Effect of Copper Segregation at Low-Angle Grain Boundaries on the Mechanisms of Plastic Relaxation in Nanocrystalline Aluminum: An Atomistic Study

Abstract

:1. Introduction

2. MD Problem Statement

2.1. Creation of MD System with GBs

2.2. Energetically Preferable Positions of Cu Atoms at GBs

2.3. MD Simulation of Shear Deformation System with Cu Segregation at GBs

3. Plastic Relaxation Mechanisms and Stress State of MD Systems

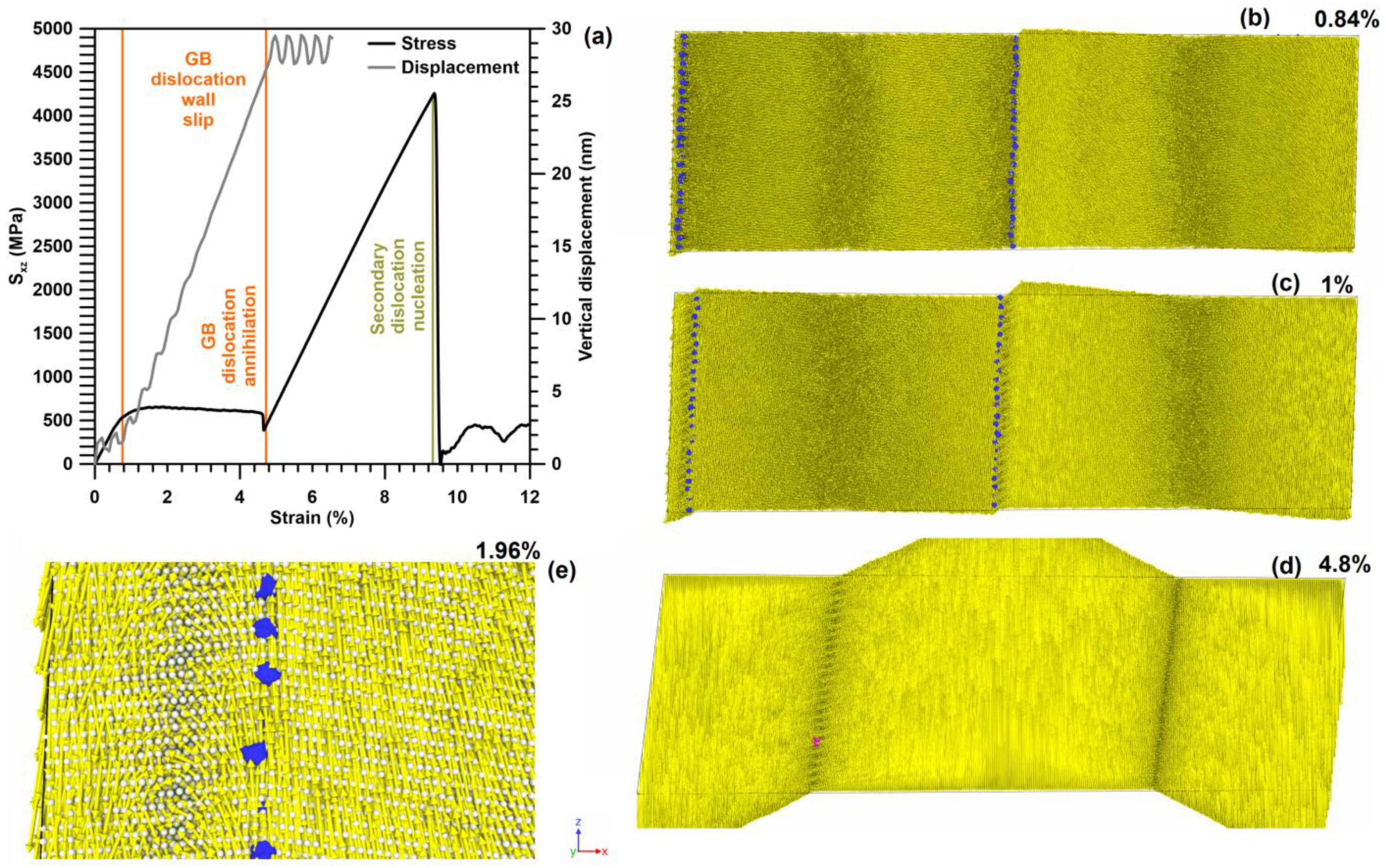

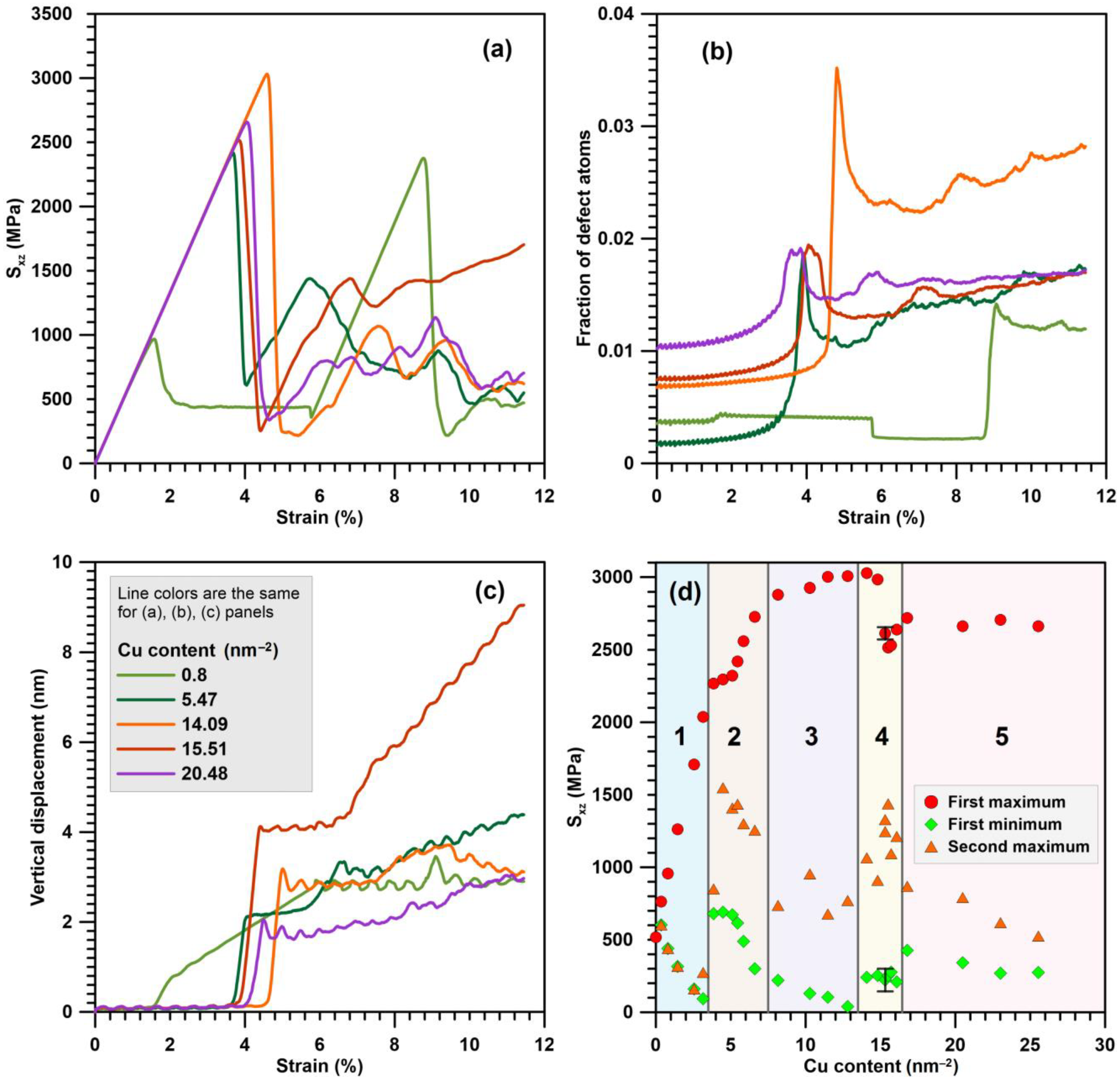

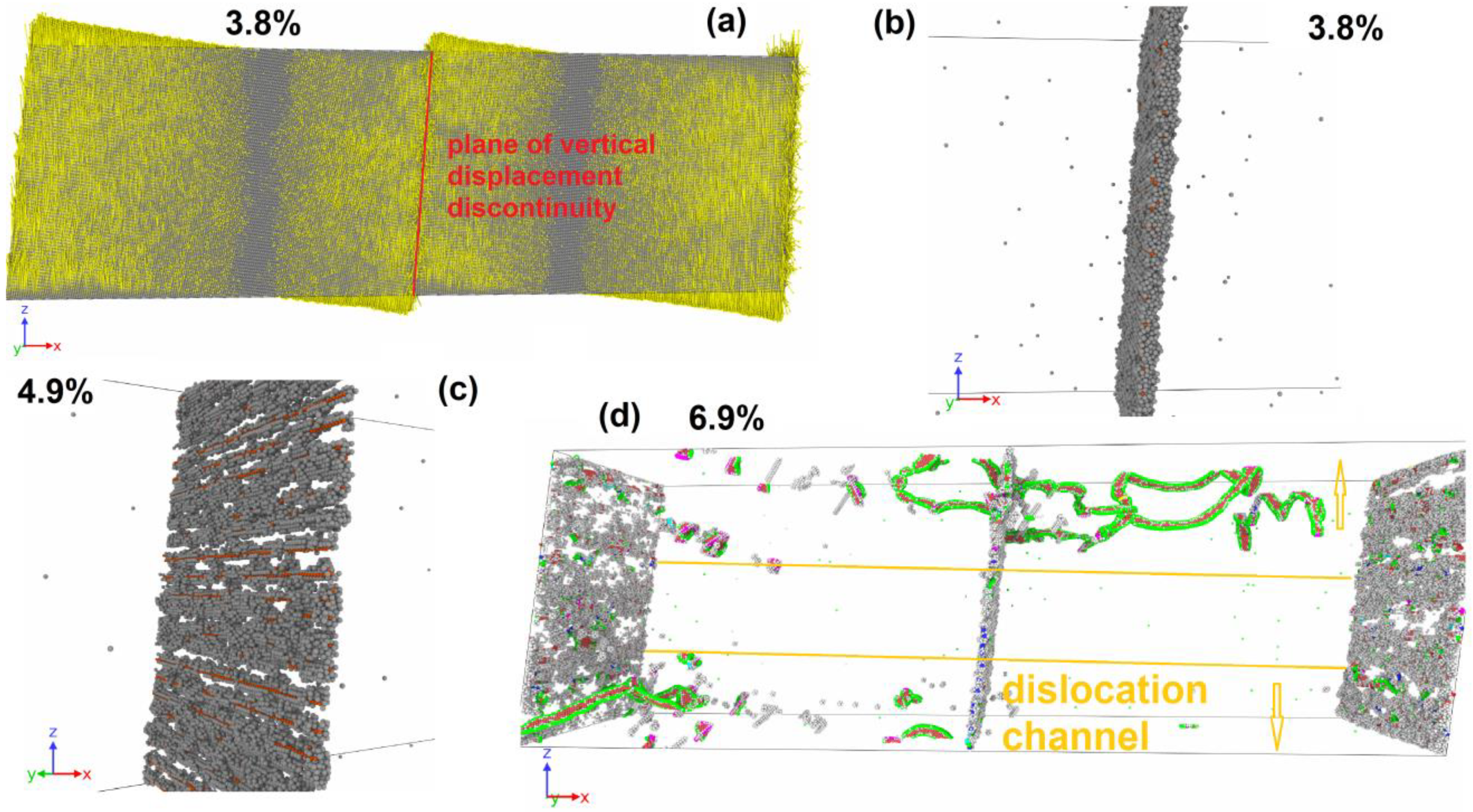

3.1. GB Slip

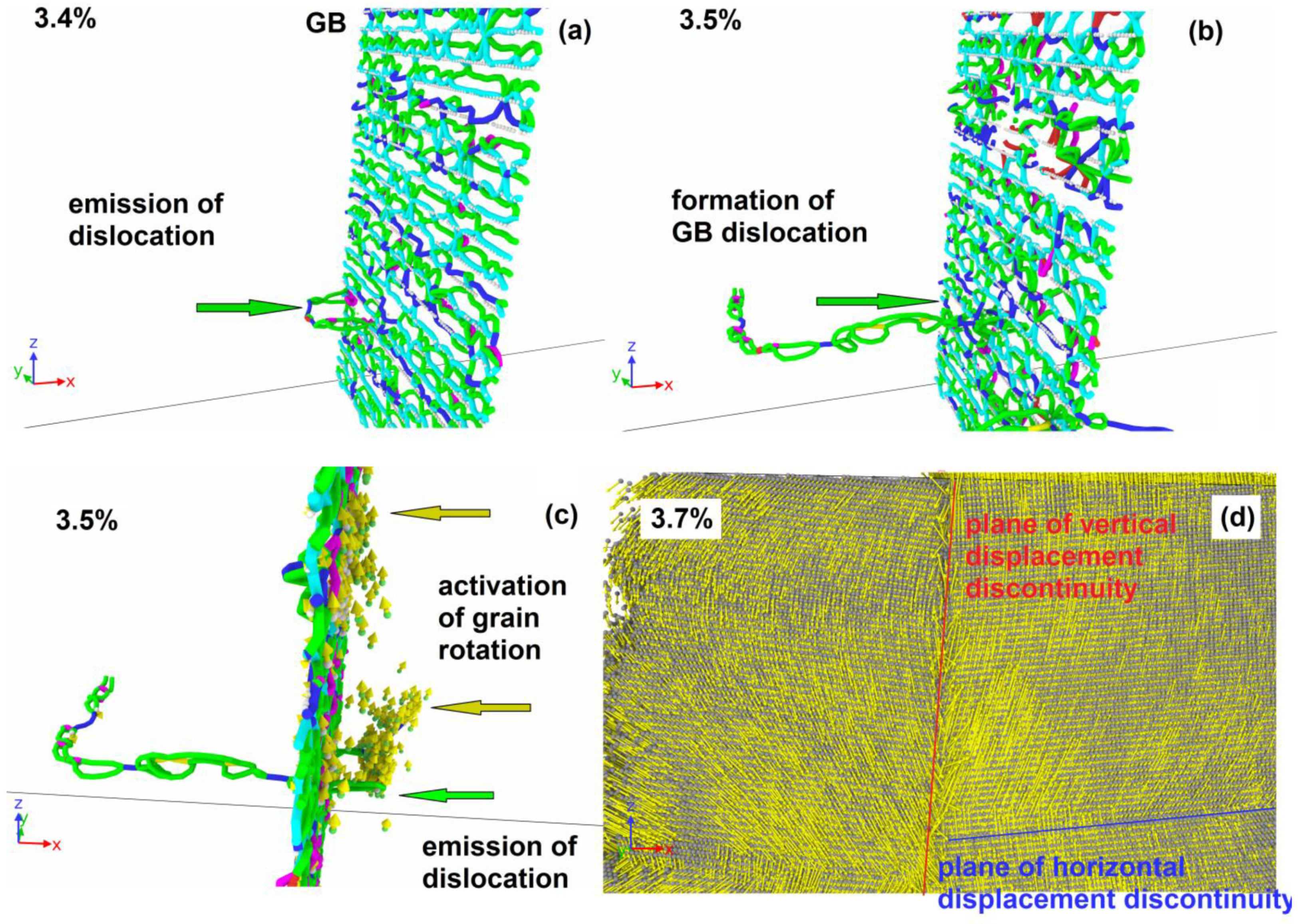

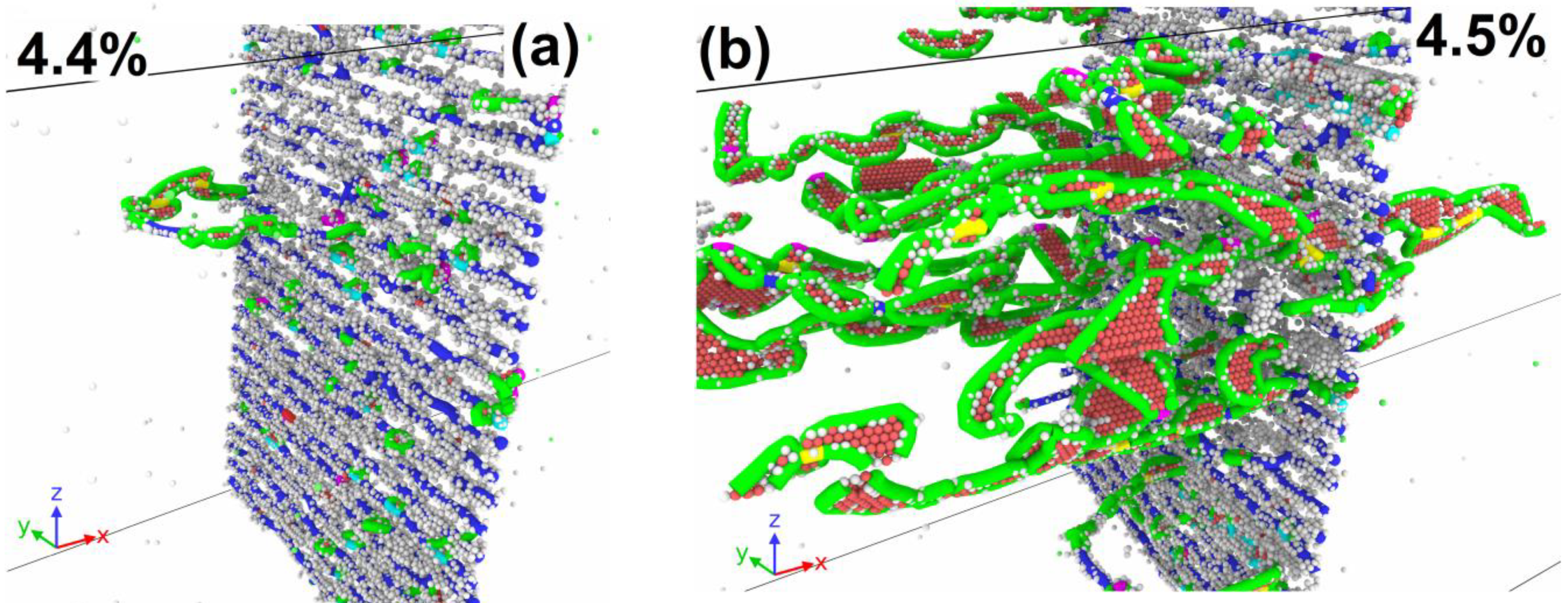

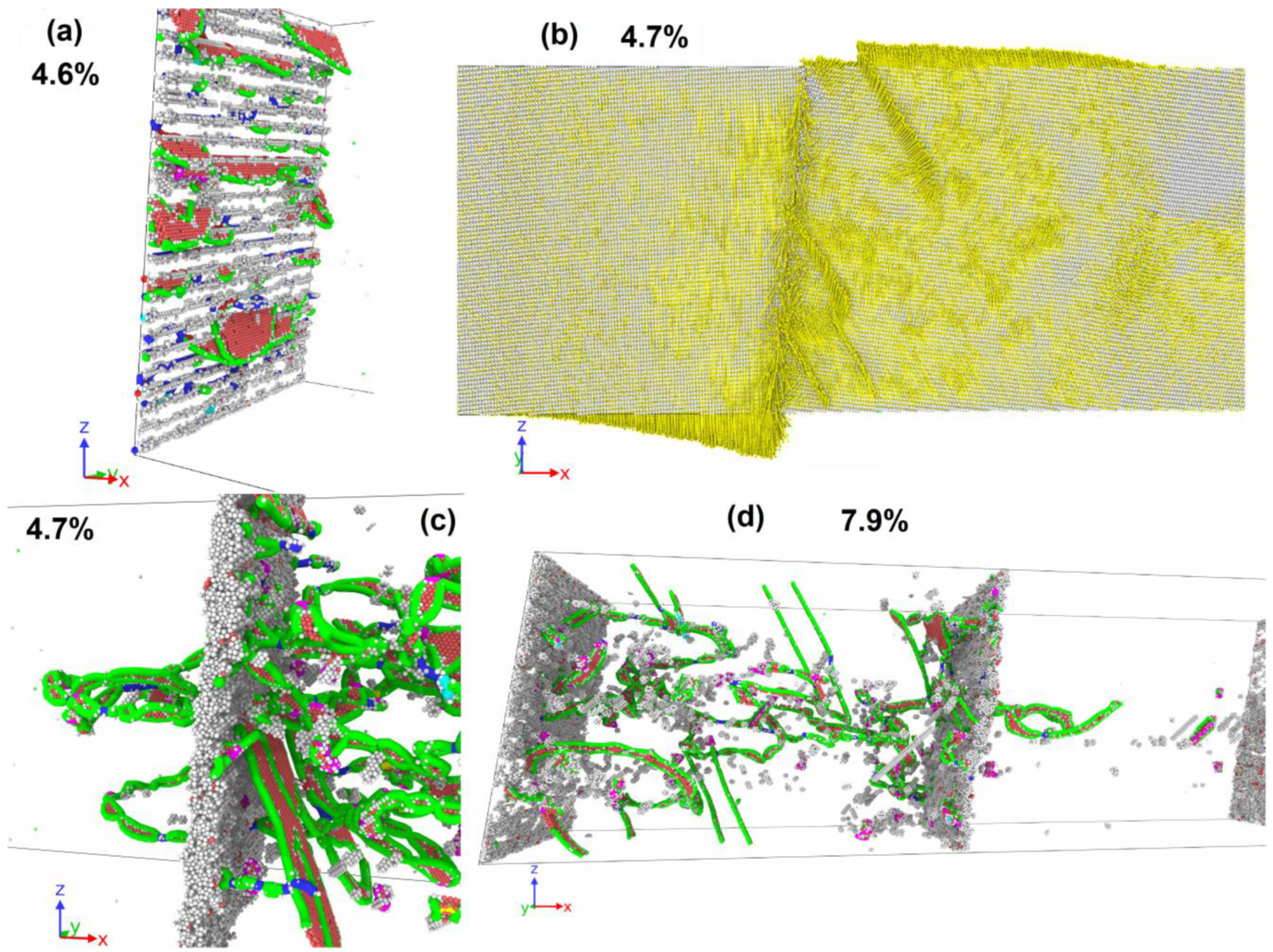

3.2. Grain Rotation

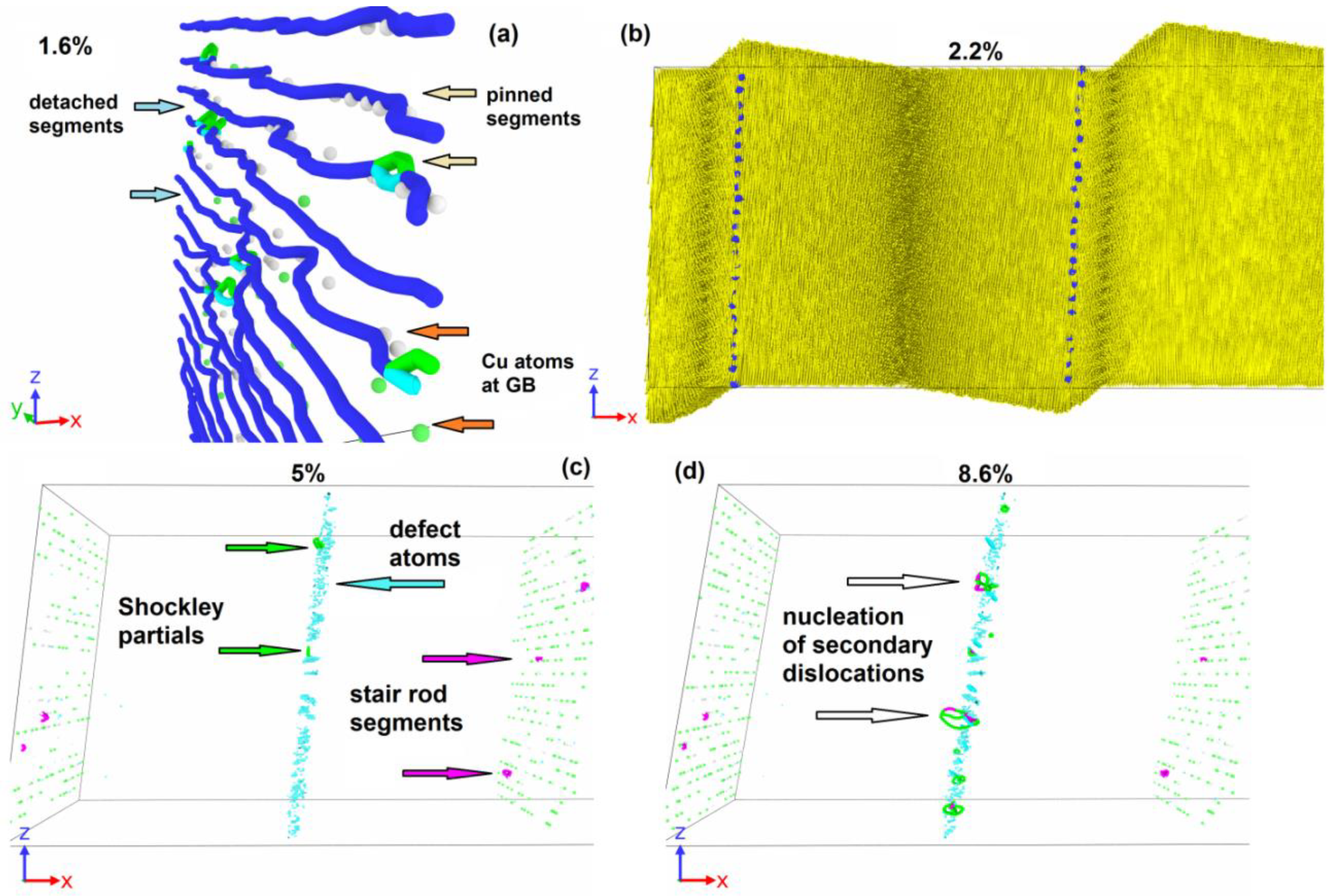

