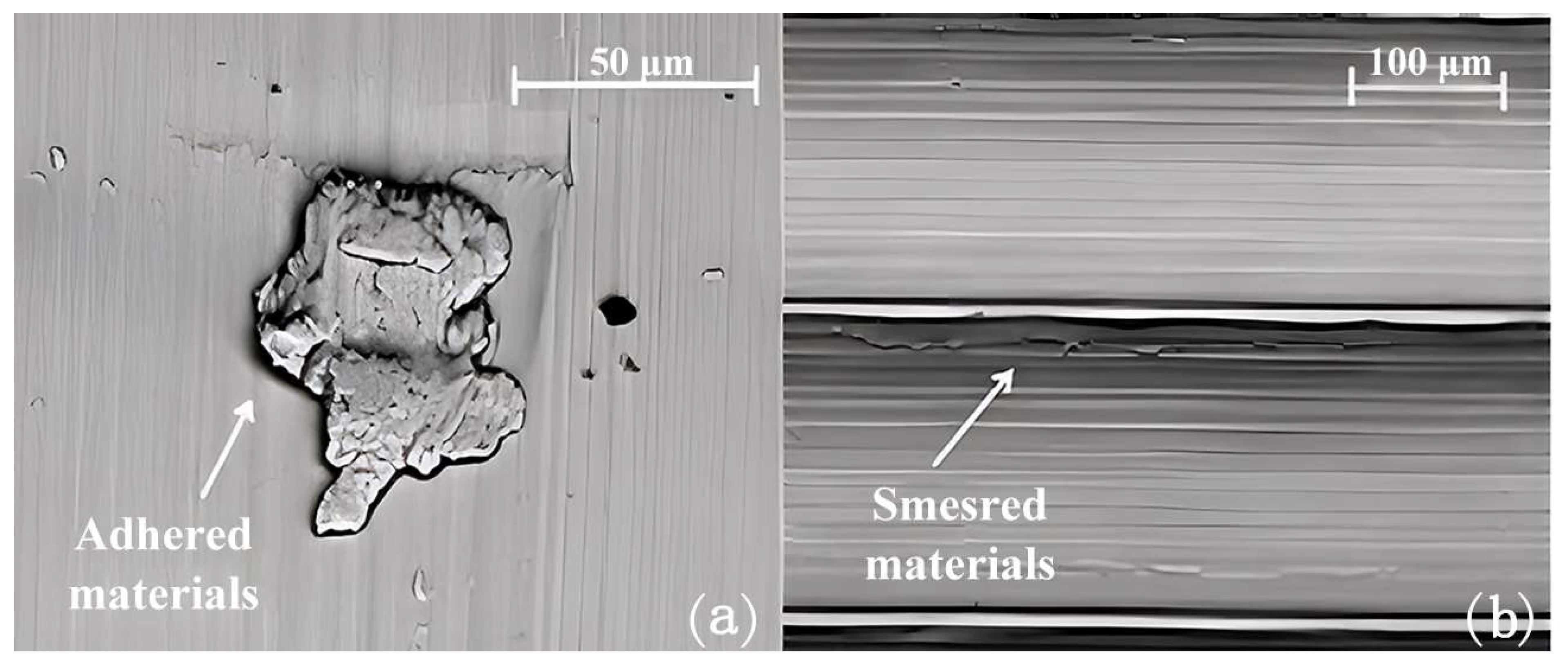

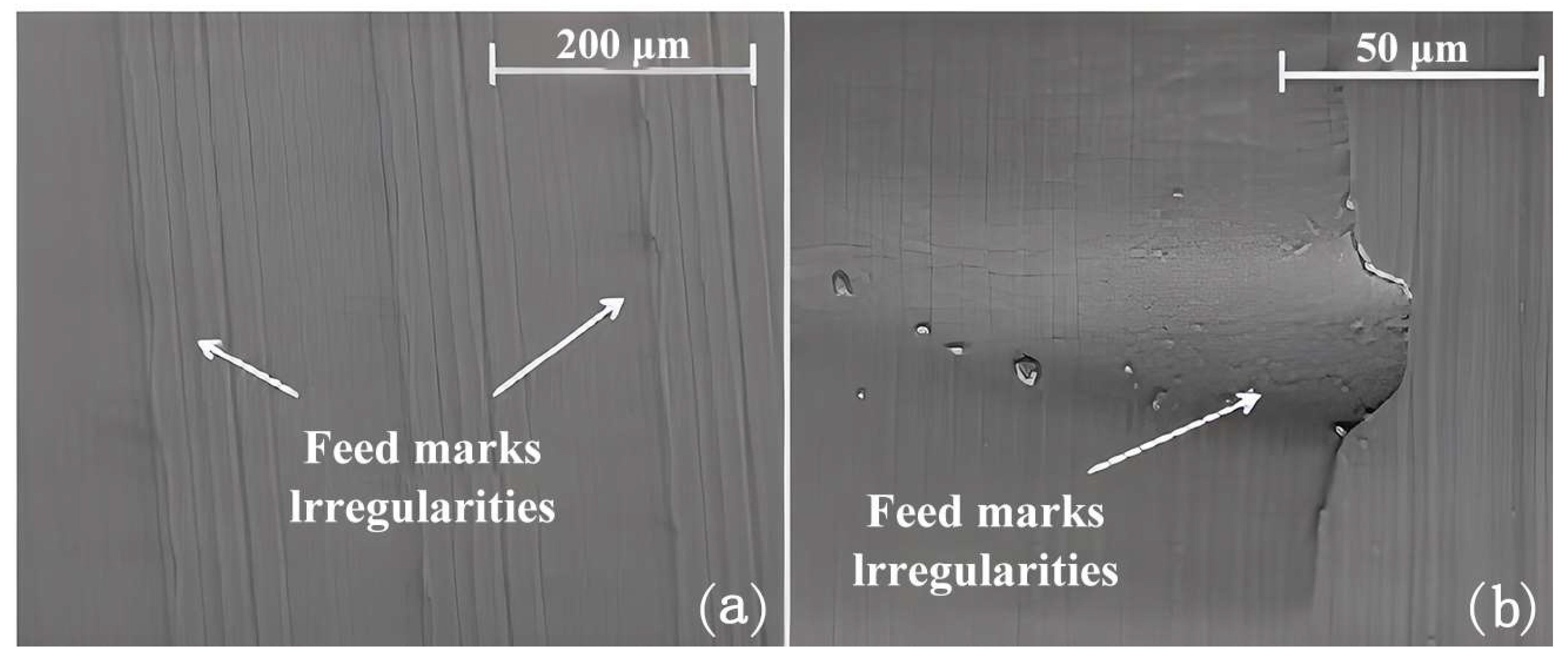

3.2. Surface Integrity

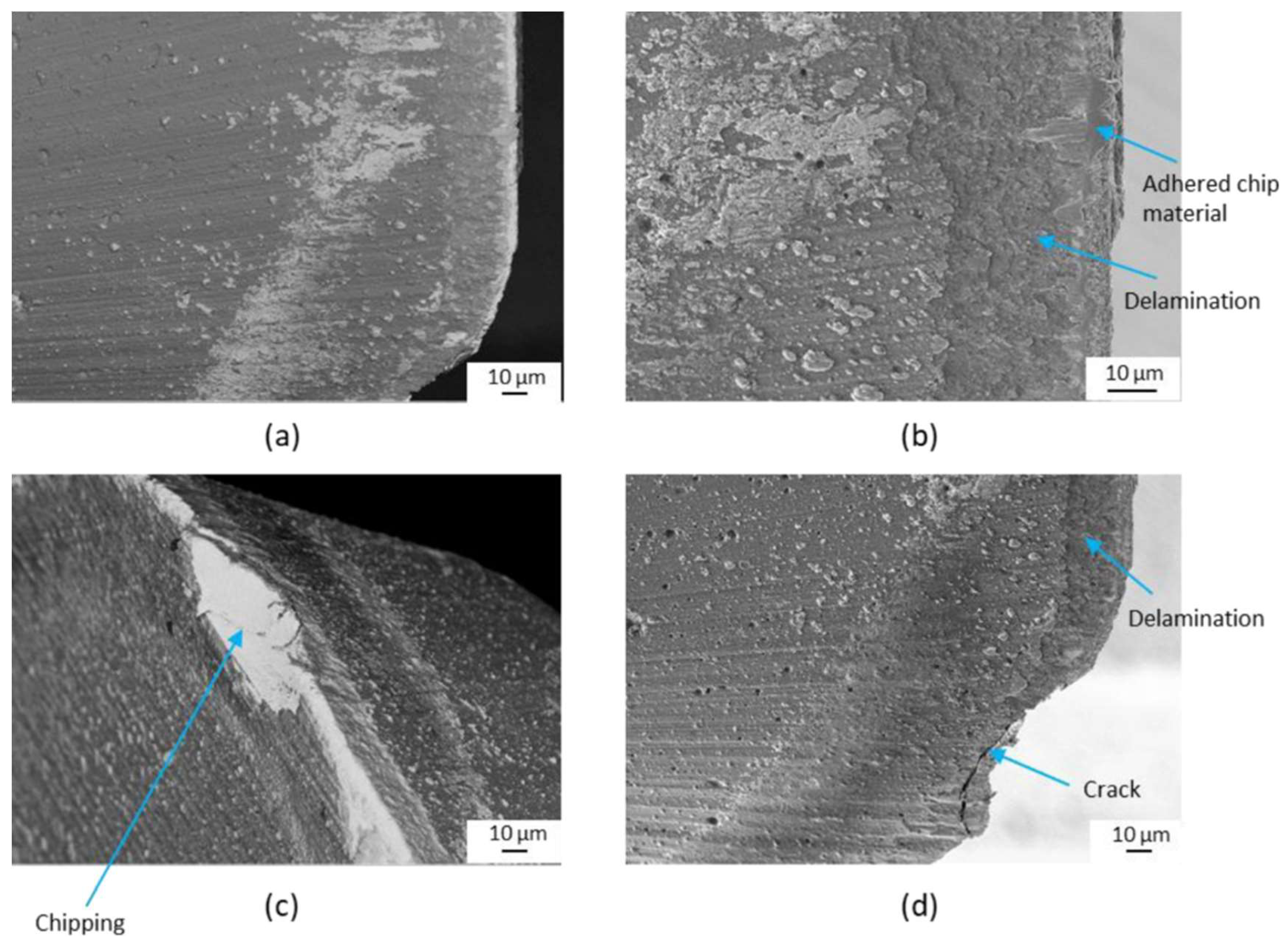

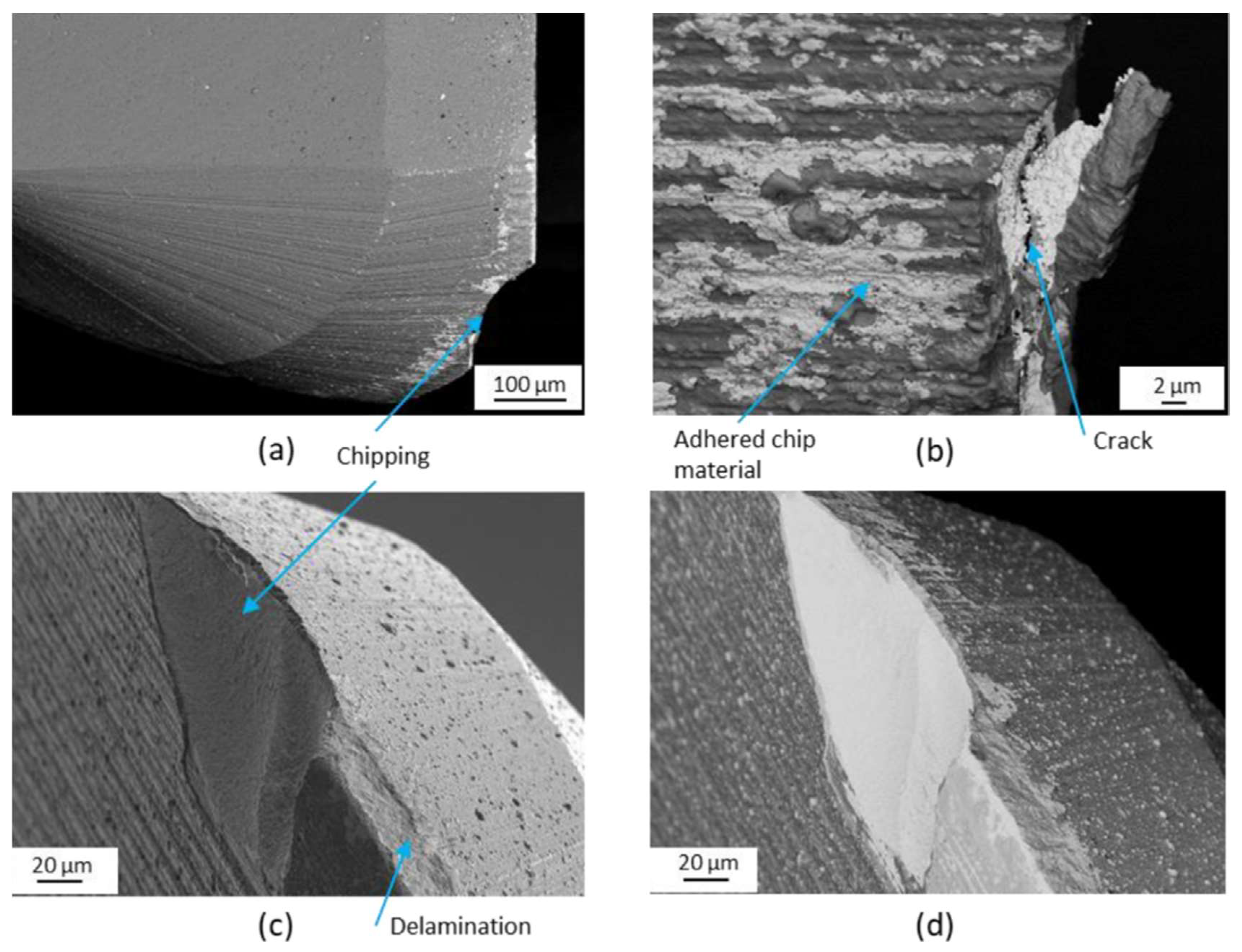

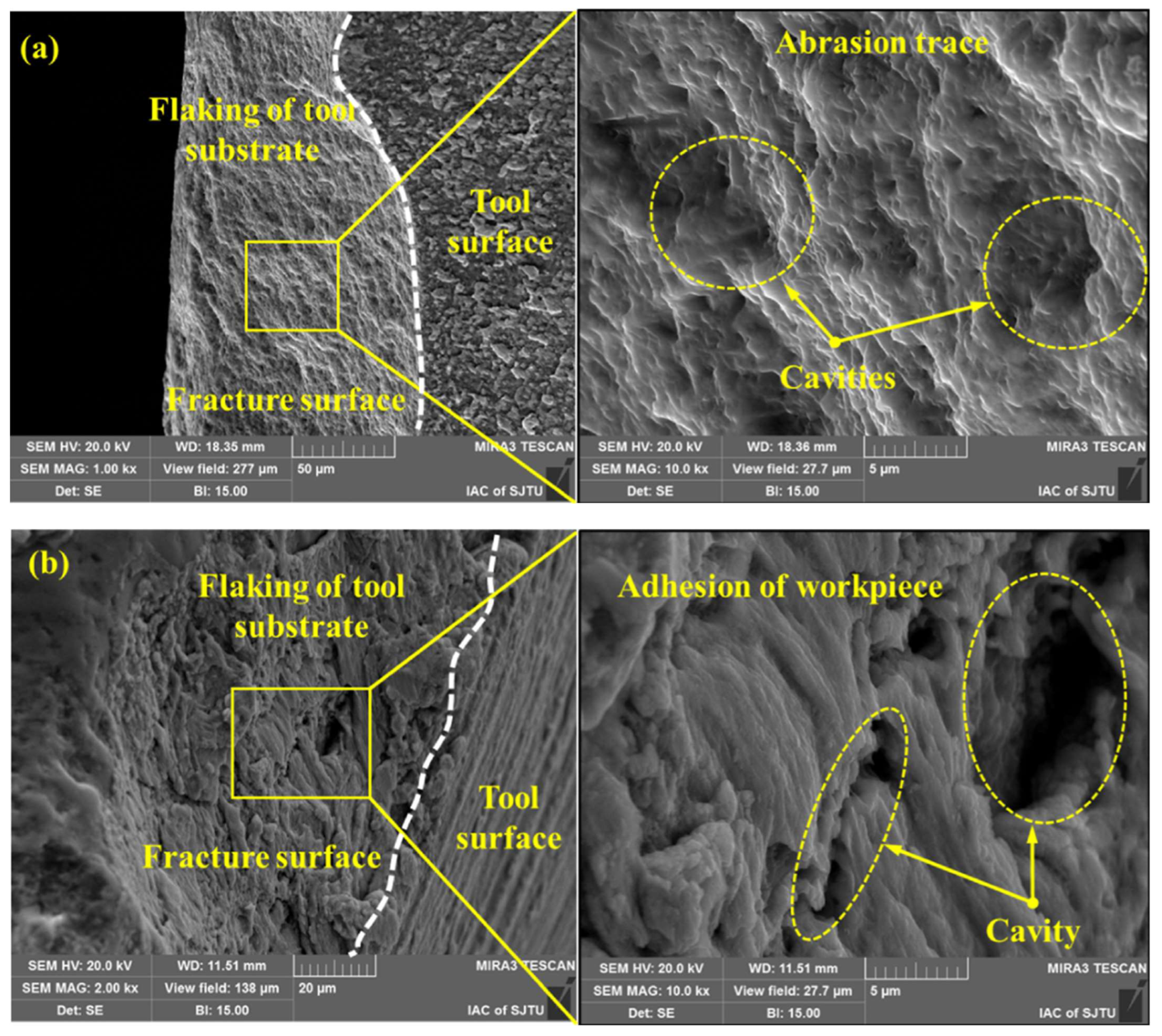

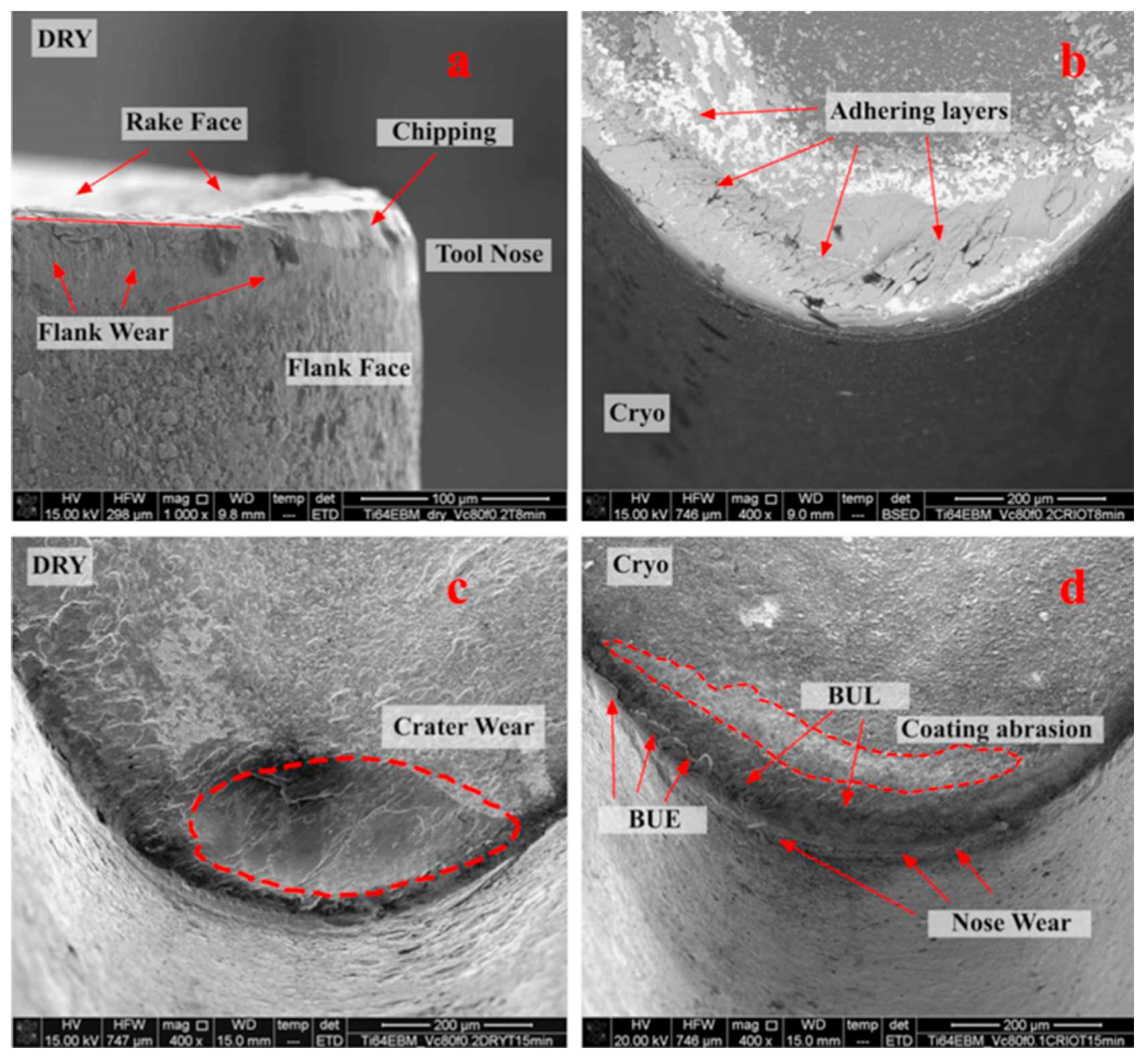

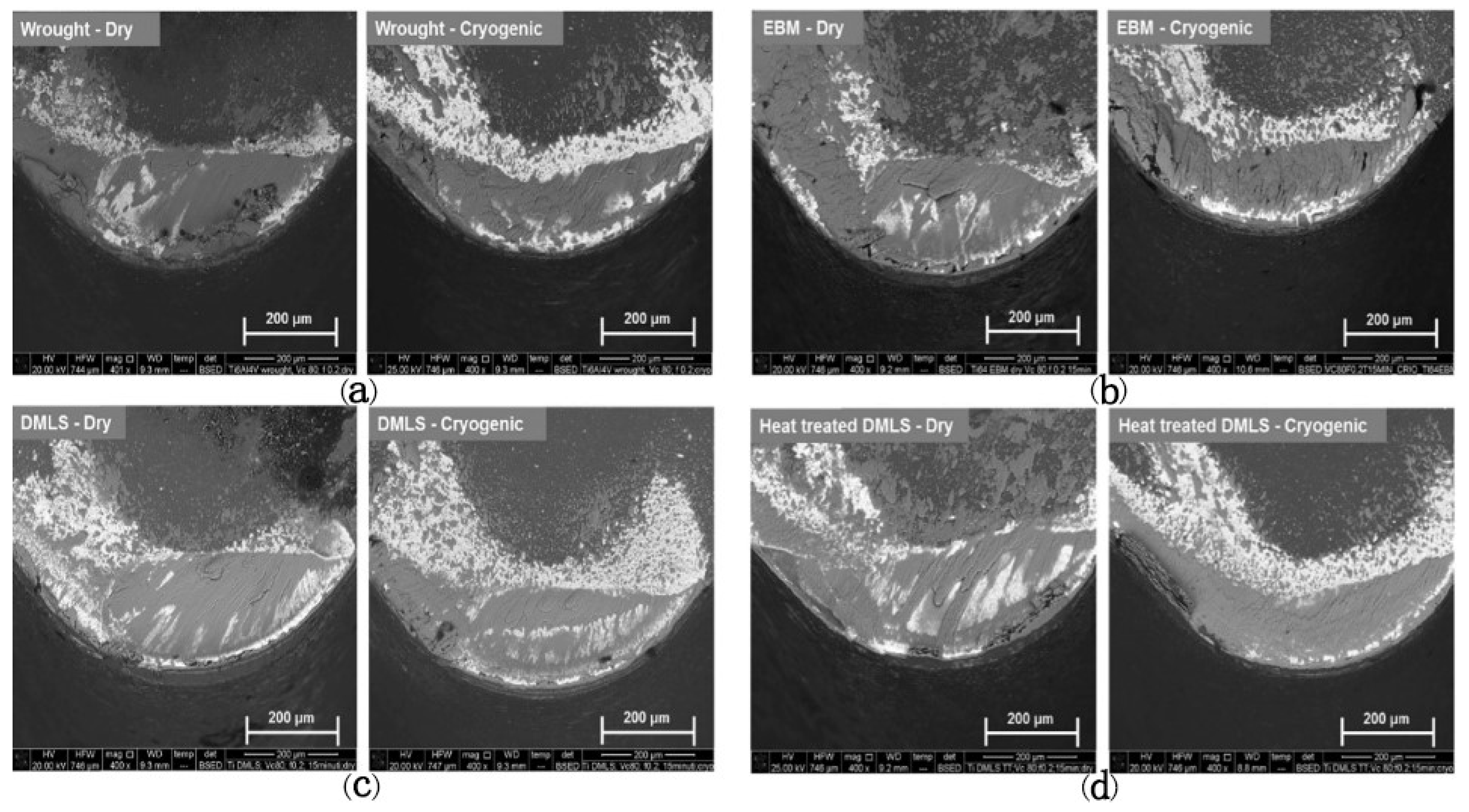

3.3. Tool Wear

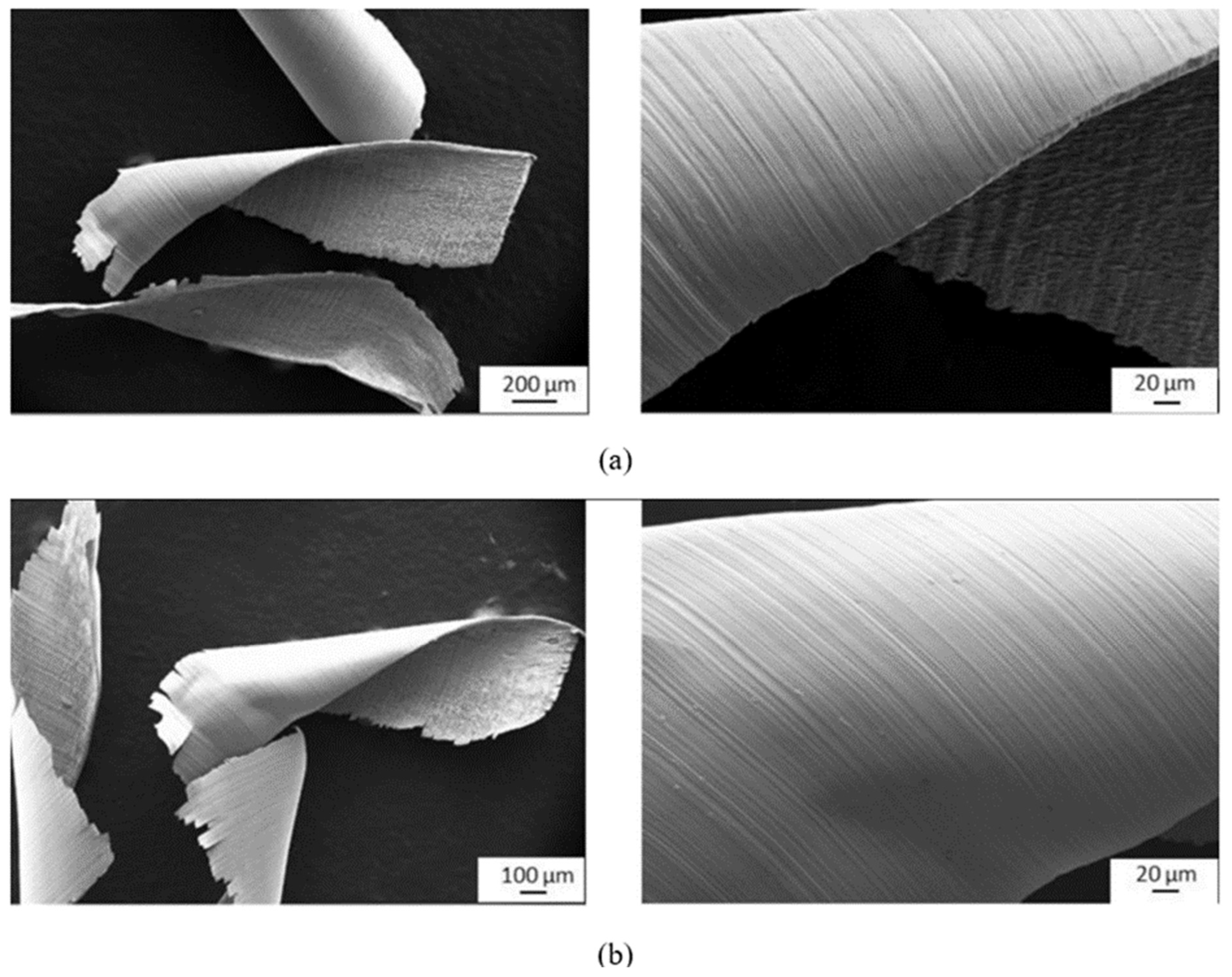

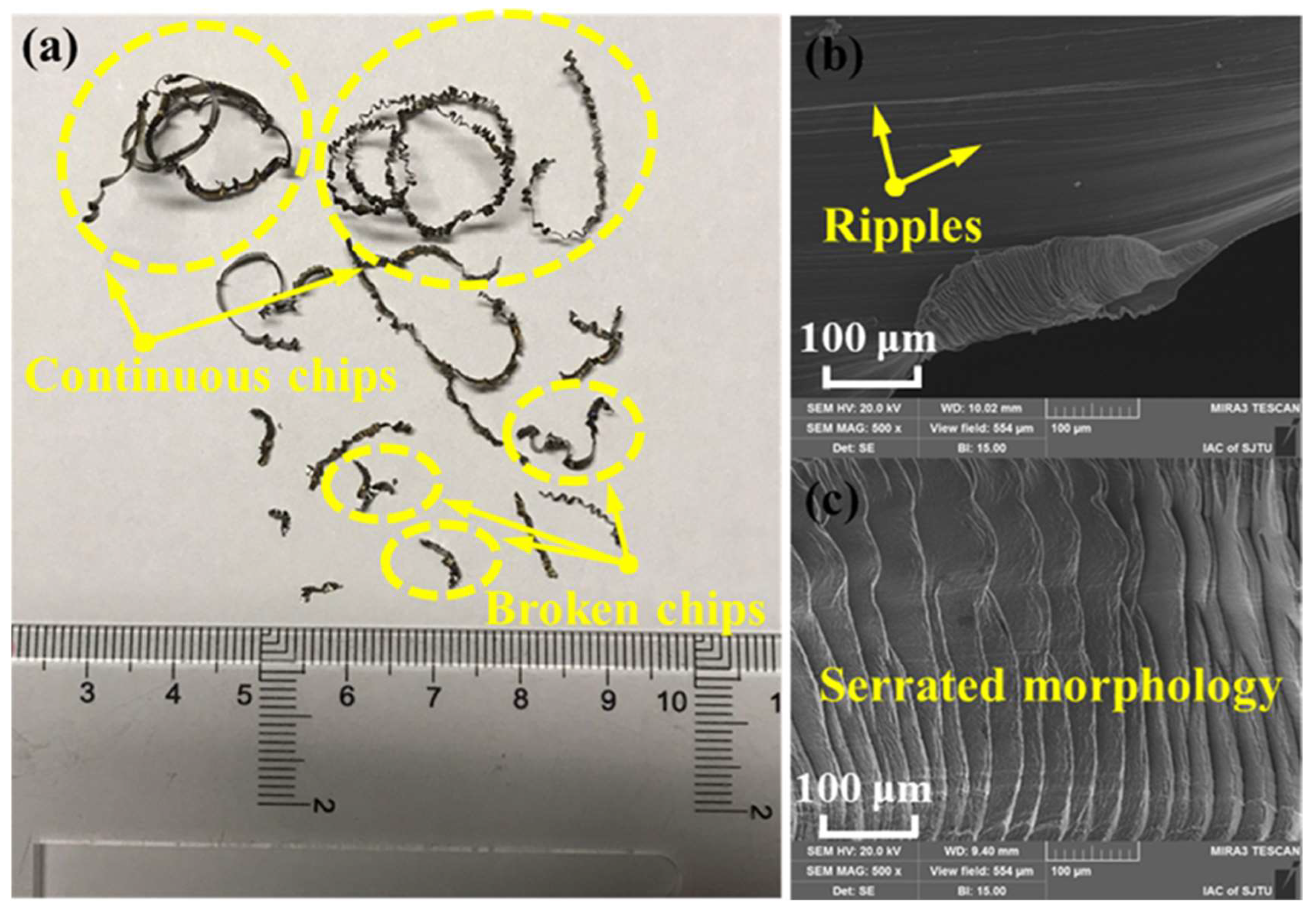

3.4. Chip Morphology

3.5. Chatter Vibration

3.6. Mechanical Properties

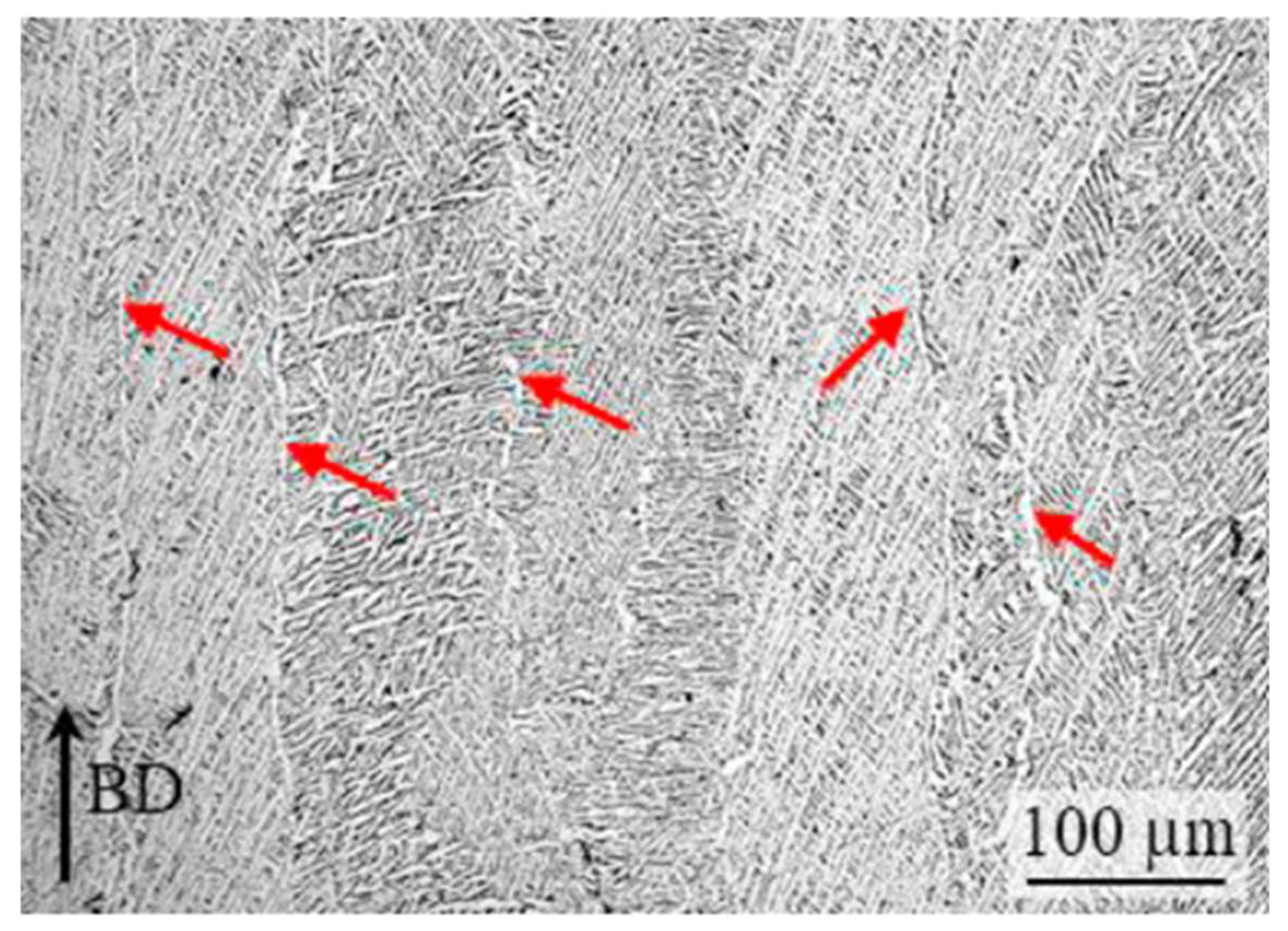

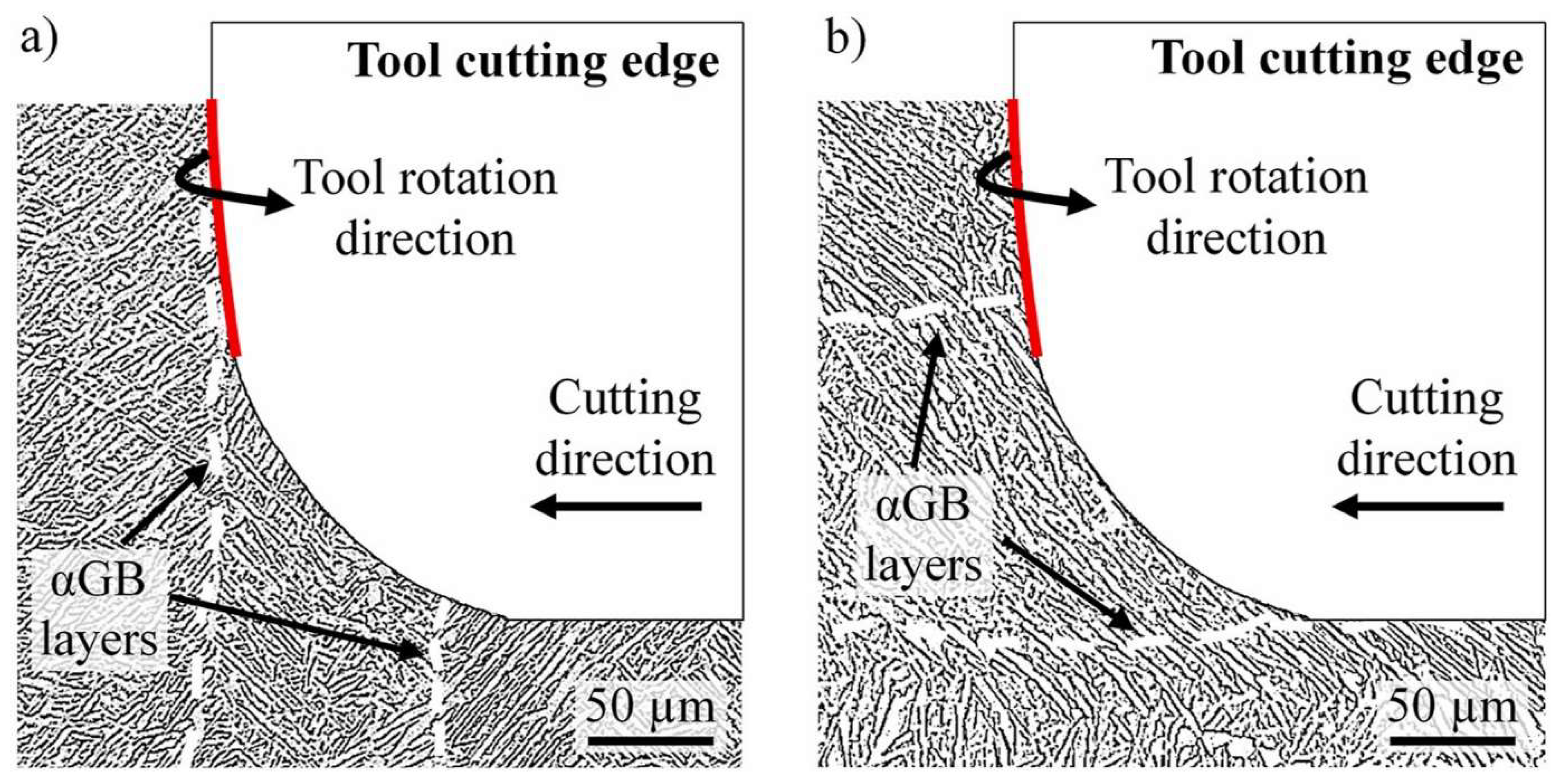

3.7. Influence of Microstructural Anisotropy

3.8. Influence of Porosity

3.9. Influence of Post-Processing Processes

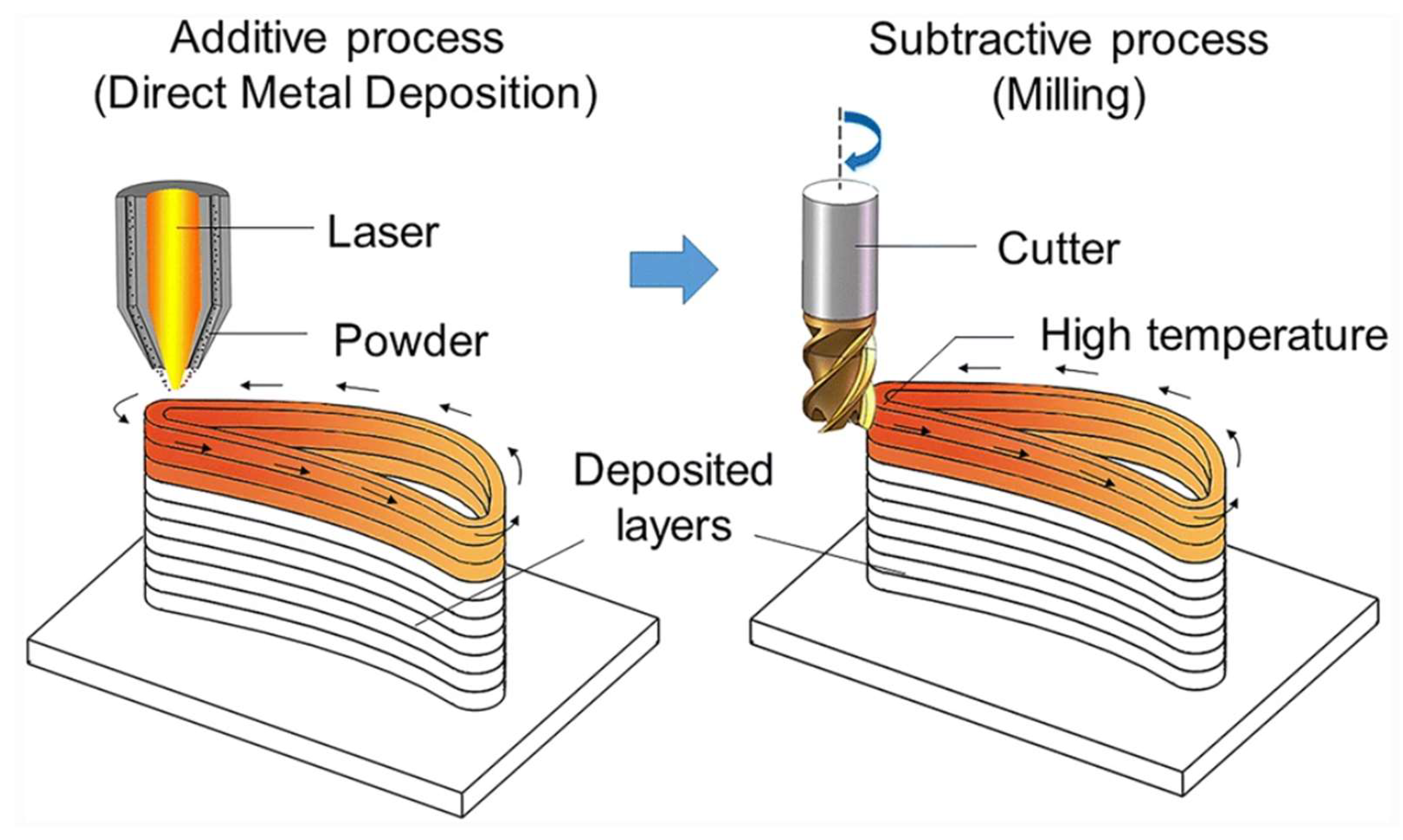

4. Hybrid Manufacturing of Additively Manufactured Ti-6Al-4V

