A New Strengthening Process for Carbon-Fiber-Reinforced Thermoplastic Polyphenylene Sulfide (CFRTP-PPS) Interlayered Composite by Electron Beam Irradiation to PPS Prior to Lamination Assembly and Hot Press

Abstract

1. Introduction

2. Experimental Procedure

2.1. Preparation of Sized CF and PPS

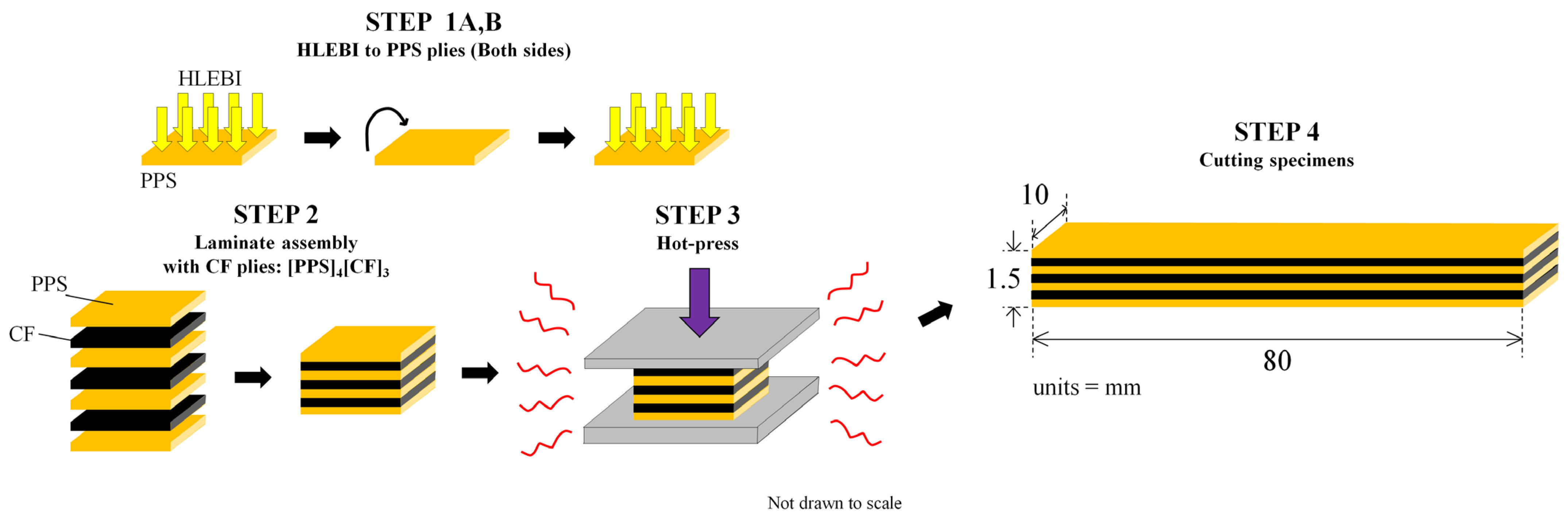

2.2. Composite Fabrication

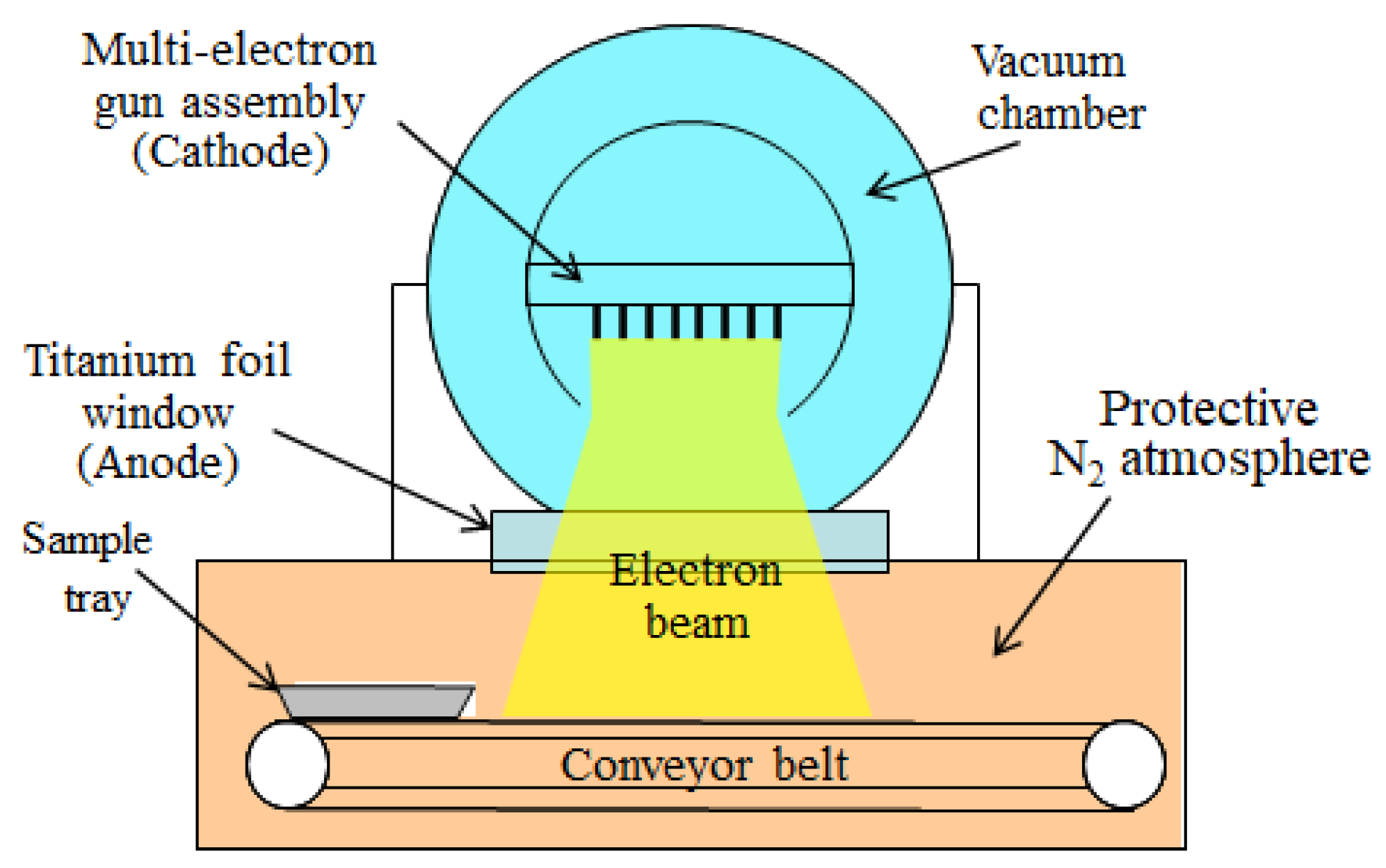

2.3. Conditions of HLEBI

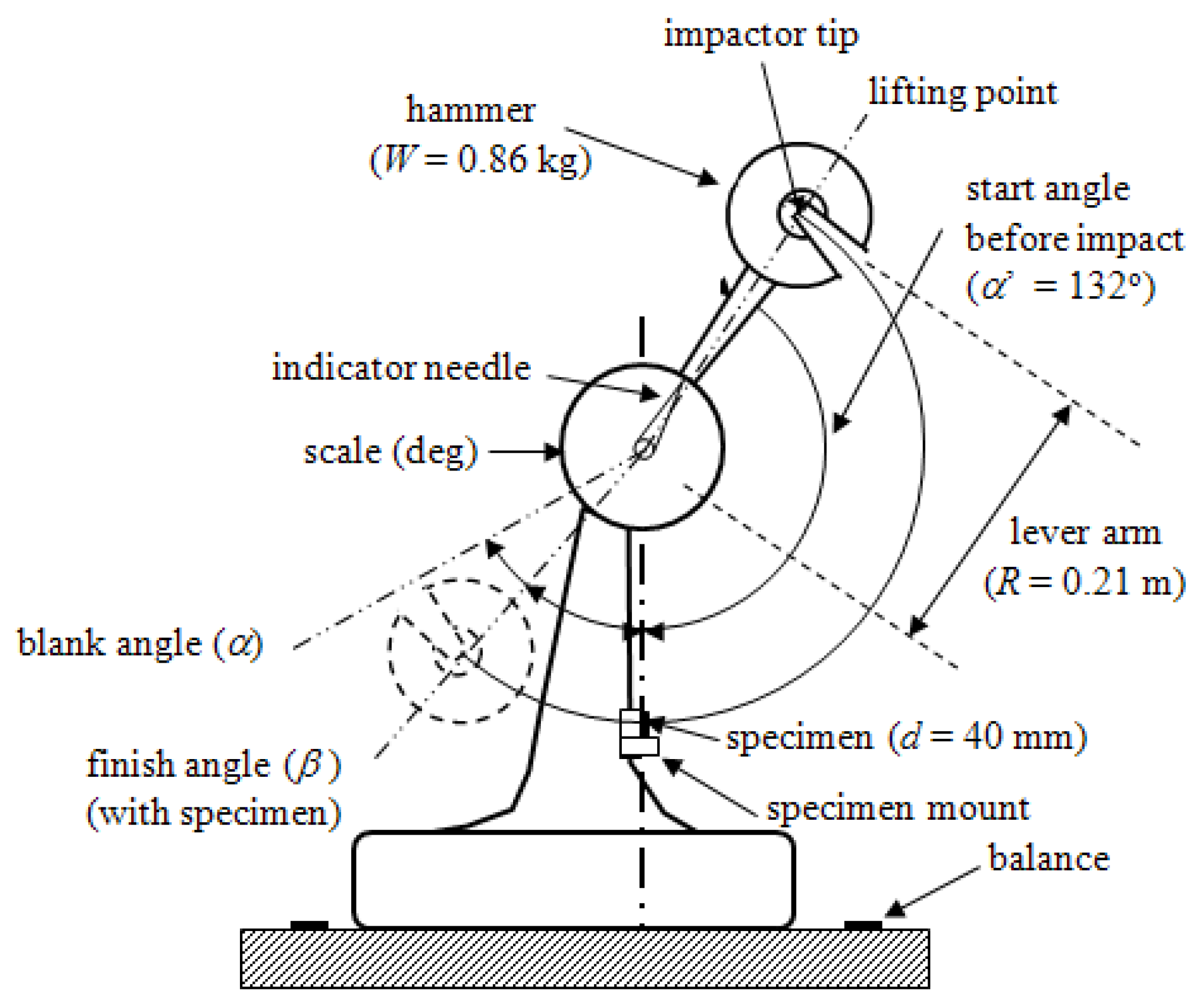

2.4. Charpy Impact Test

2.5. Accumulative Probability

2.6. Microscopy and Energy Dispersive Spectroscopy (EDS)

2.7. Electron Spin Resonance (ESR) Spectroscopy

3. Results

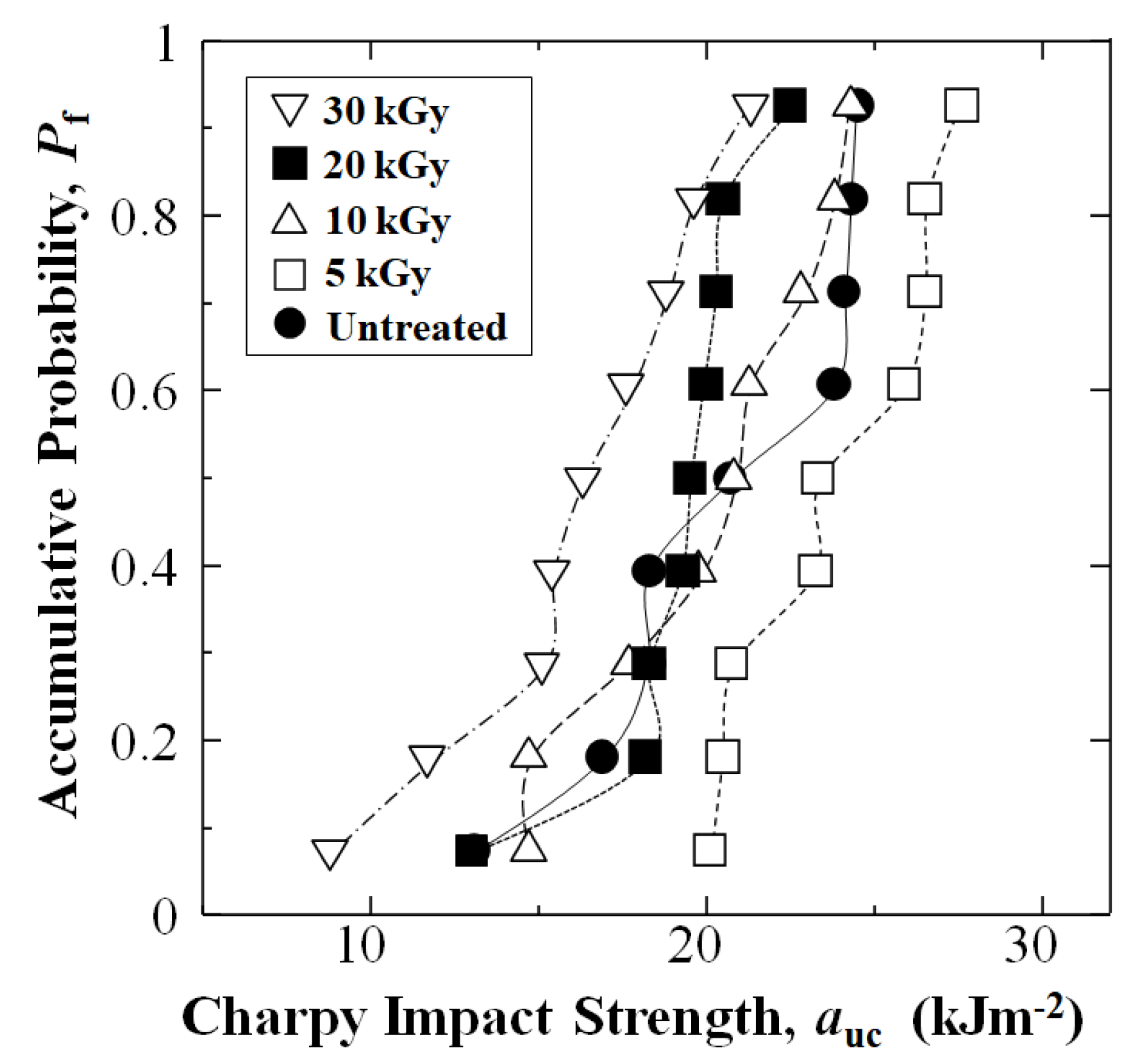

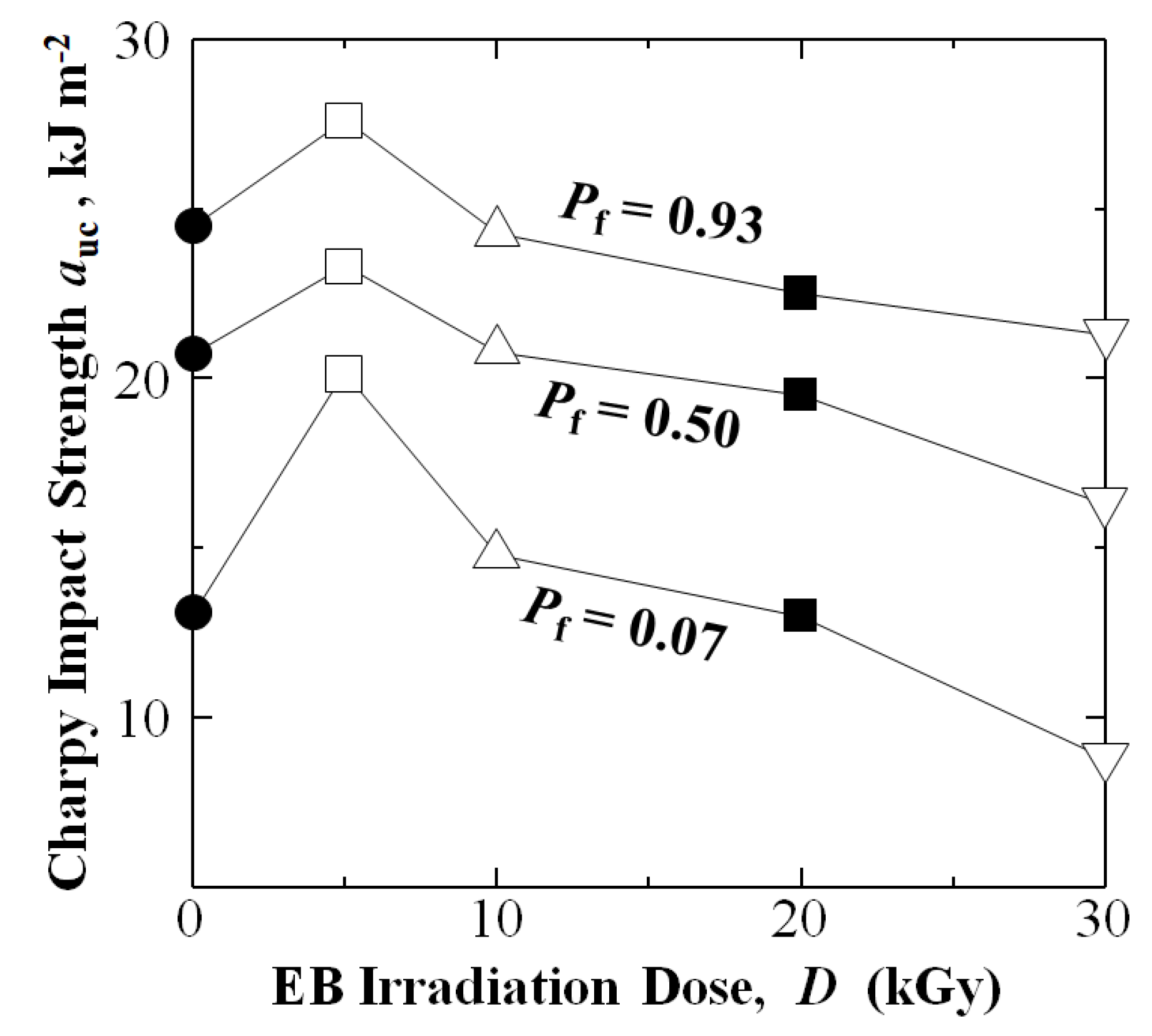

3.1. Relationship between HLEBI to PPS and Impact Strength of [PPS]4[CF]3 Samples

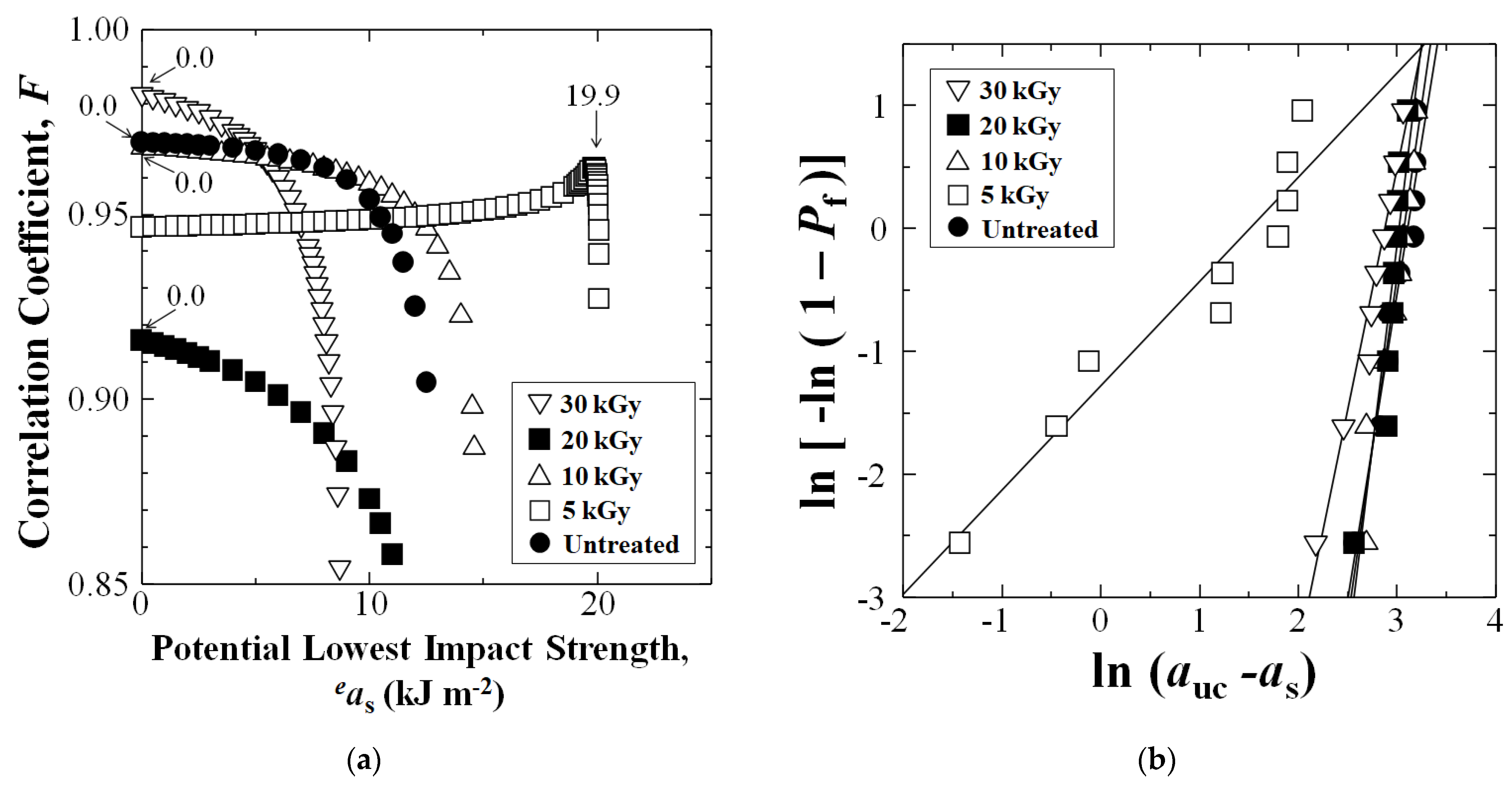

3.2. Determination of Statistically Lowest Impact Strength, as (auc at Pf = 0)

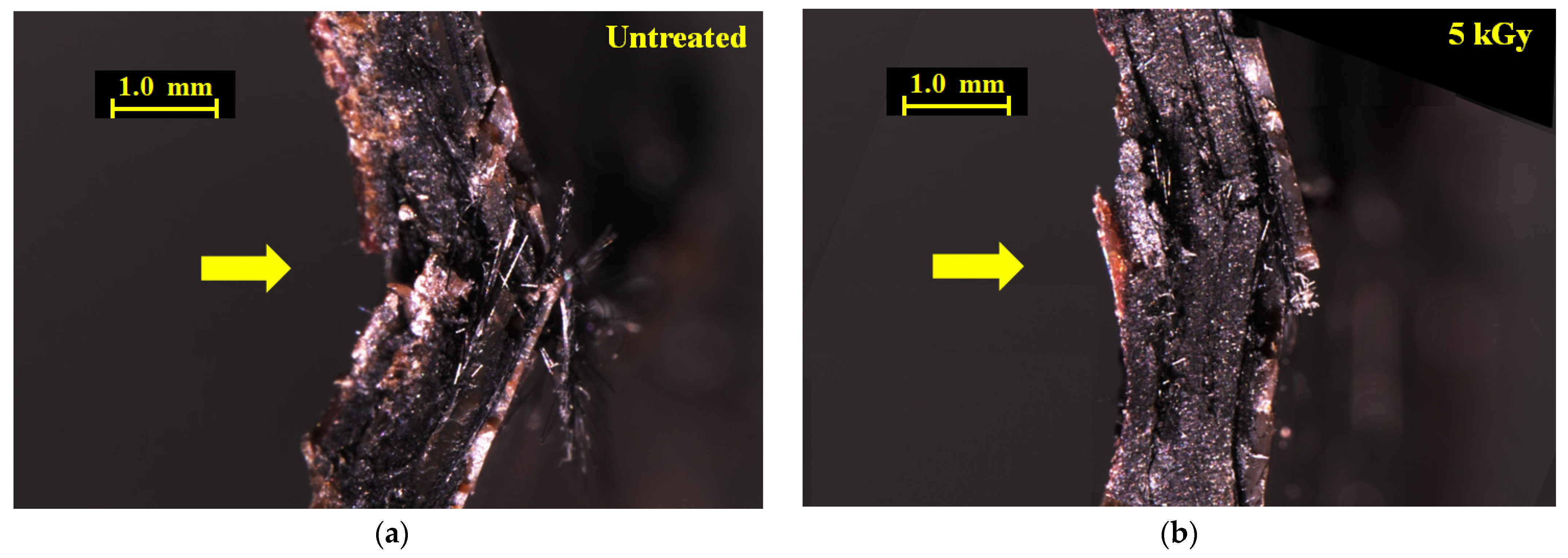

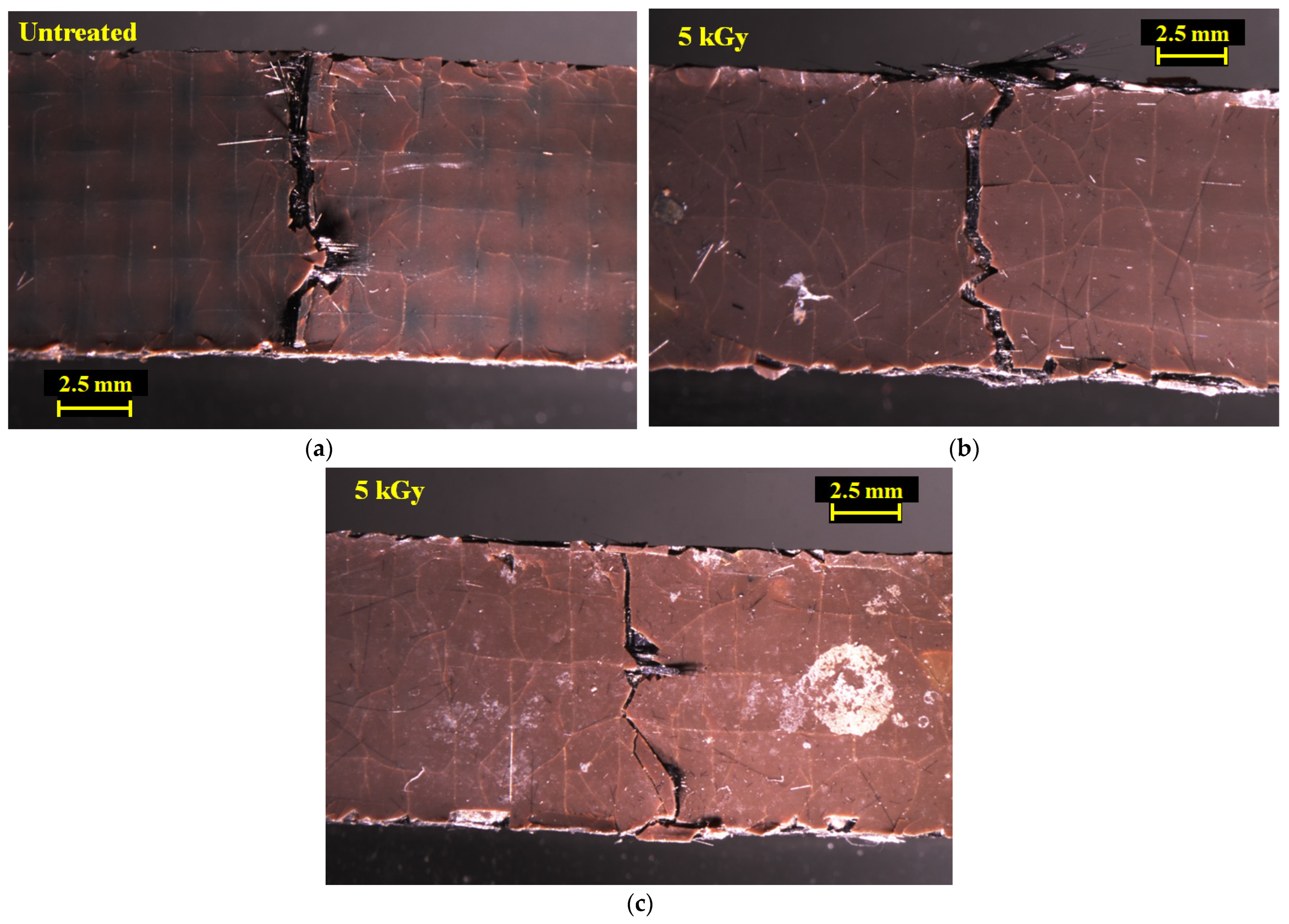

