Efficient Environmentally Friendly Flexible CZTSSe/ZnO Solar Cells by Optimizing ZnO Buffer Layers

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of ZnO Buffer Layers

2.2. Fabrication of Solar Cells

2.3. Characterizations and Measurements

3. Results and Discussion

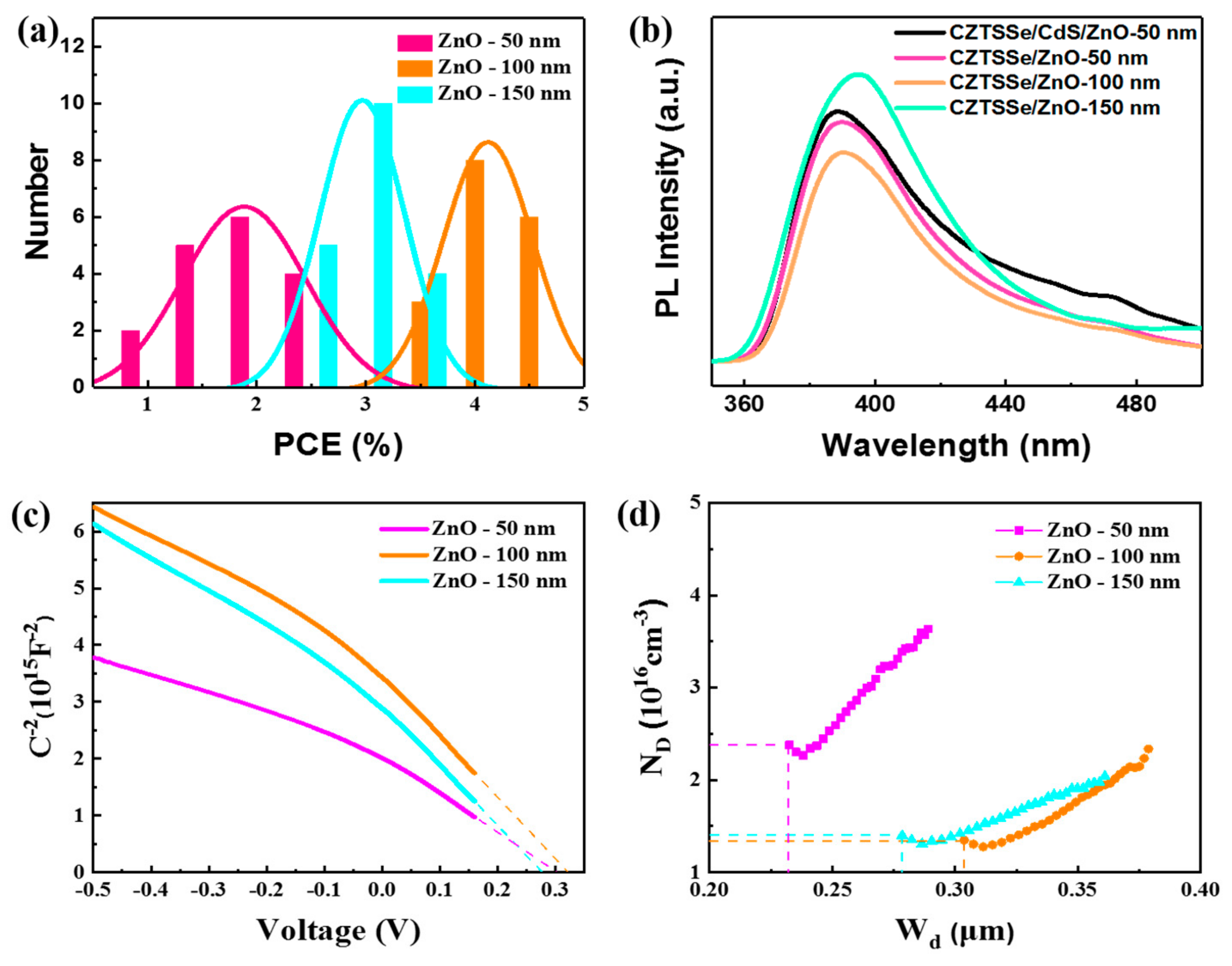

3.1. Optimization of ZnO Buffer Layer Thickness

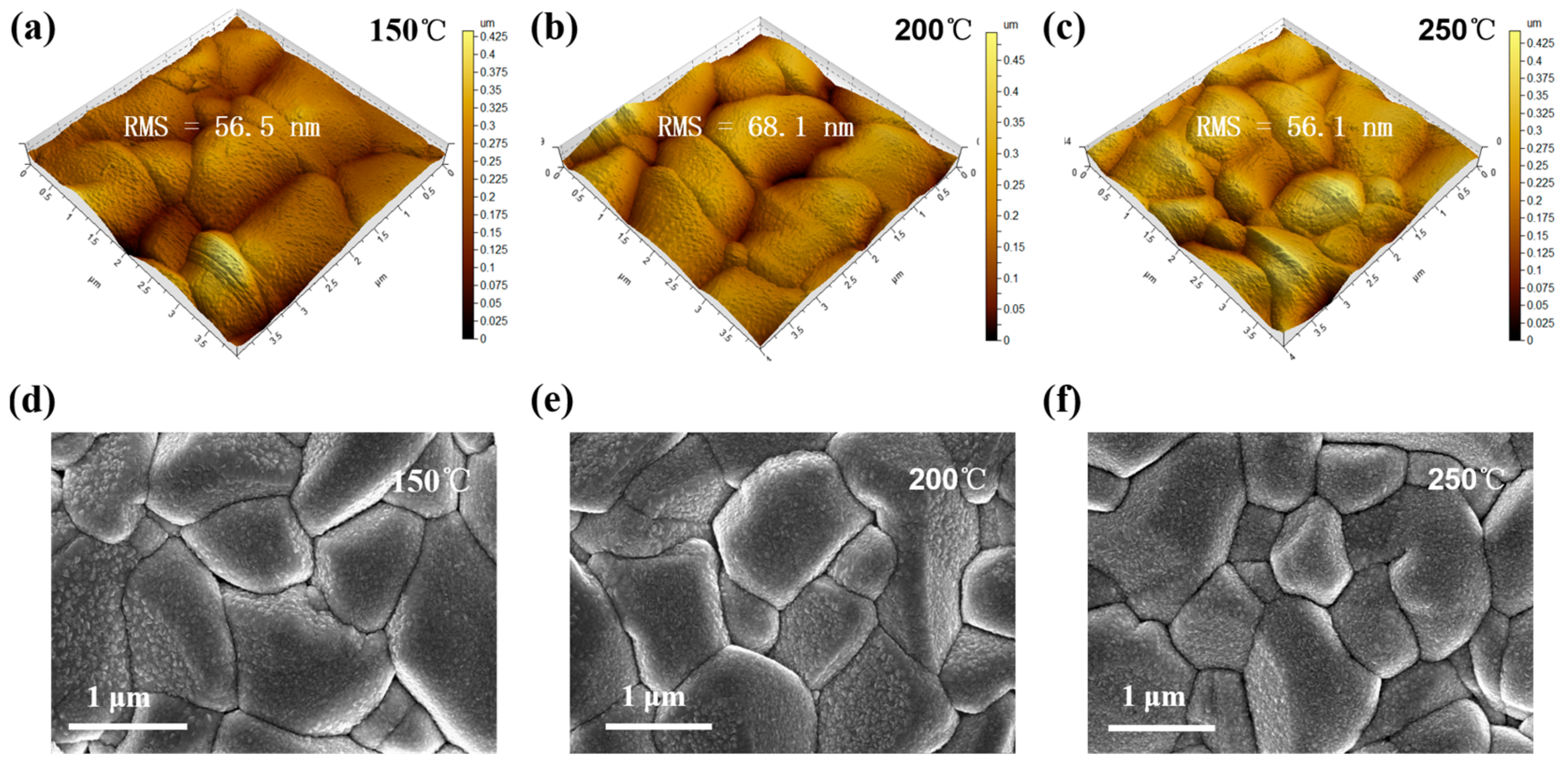

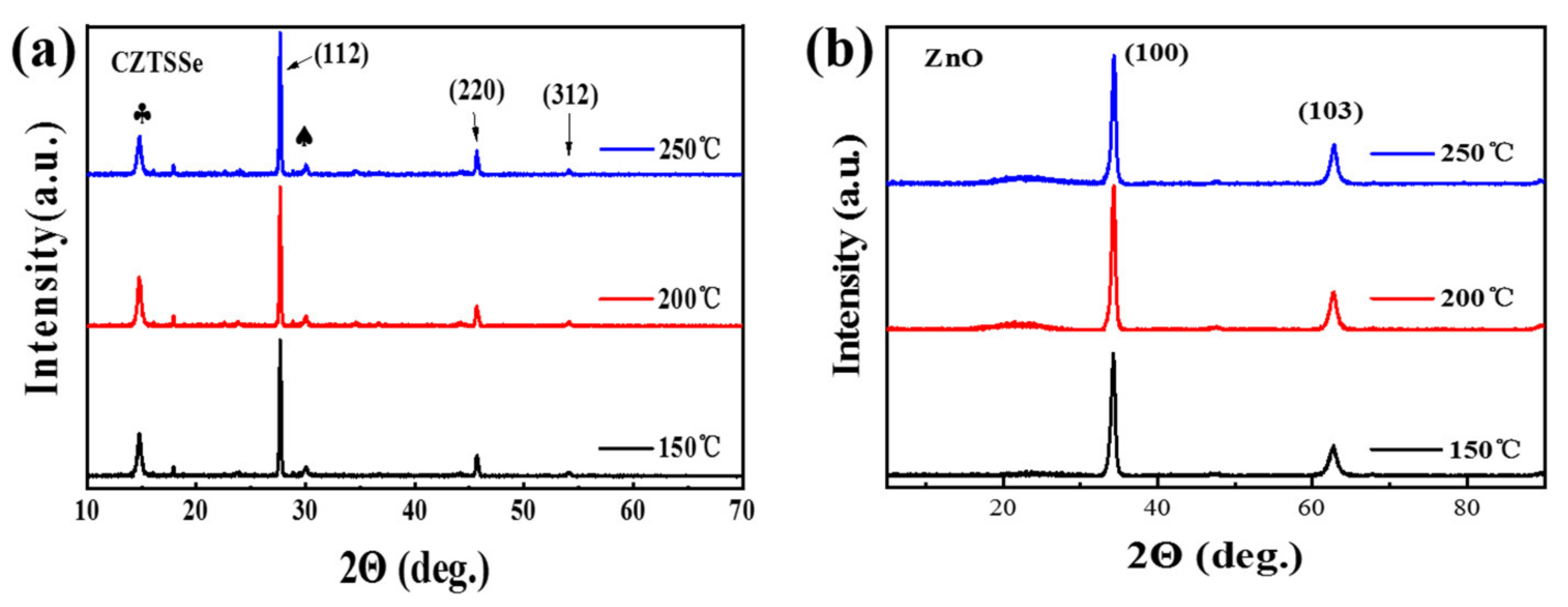

3.2. Optimization of Annealing Temperature of CZTSSe/ZnO Heterojunction

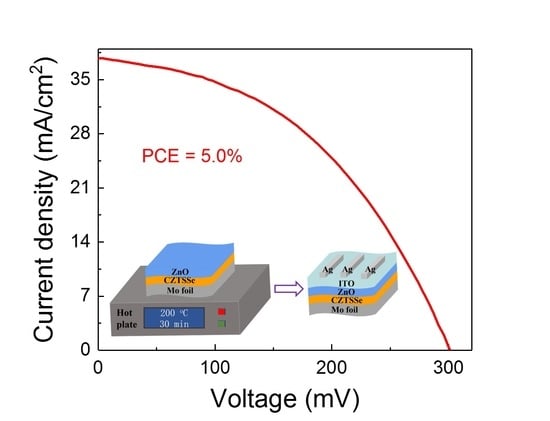

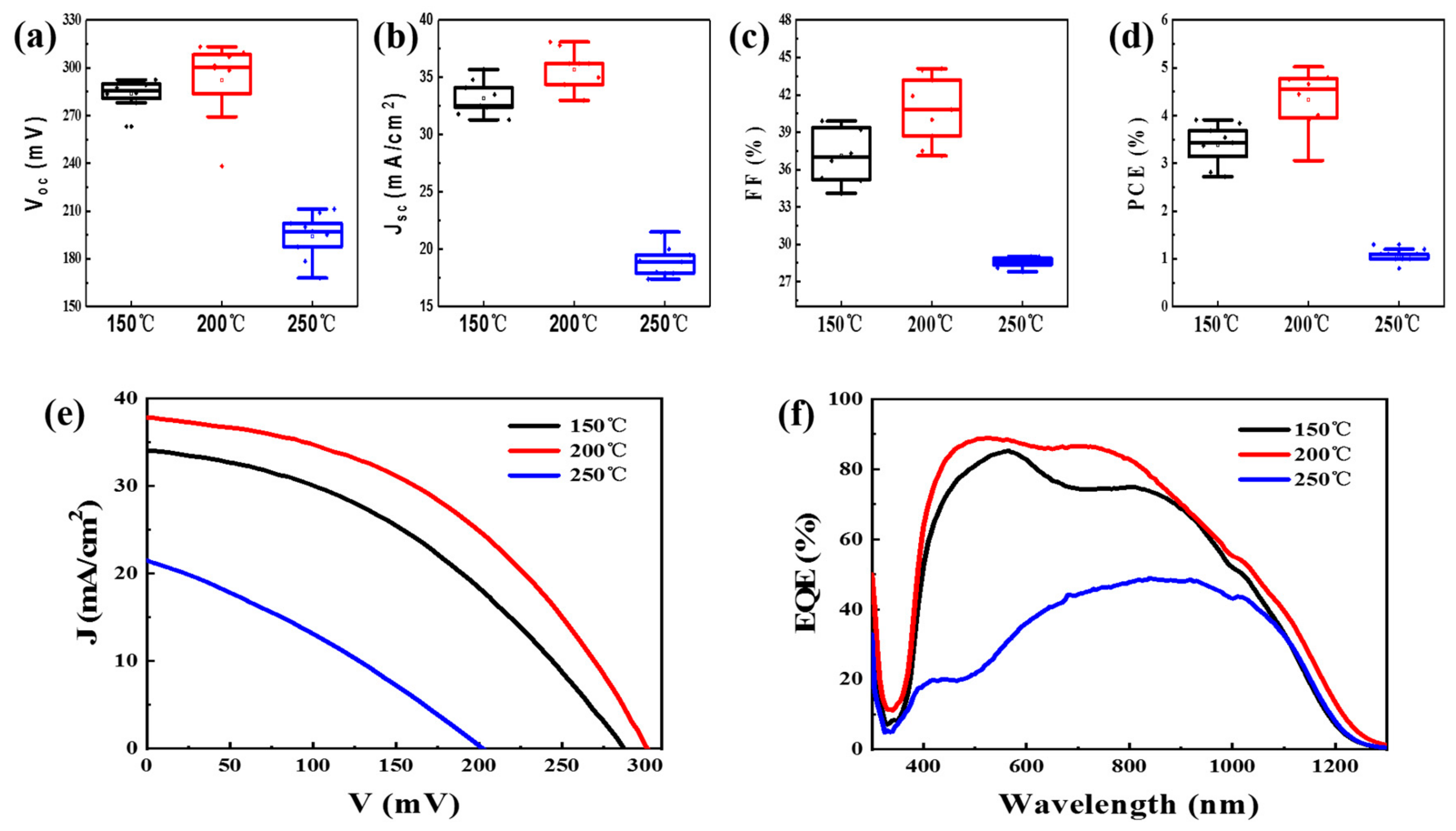

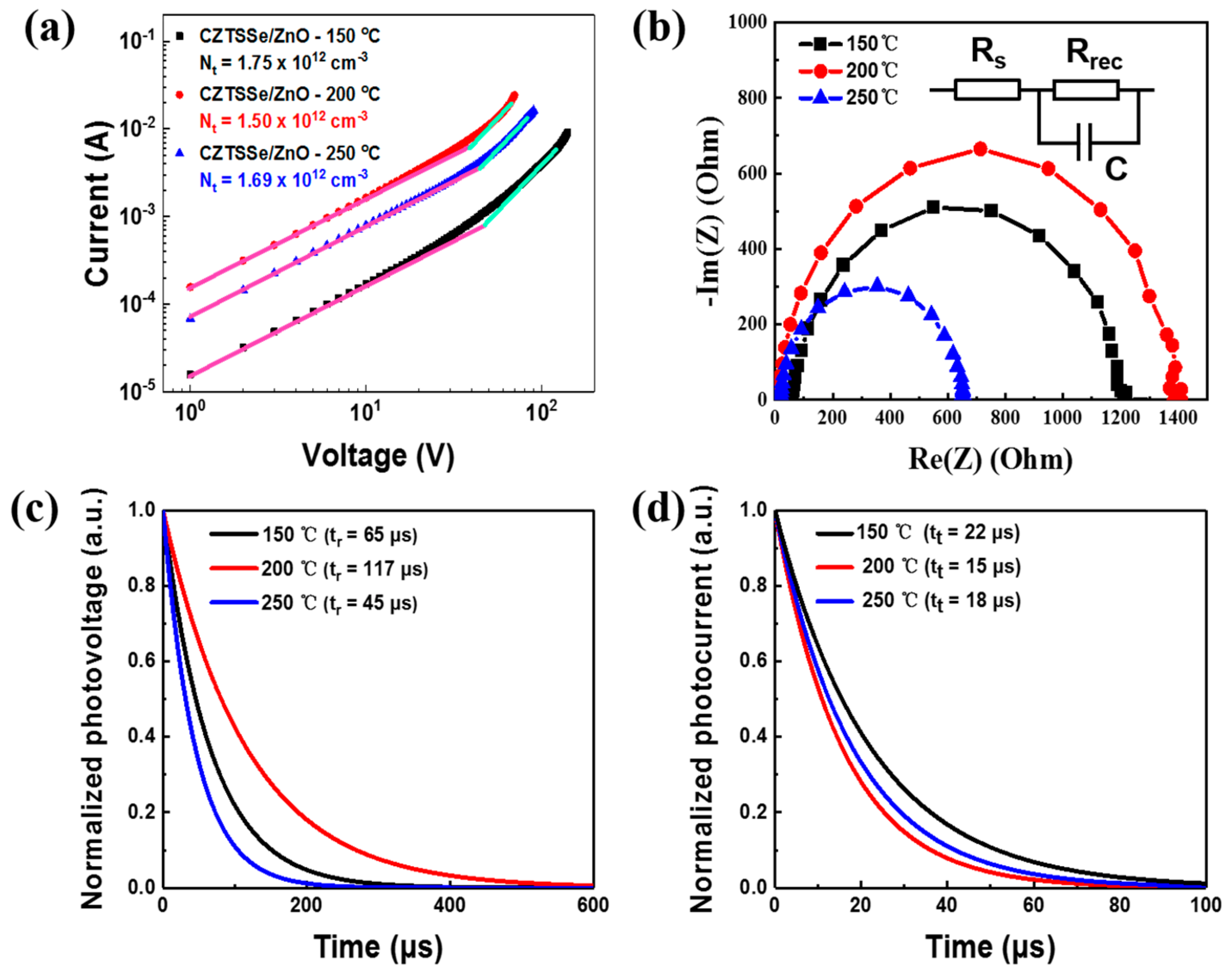

