Abstract

Phosphogypsum is an industrial by-product from the wet preparation of phosphoric acid. Phosphorus building gypsum (PBG) can be obtained from phosphogypsum after high-thermal dehydration. Improving the mechanical properties of PBG is of great significance to extending its application range. In this paper, PBG was modified by adding nano-CaCO3. Specifically, this study, conducted on 0.25–2% nano-CaCO3-doped PBG, tested effects on the fluidity, setting time, absolute dry flexural strength, absolute dry compressive strength, water absorption and softening coefficient of PBG, followed by its microscopic analysis with SEM and XRD. The experimental results showed that, with an increase in nano-CaCO3 content, the fluidity and setting time of PBG-based mixes were decreased. When the content was 2%, the fluidity was 120 mm, which was 33% lower than that of the blank group; the initial setting time was 485 s, which was 38% lower than that in the blank group; the final setting time was 1321 s, which was reduced by 29%. Nano-CaCO3 evidently improved the absolute dry flexural strength, absolute dry compressive strength, water absorption and softening coefficient of PBG to a certain extent. When the content was 1%, the strengthening effect reached the optimum, with the absolute dry flexural strength and absolute dry compressive strength being increased to 8.1 MPa and 20.5 MPa, respectively, which were 50% and 24% higher than those of the blank group; when the content was 1.5%, the water absorption was 0.22, which was 33% lower than that of the blank group; when the content approached 0.75%, the softening coefficient reached the peak of 0.63, which was 66% higher than that of the blank group. Doping with nano-CaCO3 could significantly improve the performance of PBG, which provides a new scheme for its modification.

1. Introduction

Phosphogypsum is an industrial by-product from the wet preparation of phosphoric acid. Its major component is CaSO4·2H2O, which is usually gray-white or gray-black. About 4~5 t of phosphogypsum is produced per 1 t of phosphoric acid. At present, the annual discharge of phosphogypsum in China is about 30 million t [1,2,3], which is one of the largest solid wastes from the chemical industry. Phosphorus building gypsum (PBG) can be obtained from phosphogypsum after high-thermal dehydration. The major component is CaSO4·1/2H2O. When PBG is used as a building material, it exhibits low strength and poor water resistance due to a large number of pores, which makes it difficult to be more widely applied [4,5,6,7].

To improve various properties of PBG, other materials are usually introduced as reinforcement. Wu [8,9,10] studied the effects of short-cut basalt fiber, glass fiber and polypropylene fiber on the properties of PBG and obtained the best mixing ratio of these different fibers. Liang [11] explored the influences of ordinary silicate cement on the mechanical properties of PBG, with the results showing that the addition of this cement could effectively promote the late strength of PBG. Ma [12] investigated the doping effects of the amount of recycled brick powders and the type of activators on the compressive strength and water resistance of PBG, with the results exhibiting that the introduction of brick powders could raise the compressive strength of PBG. Li [13] researched the impacts of doping limes and cements on the strength and water resistance of PBG-based cementitious materials and found these properties of the modified materials were both significantly increased in the later stages. Ji [14] applied multi-wall carbon nanotube materials to modify the PBG to make its internal structure more dense and its mechanical properties stronger. Zhao [15] adopted fly ashes and silica fumes to modify PBG-based mortar, which also improved its performance.

Nano-materials are ultra-fine, with particle sizes less than 100 nm [16,17]. This type of nano-admixture has already been broadly applied to, and has significantly improved the various properties of, building materials [18,19,20,21,22]. Given that the ultra-refinement of nano-CaCO3 particles changes the crystal structure and surface electronic structure, many characteristics have been generated [23,24]. The research of Kawashima [25] showed that, after doping with nano-CaCO3, the initial setting and final setting times of the cement were both shortened, while its hydration rate was significantly improved. Camiletti [26] studied the effect of nano-CaCO3 on the early properties of ultra-high performance concrete, with the test results exhibiting that nano-CaCO3 could improve the early mechanical properties of cement-based materials. The research of Liu [27] presented that the addition of nano-CaCO3 could promote both the compressive strength and flexural strength of cement-based materials at the optimal content of 1%. Detwiler [28] found that for the hydration product, C-S-H gel, of cements, the action of nano-CaCO3 crystal nuclei, accelerated its formation rate on the particle surface. The research results of Qian [29] demonstrated that nano-CaCO3 was able to fill the pores of cement-based materials, making the concrete structure more compact, improving its mechanical properties.

