Influence of the Large-Span Pile-Beam-Arch Construction Method on the Surface Deformation of a Metro Station in the Silty Clay–Pebble Composite Stratum

(This article belongs to the Section Construction and Building Materials)

Abstract

:1. Introduction

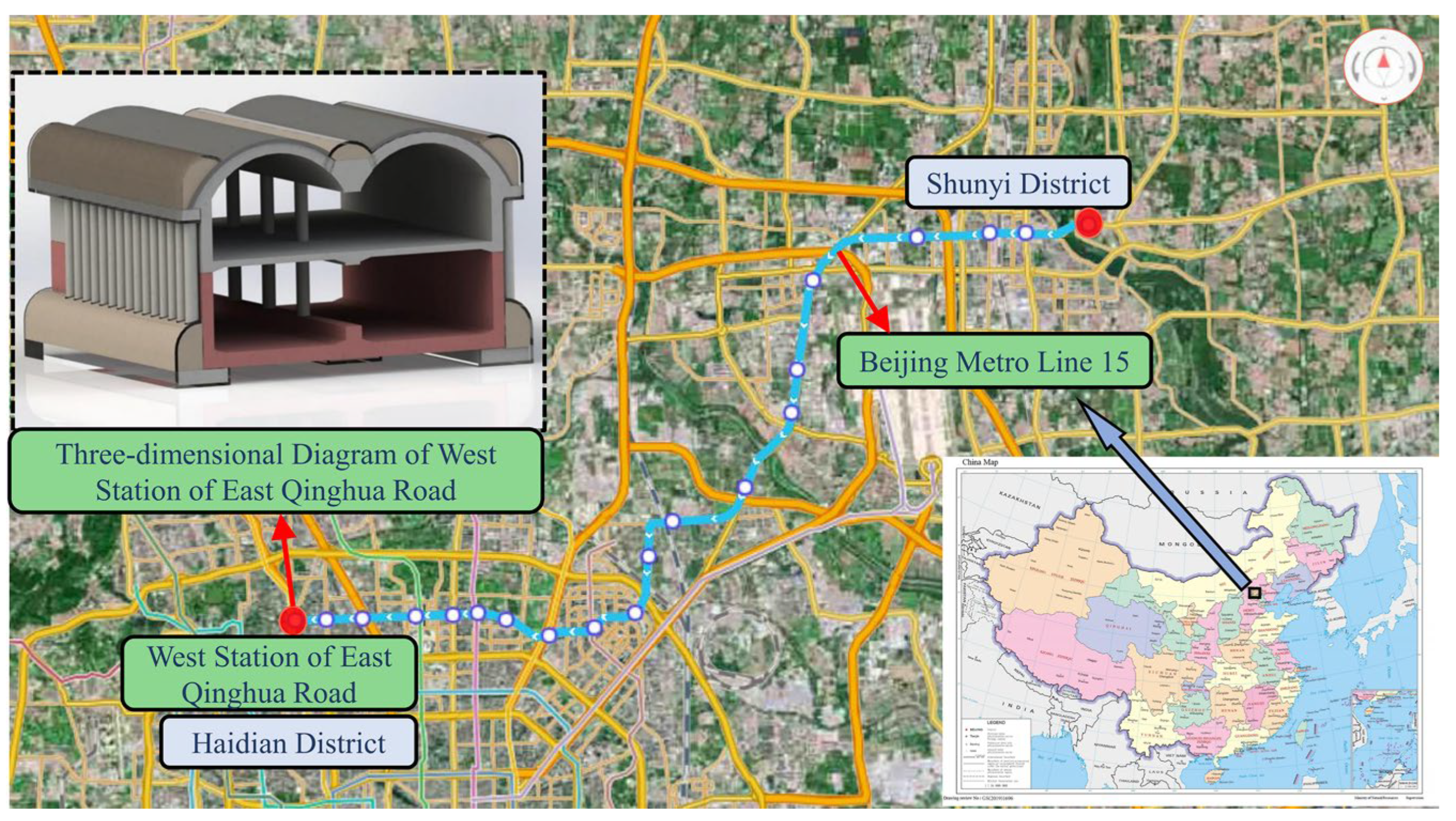

2. Project Overview

2.1. Overview of Station Structure

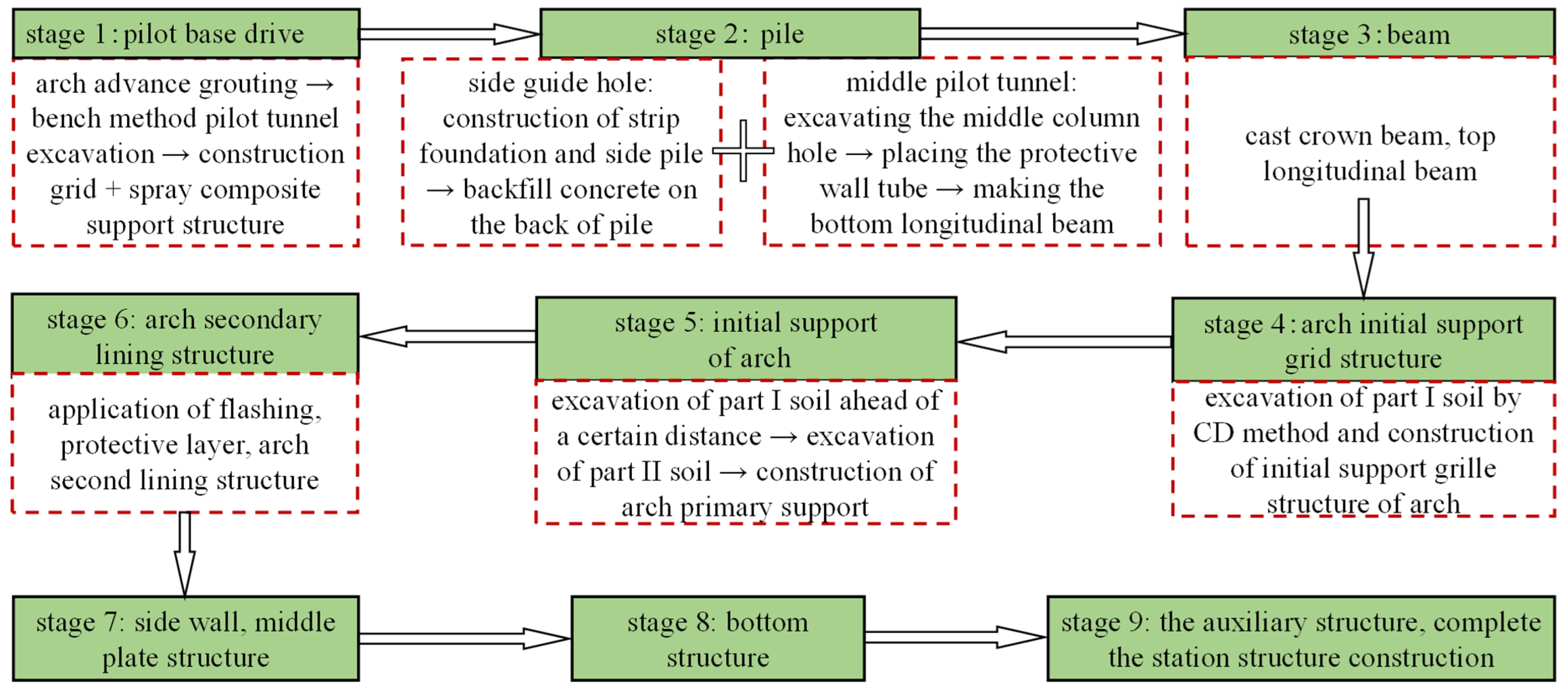

2.2. Station Construction Procedure

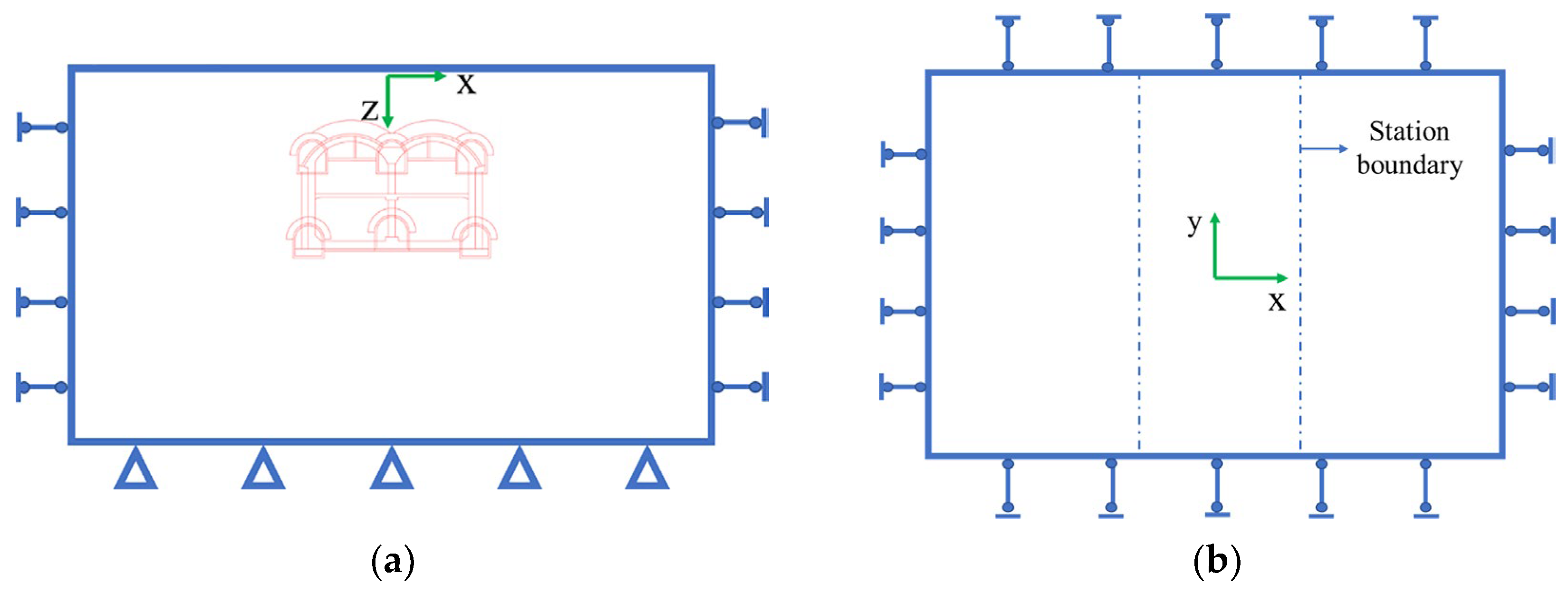

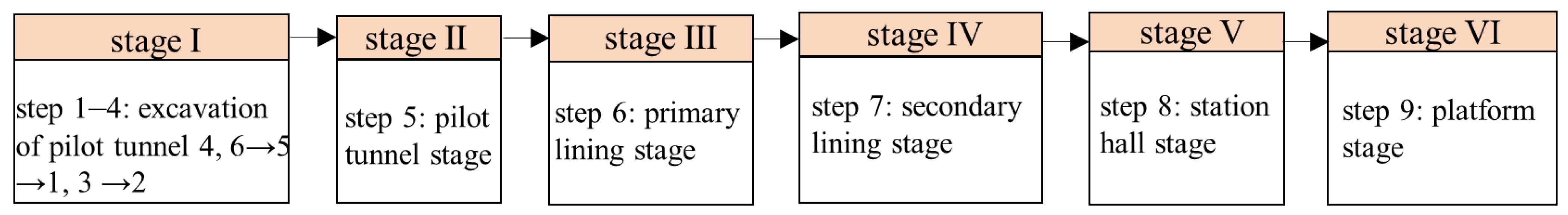

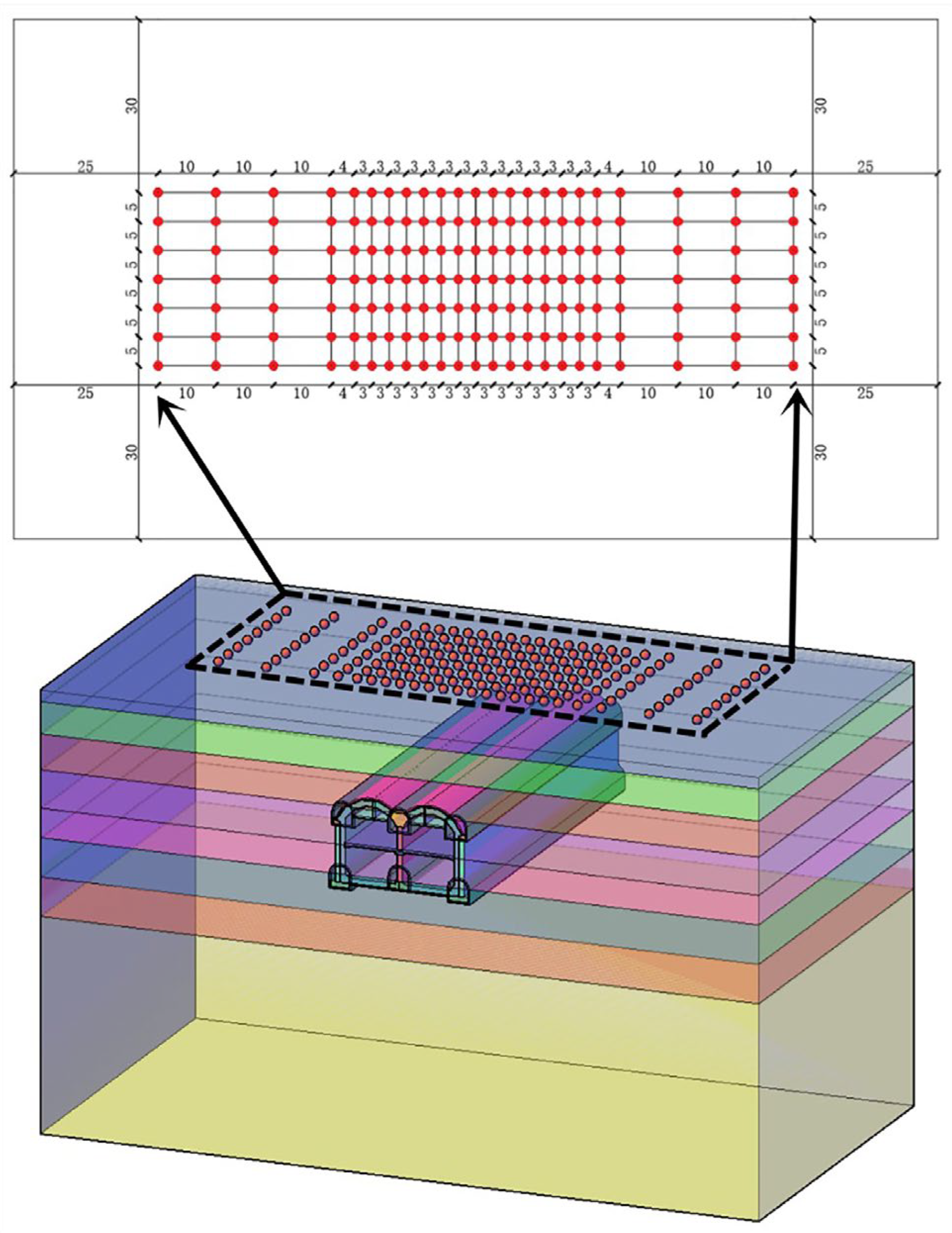

3. Construction of Numerical Model

- The numerical model assumes that the soil is homogeneous and isotropic, and the same stratum in the soil is uniform, of equal thickness, and horizontal.

- In this study, the load mainly includes the soil, structure weight and ground based on the addition of overload of 20 kPa.

- In the pre-grouting consolidation simulation, the material parameters of the surrounding soil around the tunnel face were improved to simulate its effect equivalently. First, the pre-grouting part of the pilot tunnel was equivalent to the fan-shaped reinforcement with a thickness of 1 m combined with the actual construction situation. Second, the deep-hole grouting part of the arch is equivalent to the fan-shaped reinforcement of the 2-m thickness in consideration of the actual construction situation.

- Grid mechanics simulation: As this is a steel, grid-shotcrete, composite supporting structure, its mechanical properties are relatively complex. Typically, it is usually simplified by the equivalent stiffness method in simulations,where is the elastic modulus of the entire structure; is the elastic modulus of the concrete; is the elastic modulus of steel; and is the area of the concrete per unit area.