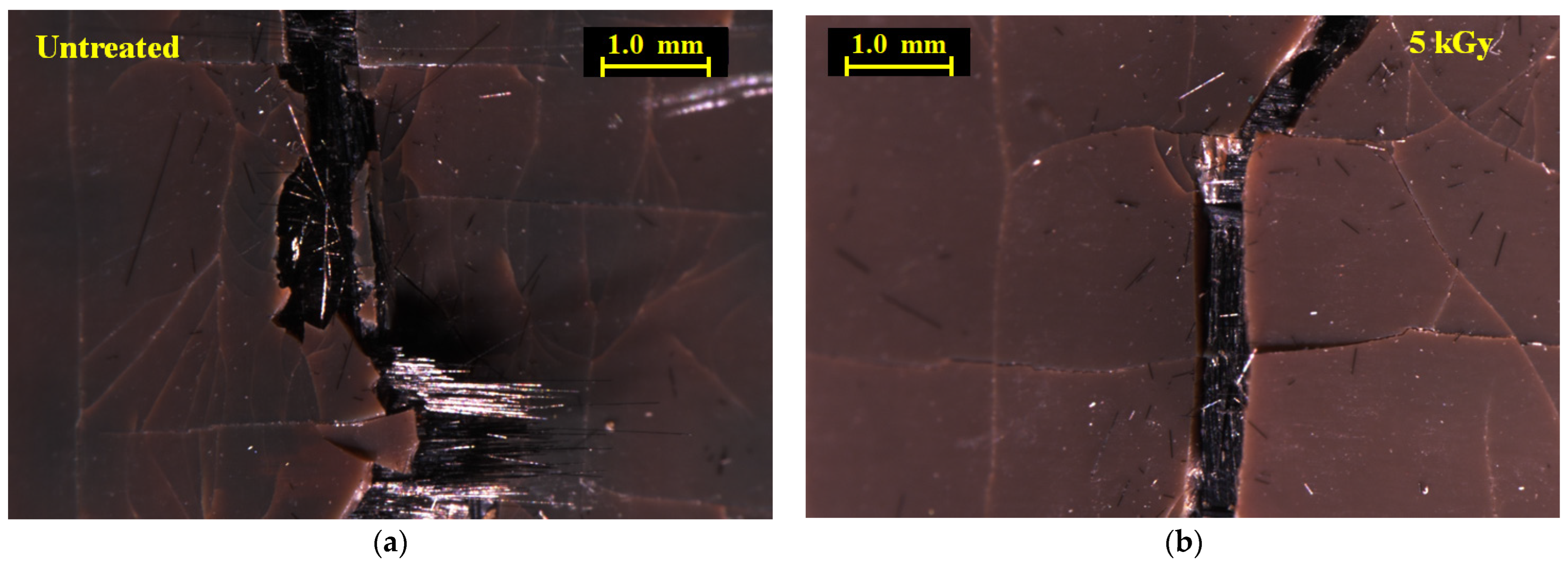

3.3. Optical Microscopy Observation

3.4. SEM and EDS Observation

3.5. Increasing Fiber Pull-Out Resistance and ESR Results

4. Discussion

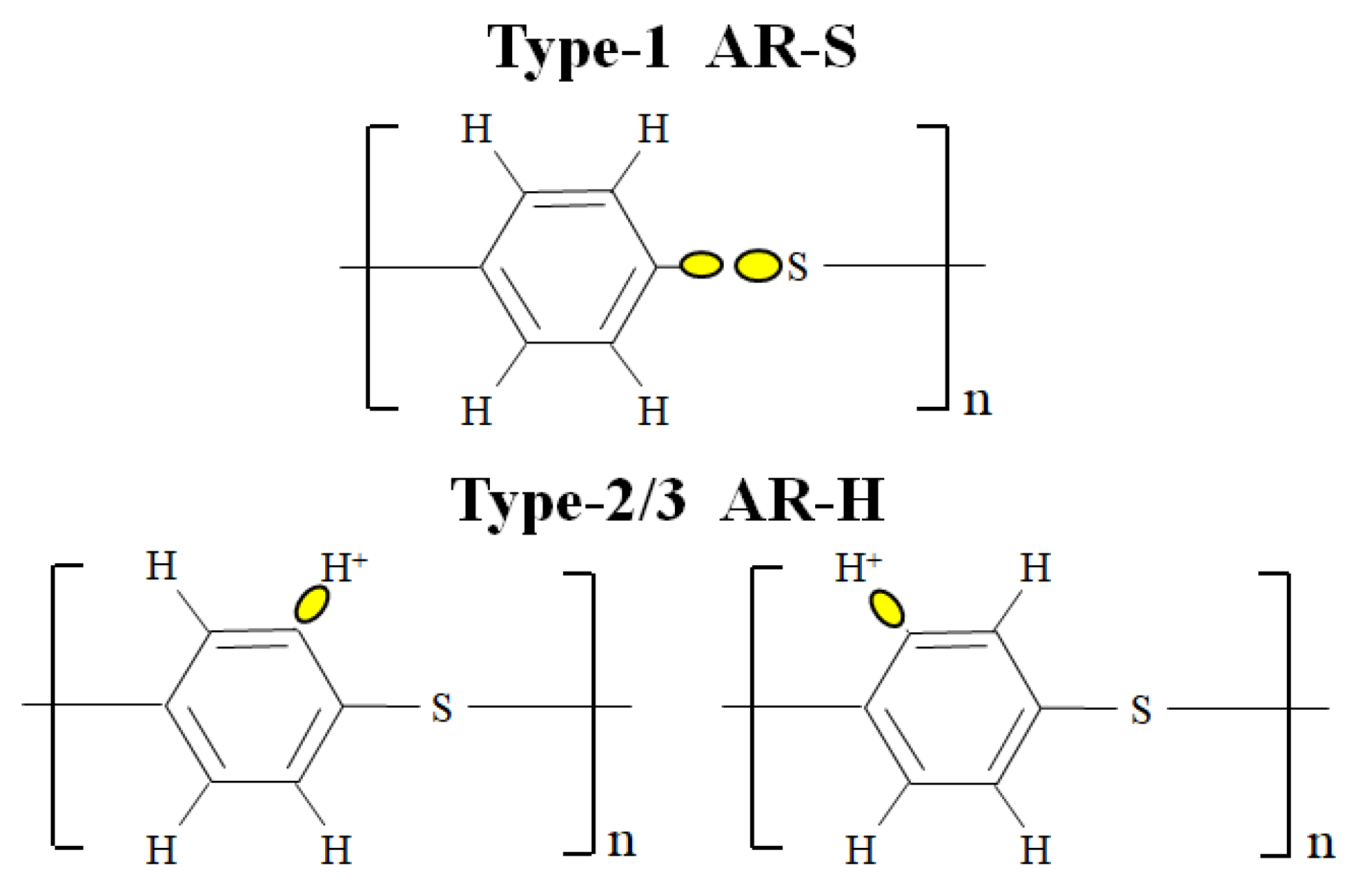

4.1. Dangling Bond Formation

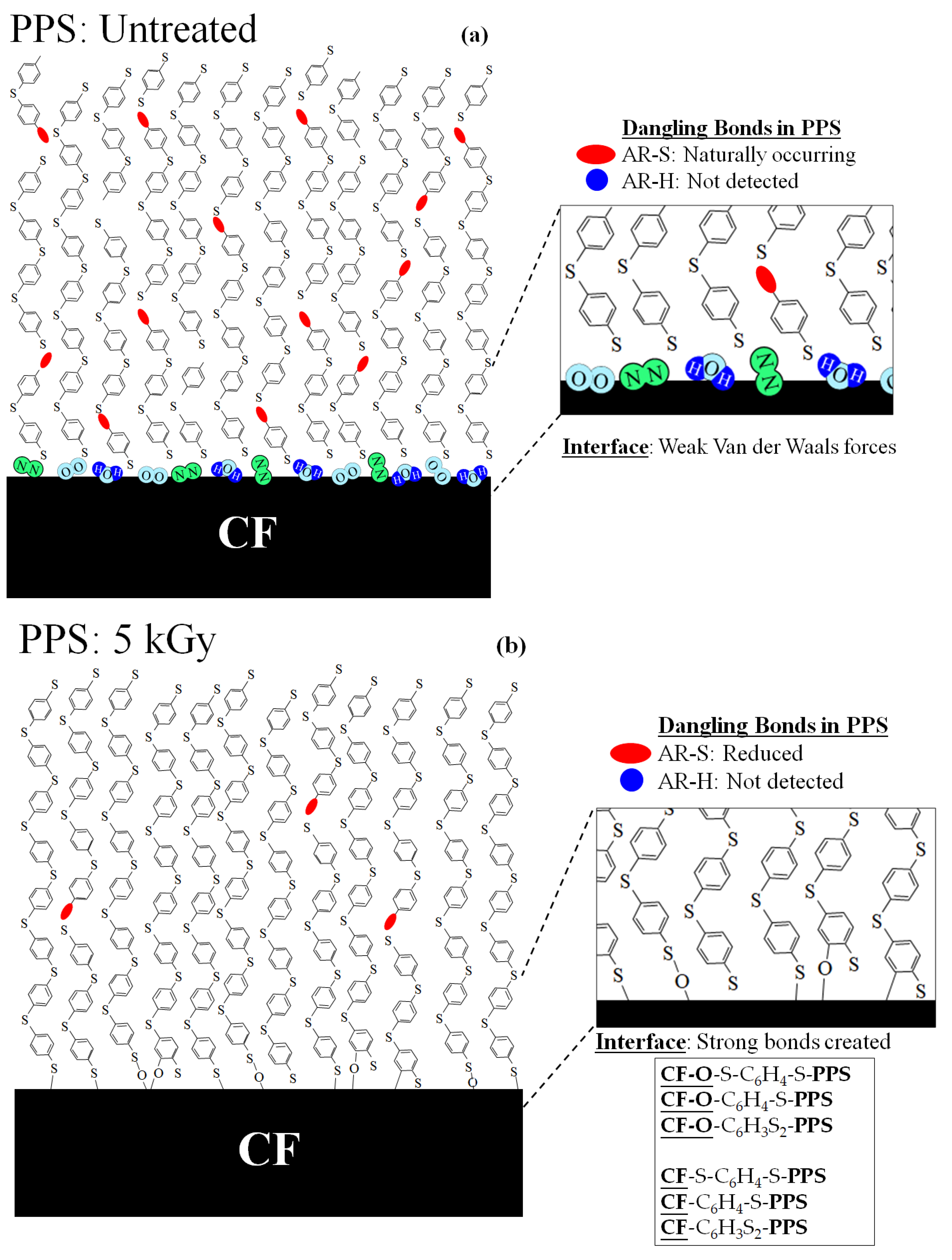

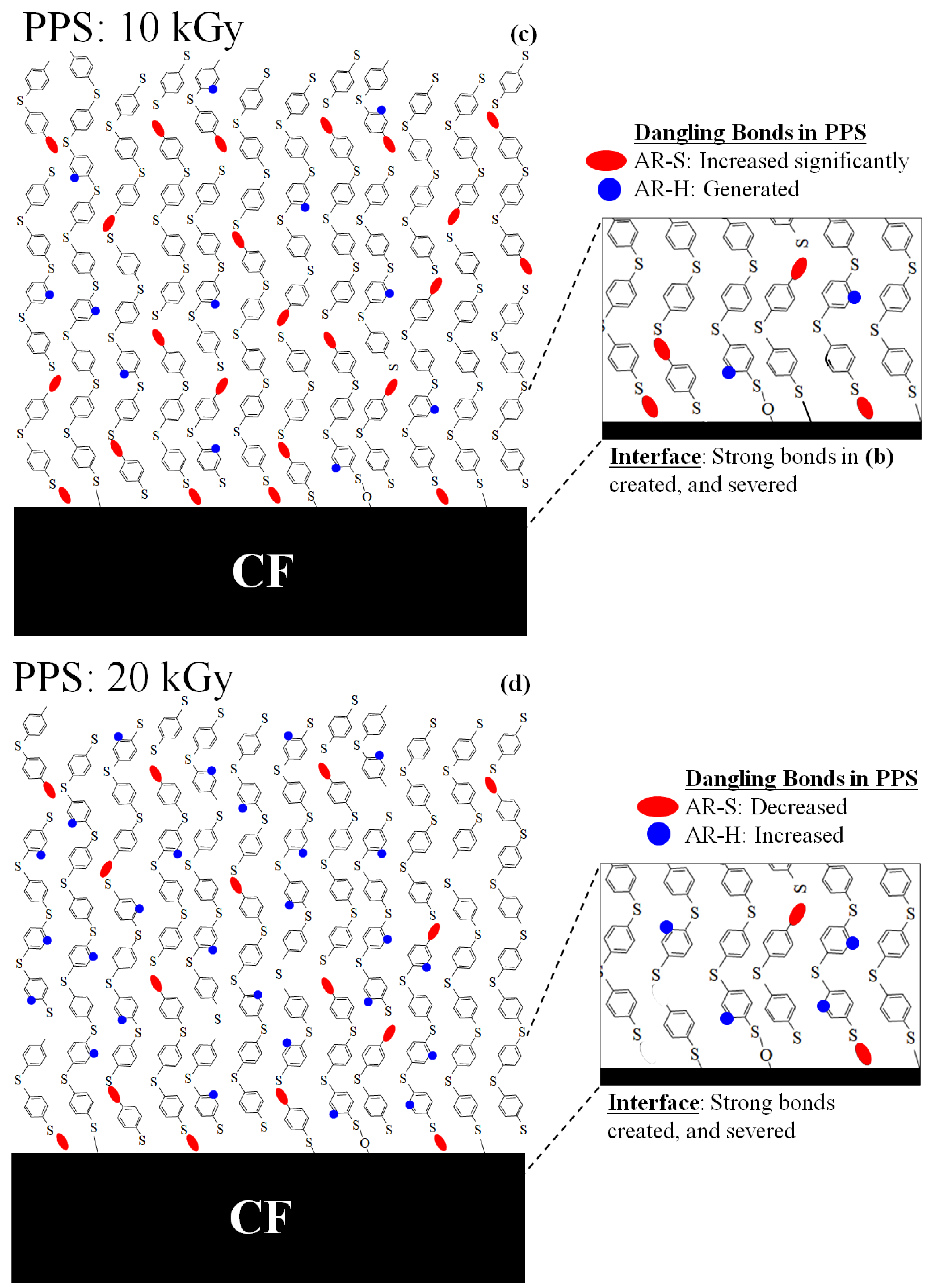

4.2. Model of Proposed Strengthening Mechanism by HLEBI in PPS Plies and at CF-PPS Interface

5. Conclusions

- (1)

- Applying 5 kGy-HLEBI to PPS improved Charpy impact strength (auc) at accumulative fracture probabilities Pf of 0.07, 0.50, and 0.93: from 13.1, 20.7, and 24.5 kJ m−2 to 20.1, 23.3, and 27.6 kJ m−2, respectively; increases of 53%, 12%, and 13%. The auc was improved most at the low-Pf of 0.07 (53%), indicating increased reliability by strengthening of the weakest samples in the data set.

- (2)

- The 3-dimensional Weibull analysis, often used for QC, showed the 5 kGy-HLEBI data set exhibited the highest as at Pf = 0 at 19.9 kJ m−2, indicating an increase in safety and reliability of the 5 kGy [PPS]4[CF]3 samples.

