Fatigue Properties of Spring Steels after Advanced Processing

Abstract

:1. Introduction

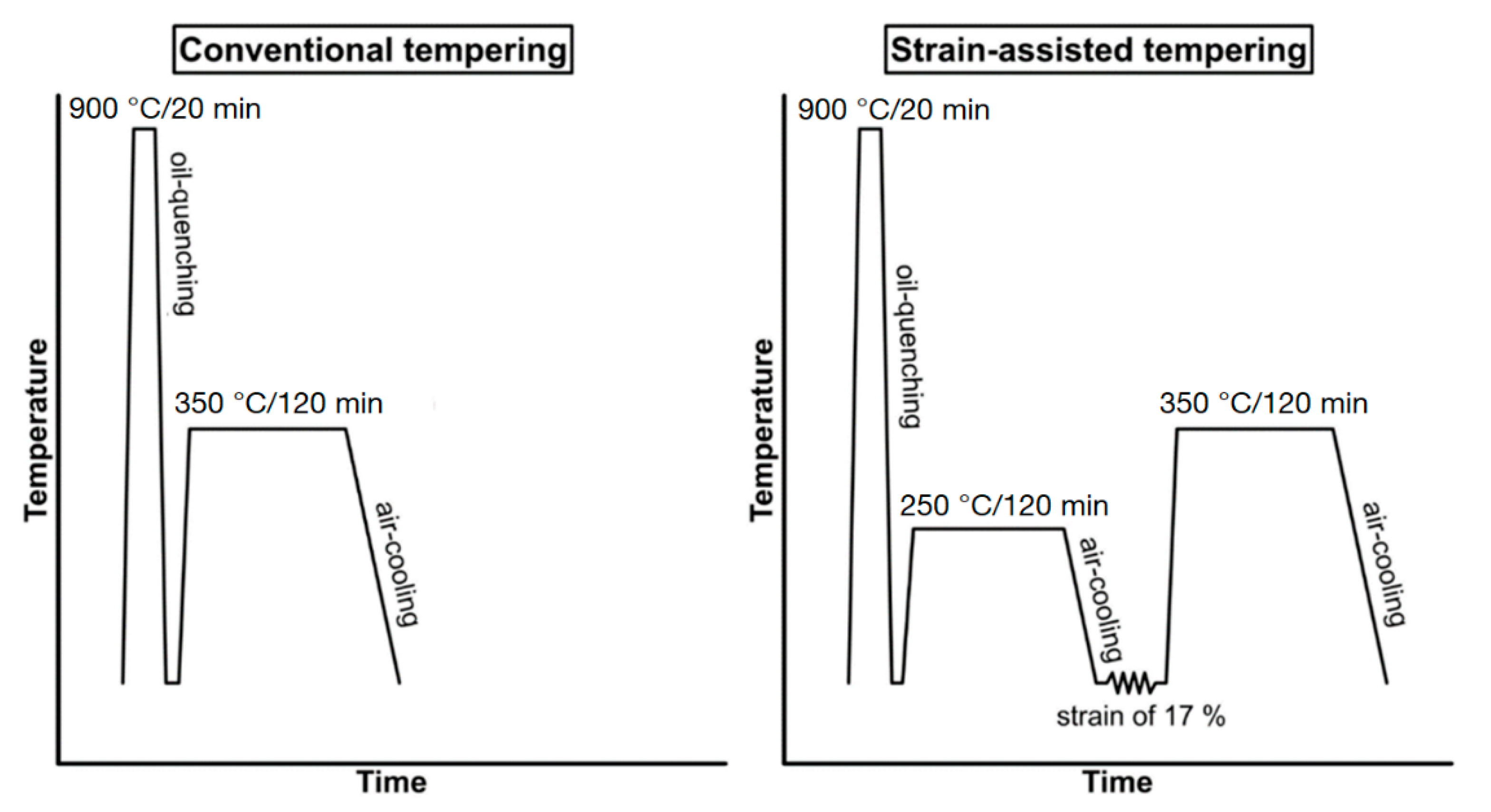

2. Materials and Methods

- N is the number of cycles to failure;

- A is constant parameter;

- B is slope parameter;

- σa is stress amplitude during the fatigue test.