Despite these study results, there remains a lack of research on the modification of PBG by nano-CaCO3. In this study, nano-CaCO3 was added into PBG as a reinforcing material to study its influence on fluidity, setting time, absolute dry flexural strength, absolute dry compressive strength, water absorption and softening coefficient of PBG, explore its optimal content and analyze its influence mechanism. The properties of PBG can be improved effectively by adding nano-CaCO3 into PBG, so that PBG can be widely used. At the same time, nano-CaCO3 is a type of environmental protection material. The combination of nano-CaCO3 and PBG and their application in the building materials industry not only meet the requirements of green building materials, but also achieves waste utilization. Therefore, using nano-CaCO3 to modify PBG is a problem worth studying.

2. Materials and Methods

2.1. Raw Materials

Phosphogypsum: light-yellow powder from a phosphogypsum yard of Yunnan Yuntianhua Co., Ltd. (Kunming, China). Its chemical composition is shown in Table 1.

Table 1.

Chemical content analysis of phosphogypsum.

This phosphogypsum was washed with water, neutralized with lime and then dried at 130 °C for 6 h to obtain PBG.

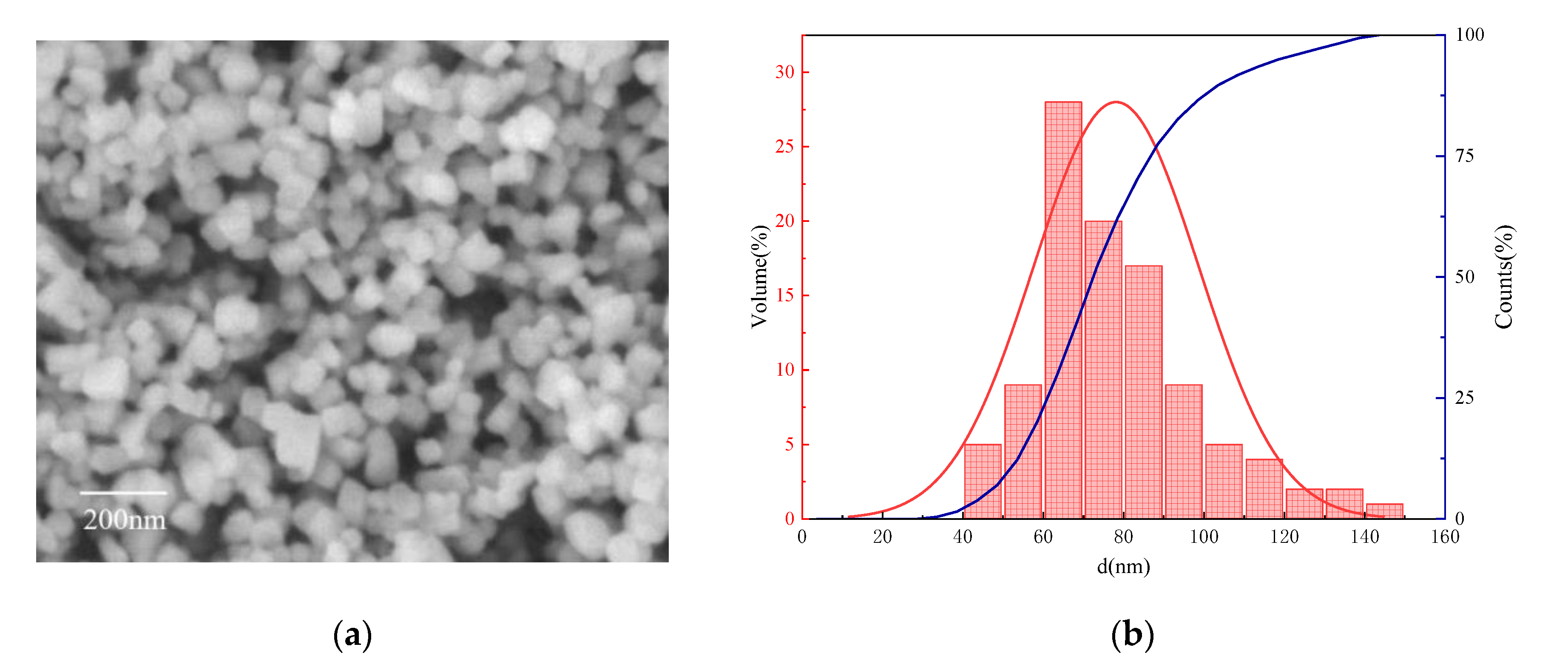

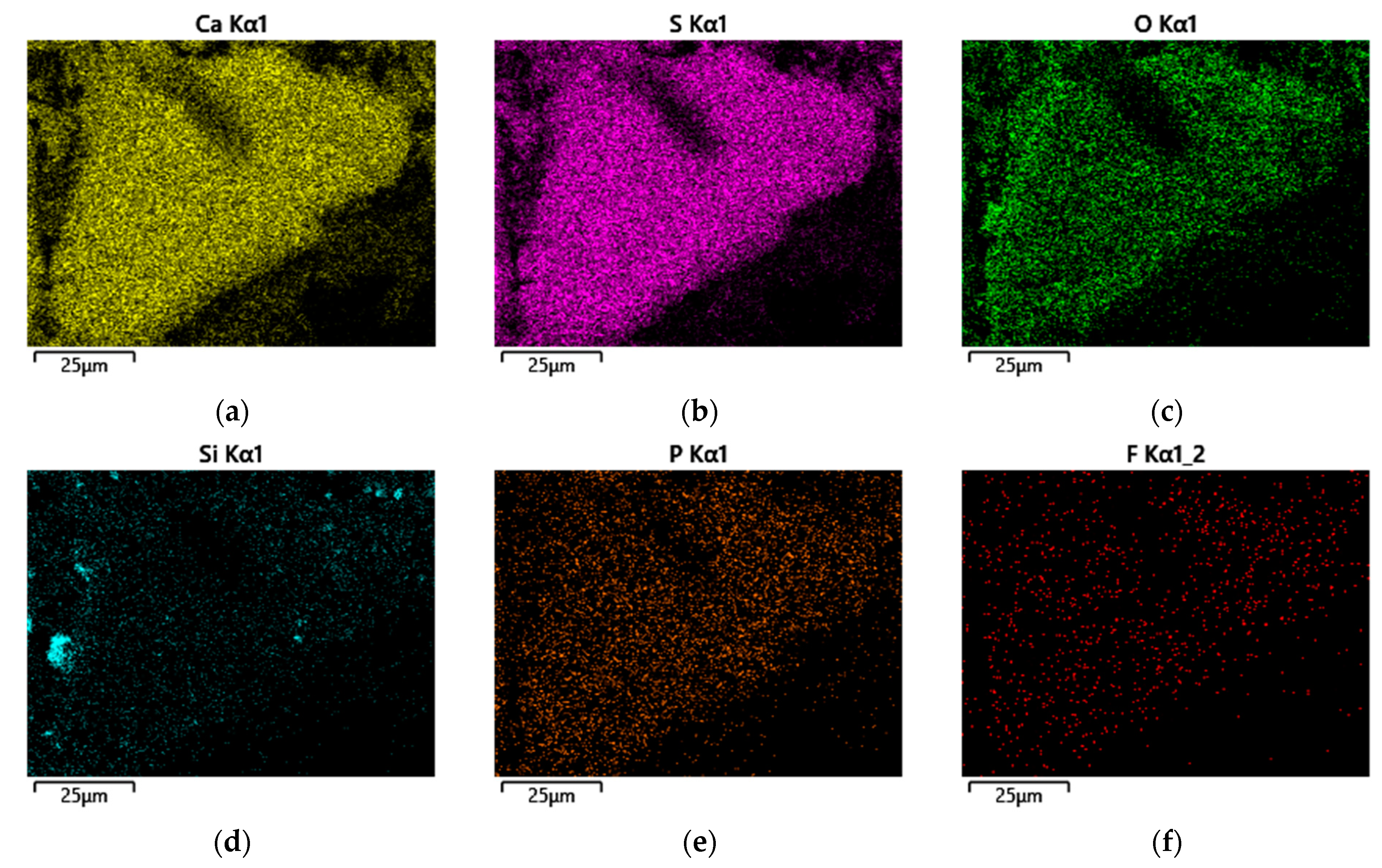

