Thermomechanical Process Simulation and Experimental Verification for Laser Additive Manufacturing of Inconel®718

Abstract

:1. Introduction

2. Materials and Methods

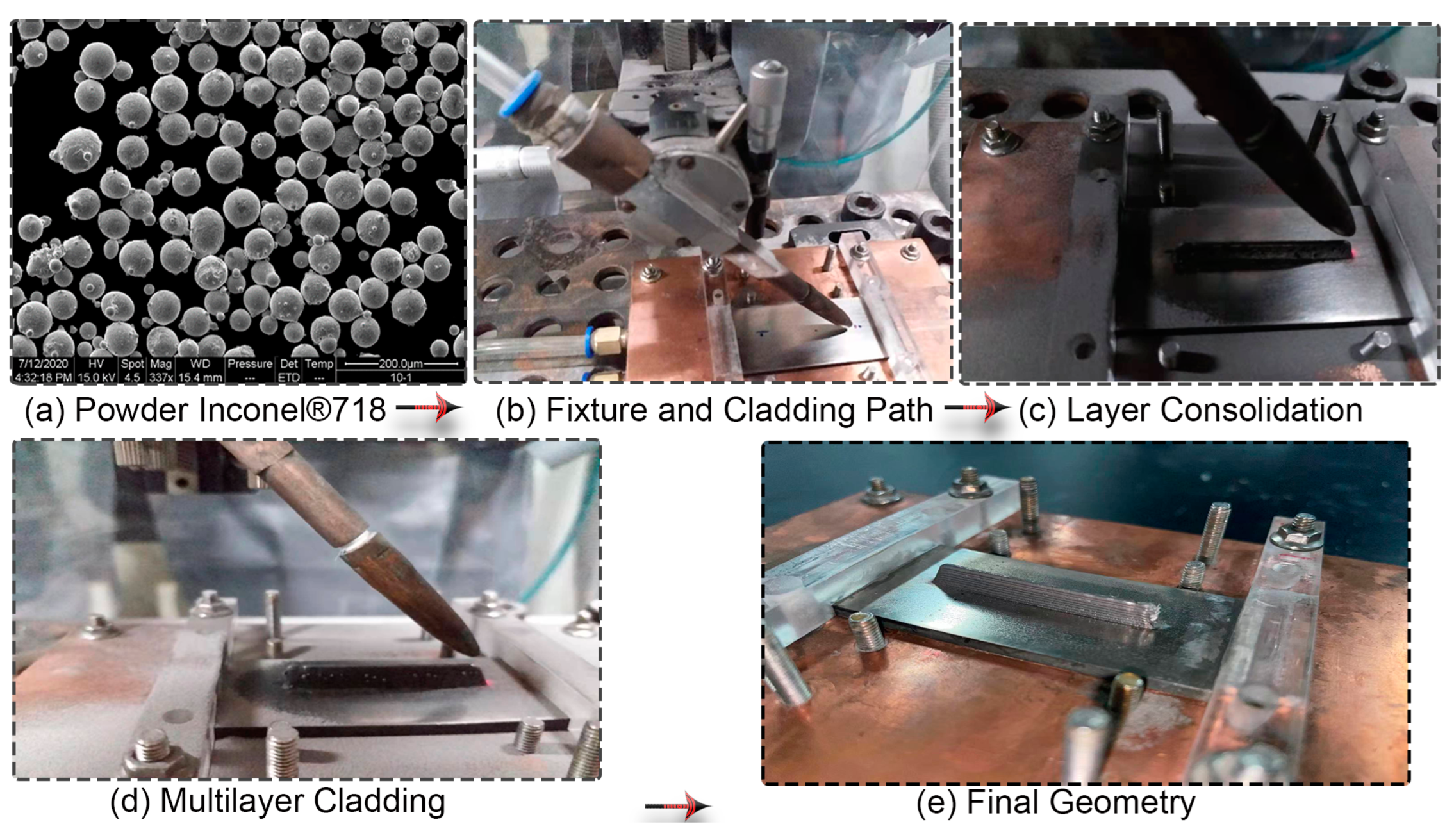

2.1. Material Specifications

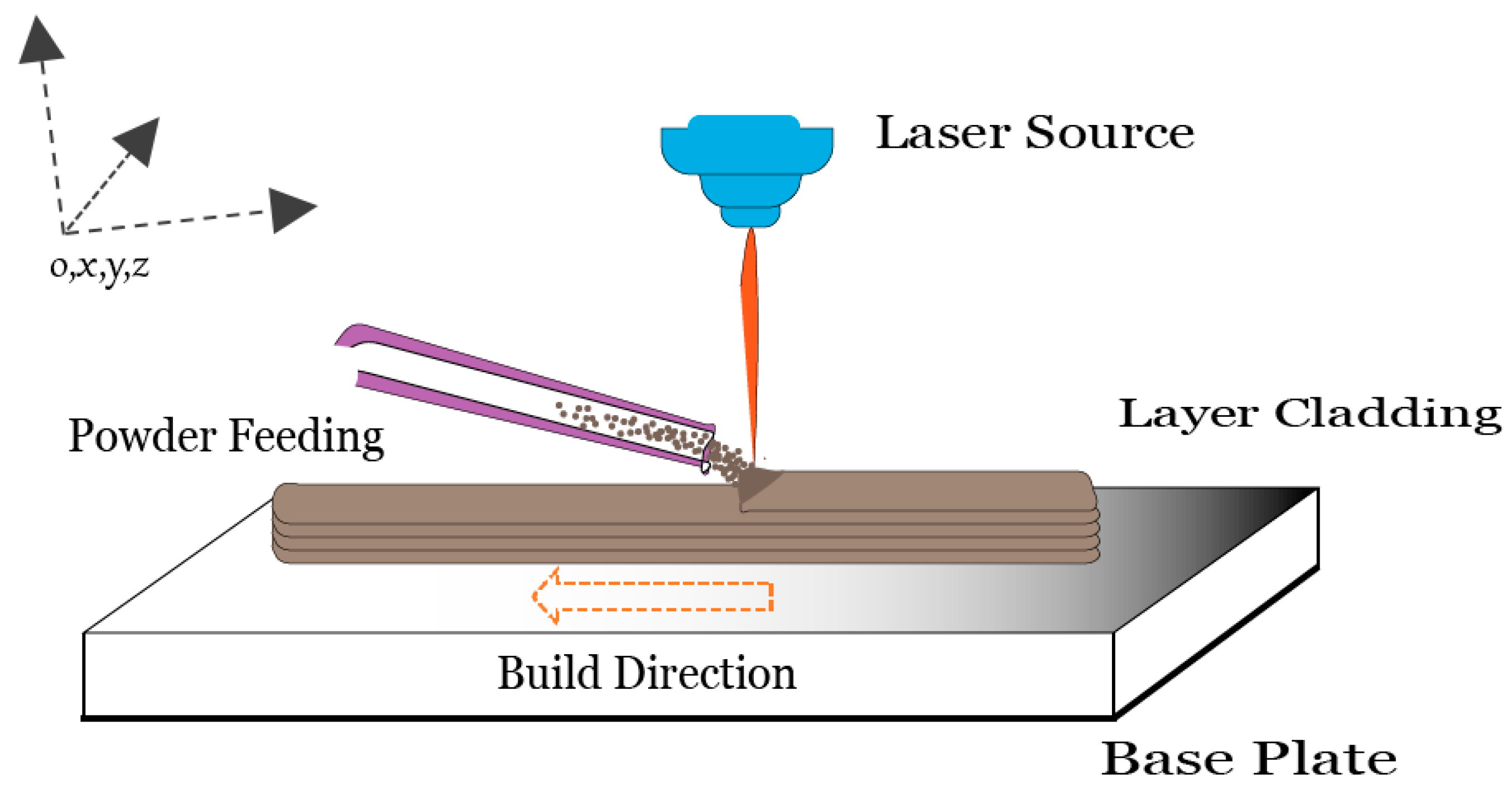

2.2. Equipment and Process Detail

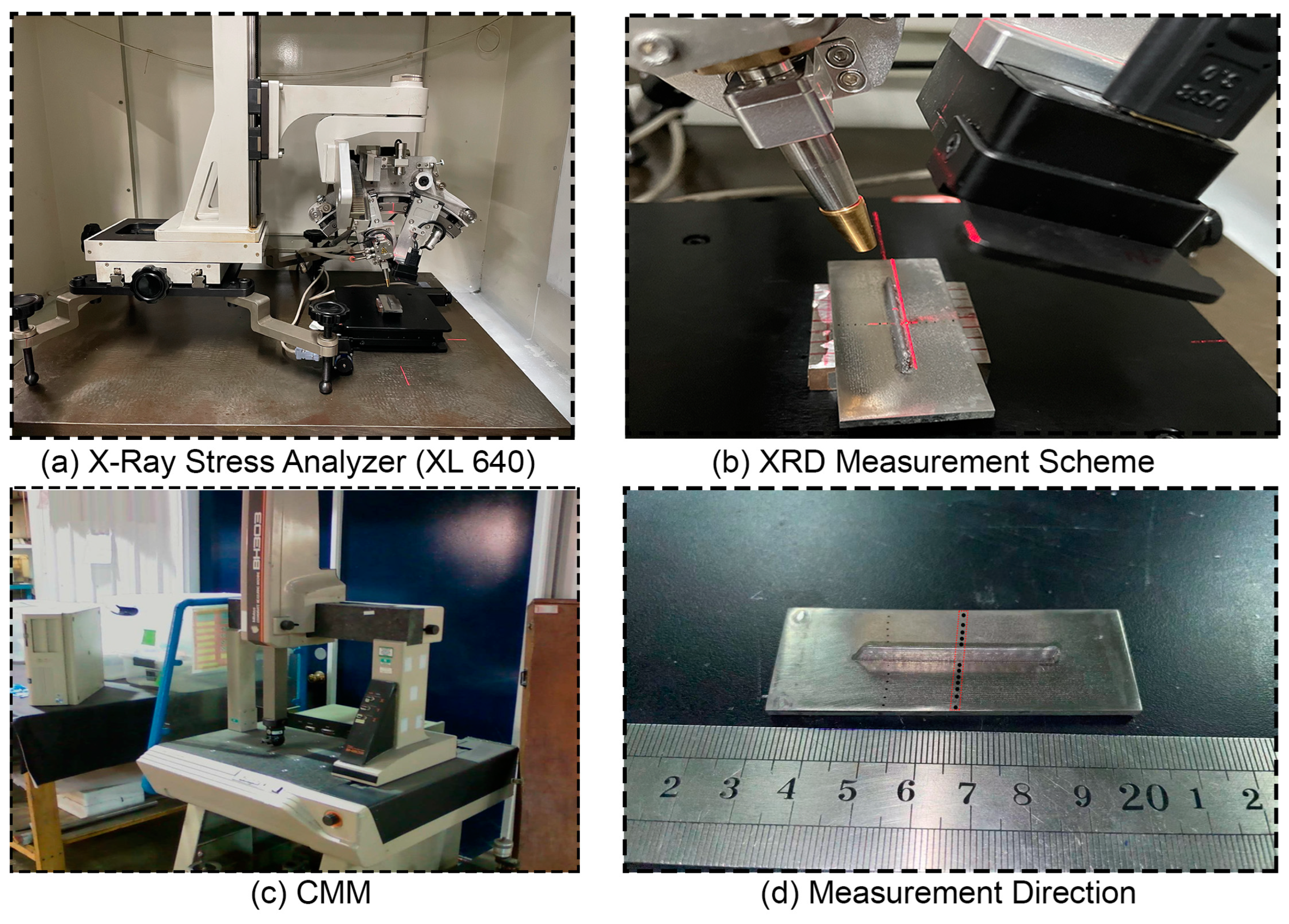

2.3. Experimental Determination of Residual Stress and Distortion

3. Hybrid Numerical Simulation

3.1. FE Model and Mesh

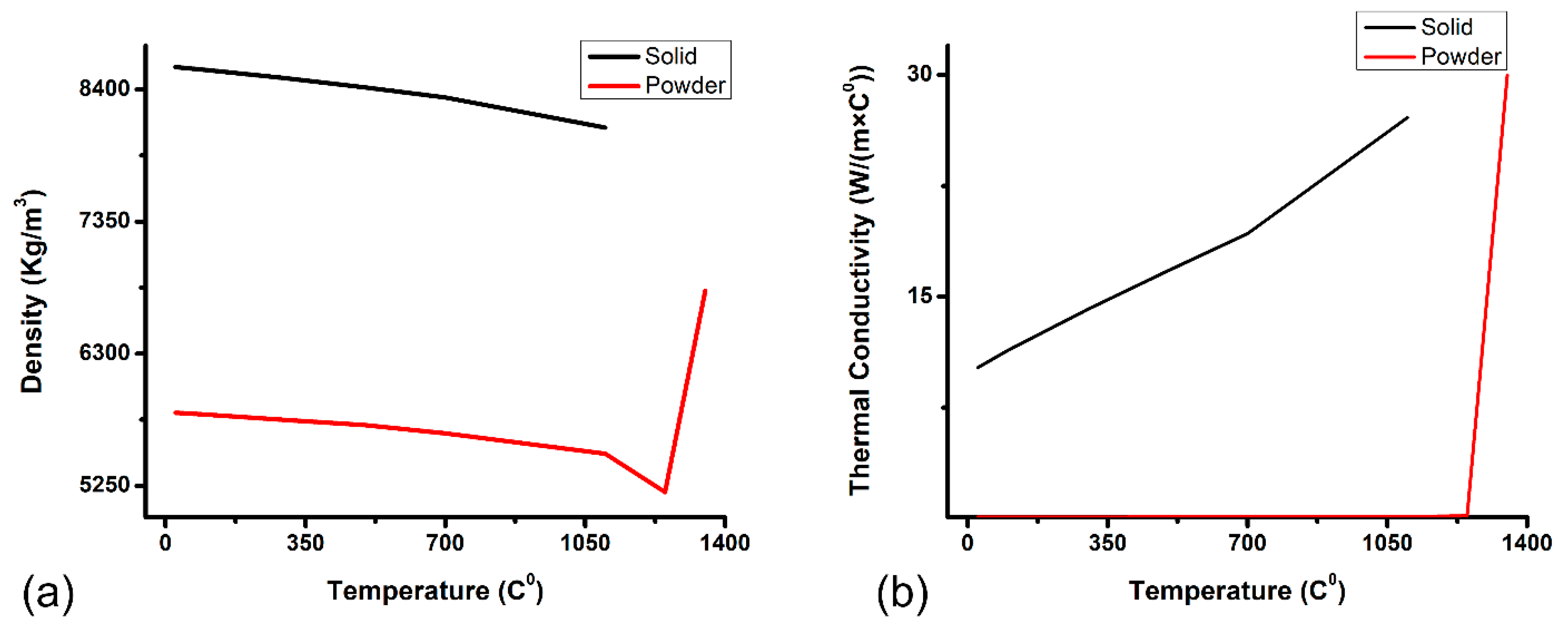

3.2. Material Modeling

3.3. Heat Source Configuration

3.4. Transient Materials Deposition

3.5. Thermal Analysis

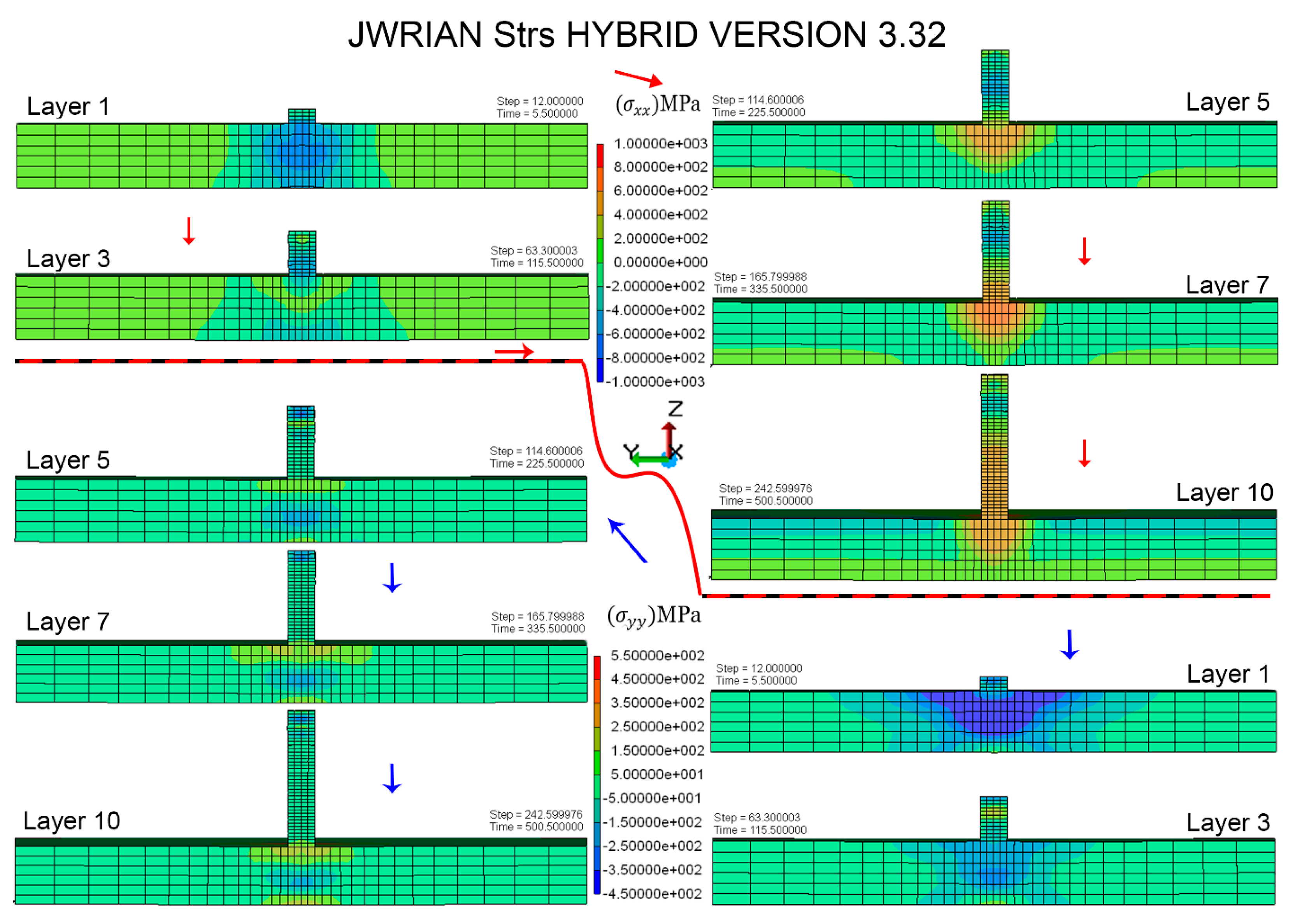

3.6. Mechanical Analysis

4. Results and Discussion

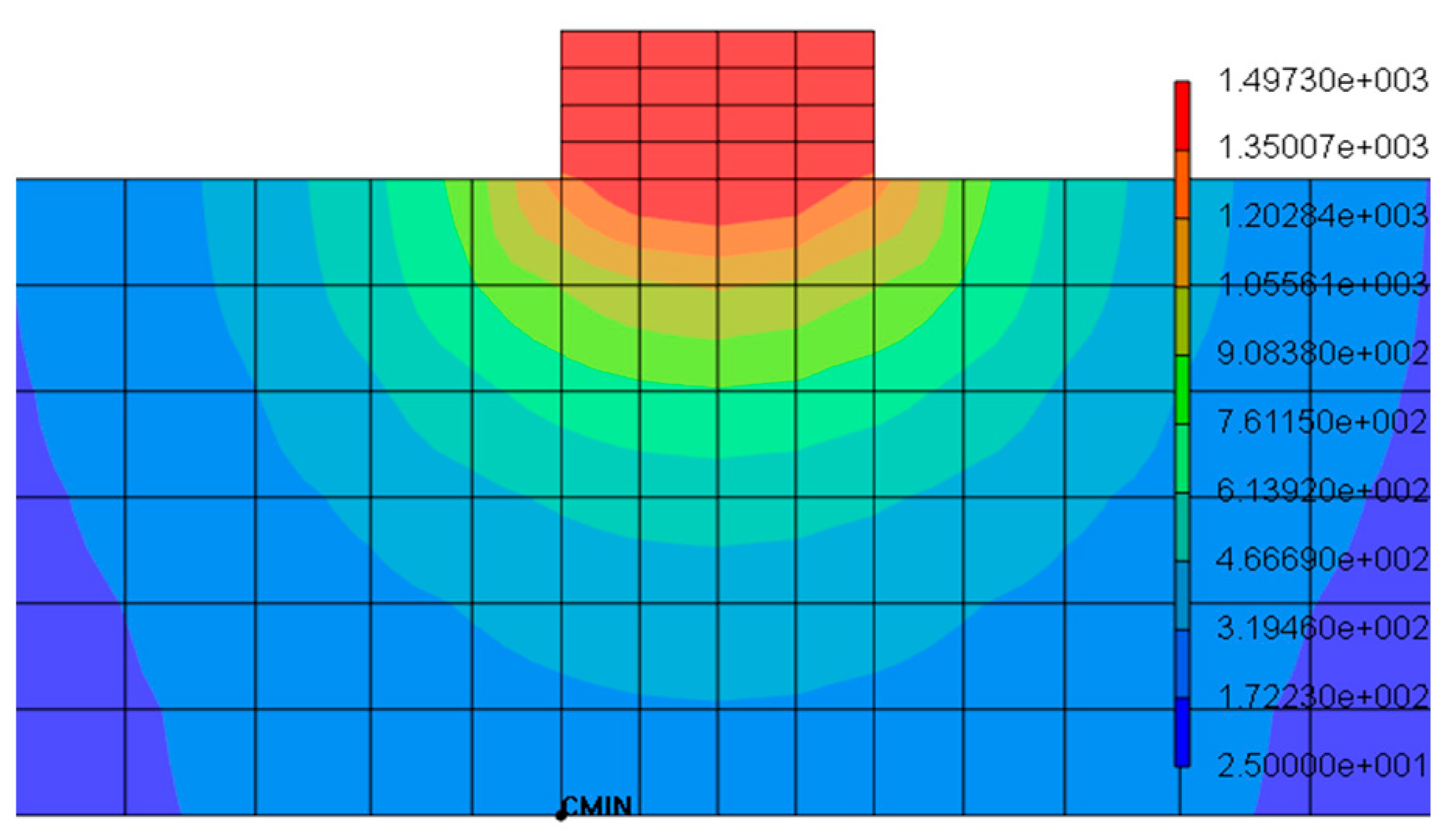

4.1. Melt Pool Validation

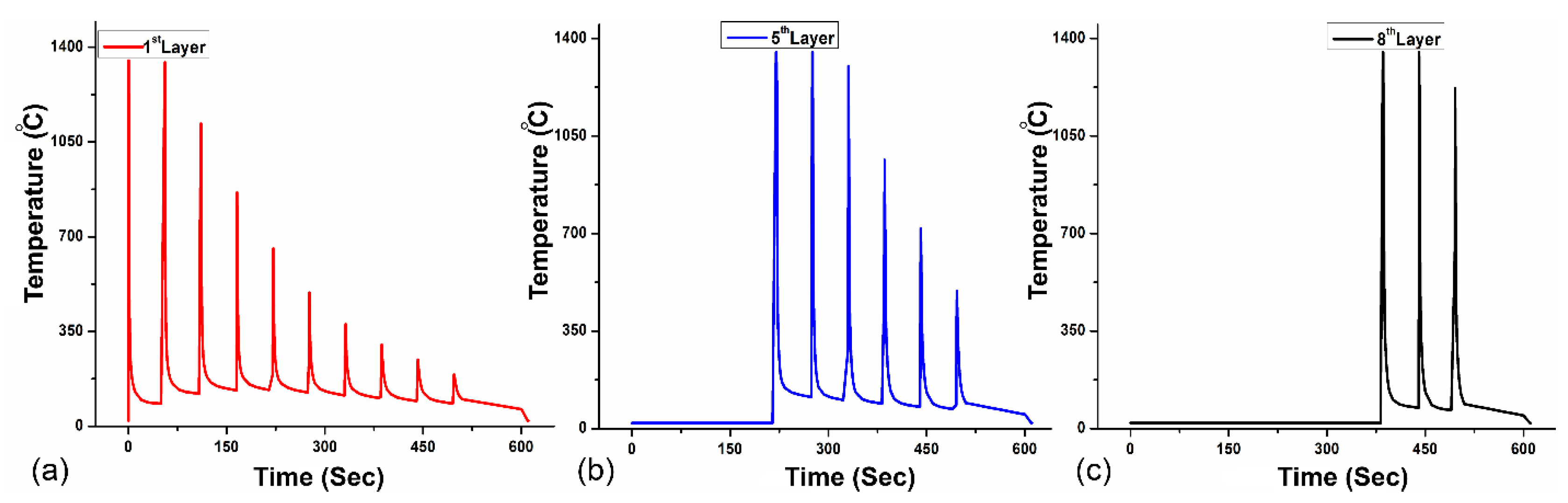

4.2. Temperature Distribution

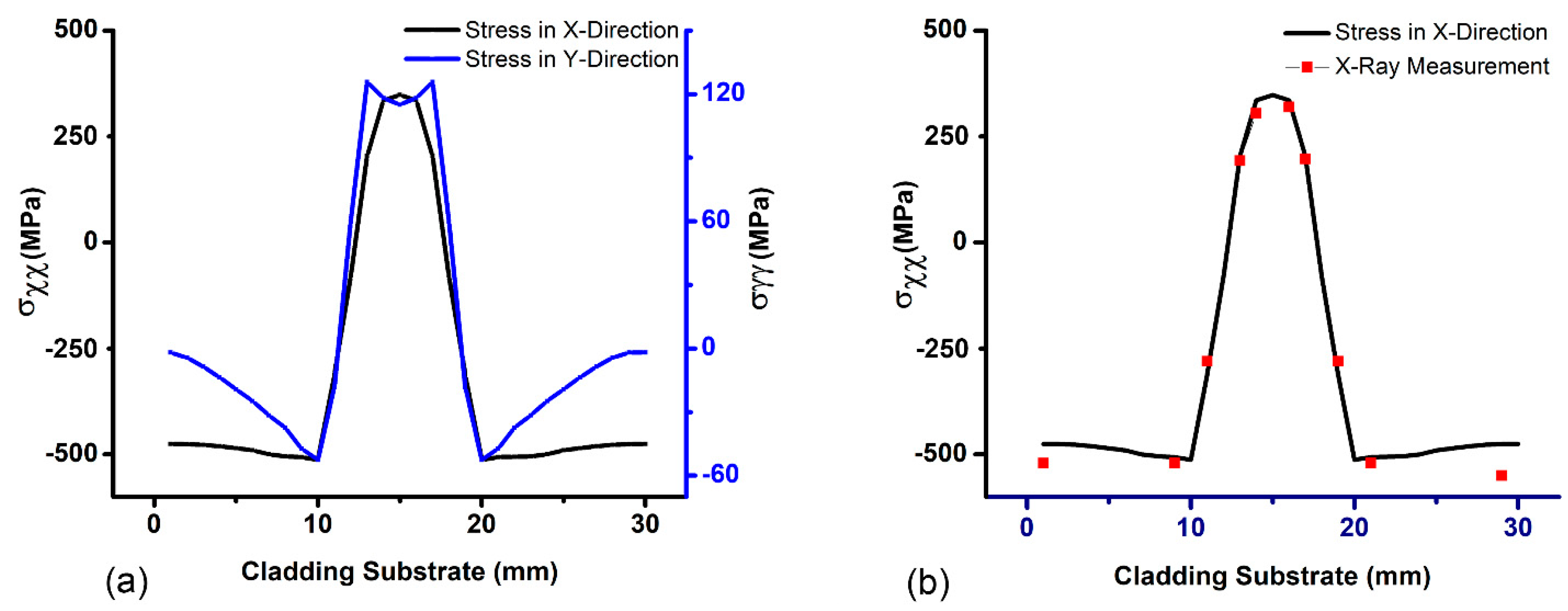