3. Results

3.1. Microstructural Observation

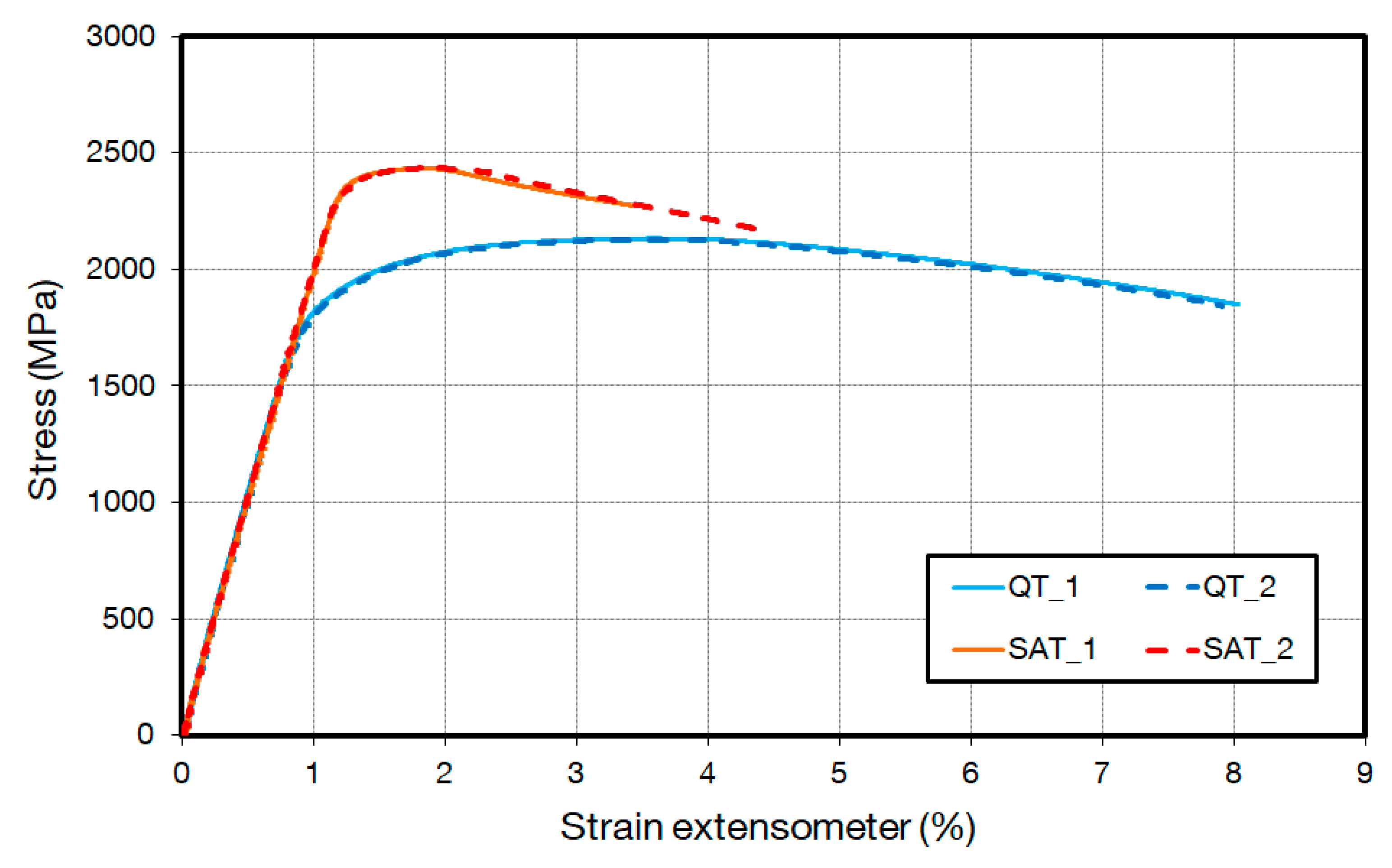

3.2. Basic Mechanical Properties

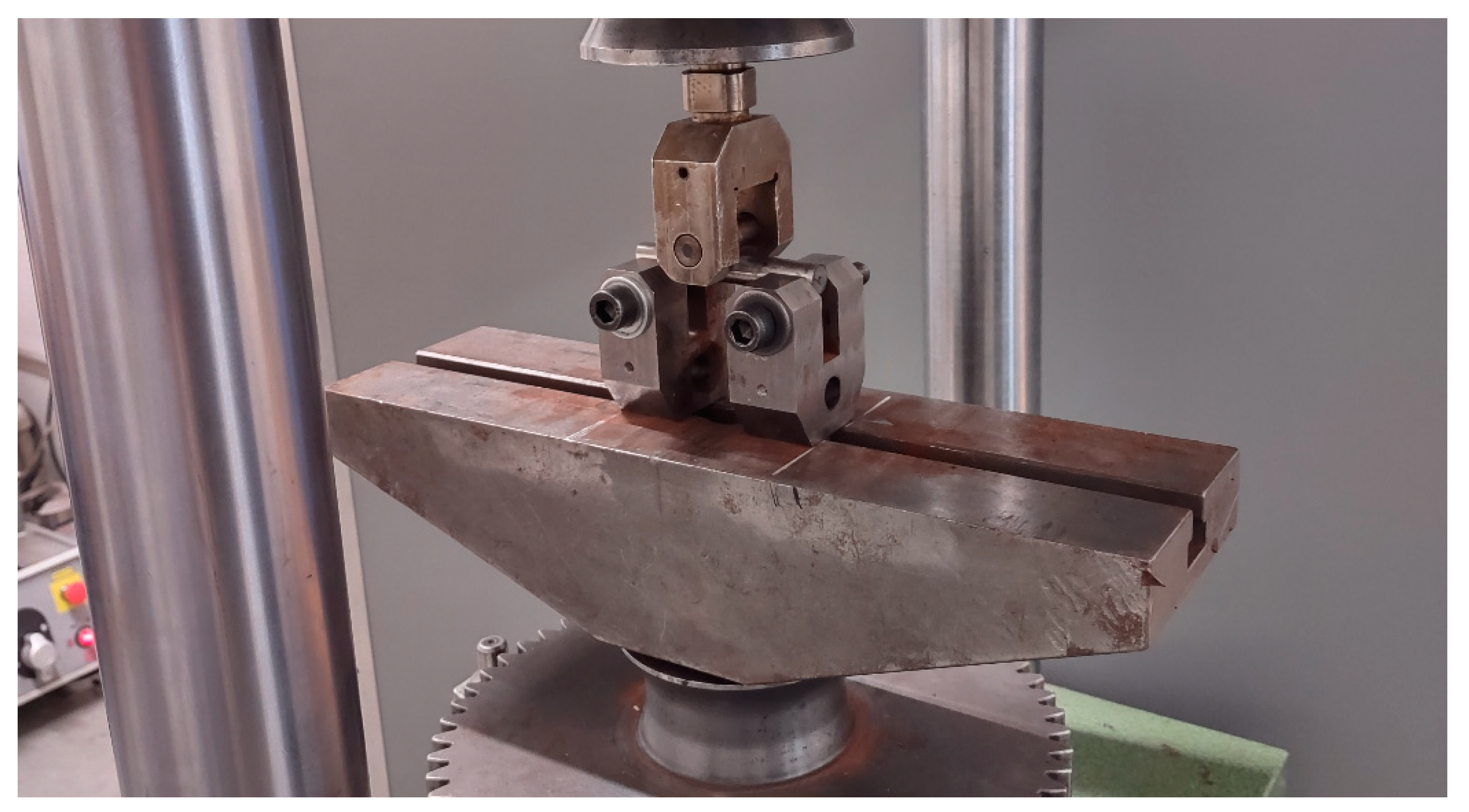

