Generation of Photonic Nanojet Using Gold Film Dielectric Microdisk Structure

Abstract

:1. Introduction

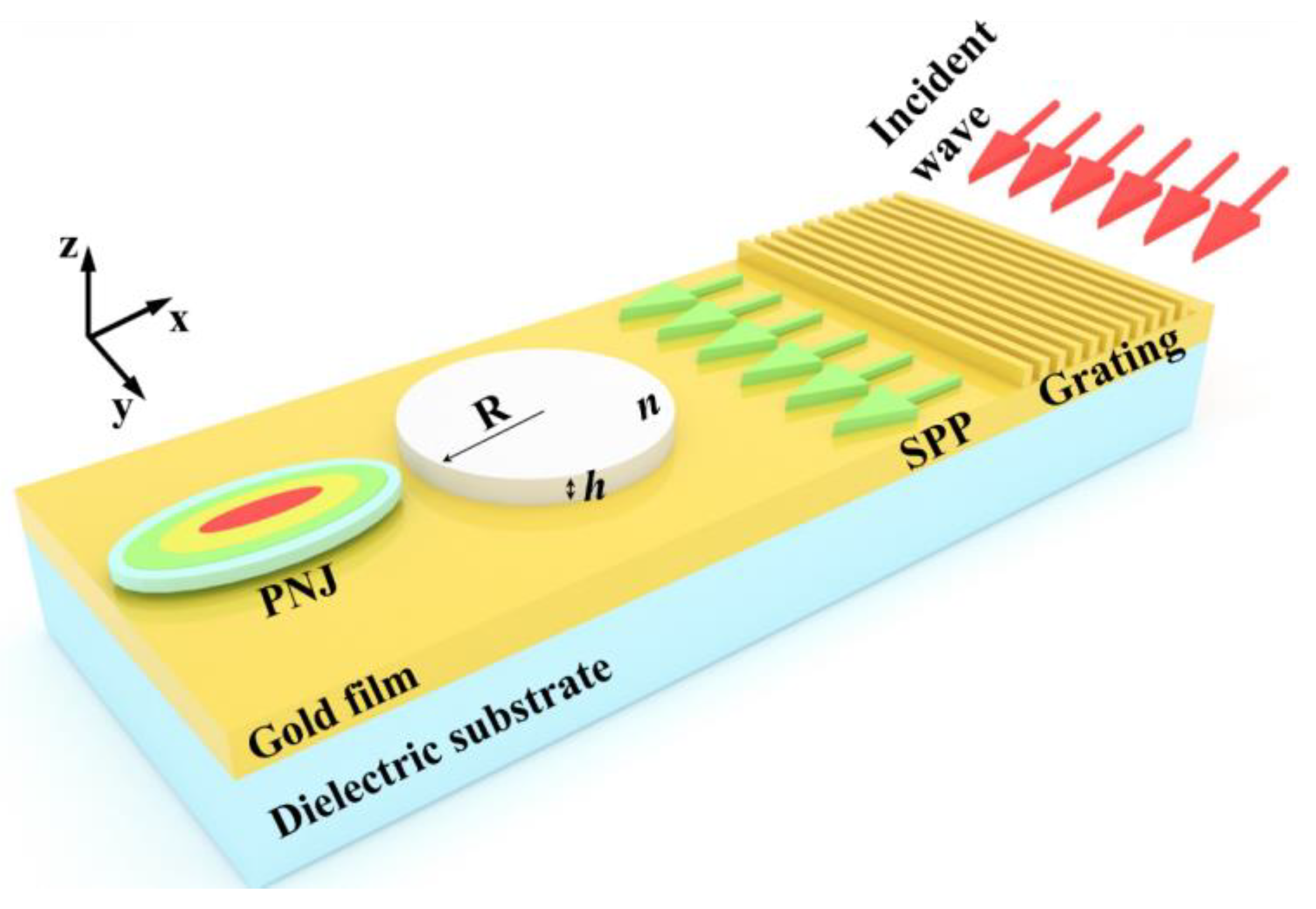

2. Structure of Gold-Film Dielectric Microdisk

3. Simulations

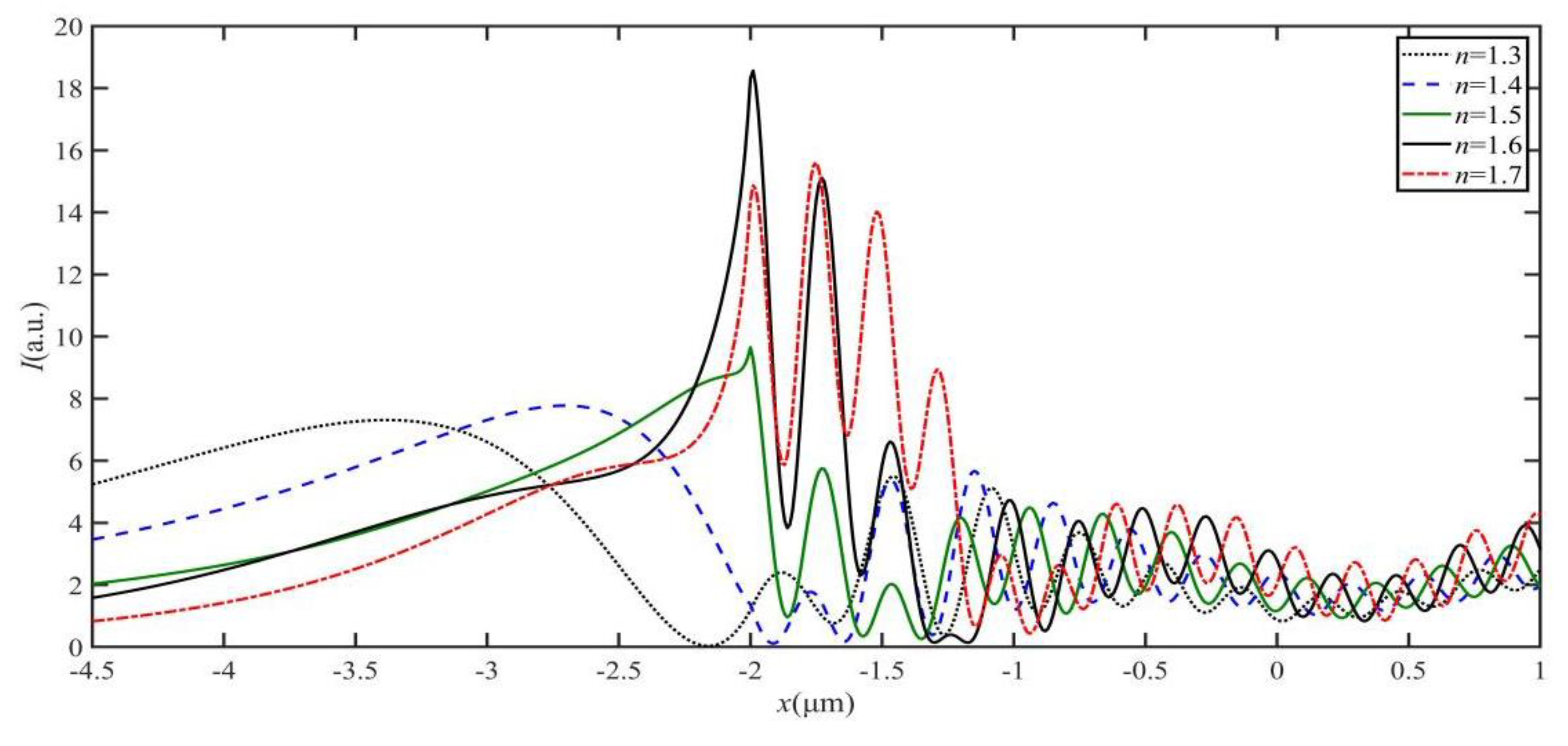

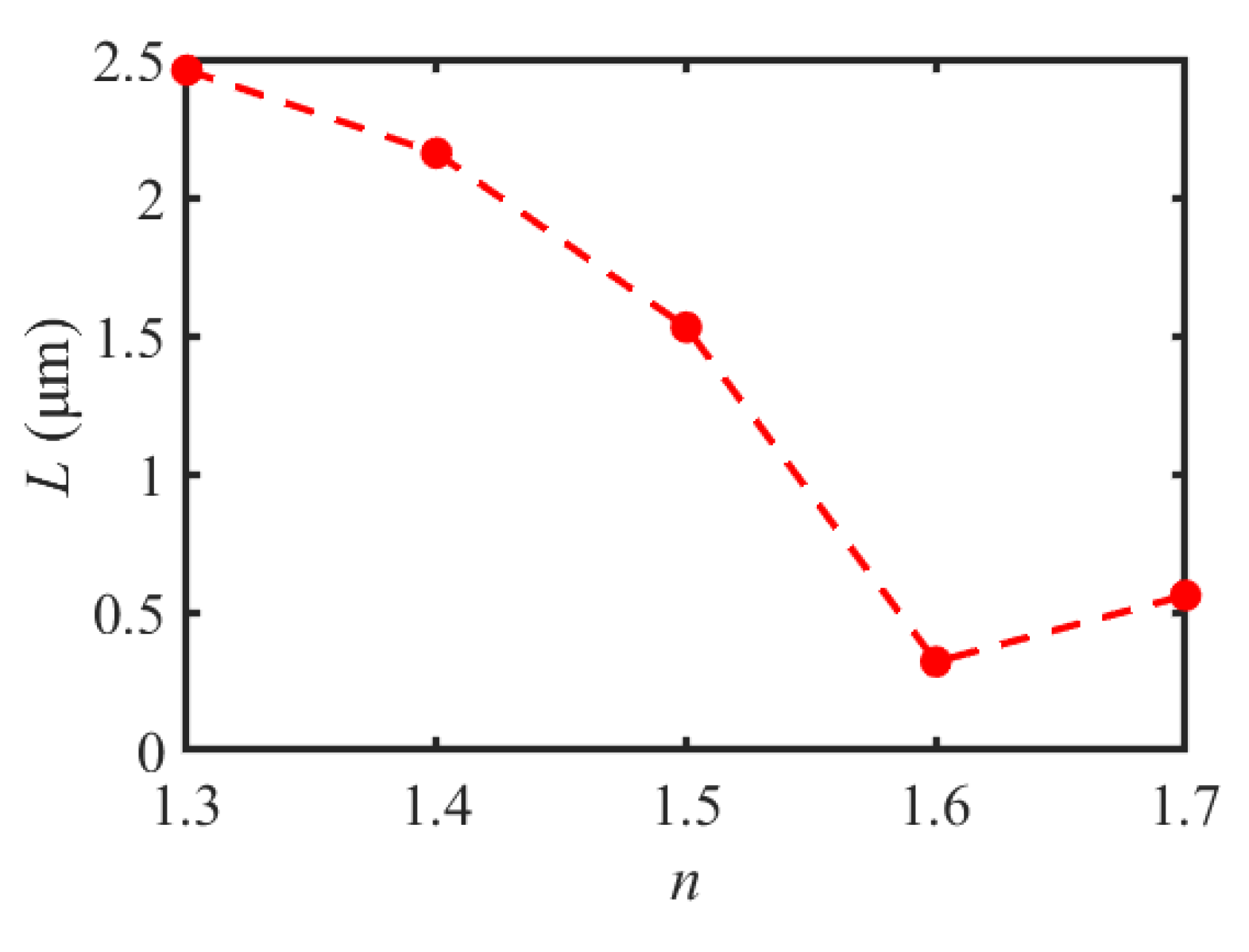

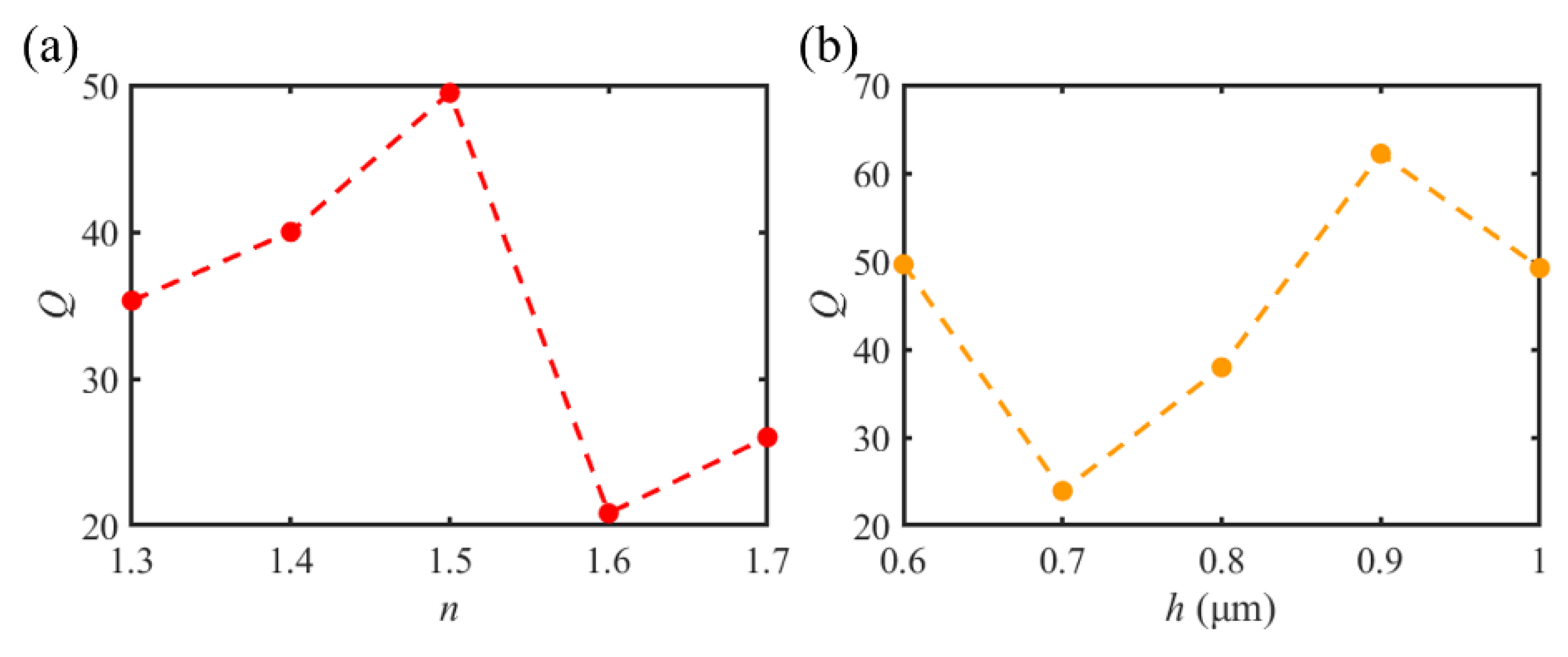