3.3. Performance Characterizations of Flexible CZTSSe/ZnO Devices with Different Annealing Temperatures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sahu, M.; Reddy, V.R.M.; Kim, B.; Patro, B.; Park, C.; Kim, W.K.; Sharma, P. Fabrication of Cu2ZnSnS4 Light Absorber Using a Cost-Effective Mechanochemical Method for Photovoltaic Applications. Materials 2022, 15, 1708. [Google Scholar] [CrossRef] [PubMed]

- Jeong, W.-L.; Park, S.-H.; Jho, Y.-D.; Joo, S.-K.; Lee, D.-S. The Role of the Graphene Oxide (GO) and Reduced Graphene Oxide (RGO) Intermediate Layer in CZTSSe Thin-Film Solar Cells. Materials 2022, 15, 3419. [Google Scholar] [CrossRef]

- Xie, W.; Yan, Q.; Sun, Q.; Li, Y.; Zhang, C.; Deng, H.; Cheng, S. A Progress Review on Challenges and Strategies of Flexible Cu2ZnSn(S, Se)4 Solar Cells. Sol. RRL 2023, 7, 2201036. [Google Scholar] [CrossRef]

- Lin, B.; Sun, Q.; Zhang, C.; Deng, H.; Li, Y.; Xie, W.; Li, Y.; Zheng, Q.; Wu, J.; Cheng, S. Efficient Cd-Free Flexible CZTSSe Solar Cells with Quality Interfaces by Using the Zn1–xSnxO Buffer Layer. ACS Appl. Energy Mater. 2023, 6, 1037–1045. [Google Scholar] [CrossRef]

- Rondiya, S.; Jadhav, Y.; Nasane, M.; Jadkar, S.; Dzade, N.Y. Interface Structure and Band Alignment of CZTS/CdS Heterojunction: An Experimental and First-Principles DFT Investigation. Materials 2019, 12, 4040. [Google Scholar] [CrossRef]