- (3)

- Optical microscopy along with SEM and EDS showed the 5 kGy HLEBI dose increased PPS/CF adhesion and increased cohesion within the interlayered structure to raise the impact strength.

- (4)

- A model was constructed to explain strengthening of PPS plies themselves and increased adhesion at the CF/PPS interface. (1) In the PPS matrix, reduced AR-S dangling bond density (which exists naturally in untreated PPS) acts to lengthen the chains as evidenced by a reduction in ESR peak with an inflection point at 320.3 mT. (2) At the CF/PPS interface, strong bonding is maximized in the form of CF-O-S-C6H4-S-PPS, CF-O-C6H4-S-PPS and CF-O-C6H3S2-PPS; and with CF itself, as CF-S-C6H4-S-PPS, CF-C6H4-S-PPS and CF-C6H3S2-PPS, where “CF-O” is sizing, “CF” is CF surface, and “-C6Hx-“ = -AR-. On the CF surface, EDS results detected sulfur, while SEM detected PPS remaining. This is instead of the weak intermolecular bonding CF(H2O, N2, O2)PPS of untreated samples. Since HLEBI doses above 10 kGy appear to degrade the composite, carefulness is always recommended in adjusting for optimum HLEBI dose for practical applications.

- (5)

- Specific future plans for this research are proprietary. However, in general, included are investigating specimens with different geometries, materials, tests, or treatments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chiang, Y.-C.; Chen, Y.-J.; Wu, C.-Y. Effect of Relative Humidity on Adsorption Breakthrough of CO2 on Activated Carbon Fibers. Materials 2017, 10, 1296. [Google Scholar] [CrossRef]

- Kamedulski, P.; Lukaszewicz, J.P.; Witczak, L.; Szroeder, P.; Ziolkowski, P. The Importance of Structural Factors for the Electrochemical Performance of Graphene/Carbon Nanotube/Melamine Powders towards the Catalytic Activity of Oxygen Reduction Reaction. Materials 2021, 14, 2448. [Google Scholar] [CrossRef] [PubMed]

