Material Recycling for Manufacturing Aggregates Using Melting Slag of Automobile Shredder Residues

Abstract

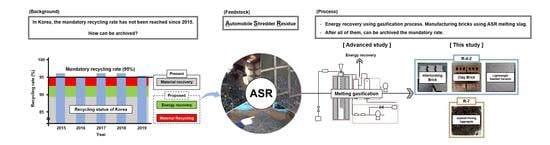

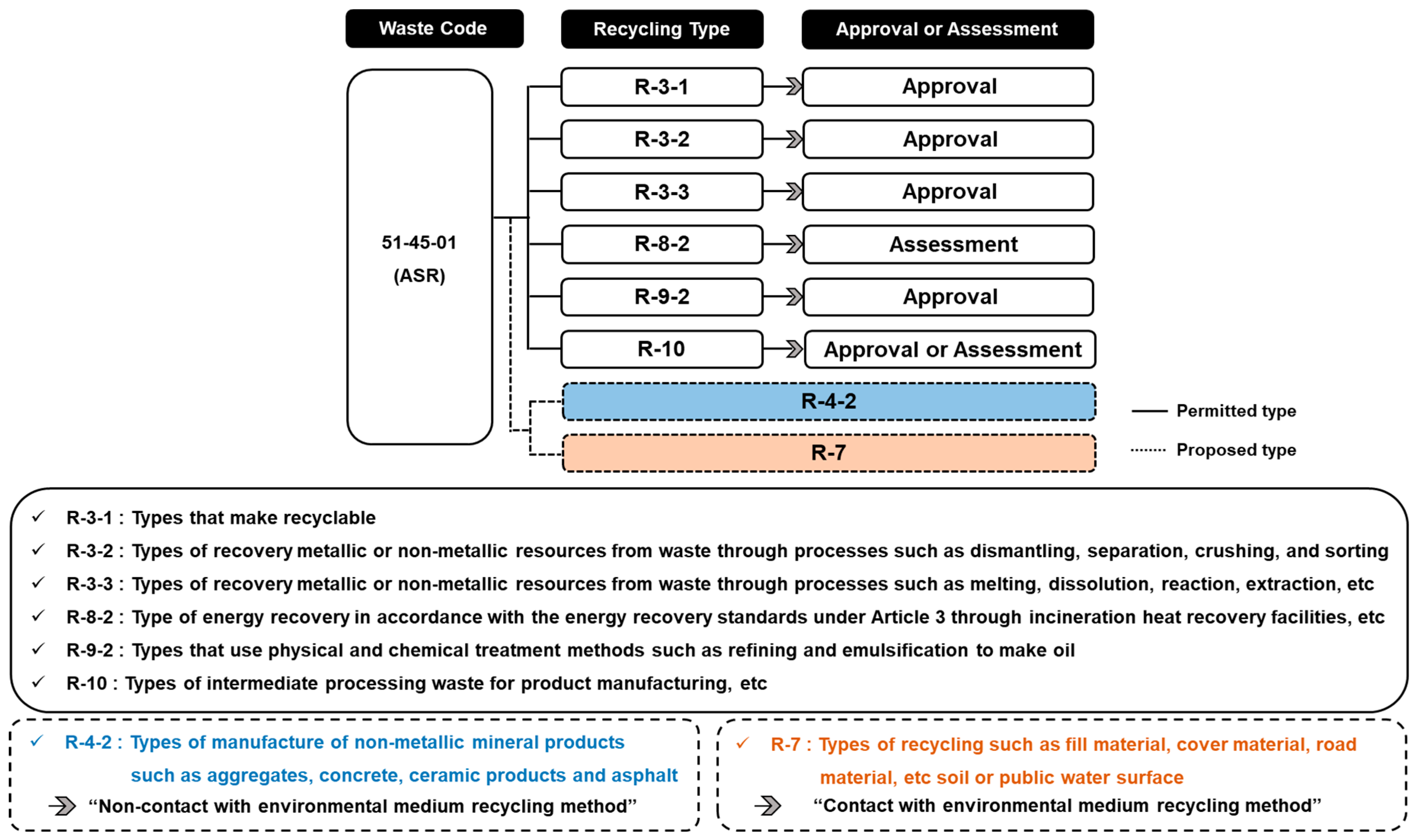

:1. Introduction

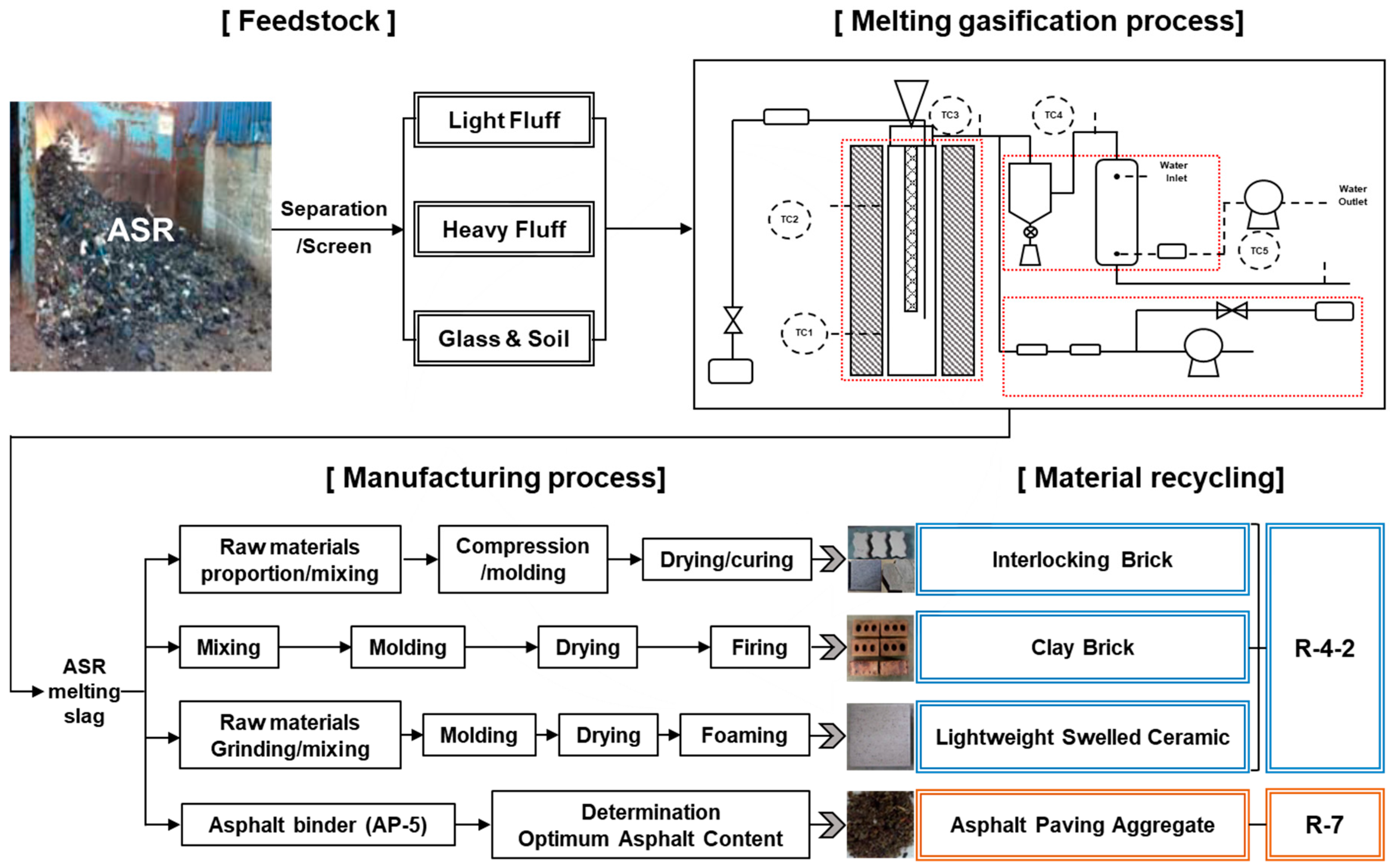

2. Materials and Methods

2.1. Environmental Assessment of Recycling

2.2. Sampling and Analysis of Material Characteristics