- Supporting structure simulations of the CD method: The joint steel is used for support, and the horizontal interval is the excavation spacing. The force is mainly based on the vertical load and transversal flexure, so it can serve as an equivalent wall based on the principle of equal flexural rigidity,where is the elastic modulus of steel; is the moment of inertia of steel; is the elastic modulus of the equivalent diaphragmatic wall; is the moment of inertia of the equivalent diaphragmatic wall; is the I-beam erection span; and is the thickness of the equivalent diaphragmatic wall.

- In the numerical simulation of this study, the Mohr-Coulomb model was selected as the constitutive model of the soil, and each soil layer was considered as an ideal elastoplastic body. The lining, beam and plate all adopted the elastic model. In addition, the mechanical characteristics of the side piles were simulated by the pile element. The interior column was mainly subjected to vertical loads, and there was no coupling effect with the surrounding soil after construction. However, the two ends of the column have similar constraints to those of the beam element. Thus, the beam element is used to simulate the interior column.

4. Results

4.1. Analysis of the Surface Displacement in the Entire Construction

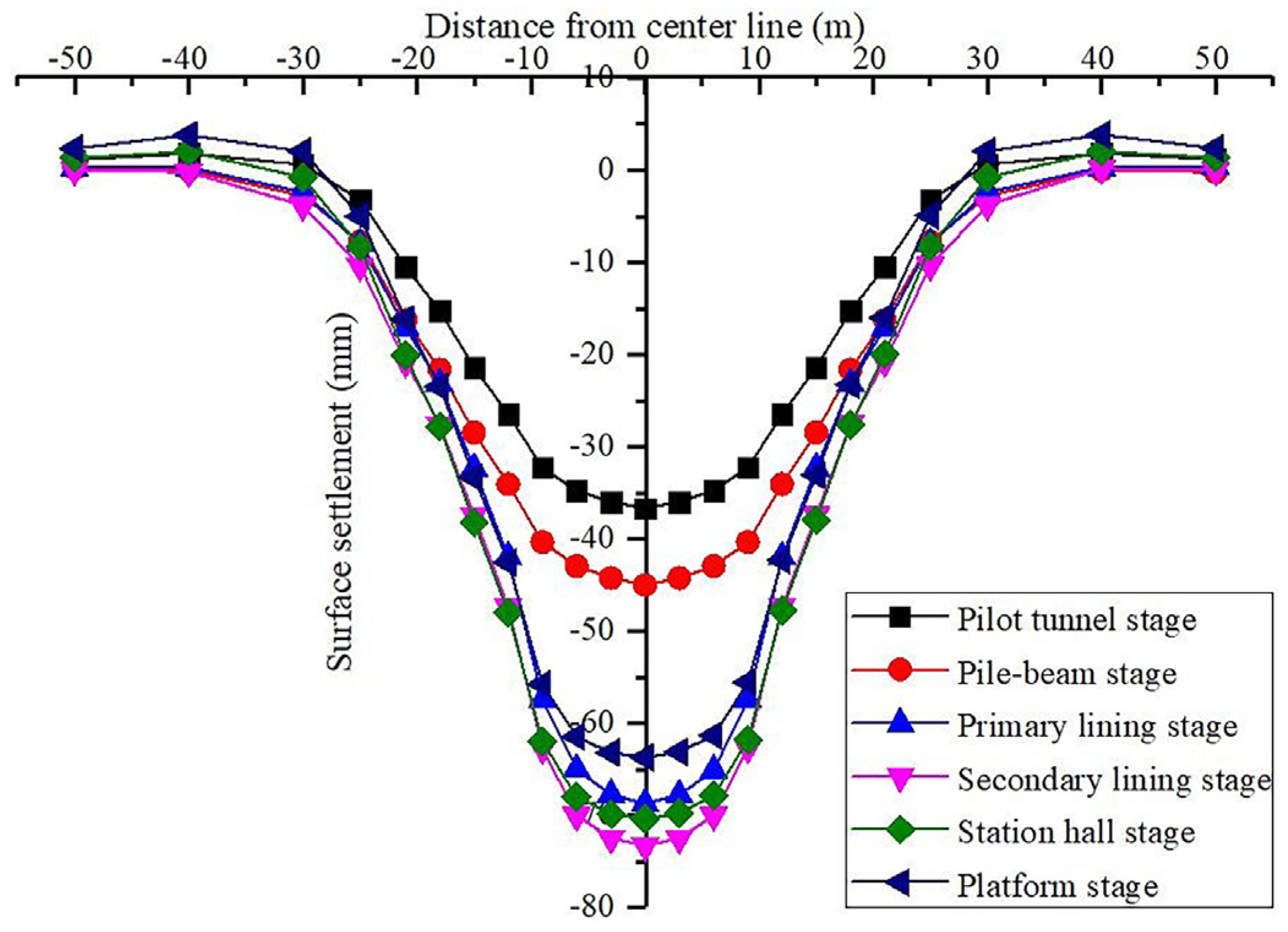

4.1.1. Vertical Displacement Analysis of Ground Surface

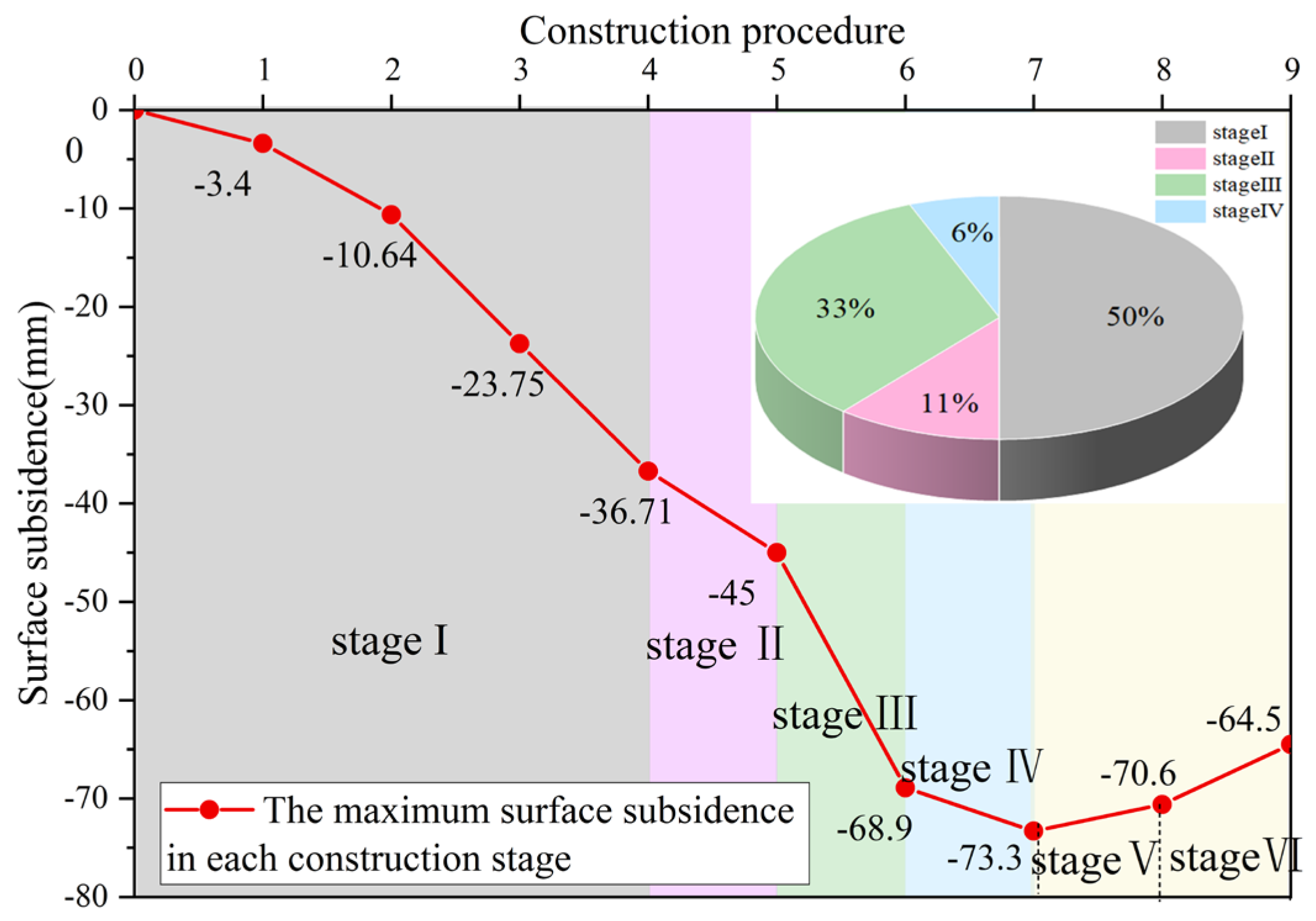