3.3. Dislocation Emission

3.4. Dislocation Emission and System Rotation

4. Discussion

5. Conclusions

- Plastic relaxation mechanisms provided by a symmetric tilt LAGB with the misorientation angle θ of 12° and segregated Cu atoms with the maximal concentration of 13 at.% in the GB region are studied using MD simulations.

- Cu segregation at GB most often leads to an increase in the critical resolved shear stress required to activate plastic relaxation that is consistent with experimental and computational works considering the effect of Cu segregation on macroscopic strength properties.

- An increase in the Cu content at the GBs leads to a non-monotonic dependence of the critical resolved shear stress and change in plastic relaxation mechanisms.

- Activation of GB sliding with grain rotation takes place in relatively narrow ranges of Cu content near the values of about 5 and 15 nm−2. This mode of deformation produces a lower number of lattice defects and can be of interest for GB engineering.

- Complex interplay of plasticity mechanisms and non-monotonic variation in the flow stress with strain and the Cu content are the challenge for the theoretical description of this phenomenon.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, T.; Xia, S.; Bai, Q.; Zhou, B.; Lu, Y.; Shoji, T. Evaluation of grain boundary network and improvement of intergranular cracking resistance in 316l stainless steel after grain boundary engineering. Materials 2019, 12, 242. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Humphreys, F.J.; Hatherly, M. Recrystalisation and Related Annealing Phenomena, 2nd ed.; Elsevier Ltd.: Oxford, UK, 2004. [Google Scholar]

- Polmear, I.J. Light Alloys: From Traditional Alloys to Nanocrystals, 3rd ed.; Butterworth-Heinemann/Elsevier: Oxford, UK, 2006. [Google Scholar]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Nie, J.F. Physical Metallurgy of Light Alloys, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 3. [Google Scholar]

- Nie, J.F.; Muddle, B.C. Strengthening of an Al-Cu-Sn alloy by deformation-resistant precipitate plates. Acta Mater. 2008, 56, 3490–3501. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, H. Precipitation behavior during aging operations in an ultrafine-grained Al-Cu-Mg alloy produced by high-strain-rate processing. Materials 2022, 15, 8687. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Zuo, R.; Xue, D.; Wen, S.; Wu, Y.; Shi, W.; Zhou, X.; Huang, H.; Wu, X.; Gao, K.; et al. Effect of aging treatment on the precipitation behavior of a novel Al-Cu-Zr cast alloy. Materials 2022, 15, 8163. [Google Scholar] [CrossRef] [PubMed]

- Krasnikov, V.S.; Gazizov, M.R.; Mayer, A.E.; Bezborodova, P.A.; Pogorelko, V.V.; Kaibyshev, R.O. Prediction of the Strength of aged Al-Cu alloys with non-hybrid and hybrid {100}Al plates. Comput. Mater. Sci. 2022, 207, 111331. [Google Scholar] [CrossRef]

- Sahu, B.P.; Dutta, A.; Mitra, R. Mechanism of negative strain rate sensitivity in metallic glass film. J. Alloys Compd. 2019, 784, 488–499. [Google Scholar] [CrossRef]

- Fomin, E.V.; Mayer, A.E. Slip of low-angle tilt grain boundary (110) in FCC metals at perpendicular shear. Int. J. Plast. 2020, 134, 102843. [Google Scholar] [CrossRef]

- Zhou, G.; Huang, Q.; Chen, Y.; Yu, X.; Zhou, H. Annihilation mechanism of low-angle grain boundary in nanocrystalline metals. Metals 2022, 12, 451. [Google Scholar] [CrossRef]

- Huang, Q.; Zhao, Q.; Zhou, H.; Yang, W. Misorientation-dependent transition between grain boundary migration and sliding in FCC metals. Int. J. Plast. 2022, 159, 103466. [Google Scholar] [CrossRef]

- Ma, N.; Zhao, D.; Shi, C.; He, C.; Liu, E.; Sha, J.; Li, Y.; Zhao, N. Unraveling the enhanced stability and strength of Al Σ9(221)[110] symmetric tilt grain boundary with Mg segregation. J. Mater. Sci. 2022, 57, 21591–21606. [Google Scholar] [CrossRef]

