Specimen Size Effect on the Tensile Properties of Rolled Steel of Long-Term-Operated Portal Crane

Abstract

:1. Introduction

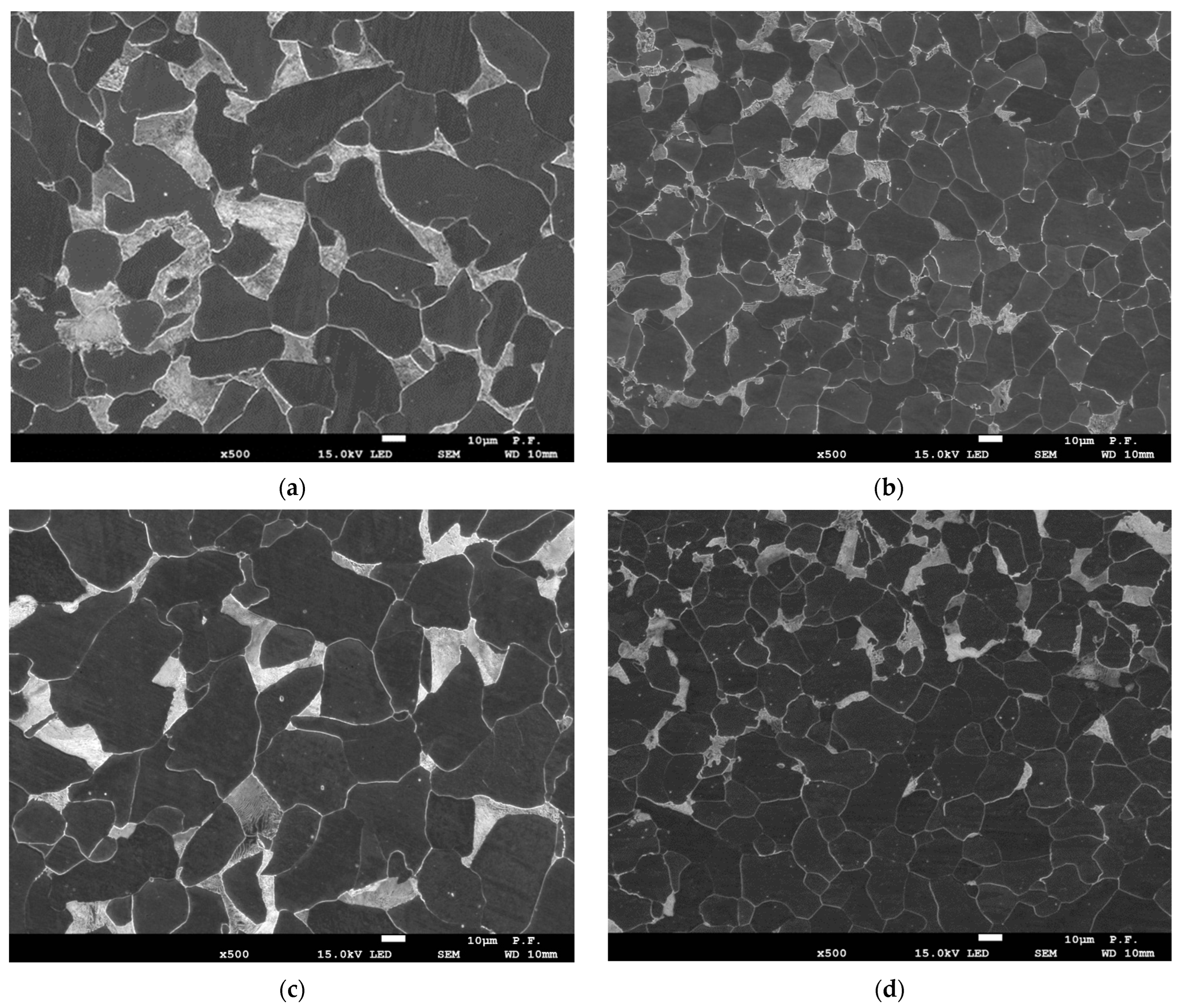

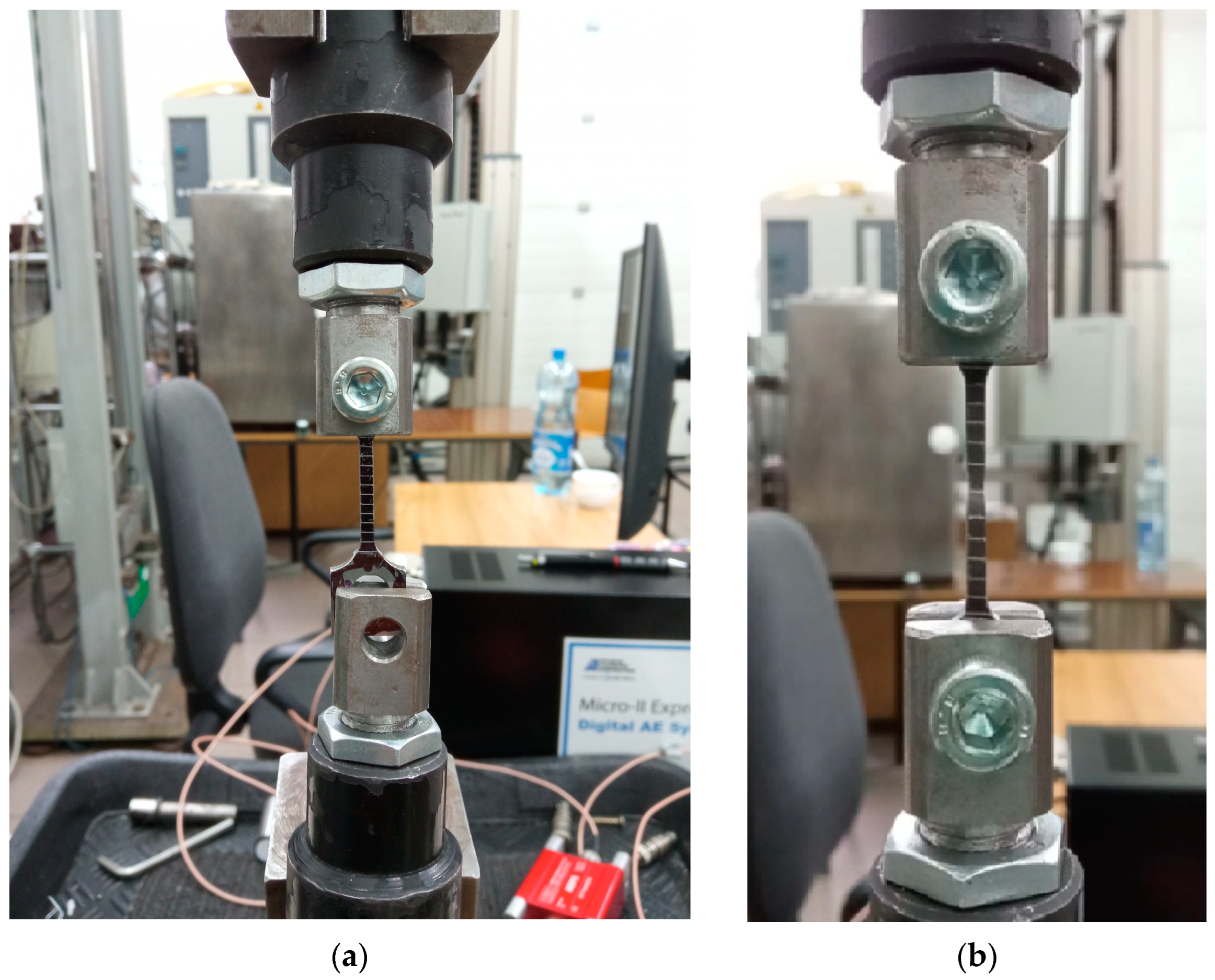

2. Materials and Testing Methods

3. Experimental Results and Discussion

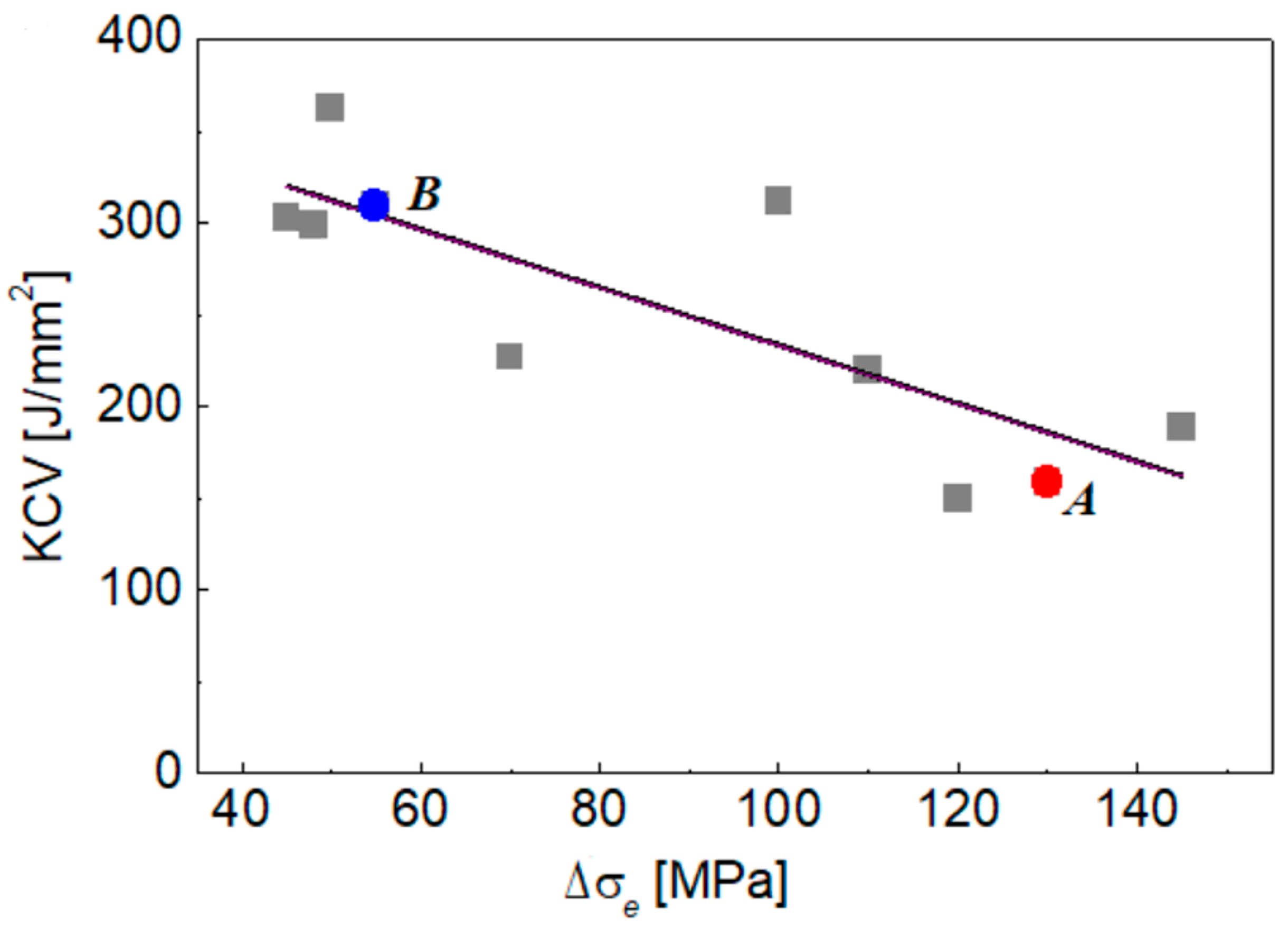

3.1. Impact Toughness Testing

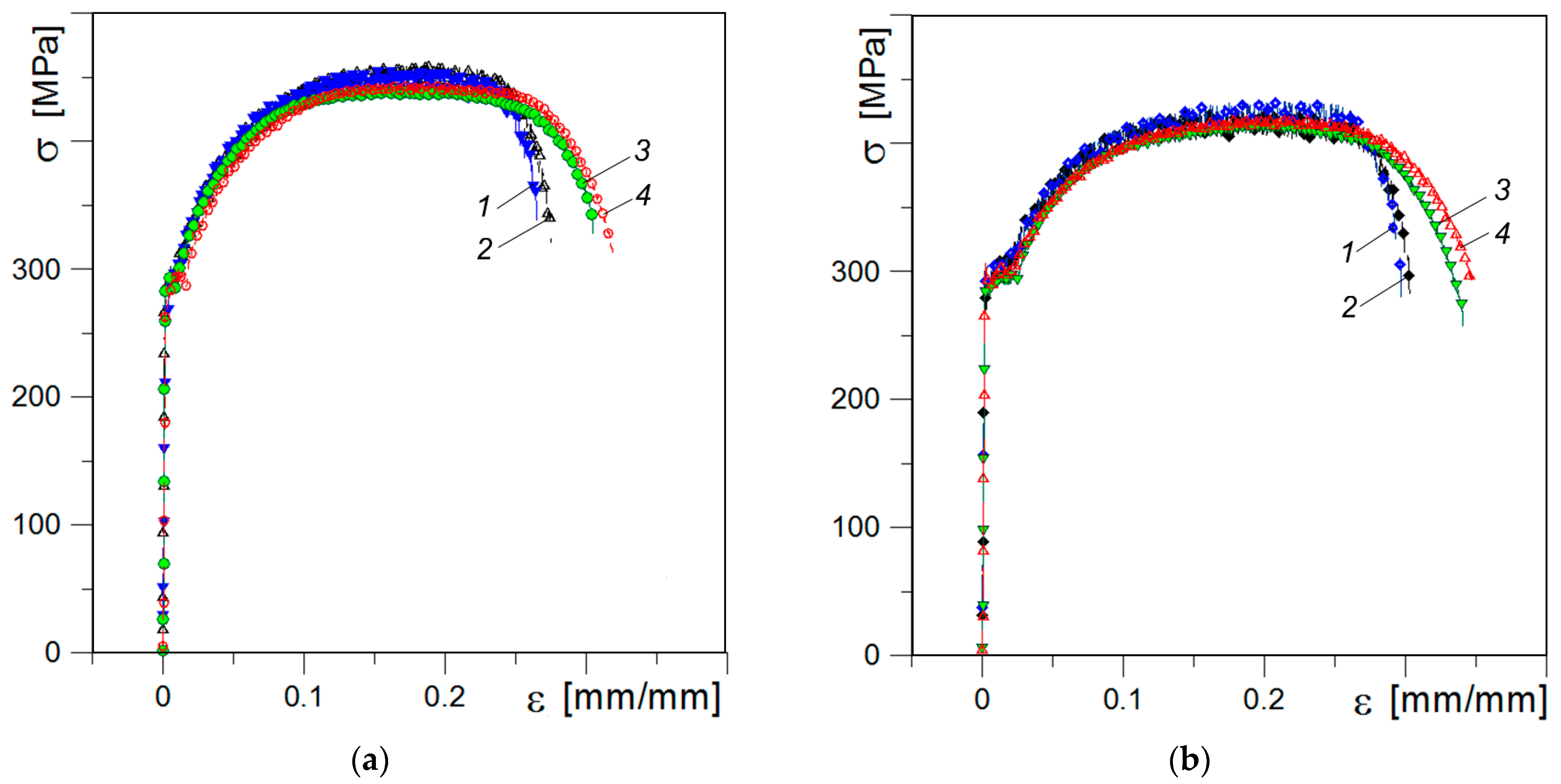

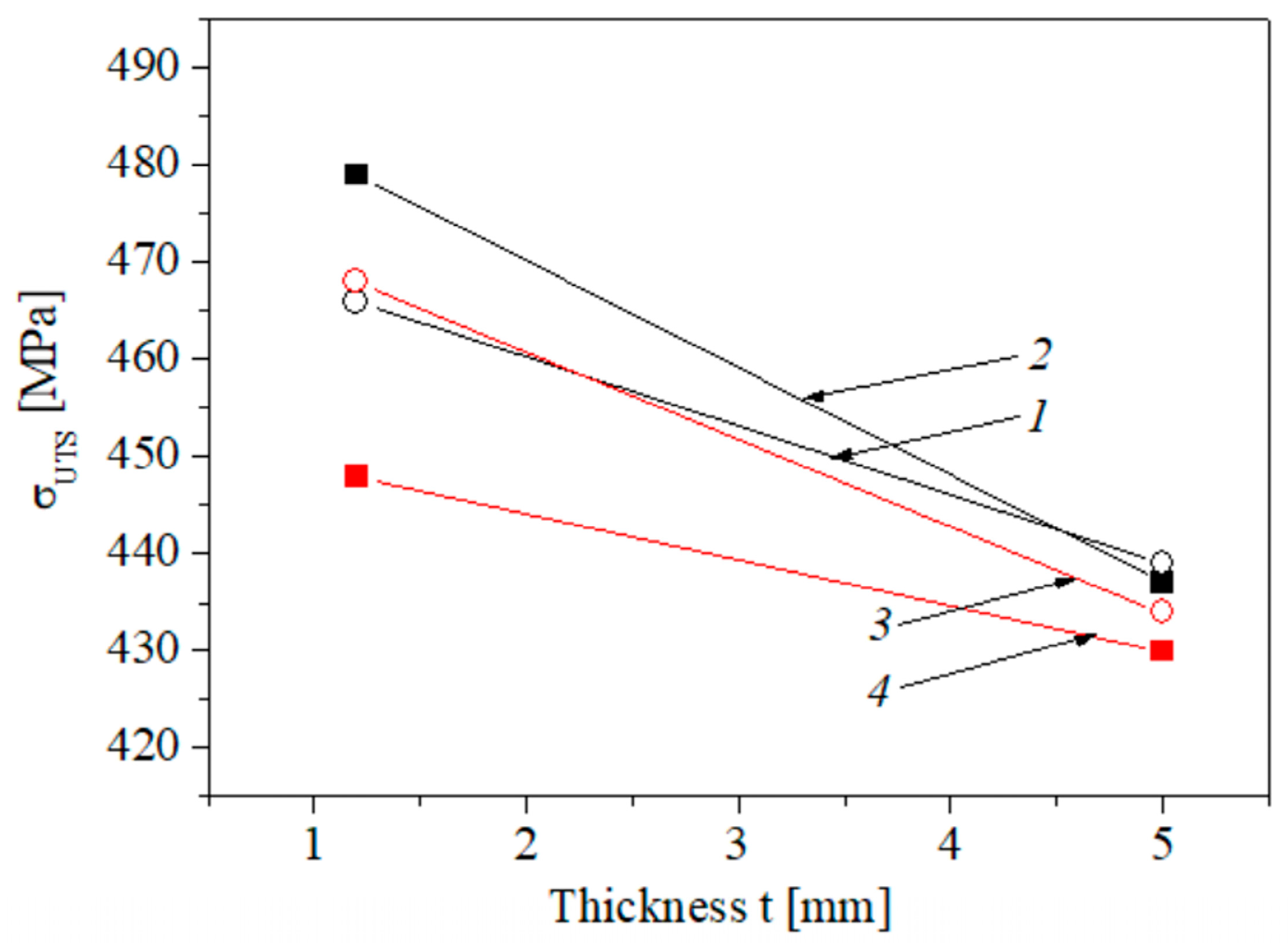

3.2. Stress–Strain Curves

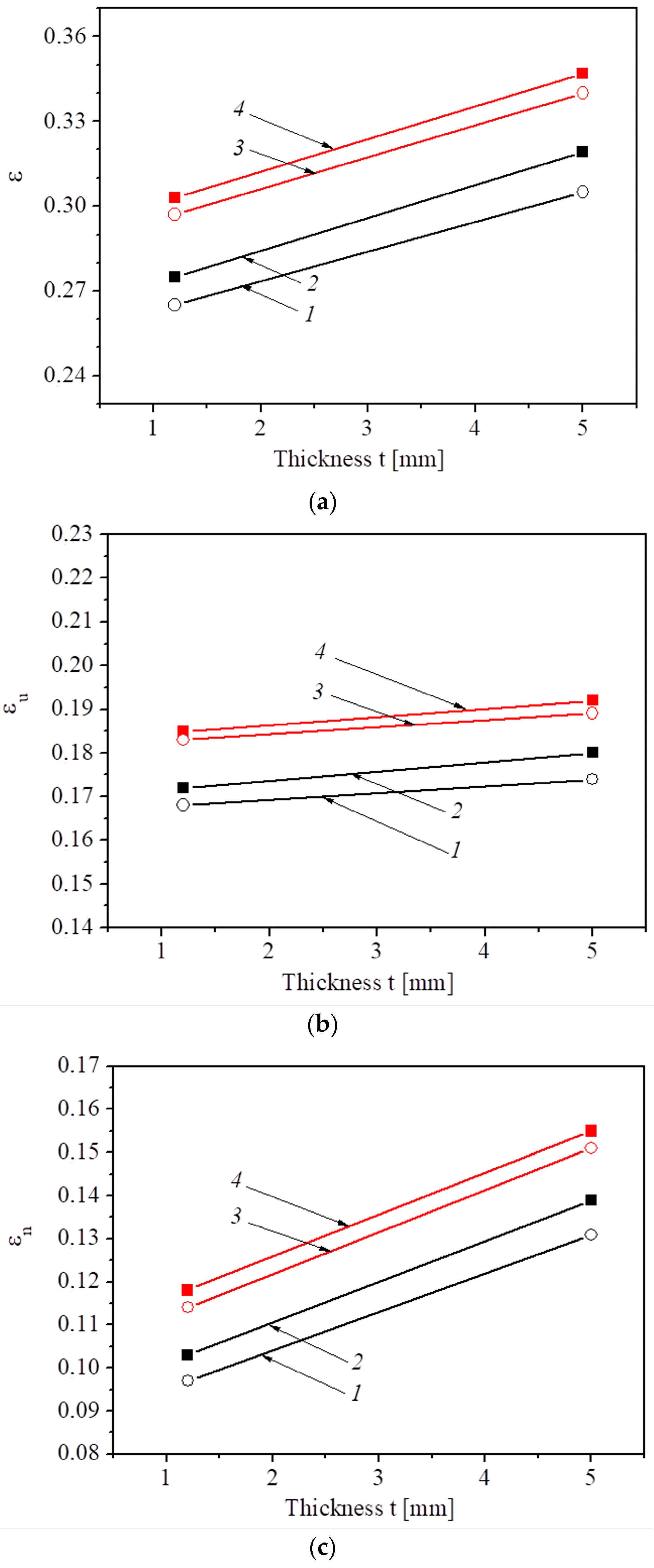

3.3. Elongation

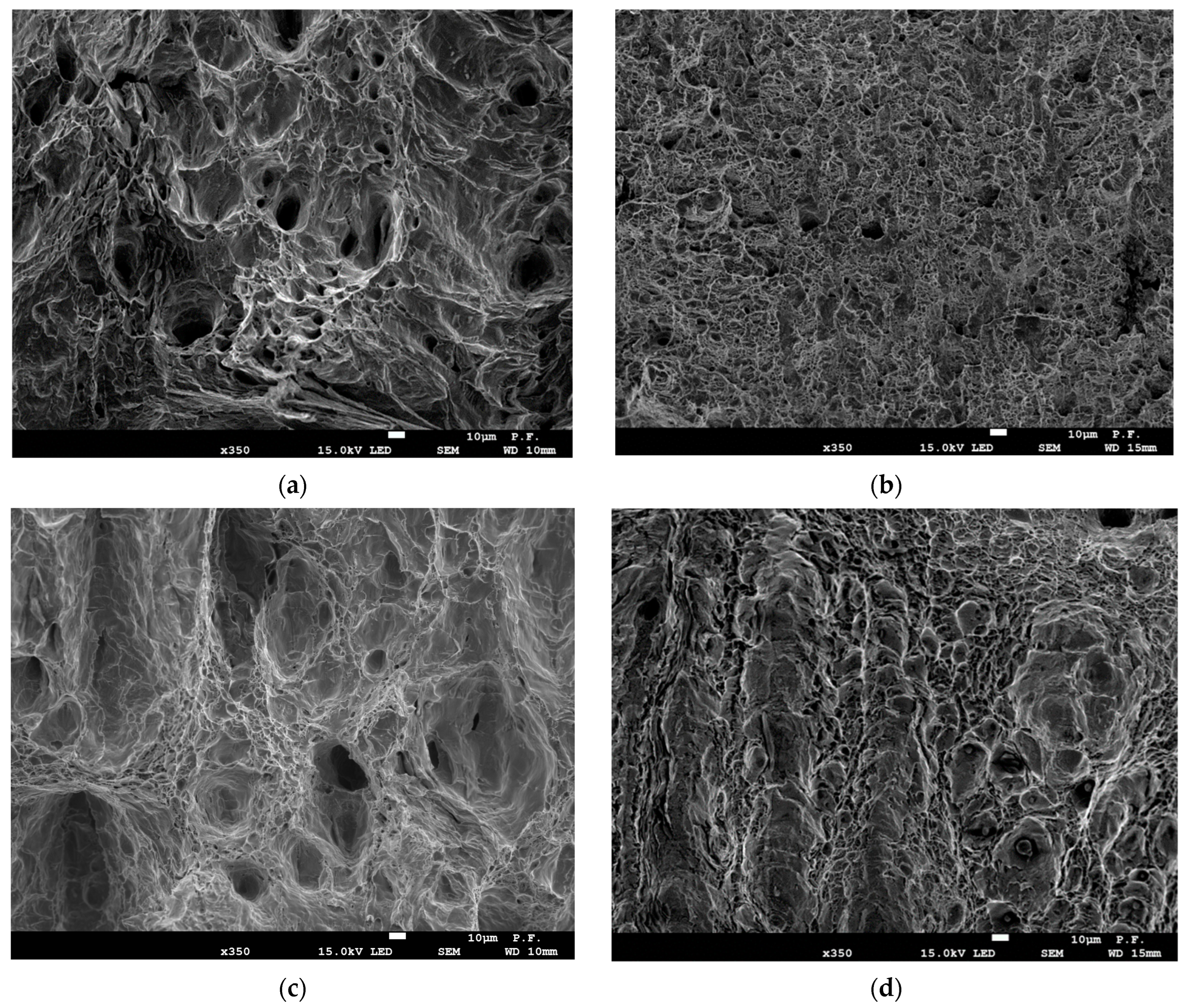

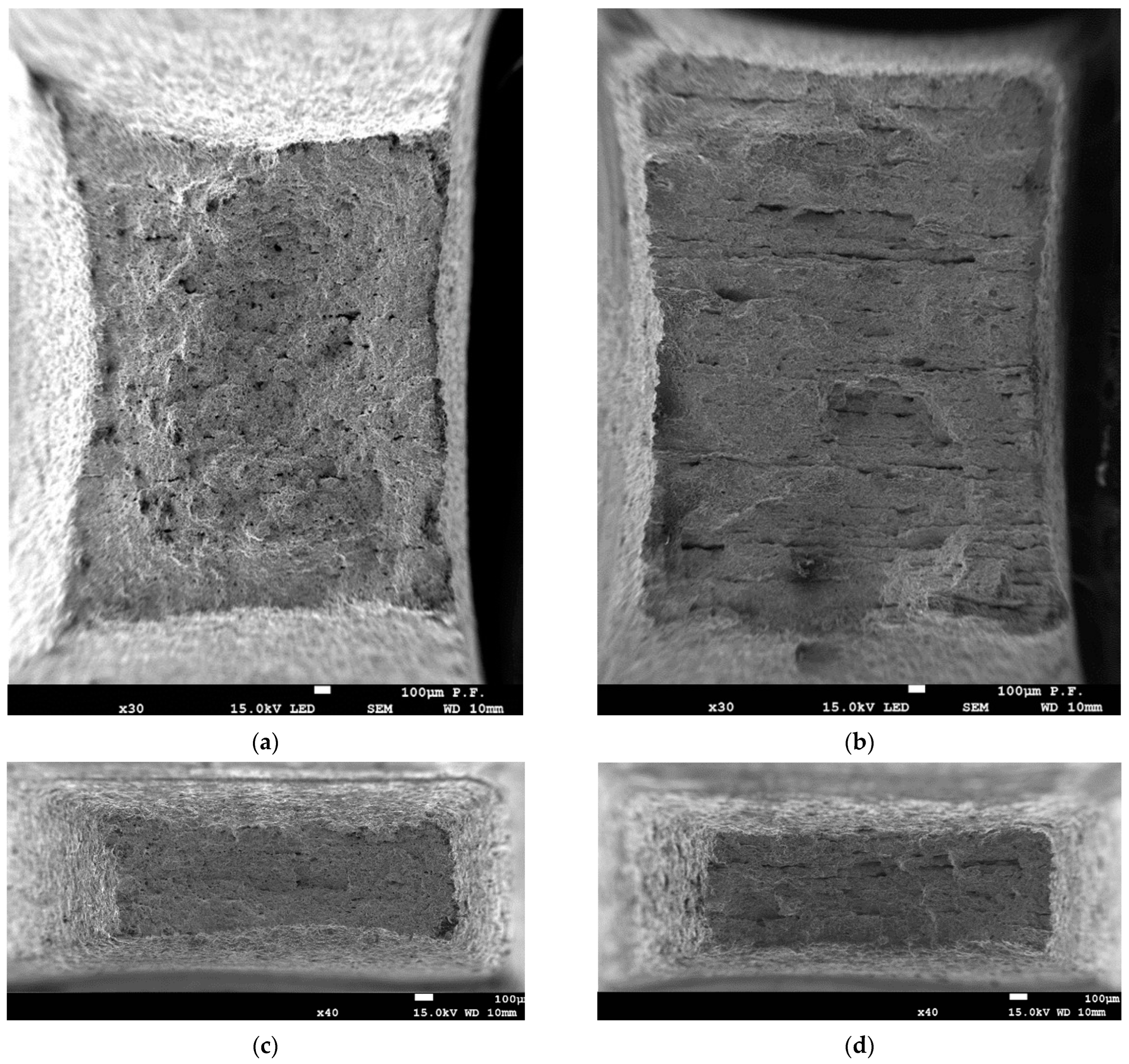

3.4. Fractographic Analysis of Tensile Failures