4.3. Residual Stress Verification

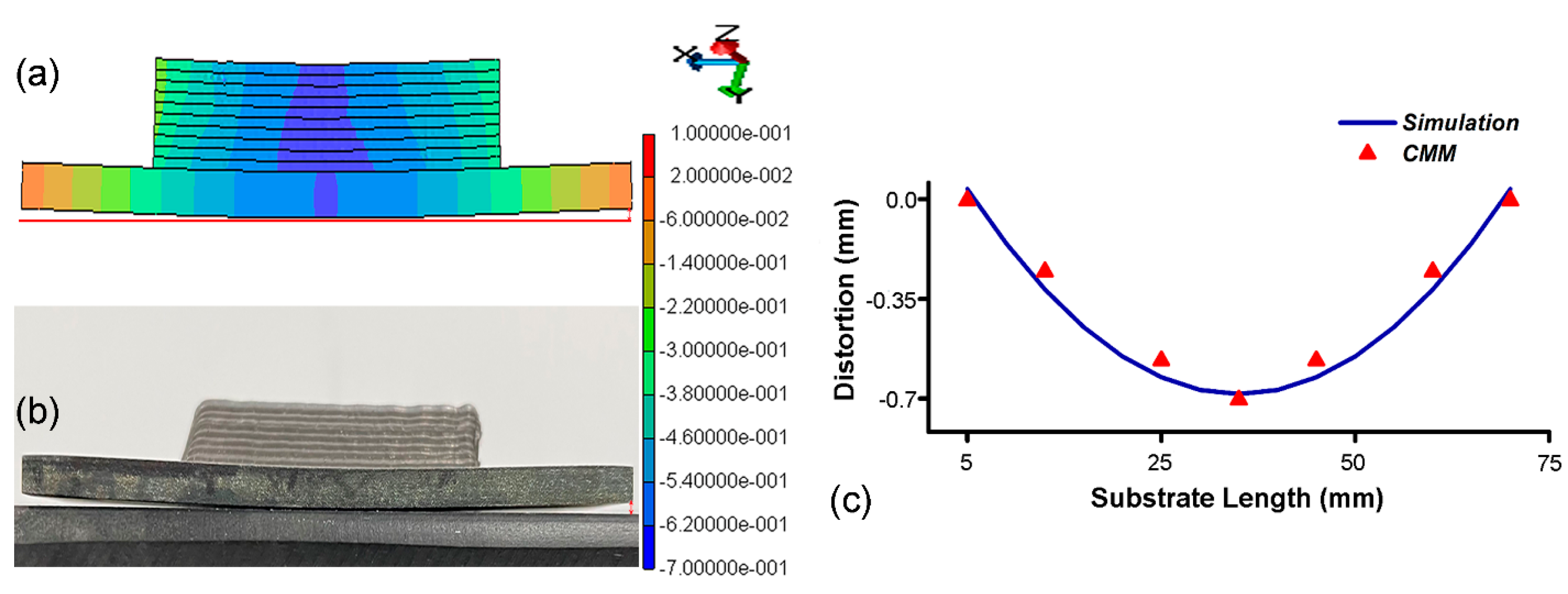

4.4. Distortion Validation

5. Conclusions

- Processing conditions—e.g., applied energy density, scan velocity, material feed, and layer interval time—are adequate to achieve consolidated temperature (1497 °C) above the melting point and excellent formability with a layer thickness of 0.7 ± 0.1 mm throughout the fabrication.

- Transient material deposition with exclusive powder modeling can yield precise results for FEM simulation for thermomechanical process evaluation in multilayer cladding.

- The simulated melt pool with Gaussian heat distribution is consistent with the consolidated layers and penetration of heat to fuse powder particles adequately.

- Residual stresses in the transverse direction of the build plate were approximately 373 ± 5 MPa in the cladding vicinity, tensile in nature, decreased gradually, and transitioned to