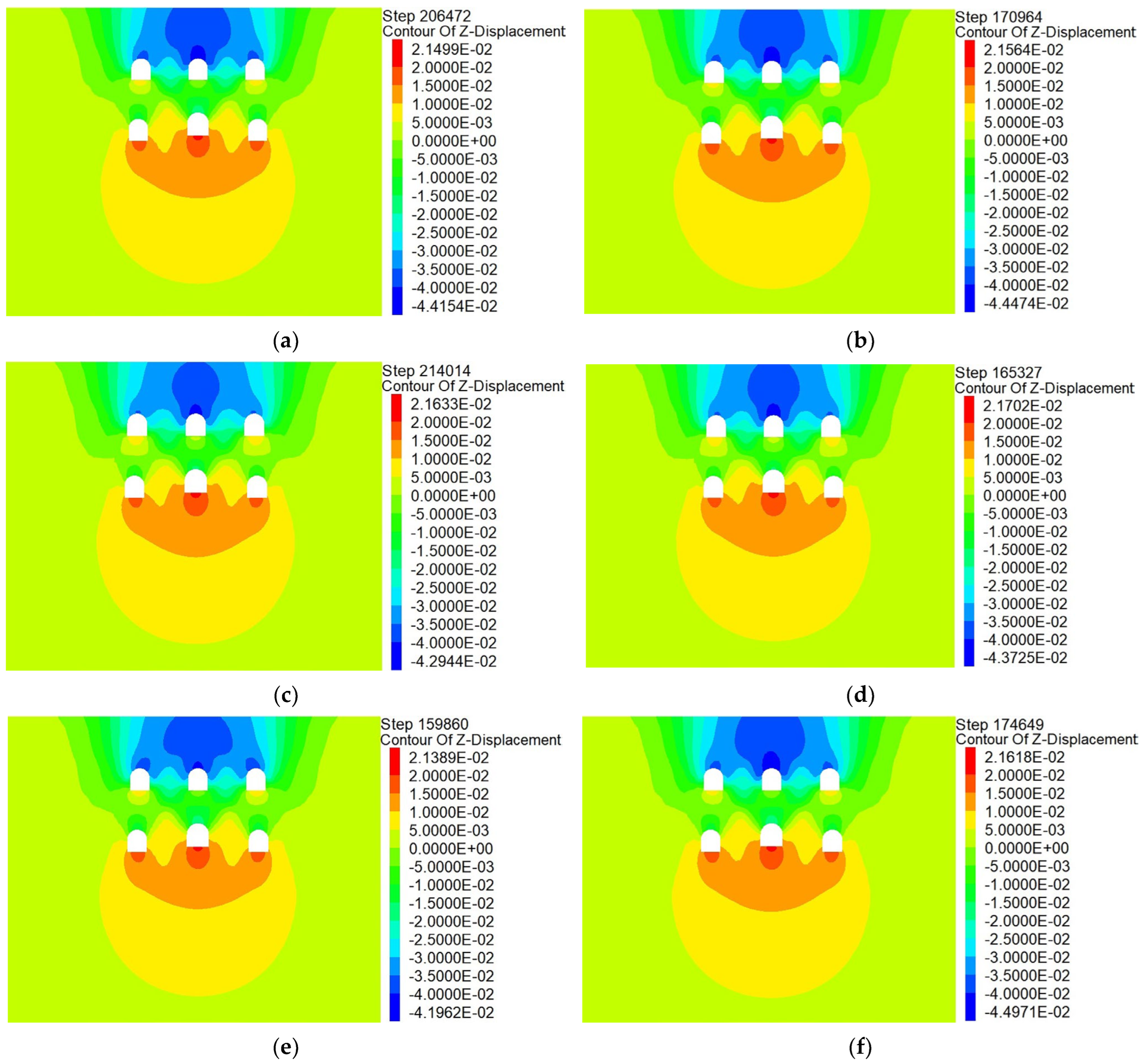

- When the pilot tunnel is excavated for 4, 6→5→1, 3→2, the maximum ground settlement is 3.4 mm, 10.64 mm, 23.75 mm and 36.71 mm, respectively. It indicates that the excavation of the upper pilot tunnel has more obvious influence on the surface settlement than that of the lower pilot tunnel.

- In the excavation stage of the pilot tunnel on both sides, the maximum point of the entire ground settlement is not on the medial axis of the station, which is a unique feature of large-span PBA construction. However, single-groove settlement usually occurs in the construction of the PBA with the conventional span. The main reason for this difference is that the pilot tunnel spacing of the same layer in the large-span PBA method is larger than that in other cases, and the multicavern effect between pilot tunnels is weaker than that for the small pilot tunnel with clear spacing.

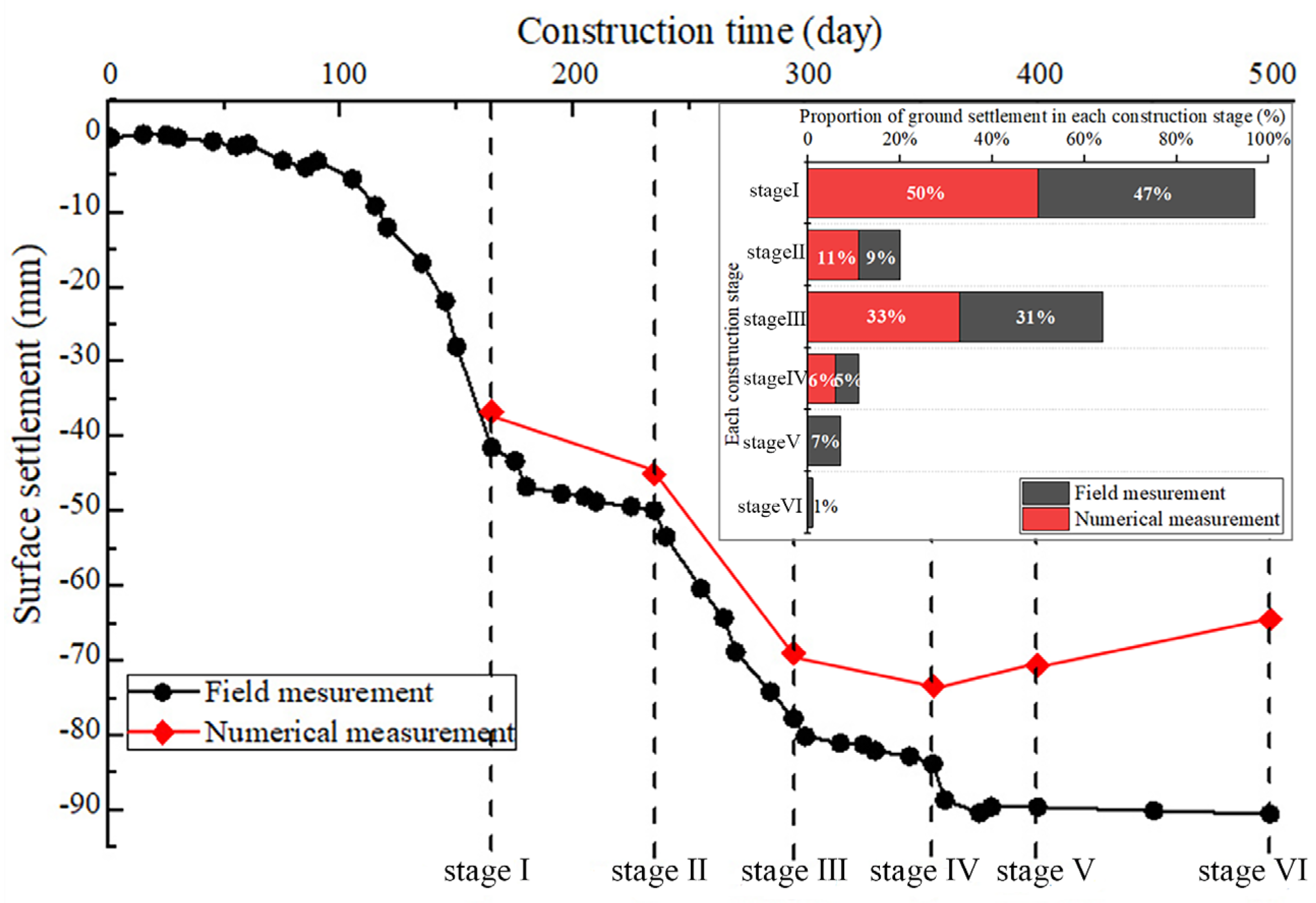

- During the entire building period of the station, the maximum value of surface settlement always appears at the middle line of the station structure. The settlement in the range of 30 m around the central line of the station has obvious changes with different construction stages. The surface deformation outside 30 m does not change significantly with different construction stages. The overall variation trend of the settlement trough curve is generally consistent with the Peck formula.