3.5. Future Research Prospects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, N.; Mishra, R.S.; Huskamp, C.S.; Sankaran, K.K. Critical grain size for change in deformation behavior in ultrafine grained Al–Mg–Sc alloy. Scripta Mater. 2011, 64, 576–579. [Google Scholar] [CrossRef]

- Zvirko, O.I.; Tsyrulnyk, O.T.; Dzioba, I.; Kret, N.V.; Lipiec, S. Influence of the structural features of steels of casing pipes on their mechanical properties and hydrogen brittleness. Mater. Sci. 2021, 56, 748–754. [Google Scholar] [CrossRef]

- Zvirko, O.; Tsyrulnyk, O.; Lipiec, S.; Dzioba, I. Evaluation of corrosion, mechanical properties and hydrogen embrittlement of casing pipe steels with different microstructure. Materials 2021, 14, 7860. [Google Scholar] [CrossRef]

- Morris, J.W., Jr. The Influence of Grain Size on the Mechanical Properties of Steel. May 2001. Available online: https://escholarship.org/uc/item/88g8n6f8 (accessed on 24 November 2022).

- Morquio, A.; Riera, J.D. Size and strain rate effects in steel structures. Eng. Struct. 2004, 26, 669–679. [Google Scholar] [CrossRef]

- Motra, H.B.; Hildebrand, J.; Dimmig-Osburg, A. Assessment of strain measurement techniques to characterise mechanical properties of structural steel. Eng. Sci. Technol. Int. J. 2014, 17, 260–269. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.H.; Guo, Y.Z.; Wei, Q.; Topping, T.D.; Dangelewicz, A.M.; Zhu, Y.T.; Langdon, T.G.; Lavernia, E.J. Influence of specimen dimensions and strain measurement methods on tensile stress–strain curves. Mater. Sci. Eng. A 2009, 525, 68–77. [Google Scholar] [CrossRef]