compressive stress away from the consolidated layers. FEM results show a good agreement with experimental results collected with XRD measurement.

- Further, substrate distortion caused by the residual stresses resulted in a 0.68 ± 0.01 mm warpage of the substrate from the middle of the part. The magnitude and pattern of the distorted substrate provided quantitative analysis and were found consistent with the simulation results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Zafar, M.Q.; Zhao, H. 4D Printing: Future Insight in Additive Manufacturing. Met. Mater. Int. 2020, 26, 564–585. [Google Scholar] [CrossRef]

- Liu, Q.; Janardhana, M.; Hinton, B.; Brandt, M.; Sharp, K. Laser Cladding as a Potential Repair Technology for Damaged Aircraft Components. Int. J. Struct. Integr. 2011, 2, 314–331. [Google Scholar] [CrossRef]

- Brückner, F.; Lepski, D. Laser Cladding. In Springer Series in Materials Science; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Stanciu, E.M.; Pascu, A.; Ţierean, M.H.; Voiculescu, I.; Roată, I.C.; Croitoru, C.; Hulka, I. Dual Coating Laser Cladding of NiCrBSi and Inconel 718. Mater. Manuf. Process. 2016, 31, 1556–1564. [Google Scholar] [CrossRef]

- Mukherjee, T.; Wei, H.L.; De, A.; DebRoy, T. Heat and Fluid Flow in Additive Manufacturing—Part I: Modeling of Powder Bed Fusion. Comput. Mater. Sci. 2018, 150, 304–313. [Google Scholar] [CrossRef] [Green Version]

- Zafar, M.Q.; Wu, C.C.; Zhao, H.; Wang, J.; Hu, X. Finite Element Framework for Electron Beam Melting Process Simulation. Int. J. Adv. Manuf. Technol. 2020, 109, 2095–2112. [Google Scholar] [CrossRef]

- Chew, Y.; Pang, J.H.L.; Bi, G.; Song, B. Thermo-Mechanical Model for Simulating Laser Cladding Induced Residual Stresses with Single and Multiple Clad Beads. J. Mater. Process. Technol. 2015, 224, 89–101. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An Improved Prediction of Residual Stresses and Distortion in Additive Manufacturing. Comput. Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef] [Green Version]

- Zafar, M.Q.; Wu, C.; Zhao, H.; Kai, D.; Gong, Q. Numerical Simulation for Electron Beam Selective Melting PBF Additive Manufacturing of Molybdenum. Int. J. Adv. Manuf. Technol. 2021, 117, 1575–1588. [Google Scholar] [CrossRef]

- Zafar, M.Q.; Zhao, H.; Hussain, G. Part-Scale Numerical Simulation for Direct Energy Deposition of Ti6Al4V. In Proceedings of the International Conference on Mechanical Engineering 2022 (ICME-22), London, UK, 6–8 July 2022; Faculty of Mechanical Engineering, University of Engineering & Technology Lahore: Lahore, Pakistan, 2022; pp. 435–441. [Google Scholar]

- Galati, M.; Snis, A.; Iuliano, L. Powder Bed Properties Modelling and 3D Thermo-Mechanical Simulation of the Additive Manufacturing Electron Beam Melting Process. Addit. Manuf. 2019, 30, 100897. [Google Scholar] [CrossRef]

- Mukherjee, T.; Manvatkar, V.; De, A.; DebRoy, T. Mitigation of Thermal Distortion during Additive Manufacturing. Scr. Mater. 2017, 127, 79–83. [Google Scholar] [CrossRef] [Green Version]

- Kaierle, S.; Overmeyer, L.; Alfred, I.; Rottwinkel, B.; Hermsdorf, J.; Wesling, V.; Weidlich, N. Single-Crystal Turbine Blade Tip Repair by Laser Cladding and Remelting. CIRP J. Manuf. Sci. Technol. 2017, 19, 196–199. [Google Scholar] [CrossRef]

- Gabriel, T.; Rommel, D.; Scherm, F.; Gorywoda, M.; Glatzel, U. Laser Cladding of Ultra-Thin Nickel-Based Superalloy Sheets. Materials 2017, 10, 279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, D. Additively Manufactured Inconel 718: Microstructures and Mechanical Properties; Linköping University Electronic Press: Linköping, Sweden, 2018; ISBN 9789176853832. [Google Scholar]