5. Future Development and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Williams, J.C.; Boyer, R.R. Opportunities and Issues in the Application of Titanium Alloys for Aerospace Components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Bartolo, P.; Kruth, J.-P.; Silva, J.; Levy, G.; Malshe, A.; Rajurkar, K.; Mitsuishi, M.; Ciurana, J.; Leu, M. Biomedical production of implants by additive electro-chemical and physical processes. CIRP Ann. 2012, 61, 635–655. [Google Scholar] [CrossRef]

- Veiga, C.; Davim, J.; Loureiro, A. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 133–148. [Google Scholar]

- Veiga, C.; Davim, J.P.; Loureiro, A. Review on machinability of titanium alloys: The process perspective. Rev. Adv. Mater. Sci. 2013, 34, 148–164. [Google Scholar]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, H.; Wang, H.; Xiao, G.; Meng, F. Multi-objective titanium alloy belt grinding parameters optimization oriented to resources allocation and environment. Int. J. Adv. Manuf. 2021, 113, 449–463. [Google Scholar] [CrossRef]

- Muhammad, R.; Maurotto, A.; Demiral, M.; Roy, A.; Silberschmidt, V.V. Thermally enhanced ultrasonically assisted machining of Ti alloy. CIRP J. Manuf. Sci. Technol. 2014, 7, 159–167. [Google Scholar] [CrossRef] [Green Version]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Pruncu, C.I.; Hopper, C.; Hooper, P.A.; Tan, Z.; Zhu, H.; Lin, J.; Jiang, J. Study of the Effects of Hot Forging on the Additively Manufactured Stainless Steel Preforms. J. Manuf. Process. 2020, 57, 668–676. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. State-of-the-art in heat exchanger additive manufacturing. Int. J. Heat Mass Transf. 2021, 178, 121600. [Google Scholar] [CrossRef]

- Vithani, K.; Goyanes, A.; Jannin, V.; Basit, A.W.; Gaisford, S.; Boyd, B.J. An Overview of 3D Printing Technologies for Soft Materials and Potential Opportunities for Lipid-based Drug Delivery Systems. Pharm. Res. 2018, 36, 4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pratheesh Kumar, S.; Elangovan, S.; Mohanraj, R.; Ramakrishna, J.R. Review on the evolution and technology of State-of-the-Art metal additive manufacturing processes. Mater. Today Proc. 2021, 46, 7907–7920. [Google Scholar] [CrossRef]

- Duda, T.; Raghavan, L.V. 3D Metal Printing Technology. IFAC-Pap. 2016, 49, 103–110. [Google Scholar] [CrossRef]

- MANUFACTUR3D. GE Aviation Produced Its 100,000th 3D Printed Fuel Nozzle Tip. Available online: https://manufactur3dmag.com/ge-aviation-produced-its-100000th-3d-printed-fuel-nozzle-tip/ (accessed on 19 August 2022).

- Electric, G. GE9X Additive Parts. Available online: https://www.ge.com/additive/sites/default/files/2020-08/GE9X%20Additive%20parts.pdf (accessed on 19 August 2022).

