Numerical Prediction of Microstructure Evolution of Small-Diameter Stainless Steel Balls during Cold Skew Rolling

Abstract

:1. Introduction

2. Development of a Mechanism-Based Constitutive Model of 316L under Cold Deformation

2.1. Establishment of Multiscale Constitutive Equations

2.2. Solution of Model Parameters

3. Validation of Numerical Simulation of Cold Skew Rolling

3.1. FE Modeling

3.2. Experiment Detail

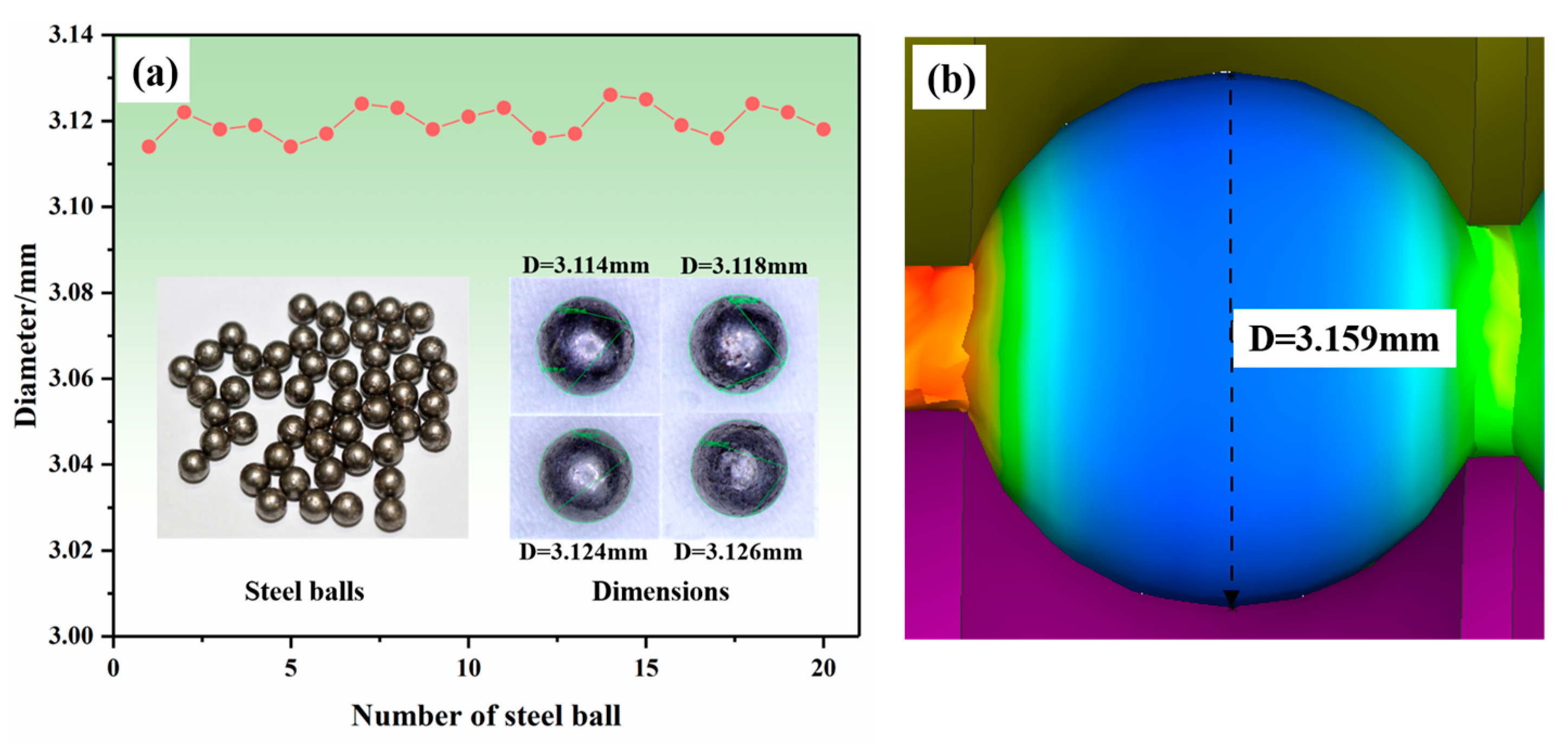

3.3. Comparison of Steel Ball Diameter

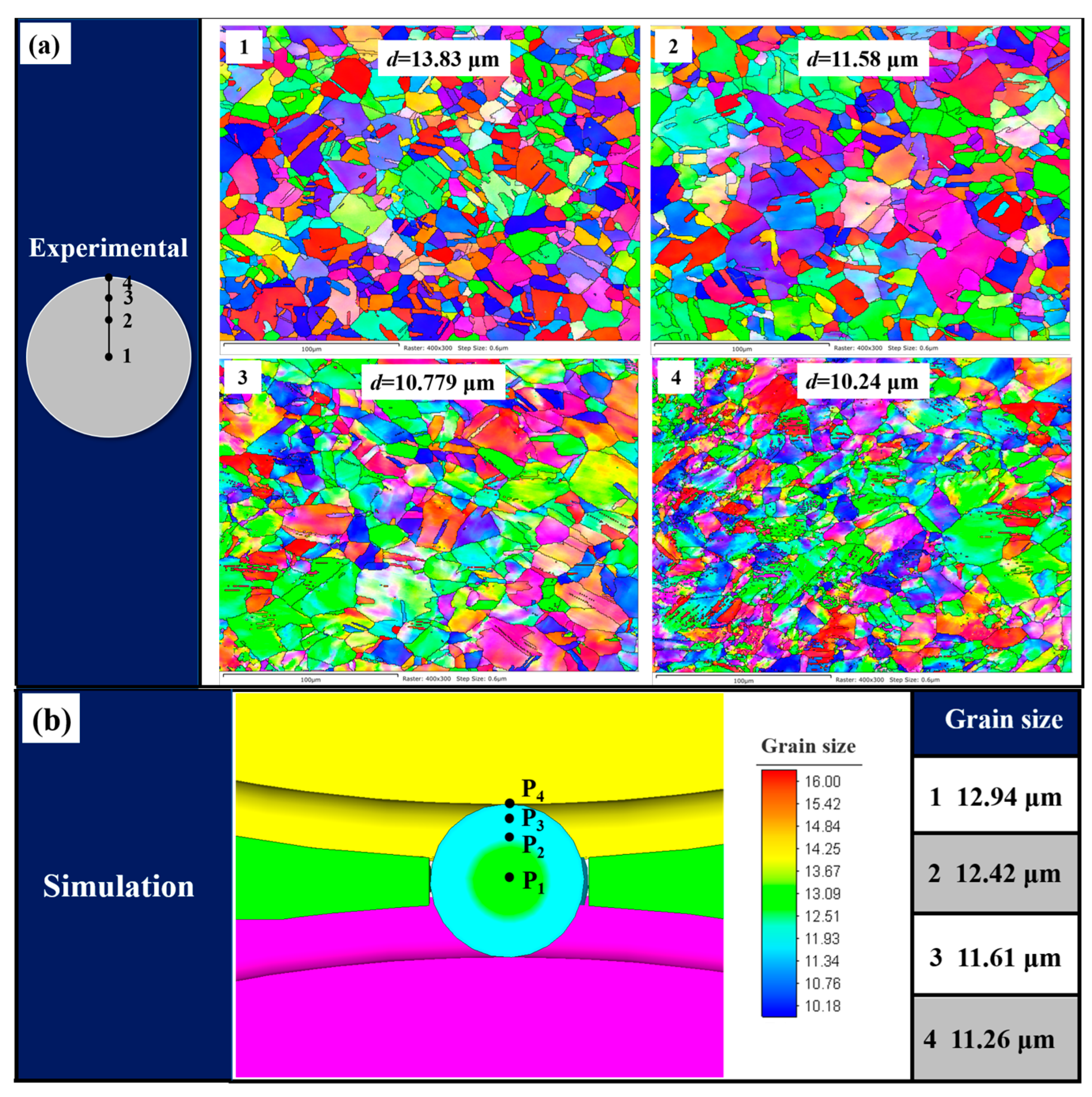