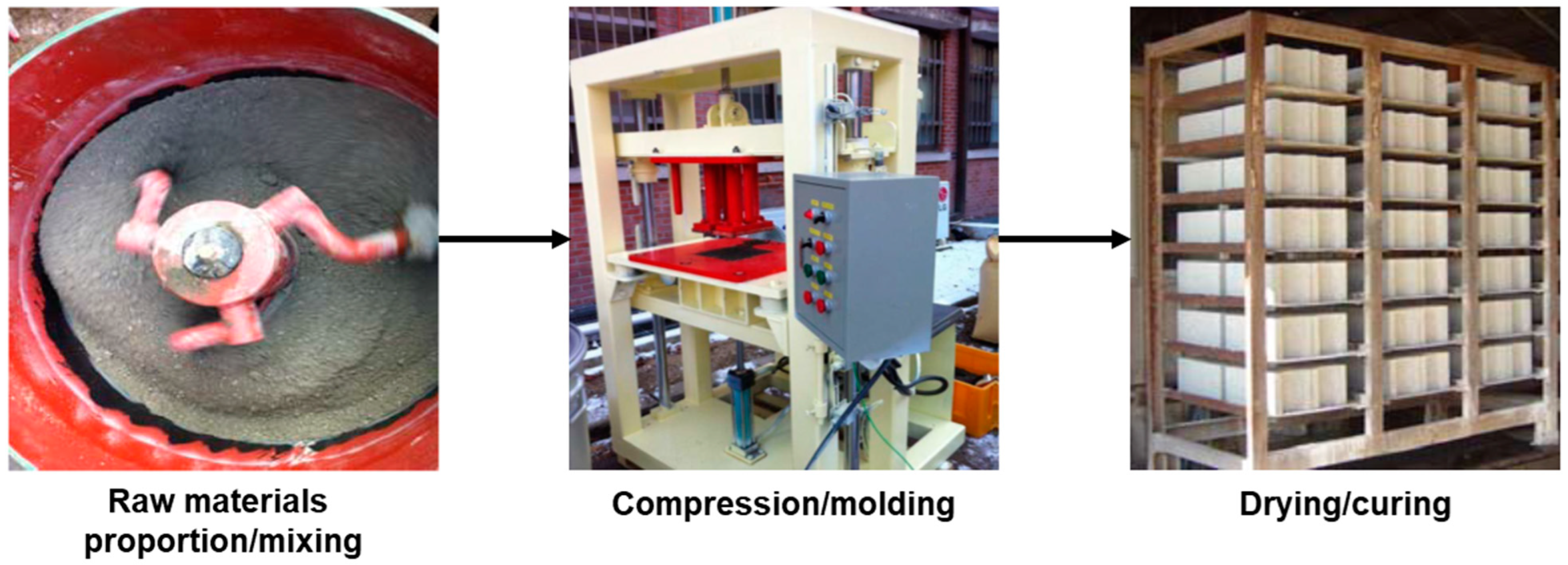

2.3. Manufacturing Bricks

2.3.1. Interlocking Brick

2.3.2. Clay Brick

2.3.3. Lightweight Swelled Ceramic Brick

2.3.4. Asphalt Paving Aggregate

3. Results and Discussion

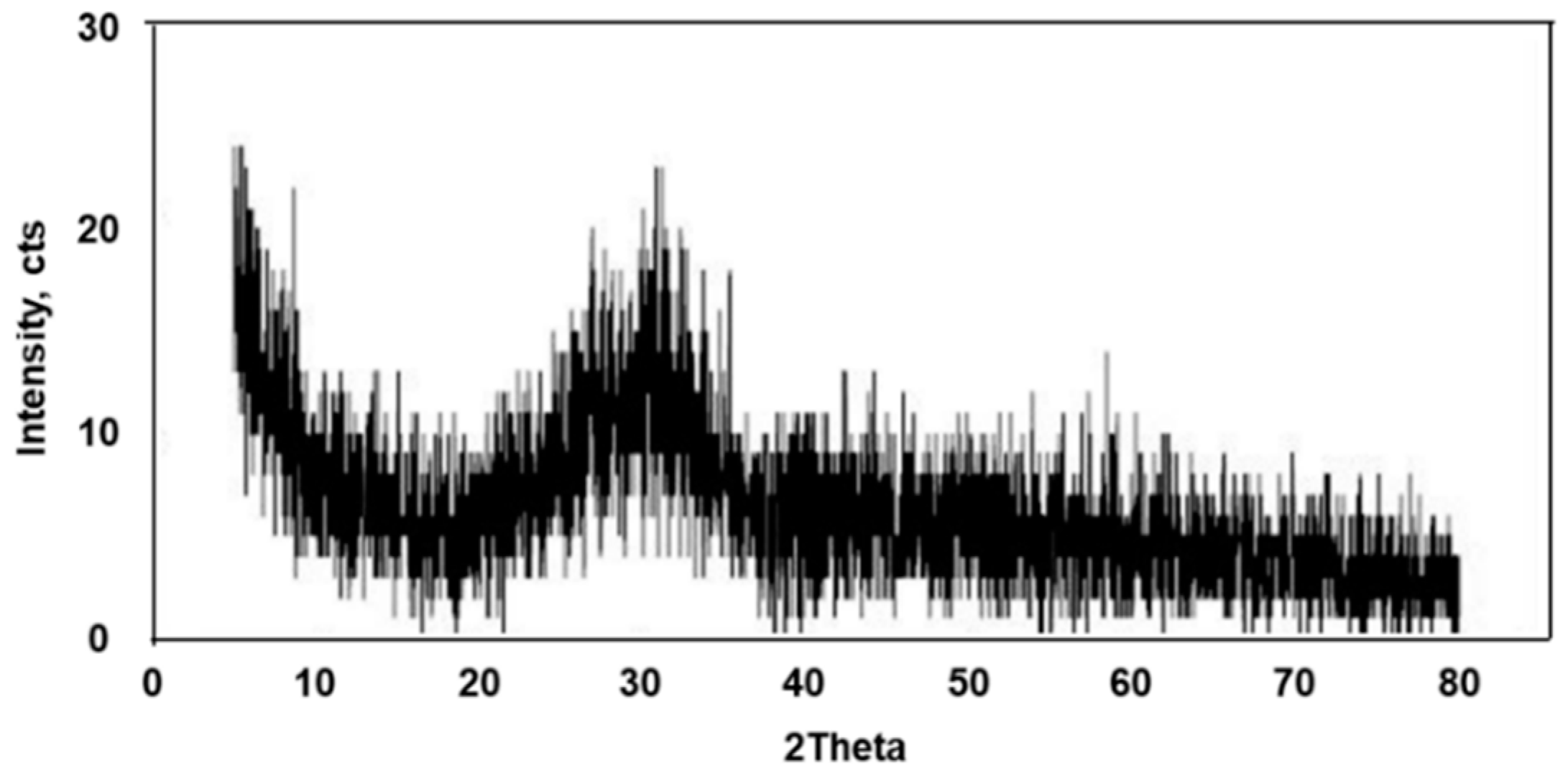

3.1. Characteristics of ASRMS

Evaluation of the Quality of ASRMS as an Aggregate