- Mishurova, T.; Artzt, K.; Rehmer, B.; Haubrich, J.; Ávila, L.; Schoenstein, F.; Serrano-Munoz, I.; Requena, G.; Bruno, G. Separation of the impact of residual stress and microstructure on the fatigue performance of LPBF Ti-6Al-4V at elevated temperature. Int. J. Fatigue 2021, 148, 106239. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Surface Morphology in Selective Laser Melting of Metal Powders. Phys. Procedia 2011, 12, 264–270. [Google Scholar] [CrossRef] [Green Version]

- Shunmugavel, M.; Polishetty, A.; Nomani, J.; Goldberg, M.; Littlefair, G. Metallurgical and machinability characteristics of wrought and selective laser melted Ti-6Al-4V. J. Metall. 2016, 2016, 7407918. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Patel, K.V.; Jarosz, K.; Özel, T. Surface integrity induced in machining additively fabricated nickel alloy Inconel 625. Procedia CIRP 2020, 87, 351–354. [Google Scholar] [CrossRef]

- Basha, M.M.; Basha, S.M.; Jain, V.K.; Sankar, M.R. State of the art on chemical and electrochemical based finishing processes for additive manufactured features. Addit. Manuf. 2022, 58, 103028. [Google Scholar] [CrossRef]

- Wysocki, B.; Idaszek, J.; Szlązak, K.; Strzelczyk, K.; Brynk, T.; Kurzydłowski, K.J.; Święszkowski, W. Post Processing and Biological Evaluation of the Titanium Scaffolds for Bone Tissue Engineering. Materials 2016, 9, 197. [Google Scholar] [CrossRef]

- Pyka, G.; Kerckhofs, G.; Papantoniou, I.; Speirs, M.; Schrooten, J.; Wevers, M. Surface Roughness and Morphology Customization of Additive Manufactured Open Porous Ti-6Al-4V Structures. Materials 2013, 6, 4737–4757. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Rahim, M.Z.; Pan, W.; Wen, C.; Ding, S. The manufacturing and the application of polycrystalline diamond tools—A comprehensive review. J. Manuf. Process. 2020, 56, 400–416. [Google Scholar] [CrossRef]

- Li, G.; Wu, G.; Pan, W.; Rahman Rashid, R.A.; Palanisamy, S.; Ding, S. The Performance of Polycrystalline Diamond (PCD) Tools Machined by Abrasive Grinding and Electrical Discharge Grinding (EDG) in High-Speed Turning. J. Manuf. Mater. Process. 2021, 5, 34. [Google Scholar] [CrossRef]

- Yi, S.; Li, N.; Solanki, S.; Mo, J.; Ding, S. Effects of graphene oxide nanofluids on cutting temperature and force in machining Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 103, 1481–1495. [Google Scholar] [CrossRef]

- Niknam, S.A.; Khettabi, R.; Songmene, V. Machinability and Machining of Titanium Alloys: A Review. In Machining of Titanium Alloys; Davim, J.P., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–30. [Google Scholar]

- Dandekar, C.R.; Shin, Y.C.; Barnes, J. Machinability improvement of titanium alloy (Ti-6Al-4V) via LAM and hybrid machining. Int. J. Mach. Tool Manuf. 2010, 50, 174–182. [Google Scholar] [CrossRef]

- Hourmand, M.; Sarhan, A.A.D.; Sayuti, M.; Hamdi, M. A Comprehensive Review on Machining of Titanium Alloys. Arab. J. Sci. Eng. 2021, 46, 7087–7123. [Google Scholar] [CrossRef]

- Sommer, D.; Götzendorfer, B.; Esen, C.; Hellmann, R. Design Rules for Hybrid Additive Manufacturing Combining Selective Laser Melting and Micromilling. Materials 2021, 14, 5753. [Google Scholar] [CrossRef]

- Sommer, D.; Pape, D.; Esen, C.; Hellmann, R. Tool Wear and Milling Characteristics for Hybrid Additive Manufacturing Combining Laser Powder Bed Fusion and In Situ High-Speed Milling. Materials 2022, 15, 1236. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. (Eds.) Titanium Matrix Composites. In Titanium; Springer: Berlin/Heidelberg, Germany, 2007; pp. 367–382. [Google Scholar]

- Arrazola, P.J.; Garay, A.; Iriarte, L.M.; Armendia, M.; Marya, S.; Le Maître, F. Machinability of titanium alloys (Ti-6Al-4V and Ti555.3). J. Mater. Process. Technol. 2009, 209, 2223–2230. [Google Scholar] [CrossRef] [Green Version]

- Palanisamy, S.; McDonald, S.D.; Dargusch, M.S. Effects of coolant pressure on chip formation while turning Ti-6Al-4V alloy. Int. J. Mach. Tool Manuf. 2009, 49, 739–743. [Google Scholar] [CrossRef]

- Baufeld, B.; Biest, O.V.d.; Gault, R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Rotella, G.; Imbrogno, S.; Candamano, S.; Umbrello, D. Surface integrity of machined additively manufactured Ti alloys. J. Mater. Process. Technol. 2018, 259, 180–185. [Google Scholar] [CrossRef]

- Ren, X.P.; Li, H.Q.; Guo, H.; Shen, F.L.; Qin, C.X.; Zhao, E.T.; Fang, X.Y. A comparative study on mechanical properties of Ti-6Al-4V alloy processed by additive manufacturing vs. traditional processing. Mater. Sci. Eng. A 2021, 817, 141384. [Google Scholar] [CrossRef]

- Mierzejewska, Ż.A.; Hudák, R.; Sidun, J. Mechanical Properties and Microstructure of DMLS Ti-6Al-4V Alloy Dedicated to Biomedical Applications. Materials 2019, 12, 176. [Google Scholar] [CrossRef] [Green Version]

- Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydłowski, K.J.; Święszkowski, W. Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Appl. Sci. 2017, 7, 657. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Krawczyńska, A.; Rożniatowski, K.; Zdunek, J.; Kurzydłowski, K.J.; Święszkowski, W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). J. Mater. Process. Technol. 2017, 241, 13–23. [Google Scholar] [CrossRef]

- Sitek, R.; Szustecki, M.; Zrodowski, L.; Wysocki, B.; Jaroszewicz, J.; Wisniewski, P.; Mizera, J. Analysis of Microstructure and Properties of a Ti–AlN Composite Produced by Selective Laser Melting. Materials 2020, 13, 2218. [Google Scholar] [CrossRef]

- Jiménez, A.; Bidare, P.; Hassanin, H.; Tarlochan, F.; Dimov, S.; Essa, K. Powder-based laser hybrid additive manufacturing of metals: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 63–96. [Google Scholar] [CrossRef]

- Kalpakjian, S. Manufacturing Processes for Engineering Materials; Pearson Education India: New Delhi, India, 1984. [Google Scholar]

- Hamza, H.M.; Deen, K.M.; Khaliq, A.; Asselin, E.; Haider, W. Microstructural, corrosion and mechanical properties of additively manufactured alloys: A review. Crit. Rev. Solid State Mater. Sci. 2022, 47, 46–98. [Google Scholar] [CrossRef]

- Zhai, Y.; Lados, D.A.; Brown, E.J.; Vigilante, G.N. Understanding the microstructure and mechanical properties of Ti-6Al-4V and Inconel 718 alloys manufactured by Laser Engineered Net Shaping. Addit. Manuf. 2019, 27, 334–344. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.S.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, E.S.; Park, S.; Park, J.M.; Seol, J.B.; Kim, H.S.; Lee, T.; Sung, H.; Kim, J.G. Effects of Laser Power on the Microstructure Evolution and Mechanical Properties of Ti-6Al-4V Alloy Manufactured by Direct Energy Deposition. Met. Mater. Int. 2022, 28, 197–204. [Google Scholar] [CrossRef]

- Chen, B.; Wu, Z.; Yan, T.; He, Z.; Sun, B.; Guo, G.; Wu, S. Experimental study on mechanical properties of laser powder bed fused Ti-6Al-4V alloy under post-heat treatment. Eng. Fract. Mech. 2022, 261, 108264. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Kang, N.; Lin, X.; Lv, S.; Kondoh, K.; Li, S.; Li, J.S. Comparison study on microstructure and mechanical properties of Ti-6Al-4V alloys fabricated by powder-based selective-laser-melting and sintering methods. Mater. Charact. 2020, 164, 110358. [Google Scholar] [CrossRef]

- Tong, J.; Bowen, C.R.; Persson, J.; Plummer, A. Mechanical properties of titanium-based Ti-6Al-4V alloys manufactured by powder bed additive manufacture. Mater. Sci. Technol. 2017, 33, 138–148. [Google Scholar] [CrossRef] [Green Version]

- Khanna, N.; Zadafiya, K.; Patel, T.; Kaynak, Y.; Rahman Rashid, R.A.; Vafadar, A. Review on machining of additively manufactured nickel and titanium alloys. J. Mater. Res. Technol. 2021, 15, 3192–3221. [Google Scholar] [CrossRef]

- Li, G.; Chandra, S.; Rahman Rashid, R.A.; Palanisamy, S.; Ding, S. Machinability of additively manufactured titanium alloys: A comprehensive review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Lalbondre, R.; Krishna, P.; Mohankumar, G.C. An Experimental Investigation on Machinability Studies of Steels by Face Turning. Procedia Mater. Sci. 2014, 6, 1386–1395. [Google Scholar] [CrossRef] [Green Version]

- Kechagias, J.D.; Aslani, K.-E.; Fountas, N.A.; Vaxevanidis, N.M.; Manolakos, D.E. A comparative investigation of Taguchi and full factorial design for machinability prediction in turning of a titanium alloy. Measurement 2020, 151, 107213. [Google Scholar] [CrossRef]

- Pegues, J.W.; Shao, S.; Shamsaei, N.; Sanaei, N.; Fatemi, A.; Warner, D.H.; Li, P.; Phan, N. Fatigue of additive manufactured Ti-6Al-4V, Part I: The effects of powder feedstock, manufacturing, and post-process conditions on the resulting microstructure and defects. Int. J. Fatigue 2020, 132, 105358. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Beese, A.M.; Carroll, B.E. Review of Mechanical Properties of Ti-6Al-4V Made by Laser-Based Additive Manufacturing Using Powder Feedstock. JOM 2016, 68, 724–734. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf. 2018, 26, 834–845. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- de Formanoir, C.; Paggi, U.; Colebrants, T.; Thijs, L.; Li, G.; Vanmeensel, K.; Van Hooreweder, B. Increasing the productivity of laser powder bed fusion: Influence of the hull-bulk strategy on part quality, microstructure and mechanical performance of Ti-6Al-4V. Addit. Manuf. 2020, 33, 101129. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Nzeukou, R.A.; Onawale, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2021, 11, 58. [Google Scholar] [CrossRef]

- Polozov, I.; Gracheva, A.; Popovich, A. Processing, Microstructure, and Mechanical Properties of Laser Additive Manufactured Ti2AlNb-Based Alloy with Carbon, Boron, and Yttrium Microalloying. Metals 2022, 12, 1304. [Google Scholar] [CrossRef]

- Aconity3D, Aconity Inline Process-Monitoring. Available online: https://aconity3d.com/products/aconity-midi/ (accessed on 10 March 2023).

- Uçak, N.; Çiçek, A.; Aslantas, K. Machinability of 3D printed metallic materials fabricated by selective laser melting and electron beam melting: A review. J. Manuf. Process. 2022, 80, 414–457. [Google Scholar] [CrossRef]

- ISO/ASTM52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ASTM: West Conshohocken, PA, USA, 2015.