3.3. Feasibility of Using Spring Wire for Coil Spring Applications

3.4. Laser Shock Peening

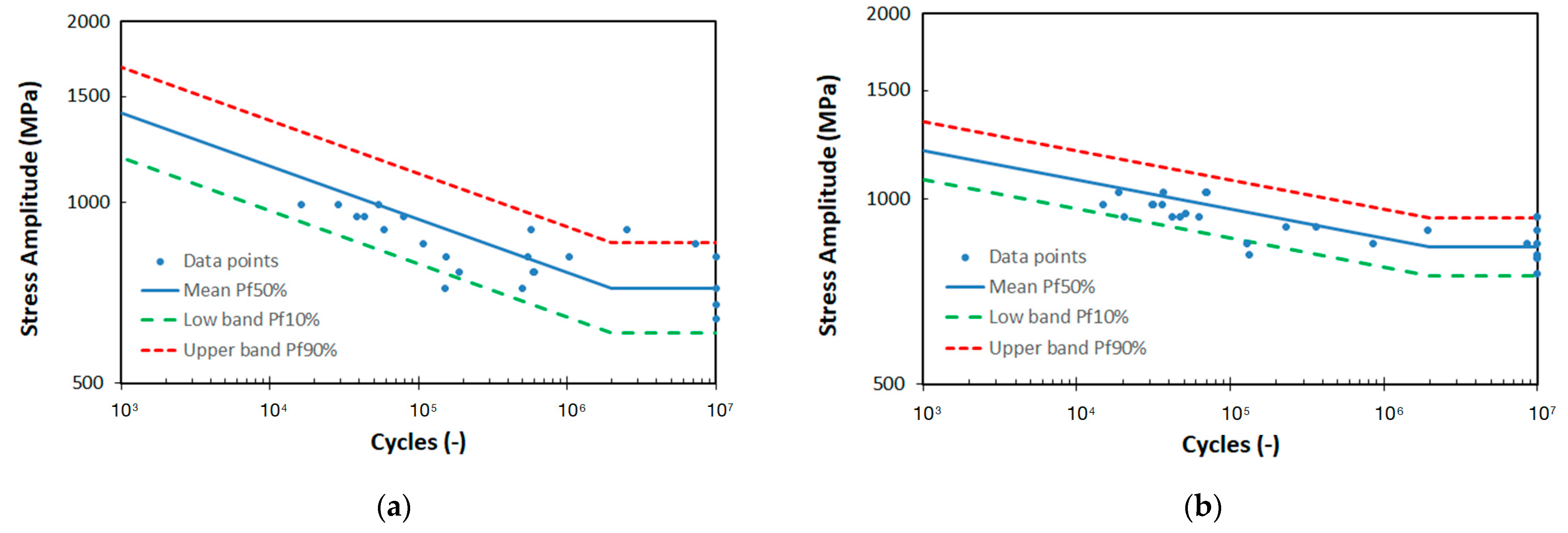

3.5. Advanced Mechanical Properties