Nano-CaCO3: produced by Jiangxi Bairui Calcium Carbonate Co., Ltd. (Yichun, China). The SEM and particle size distribution are shown in Figure 1 and the technology parameters are shown in Table 2.

Figure 1.

(a) SEM photo of nano-CaCO3; (b) Particle size distribution.

Table 2.

Technology parameters of nano-CaCO3.

2.2. Experimental Design

Different contents of nano-CaCO3 were added into PBG according to Table 3, stirred and dispersed evenly, then added to water, mixed evenly and poured into a 40 mm × 40 mm × 160 mm mold; mixtures then underwent vibration for 30 s on the vibration table.

Table 3.

Contents of nano-CaCO3.

2.3. Experimental Methods

2.3.1. Fluidity and Setting Time

For each mixture proportion, the fluidity of specimens was measured using the gypsum consistency testing meter and the initial and final setting times of specimens were measured using the Vicat apparatus, according to the Chinese national standard “Gypsum plasters Determination of physical properties of pure paste” (GB/T17669.4-1999) [30].

2.3.2. Absolute Dry Flexural Strength and Absolute Dry Compressive Strength

For each mixture proportion, three specimens were molded for the tests. Specimens were demolded after curing at 25 °C, 50 ± 5% RH for 24 h and cured at the same environment for 7 days. Then, all the specimens were dried at the temperature of 45 °C in an electric thermostatic drying oven until the weight was constant. The absolute dry compressive strength and absolute dry flexural strength of specimens were tested in accordance with the Chinese national standard “Determination of Mechanical Properties of Building Plaster” (GB/T 17669.3-1999) [31].

2.3.3. Water Absorption and Softening Coefficient

Three specimens were immersed in water for 24 h and the saturated specimens were prepared by wiping off the water on their surfaces with towels. The masses of the specimens were measured by an electronic balance with 0.01 g accuracy. The breaking load of the specimens, F, was measured according to the standard GB/T 17669.3-1999. The water absorption was calculated by Formula (1) and the softening coefficient was calculated by Formula (2):

where W is the water absorption, m0 is the dry mass of the sample and m1 is the mass of the sample saturated in water.

W = (m1 − m0)/m0,

K = F2/F1,

In addition, K is the softening coefficient, F1 is the breaking load of the dry sample and F2 is the breaking load of the saturated sample.

2.3.4. Microscopic Morphology of Gypsum Particles

A small number of samples were taken from the middle of the broken block, from which the micromorphology was observed under a scanning electron microscope after vacuum metal spraying.

3. Results

3.1. Effect of Nano-CaCO3 on PBG Fluidity

Table 4 shows the influence of different contents of Nano-CaCO3 on properties of PBG.

Table 4.

Effects of different contents of nano-CaCO3 on properties of PBG.