- Yuan, W.J.; Zhang, Z.L.; Su, Y.J.; Qiao, L.J.; Chu, W.Y. Influence of specimen thickness with rectangular cross-section on the tensile properties of structural steels. Mater. Sci. Eng. A 2012, 532, 601–605. [Google Scholar] [CrossRef]

- Motra, H.B.; Hildebrand, J.; Dimmig-Osburg, A. Influence of specimen dimensions and orientation on the tensile properties of structural steel. Mater. Test. 2014, 56, 929–936. [Google Scholar] [CrossRef]

- Kumar, K.; Pooleery, A.; Madhusoodanan, K.; Singh, R.N.; Chatterjee, A.; Dutta, B.K.; Sinha, R.K. Optimisation of thickness of miniature tensile specimens for evaluation of mechanical properties. Mater. Sci. Eng. A 2016, 675, 32–43. [Google Scholar] [CrossRef]

- Trieu, K.; Wang, X.; Zhang, X. The effect of size on the mechanical properties of rolled specimen: Predictions and experimental evaluation. Mater. Res. Express 2019, 6, 115801. [Google Scholar] [CrossRef]

- Zhang, L.; Harrison, W.; Yar, M.A.; Brown, S.G.R.; Lavery, N.P. The development of miniature tensile specimens with non-standard aspect and slimness ratios for rapid alloy prototyping processes. J. Mater. Res. Technol. 2021, 15, 1830–1843. [Google Scholar] [CrossRef]

- Kazakeviciute, J.; Rouse, J.P.; De Focatiis, D.S.A.; Hyde, C.J. Small specimen techniques for estimation of tensile, fatigue, fracture and crack propagation material model parameters. J. Strain Anal. Eng. Des. 2022, 57, 227–254. [Google Scholar] [CrossRef]

- Neuenschwander, M.; Knobloch, M.; Fontana, M. Elevated temperature mechanical properties of solid section structural steel. Constr. Build. Mater. 2017, 149, 186–201. [Google Scholar] [CrossRef]

- Dzioba, I.; Lipiec, S. Fracture mechanisms of S355 steel—Experimental research, FEM simulation and SEM observation. Materials 2019, 12, 3959. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tu, S.; Ren, X.; He, J.; Zhang, Z. Experimental measurement of temperature-dependent equivalent stress-strain curves of a 420 MPa structural steel with axisymmetric notched tensile specimens. Eng. Fail. Anal. 2019, 100, 312–321. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16ae1; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- PN-EN ISO 6892-1:2020-05; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2019.