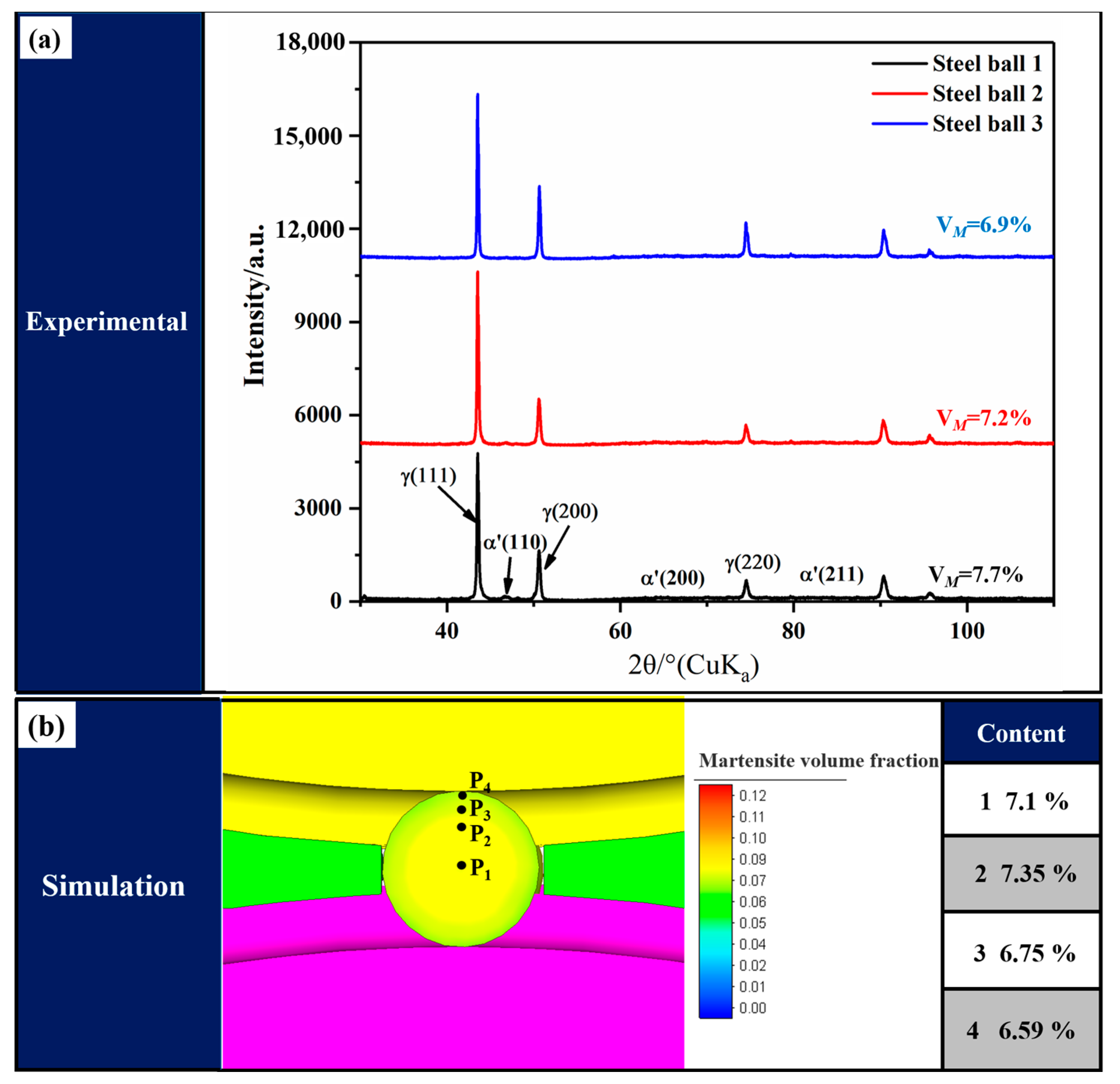

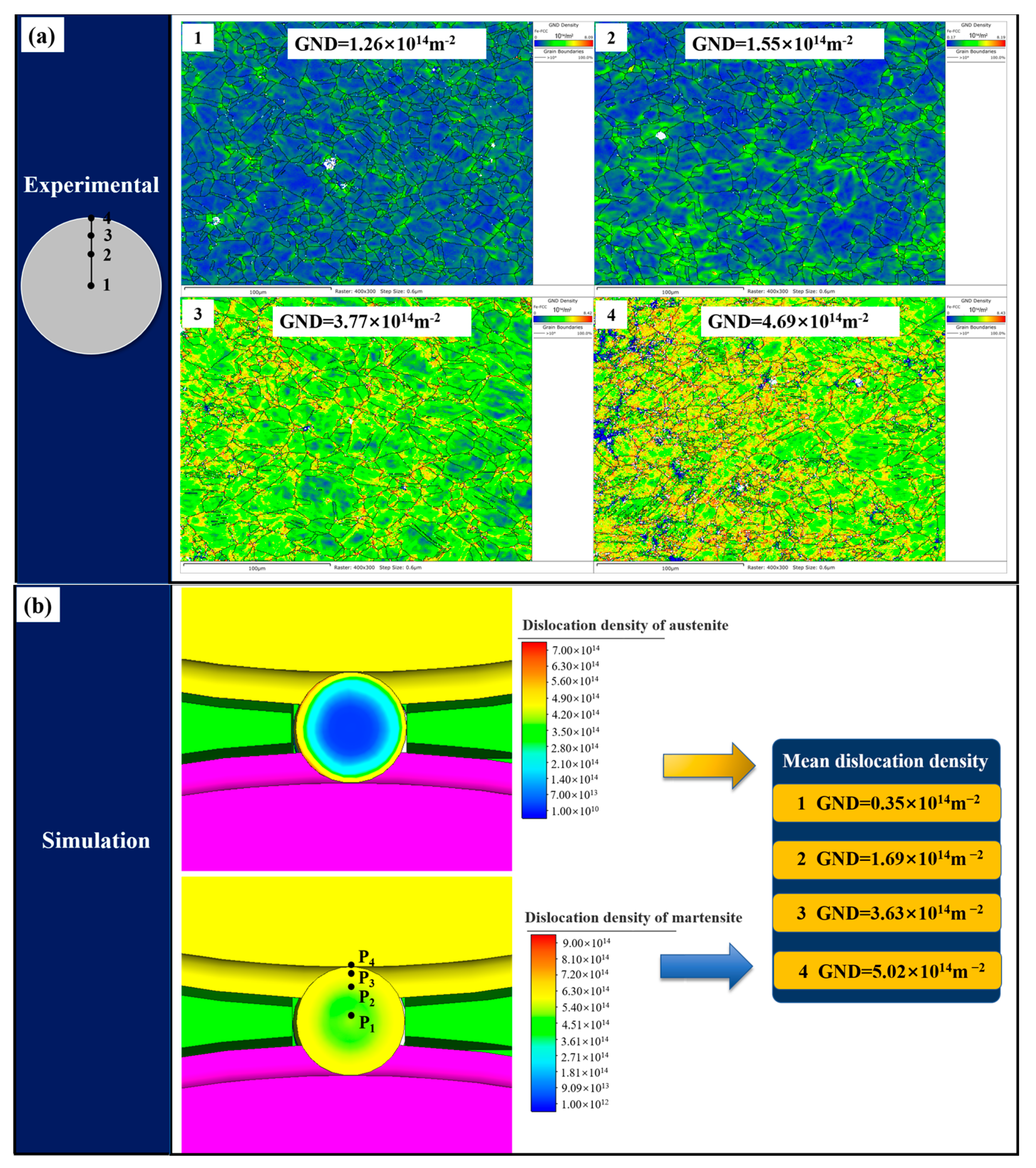

3.4. Comparison of Steel Ball Microstructure

4. Numerical Simulation Analysis of the Skew Rolling Process

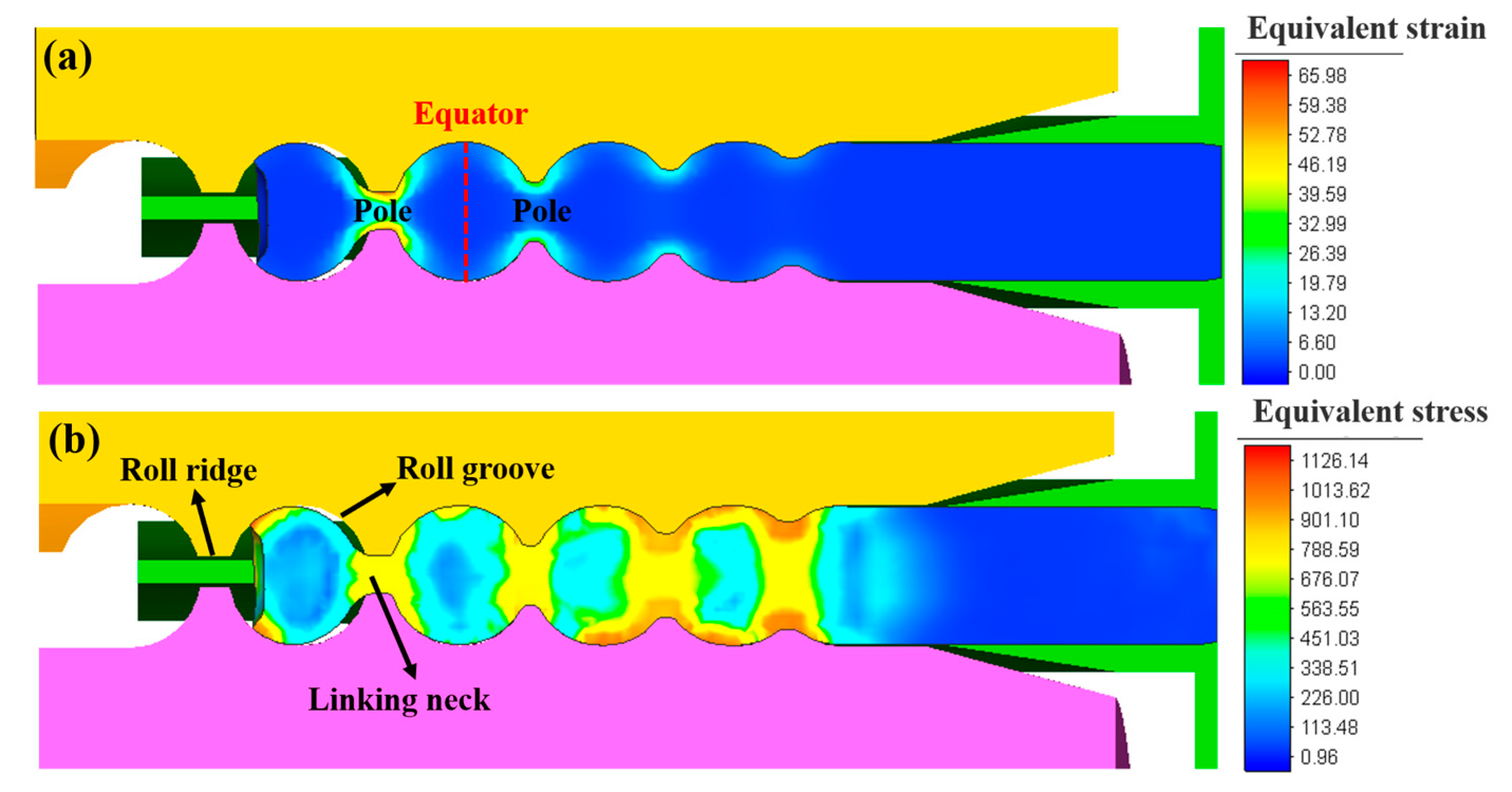

4.1. Equivalent Strain and Stress of Small-Diameter Steel Balls