- Irshad, H.M.; Hakeem, A.S.; Raza, K.; Baroud, T.N.; Ehsan, M.A.; Ali, S.; Tahir, M.S. Design, Development and Evaluation of Thermal Properties of Polysulphone–CNT/GNP Nanocomposites. Nanomaterials 2021, 11, 2080. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Zhang, G.; Liu, B.; Wang, X.; Long, S.; Yang, J. Effect of aminated polyphenylene sulfide on the mechanical properties of short carbon fiber reinforced polyphenylene sulfide composites. Compos. Sci. Technol. 2014, 98, 57–63. [Google Scholar] [CrossRef]

- Dong, Y.; Yu, T.; Wang, X.-J.; Zhang, G.; Lu, J.-H.; Zhang, M.-L.; Long, S.-R.; Yang, J. Improved interfacial shear strength in polyphenylene sulfide/carbon fiber composites via the carboxylic polyphenylene sulfide sizing agent. Compos. Sci. Technol. 2020, 190, 108056. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Naffakh, M. Towards the development of poly(phenylene sulphide) based nanocomposites with enhanced mechanical, electrical and tribological properties. Maters. Chem. Phys. 2012, 135, 348–357. [Google Scholar] [CrossRef]

- Soni, S.K.; Thomas, B.; Swain, A.; Roy, T. Functionally graded carbon nanotubes reinforced composite structures: An extensive review. Compos. Struct. 2022, 299, 116075. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Y.; Zhang, C.; Duan, G.; Jiang, S. Electrospun carbon nanofibers and their reinforced composites: Preparation, modification, applications, and perspectives. Compos. B Eng. 2023, 249, 110386. [Google Scholar] [CrossRef]

- Chen, G.; Mohanty, A.K.; Misra, M. Progress in research and applications of polyphenylene sulfide blends and composites with carbons. Compos. Part B 2021, 209, 108553. [Google Scholar] [CrossRef]

- Ou, Y.; Wu, L.; Yi, X.; Mao, D. Understanding Mode I interlaminar toughening of unidirectional CFRP laminates interleaved with aligned ultrathin CNT fiber veils: Thickness and orientation effects. Compos. B Eng. 2023, 254, 110578. [Google Scholar] [CrossRef]

- Mahat, K.B.; Alarifi, I.; Alharbi, A.; Asmatulu, R. Effects of UV Light on Mechanical Properties of Carbon Fiber Reinforced PPS Thermoplastic Composites. Macromol. Symp. 2016, 365, 157–168. [Google Scholar] [CrossRef]