- Hosseini, E.; Popovich, V.A. A Review of Mechanical Properties of Additively Manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Jinoop, A.N.; Paul, C.P.; Bindra, K.S. Laser-Assisted Directed Energy Deposition of Nickel Super Alloys: A Review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 2376–2400. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, K.; Huang, J.; Hosseini, S.R.E.; Li, Z. Characterization of Heat Affected Zone Liquation Cracking in Laser Additive Manufacturing of Inconel 718. Mater. Des. 2016, 90, 586–594. [Google Scholar] [CrossRef]

- Xie, H.; Yang, K.; Li, F.; Sun, C.; Yu, Z. Investigation on the Laves Phase Formation during Laser Cladding of IN718 Alloy by CA-FE. J. Manuf. Process. 2020, 52, 132–144. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, P.; Cheng, L.; Min, Z.; Chyu, M.; To, A.C. Finite Element Modeling and Validation of Thermomechanical Behavior of Ti-6Al-4V in Directed Energy Deposition Additive Manufacturing. Addit. Manuf. 2016, 12, 169–177. [Google Scholar] [CrossRef]

- Murakawa, H.; Ma, N.; Huang, H. Iterative Substructure Method Employing Concept of Inherent Strain for Large-Scale Welding Problems. Weld. World 2015, 59, 53–63. [Google Scholar] [CrossRef]

- Huang, H.; Ma, N.; Chen, J.; Feng, Z.; Murakawa, H. Toward Large-Scale Simulation of Residual Stress and Distortion in Wire and Arc Additive Manufacturing. Addit. Manuf. 2020, 34, 101248. [Google Scholar] [CrossRef]

- Ou, C.Y.; Liu, C.R. A Computational Efficient Approach to Compute Temperature for Energy Beam Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2021, 143, 091009. [Google Scholar] [CrossRef]

- Ma, N.; Tateishi, J.; Hiroi, S.; Kunugi, A.; Huang, H. Fast Prediction of Welding Distortion of Large Structures Using Inherent Deformation Database and Comparison with Measurement. Yosetsu Gakkai Ronbunshu Q. J. Jpn. Weld. Soc. 2017, 35, 137–140. [Google Scholar] [CrossRef] [Green Version]

- Ma, N.; Narasaki, K. Simulation of Welding Thermal Conduction and Thermal Stress Using Hybrid Method of Accelerated Explicit and Implicit FEM. J. Phys. Conf. Ser. 2018, 1063, 012073. [Google Scholar] [CrossRef]

- Fitzpatrick, M.E.; Fry, A.; Holdway, P.; Kandil, F.A.; Shackleton, J.; Suominen, L. Measurement Good Practice Guide No. 52. Determination of Residual Stresses by X-ray Diffraction; National Physical Laboratory: Teddington, UK, 2005. [Google Scholar]

- Rangaswamy, P.; Griffith, M.L.; Prime, M.B.; Holden, T.M.; Rogge, R.B.; Edwards, J.M.; Sebring, R.J. Residual Stresses in LENS® Components Using Neutron Diffraction and Contour Method. Mater. Sci. Eng. A 2005, 399, 72–83. [Google Scholar] [CrossRef]

- ASTM International ASTM E2860-12; Standard Test Method for Residual Stress Measurement by X-Ray Diffraction for Bearing Steels. ASTM International: West Conshohocken, PA, USA, 2012.

- Manual, I. Jwrian-Hybrid. Input Manual. 2020; pp. 1–139. [Google Scholar]

- Ma, N.; Li, L.; Huang, H.; Chang, S.; Murakawa, H. Residual Stresses in Laser-Arc Hybrid Welded Butt-Joint with Different Energy Ratios. J. Mater. Process. Technol. 2015, 220, 36–45. [Google Scholar] [CrossRef]

- Tolochko, N.K.; Arshinov, M.K.; Gusarov, A.V.; Titov, V.I.; Laoui, T.; Froyen, L. Mechanisms of Selective Laser Sintering and Heat Transfer in Ti Powder. Rapid Prototyp. J. 2003, 9, 314–326. [Google Scholar] [CrossRef]

- Sih, S.S.; Barlow, J.W. The Prediction of the Emissivity and Thermal Conductivity of Powder Beds. Part. Sci. Technol. 2004, 22, 427–440. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A New Finite Element Model for Welding Heat Sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Michaleris, P. Effect of Stress Relaxation on Distortion in Additive Manufacturing Process Modeling. Addit. Manuf. 2016, 12, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Shah, K.; Haq, I.U.; Shah, S.A.; Khan, F.U.; Khan, M.T.; Khan, S. Experimental Study of Direct Laser Deposition of Ti-6al-4v and Inconel 718 by Using Pulsed Parameters. Sci. World J. 2014, 2014, 841549. [Google Scholar] [CrossRef]

- Ma, N. An Accelerated Explicit Method with GPU Parallel Computing for Thermal Stress and Welding Deformation of Large Structure Models. Int. J. Adv. Manuf. Technol. 2016, 87, 2195–2211. [Google Scholar] [CrossRef]

- Poirier, D.R.; Geiger, G.H. Transport Phenomena in Materials Processing; Springer: Cham, Switzerland, 2016; ISBN 9783319480909. [Google Scholar]

- Denlinger, E.R.; Heigel, J.C.; Michaleris, P.; Palmer, T.A. Effect of Inter-Layer Dwell Time on Distortion and Residual Stress in Additive Manufacturing of Titanium and Nickel Alloys. J. Mater. Process. Technol. 2015, 215, 123–131. [Google Scholar] [CrossRef]

- Chua, B.L.; Ahn, D.G. Estimation Method of Interpass Time for the Control of Temperature during a Directed Energy Deposition Process of a Ti–6Al–4V Planar Layer. Materials 2020, 13, 4935. [Google Scholar] [CrossRef] [PubMed]

- Sreekanth, S.; Ghassemali, E.; Hurtig, K.; Joshi, S. Effect of Direct Energy Deposition Process Parameters. Metals 2020, 10, 96. [Google Scholar] [CrossRef] [Green Version]