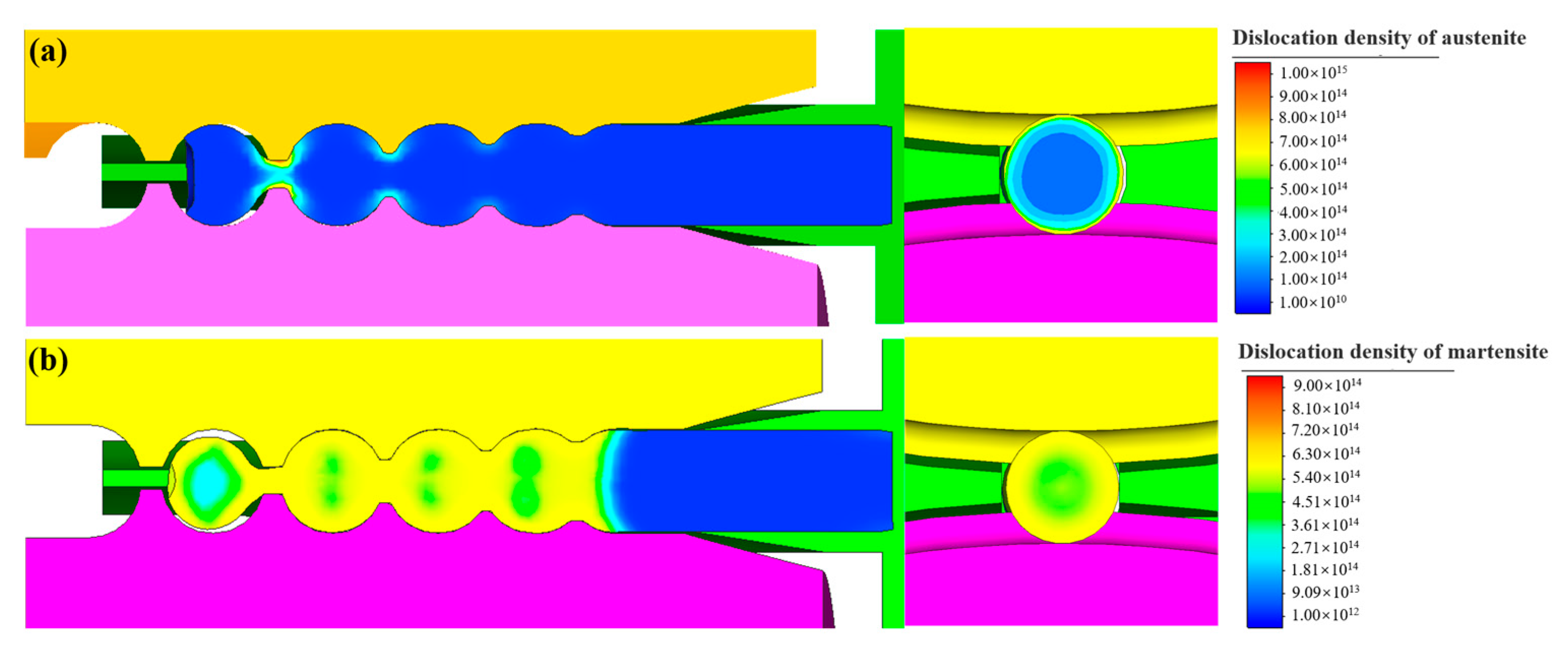

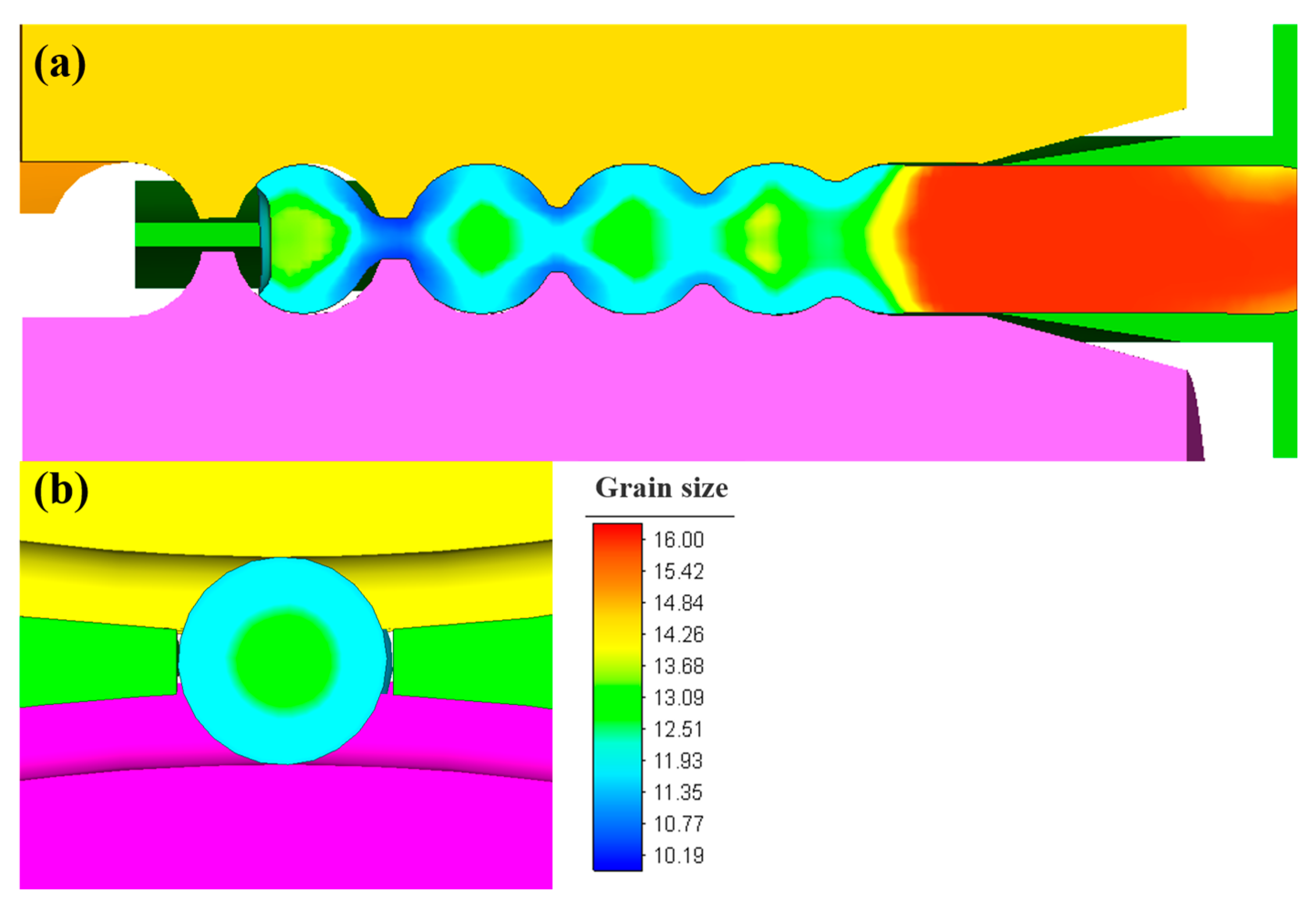

4.2. Microstructure of Small-Diameter Stainless Steel Balls

5. Conclusions

- Based on the mixing rule, a multiscale constitutive model of 316L SS was established by coupling martensitic transformation and grain refinement. By embedding the developed model into the FE software Simufact 16.0, a numerical simulation model of the cold skew rolling process of small-diameter 316L SS steel balls was developed.

- The simulation results were compared with the experimental results to verify the reliability of the established simulation model. It is found that the diameter size, dislocation density, grain size, and martensite content of the steel balls are in good agreement, which proves the prediction capability of the established model.