- During the entire construction period, the ground settlement in the first four construction stages exhibits an increasing trend, and the range of the settlement groove exhibits a widening trend. In the last two construction stages, the ground settlement depicts a decreasing trend, and the range of the settlement groove also appears to be narrowing. This shows that in the large-span pile-beam-arch method’s construction process, the process prior to the arch secondary lining is the primary stage that contributes to surface deformation due to settlement, and the platform layer and station hall layer construction are the primary stages that contribute to surface uplift.

- With the exception of the uplift stage, the ground settlement brought on by the building of the pilot tunnel makes up 50% of the total station settlement, while the ground settlement brought on by the construction of the pile-beam supporting system makes up 11% of the total. The ground settlement generated by the second lining of the arch construction accounts for 6% of the overall settlement, while the ground settlement induced by the initial arch supporting construction accounts for 33% of the total station settlement. The findings indicate that the settlement ratio of the excavation of the pilot tunnel: pile-beam construction: arch initial support: arch secondary lining is about 5:1.1:3.3:0.6. Settlement deformation mainly occurs in the pilot tunnel excavation stage. Therefore, the actual construction should focus on the prevention and control of the ground subsidence pilot tunnel excavation stage.

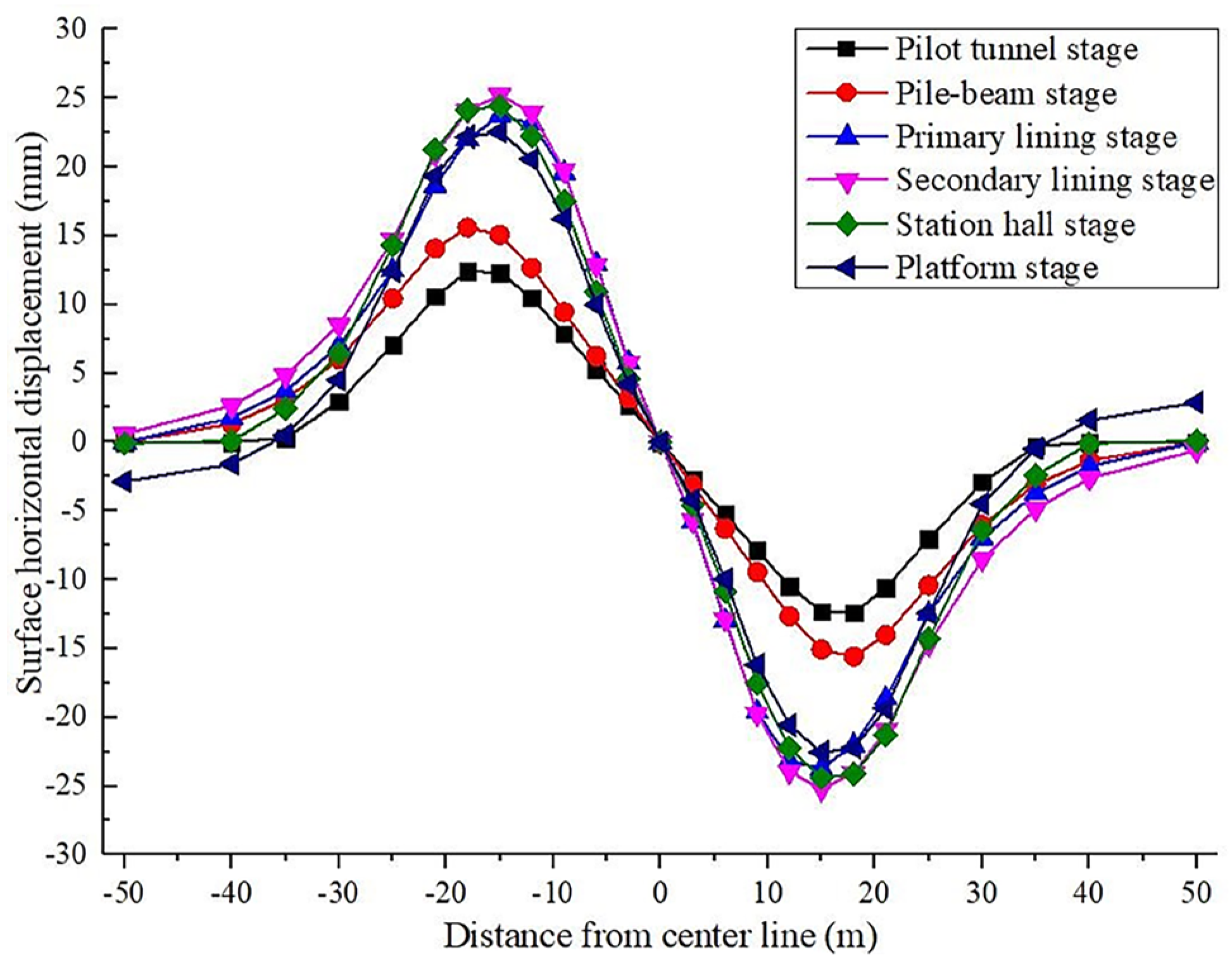

4.1.2. Horizontal Displacement Analysis of Ground Surface

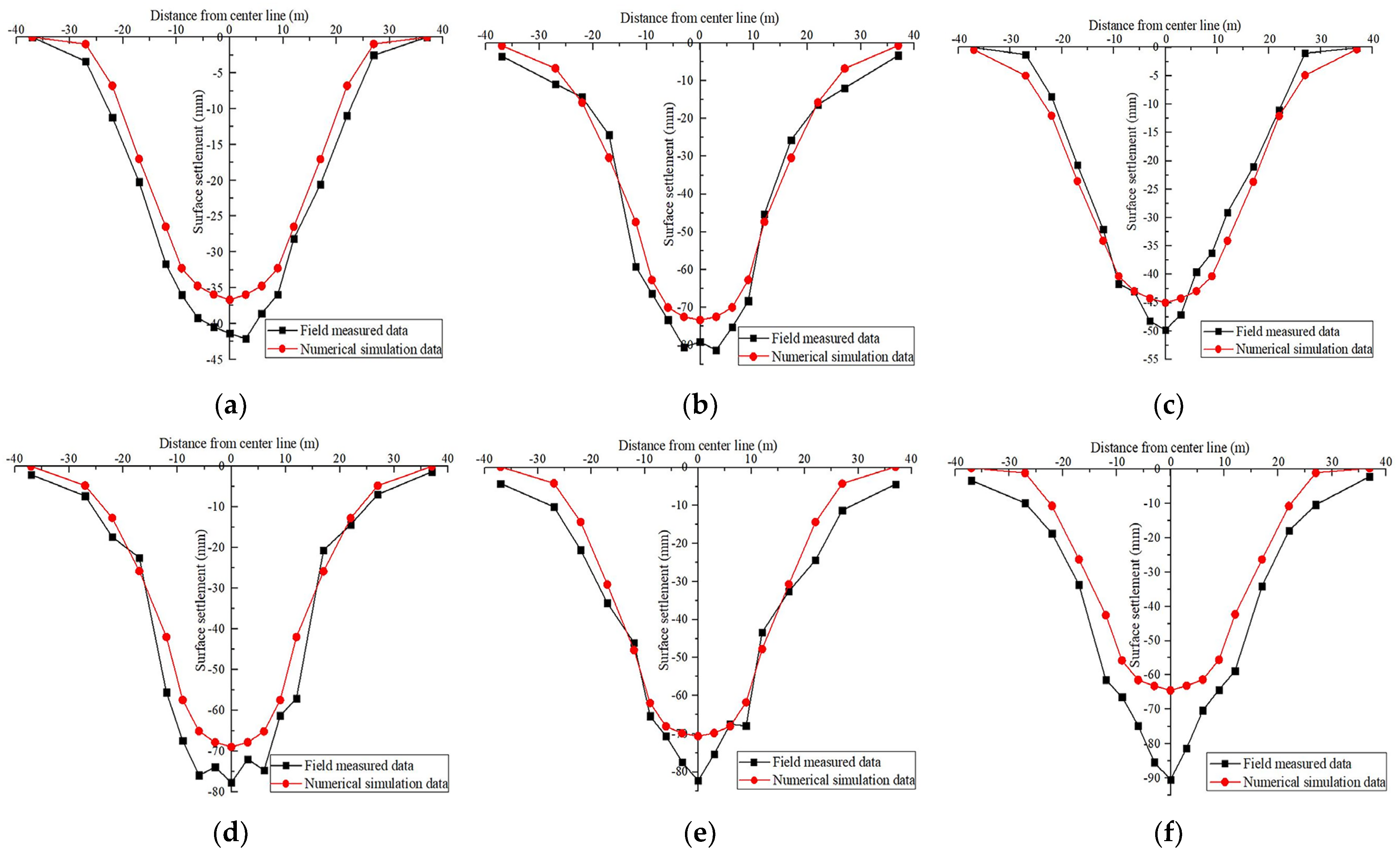

4.2. Comparison of Field Measurements and Simulation Results

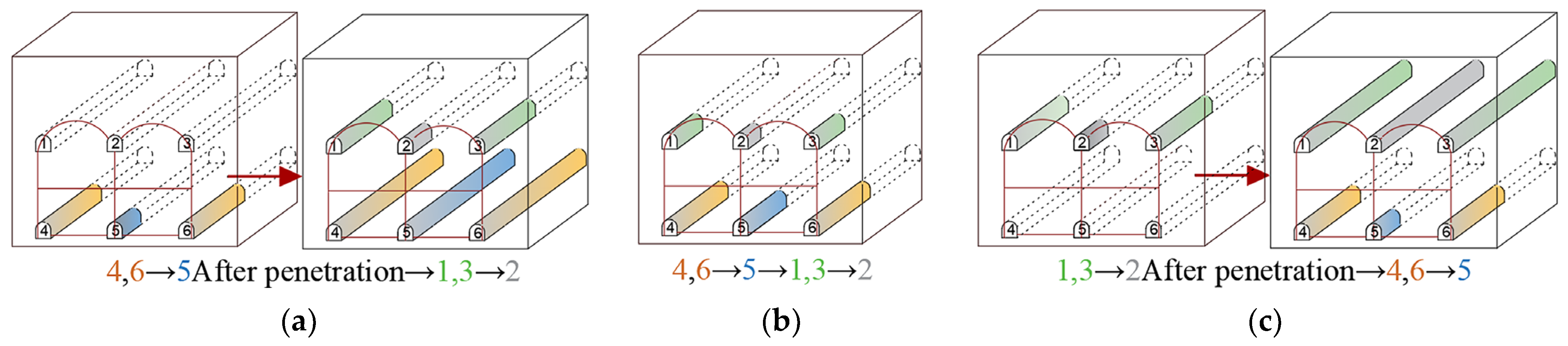

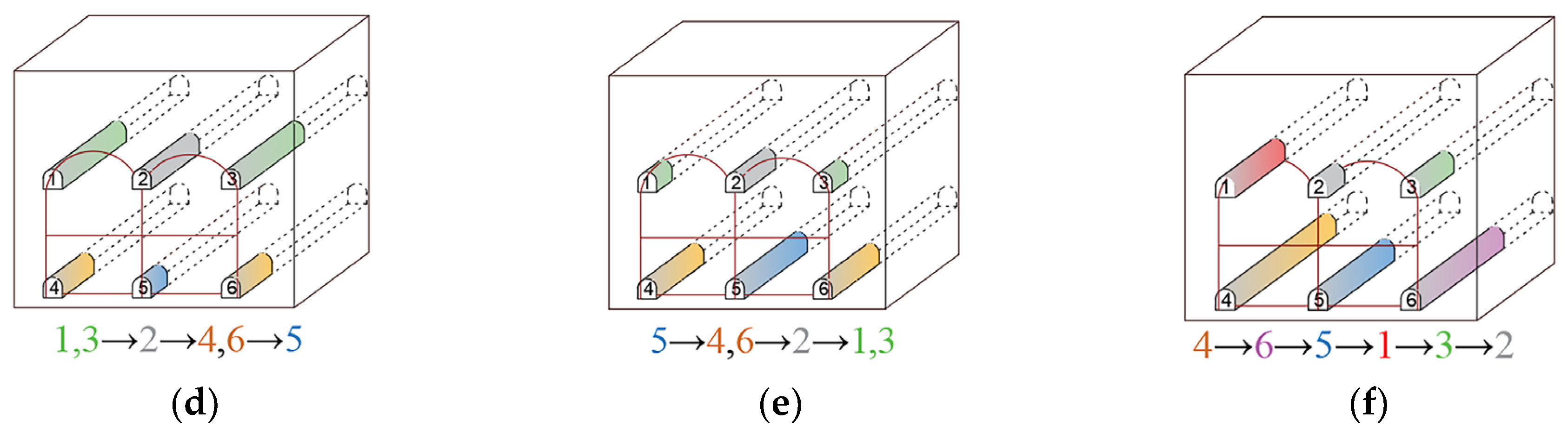

4.3. Comparative Study on Different Excavation Schemes of Pilot Tunnels

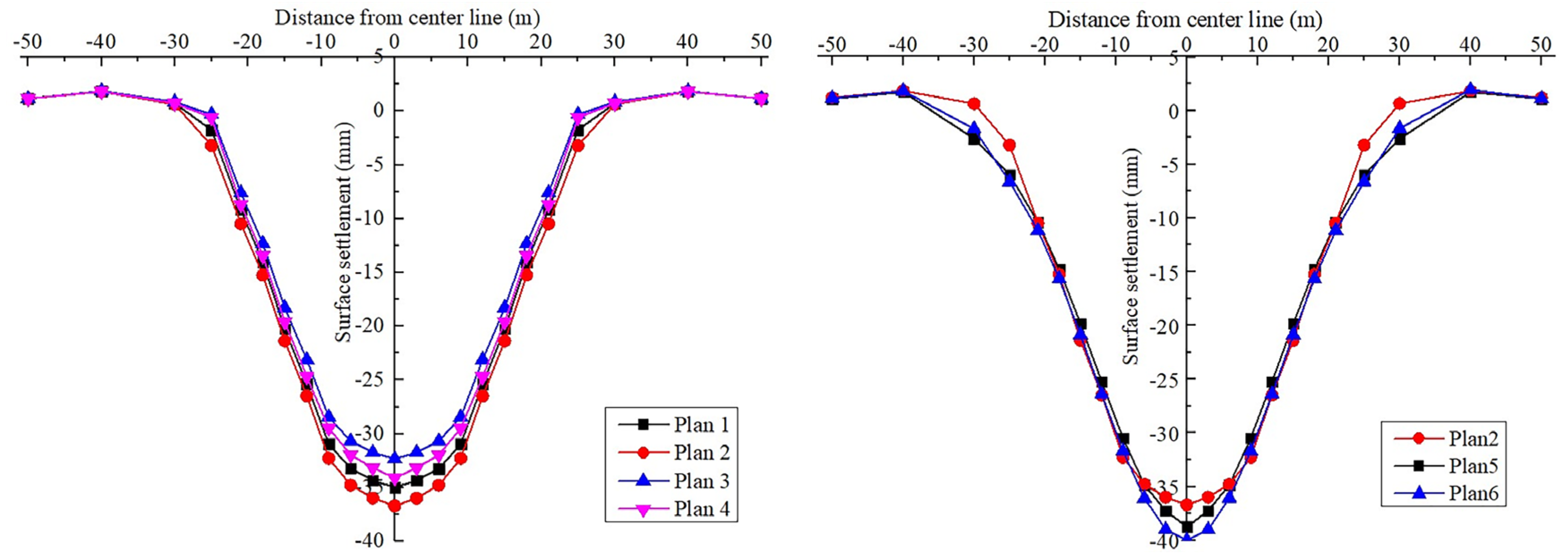

- It is better to control the development of surface settlement after the construction of one layer of pilot tunnel first and then another layer of pilot tunnel than the staggered construction plan of two layers of pilot tunnels at the same time, and the plan of penetrating the upper layer of pilot tunnel first is better than the plan of penetrating the lower layer of pilot tunnel first in construction.

- For the excavation sequence of the same layer pilot tunnel, the symmetrical excavation method of first middle and then side is better than the symmetrical excavation method of first side and then middle. The method of staggered excavation of single pilot tunnel has the worst effect on controlling ground settlement deformation and will cause uneven settlement on both sides of the station.