- Guo, Q.; Ford, G.M.; Yang, W.-C.; Walker, B.C.; Stach, E.A.; Hillhouse, H.W.; Agrawal, R. Fabrication of 7.2% Efficient CZTSSe Solar Cells Using CZTS Nanocrystals. J. Am. Chem. Soc. 2010, 132, 17384–17386. [Google Scholar] [CrossRef]

- Gong, Y.; Zhu, Q.; Li, B.; Wang, S.; Duan, B.; Lou, L.; Xiang, C.; Jedlicka, E.; Giridharagopal, R.; Zhou, Y.; et al. Elemental de-mixing-induced epitaxial kesterite/CdS interface enabling 13%-efficiency kesterite solar cells. Nat. Energy 2022, 7, 966–977. [Google Scholar] [CrossRef]

- Yang, K.J.; Kim, S.; Kim, S.Y.; Son, D.H.; Lee, J.; Kim, Y.I.; Sung, S.J.; Kim, D.H.; Enkhbat, T.; Kim, J.; et al. Sodium Effects on the Diffusion, Phase, and Defect Characteristics of Kesterite Solar Cells and Flexible Cu2ZnSn(S,Se)4 with Greater than 11% Efficiency. Adv. Funct. Mater. 2021, 31, 2102238. [Google Scholar] [CrossRef]

- Xu, H.; Ge, S.; Yang, W.; Khan, S.N.; Huang, Y.; Mai, Y.; Gu, E.; Lin, X.; Yang, G. 9.63% efficient flexible Cu2ZnSn(S,Se)4 solar cells fabricated via scalable doctor-blading under ambient conditions. J. Mater. Chem. A 2021, 9, 25062–25072. [Google Scholar] [CrossRef]

- Sun, Q.-Z.; Jia, H.-J.; Cheng, S.-Y.; Deng, H.; Yan, Q.; Duan, B.-W.; Zhang, C.-X.; Zheng, Q.; Yang, Z.-Y.; Luo, Y.-H.; et al. A 9% efficiency of flexible Mo-foil-based Cu2ZnSn(S,Se)4 solar cells by improving CdS buffer layer and heterojunction interface. Chin. Phys. B 2020, 29, 128801. [Google Scholar] [CrossRef]