- Metalnikov, P.; Ben-Hamu, G.; Eliezer, D. Corrosion behavior of AM-Ti-6Al-4V: A comparison between EBM and SLM. Prog. Addit. Manuf. 2022, 7, 509–520. [Google Scholar] [CrossRef]

- Tamayo, J.A.; Riascos, M.; Vargas, C.A.; Baena, L.M. Additive manufacturing of Ti-6Al-4V alloy via electron beam melting for the development of implants for the biomedical industry. Heliyon 2021, 7, e06892. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti-6Al-4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1, 87–98. [Google Scholar] [CrossRef]

- Kang, C.-W.; Fang, F.-Z. State of the art of bioimplants manufacturing: Part I. Adv. Manuf. 2018, 6, 20–40. [Google Scholar] [CrossRef] [Green Version]

- Rehme, O.; Emmelmann, C. Rapid manufacturing of lattice structures with selective laser melting. In Proceedings of the Lasers and Applications in Science and Engineering, San Jose, CA, USA, 25–26 January 2006; pp. 192–203. [Google Scholar]

- Mazur, M.; Selvakannan, P.R. Laser Powder Bed Fusion—Principles, Challenges, and Opportunities. In Additive Manufacturing for Chemical Sciences and Engineering; Bhargava, S.K., Ramakrishna, S., Brandt, M., Selvakannan, P.R., Eds.; Springer Nature: Singapore, 2022; pp. 77–108. [Google Scholar]

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; O’Donnell, G.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Jang, T.-S.; Kim, D.; Han, G.; Yoon, C.-B.; Jung, H.-D. Powder based additive manufacturing for biomedical application of titanium and its alloys: A review. Biomed. Eng. Lett. 2020, 10, 505–516. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-based directed energy deposition (DED-LB) of advanced materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Duda, T.; Raghavan, L.V. 3D metal printing technology: The need to re-invent design practice. AI Soc. 2018, 33, 241–252. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The Additive Manufacturing (AM) of titanium alloys. Metal Powder Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti-6Al-4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Gasser, A.; Backes, G.; Kelbassa, I.; Weisheit, A.; Wissenbach, K. Laser additive manufacturing: Laser Metal Deposition (LMD) and Selective Laser Melting (SLM) in turbo-engine applications. Laser Tech. J. 2010, 7, 58–63. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Dumas, M.; Cabanettes, F.; Kaminski, R.; Valiorgue, F.; Picot, E.; Lefebvre, F.; Grosjean, C.; Rech, J. Influence of the finish cutting operations on the fatigue performance of Ti-6Al-4V parts produced by Selective Laser Melting. Procedia CIRP 2018, 71, 429–434. [Google Scholar] [CrossRef]

- Fortunato, A.; Lulaj, A.; Melkote, S.; Liverani, E.; Ascari, A.; Umbrello, D. Milling of maraging steel components produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2018, 94, 1895–1902. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, C.; Liu, X.; Liu, R.; Xiao, Z. Improved surface integrity of Ti-6Al-4V fabricated by selective electron beam melting using ultrasonic surface rolling processing. J. Mater. Process. Technol. 2021, 297, 117264. [Google Scholar] [CrossRef]

- Cerri, E.; Ghio, E.; Bolelli, G. Effect of surface roughness and industrial heat treatments on the microstructure and mechanical properties of Ti-6Al-4V alloy manufactured by laser powder bed fusion in different built orientations. Mater. Sci. Eng. A 2022, 851, 143635. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Gulizia, S.; Oh, C.H.; Fraser, D.; Leary, M.; Yang, Y.F.; Qian, M. The Influence of As-Built Surface Conditions on Mechanical Properties of Ti-6Al-4V Additively Manufactured by Selective Electron Beam Melting. JOM 2016, 68, 791–798. [Google Scholar] [CrossRef]

- Gorsse, S.; Hutchinson, C.; Gouné, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef] [Green Version]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Ding, S.; Yang, D.C.H.; Han, Z. Boundary-conformed machining of turbine blades. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2005, 219, 255–263. [Google Scholar] [CrossRef]

- Yang, D.C.H.; Chuang, J.J.; Han, Z.; Ding, S. Boundary-conformed toolpath generation for trimmed free-form surfaces via Coons reparametrization. J. Mater. Process. Technol. 2003, 138, 138–144. [Google Scholar] [CrossRef]

- Pan, W.; Ding, S.; Mo, J. The prediction of cutting force in end milling titanium alloy (Ti-6Al-4V) with polycrystalline diamond tools. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2017, 231, 3–14. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M.S. Characteristics of cutting forces and chip formation in machining of titanium alloys. Int. J. Mach. Tools Manuf. 2009, 49, 561–568. [Google Scholar] [CrossRef]

- Shunmugavel, M.; Polishetty, A.; Goldberg, M.; Singh, R.; Littlefair, G. A comparative study of mechanical properties and machinability of wrought and additive manufactured (selective laser melting) titanium alloy–Ti-6Al-4V. Rapid Prototyp. J. 2017, 23, 1051–1056. [Google Scholar] [CrossRef]

- Polishetty, A.; Shunmugavel, M.; Goldberg, M.; Littlefair, G.; Singh, R.K. Cutting Force and Surface Finish Analysis of Machining Additive Manufactured Titanium Alloy Ti-6Al-4V. Procedia Manuf. 2017, 7, 284–289. [Google Scholar] [CrossRef] [Green Version]

- Shunmugavel, M.; Polishetty, A.; Goldberg, M.; Singh, R.; Littlefair, G. Tool Wear and Surface Integrity Analysis of Machined Heat Treated Selective Laser Melted Ti-6Al-4V. Int. J. Mater. Form. Mach. Process. 2016, 3, 50–63. [Google Scholar] [CrossRef] [Green Version]

- Ming, W.; Chen, J.; An, Q.; Chen, M. Dynamic mechanical properties and machinability characteristics of selective laser melted and forged Ti-6Al-4V. J. Mater. Process. Technol. 2019, 271, 284–292. [Google Scholar] [CrossRef]

- Schur, R.; Ghods, S.; Wisdom, C.; Pahuja, R.; Montelione, A.; Arola, D.; Ramulu, M. Mechanical anisotropy and its evolution with powder reuse in Electron Beam Melting AM of Ti-6Al-4V. Mater. Des. 2021, 200, 109450. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ishimoto, T.; Hibino, S.; Yasutomi, J.; Narushima, T.; Nakano, T. Unique crystallographic texture formation in Inconel 718 by laser powder bed fusion and its effect on mechanical anisotropy. Acta Mater. 2021, 212, 116876. [Google Scholar] [CrossRef]

- Zheng, M.; Li, C.; Zhang, L.; Zhang, X.; Ye, Z.; Yang, X.; Gu, J. In-situ investigation of deformation behavior in additively manufactured FeCoCrNiMn high entropy alloy. Mater. Sci. Eng. A 2022, 840, 142933. [Google Scholar] [CrossRef]

- Kallel, A.; Duchosal, A.; Hamdi, H.; Altmeyer, G.; Morandeau, A.; Méo, S. Analysis of the surface integrity induced by face milling of Laser Metal Deposited Ti-6Al-4V. Procedia CIRP 2020, 87, 345–350. [Google Scholar] [CrossRef]

- Lizzul, L.; Bertolini, R.; Ghiotti, A.; Bruschi, S. Effect of AM-induced Anisotropy on the Surface Integrity of Laser Powder Bed Fused Ti-6Al-4V Machined Parts. Procedia Manuf. 2020, 47, 505–510. [Google Scholar] [CrossRef]

- Sharma, H.; Parfitt, D.; Syed, A.K.; Wimpenny, D.; Muzangaza, E.; Baxter, G.; Chen, B. A critical evaluation of the microstructural gradient along the build direction in electron beam melted Ti-6Al-4V alloy. Mater. Sci. Eng. A 2019, 744, 182–194. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti-6Al-4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Bertolini, R.; Lizzul, L.; Pezzato, L.; Ghiotti, A.; Bruschi, S. Improving surface integrity and corrosion resistance of additive manufactured Ti-6Al-4V alloy by cryogenic machining. Int. J. Adv. Manuf. Technol. 2019, 104, 2839–2850. [Google Scholar] [CrossRef]

- Bordin, A.; Sartori, S.; Bruschi, S.; Ghiotti, A. Experimental investigation on the feasibility of dry and cryogenic machining as sustainable strategies when turning Ti-6Al-4V produced by Additive Manufacturing. J. Clean. Prod. 2017, 142, 4142–4151. [Google Scholar] [CrossRef]

- Sartori, S.; Pezzato, L.; Dabalà, M.; Maurizi Enrici, T.; Mertens, A.; Ghiotti, A.; Bruschi, S. Surface Integrity Analysis of Ti-6Al-4V After Semi-finishing Turning Under Different Low-Temperature Cooling Strategies. J. Mater. Eng. Perform. 2018, 27, 4810–4818. [Google Scholar] [CrossRef]

- Sartori, S.; Bordin, A.; Ghiotti, A.; Bruschi, S. Analysis of the Surface Integrity in Cryogenic Turning of Ti-6Al-4V Produced by Direct Melting Laser Sintering. Procedia CIRP 2016, 45, 123–126. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. Machining of Additively Manufactured Parts: Implications for Surface Integrity. Procedia CIRP 2016, 45, 119–122. [Google Scholar] [CrossRef]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Surface integrity when machining age hardened Inconel 718 with coated carbide cutting tools. Int. J. Mach. Tools Manuf. 2004, 44, 1481–1491. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. On the machinability of directed energy deposited Ti-6Al-4V. Addit. Manuf. 2018, 19, 39–50. [Google Scholar] [CrossRef]

- Jawaid, A.; Che-Haron, C.H.; Abdullah, A. Tool wear characteristics in turning of titanium alloy Ti-6246. J. Mater. Process. Technol. 1999, 92, 329–334. [Google Scholar] [CrossRef]

- Jaffery, S.I.; Mativenga, P.T. Assessment of the machinability of Ti-6Al-4V alloy using the wear map approach. Int. J. Adv. Manuf. Technol. 2009, 40, 687–696. [Google Scholar] [CrossRef]

- Zareena, A.R.; Veldhuis, S.C. Tool wear mechanisms and tool life enhancement in ultra-precision machining of titanium. J. Mater. Process. Technol. 2012, 212, 560–570. [Google Scholar] [CrossRef]

- Pan, W.; Ding, S.; Mo, J. Thermal characteristics in milling Ti-6Al-4V with polycrystalline diamond tools. Int. J. Adv. Manuf. Technol. 2014, 75, 1077–1087. [Google Scholar] [CrossRef]

- Pan, W.; Kamaruddin, A.; Ding, S.; Mo, J. Experimental investigation of end milling of titanium alloys with polycrystalline diamond tools. Proc. Inst. Mech. Eng. B 2014, 228, 832–844. [Google Scholar] [CrossRef]

- Ayed, Y.; Germain, G.; Ammar, A.; Furet, B. Degradation modes and tool wear mechanisms in finish and rough machining of Ti17 Titanium alloy under high-pressure water jet assistance. Wear 2013, 305, 228–237. [Google Scholar] [CrossRef] [Green Version]

- Sartori, S.; Moro, L.; Ghiotti, A.; Bruschi, S. On the tool wear mechanisms in dry and cryogenic turning Additive Manufactured titanium alloys. Tribol. Int. 2017, 105, 264–273. [Google Scholar] [CrossRef]

- Su, Y.; Li, L.; Wang, G. Machinability performance and mechanism in milling of additive manufactured Ti-6Al-4V with polycrystalline diamond tool. J. Manuf. Process. 2022, 75, 1153–1161. [Google Scholar] [CrossRef]

- Al-Rubaie, K.S.; Melotti, S.; Rabelo, A.; Paiva, J.M.; Elbestawi, M.A.; Veldhuis, S.C. Machinability of SLM-produced Ti-6Al-4V titanium alloy parts. J. Manuf. Process. 2020, 57, 768–786. [Google Scholar] [CrossRef]

- Wu, G.; Li, G.; Pan, W.; Raja, I.; Wang, X.; Ding, S. Experimental investigation of eco-friendly cryogenic minimum quantity lubrication (CMQL) strategy in machining of Ti-6Al-4V thin-wall part. J. Clean. Prod. 2022, 357, 131993. [Google Scholar] [CrossRef]

- Khaliq, W.; Zhang, C.; Jamil, M.; Khan, A.M. Tool wear, surface quality, and residual stresses analysis of micro-machined additive manufactured Ti-6Al-4V under dry and MQL conditions. Tribol. Int. 2020, 151, 106408. [Google Scholar] [CrossRef]

- Dang, J.; Zhang, H.; Ming, W.; An, Q.; Chen, M. New observations on wear characteristics of solid Al2O3/Si3N4 ceramic tool in high speed milling of additive manufactured Ti-6Al-4V. Ceram. Int. 2020, 46, 5876–5886. [Google Scholar] [CrossRef]

- Zhang, H.; Dang, J.; Ming, W.; Xu, X.; Chen, M.; An, Q. Cutting responses of additive manufactured Ti-6Al-4V with solid ceramic tool under dry high-speed milling processes. Ceram. Int. 2020, 46, 14536–14547. [Google Scholar] [CrossRef]

- Schulz, H.; Moriwaki, T. High-speed Machining. CIRP Ann. 1992, 41, 637–643. [Google Scholar] [CrossRef]