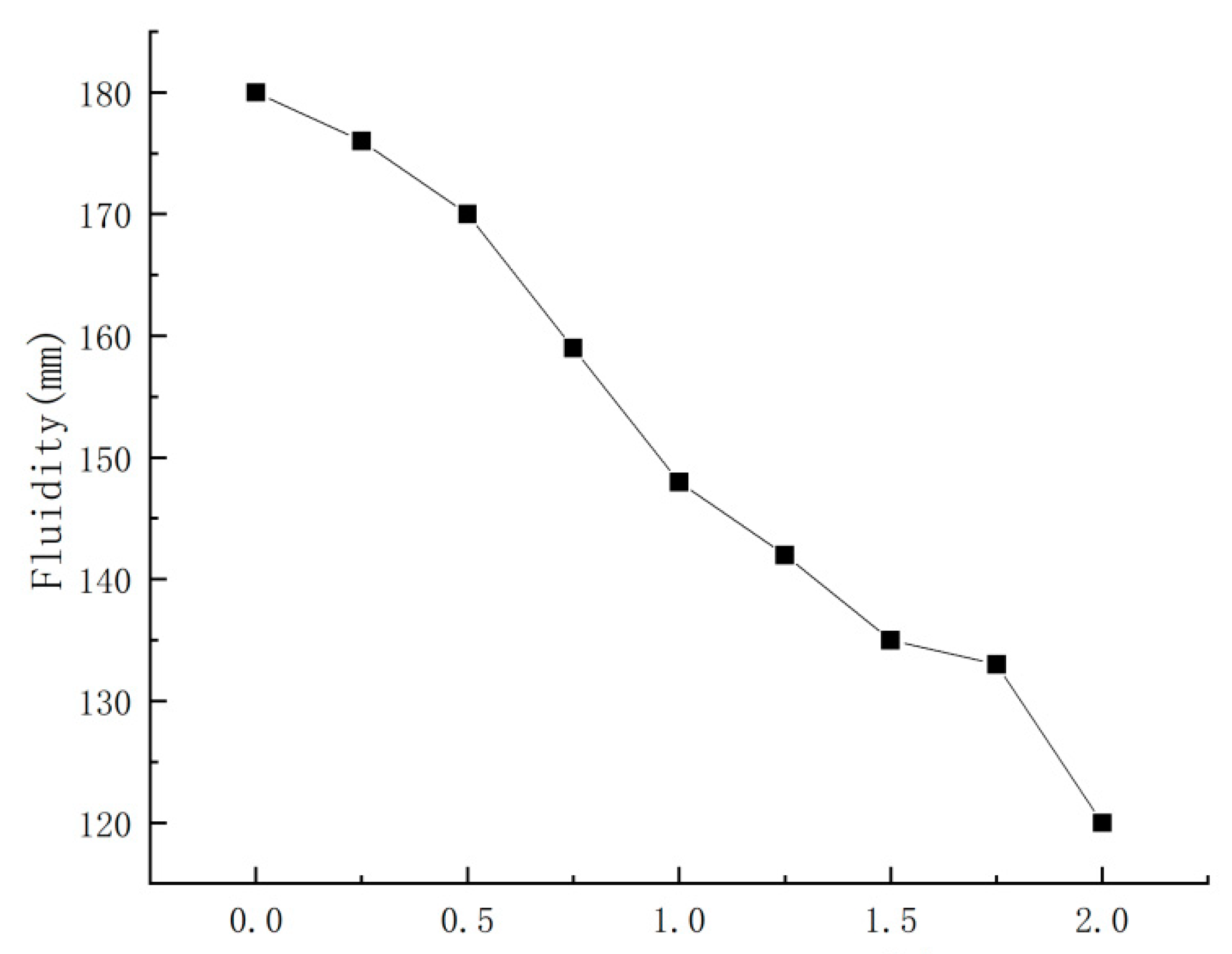

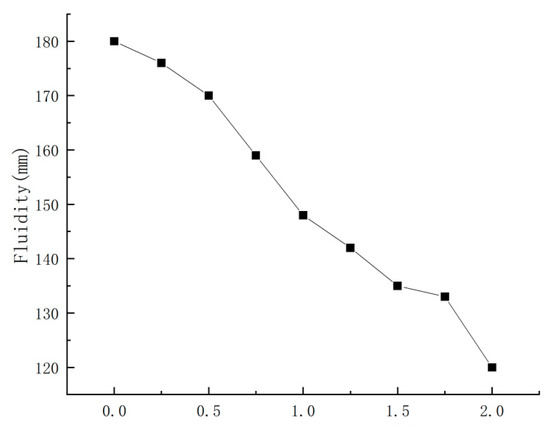

Firstly, the water requirement was adjusted to make the fluidity of PBG in the blank group reach 180 mm, then nano-CaCO3 was added according to the mixing proportions in Table 3 to compare the effects of different contents of nano-CaCO3 on the PBG fluidity. The comparison results were shown in Figure 2.

Figure 2.

Effects of nano-CaCO3 on the fluidity of PBG.

It could be seen from Figure 2 that, with the increase in nano-CaCO3 content, the fluidity of PBG decreased continuously. When the content of nano-CaCO3 was 2%, the fluidity of PBG was reduced to 120 mm as the minimum, which was 33% lower than that of the blank group.