- Yang, K.-J.; Kim, S.; Kim, S.-Y.; Ahn, K.; Son, D.-H.; Kim, S.-H.; Lee, S.-J.; Kim, Y.-I.; Park, S.-N.; Sung, S.-J.; et al. Flexible Cu2ZnSn(S,Se)4 solar cells with over 10% efficiency and methods of enlarging the cell area. Nat. Commun. 2019, 10, 2959. [Google Scholar] [CrossRef]

- Xie, W.; Sun, Q.; Yan, Q.; Wu, J.; Zhang, C.; Zheng, Q.; Lai, Y.; Deng, H.; Cheng, S. 10.24% Efficiency of Flexible Cu2ZnSn(S,Se)4 Solar Cells by Pre-Evaporation Selenization Technique. Small 2022, 18, 2201347. [Google Scholar] [CrossRef]

- Yan, Q.; Sun, Q.; Deng, H.; Xie, W.; Zhang, C.; Wu, J.; Zheng, Q.; Cheng, S. Enhancing carrier transport in flexible CZTSSe solar cells via doping Li strategy. J. Energy Chem. 2022, 75, 8–15. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Z.; Deng, H.; Yan, Q.; Xie, W.; Sun, Q.; Sheng, X.; Cheng, S. Numerical Study to Improve the Back Interface Contact of CZTSSe Solar Cells Using Oxygen-Doped Mo(Se1–x, Ox)2. J. Phys. Chem. C 2021, 125, 16746–16752. [Google Scholar] [CrossRef]

- Nguyen, M.; Ernits, K.; Tai, K.F.; Ng, C.F.; Pramana, S.S.; Sasangka, W.A.; Batabyal, S.K.; Holopainen, T.; Meissner, D.; Neisser, A.; et al. ZnS buffer layer for Cu2ZnSn(SSe)4 monograin layer solar cell. Sol. Energy 2015, 111, 344–349. [Google Scholar] [CrossRef]

- Larsen, J.K.; Larsson, F.; Törndahl, T.; Saini, N.; Riekehr, L.; Ren, Y.; Biswal, A.; Hauschild, D.; Weinhardt, L.; Heske, C.; et al. Cadmium Free Cu2ZnSnS4 Solar Cells with 9.7% Efficiency. Adv. Energy Mater. 2019, 9, 1900439. [Google Scholar] [CrossRef]

- Naghavi, N.; Abou-Ras, D.; Allsop, N.; Barreau, N.; Bücheler, S.; Ennaoui, A.; Fischer, C.H.; Guillen, C.; Hariskos, D.; Herrero, J.; et al. Buffer layers and transparent conducting oxides for chalcopyrite Cu(In,Ga)(S,Se)2 based thin film photovoltaics: Present status and current developments. Prog. Photovolt. Res. Appl. 2010, 18, 411–433. [Google Scholar] [CrossRef]

- Mahmood, K.; Hameed, M.; Rehman, F.; Khalid, A.; Imran, M.; Mehran, M.T. A multifunctional blade-coated ZnO seed layer for high-efficiency perovskite solar cells. Appl. Phys. A 2019, 125, 83. [Google Scholar] [CrossRef]

- Lee, D.; Kang, T.; Choi, Y.-Y.; Oh, S.-G. Preparation of electron buffer layer with crystalline ZnO nanoparticles in inverted organic photovoltaic cells. J. Phys. Chem. Solids 2017, 105, 66–71. [Google Scholar] [CrossRef]

- Wang, L.; Li, D.-B.; Li, K.; Chen, C.; Deng, H.-X.; Gao, L.; Zhao, Y.; Jiang, F.; Li, L.; Huang, F.; et al. Stable 6%-efficient Sb2Se3 solar cells with a ZnO buffer layer. Nat. Energy 2017, 2, 17046. [Google Scholar] [CrossRef]

- Arepalli, V.K.; Lee, W.-J.; Chung, Y.-D.; Kim, J. Growth and device properties of ALD deposited ZnO films for CIGS solar cells. Mater. Sci. Semicond. Process 2021, 121, 105406. [Google Scholar] [CrossRef]

- Lin, B.; Sun, Q.; Zhang, C.; Deng, H.; Xie, W.; Tang, J.; Zheng, Q.; Wu, J.; Zhou, H.; Cheng, S. 9.3% Efficient Flexible Cu2ZnSn(S,Se)4 Solar Cells with High-Quality Interfaces via Ultrathin CdS and Zn0.8Sn0.2O Buffer Layers. Energy Technol. 2022, 10, 2200571. [Google Scholar] [CrossRef]

- Lee, J.; Enkhbat, T.; Han, G.; Sharif, M.H.; Enkhbayar, E.; Yoo, H.; Kim, J.H.; Kim, S.; Kim, J. Over 11 % efficient eco-friendly kesterite solar cell: Effects of S-enriched surface of Cu2ZnSn(S,Se)4 absorber and band gap controlled (Zn,Sn)O buffer. Nano Energy 2020, 78, 105206. [Google Scholar] [CrossRef]