- Diniz, A.E.; Ferrer, J.A.G. A comparison between silicon nitride-based ceramic and coated carbide tools in the face milling of irregular surfaces. J. Mater. Process. Technol. 2008, 206, 294–304. [Google Scholar] [CrossRef]

- TAN, G.; ZHANG, Y.; LI, G.; LIU, G.; RONG, Y. Performance of a coated cemented carbide tool in high speed milling of Ti-6Al-4V alloy. J. Adv. Manuf. Syst. 2013, 12, 131–146. [Google Scholar] [CrossRef]

- Bordin, A.; Bruschi, S.; Ghiotti, A.; Bariani, P.F. Analysis of tool wear in cryogenic machining of additive manufactured Ti-6Al-4V alloy. Wear 2015, 328, 89–99. [Google Scholar] [CrossRef]

- Bruschi, S.; Bertolini, R.; Bordin, A.; Medea, F.; Ghiotti, A. Influence of the machining parameters and cooling strategies on the wear behavior of wrought and additive manufactured Ti-6Al-4V for biomedical applications. Tribol. Int. 2016, 102, 133–142. [Google Scholar] [CrossRef]

- Oyelola, O.; Crawforth, P.; M’Saoubi, R.; Clare, A.T. Machining of functionally graded Ti-6Al-4V/WC produced by directed energy deposition. Addit. Manuf. 2018, 24, 20–29. [Google Scholar] [CrossRef]

- Di Ilio, A.; Paoletti, A. Machinability Aspects of Metal Matrix Composites. In Machining of Metal Matrix Composites; Davim, J.P., Ed.; Springer: London, UK, 2012; pp. 63–77. [Google Scholar]

- Li, G.; Munir, K.; Wen, C.; Li, Y.; Ding, S. Machinablility of titanium matrix composites (TMC) reinforced with multi-walled carbon nanotubes. J. Manuf. Process. 2020, 56, 131–146. [Google Scholar] [CrossRef]

- Li, G.; Li, N.; Wen, C.; Ding, S. Investigation and modeling of flank wear process of different PCD tools in cutting titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2018, 95, 719–733. [Google Scholar] [CrossRef]

- Barry, J.; Byrne, G.; Lennon, D. Observations on chip formation and acoustic emission in machining Ti-6Al-4V alloy. Int. J. Mach. Tools Manuf. 2001, 41, 1055–1070. [Google Scholar] [CrossRef]

- Komanduri, R.; Hou, Z.-B. On thermoplastic shear instability in the machining of a titanium alloy (Ti-6Al-4V). Metall. Mater. Trans. A 2002, 33, 2995–3010. [Google Scholar] [CrossRef]

- Le Coz, G.; Fischer, M.; Piquard, R.; D’Acunto, A.; Laheurte, P.; Dudzinski, D. Micro Cutting of Ti-6Al-4V Parts Produced by SLM Process. Procedia CIRP 2017, 58, 228–232. [Google Scholar] [CrossRef]

- Wu, G.; Li, G.; Pan, W.; Raja, I.; Wang, X.; Ding, S. A state-of-art review on chatter and geometric errors in thin-wall machining processes. J. Manuf. Process. 2021, 68, 454–480. [Google Scholar] [CrossRef]

- Yue, C.; Gao, H.; Liu, X.; Liang, S.Y.; Wang, L. A review of chatter vibration research in milling. Chin. J. Aeronaut. 2019, 32, 215–242. [Google Scholar] [CrossRef]

- Siddhpura, M.; Paurobally, R. A review of chatter vibration research in turning. Int. J. Mach. Tools Manuf. 2012, 61, 27–47. [Google Scholar] [CrossRef]

- Raval, J.K.; Kazi, A.A.; Guo, X.; Zvanut, R.; Lee, C.; Tai, B.L. Preliminary Study on Machining of Additively Manufactured Ti-6Al-4V. JOM 2022, 74, 1120–1125. [Google Scholar] [CrossRef]

- Umbrello, D.; Bordin, A.; Imbrogno, S.; Bruschi, S. 3D finite element modelling of surface modification in dry and cryogenic machining of EBM Ti-6Al-4V alloy. CIRP J. Manuf. Sci. Technol. 2017, 18, 92–100. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Gockel, J.; Beuth, J.; Taminger, K. Integrated control of solidification microstructure and melt pool dimensions in electron beam wire feed additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2014, 1, 119–126. [Google Scholar] [CrossRef]

- Simonelli, M.; McCartney, D.G.; Barriobero-Vila, P.; Aboulkhair, N.T.; Tse, Y.Y.; Clare, A.; Hague, R. The Influence of Iron in Minimizing the Microstructural Anisotropy of Ti-6Al-4V Produced by Laser Powder-Bed Fusion. Metall. Mater. Trans. A 2020, 51, 2444–2459. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.-W.; Lai, P.-H.; Chen, J.-K. Anisotropy in the impact toughness of selective laser melted Ti-6Al-4V alloy. Mater. Sci. Eng. A 2016, 650, 295–299. [Google Scholar] [CrossRef]

- Singla, A.K.; Banerjee, M.; Sharma, A.; Singh, J.; Bansal, A.; Gupta, M.K.; Khanna, N.; Shahi, A.S.; Goyal, D.K. Selective laser melting of Ti-6Al-4V alloy: Process parameters, defects and post-treatments. J. Manuf. Process. 2021, 64, 161–187. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Semiatin, S. Microstructure and texture evolution during solidification processing of Ti-6Al-4V. J. Mater. Process. Technol. 2003, 135, 330–339. [Google Scholar] [CrossRef]

- Kobryn, P.; Semiatin, S.L. The laser additive manufacture of Ti-6Al-4V. JOM 2001, 53, 40–42. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Kobryn, P.; Moore, E.; Semiatin, S.L. The effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti-6Al-4V. Scr. Mater. 2000, 43, 299–305. [Google Scholar] [CrossRef]

- Baufeld, B.; Van der Biest, O.; Dillien, S. Texture and Crystal Orientation in Ti-6Al-4V Builds Fabricated by Shaped Metal Deposition. Metall. Mater. Trans. A 2010, 41, 1917–1927. [Google Scholar] [CrossRef]

- de Formanoir, C.; Michotte, S.; Rigo, O.; Germain, L.; Godet, S. Electron beam melted Ti-6Al-4V: Microstructure, texture and mechanical behavior of the as-built and heat-treated material. Mater. Sci. Eng. A 2016, 652, 105–119. [Google Scholar] [CrossRef]

- Barba, D.; Alabort, C.; Tang, Y.; Viscasillas, M.; Reed, R.; Alabort, E. On the size and orientation effect in additive manufactured Ti-6Al-4V. Mater. Des. 2020, 186, 108235. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Fernandez-Zelaia, P.; Nguyen, V.; Zhang, H.; Kumar, A.; Melkote, S.N. The effects of material anisotropy on secondary processing of additively manufactured CoCrMo. Addit. Manuf. 2019, 29, 100764. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition. J. Mater. Process. Technol. 2017, 240, 12–22. [Google Scholar] [CrossRef]

- Lizzul, L.; Sorgato, M.; Bertolini, R.; Ghiotti, A.; Bruschi, S. Anisotropy effect of additively manufactured Ti-6Al-4V titanium alloy on surface quality after milling. Precis. Eng. 2021, 67, 301–310. [Google Scholar] [CrossRef]

- Lizzul, L.; Sorgato, M.; Bertolini, R.; Ghiotti, A.; Bruschi, S. Influence of additive manufacturing-induced anisotropy on tool wear in end milling of Ti-6Al-4V. Tribol. Int. 2020, 146, 106200. [Google Scholar] [CrossRef]

- Zhai, Y.; Galarraga, H.; Lados, D.A. Microstructure, static properties, and fatigue crack growth mechanisms in Ti-6Al-4V fabricated by additive manufacturing: LENS and EBM. Eng. Fail. Anal. 2016, 69, 3–14. [Google Scholar] [CrossRef]

- Biswal, R.; Zhang, X.; Syed, A.K.; Awd, M.; Ding, J.; Walther, F.; Williams, S. Criticality of porosity defects on the fatigue performance of wire + arc additive manufactured titanium alloy. Int. J. Fatigue 2019, 122, 208–217. [Google Scholar] [CrossRef] [Green Version]

- Aliprandi, P.; Giudice, F.; Guglielmino, E.; Sili, A. Tensile and Creep Properties Improvement of Ti-6Al-4V Alloy Specimens Produced by Electron Beam Powder Bed Fusion Additive Manufacturing. Metals 2019, 9, 1207. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Ning, J.; Zhu, L.; Yang, Z.; Yan, W.; Dun, Y.; Xue, P.; Xu, P.; Bose, S.; Bandyopadhyay, A. Role of porosity defects in metal 3D printing: Formation mechanisms, impacts on properties and mitigation strategies. Mater. Today 2022, 59, 133–160. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Prog. Mater. Sci. 2021, 117, 100724. [Google Scholar] [CrossRef]

- Li, J.; Fang, Q.; Liu, B.; Liu, Y. The effects of pore and second-phase particle on the mechanical properties of machining copper matrix from molecular dynamic simulation. Appl. Surf. Sci. 2016, 384, 419–431. [Google Scholar] [CrossRef]

- Ahmad, S.; Mujumdar, S.; Varghese, V. Role of porosity in machinability of additively manufactured Ti-6Al-4V. Precis. Eng. 2022, 76, 397–406. [Google Scholar] [CrossRef]

- Varghese, V.; Mujumdar, S. Micromilling-induced Surface Integrity of Porous Additive Manufactured Ti-6Al-4V Alloy. Procedia Manuf. 2021, 53, 387–394. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti-6Al-4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloy. Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Brandl, E.; Greitemeier, D. Microstructure of additive layer manufactured Ti-6Al-4V after exceptional post heat treatments. Mater. Lett. 2012, 81, 84–87. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti-6Al-4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue properties of a titanium alloy (Ti-6Al-4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Int. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef] [Green Version]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Shui, X.; Yamanaka, K.; Mori, M.; Nagata, Y.; Kurita, K.; Chiba, A. Effects of post-processing on cyclic fatigue response of a titanium alloy additively manufactured by electron beam melting. Mater. Sci. Eng. A 2017, 680, 239–248. [Google Scholar] [CrossRef]

- Brandl, E.; Leyens, C.; Palm, F. Mechanical Properties of Additive Manufactured Ti-6Al-4V Using Wire and Powder Based Processes. IOP Conf. Ser. Mater. Sci. Eng. 2011, 26, 012004. [Google Scholar] [CrossRef]

- Bruschi, S.; Bertolini, R.; Ghiotti, A. Coupling machining and heat treatment to enhance the wear behaviour of an Additive Manufactured Ti-6Al-4V titanium alloy. Tribol. Int. 2017, 116, 58–68. [Google Scholar] [CrossRef]

- Malekipour, E.; El-Mounayri, H. Common defects and contributing parameters in powder bed fusion AM process and their classification for online monitoring and control: A review. Int. J. Adv. Manuf. Technol. 2018, 95, 527–550. [Google Scholar] [CrossRef]

- Mostafaei, A.; Zhao, C.; He, Y.; Reza Ghiaasiaan, S.; Shi, B.; Shao, S.; Shamsaei, N.; Wu, Z.; Kouraytem, N.; Sun, T.; et al. Defects and anomalies in powder bed fusion metal additive manufacturing. Curr. Opin. Solid State Mater. Sci. 2022, 26, 100974. [Google Scholar] [CrossRef]

- Li, S.; Zhang, B.; Bai, Q. Effect of temperature buildup on milling forces in additive/subtractive hybrid manufacturing of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2020, 107, 4191–4200. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. Machining characteristics of 18Ni-300 steel in additive/subtractive hybrid manufacturing. Int. J. Adv. Manuf. Technol. 2018, 95, 2509–2519. [Google Scholar] [CrossRef]

- Bai, Q.; Wu, B.; Qiu, X.; Zhang, B.; Chen, J. Experimental study on additive/subtractive hybrid manufacturing of 6511 steel: Process optimization and machining characteristics. Int. J. Adv. Manuf. Technol. 2020, 108, 1389–1398. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Li, C.; Wen, X.; Sun, J. Mechanical performance of 316 L stainless steel by hybrid directed energy deposition and thermal milling process. J. Mater. Process. Technol. 2021, 291, 117023. [Google Scholar] [CrossRef]