3.2. Evaluation of Environmental Performance of Raw Materials

4. Evaluation of Product Quality

4.1. Interlocking Brick

4.1.1. Appearance and Size

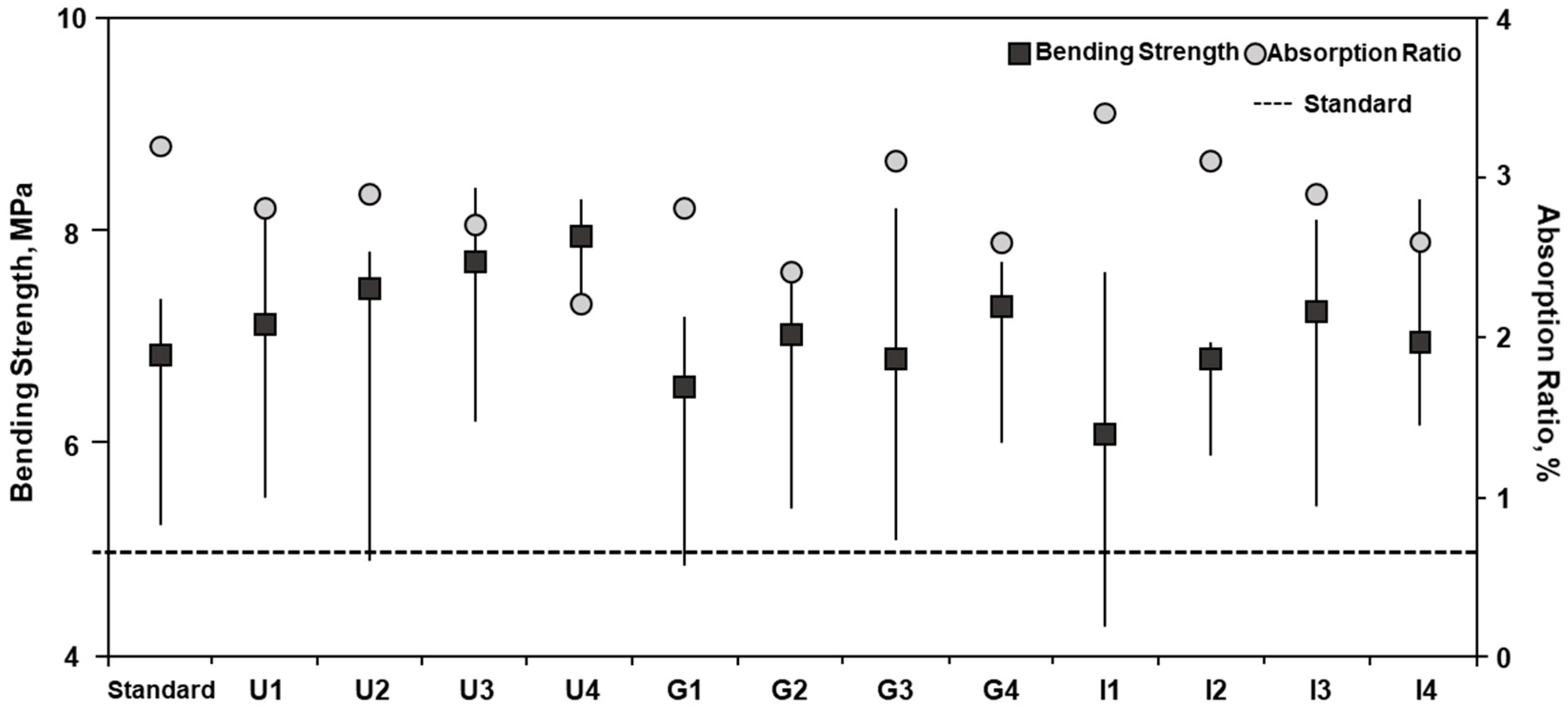

4.1.2. Bending Strength and Water Absorption Ratio

4.2. Clay Brick

4.2.1. Appearance and Size

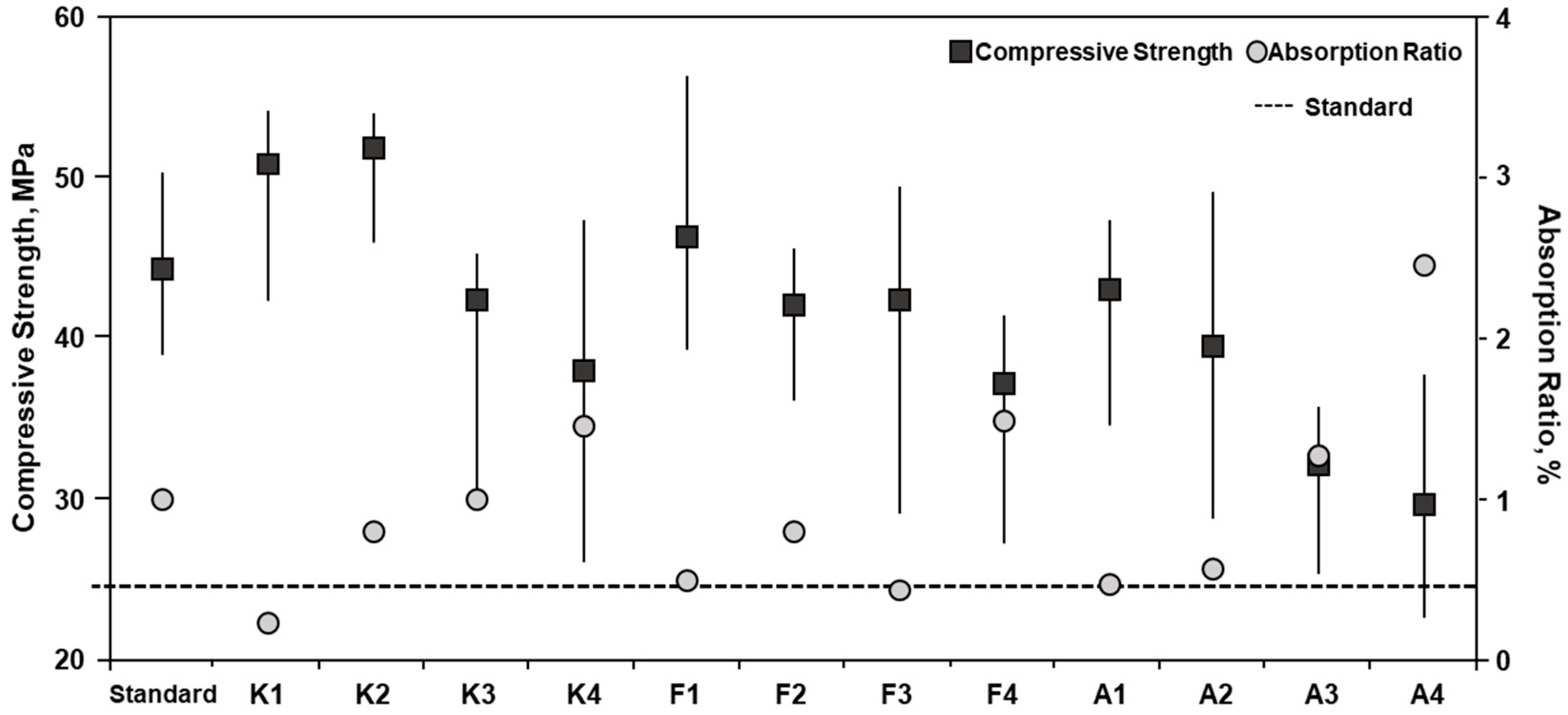

4.2.2. Compressive Strength and Water Absorption Ratio