- Barkhouse, D.A.R.; Haight, R.; Sakai, N.; Hiroi, H.; Sugimoto, H.; Mitzi, D.B. Cd-free buffer layer materials on Cu2ZnSn(SxSe1−x)4: Band alignments with ZnO, ZnS, and In2S3. Appl. Phys. Lett. 2012, 100, 193904. [Google Scholar] [CrossRef]

- Hedibi, A.; Gueddim, A.; Bentria, B. Numerical Modeling and Optimization of ZnO:Al/iZnO/ZnMgO/CZTS Photovoltaic Solar Cell. Trans. Electr. Electron. Mater. 2021, 22, 666–672. [Google Scholar] [CrossRef]

- Htay, M.T.; Hashimoto, Y.; Momose, N.; Sasaki, K.; Ishiguchi, H.; Igarashi, S.; Sakurai, K.; Ito, K. A Cadmium-Free Cu2ZnSnS4/ZnO Hetrojunction Solar Cell Prepared by Practicable Processes. Jpn. J. Appl. Phys. 2011, 50, 032301. [Google Scholar] [CrossRef]

- Hironori, K.; Kazuo, J.; Masami, T.; Hideaki, A.; Koichiro, O. The influence of the composition ratio on CZTS-based thin film solar cells. Mater. Res. Soc. Symp. Proc. 2009, 1165, 1–12. [Google Scholar]

- Alam, M.W.; Ansari, M.Z.; Aamir, M.; Waheed-Ur-Rehman, M.; Parveen, N.; Ansari, S.A. Preparation and Characterization of Cu and Al Doped ZnO Thin Films for Solar Cell Applications. Crystals 2022, 12, 128. [Google Scholar] [CrossRef]

- Alam, M.W.; Wang, Z.; Naka, S.; Okada, H. Performance Enhancement of Top-Contact Pentacene-Based Organic Thin-Film Transistors with Bilayer WO3/Au Electrodes. Jpn. J. Appl. Phys. 2013, 52, 03BB08. [Google Scholar] [CrossRef]

- Li, X.; Su, Z.; Venkataraj, S.; Batabyal, S.K.; Wong, L.H. 8.6% Efficiency CZTSSe solar cell with atomic layer deposited Zn-Sn-O buffer layer. Sol. Energy Mater. Sol. Cells 2016, 157, 101–107. [Google Scholar] [CrossRef]

- Yan, Q.; Cheng, S.; Li, H.; Yu, X.; Fu, J.; Tian, Q.; Jia, H.; Wu, S. High flexible Cu2ZnSn(S,Se)4 solar cells by green solution-process. Sol. Energy 2019, 177, 508–516. [Google Scholar] [CrossRef]

- Sun, Q.; Deng, H.; Yan, Q.; Lin, B.; Xie, W.; Tang, J.; Zhang, C.; Zheng, Q.; Wu, J.; Yu, J.; et al. Efficiency Improvement of Flexible Cu2ZnSn(S,Se)4 Solar Cells by Window Layer Interface Engineering. ACS Appl. Energy Mater. 2021, 4, 14467–14475. [Google Scholar] [CrossRef]

- Kattoor, V.; Awasthi, K.; Jokar, E.; Diau, E.W.-G.; Ohta, N. Integral Method Analysis of Electroabsorption Spectra and Electrophotoluminescence Study of (C4H9NH3)2PbI4 Organic–Inorganic Quantum Well. J. Phys. Chem. C 2018, 122, 26623–26634. [Google Scholar] [CrossRef]

- Yu, X.; Cheng, S.; Yan, Q.; Fu, J.; Jia, H.; Sun, Q.; Yang, Z.; Wu, S. Efficient flexible Mo foil-based Cu2ZnSn(S, Se)4 solar cells from In-doping technique. Sol. Energy Mater. Sol. Cells 2020, 209, 110434. [Google Scholar] [CrossRef]

- Hirahara, N.; Onwona-Agyeman, B.; Nakao, M. Preparation of Al-doped ZnO thin films as transparent conductive substrate in dye-sensitized solar cell. Thin Solid Film 2012, 520, 2123–2127. [Google Scholar] [CrossRef]

- Iqbal, J.; Jilani, A.; Ziaul Hassan, P.M.; Rafique, S.; Jafer, R.; Alghamdi, A.A. ALD grown nanostructured ZnO thin films: Effect of substrate temperature on thickness and energy band gap. J. King Saud Univ.-Sci. 2016, 28, 347–354. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, W.-H.; Pei, Y.-L.; Tian, Q.-W.; Kou, D.-X.; Zhou, Z.-J.; Meng, Y.-N.; Wu, S.-X. High efficiency CZTSSe thin film solar cells from pure element solution: A study of additional Sn complement. Sol. Energy Mater. Sol. Cells 2016, 155, 209–215. [Google Scholar] [CrossRef]