3.1. The Characteristic Parameters of SPP-PNJs with Different Refractive Indices of the Dielectric Microdisk

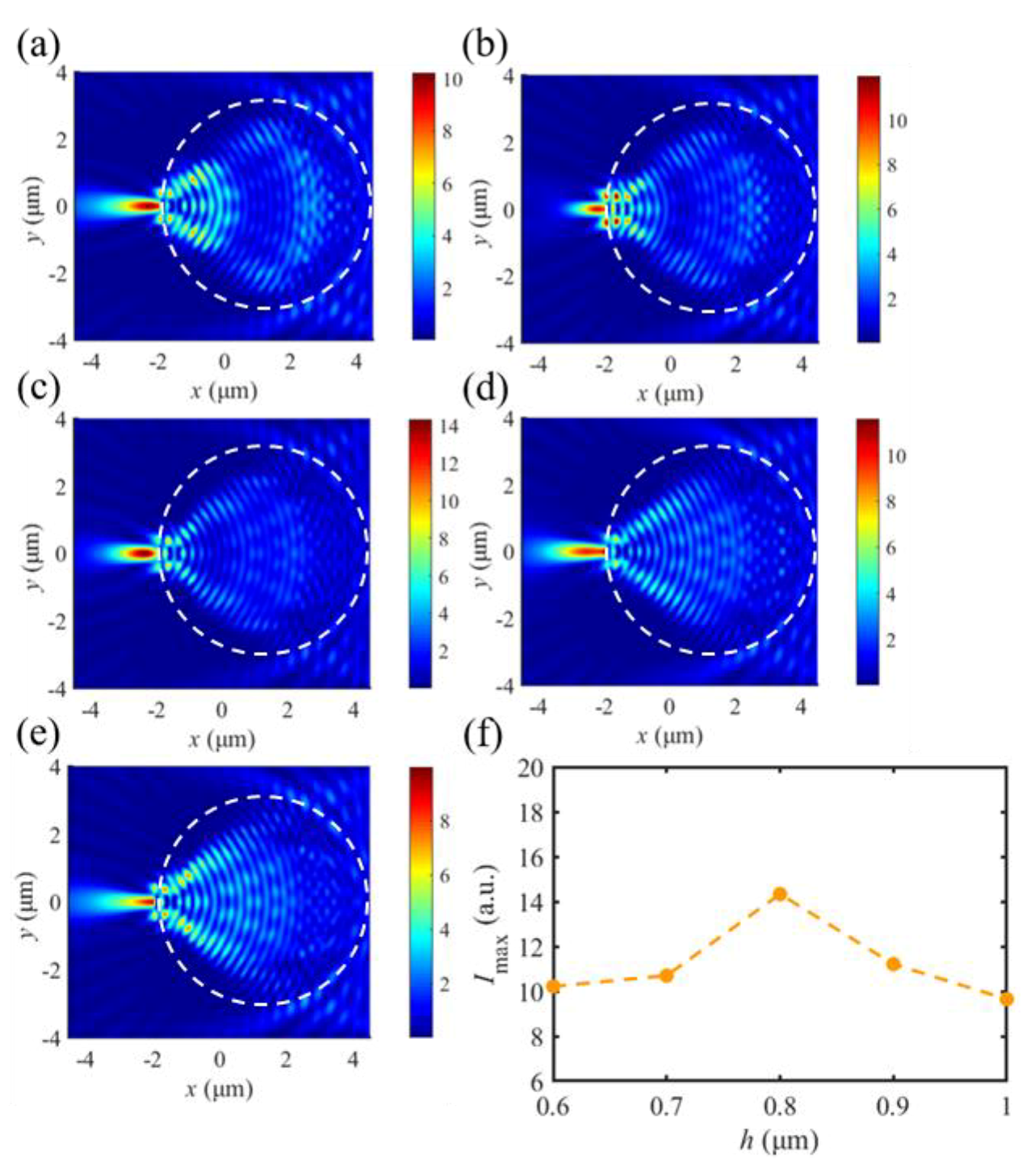

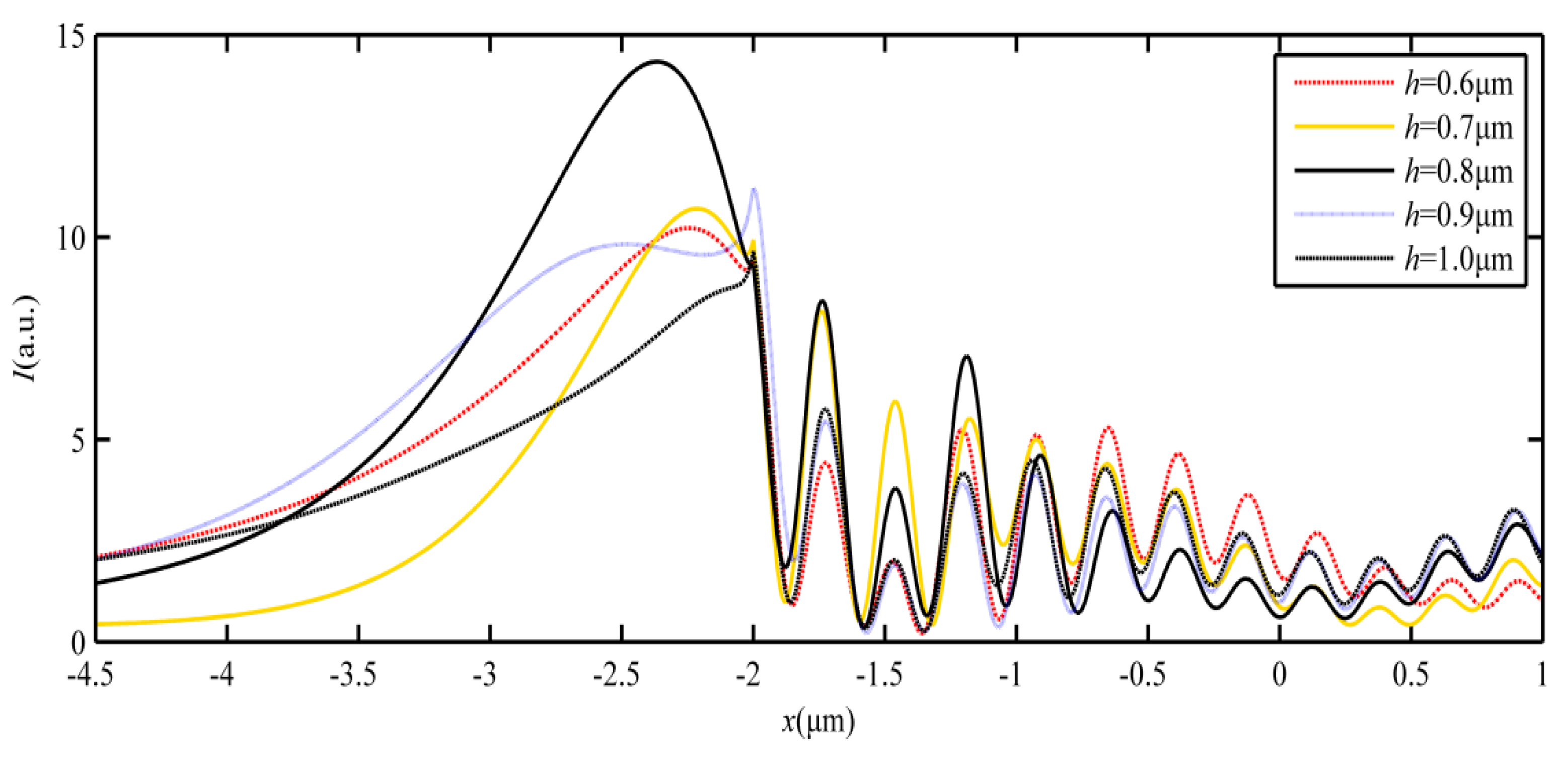

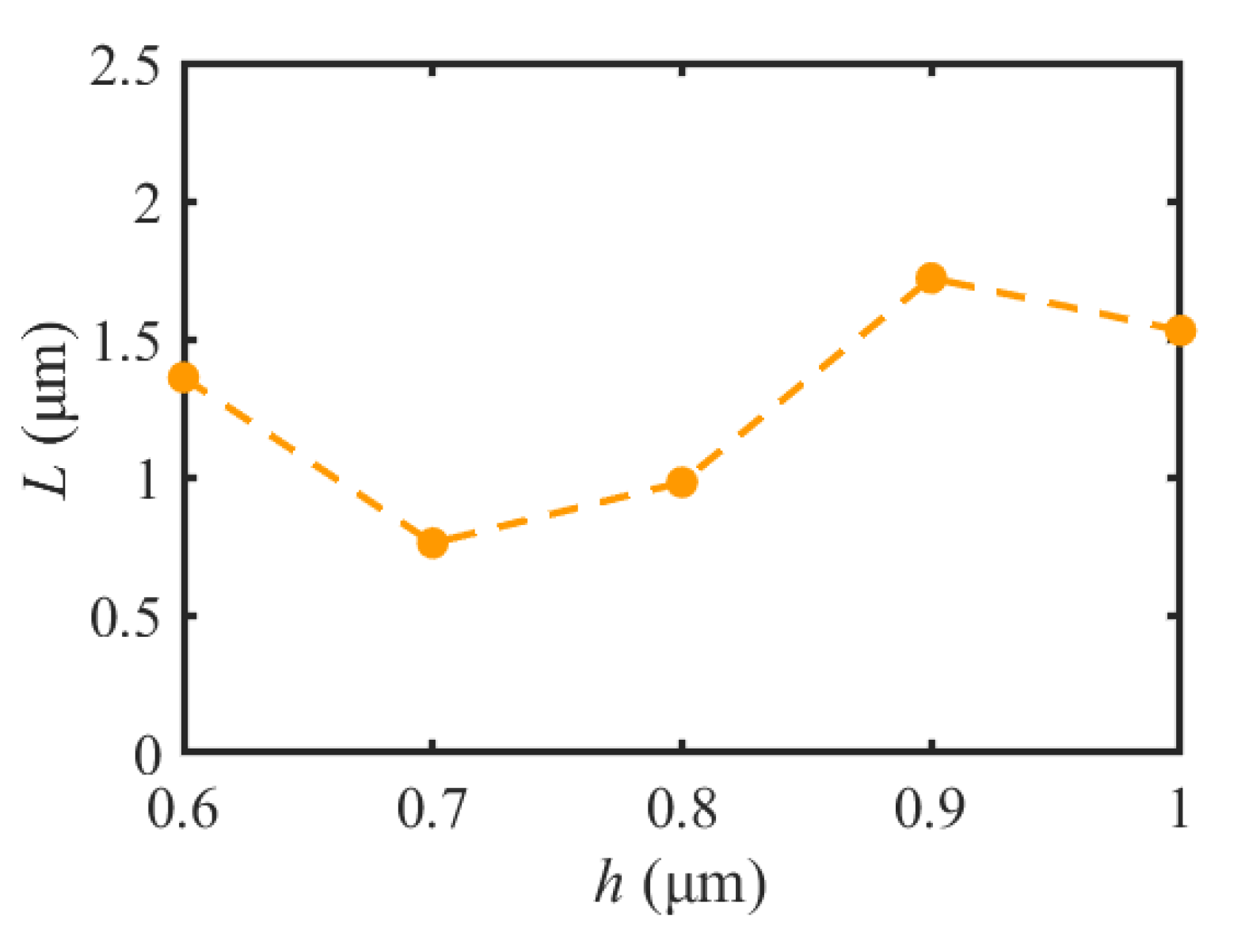

3.2. The Characteristic Parameters of SPP-PNJs with Different Thicknesses of the Dielectric Microdisk

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Darafsheh, A. Photonic