- The dislocation density in the large deformation of the steel balls is high. Consequently, the grain size in there is relatively small, which was determined through the analysis of the numerical simulation of microstructure evolution. Observing from the transverse section of the steel ball, the martensite content exhibited a slight difference between the areas in the surface and core. The martensite content in the longitudinal section of the steel ball was uniformly distributed in each region.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kheiri, S.; Mirzadeh, H.; Naghizadeh, M. Tailoring the Microstructure and Mechanical Properties of AISI 316L Austenitic Stainless Steel Via Cold Rolling and Reversion Annealing. Mater. Sci. Eng. A 2019, 759, 90–96. [Google Scholar] [CrossRef]

- Pater, Z.; Tomczak, J.; Bartnicki, J.; Lovell, M.R.; Menezes, P.L. Experimental and Numerical Analysis of Helical-Wedge Rolling Process for Producing Steel Balls. Int. J. Mach. Tools Manuf. 2013, 67, 1–7. [Google Scholar] [CrossRef]

- Gontarz, A.; Tomczak, J.; Pater, Z.; Bulzak, T. Effect of the Forming Zone Length on Helical Rolling Processes for Manufacturing Steel Balls. Materials 2019, 12, 2917. [Google Scholar] [CrossRef]

- Tomczak, J.; Pater, Z.; Bulzak, T. Designing of Screw Impressions in the Helical Rolling of Balls. Arch. Civ. Mech. Eng. 2014, 14, 104–113. [Google Scholar] [CrossRef]

- Liu, S.; Liu, J.; Xu, H.; Wang, Z.; Shen, J.; Wang, B. Experimental and Numerical Study of Cold Helical Rolling of Small-Diameter Steel Balls. Int. J. Adv. Manuf. Technol. 2022, 119, 599–613. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, H.; Wang, Y.; Wang, S.; Li, R.; Li, S.; Wang, Y. Deformation-Induced Martensitic Transformation Kinetics and Correlative Micromechanical Behavior of medium-Mn Transformation-Induced Plasticity Steel. J. Mater. Sci. Technol. 2019, 35, 1779–1786. [Google Scholar] [CrossRef]

- Xiong, Y.; Yue, Y.; Lu, Y.; He, T.; Fan, M.; Ren, F.; Cao, W. Cryorolling Impacts on Microstructure and Mechanical Properties of AISI 316 LN Austenitic Stainless Steel. Mater. Sci. Eng. A 2018, 709, 270–276. [Google Scholar] [CrossRef]

- Eskandari, M.; Najafizadeh, A.; Kermanpur, A. Effect of Strain-Induced Martensite on the Formation of Nanocrystalline 316L Stainless Steel After Cold Rolling and Annealing. Mater. Sci. Eng. A 2009, 519, 46–50. [Google Scholar] [CrossRef]

- Huo, Y.; He, T.; Wang, B.; Zheng, Z.; Xue, Y. Numerical Prediction and Experimental Validation of the Microstructure of Bearing Steel Ball Formation in Warm Skew Rolling. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 1254–1263. [Google Scholar] [CrossRef]

- Peng, L.; Xu, Z.; Gao, Z.; Fu, M.W. A Constitutive Model for Metal Plastic Deformation at Micro/Meso Scale with Consideration of Grain Orientation and its Evolution. Int. J. Mech. Sci. 2018, 138–139, 74–85. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, Z.; Panicaud, B. Constitutive Modeling of TWIP/TRIP Steels and Numerical Simulation of Single Impact During Surface Mechanical Attrition Treatment. Mech. Mater. 2018, 122, 69–75. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Wan, M.; Meng, B. Multiscale Modeling of Coupling Mechanisms in Electrically Assisted Deformation of Ultrathin Sheets: An Example on a Nickel-Based Superalloy. Int. J. Mach. Tools Manuf. 2021, 162, 103689. [Google Scholar] [CrossRef]

- Meng, B.; Liu, Y.Z.; Wan, M.; Fu, M.W. A Multiscale Constitutive Model Coupled with Martensitic Transformation Kinetics for Micro-Scaled Plastic Deformation of Metastable Metal Foils. Int. J. Mech. Sci. 2021, 202–203, 106503. [Google Scholar] [CrossRef]

- Tang, X.; Wang, B.; Huo, Y.; Ma, W.; Zhou, J.; Ji, H.; Fu, X. Unified Modeling of Flow Behavior and Microstructure Evolution in Hot Forming of a Ni-based Superalloy. Mater. Sci. Eng. A 2016, 662, 54–64. [Google Scholar] [CrossRef]