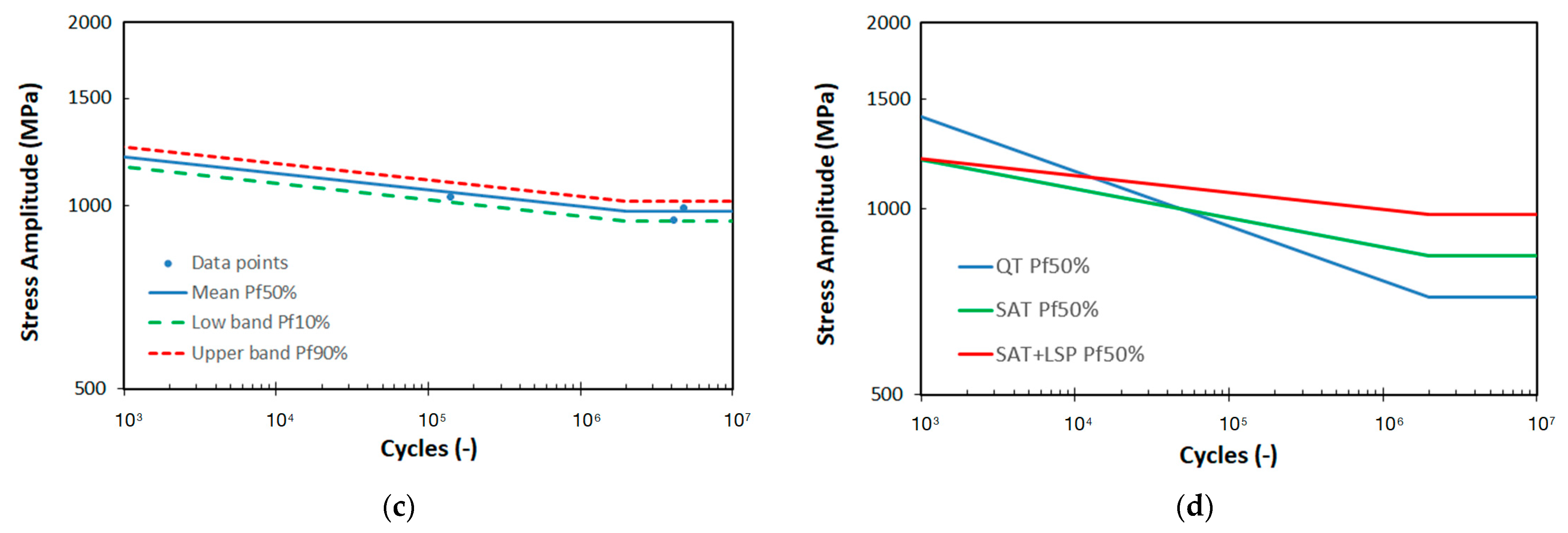

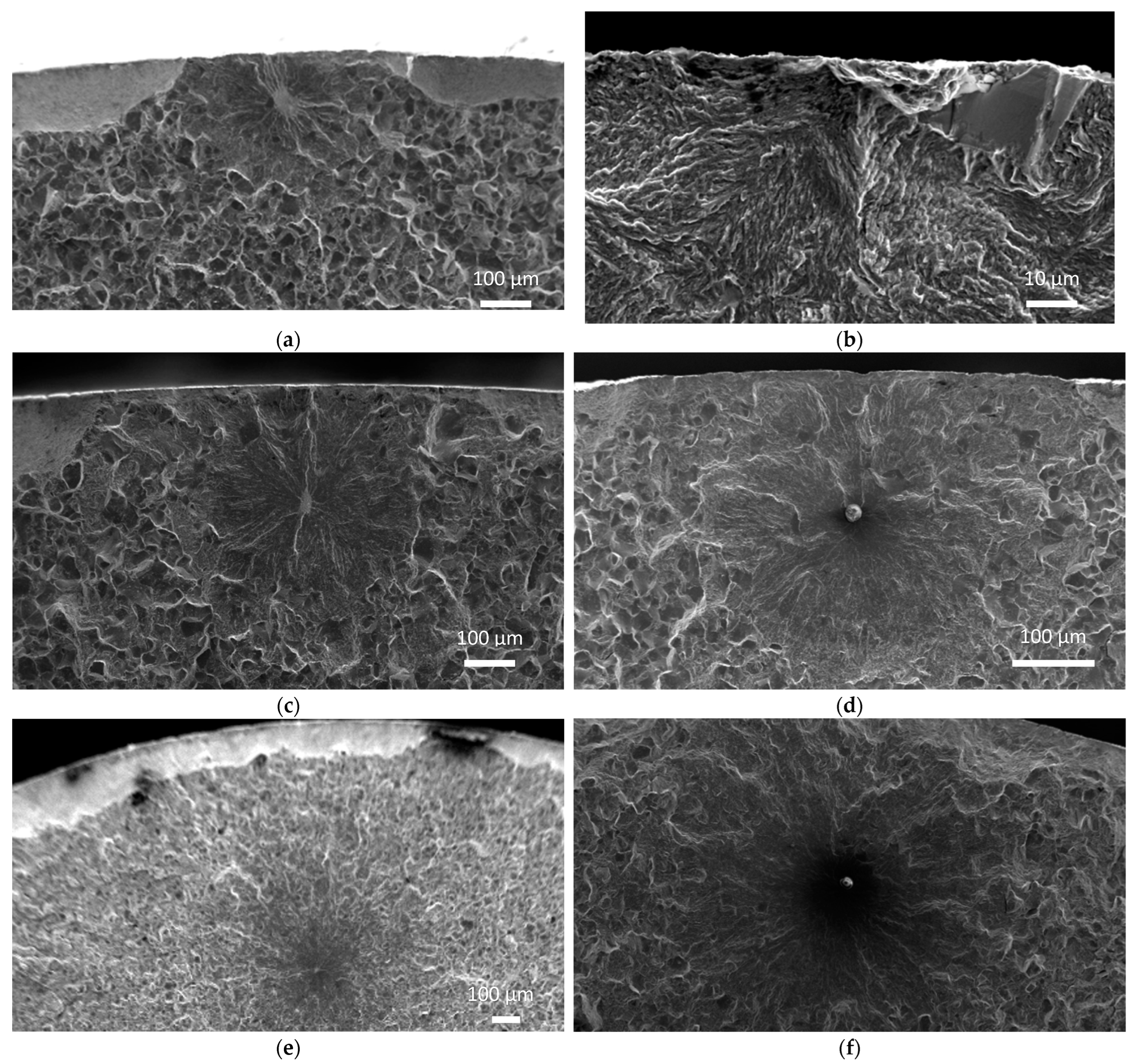

3.6. Fractographic Analysis

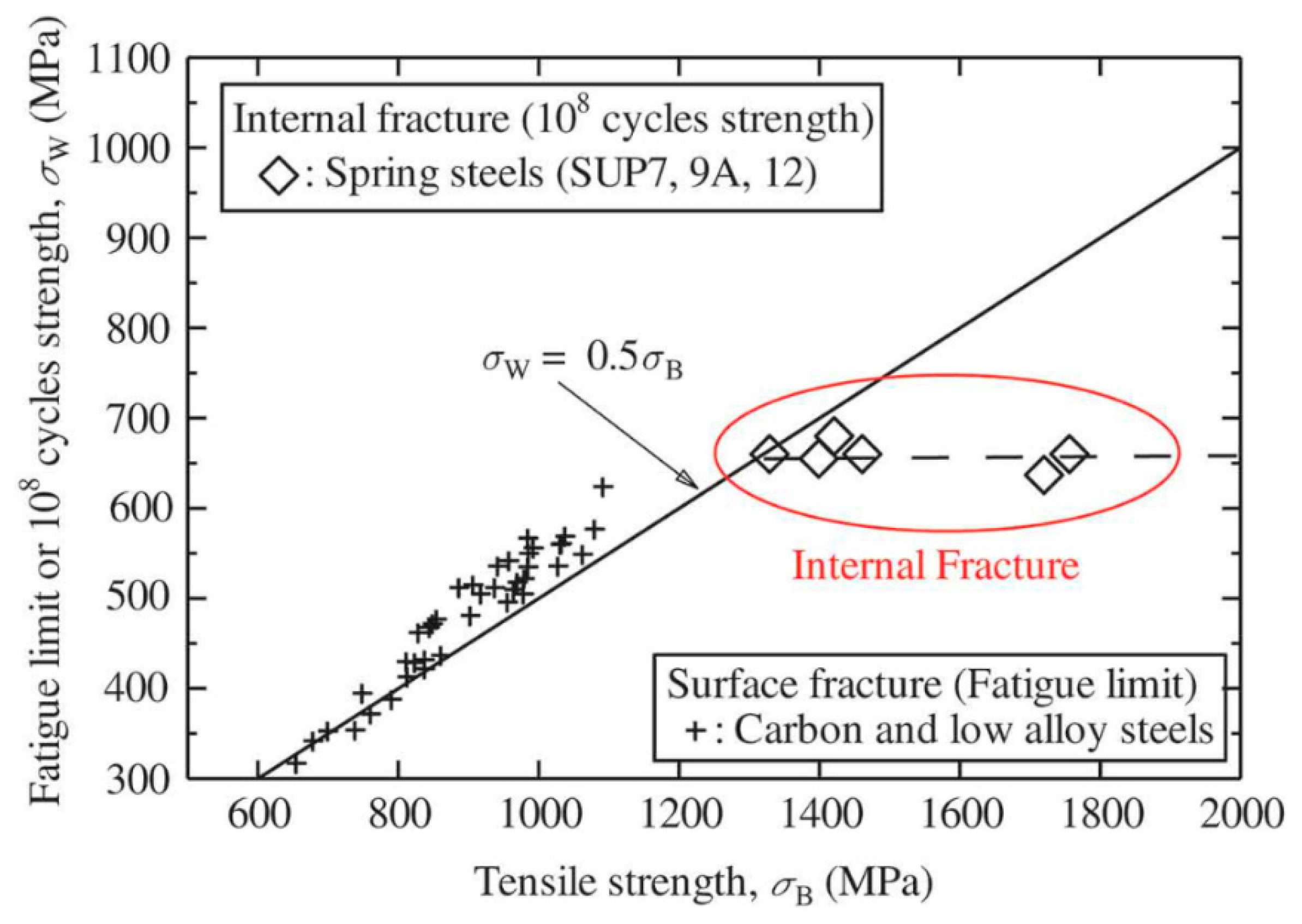

4. Discussion

5. Conclusions

- Enhanced quasi-static tensile properties of SAT material can be seen in YS and UTS of 28% and 15%, respectively, compared to the basic QT heat treatment. The increase of 28% in YS means a significant improvement of the spring steel for absorbing an extra amount of strain energy;