nanojets and their applications. J. Phys. Photon. 2021, 3, 022001. [Google Scholar] [CrossRef]

- Benincasa, D.S.; Barber, P.W.; Zhang, J.Z.; Hsieh, W.F.; Chang, R.K. Spatial distribution of the internal and near-field intensities of large cylindrical and spherical scatterers. Appl. Opt. 1987, 26, 1348. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Taflove, A.; Backman, V. Photonic nanojet enhancement of backscattering of light by nanoparticles: A potential novel visible-light ultramicroscopy technique. Opt. Express 2004, 12, 1214–1220. [Google Scholar] [CrossRef]

- Gašparić, V.; Mayerhöfer, T.G.; Zopf, D.; Ristić, D.; Popp, J.; Ivanda, M. To generate a photonic nanojet outside a high refractive index microsphere illuminated by a Gaussian beam. Opt. Lett. 2022, 47, 2534–2537. [Google Scholar] [CrossRef]

- Yang, J.; Twardowski, P.; Gérard, P.; Duo, Y.; Fontaine, J.; Lecler, S. Ultra-narrow photonic nanojets through a glass cuboid embedded in a dielectric cylinder. Opt. Express 2018, 26, 3723–3731. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhen, Z.; Shen, Y.; Min, C.; Veronis, G. Optimization of photonic nanojets generated by multilayer microcylinders with a genetic algorithm. Opt. Express 2019, 27, 1310–1325. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Gao, R.; Wang, Y.; Zhou, S.; Zhang, J. Reflective photonic nanojets generated from cylindrical concave micro-mirrors. Appl. Phys. A 2020, 126, 1–8. [Google Scholar] [CrossRef]