- Zhao, X.; Kou, D.; Zhou, W.; Zhou, Z.; Meng, Y.; Meng, Q.; Zheng, Z.; Wu, S. Nanoscale electrical property enhancement through antimony incorporation to pave the way for the development of low-temperature processed Cu2ZnSn(S,Se)4 solar cells. J. Mater. Chem. A 2019, 7, 3135–3142. [Google Scholar] [CrossRef]

- Deng, Y.; Zhou, Z.; Zhang, X.; Cao, L.; Zhou, W.; Kou, D.; Qi, Y.; Yuan, S.; Zheng, Z.; Wu, S. Adjusting the SnZn defects in Cu2ZnSn(S,Se)4 absorber layer via Ge4+ implanting for efficient kesterite solar cells. J. Energy Chem. 2021, 61, 1–7. [Google Scholar] [CrossRef]

- Al-Ariki, S.; Yahya, N.A.A.; Al-A’nsi, S.A.A.; Jumali, M.H.H.; Jannah, A.N.; Abd-Shukor, R. Synthesis and comparative study on the structural and optical properties of ZnO doped with Ni and Ag nanopowders fabricated by sol gel technique. Sci. Rep. 2021, 11, 11948. [Google Scholar] [CrossRef]

- Vaiano, V.; Matarangolo, M.; Murcia, J.J.; Rojas, H.; Navío, J.A.; Hidalgo, M.C. Enhanced photocatalytic removal of phenol from aqueous solutions using ZnO modified with Ag. Appl. Catal. B Environ. 2018, 225, 197–206. [Google Scholar] [CrossRef]

- Pockett, A.; Lee, H.K.H.; Coles, B.L.; Tsoi, W.C.; Carnie, M.J. A combined transient photovoltage and impedance spectroscopy approach for a comprehensive study of interlayer degradation in non-fullerene acceptor organic solar cells. Nanoscale 2019, 11, 10872–10883. [Google Scholar] [CrossRef]

- Bisquert, J.; Janssen, M. From Frequency Domain to Time Transient Methods for Halide Perovskite Solar Cells: The Connections of IMPS, IMVS, TPC, and TPV. J. Phys. Chem. Lett. 2021, 12, 7964–7971. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, S.; Li, X.; Liu, M.; Chen, Z.; Zhang, P.; Li, S. Efficient and stable low-cost perovskite solar cells enabled by using surface passivated carbon as the counter electrode. J. Mater. Chem. C 2022, 10, 1270–1275. [Google Scholar] [CrossRef]

| Annealing Temperature (°C) | Voc (mV) | Jsc (mA/cm2) | FF (%) | PCE (%) | Gsh (mS/cm2) | Rs (Ω·cm2) | A | J0 (10−3mA/cm2) |

|---|---|---|---|---|---|---|---|---|

| 150 | 287.0 | 34.9 | 44.8 | 4.4 | 12.0 | 2.2 | 2.6 | 1.8 |

| 200 | 301.3 | 37.8 | 44.0 | 5.0 | 8.4 | 1.7 | 2.4 | 2.2 |

| 250 | 206.1 | 24.3 | 31.7 | 1.6 | 60.2 | 2.8 | 2.6 | 8.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Tang, J.; Zhang, C.; Li, Y.; Xie, W.; Deng, H.; Zheng, Q.; Wu, J.; Cheng, S. Efficient Environmentally Friendly Flexible CZTSSe/ZnO Solar Cells by Optimizing ZnO Buffer Layers. Materials 2023, 16, 2869. https://doi.org/10.3390/ma16072869

Sun Q, Tang J, Zhang C, Li Y, Xie W, Deng H, Zheng Q, Wu J, Cheng S. Efficient Environmentally Friendly Flexible CZTSSe/ZnO Solar Cells by Optimizing ZnO Buffer Layers. Materials. 2023; 16(7):2869. https://doi.org/10.3390/ma16072869

Chicago/Turabian StyleSun, Quanzhen, Jianlong Tang, Caixia Zhang, Yaling Li, Weihao Xie, Hui Deng, Qiao Zheng, Jionghua Wu, and Shuying Cheng. 2023. "Efficient Environmentally Friendly Flexible CZTSSe/ZnO Solar Cells by Optimizing ZnO Buffer Layers" Materials 16, no. 7: 2869. https://doi.org/10.3390/ma16072869

APA StyleSun, Q., Tang, J., Zhang, C., Li, Y., Xie, W., Deng, H., Zheng, Q., Wu, J., & Cheng, S. (2023). Efficient Environmentally Friendly Flexible CZTSSe/ZnO Solar Cells by Optimizing ZnO Buffer Layers. Materials, 16(7), 2869. https://doi.org/10.3390/ma16072869