- Benzing, J.T.; Liu, Y.; Zhang, X.; Luecke, W.E.; Ponge, D.; Dutta, A.; Oskay, C.; Raabe, D.; Wittig, J.E. Experimental and Numerical Study of Mechanical Properties of Multi-Phase medium-Mn TWIP-TRIP Steel: Influences of Strain Rate and Phase Constituents. Acta Mater. 2019, 177, 250–265. [Google Scholar] [CrossRef] [PubMed]

- Wong, S.L.; Madivala, M.; Prahl, U.; Roters, F.; Raabe, D. A Crystal Plasticity Model for Twinning- and Transformation-Induced Plasticity. Acta Mater. 2016, 118, 140–151. [Google Scholar] [CrossRef]

- Srivastava, A.; Ghassemi-Armaki, H.; Sung, H.; Chen, P.; Kumar, S.; Bower, A.F. Micromechanics of Plastic Deformation and Phase Transformation in a Three-Phase TRIP-assisted Advanced High Strength Steel: Experiments and Modeling. J. Mech. Phys. Solids 2015, 78, 46–69. [Google Scholar] [CrossRef]

- Liu, S.; Li, W.; Shen, J.; Yang, X.; Wang, B.; Liu, J. Size-Dependent Constitutive Model Incorporating Grain Refinement and Martensitic Transformation. Arch. Civ. Mech. Eng. 2023, 23, 38. [Google Scholar] [CrossRef]

- Cao, Q.; Hua, L.; Qian, D. Finite Element Analysis of Deformation Characteristics in Cold Helical Rolling of Bearing Steel-Balls. J. Cent. South Univ. 2015, 22, 1175–1183. [Google Scholar] [CrossRef]

- Shen, Y.F.; Li, X.X.; Sun, X.; Wang, Y.D.; Zuo, L. Twinning and Martensite in a 304 Austenitic Stainless Steel. Mater. Sci. Eng. A 2012, 552, 514–522. [Google Scholar] [CrossRef]

- Naghizadeh, M.; Mirzadeh, H. Effects of Grain Size on Mechanical Properties and Work—Hardening Behavior of AISI 304 Austenitic Stainless Steel. Steel Res. Int. 2019, 90, 1900153. [Google Scholar] [CrossRef]

- Yeddu, H.K. Phase-Field Modeling of Austenite Grain Size Effect on Martensitic Transformation in Stainless Steels. Comp. Mater. Sci. 2018, 154, 75–83. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| (MPa) | 1.0000 ×101 | (MPa) | 7.0746 × 102 |

| (MPa·μm1/2) | 6.5222 × 102 | (MPa·μm1/2) | 1.1347 × 102 |

| 1.0515 × 10−1 | 4.1500 × 101 | ||

| 2.1464 × 10−6 | 3.1500 × 1017 | ||

| 3.9676 × 101 | 1.5088 × 10−1 | ||

| 1.5520 × 103 | 4.1151 × 10−1 | ||

| m | 2.4255 × 102 | K | 1.0000 × 105 |

| 1.1090 × 10−1 | 4.0200 × 10−1 | ||

| 7.7166 × 106 | (nm) | 1.4700 × 10−1 | |

| (MPa) | 6.8790 × 102 | 3.06 × 100 | |

| (nm) | 2.5600 × 10−1 | (MPa) | 7.5000 × 104 |

| (μm) | 1.1000 × 100 | (MPa) | 8.0000 × 104 |

| C | Mn | Si | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|

| 0.03 | 1.74 | 0.27 | 16.82 | 10.26 | 2.08 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Liu, S.; Wang, B.; Xu, H. Numerical Prediction of Microstructure Evolution of Small-Diameter Stainless Steel Balls during Cold Skew Rolling. Materials 2023, 16, 3246. https://doi.org/10.3390/ma16083246

Zhou J, Liu S, Wang B, Xu H. Numerical Prediction of Microstructure Evolution of Small-Diameter Stainless Steel Balls during Cold Skew Rolling. Materials. 2023; 16(8):3246. https://doi.org/10.3390/ma16083246

Chicago/Turabian StyleZhou, Jing, Shengqiang Liu, Baoyu Wang, and Hao Xu. 2023. "Numerical Prediction of Microstructure Evolution of Small-Diameter Stainless Steel Balls during Cold Skew Rolling" Materials 16, no. 8: 3246. https://doi.org/10.3390/ma16083246

APA StyleZhou, J., Liu, S., Wang, B., & Xu, H. (2023). Numerical Prediction of Microstructure Evolution of Small-Diameter Stainless Steel Balls during Cold Skew Rolling. Materials, 16(8), 3246. https://doi.org/10.3390/ma16083246