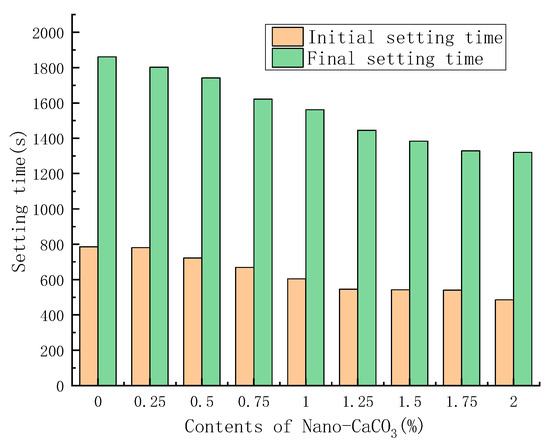

3.2. Effect of Nano-CaCO3 on Setting Time of PBG

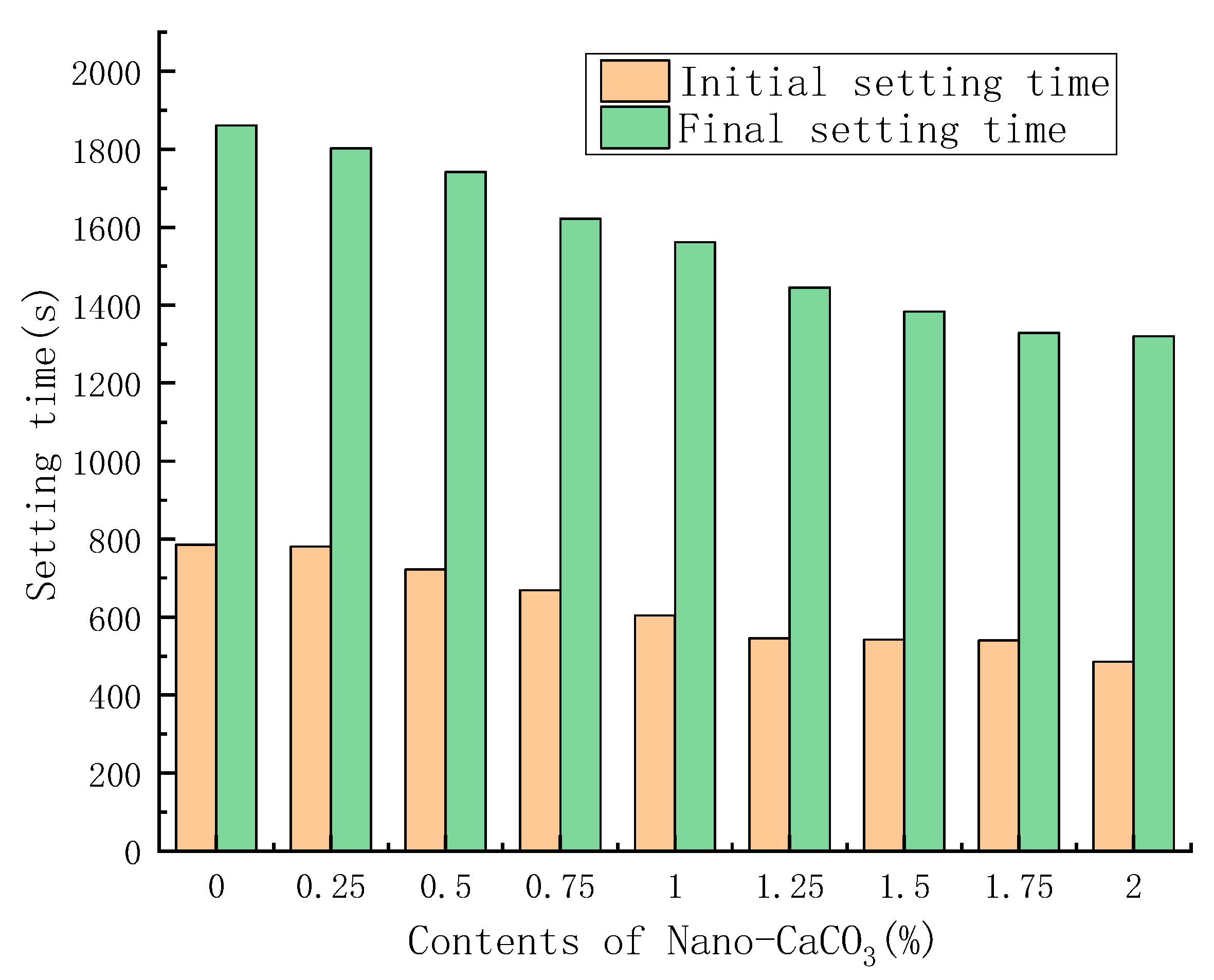

With the water requirement of standard consistency of PBG being unchanged, nano-CaCO3 was added according to the mixing proportions in Table 3 to compare the effects of different contents of nano-CaCO3 on the initial and final setting times of PBG. The comparison results were shown in Figure 3.

Figure 3.

Effects of nano-CaCO3 on setting times of PBG.