- Kazemi, A.; Yang, S. Effects of magnesium dopants on grain boundary migration in aluminum-magnesium alloys. Comp. Mater. Sci. 2021, 188, 110130. [Google Scholar] [CrossRef]

- Kuznetsov, A.; Karkina, L.; Gornostyrev, Y.; Korzhavyi, P. Effects of Zn and Mg segregations on the grain boundary sliding and cohesion in Al: Ab initio modeling. Metals 2021, 11, 631. [Google Scholar] [CrossRef]

- Zhao, D.; Løvvik, O.M.; Marthinsen, K.; Li, Y. Segregation of Mg, Cu and their effects on the strength of Al Σ5 (210)[001] symmetrical tilt grain boundary. Acta Mater. 2018, 145, 235–246. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Vergazov, A.N.; Gertsman, V.Y. Kristallogeometricheskiy Analiz Mezhkristallitnykh Granits v Praktike Elektronnoy Mikroskopii; Nauka: Moscow, Russia, 1991. [Google Scholar]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Apostol, F.; Mishin, Y. Angular-dependent interatomic potential for the aluminum-hydrogen system. Phys. Rev. B 2010, 82, 144115. [Google Scholar] [CrossRef] [Green Version]

- Adlakha, I.; Garg, P.; Solanki, K.N. Revealing the atomistic nature of dislocation-precipitate interactions in Al-Cu alloys. J. Alloys Compd. 2019, 797, 325–333. [Google Scholar] [CrossRef]

- Krasnikov, V.S.; Mayer, A.E.; Pogorelko, V.V.; Gazizov, M.R. Influence of θ’ phase cutting on precipitate hardening of Al–Cu alloy during prolonged plastic deformation: Molecular dynamics and continuum modeling. Appl. Sci. 2021, 11, 4906. [Google Scholar] [CrossRef]

- Fomin, E.V.; Mayer, A.E.; Krasnikov, V.S. Prediction of shear strength of cluster-strengthened aluminum with multi-scale approach describing transition from cutting to bypass of precipitates by dislocations. Int. J. Plast. 2021, 146, 103095. [Google Scholar] [CrossRef]

- Fomin, E.V.; Krasnikov, V.S. Interaction of edge dislocation with copper atoms in an aluminum crystal. J. Phys. Conf. Ser. 2020, 1556, 012050. [Google Scholar] [CrossRef]

- Krasnikov, V.S.; Mayer, A.E. Initiation and Mechanisms of Plasticity in Bimetallic Al-Cu Composite. Metals 2023, 13, 102. [Google Scholar] [CrossRef]

- Sha, G.; Yao, L.; Liao, X.; Ringer, S.P.; Duan, Z.C.; Langdon, T.G. Segregation of solute elements at grain boundaries in an ultrafine grained Al-Zn-Mg-Cu alloy. Ultramicroscopy 2011, 111, 500–505. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-Y.; Liu, C.-L.; Borucki, L.J. A new investigation of copper’s role in enhancing Al-Cu interconnect electromigration resistance from an atomistic view. Acta Mater. 1999, 47, 3227–3231. [Google Scholar] [CrossRef]

- Campbell, G.H.; Plitzko, J.M.; King, W.E. Copper segregation to the 5(310)/[001] symmetric tilt grain boundary in aluminum. Interf. Sci. 2004, 12, 165–174. [Google Scholar] [CrossRef]

- Jia, H.; Bjørge, R.; Cao, L.; Song, H.; Marthinsen, K.; Li, Y. Quantifying the grain boundary segregation strengthening induced by post-ECAP aging in an Al-5Cu alloy. Acta Mater. 2018, 155, 199–213. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Liu, X.C.; Li, X.Y.; Lu, K. Deformation induced grain boundary segregation in nanolaminated Al–Cu alloy. Acta Mater. 2020, 182, 207–214. [Google Scholar] [CrossRef]

- Masuda, T.; Sauvage, X.; Hirosawa, S.; Horita, Z. Achieving highly strengthened Al–Cu–Mg alloy by grain refinement and grain boundary segregation. Mater. Sci. Eng. A 2020, 793, 139668. [Google Scholar] [CrossRef]

- Orlova, T.S.; Sadykov, D.I.; Murashkin, M.Y.; Kazykhanov, V.U.; Enikeev, N.A. Peculiarities of strengthening of Al–Cu–Zr alloy structured by severe plastic deformation. Phys. Solid State 2021, 63, 1744–1756. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Kelchner, C.L.; Plimpton, S.J.; Hamilton, J.C. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 1998, 58, 11085. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Thomas, S.L.; Chen, K.; Han, J.; Purohit, P.K.; Srolovitz, D.J. Reconciling grain growth and shear-coupled grain boundary migration. Nat. Commun. 2017, 8, 1764. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jin, M.; Minor, A.M.; Stach, E.A.; Morris, J.W. Direct observation of deformation-induced grain growth during the nanoindentation of ultrafine-grained Al at room temperature. Acta Mater. 2004, 52, 5381–5387. [Google Scholar] [CrossRef]