- McKague, L. Thermoplastic Resins; Composites Consulting Inc.: DeSoto, TX, USA, 1990; Volume 1, p. 132. [Google Scholar]

- Newaz, G.M. Advances in Thermoplastic Matrix Composite Materials; ASTM International: Philadelphia, PA, USA, 1989; Volume 1, p. 1. [Google Scholar]

- Rahate, A.S.; Nemade, K.R.; Waghuley, S.A. Polyphenylene sulfide (PPS): State of the art and applications. Rev. Chem. Eng. 2013, 29, 471–489. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, J.; Qiu, S.; Jia, Y.; Wang, L.; Wang, H. Tailoring the pore size of polyphenylene sulfide nonwoven with bacterial cellulose (BC) for heat-resistant and high-wettability separator in lithium-ion battery. Comp. Comm. 2021, 24, 100659. [Google Scholar] [CrossRef]

- Kishore, V.; Chen, X.; Hassen, A.A.; Lindahl, J.; Kunc, V.; Duty, C. Post-process annealing of large-scale 3D printed polyphenylene sulfide composites. Addit. Manuf. 2020, 35, 101837. [Google Scholar] [CrossRef]

- Parker, M.; Inthavong, A.; Lew, E.; Waddell, S.; Ezeokeke, N.; Matsuzaki, R.; Arola, D. 3D printing of continuous carbon fiber reinforced polyphenylene sulfide: Exploring printability and importance of fiber volume fraction. Addit. Manuf. 2022, 54, 102763. [Google Scholar] [CrossRef]

- Oshima, S.; Higuchi, R.; Kato, M.; Minakuchi, S.; Yokozeki, T.; Aoki, T. Cooling rate-dependent mechanical properties of polyphenylene sulfide (PPS) and carbon fiber reinforced PPS (CF/PPS). Compos. A Appl. Sci. Manuf. 2023, 164, 107250. [Google Scholar] [CrossRef]

- Kiss, P.; Glinz, J.; Stadlbauer, W.; Burgstaller, C.; Archodoulaki, V.M. The effect of thermally desized carbon fibre reinforcement on the flexural and impact properties of PA6, PPS and PEEK composite laminates: A comparative study. Compos. B Eng. 2021, 215, 108844. [Google Scholar] [CrossRef]

- Lacoma, V.; Bailleul, J.-L.; Moisan, S.; Vincent, G.; Binetruy, C.; Kerbrat, O. Inventory analysis of the carbon fibres reinforced polyphenylene sulfide thermo-stamping manufacturing process. J. Clean. Prod. 2023, 393, 136337. [Google Scholar] [CrossRef]

- Benson, S.W. Bond energies. J. Chem. Educ. 1965, 42, 502–518. [Google Scholar] [CrossRef]

- James, A.; Lord, M. Macmillan’s Chemical and Physical Data; The Macmillan Press, Ltd.: London, UK; Basingstoke, UK, 1992; pp. 484–485. ISBN 0-333-51167-0. [Google Scholar]

- Gardiner, G. Thermoplastic Composite the Inside Story. High Perform. Compos. 2009, 1, 8. [Google Scholar]

- Nishi, Y.; Kitagawa, S.; Faudree, M.C.; Uchida, H.T.; Kanda, M.; Takase, S.; Kaneko, S.; Endo, T.; Tonegawa, A.; Salvia, M.; et al. Improvements of strength of layered polypropylene reinforced by carbon fiber by its sizing film and electron beam under protective nitrogen gas atmosphere. In Carbon Related Materials; Kaneko, S., Aono, M., Pruna, A., Can, M., Mele, P., Ertugrul, M., Endo, T., Eds.; Springer: Singapore, 2021; pp. 279–302. [Google Scholar]

- Tang, L.-G.; Kardos, J.L. A review of methods for improving the interfacial adhesion between carbon fiber and polymer matrix. Polym. Compos. 1997, 18, 100–113. [Google Scholar] [CrossRef]

- Jones, C. Effects of electrochemical and plasma treatments on carbon fibre surfaces. Surf. Interf. Anal. 1993, 20, 357–367. [Google Scholar] [CrossRef]

- Pittman, C.U., Jr.; Jiang, W.; Yue, Z.R.; Gardner, S.; Wang, L.; Toghiani, H.; Leon y Leon, C.A. Surface properties of electrochemically oxidized carbon fibers. Carbon 1999, 37, 1797–1807. [Google Scholar] [CrossRef]

- Park, S.J.; Kim, B.J. Roles of acidic functional groups of carbon fiber surfaces in enhancing interfacial adhesion behavior. Mater Sci Eng A 2005, 408, 269–274. [Google Scholar] [CrossRef]

- Takei, H.; Salvia, M.; Vautrin, A.; Tonegawa, A.; Nishi, Y. Effects of electron beam irradiation on elasticity of CFRTP (CF/PEEK). Mater. Trans. 2011, 52, 734–739. [Google Scholar] [CrossRef]

- Nishi, Y.; Takei, H.; Iwata, K.; Salvia, M.; Vautrin, A. Effects of electron beam irradiation on impact value of carbon fiber reinforced thermoplastic polyetheretherketone. Mater. Trans. 2009, 50, 2826–2832. [Google Scholar] [CrossRef]

- Nomura, R.; Kanda, M.; Faudree, M.C.; Jimbo, I.; Nishi, Y. Improving impact value of interlayered glass fiber chopped strand mat reinforced thermoplastic polypropylene externally irradiated by homogeneous low potential electron beam. Mater. Trans. 2014, 57, 1915–1921. [Google Scholar] [CrossRef]

- Nishi, Y.; Kobayashi, H.; Salvia, M. Effects of Electron Beam Irradiation on Charpy Impact Value of GFRP. Mater. Trans. 2007, 48, 1924–1927. [Google Scholar] [CrossRef]

- Faudree, M.; Nishi, Y.; Gruskiewicz, M. Effects of electron beam irradiation on Charpy impact value of short glass fiber (GFRP) samples with random distribution of solidification texture angles from zero to 90 degrees. Mater. Trans. 2012, 53, 1412–2310. [Google Scholar] [CrossRef]

- Mizutani, A.; Nishi, Y. Improved strength in carbon fiber reinforced plastics due after electron beam irradiation. Mater. Trans. 2003, 44, 1857–1860. [Google Scholar] [CrossRef]

- Nishi, Y.; Inoue, K.; Salvia, M. Improvement of Charpy Impact of Carbon Fiber Reinforced Polymer by Low Energy Sheet Electron Beam Irradiation. Mater. Trans. 2006, 47, 2846–2851. [Google Scholar] [CrossRef]

- Nishi, Y.; Toriyama, T.; Oguri, K.; Tonegawa, A.; Takayama, K. High fracture resistance of carbon fiber treated by electron beam irradiation. J. Mater. Res. 2001, 16, 1632–1635. [Google Scholar] [CrossRef]

- Nishi, Y.; Mizutani, A.; Kimura, A.; Toriyama, T.; Oguri, K.; Tonegawa, A. Effects of sheet electron beam irradiation on aircraft design stress of carbon fiber. J. Mater. Sci. 2003, 38, 89–92. [Google Scholar] [CrossRef]

- Kimura, H.; Takeda, K.; Uchida, H.T.; Faudree, M.C.; Sagawa, K.; Kaneko, S.; Salvia, M.; Nishi, Y. Strengthening process by electron beam to carbon fiber for impact strength enhancement of interlayered thermoplastic polypropylene carbon fiber composite. Materials 2022, 15, 7620. [Google Scholar] [CrossRef]

- Faudree, M.C.; Uchida, H.T.; Kimura, H.; Kaneko, S.; Salvia, M.; Nishi, Y. Advances in Titanium/Polymer Hybrid Joints by Carbon Fiber Plug Insert: Current Status and Review. Materials 2022, 15, 3220. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, H.; Faudree, M.C.; Enomoto, Y.; Takase, S.; Kimura, A.; Tonegawa, A.; Jimbo, I.; Salvia, M.; Nishi, Y. Enhanced tensile strength of Titanium/Polycarbonate joint connected by electron beam activated cross-weave carbon fiber cloth insert. Mater. Trans. 2017, 58, 1606–1615. [Google Scholar] [CrossRef]