4.3. Lightweight Swelled Ceramic Brick

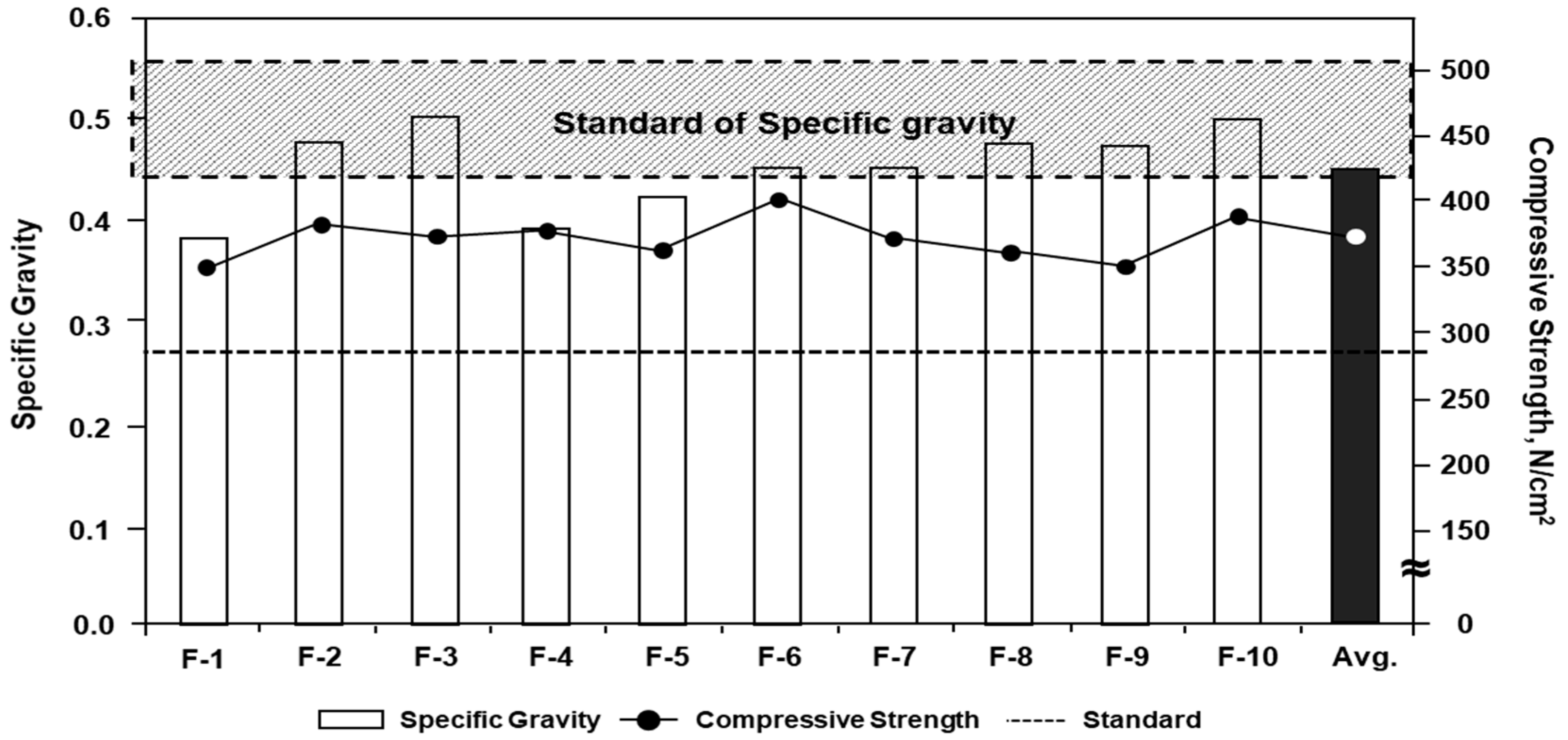

Specific Gravity and Compressive Strength

4.4. Asphalt Paving Aggregate

4.4.1. Physical Characteristics of ASRMS for Use as Aggregate

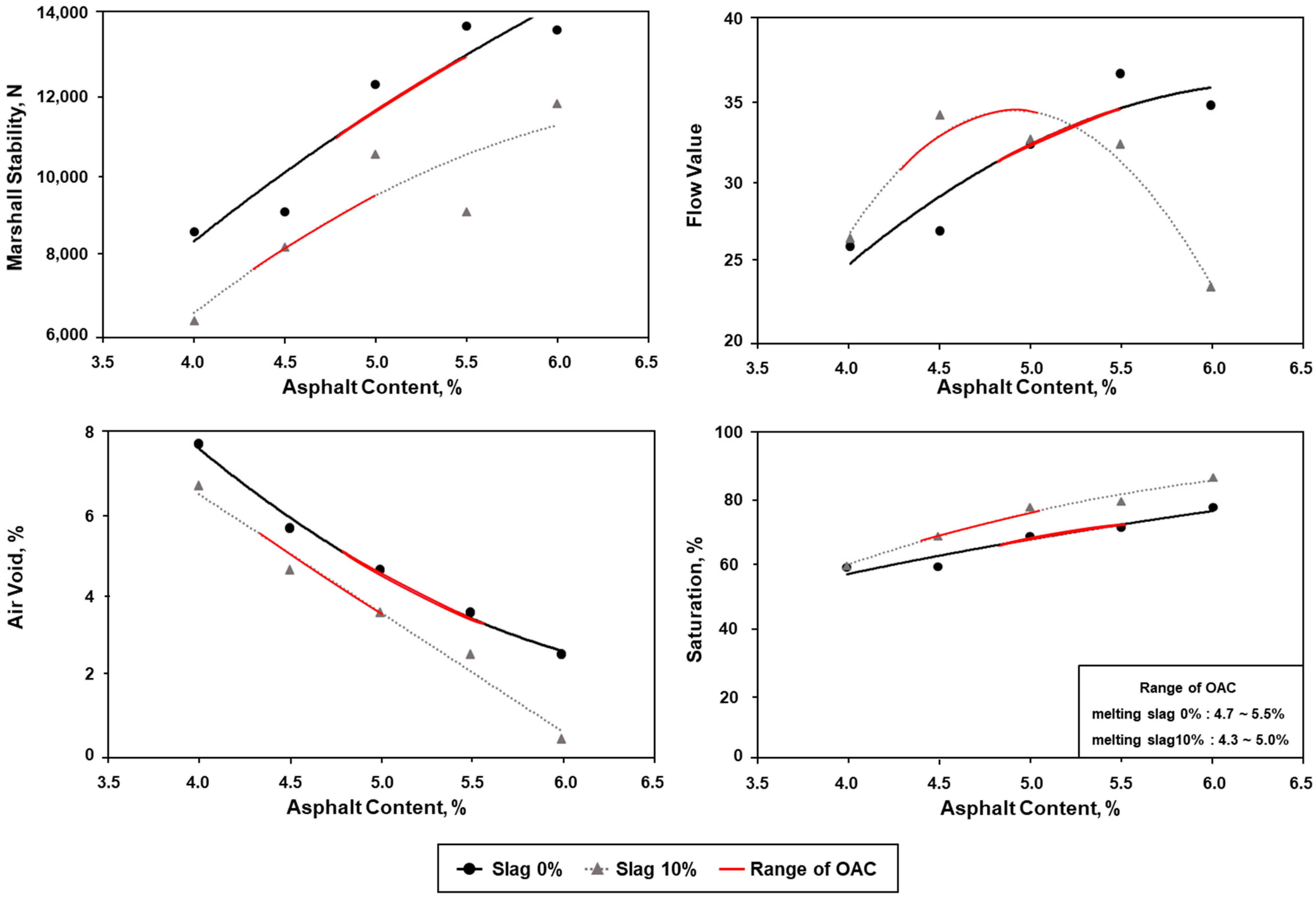

4.4.2. Optimum Asphalt Content

4.5. Final Technical Evaluation for Feasibility of Material Recycling

5. Conclusions

- The ASRMS used in this study had a density of 2.24 g/cm2, a water absorption ratio of 0.34%, and a basicity of 1.01, thereby exhibiting its applicability as an aggregate. Trace quantities of Pb, Cu, As, and Cd were detected in the leaching test, but they satisfied the leaching test criteria of Korea, indicating that the ASRMS is suitable for recycling as an aggregate.