- Mompiou, F.; Legros, M.; Radetic, T.; Dahmen, U.; Gianola, D.S.; Hemker, K.J. In situ TEM observation of grain annihilation in tricrystalline aluminum films. Acta Mater. 2012, 60, 2209–2218. [Google Scholar] [CrossRef]

- Wang, L.; Teng, J.; Liu, P.; Hirata, A.; Ma, E.; Zhang, Z.; Chen, M.; Han, X. Grain rotation mediated by grain boundary dislocations in nanocrystalline platinum. Nat. Commun. 2014, 5, 4402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuk, J.M.; Jeong, M.; Kim, S.Y.; Seo, H.K.; Kim, J.; Lee, J.Y. In situ atomic imaging of coalescence of Au nanoparticles on graphene: Rotation and grain boundary migration. Chem. Commun. 2013, 49, 11479–11481. [Google Scholar] [CrossRef]

| GB State | Copper Content (nm−2) | Mechanisms of Plasticity Activation | First Maximal Stress (MPa) | First Minimal Stress (MPa) | Second Maximal Stress (MPa) |

|---|---|---|---|---|---|

| Pure Al | 0 | GB slip | 517 | 637 | 637 |

| 1 Cu column | |||||

| 7.5 | 0.34 | GB slip | 763 | 603 | 603 |

| 15 | 0.81 | GB slip | 956 | 438 | 438 |

| 30 | 1.46 | GB slip | 1262 | 316 | 316 |

| 50 | 2.56 | GB slip | 1708 | 160 | 160 |

| 62.5 | 3.16 | GB slip | 2037 | 93 | 275 |

| 75 | 3.85 | Dislocation emission from GBs + two grain rotation | 2267 | 680 | 850 |

| 87.5 | 4.47 | Two grain rotation | 2294 | 689 | 1549 |

| 100 | 5.11 | Two grain rotation | 2320 | 672 | 1407 |

| 3 Cu columns | |||||

| 3.75 | 5.47 | Two grain rotation | 2420 | 614 | 1435 |

| 7.5 | 5.87 | Two grain rotation + dislocation emission from GBs | 2560 | 489 | 1300 |

| 15 | 6.61 | System rotation + dislocation emission from GBs | 2725 | 300 | 1257 |

| 30 | 8.17 | Dislocation emission from GBs | 2879 | 220 | 736 |

| 50 | 10.28 | Dislocation emission from GBs | 2925 | 130 | 954 |

| 62.5 | 11.49 | Dislocation emission from GBs | 3000 | 104 | 678 |

| 75 | 12.8 | Dislocation emission from GBs | 3006 | 40 | 769 |

| 87.5 | 14.09 | Dislocation emission from GBs + system rotation | 3026 | 240 | 1065 |

| 95 | 14.82 | Dislocation emission from GBs + system rotation | 2982 | 252 | 910 |

| 100 | 15.32 | Dislocation emission from GBs + system rotation | 2614 | 221 | 1246 |

| 5 Cu columns | |||||

| 1.88 | 15.51 | Dislocation emission from GBs + system rotation | 2516 | 252 | 1436 |

| 3.75 | 15.72 | Dislocation emission from GBs + system rotation | 2531 | 277 | 1094 |

| 7.5 | 16.08 | Dislocation emission from GBs + system rotation | 2640 | 209 | 1212 |

| 15 | 16.8 | Dislocation emission from GBs | 2720 | 427 | 869 |

| 50 | 20.48 | Dislocation emission from GBs | 2663 | 340 | 792 |

| 75 | 23.01 | Dislocation emission from GBs | 2707 | 269 | 618 |

| 100 | 25.53 | Dislocation emission from GBs | 2663 | 275 | 525 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krasnikov, V.; Mayer, A.; Bezborodova, P.; Gazizov, M. Effect of Copper Segregation at Low-Angle Grain Boundaries on the Mechanisms of Plastic Relaxation in Nanocrystalline Aluminum: An Atomistic Study. Materials 2023, 16, 3091. https://doi.org/10.3390/ma16083091

Krasnikov V, Mayer A, Bezborodova P, Gazizov M. Effect of Copper Segregation at Low-Angle Grain Boundaries on the Mechanisms of Plastic Relaxation in Nanocrystalline Aluminum: An Atomistic Study. Materials. 2023; 16(8):3091. https://doi.org/10.3390/ma16083091

Chicago/Turabian StyleKrasnikov, Vasiliy, Alexander Mayer, Polina Bezborodova, and Marat Gazizov. 2023. "Effect of Copper Segregation at Low-Angle Grain Boundaries on the Mechanisms of Plastic Relaxation in Nanocrystalline Aluminum: An Atomistic Study" Materials 16, no. 8: 3091. https://doi.org/10.3390/ma16083091

APA StyleKrasnikov, V., Mayer, A., Bezborodova, P., & Gazizov, M. (2023). Effect of Copper Segregation at Low-Angle Grain Boundaries on the Mechanisms of Plastic Relaxation in Nanocrystalline Aluminum: An Atomistic Study. Materials, 16(8), 3091. https://doi.org/10.3390/ma16083091