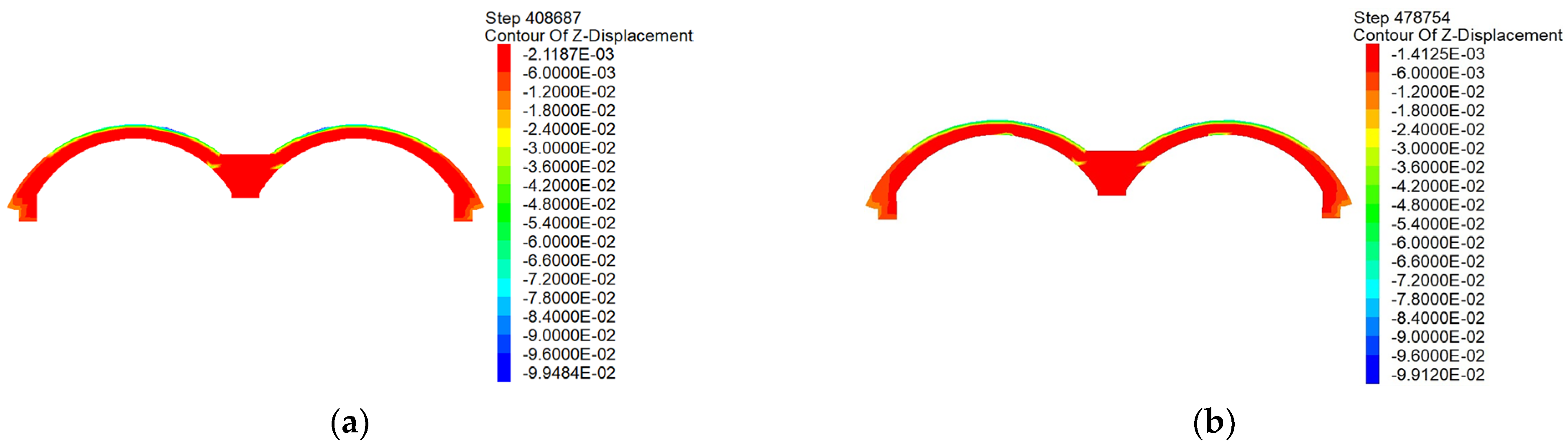

4.4. Comparative Study on Different Construction Schemes of the Second Arch Lining

4.4.1. Analysis of the Difference of the Influences on Surface Displacement

4.4.2. Analysis of Structural Stability Differences

5. Conclusions

- During the excavation of the pilot tunnel of the station, the development of the settlement groove yields the obvious multicavern effect, and dual and single grooves appear alternately after different pilot tunnel excavations. Compared with the lower pilot tunnel excavation, the effects of upper pilot tunnel excavation on ground settlement and surface deformation are more apparent, and the development of settlement groove is more severe.

- It is obvious that the development of ground settlement groove progresses in stages during the construction of the large-span PBA method. Through the numerical simulation, it is concluded that the settlement ratio of pilot tunnel excavation: pile-beam construction: arch initial support: arch secondary lining is about 5:1.1:3.3:0.6. Settlement deformation mainly occurs in pilot tunnel excavation stage. Therefore, the actual construction should focus on the prevention and control of ground subsidence during the excavation stage of the pilot tunnel.

- The comparison of the field monitoring findings and the numerical simulation results reveal that the two are extremely compatible, confirming the accuracy of the numerical simulation results.

- By comparing and analyzing six groups of pilot tunnel excavation schemes, the optimal pilot tunnel excavation scheme of large span PBA method is established, which excavates the middle first and then excavates both sides, and first through the upper layer and then through the lower layer.

- The second lining of the arch completed in a single attempt was better than that completed in two attempts in the case of the large-span PBA method. Although the effects of the two schemes on the ground deformation are almost similar, in terms of the stability of the arch structure, the scheme completed in two attempts will lead to an uneven distribution of stress. In addition, greater ground deformation is caused by the removal of the central partition wall and will result in the construction of arch joints in the case in which construction was completed in two attempts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.H.; Xu, X.M.; Hong, L.; Wang, S.L.; Fei, Q. Networked analysis of the Shanghai subway network, in China. Phys. A Stat. Mech. Its Appl. 2011, 390, 4562–4570. [Google Scholar] [CrossRef]

- Peng, Y.-T.; Li, Z.-C.; Schonfeld, P. Development of rail transit network over multiple time periods. Transp. Res. Part A Policy Pract. 2019, 121, 235–250. [Google Scholar] [CrossRef]

- Choi, J.-Y.; Kim, S.-H.; Lee, H.-H.; Chung, J.-S. Improvement of automatic measurement evaluation system for subway structures by adjacent excavation. Materials 2021, 14, 7492. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Pham, K.; Park, S.; Oh, J.Y.; Choi, H. Determination of effective parameters on surface settlement during shield TBM. Geomech. Eng. 2020, 21, 153–164. [Google Scholar]

- Liu, T.; Wang, H.T.; Su, X.T.; Li, K.X.; Liu, S.Q.; Guo, F.S. Instability mechanism of cavity-bearing formation under tunnel excavation disturbance. Adv. Civ. Eng. 2020, 2020, 9038421. [Google Scholar] [CrossRef]

- Ding, Z.; Wei, X.-J.; Wei, G. Prediction methods on tunnel-excavation induced surface settlement around adjacent building. Geomech. Eng. 2017, 12, 185–195. [Google Scholar] [CrossRef]

- Xiang, Y.Y.; He, S.H.; Cui, Z.J.; Ma, S.Z. A subsurface “drift and pile” protection scheme for the construction of a shallow metro tunnel. Tunn. Undergr. Space Technol. 2005, 20, 1–5. [Google Scholar] [CrossRef]

- Wu, D.; Deng, T.F.; Zhao, R.K.; Wang, Y.H. THM modeling of ground subsidence induced by excavation of subway tunnel. Comput. Geotech. 2018, 94, 1–11. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Kolivand, F.; Ghorbani, M.; Yasrobi, S. Design of sequential excavation method for large span urban tunnels in soft ground—Niayesh tunnel. Tunn. Undergr. Space Technol. 2013, 35, 178–188. [Google Scholar] [CrossRef]

- Sharifi, A.; Hosseingholizadeh, M. The effect of rapid population growth on urban expansion and destruction of green space in Tehran from 1972 to 2017. J. Indian Soc. Remote Sens. 2019, 47, 1063–1071. [Google Scholar] [CrossRef]

- Sharifi, A.; Mahdipour, H.; Moradi, E.; Tariq, A. Agricultural field extraction with deep learning algorithm and satellite imagery. J. Indian Soc. Remote Sens. 2022, 50, 417–423. [Google Scholar] [CrossRef]

- Zhang, G.H.; Chen, H.Y.; Deng, K.; Tong, J.J.; Ma, X.Y. Comparison of Chongqing metro Station construction method in super-large section tunnel of the stratigraphic strata. Urban Mass Teansit 2019, 22, 137–141, 173. (In Chinese) [Google Scholar]

- Yu, L.; Zhang, D.L.; Fang, Q.; Cao, L.Q.; Xu, T.; Li, Q.Q. Surface settlement of subway station construction using Pile-Beam-Arch approach. Tunn. Undergr. Space Technol. 2019, 90, 340–356. [Google Scholar] [CrossRef]

- Xu, Y.S.; Tang, B.; Duan, Y.W. Research on surface settlement of subway station construction using Pile-Beam-Arch approach. IOP Conf. Series Earth Environ. Sci. 2020, 455, 012167. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Z.Y.; Luo, M.C.; Liu, B.; Wang, Y.L.; Li, L.F. Analytical solution of loosening pressure model for shallow tunnel based on pile-beam-arch method. KSCE J. Civ. Eng. 2022, 26, 3648–3662. [Google Scholar] [CrossRef]

- Liu, W.; Luo, F.; Mei, J. A new construction method for a metro station in Beijing. Tunn. Undergr. Space Technol. 2000, 15, 409–413. [Google Scholar] [CrossRef]

- Huang, B.; Du, Y.H.; Zeng, Y.; Cao, B.; Zou, Y.; Yu, Q. Study on stress field distribution during the construction of a group of tunnels using the pile-beam-arch method. Buildings 2022, 12, 300. [Google Scholar] [CrossRef]