- ASRMS substituted for sand and stone powder as an aggregate in the manufacturing of interlocking brick. Quality evaluation of interlocking brick according to KS F 4419 in terms of appearance, size, bending strength, and water absorption ratio was satisfactory. As ASRMS content increased, absorption decreased and bending strength increased. The bending strength was ≥5.0 MPa. Therefore, a large quantity of ASR can be recycled in brick production with profits for the manufacturer due to a reduction in raw material costs.

- Clay brick was manufactured by replacing kaolin and feldspar with ASRMS to an extent of 20%. The quality evaluation of clay bricks according to KS L 4201 in terms of appearance, size, compressive strength, and water absorption ratio was satisfactory. However, the quality of clay bricks manufactured with >15% ASRMS was not better than that of the standard clay brick.

- A lightweight swelled ceramic brick was manufactured using ASRMS, zeolite, and other materials. The quality of the manufactured bricks was evaluated in accordance with KS 8551. Because all the manufactured bricks met the required criteria, manufacturing them is an appropriate recycling method for ASRMS. However, the consumption of a large quantity of ASR is unlikely for LSC because its usage is low compared to that of other bricks. It is expected that ASRMS can be utilised in many fields because it can be manufactured in various forms. Therefore, the material recycling method using ASRMS is an appropriate treatment method with many environmental benefits.

- To utilise ASRMS as APA for road fill materials, the particle size distribution and characteristics of the aggregate were analysed, and the OAC was obtained. The standard requirements were met for most particle size ranges, indicating that the ASRMS can be used as an aggregate. Experimental results for asphalt paving mixture with ASRMS content show that the OAC was from 4.7 to 5.5% at an ASRMS content of 0% and from 4.3 to 5.0% at an ASRMS content of 10%. As a large quantity of ASRMS can be used for asphalt manufacturing, it would be an excellent eco-friendly option.

- The products manufactured in this study were evaluated for recyclability in terms of waste usage, conformance to quality standards, market size, and demand prediction. Results show that APA achieved the highest rank, followed by interlocking, clay, and LSC bricks. Thus, the recyclability of ASRMS was confirmed. If this technology is continuously developed through further research, it would have positive effects on the environment and industries owing to its waste treatment and recycling potential accompanied by the lowering of the cost of raw materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Korea Statistical Information Service, Automobile Production. 2021. Available online: https://kosis.kr/statHtml/statHtml.do?orgId=101&tblId=DT_2KAA511 (accessed on 3 January 2023).

- Ministry of Environment, The Ministry of Environment to Extend Its Vehicle Scrappage—Subsidy Program to Grade 4 Diesel Vehicles from 2023. 2022. Available online: http://m.me.go.kr/eng/web/board/read.do?menuId=461&boardMasterId=522&boardId=1543110 (accessed on 3 January 2023).

- Korea Auto Dismantlement Recycling Association, Scrapping Statistics 2021. 2022. Available online: http://www.kadra.or.kr/kadra/contents/sub02/02_01.html?idx_num=2515&pidx_num=&skin=4&mode=view&GotoPage=1&column=&keyword=&BbsId_01=&BbsId_02=&BbsId_03=&MenuNum=&BbsId=2010316112316&Tbn=&srhData1= (accessed on 3 January 2023).

- Korea Environment Corporation, National Waste Generation and Disposal Status 2020. 2021. Available online: https://www.allbaro.or.kr (accessed on 3 January 2023).

- EUR-Lex, Directive 2000/53/EC- End of Life Vehicles. 2000. Available online: http://data.europa.eu/eli/dir/2000/53/oj (accessed on 3 January 2023).

- Ministry of Environment, Act on Resource Circulation of Electrical and Electronic Equipment and Vehicles. 2022. Available online: https://www.law.go.kr (accessed on 3 January 2023).

- National Institute of Environment Research. A Study on Life Cycle Assessment of Plastic Waste Recycling (III)—ELV and WEEE Plastic Waste; Korean Government Report; National Institute of Environment Research: Incheon, Republic of Korea, 2021.

- Yoo, H.M.; Lee, S.Y.; Cho, S.J.; Seo, Y.C.; Jang, H.N. Evaluation of the Melting Gasification Process for Recovery of Energy and Resources from Automobile Shredder Residues. Energies 2022, 15, 1248. [Google Scholar] [CrossRef]

- Ministry of Environment. Development of Intergrated System for Recovering Valuable Metals and Energy from ASR; Korean Government Report; Ministry of Environment: Sejong, Republic of Korea, 2014.

- Ministry of Environment, Waste Control Act. 2022. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%ED%8F%90%EA%B8%B0%EB%AC%BC%EA%B4%80%EB%A6%AC%EB%B2%95 (accessed on 3 January 2023).

- Ministry of Environment. Environmental Assessment Recycling Manual; Korean Government Report; Ministry of Environment: Sejong, Republic of Korea, 2019.

- KS F 2503; Testing Method for Density and 107 Absorption of Coarse Aggregate. Korea Agency for Technology and Standard: Seoul, Republic of Korea, 2019.