- Wang, Y.J.; Dai, C.A.; Li, J.H. Numerical study of tunable photonic nanojets generated by biocompatible hydrogel core-shell microspheres for surface-enhanced Raman scattering applications. Polymer 2019, 11, 431. [Google Scholar] [CrossRef]

- Zhou, S.; Li, K.; Wang, Y. Tunable photonic nanojets from a micro-cylinder with a dielectric nano-layer. Optik 2021, 225, 165878. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yeh, M.J. Experimental verification of twin photonic nanojets from a dielectric microcylinder. Opt. Lett. 2019, 44, 3262–3265. [Google Scholar] [CrossRef]

- Gu, G.; Zhang, P.; Chen, S.; Zhang, Y.; Yang, H. Inflection point: A perspective on photonic nanojets. Photonics Res. 2021, 9, 1157–1171. [Google Scholar] [CrossRef]

- Poteet, A.; Zhang, X.A.; Nagai, H.; Chang, C.H. Twin photonic nanojets generated from coherent illumination of microscale sphere and cylinder. Nanotechnology 2018, 29, 075204. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, H.; Yang, M.; Xie, Z.; Han, Q.; Gou, J.; Wang, J. Photonic nanojets with ultralong working distance and narrowed beam waist by immersed engineered dielectric hemisphere. Opt. Express 2020, 28, 33959–33970. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.B.; Huang, Z.H.; Liu, C.Y. Formation of high-quality photonic nanojets by decorating spider silk. Opt. Lett. 2019, 44, 667–670. [Google Scholar] [CrossRef] [PubMed]

- Horiuchi, N. Photonic nanojets. Nat. Photon 2012, 6, 138–139. [Google Scholar] [CrossRef]

- Zhu, J.; Goddard, L.L. All-dielectric concentration of electromagnetic fields at the nanoscale: The role of photonic nanojets. Nanoscale Adv. 2019, 1, 4615–4643. [Google Scholar] [CrossRef]

- Patel, H.S.; Kushwaha, P.K.; Swami, M.K. Generation of highly confined photonic nanojet using crescent-shape refractive index profile in microsphere. Opt. Commun. 2018, 415, 140–145. [Google Scholar] [CrossRef]

- Lin, C.B.; Lee, Y.T.; Liu, C.Y. Optimal photonic nanojet beam shaping by mesoscale dielectric dome lens. J. Appl. Phys. 2020, 127, 243110. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, Y.; Yang, G. Intensity of photonic nanojets improved by means of a mirror. Indian J. Phys. 2022, 97, 907–913. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, Y.; Wu, M.; Hong, M. Remote-mode microsphere nano-imaging: New boundaries for optical microscopes. OEA 2018, 1, 01170001. [Google Scholar] [CrossRef]

- Agrawal, T.; Dey, S.; Bisht, P.B. Single nanoparticle sensing and waveguide applications using photonic nanojet from an array of shaped microparticles. Opt. Commun. 2022, 529, 129110. [Google Scholar] [CrossRef]

- Sergeeva, K.A.; Sergeev, A.A.; Minin, O.V.; Minin, I.V. A Closer Look at Photonic Nanojets in Reflection Mode: Control of Standing Wave Modulation. Photonics 2021, 8, 54. [Google Scholar] [CrossRef]

- Alabed, S.; Mahariq, I.; Salman, M.; Kuzuoğlu, M. A novel beamforming emulating photonic nanojets for wireless relay networks. Comput. Mater. Contin. 2021, 69, 575–588. [Google Scholar] [CrossRef]

- Li, H.; Song, W.; Zhao, Y.; Cao, Q.; Wen, A. Optical Trapping, Sensing, and Imaging by Photonic Nanojets. Photonics 2021, 8, 434. [Google Scholar] [CrossRef]

- Surdo, S.; Duocastella, M.; Diaspro, A. Nanopatterning with photonic nanojets: Review and perspectives in biomedical research. Micromachines 2021, 12, 256. [Google Scholar] [CrossRef]

- Al-Jarwany, Q.A.; Mohammed, A.F.; Hamza, A.O.; Bouillard, J.G.; Adawi, A.M.; Pamme, N.; Walton, C.D. Realisation of a sub-wavelength dimple using a 193 nm wavelength photonic nano jet. Chem. Phys. Lett. 2020, 750, 137400. [Google Scholar] [CrossRef]

- Ferrand, P.; Wenger, J.; Devilez, A.; Pianta, M.; Stout, B.; Bonod, N. Direct imaging of photonic nanojets. Opt. Express 2008, 16, 6930–6940. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, L.V.; Shen, J.T. Ultralong photonic nanojet formed by a two-layer dielectric microsphere. Opt. Lett. 2014, 39, 4120. [Google Scholar] [CrossRef]