- Li, T.; Wang, L.Y.; Wang, Y.; Liu, S.; Li, Y.Y.; Li, B.R. Influence of step lengths of pilot tunnel excavation on surface subsidence based on PBA method. J. Jinan Univ. Sci. Technol. 2017, 31, 250–255. (In Chinese) [Google Scholar]

- Guan, Y.-P.; Zhao, W.; Li, S.-G.; Zhang, G.-B. Key techniques and risk management for the application of the pile-beam-arch (PBA) excavation method: A case study of the Zhongjie subway station. Sci. World J. 2014, 2014, 275362. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.R.; Liu, Y.Q.; Qu, W.B.; Tu, Y.L. Internal force calculation and supporting parameters sensitivity analysis of side piles in the subway station excavated by Pile-Beam-Arch method. Tunn. Undergr. Space Technol. 2016, 56, 186–201. [Google Scholar] [CrossRef]

- Zhang, M.J.; Liu, Y.; Fan, L.F.; Li, P.F. Performance of constructing a double-deck subway station by combining the shield method and cavern-pile method. Tunn. Undergr. Space Technol. 2017, 67, 120–131. [Google Scholar] [CrossRef]

- Liu, X.R.; Liu, Y.Q.; Yang, Z.P.; He, C.M. Numerical analysis on the mechanical performance of supporting structures and ground settlement characteristics in construction process of subway station built by Pile-Beam-Arch method. KSCE J. Civ. Eng. 2017, 21, 1690–1705. [Google Scholar] [CrossRef]

- Guo, X.Y.; Wang, Z.Z.; Geng, P.; Chen, C.J.; Zhang, J. Ground surface settlement response to subway station construction activities using Pile-Beam-Arch method. Tunn. Undergr. Space Technol. 2021, 108, 103729. [Google Scholar] [CrossRef]

- Liu, J.; Wang, F.; He, S.H.; Wang, E.; Zhou, H. Enlarging a large-diameter shield tunnel using the Pile-Beam-Arch method to create a metro station. Tunn. Undergr. Space Technol. 2015, 49, 130–143. [Google Scholar] [CrossRef]

- Jia, P.-J.; Zhao, W.; Chen, Y.; Li, S.-G.; Han, J.-Y.; Dong, J.-C. A case study on the application of the steel tube slab structure in construction of a subway station. Appl. Sci. 2018, 8, 1437. [Google Scholar] [CrossRef] [Green Version]

- Su, J.; Fang, Q.; Zhang, D.L.; Niu, X.K.; Liu, X.; Jie, Y.M. Bridge responses induced by adjacent subway station construction using shallow tunneling method. Adv. Civ. Eng. 2018, 2018, 8918749. [Google Scholar] [CrossRef] [Green Version]

- Jiang, B.F.; Jia, P.J.; Zhao, W.; Wang, W.T. The application of compressive sampling in rapid ultrasonic computerized tomography (UCT) technique of steel tube slab (STS). PLoS ONE 2018, 13, e0190281. [Google Scholar] [CrossRef] [Green Version]

- Pan, X.M.; Lei, C.H. Comprehensive Engineering Technology for Sand and Pebble Conglomerate Strata of Beijing Metro; China Communications Press: Beijing, China, 2012; pp. 22–31. [Google Scholar]

| Soil | Thickness (mm) | Density ρ (kg/m3) | Bulk Modulus K (MPa) | Shear Modulus G (MPa) | Cohesion C (kPa) | Internal Friction Angle φ (°) |

|---|---|---|---|---|---|---|

| Filling | 2300 | 1750 | 10.3 | 3.9 | 10 | 10 |

| Silty clay | 6540 | 1970 | 14.5 | 6.3 | 19 | 17 |

| Silty clay | 7270 | 1960 | 25.0 | 10.2 | 22 | 16 |

| Silty clay | 7800 | 1980 | 31.6 | 13.7 | 26 | 18 |

| Pebbles | 6000 | 2020 | 27.8 | 18.3 | 10 | 40 |

| Silt | 8000 | 1980 | 25.0 | 11.5 | 25 | 22 |

| Pebbles | 11,800 | 2050 | 29.8 | 20.5 | 10 | 40 |

| Pebbles | 30,290 | 2080 | 30.0 | 20.6 | 10 | 45 |

| Terrain | Impact of Unfavorable Geology | Climate | Climatic Characteristics | Weather Disaster |

|---|---|---|---|---|

| Plain card country | The partially saturated sand and silt layers at the top of the station are prone to quicksand and quicksand. | Temperate monsoon | Summer is hot and rainy; winter is cold and dry. | Precipitation, low temperature |

| Structural Material Type | Structure | Elastic Modulus E (MPa) | Poisson’s Ratio ν | Density (kg/m3) |

|---|---|---|---|---|

| Pregrouting | Grouting reinforcement ring | 15,000 | 0.28 | 2300 |

| C20 concrete | Concrete backfill | 25,500 | 0.20 | 2400 |

| C20 grid steel frame Reinforced concrete | Pilot tunnel support | 26,000 | 0.20 | 2500 |

| Primary lining | ||||

| I-beam (equivalent to the wall) | Middle wall steel support | 6000 (equivalent to the wall) | 0.29 | 7900 |

| C30 concrete | Crown beam | 30,000 | 0.20 | 2500 |

| Strip foundation | ||||

| Side pile | ||||

| C40 concrete | Top stringer | 32,500 | 0.20 | 2500 |

| Bottom stringer | ||||

| Secondary lining | ||||

| Middle floor slab | ||||

| Station floor slab | ||||

| Steel pipe pile and C50 concrete | Center column | 59,000 | 0.20 | 3200 |

| Plan Number | Detailed Construction Plan | Influencing Factor |

|---|---|---|

| Plan 1 | (4, 6→5) after penetration→(1, 3→2) after penetration | Whether the pilot tunnel of each layer is through construction respectively: (1) plan 1 contrast plan 2; (2) plan 3 contrast plan 4 Horizontal excavation sequence: plan 2 contrast plan 5 contrast plan 6 Vertical excavation sequence: plan 2 contrast plan 4 |

| Plan 2 | 4, 6→5→1, 3→2 | |

| Plan 3 | (1, 3→2) after penetration→(4, 6→5) after penetration | |

| Plan 4 | 1, 3→2→4, 6→5 | |

| Plan 5 | 5→4, 6→2→1, 3 | |

| Plan 6 | 4→6→5→1→3→2 |

| Plan Number | Maximum Surface Settlement Smax (mm) | Backbend Distance i (m) | Fitting Correlation Coefficient R2 | Formation Loss Rate V1 (%) |

|---|---|---|---|---|

| Plan 1 | −37.221 | 12.655 | 0.9802 | 0.00906 |

| Plan 2 | −38.735 | 12.926 | 0.9840 | 0.00963 |

| Plan 3 | −34.536 | 12.304 | 0.9764 | 0.00817 |

| Plan 4 | −36.021 | 12.524 | 0.9769 | 0.00869 |

| Plan 5 | −37.962 | 12.905 | 0.9796 | 0.00942 |

| Plan 6 | −39.979 | 13.125 | 0.9838 | 0.01009 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Li, Y.; Yang, T.; Hou, R.; Gao, Y.; Liu, B.; Qiao, G. Influence of the Large-Span Pile-Beam-Arch Construction Method on the Surface Deformation of a Metro Station in the Silty Clay–Pebble Composite Stratum. Materials 2023, 16, 2934. https://doi.org/10.3390/ma16072934

Li T, Li Y, Yang T, Hou R, Gao Y, Liu B, Qiao G. Influence of the Large-Span Pile-Beam-Arch Construction Method on the Surface Deformation of a Metro Station in the Silty Clay–Pebble Composite Stratum. Materials. 2023; 16(7):2934. https://doi.org/10.3390/ma16072934

Chicago/Turabian StyleLi, Tao, Yue Li, Tengyu Yang, Rui Hou, Yuan Gao, Bo Liu, and Guogang Qiao. 2023. "Influence of the Large-Span Pile-Beam-Arch Construction Method on the Surface Deformation of a Metro Station in the Silty Clay–Pebble Composite Stratum" Materials 16, no. 7: 2934. https://doi.org/10.3390/ma16072934

APA StyleLi, T., Li, Y., Yang, T., Hou, R., Gao, Y., Liu, B., & Qiao, G. (2023). Influence of the Large-Span Pile-Beam-Arch Construction Method on the Surface Deformation of a Metro Station in the Silty Clay–Pebble Composite Stratum. Materials, 16(7), 2934. https://doi.org/10.3390/ma16072934

_Varveri.png)