- Shi, T.; Zhang, X.; Hao, H.; Chen, C. Experimental and numerical investigation on the compressive properties of interlocking blocks. Eng. Struct. 2021, 228, 111561. [Google Scholar] [CrossRef]

- Ketov, A.; Rudakova, L.; Vaisman, I.; Ketov, I.; Haritonovs, V.; Sahmenko, G. Recycling of rice husks ash for thepreparation of resistant, lightweight and environment-friendly fired bricks. Constr. Build. Mater. 2021, 302, 124385. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Cho, S.J.; Joung, H.T.; Jung, H.Y.; Yoo, H.M.; Seo, Y.C. Recyclability evaluation of melting slag as asphalt paving aggregates. J. KSWM 2012, 29, 113–120. [Google Scholar]

- Yoo, H.M.; Lee, J.S.; Yang, W.S.; Park, J.K.; Park, S.W.; Han, B.H.; Cho, S.J.; Kim, M.H.; Seo, Y.C. Recyclability evaluation of waste CRT glass as a concrete brick aggregate. J. KSWM 2013, 30, 78–85. [Google Scholar] [CrossRef]

- KS F 4419; Concrete Interlocking Block for Sidewalk and Road. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2022. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS L 4201; Clay Brick. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2020. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS L 8551; Lightweight Swelled Ceramic Block. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2017. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- Korea Institute of Civil Engineering and Building Technology, Guidelines for Desinging Asphalt Mixtures. 2005. Available online: https://www.codil.or.kr/viewDtlConWrkDtlSch.do?gubun=tch&pMetaCode=CIGCTG510028 (accessed on 3 January 2023).

- KS M 2252; Testing Method for Penetrating of Bituminous Materials. Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2017. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS M2010; Testing Methods for Flash Point of Crude Oil and Petroleum Products-Determination of Flash Point-Tag Closed Cup Method. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2017. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS M 2254; Testing Method for Ductility of Bituminous Materials. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2017. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS M 2258; Testing Method for Effect of Heat on Thin-Film of Asphaltic Materials. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2017. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS M 2256; Testing Method for Solubility of Bituminous Materials in Trichloroethane. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2017. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS M 2250; Petroleum Product-Testing Method for Softening Point of Bituminous Materials (Ring and Ball Method). Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2019. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS M 2001; Method of Sampling Crude Oil and Petroleum Products. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2020. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- KS M ISO3657; Crude Petroleum and Liquid Petroleum Product-Laboratory Determination of Density—Hydrometer Method. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2017. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- SPS-KAI0002-F2349-5687; Hot Mix Asphalt Mixture. Korea Agency for Technology and Standard: Maengdong-myeon, Republic of Korea, 2018. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchList.do (accessed on 3 January 2023).

- Korea Institute of Civil Engineering and Building Technology, Quality Standard for Recycled Aggregate. 2021. Available online: https://www.law.go.kr (accessed on 3 January 2023).

- Ministry of Environment, Soil Environment Conservation Act. 2020. Available online: https://www.law.go.kr (accessed on 3 January 2023).

- Ministry of Environment, Enforcement Rule of Waste Control Act. 2022. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%ED%8F%90%EA%B8%B0%EB%AC%BC%EA%B4%80%EB%A6%AC%EB%B2%95%20%EC%8B%9C%ED%96%89%EA%B7%9C%EC%B9%99 (accessed on 3 January 2023).

- Lee, J.S.; Yoo, H.M.; Yang, W.S.; Park, J.K.; Cho, S.J.; Kim, B.S.; Seo, Y.C. A study on clay brick manufacturing with powders of CRT glass waste. J. KSWM 2021, 30, 86. [Google Scholar] [CrossRef]

- Korea Statistical Information Service, Number of Establishments, Gross Output, Value of Shipments and Year-End Invertory by Product. 2020. Available online: https://kostat.go.kr/wnsearch/search.jsp (accessed on 3 January 2023).

- Korea Statistical Information Service, Producer Price Index. 2022. Available online: https://url.kr/3c1qhi (accessed on 3 January 2023).

- National Institute of Environmental Research. Study on Management of Industrial Waste for Alternative Resource of Natural Materials (III); Korea Government Report; National Institute of Environmental Research: Incheon, Republic of Korea, 2015.

| Material | Analysis | Instrument | Method |

|---|---|---|---|

| Density | Electronics densimeter MD-300S, Alfa Mirage | KS F 2503 |

| XRD | X-pert Pro, PNanlytical | ASTM E 82 | |

| XRF | EDX-720, Shimadzu | ASTM D 5381 | |

| Heavy metal | ICP-OES 720ES, Varian | US EPA Method M-3050B | |

| Leaching test | ES 06150. d |

| (Unit: %) | ||||||

|---|---|---|---|---|---|---|

| Cement | Aggregate | Water/Cement | Standard (KS F 4419) | |||

| ASRMS | Sand | Stone Powder | ||||

| Standard | 25.0 | 0.0 | 50.0 | 50.0 | 20.0 | Bending strength: ≥5 MPa Water absorption ratio: ≤10% |

| U-1 | 10.0 | 45.0 | 45.0 | |||

| U-2 | 20.0 | 40.0 | 40.0 | |||

| U-3 | 30.0 | 35.0 | 35.0 | |||

| U-4 | 40.0 | 30.0 | 30.0 | |||

| G-1 | 10.0 | 50.0 | 40.0 | |||

| G-2 | 20.0 | 50.0 | 30.0 | |||

| G-3 | 30.0 | 50.0 | 20.0 | |||

| G-4 | 40.0 | 50.0 | 10.0 | |||

| I-1 | 10.0 | 40.0 | 50.0 | |||

| I-2 | 20.0 | 30.0 | 50.0 | |||

| I-3 | 30.0 | 20.0 | 50.0 | |||

| I-4 | 40.0 | 10.0 | 50.0 | |||

| (Unit: %) | |||||

|---|---|---|---|---|---|

| ASRMS | Kaolin | Feldspar | Clay | Standard (KS L 4201) | |

| Standard | 0.0 | 50.0 | 20.0 | 30.0 | Compressive strength : ≥24.50 MPa Water absorption ratio : ≤10% |

| K-1 | 5.0 | 47.5 | 17.5 | ||

| K-2 | 10.0 | 45.0 | 15.0 | ||

| K-3 | 15.0 | 42.5 | 12.5 | ||

| K-4 | 20.0 | 40.0 | 10.0 | ||

| F-1 | 5.0 | 50.0 | 15.0 | ||

| F-2 | 10.0 | 50.0 | 10.0 | ||

| F-3 | 15.0 | 50.0 | 5.0 | ||

| F-4 | 20.0 | 50.0 | 0.0 | ||

| A-1 | 5.0 | 45.0 | 20.0 | ||

| A-2 | 10.0 | 40.0 | 20.0 | ||

| A-3 | 15.0 | 35.0 | 20.0 | ||

| A-4 | 20.0 | 30.0 | 20.0 | ||

| Material | Mixing Ratio | Size | Standard (K) | |

|---|---|---|---|---|

| Raw material | ASRMS | 20% | 150 mesh | Specific gravity: 0.45–0.55 Compressive strength : 294.20 N/cm2 |