- Hasegawa, H.; Faudree, M.C.; Matsumuara, Y.; Jimbo, I.; Nishi, Y. Tensile Strength of a Ti/Thermoplastic ABS Matrix CFRTP Joint Connected by Surface Activated Carbon Fiber Cross-Weave Irradiated by Electron Beam. Mater. Trans. 2016, 57, 1202–1208. [Google Scholar] [CrossRef]

- Nomura, R.; Kanda, M.; Faudree, M.C.; Jimbo, I.; Nishi, Y. Internal activation of thermoplastic polypropylene GFRTP composite by homogeneous low energy electron beam irradiation (HLEBI) of the interlayered glass fiber chopped strand mats (GF-CSM) prior to assembly. Mater. Trans. 2016, 57, 417–422. [Google Scholar] [CrossRef]

- Nishi, Y.; Iwata, K. Effects of electron beam irradiation on impact value for soda glass. Mater. Trans. 2005, 46, 2241–2245. [Google Scholar] [CrossRef]

- Iwata, K.; Nishi, Y. Effects of electron beam irradiation on impact value of borosilicate glass. Mater Trans 2010, 51, 121–127. [Google Scholar] [CrossRef]

- Strong, A.B.; Black, S.R.; Bryce, G.R.; Olcott, D.D. Crosslinking of thermoplastic composites using electron beam radiation. Soc. Adv. Mater. Process Eng. (SAMPE) Q. 1991, 22, 45–54. [Google Scholar]

- Technical Sheet for CF. Available online: https://shop.lab-cast.com/?pid=93479046 (accessed on 15 March 2023).

- Kitagawa, S.; Kimura, H.; Takase, S.; Tsuyuki, N.; Kitahara, D.; Takahashi, A.; Faudree, M.C.; Uchida, H.T.; Tonegawa, A.; Kanda, M.; et al. Tensile strength of polypropylene reinforced by carbon fiber covered with and without sizing epoxy film. Trans. Mat. Res. Soc. Jpn. 2018, 43, 125–128. [Google Scholar] [CrossRef]

- Sastri, V.R. Ch. 8 High temperature engineering thermoplastics. In Plastics in Medical Devices: Properties, Requirements and Applications, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 173–213. [Google Scholar]

- Christenhusz, R.; Reimer, L. Schichtdickenabhangigkeit der warmerzeugungdurch elektronenbestrahlung im energiebereich zwischen 9 und 100 keV (Layer thickness dependency of heat generation by electron irradiation in the energy range between 9 and 100 keV). Z. Angew. Phys. 1967, 23, 396–404. [Google Scholar]

- Japanese Industrial Standard JIS K 7077; Testing Method for Charpy Impact Strength Ofcarbon Fiber Reinforced Plastics. Japanese Standards Association: Tokyo, Japan, 1991.

- Faudree, M.C.; Nishi, Y.; Gruskiewicz, M.; Salvia, M. A New Glass Fibered Reinforced Composite with Improved Charpy Impact Properties at Low and High Temperatures beyond the Extremes of Aircraft Flight. Mater. Trans. 2018, 59, 1280–1287. [Google Scholar] [CrossRef]

- Nishida, T.; Yasuda, E. Evaluation of Dynamic Properties of Ceramics (In Japanese, Ceramics No Rikigaku Tokusei Hyouka); Nikkan Kogaku Shimbun Sha: Tokyo, Japan, 1986; pp. 50–51. (In Japanese) [Google Scholar]

- Weibull, W. A Statistical Theory of the Strength of Materials; Ingeniörs vetenskaps akademien; nr. 153; (Generalstabens litografiska anstalts förlag); Engineer Science Academy, Lithographic Institution Publisher: Stockholm, Sweden, 1939; pp. 16–22. [Google Scholar]

- Ichikawa, M. Some Problems in Application of Three-Parameter Weibull Distributions to Reliability Evaluation of Ceramics. Jpn. Soc. Mech. Engrs. (JSME) Intl. J. 1992, 35, 12–21. [Google Scholar]

- Nishi, Y.; Ourahmoune, R.; Kanda, M.; Quan, J.; Faudree, M.C.; Salvia, M. Improvement of Bending Modulus and Impact Value in Injection-Molded Short Carbon Fiber Reinforced Polyetheretherketone with Homogeneous Low-Voltage Electron Beam Irradiation. Mater. Trans. 2014, 55, 1304–1310. [Google Scholar] [CrossRef]

- Schlick, S.; Jeschke, G. 2.08 Electron Spin Resonance Spectroscopy. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2012; pp. 221–253. ISBN 978-0-08-087862-1. [Google Scholar]

- Nishi, Y.; Mizutani, A.; Uchida, N. Electron Beam Strengthening for Carbon Fiber-Reinforced Composite Materials. J. Thermoplast. Compos. Mater. 2004, 17, 289–302. [Google Scholar] [CrossRef]

| Pf | auc (kJ m−2) | ||||

|---|---|---|---|---|---|

| Unt’d | 5 kGy | 10 kGy | 20 kGy | 30 kGy | |

| 0.07 | 13.1 | 20.1 | 14.7 | 13.0 | 8.8 |

| 0.18 | 16.9 | 20.5 | 14.7 | 18.2 | 11.7 |

| 0.29 | 18.3 | 20.8 | 17.7 | 18.3 | 15.1 |

| 0.39 | 18.3 | 23.3 | 19.8 | 19.3 | 15.4 |

| 0.50 | 20.7 | 23.3 | 20.8 | 19.5 | 16.3 |

| 0.61 | 23.8 | 25.9 | 21.3 | 20.0 | 17.6 |

| 0.71 | 24.1 | 26.5 | 22.8 | 20.3 | 18.8 |

| 0.82 | 24.3 | 26.5 | 23.8 | 20.5 | 19.6 |

| 0.93 | 24.5 | 27.6 | 24.3 | 22.5 | 21.3 |

| HLEBI Dose (kGy) | AR-S Peak 1 ~285 kJmol−1 | AR-H Peaks 2 and 3 ~461 kJmol−1 | auc at Pf = 0.50 (kJ m−2) |

|---|---|---|---|

| 0 | YES | NO | 20.7 |

| 5 | <UNTREATED | NO | 23.3 |

| 10 | >>UNTREATED | YES | 20.8 |

| 15 | >UNTREATED | YES | - |

| 20 | >UNTREATED | YES | 19.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takeda, K.; Kimura, H.; Faudree, M.C.; Uchida, H.T.; Sagawa, K.; Miura, E.; Salvia, M.; Nishi, Y. A New Strengthening Process for Carbon-Fiber-Reinforced Thermoplastic Polyphenylene Sulfide (CFRTP-PPS) Interlayered Composite by Electron Beam Irradiation to PPS Prior to Lamination Assembly and Hot Press. Materials 2023, 16, 2823. https://doi.org/10.3390/ma16072823

Takeda K, Kimura H, Faudree MC, Uchida HT, Sagawa K, Miura E, Salvia M, Nishi Y. A New Strengthening Process for Carbon-Fiber-Reinforced Thermoplastic Polyphenylene Sulfide (CFRTP-PPS) Interlayered Composite by Electron Beam Irradiation to PPS Prior to Lamination Assembly and Hot Press. Materials. 2023; 16(7):2823. https://doi.org/10.3390/ma16072823

Chicago/Turabian StyleTakeda, Keisuke, Hideki Kimura, Michael C. Faudree, Helmut Takahiro Uchida, Kohei Sagawa, Eiichi Miura, Michelle Salvia, and Yoshitake Nishi. 2023. "A New Strengthening Process for Carbon-Fiber-Reinforced Thermoplastic Polyphenylene Sulfide (CFRTP-PPS) Interlayered Composite by Electron Beam Irradiation to PPS Prior to Lamination Assembly and Hot Press" Materials 16, no. 7: 2823. https://doi.org/10.3390/ma16072823

APA StyleTakeda, K., Kimura, H., Faudree, M. C., Uchida, H. T., Sagawa, K., Miura, E., Salvia, M., & Nishi, Y. (2023). A New Strengthening Process for Carbon-Fiber-Reinforced Thermoplastic Polyphenylene Sulfide (CFRTP-PPS) Interlayered Composite by Electron Beam Irradiation to PPS Prior to Lamination Assembly and Hot Press. Materials, 16(7), 2823. https://doi.org/10.3390/ma16072823