- Ye, Z.-P.; Zhang, Z.-J.; Jin, X.; Xiao, M.-Z.; Su, J.-Z. Study of hybrid additive manufacturing based on pulse laser wire depositing and milling. Int. J. Adv. Manuf. Technol. 2017, 88, 2237–2248. [Google Scholar] [CrossRef]

- Jeng, J.-Y.; Lin, M.-C. Mold fabrication and modification using hybrid processes of selective laser cladding and milling. J. Mater. Process. Technol. 2001, 110, 98–103. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M.S. Thermally enhanced machining of hard-to-machine materials—A review. Int. J. Mach. Tools Manuf. 2010, 50, 663–680. [Google Scholar] [CrossRef]

- Lauwers, B. Surface Integrity in Hybrid Machining Processes. Procedia Eng. 2011, 19, 241–251. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Wang, G.; Bermingham, M.J.; Dargusch, M.S. Cutting force, chip formation, and tool wear during the laser-assisted machining a near-alpha titanium alloy BTi-6431S. Int. J. Adv. Manuf. Technol. 2015, 79, 1949–1960. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Kent, D.; Dargusch, M.S. A new understanding of the wear processes during laser assisted milling 17-4 precipitation hardened stainless steel. Wear 2015, 328–329, 518–530. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Sivarupan, T.; Bermingham, M.; Rashid, R.A.R.; Palanisamy, S.; Sun, S. Challenges in laser-assisted milling of titanium alloys. Int. J. Extreme Manuf. 2021, 3, 015001. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Sun, S.; Kim, J.W.; Li, T.; Trimby, P.; Cairney, J. Effect of tool wear evolution on chip formation during dry machining of Ti-6Al-4V alloy. Int. J. Mach. Tools Manuf. 2018, 126, 13–17. [Google Scholar] [CrossRef]

- Garcí, V.; Arriola, I.; Gonzalo, O.; Leunda, J. Mechanisms involved in the improvement of Inconel 718 machinability by laser assisted machining (LAM). Int. J. Mach. Tools Manuf. 2013, 74, 19–28. [Google Scholar] [CrossRef]

- Swarnakar, A.K.; Van der Biest, O.; Baufeld, B. Thermal expansion and lattice parameters of shaped metal deposited Ti-6Al-4V. J. Alloys Compd. 2011, 509, 2723–2728. [Google Scholar] [CrossRef]

- Moritz, J.; Seidel, A.; Kopper, M.; Bretschneider, J.; Gumpinger, J.; Finaske, T.; Riede, M.; Schneeweiß, M.; López, E.; Brückner, F.; et al. Hybrid manufacturing of titanium Ti-6Al-4V combining laser metal deposition and cryogenic milling. Int. J. Adv. Manuf. Technol. 2020, 107, 2995–3009. [Google Scholar] [CrossRef] [Green Version]

- Du, W.; Bai, Q.; Wang, Y.; Zhang, B. Eddy current detection of subsurface defects for additive/subtractive hybrid manufacturing. Int. J. Adv. Manuf. Technol. 2018, 95, 3185–3195. [Google Scholar] [CrossRef]

- Hojati, F.; Daneshi, A.; Soltani, B.; Azarhoushang, B.; Biermann, D. Study on machinability of additively manufactured and conventional titanium alloys in micro-milling process. Precis. Eng. 2020, 62, 1–9. [Google Scholar] [CrossRef]

- Oyelola, O.; Jackson-Crisp, A.; Crawforth, P.; Pieris, D.M.; Smith, R.J.; M’Saoubi, R.; Clare, A.T. Machining of directed energy deposited Ti-6Al-4V using adaptive control. J. Manuf. Process. 2020, 54, 240–250. [Google Scholar] [CrossRef]

- Sartori, S.; Bordin, A.; Moro, L.; Ghiotti, A.; Bruschi, S. The Influence of Material Properties on the Tool Crater Wear When Machining Ti-6Al-4V Produced by Additive Manufacturing Technologies. Procedia CIRP 2016, 46, 587–590. [Google Scholar] [CrossRef]

- de Oliveira Campos, F.; Araujo, A.C.; Jardini Munhoz, A.L.; Kapoor, S.G. The influence of additive manufacturing on the micromilling machinability of Ti-6Al-4V: A comparison of SLM and commercial workpieces. J. Manuf. Process. 2020, 60, 299–307. [Google Scholar] [CrossRef]

- Gong, X.; Manogharan, G. Machining Behavior and Material Properties in Additive Manufacturing Ti-6Al-4V Parts. In Proceedings of the ASME 2020 15th International Manufacturing Science and Engineering Conference, Virtual, 3 September 2020. [Google Scholar]

- Lizzul, L.; Sorgato, M.; Bertolini, R.; Ghiotti, A.; Bruschi, S. Ball end milling machinability of additively and conventionally manufactured Ti-6Al-4V tilted surfaces. J. Manuf. Process. 2021, 72, 350–360. [Google Scholar] [CrossRef]

- Lizzul, L.; Bertolini, R.; Ghiotti, A.; Bruschi, S. Turning of Additively Manufactured Ti-6Al-4V: Effect of the Highly Oriented Microstructure on the Surface Integrity. Materials 2021, 14, 2842. [Google Scholar] [CrossRef] [PubMed]

- Lizzul, L.; Sorgato, M.; Bertolini, R.; Ghiotti, A.; Bruschi, S. Surface finish of additively manufactured Ti-6Al-4V workpieces after ball end milling. Procedia CIRP 2021, 102, 228–233. [Google Scholar] [CrossRef]

- Su, Y.; Li, L. Surface integrity of ultrasonic-assisted dry milling of SLM Ti-6Al-4V using polycrystalline diamond tool. Int. J. Adv. Manuf. Technol. 2022, 119, 5947–5956. [Google Scholar] [CrossRef]

- Airao, J.; Kishore, H.; Nirala, C.K. Measurement and analysis of tool wear and surface characteristics in micro turning of SLM Ti-6Al-4V and wrought Ti-6Al-4V. Measurement 2023, 206, 112281. [Google Scholar] [CrossRef]

- Li, G.; Rahman Rashid, R.A.; Ding, S.; Sun, S.; Palanisamy, S. Machinability Analysis of Finish-Turning Operations for Ti-6Al-4V Tubes Fabricated by Selective Laser Melting. Metals 2022, 12, 806. [Google Scholar] [CrossRef]

- Ni, C.; Wang, X.; Zhu, L.; Liu, D.; Wang, Y.; Zheng, Z.; Zhang, P. Machining performance and wear mechanism of PVD TiAlN/AlCrN coated carbide tool in precision machining of selective laser melted Ti-6Al-4V alloys under dry and MQL conditions. J. Manuf. Process. 2022, 79, 975–989. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Z. Effects of Heat Treatment on Sliding Wear and Milling Properties of Ti-6Al-4V Prepared by Selective Laser Melting. J. Tribol. 2023, 145, 061701. [Google Scholar] [CrossRef]

- Km, R.; Sahoo, A.K.; Routara, B.C.; Panda, A.; Kumar, R. Study on machinability characteristics of novel additive manufactured titanium alloy (Ti-6Al-4V) fabricated by direct metal laser sintering. Proc. Inst. Mech. Eng. C-J. Mec. 2022, 237, 865–885. [Google Scholar] [CrossRef]

- Cai, C.; An, Q.; Ming, W.; Chen, M. Microstructure- and cooling/lubrication environment-dependent machining responses in side milling of direct metal laser-sintered and rolled Ti-6Al-4V alloys. J. Mater. Process. Technol. 2022, 300, 117418. [Google Scholar] [CrossRef]

- Alves, U.C.; Hassui, A.; de Oliveira, M.F.; Neto, P.I.; Ventura, C.E.H. Microstructural and machinability aspects of electron beam melted Ti-6Al-4V with different building orientations. Progr. Addit. Manuf. 2022, 1–11. [Google Scholar] [CrossRef]

| Reference | AM Process | Machining Process | Investigated Machining Characteristics | Year of Publication |

|---|---|---|---|---|

| [18] | SLM | Turning | Cutting force, tool wear, and surface roughness | 2016 |

| [97] | SLM | Turning | Tool wear and surface integrity | 2016 |

| [96] | SLM | Turning | Cutting force and surface integrity | 2017 |

| [98] | SLM | Milling | Cutting force and surface integrity | 2019 |

| [121] | SLM | Milling | Cutting force and tool wear | 2020 |

| [120] | SLM | Milling | Cutting force, tool wear, and surface roughness | 2022 |

| [107] | EBM | Turning | Tool wear, surface integrity, and chip morphology | 2017 |

| [106] | EBM | Turning | Surface integrity | 2019 |

| [35] | EBM | Milling | Surface integrity | 2018 |

| [196] | EBM | Milling | Cutting force and surface quality | 2020 |

| [112] | DED | Turning | Surface integrity and tool wear | 2018 |

| [131] | DED | Turning | Cutting force, surface finish, and tool wear | 2018 |

| [197] | DED | Milling | Subsurface deformation | 2022 |

| [198] | EBM/DMLS | Turning | Tool wear | 2016 |

| [119] | EBM/DMLS | Turning | Tool wear | 2017 |

| [110] | DMD | Turning | Surface integrity | 2016 |

| [109] | DMLS | Turning | Surface integrity | 2016 |

| [129] | EBM | Turning | Tool wear | 2015 |

| [137] | SLM | Turning | Cutting force, chip morphology, and microstructural characteristics | 2017 |

| [159] | PBF-LB | Milling | Tool wear, surface roughness, and chip morphology | 2020 |

| [123] | SLM | Milling | Tool wear, residual stresses, and surface quality | 2020 |

| [180] | DMD | Milling | Cutting force and tool wear | 2020 |

| [199] | SLM | Milling | Cutting force, tool wear, and chip morphology | 2020 |

| [125] | DMLS | Milling | Cutting force, tool wear, chip morphology, and surface integrity | 2020 |

| [200] | EBM | Milling | Surface finish, tool wear, and microstructure | 2020 |

| [201] | PBF-LB | Milling | Cutting force, surface topography, and chip morphology | 2021 |

| [202] | PBF-LB | Turning | Microstructure and surface topography | 2021 |

| [203] | PBF-LB | Milling | Surface quality and chip morphology | 2021 |

| [204] | SLM | Milling | Surface integrity | 2022 |

| [205] | SLM | Turning | Tool wear and surface characteristics | 2022 |

| [206] | SLM | Turning | Cutting force, surface integrity, and tool wear | 2022 |

| [207] | SLM | Turning | Cutting force, surface quality, and tool wear | 2022 |

| [208] | SLM | Milling | Cutting force and surface roughness | 2022 |

| [209] | DMLS | Turning | Tool wear, surface roughness, and chip morphology | 2022 |

| [210] | DMLS | Milling | Milling force, residual stresses, and subsurface plastic deformation | 2022 |

| [211] | EBM | Turning | Cutting force and surface roughness | 2022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zou, D.; Mazur, M.; Mo, J.P.T.; Li, G.; Ding, S. The State of the Art in Machining Additively Manufactured Titanium Alloy Ti-6Al-4V. Materials 2023, 16, 2583. https://doi.org/10.3390/ma16072583

Zhang C, Zou D, Mazur M, Mo JPT, Li G, Ding S. The State of the Art in Machining Additively Manufactured Titanium Alloy Ti-6Al-4V. Materials. 2023; 16(7):2583. https://doi.org/10.3390/ma16072583

Chicago/Turabian StyleZhang, Chen, Dongyi Zou, Maciej Mazur, John P. T. Mo, Guangxian Li, and Songlin Ding. 2023. "The State of the Art in Machining Additively Manufactured Titanium Alloy Ti-6Al-4V" Materials 16, no. 7: 2583. https://doi.org/10.3390/ma16072583

APA StyleZhang, C., Zou, D., Mazur, M., Mo, J. P. T., Li, G., & Ding, S. (2023). The State of the Art in Machining Additively Manufactured Titanium Alloy Ti-6Al-4V. Materials, 16(7), 2583. https://doi.org/10.3390/ma16072583