| Automotive glass | 70% | 200 mesh | ||

| Zeolite | 10% | 325 mesh | ||

| Foaming agent | CaCO3 | 1.5% of total raw material | 200 mesh | |

| Mixing solution | 5% NaOH solution | 8% of total raw material | - |

| Quality Evaluation | Standard | Method | ||

|---|---|---|---|---|

| Properties of asphalt binder (AP-5) | ||||

| Penetration (25 °C) | 60–80 | KS M 2252 [22] | ||

| Flash point (25 °C) | 260 | KS M 2010 [23] | ||

| Elongation (15 °C, cm) | 100 | KS M 2254 [24] | ||

| Thin firm heating | Mass change ratio (%) | 0.6 | KS M 2258 [25] | |

| Penetrate index residue ratio (%) | 60–80 | |||

| Toluene solubility | 99.0 | KS M 2256 [26] | ||

| Softening point (°C) | 44.0–52.0 | KS M 2250 [27] | ||

| Penetrate index ratio after vaporisation testing (%) | 110 | KS M 2001 [28] | ||

| Elongation after heat on thin-firm | 100 | KS M 2254 [24] | ||

| Density (15 °C, g/cm3) | 1.000 | KS M ISO3657 [29] | ||

| Asphalt paving mixture | ||||

| Marshall test | Stability (N) | 7500 | SPS-KAI0002-F2349-5687 [30] | |

| Flow value | 20–40 | |||

| Air void (%) | 3–6 | |||

| Saturation (%) | 65–80 | |||

| Indirect tensile strength test (kgf/cm2) | - | |||

| Resilient modulus (MPs) | - | |||

| Wheel tracking test | Dynamic stability (time/mm) | 2500 | ||

| Strain (mm/min) | 0.0300 | |||

| (Unit: %) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Analyte | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | TiO2 | BaO | Others |

| 31.34 | 31.09 | 19.58 | 6.97 | 3.60 | 1.87 | 1.51 | 4.04 | |

| Element | Concentration (mg/kg) | Leaching Test (mg/L) | |

|---|---|---|---|

| Korean Standard | Concentration | ||

| Pb | 4.75 | 3.0 | 0.31 |

| Cu | 798.77 | 1.0 | 0.30 |

| As | 1.72 | 1.5 | 0.03 |

| Hg | 0.03 | 0.005 | N.D. |

| Cd | 2.98 | 0.3 | 0.02 |

| Cr6+ | N.D. | 1.5 | N.D. |

| Cr | 7000.98 | - | 0.04 |

| Zn | 20.73 | - | 0.43 |

| Al | 109,320.83 | - | N.D. |

| Fe | 178,234.25 | - | 0.10 |

| Co | 13.72 | - | N.D. |

| Mn | 1751.18 | - | N.D. |

| Mo | 14.94 | - | N.D. |

| Ni | 94.81 | - | N.D. |

| Others * | - | - | N.D. |

| Quality Evaluation | Standard | This Study | |

|---|---|---|---|

| Penetration (25 °C) | 60–80 | 74 | |

| Flash point (25 °C) | 260 | 336 | |

| Elongation (15 °C, cm) | 100 | 150 | |

| Thin firm heating | Mass change ratio (%) | 0.6 | 0.04 |

| Penetration index residue ratio (%) | 60–80 | 77 | |

| Toluene solubility | 99.0 | 99.85 | |

| Softening point (°C) | 44–52 | 49.50 | |

| Penetration index ratio after vaporisation testing (%) | 110 | 96 | |

| Elongation after heat on thin-firm | 100 | 102 | |

| Density (15 °C, g/cm3) | 1.000 | 1.048 | |

| Indirect Tensile Strength | Resilient Modulus (MPa) 5 °C/25 °C/40 °C | Wheel Tracking Test | ||

|---|---|---|---|---|

| Stability (Time/mm) | Strain (mm/min) | |||

| ASRMS 0% (Asphalt content 5.5%) | 8.76 | 11,644/1926/1144 | 2916.7 | 0.0144 |

| ASRMS 10% (Asphalt content 5.0%) | 11.35 | 13,944/2986/1423 | 2451.4 | 0.0171 |

| Standard | - | - | 2500 | 0.0300 |

| (Unit: point) | ||||

|---|---|---|---|---|

| Item | Interlocking Brick | Clay Brick | Lightweight Swelled Ceramic Brick | Asphalt |

| ASR waste usage | 20 | 15 | 25 | 15 |

| Quality standard satisfaction | 25 | 15 | 10 | 25 |

| Market size | 20 | 15 | 10 | 25 |

| Demand prediction | 15 | 20 | 10 | 25 |

| SUM | 80 | 65 | 55 | 90 |

| Rank | 2 | 3 | 4 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, S.-J.; Jang, H.-N.; Cho, S.-J.; Yoon, Y.-S.; Yoo, H.-M. Material Recycling for Manufacturing Aggregates Using Melting Slag of Automobile Shredder Residues. Materials 2023, 16, 2664. https://doi.org/10.3390/ma16072664

Cho S-J, Jang H-N, Cho S-J, Yoon Y-S, Yoo H-M. Material Recycling for Manufacturing Aggregates Using Melting Slag of Automobile Shredder Residues. Materials. 2023; 16(7):2664. https://doi.org/10.3390/ma16072664

Chicago/Turabian StyleCho, Soo-Jin, Ha-Na Jang, Sung-Jin Cho, Young-Sam Yoon, and Heung-Min Yoo. 2023. "Material Recycling for Manufacturing Aggregates Using Melting Slag of Automobile Shredder Residues" Materials 16, no. 7: 2664. https://doi.org/10.3390/ma16072664

APA StyleCho, S.-J., Jang, H.-N., Cho, S.-J., Yoon, Y.-S., & Yoo, H.-M. (2023). Material Recycling for Manufacturing Aggregates Using Melting Slag of Automobile Shredder Residues. Materials, 16(7), 2664. https://doi.org/10.3390/ma16072664