- Goh, T.N.; Shang, H.M. Effects of shape and size of tensile specimens on the stress-strain relationship of sheet-metal. J. Mech. Work. Technol. 1982, 7, 23–37. [Google Scholar] [CrossRef]

- Takeda, Y.; Kiattisaksri, C.; Aramaki, M.; Munetoh, S.; Furukimi, O. Effects of specimen thickness in tensile tests on elongation and deformation energy for industrially pure iron. ISIJ Int. 2017, 57, 1129–1137. [Google Scholar] [CrossRef] [Green Version]

- Suh, C.H.; Yun-Chul, J.; Kim, Y.S. Effects of thickness and surface roughness on mechanical properties of aluminum sheets. J. Mech. Sci. Technol. 2010, 24, 2091–2098. [Google Scholar] [CrossRef]

- Nizhnik, S.B. Effect of structure and texture on the anisotropy of strength properties arising in the rolling of steel tubes. Strength Mater. 1997, 29, 84–92. [Google Scholar] [CrossRef]

- Joo, M.S.; Suh, D.W.; Bhadeshia, H.K.D.H. Mechanical anisotropy in steels for pipelines. ISIJ Int. 2013, 53, 1305–1314. [Google Scholar] [CrossRef] [Green Version]

- Masoumi, M.; Herculano, L.F.G.; de Abreu, H.F.G. Study of texture and microstructure evaluation of steel API 5L X70 under various thermomechanical cycles. Mater. Sci. Eng. A 2015, 639, 550–558. [Google Scholar] [CrossRef]

- Hutchinson, B. Critical assessment 16: Anisotropy in metals. Mater. Sci. Technol. 2015, 31, 1393–1401. [Google Scholar] [CrossRef] [Green Version]

- Nykyforchyn, H.; Zvirko, O.; Tsyrulnyk, O.; Kret, N. Analysis and mechanical properties characterization of operated gas main elbow with hydrogen assisted large-scale delamination. Eng. Fail. Anal. 2017, 82, 364–377. [Google Scholar] [CrossRef]

- Zvirko, O.I.; Kret, N.V.; Tsyrulnyk, O.T.; Vengrynyuk, T.P. Influence of textures of pipeline steels after operation on their brittle fracture resistance. Mater. Sci. 2018, 54, 400–405. [Google Scholar] [CrossRef]

- Beltran-Zuñiga, M.A.; González-Velázquez, J.L.; Rivas-López, D.I.; Dorantes Rosales, H.J.; Hernández-Santiago, F. Effect of microstructure and crystallographic texture on the toughness anisotropy of API 5L X46 steel. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 749–761. [Google Scholar] [CrossRef]

- Tankoua, F.; Crépin, J.; Thibaux, P.; Cooreman, S.; Gourgues-Lorenzon, A.-F. Quantification and microstructural origin of the anisotropic nature of the sensitivity to brittle cleavage fracture propagation for hot-rolled pipeline steels. Int. J. Fract. 2018, 212, 143–166. [Google Scholar] [CrossRef]

- Das Bakshi, S.; Javed, N.; Sasidhar, K.N.; Dhande, T.; Sharma, V.; Mukherjee, M. Effect of microstructure and crystallographic texture on mechanical anisotropy of Ti-Nb microalloyed hot rolled 800MPa HSLA steel. Mater. Charact. 2018, 136, 346–357. [Google Scholar] [CrossRef]

- Marushchak, P.O.; Kret, N.V.; Bishchak, R.T.; Kurnat, I.M. Influence of texture and hydrogenation on the mechanical properties and character of fracture of pipe steel. Mater. Sci. 2019, 55, 381–385. [Google Scholar] [CrossRef]

- Lesiuk, G.; Rymsza, B.; Rabiega, J.; Correia, J.A.F.O.; De Jesus, A.M.P.; Calcada, R. Influence of loading direction on the static and fatigue fracture properties of the long term operated metallic materials. Eng. Fail. Anal. 2019, 96, 409–425. [Google Scholar] [CrossRef]

- Nemchuk, O.O.; Nesterov, O.A. In-service brittle-fracture resistance degradation of steel in a ship-to-shore gantry crane. Strength Mater. 2020, 52, 275–280. [Google Scholar] [CrossRef]

- Semenov, P.O.; Pustovyi, V.M. Complex diagnostics of the state of operated elements of a grab reloader. Mater. Sci. 2020, 56, 181–186. [Google Scholar] [CrossRef]

- Zvirko, O.I. In-service degradation of structural steels (A survey). Mater. Sci. 2021, 57, 319–330. [Google Scholar] [CrossRef]

- Dzioba, I.; Zvirko, O.; Lipiec, S. Assessment of operational degradation of pipeline steel based on true stress–strain diagrams. In Degradation Assessment and Failure Prevention of Pipeline Systems. Lecture Notes in Civil Engineering; Bolzon, G., Gabetta, G., Nykyforchyn, H., Eds.; Springer: Cham, Switzerland, 2021; Volume 102, pp. 175–187. [Google Scholar]

- Nykyforchyn, H.; Zvirko, O.; Dzioba, I.; Krechkovska, H.; Hredil, M.; Tsyrulnyk, O.; Student, O.; Lipiec, S.; Pala, R. Assessment of operational degradation of pipeline steels. Materials 2021, 14, 3247. [Google Scholar] [CrossRef] [PubMed]