- Fatigue properties of the SAT material were compared with the basic QT treated material. The fatigue limit corresponding to the mean data was found to be higher for the SAT material than the QT material by about 16%. An even higher value of 24% was found in the fatigue limit, corresponding to 10% failure probability. The surface quality was found to influence the fatigue strength of the SAT material, indicating a high sensitivity to fatigue failure of such a material with a YS/UTS ratio of 1;

- To reduce the sensitivity to fatigue properties of the SAT material, the LSP process was involved in the wire production. The samples processed with SAT and LSP showed high fatigue resistance compared to QT and SAT conditions. LSP specimens showed an improvement compared to the SAT and QT states. Additionally, the fatigue life of the LSP material was longer than the SAT material. By employing the LSP process in the specimen treatment, the fatigue strength sensitivity of the SAT material was minimized to zero, and none of the specimens failed from the surface region. All fatigue crack initiators were located in the interior;

- The applicability of the SAT material for direct coiling was also investigated. The suitability for this was evaluated based on a simple bending test at RT and elevated temperatures. Both tests indicated a good quality of the wire surface; however, the interior was completely destroyed by internal cracks extending from the inside of the material towards the surface. Future work will focus on the coiling capabilities of the SAT material and the fatigue properties of the final product in the shape of a coil spring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Salvetr, P.; Gokhman, A.; Nový, Z.; Motyčka, P.; Kotous, J. Effect of 1.5 wt% Copper Addition and Various Contents of Silicon on Mechanical Properties of 1.7102 Medium Carbon Steel. Materials 2021, 14, 5244. [Google Scholar] [CrossRef] [PubMed]

- Nový, Z.; Salvetr, P.; Kotous, J.; Motyčka, P.; Gokhman, A.; Donik, Č.; Džugan, J. Enhanced Spring Steel’s Strength Using Strain Assisted Tempering. Materials 2022, 15, 7354. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Gao, C.; Pang, J.; Li, S.; Hu, D.; Li, X.; Zhang, Z. High-Cycle Fatigue Behavior and Fatigue Strength Prediction of Differently Heat-Treated 35CrMo Steels. Metals 2022, 12, 688. [Google Scholar] [CrossRef]

- Yamada, Y. Fatigue Characteristics. In Materials for Springs, 1st ed.; Springer: Heidelberg/Berlin, Germany, 2007; pp. 22–25. ISBN 978-3-540-73811-4. [Google Scholar]

- Murakami, Y.; Kawakami, K.; Duckworth, W.E. Quantitative evaluation of effects of shape and size of artificially introduced alumina particles on the fatigue strength of 1.5Ni–Cr–Mo (En24) steel. Int. J. Fatigue 1991, 13, 489–499. [Google Scholar] [CrossRef]

- Du, H.; Karasev, A.; Sundqvist, O.; Jönsson, P.G. Modification of Non-Metallic Inclusions in Stainless Steel by Addition of CaSi. Metals 2019, 9, 74. [Google Scholar] [CrossRef]

- Furuya, Y.; Hirukawa, H.; Takeuchi, E. Gigacycle fatigue in high strength steels. Sci. Technol. Adv. Mater. 2019, 20, 1610904. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Chen, F.; Liu, B.; Yu, H.; Deng, H. Effect of Stress Ratio and Evaluation of Crack Sizes on Very-High-Cycle-Fatigue Crack Propagation Life Prediction of Carburized Cr-Ni Steel. Metals 2022, 12, 1485. [Google Scholar] [CrossRef]

- Ding, K.; Ye, L. Laser Shock Peening, 1st ed.; Woodhead: Derbyshire, UK, 2006; ISBN 9781845691097. [Google Scholar]

- Hackel, L.; Rankin, J.R.; Rubenchik, A.; King, W.E.; Matthews, M. Laser peening: A tool for additive manufacturing post-processing. Addit. Manuf. 2018, 24, 67–75. [Google Scholar] [CrossRef]

- Kaufman, J.; Racek, J.; Cieslar, M.; Minárik, P.; Steiner, M.A.; Mannava, S.R.; Vasudevan, V.K.; Sharma, A.; Böhm, M.; Brajer, J.; et al. The effect of laser shock peening with and without protective coating on intergranular corrosion of sensitized AA5083. Corros. Sci. 2021, 194, 109925. [Google Scholar] [CrossRef]

- Powęzka, A.; Szulej, J.; Ogrodnik, P. Effect of high temperatures on the impact strength of concrete based on recycled aggregate made of heat-resistant cullet. Materials 2020, 13, 465. [Google Scholar] [CrossRef] [PubMed]

- E468-18; Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- 6892-1 ČSN EN ISO; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. European Standards: Prague, Czech Republic, 2020.