- Wolff, S.J.; Gan, Z.; Lin, S.; Bennett, J.L.; Yan, W.; Hyatt, G.; Ehmann, K.F.; Wagner, G.J.; Liu, W.K.; Cao, J. Experimentally Validated Predictions of Thermal History and Microhardness in Laser-Deposited Inconel 718 on Carbon Steel. Addit. Manuf. 2019, 27, 540–551. [Google Scholar] [CrossRef]

- Ueda, Y.; Fukuda, K.; Nakacho, K.; Endo, S. A New Measuring Method of Residual Stresses with the Aid of Finite Element Method and Reliability of Estimated Values. J. Soc. Nav. Archit. Jpn. 1975, 1975, 499–507. [Google Scholar] [CrossRef] [Green Version]

- Cao, J.; Gharghouri, M.A.; Nash, P. Finite-Element Analysis and Experimental Validation of Thermal Residual Stress and Distortion in Electron Beam Additive Manufactured Ti-6Al-4V Build Plates. J. Mater. Process. Technol. 2016, 237, 409–419. [Google Scholar] [CrossRef]

- Liang, X.; Cheng, L.; Chen, Q.; Yang, Q.; To, A.C. A Modified Method for Estimating Inherent Strains from Detailed Process Simulation for Fast Residual Distortion Prediction of Single-Walled Structures Fabricated by Directed Energy Deposition. Addit. Manuf. 2018, 23, 471–486. [Google Scholar] [CrossRef]

- Moradi, M.; Hasani, A.; Pourmand, Z.; Lawrence, J. Direct Laser Metal Deposition Additive Manufacturing of Inconel 718 Superalloy: Statistical Modelling and Optimization by Design of Experiments. Opt. Laser Technol. 2021, 144, 107380. [Google Scholar] [CrossRef]

- Wu, C.; Zafar, M.Q.; Zhao, H. Numerical Investigation of Consolidation Mechanism in Powder Bed Fusion Considering Layer Characteristics during Multilayer Process. Int. J. Adv. Manuf. Technol. 2021, 113, 2087–2100. [Google Scholar] [CrossRef]

- Hofman, J.T.; De Lange, D.F.; Pathiraj, B.; Meijer, J. FEM Modeling and Experimental Verification for Dilution Control in Laser Cladding. J. Mater. Process. Technol. 2011, 211, 187–196. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.; Zafar, M.Q.; Zhao, H.; Wang, Y.; Schöler, C.; Heinigk, C.; Nießen, M.; Schulz, W. Multi-Physics Modeling of Side Roughness Generation Mechanisms in Powder Bed Fusion. Addit. Manuf. 2021, 47, 102274. [Google Scholar] [CrossRef]

- Lee, Y.S.; Zhang, W. Modeling of Heat Transfer, Fluid Flow and Solidification Microstructure of Nickel-Base Superalloy Fabricated by Laser Powder Bed Fusion. Addit. Manuf. 2016, 12, 178–188. [Google Scholar] [CrossRef] [Green Version]

- Bartlett, J.L.; Croom, B.P.; Burdick, J.; Henkel, D.; Li, X. Revealing Mechanisms of Residual Stress Development in Additive Manufacturing via Digital Image Correlation. Addit. Manuf. 2018, 22, 1–12. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The Metallurgy and Processing Science of Metal Additive Manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Fe | Nb | Mo | Ti | Al | Co | Others |

|---|---|---|---|---|---|---|---|---|---|

| (wt%) | Bal. | 17.5 | 19.4 | 5.0 | 3.17 | 1.07 | 0.68 | 0.2 | ----- |

| Laser Power | Cladding Velocity | Defocusing Distance | Laser Emitting Mode | Frequency | Powder Feeding Rate | Carrier Gas Flow | Lift Distance |

|---|---|---|---|---|---|---|---|

| 720 W | 4 mm/s | +25 mm | Pulse | 100 Hz | 8 g/min | 6 L/min | 0.65 mm |

| Temperature (°C) | 25 | 100 | 300 | 500 | 700 | 1100 |

|---|---|---|---|---|---|---|

| Density (Kg/m3) | 8577.81 | 8555.83 | 8490.97 | 8417.53 | 8336.12 | 8097.31 |

| Thermal Conductivity W/(m × °C) | 10.2111 | 11.3806 | 14.1563 | 16.7501 | 19.2769 | 27.1181 |

| Specific Heat J/(Kg × °C) | 412 | 422 | 457 | 486 | 518 | 835 |

| Coefficient of Thermal Expansion m/(m × °C) | 1.1 × 10−5 | 1.1 × 10−5 | 1.2 × 10−5 | 1.3 × 10−5 | 1.4 × 10−5 | 1.8 × 10−5 |

| Young Modulus (GPa) | 208 | 200 | 194 | 173 | 171 | 140 |

| Yield Strength (MPa) | 700 | 650 | 600 | 500 | 560 | 480 |

| Poisson Ratio | 0.31155 | 0.3135 | 0.31875 | 0.32411 | 0.32958 | 0.35049 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zafar, M.Q.; Wang, J.; Zhang, Z.; Wu, C.; Zhao, H.; Hussain, G.; Ma, N. Thermomechanical Process Simulation and Experimental Verification for Laser Additive Manufacturing of Inconel®718. Materials 2023, 16, 2595. https://doi.org/10.3390/ma16072595

Zafar MQ, Wang J, Zhang Z, Wu C, Zhao H, Hussain G, Ma N. Thermomechanical Process Simulation and Experimental Verification for Laser Additive Manufacturing of Inconel®718. Materials. 2023; 16(7):2595. https://doi.org/10.3390/ma16072595

Chicago/Turabian StyleZafar, Muhammad Qasim, Jinnan Wang, Zhenlin Zhang, Chaochao Wu, Haiyan Zhao, Ghulam Hussain, and Ninshu Ma. 2023. "Thermomechanical Process Simulation and Experimental Verification for Laser Additive Manufacturing of Inconel®718" Materials 16, no. 7: 2595. https://doi.org/10.3390/ma16072595

APA StyleZafar, M. Q., Wang, J., Zhang, Z., Wu, C., Zhao, H., Hussain, G., & Ma, N. (2023). Thermomechanical Process Simulation and Experimental Verification for Laser Additive Manufacturing of Inconel®718. Materials, 16(7), 2595. https://doi.org/10.3390/ma16072595