- Sundaram, V.M.; Wen, S. Nanoscale high-intensity light focusing with pure dielectric nonspherical scatterer. Opt. Lett. 2014, 39, 582–585. [Google Scholar] [CrossRef]

- Gu, G.; Zhou, R.; Chen, Z.; Xu, H.; Cai, G.; Cai, Z.; Hong, M. Super-long photonic nanojet generated from liquid-filled hollow microcylinder. Opt. Lett. 2015, 40, 625. [Google Scholar] [CrossRef]

- Pacheco-Peña, V.; Minin, I.V.; Minin, O.V.; Beruete, M. Increasing Surface Plasmons Propagation via Photonic Nanojets with Periodically Spaced 3D Dielectric Cuboids. Photonics 2016, 3, 10. [Google Scholar] [CrossRef]

- Geints, Y.E.; Zemlyanov, A.A.; Minin, O.V.; Minin, I.V. Systematic study and comparison of photonic nanojets produced by dielectric microparticles in 2D-and 3D-spatial configurations. J. Optics 2018, 20, 065606. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zeng, X.; Pan, S.; Chen, M.; Zeng, Y.; Fu, B.; Wu, P.; Pan, M. Ultrahigh Quality Factor Photonic Nanojets Generated by Truncated Microtoroid Structures. IEEE Photon. J. 2021, 13, 1. [Google Scholar] [CrossRef]

- Xing, Y.; Shu, F.; Xing, H.; Wu, Y. Dynamically tunable ultralong photonic nanojets by a curved surface truncated dielectric microcylinder. Jpn. J. Appl. Phys. 2022, 61, 022002. [Google Scholar] [CrossRef]

- McCloskey, D.; Wang, J.J.; Donegan, J.F. Low divergence photonic nanojets from Si 3 N 4 microdisks. Opt. Express 2012, 20, 128–140. [Google Scholar] [CrossRef] [PubMed]

- Taflove, A. Advances in Computational Electrodynamics: The Finite-Difference Time-Domain Method; Artech House Inc.: Norwood, MA, USA, 1998; p. 4. [Google Scholar]

- Kong, S.C.; Taflove, A.; Backman, V. Quasi one-dimensional light beam generated by a graded-index microsphere. Opt. Express 2009, 17, 3722–3731. [Google Scholar] [CrossRef] [PubMed]

| N | Imax (a.u.) | F (μm) | L (μm) | Q |

|---|---|---|---|---|

| 1.3 | 7.04 | 0.49 (0.61 λ) | 2.46 (3.08 λ) | 35.31 |

| 1.4 | 7.53 | 0.41 (0.51 λ) | 2.16 (2.69 λ) | 40.00 |

| 1.5 | 9.65 | 0.30 (0.37 λ) | 1.53 (1.91 λ) | 49.47 |

| 1.6 | 18.32 | 0.28 (0.35 λ) | 0.32 (0.40 λ) | 20.83 |

| 1.7 | 14.38 | 0.31 (0.38 λ) | 0.56 (0.70 λ) | 26.01 |

| h (μm) | Imax (a.u.) | F (μm) | L (μm) | Q |

|---|---|---|---|---|

| 0.6 | 10.22 | 0.28 (0.35 λ) | 1.36 (1.70 λ) | 49.64 |

| 0.7 | 10.70 | 0.34 (0.43 λ) | 0.76 (0.95 λ) | 23.92 |

| 0.8 | 14.33 | 0.37 (0.46 λ) | 0.98 (1.23 λ) | 37.96 |

| 0.9 | 11.21 | 0.31 (0.39 λ) | 1.72 (2.15 λ) | 62.20 |

| 1.0 | 9.65 | 0.30 (0.38 λ) | 1.53 (1.91 λ) | 49.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, X.; Su, N.; Zhang, W.; Ye, Z.; Wu, P.; Liu, B. Generation of Photonic Nanojet Using Gold Film Dielectric Microdisk Structure. Materials 2023, 16, 3146. https://doi.org/10.3390/ma16083146

Zeng X, Su N, Zhang W, Ye Z, Wu P, Liu B. Generation of Photonic Nanojet Using Gold Film Dielectric Microdisk Structure. Materials. 2023; 16(8):3146. https://doi.org/10.3390/ma16083146

Chicago/Turabian StyleZeng, Xintao, Ning Su, Weiming Zhang, Zhibin Ye, Pinghui Wu, and Bin Liu. 2023. "Generation of Photonic Nanojet Using Gold Film Dielectric Microdisk Structure" Materials 16, no. 8: 3146. https://doi.org/10.3390/ma16083146