- Tiryakioğlu, M.; Campbell, J.; Nyahumwa, C. Fracture Surface Facets and Fatigue Life Potential of Castings. Metal. Mater. Trans. B 2011, 42, 1098–1103. [Google Scholar] [CrossRef]

- Miao, G.; Sun, T.; Wang, X. Effect of inclusion defect on fatigue failure of FGH96 superalloy at 600°C. J. Phys. Conf. Ser. 2020, 1605, 12145. [Google Scholar] [CrossRef]

- Saberifar, S.; Mashreghi, A.R.; Mosalaeepur, M.; Ghasemi, S.S. The interaction between non-metallic inclusions and surface roughness in fatigue failure and their influence on fatigue strength. Mater. Des. 2012, 35, 720–724. [Google Scholar] [CrossRef]

| Material | Wt.% | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Al | Nb | Ti | Fe | |

| 54SiCr6 | 0.508 | 0.688 | 0.009 | 0.007 | 1.4 | 0.654 | 0.11 | 0.022 | 0.02 | 0.004 | <0.01 | <0.01 | <0.01 | Bal. |

| Specimen | Temp. | E | YS | UTS | UL | EL | RA |

|---|---|---|---|---|---|---|---|

| °C | GPa | MPa | MPa | % | % | % | |

| QT | 23 | 202.4 ± 3.1 | 1875.2 ± 3.5 | 2130.2 ± 3.4 | 2.5 ± 0.1 | 7.8 ± 0.4 | 28 ± 1.6 |

| SAT | 23 | 201.5 ± 2.3 | 2397.7 ± 8.4 | 2433.7 ± 1.3 | 0.7 ± 0.1 | 2.8 ± 0.4 | 14 ± 3.7 |

| Specimen | Temp. | D | BA | Break | Cracks ≥ 1 mm | Cracks ≤ 1 mm |

|---|---|---|---|---|---|---|

| °C | mm | deg | YES/NO | YES/NO | YES/NO | |

| QT | 23 | 12 | 90 | NO | NO | YES |

| SAT | 23 | 10 | 90 | NO | NO | YES |

| SAT | 350 | 10 | 90 | NO | NO | NO |

| Specimen | Temp. | A | B | σ∞ Pf50% | σ∞ Pf10% | sN | |

|---|---|---|---|---|---|---|---|

| °C | - | - | MPa | MPa | - | - | |

| QT | 23 | 4.24 × 1038 | 11.3 | 720 | 606 | 0.47 | 0.66 |

| SAT | 23 | 1.08 × 1068 | 21.1 | 837 | 751 | 0.50 | 0.78 |

| SAT_LSP | 23 | 7.21 × 10116 | 37.0 | 980 | 944 | 1.00 | 0.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Procházka, R.; Stehlík, A.; Kotous, J.; Salvetr, P.; Bucki, T.; Stránský, O.; Zulić, S. Fatigue Properties of Spring Steels after Advanced Processing. Materials 2023, 16, 3327. https://doi.org/10.3390/ma16093327

Procházka R, Stehlík A, Kotous J, Salvetr P, Bucki T, Stránský O, Zulić S. Fatigue Properties of Spring Steels after Advanced Processing. Materials. 2023; 16(9):3327. https://doi.org/10.3390/ma16093327

Chicago/Turabian StyleProcházka, Radek, Adam Stehlík, Jakub Kotous, Pavel Salvetr, Tomasz Bucki, Ondřej Stránský, and Sanin Zulić. 2023. "Fatigue Properties of Spring Steels after Advanced Processing" Materials 16, no. 9: 3327. https://doi.org/10.3390/ma16093327

APA StyleProcházka, R., Stehlík, A., Kotous, J., Salvetr, P., Bucki, T., Stránský, O., & Zulić, S. (2023). Fatigue Properties of Spring Steels after Advanced Processing. Materials, 16(9), 3327. https://doi.org/10.3390/ma16093327