- Pustovyi, V.M.; Semenov, P.O.; Nemchuk, O.O.; Hredil, M.I.; Nesterov, O.A.; Strelbitskyi, V.V. Degradation of steels of the reloading equipment operating beyond its designed service life. Mater. Sci. 2022, 57, 640–648. [Google Scholar] [CrossRef]

- Nykyforchyn, H.; Pustovyi, V.; Zvirko, O.; Semenov, P.; Hredil, M.; Nemchuk, O.; Oliynyk, O.; Tsyrulnyk, O. Analysis of operational factors affecting the serviceability of seaport hoisting and transporting equipment. Procedia Struct. Integr. 2022, 41, 326–332. [Google Scholar] [CrossRef]

- Zvirko, O.; Mytsyk, B.; Nykyforchyn, H.; Tsyrulnyk, O.; Kost’, Y. Application of the various methods for assessment of in-service degradation of pipeline steel. Mech. Adv. Mater. Struct. 2022, 1–10. [Google Scholar] [CrossRef]

- Nykyforchyn, H.; Tsyrulnyk, O.; Zvirko, O.; Hredil, M. Role of hydrogen in operational degradation of pipeline steel. Procedia Struct. Integr. 2020, 28, 896–902. [Google Scholar] [CrossRef]

- Nykyforchyn, H.; Zvirko, O.; Hredil, M.; Krechkovska, H.; Tsyrulnyk, O.; Student, O.; Unigovskyi, L. Methodology of hydrogen embrittlement study of long-term operated natural gas distribution pipeline steels caused by hydrogen transport. Frat. Integrità Strutt. 2022, 16, 396–404. [Google Scholar] [CrossRef]

- ASTM E23-07a; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2018.

- Dzioba, I.; Lipiec, S.; Pala, R.; Furmanczyk, P. On characteristics of ferritic steel determined during the uniaxial tensile test. Materials 2021, 14, 3117. [Google Scholar] [CrossRef]

- Nemchuk, O.O.; Krechkovska, H.V. Fractographic substantiation of the loss of resistance to brittle fracture of steel after operation in the marine gantry crane elements. Metallofiz. Noveishie Tekhnol. 2019, 41, 825–836. [Google Scholar] [CrossRef] [Green Version]

- Khan, I.A.; Srivastava, A.; Needleman, A.; Benzerg, A.A. An analysis of deformation and failure in rectangular tensile bars accounting for void shape changes. Int. J. Fract. 2021, 230, 133–156. [Google Scholar] [CrossRef]

- Tu, S.; Ren, X.; He, J.; Zhang, Z. Stress–strain curves of metallic materials and post-necking strain hardening characterization: A review. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 3–19. [Google Scholar] [CrossRef] [Green Version]

| Steel | Crane Unit | Sheet Thickness [mm] | Cyclic Stress Range Δσe [MPa] |

|---|---|---|---|

| A | Jib | 16.0 | 130.0 |

| B | Boom | 12.0 | 55.0 |

| Steel | Specimen Orientation | Specimen Code for t1 = 5.0 mm | Specimen Code for t2 = 1.2 mm |

|---|---|---|---|

| A | Longitudinal | A-L-t1 | A-L-t2 |

| Transverse | A-T-t1 | A-T-t2 | |

| B | Longitudinal | B-L-t1 | B-L-t2 |

| Transverse | B-T-t2 | B-T-t2 |

| Steel | Crane Unit | KCVL-T [J/cm2] 1 | KCVT-L [J/cm2] 2 |

|---|---|---|---|

| A | Jib | 159 | 60 |

| B | Boom | 310 | 123 |

| Specimen Code | σYS [MPa] | σUTS [MPa] | ε [mm/mm] | εu [mm/mm] | εn [mm/mm] |

|---|---|---|---|---|---|

| A-L-t1 | 282 | 437 | 0.319 | 0.180 | 0.139 |

| A-T-t1 | 283 | 439 | 0.305 | 0.174 | 0.131 |

| B-L-t1 | 298 | 430 | 0.347 | 0.192 | 0.155 |

| B-T-t1 | 300 | 434 | 0.340 | 0.189 | 0.151 |

| A-L-t2 | 297 | 479 | 0.275 | 0.172 | 0.103 |

| A-T-t2 | 300 | 466 | 0.265 | 0.168 | 0.097 |

| B-L-t2 | 305 | 448 | 0.303 | 0.185 | 0.118 |

| B-T-t2 | 322 | 468 | 0.297 | 0.183 | 0.114 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zvirko, O.; Dzioba, I.; Hredil, M.; Pała, R.; Oliynyk, O.; Furmańczyk, P. Specimen Size Effect on the Tensile Properties of Rolled Steel of Long-Term-Operated Portal Crane. Materials 2023, 16, 3017. https://doi.org/10.3390/ma16083017

Zvirko O, Dzioba I, Hredil M, Pała R, Oliynyk O, Furmańczyk P. Specimen Size Effect on the Tensile Properties of Rolled Steel of Long-Term-Operated Portal Crane. Materials. 2023; 16(8):3017. https://doi.org/10.3390/ma16083017

Chicago/Turabian StyleZvirko, Olha, Ihor Dzioba, Myroslava Hredil, Robert Pała, Oleksandr Oliynyk, and Piotr Furmańczyk. 2023. "Specimen Size Effect on the Tensile Properties of Rolled Steel of Long-Term-Operated Portal Crane" Materials 16, no. 8: 3017. https://doi.org/10.3390/ma16083017

APA StyleZvirko, O., Dzioba, I., Hredil, M., Pała, R., Oliynyk, O., & Furmańczyk, P. (2023). Specimen Size Effect on the Tensile Properties of Rolled Steel of Long-Term-Operated Portal Crane. Materials, 16(8), 3017. https://doi.org/10.3390/ma16083017