It could be seen from Figure 3 that, with the increase in nano-CaCO3 content, the initial and final setting times of PBG were both continuously shortened. When the content of nano-CaCO3 reached 2%, the initial setting time of PBG fell to 485 s as the minimum, which was 38% lower than the 786 s of the blank group; also, the final setting time dropped to 1321 s as the minimum, which was 29% lower than the 1861 s of the blank group.

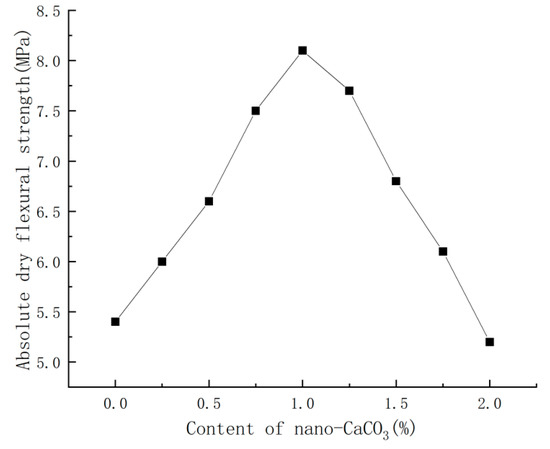

3.3. Effect of Nano-CaCO3 on Absolute Dry Flexural Strength of PBG

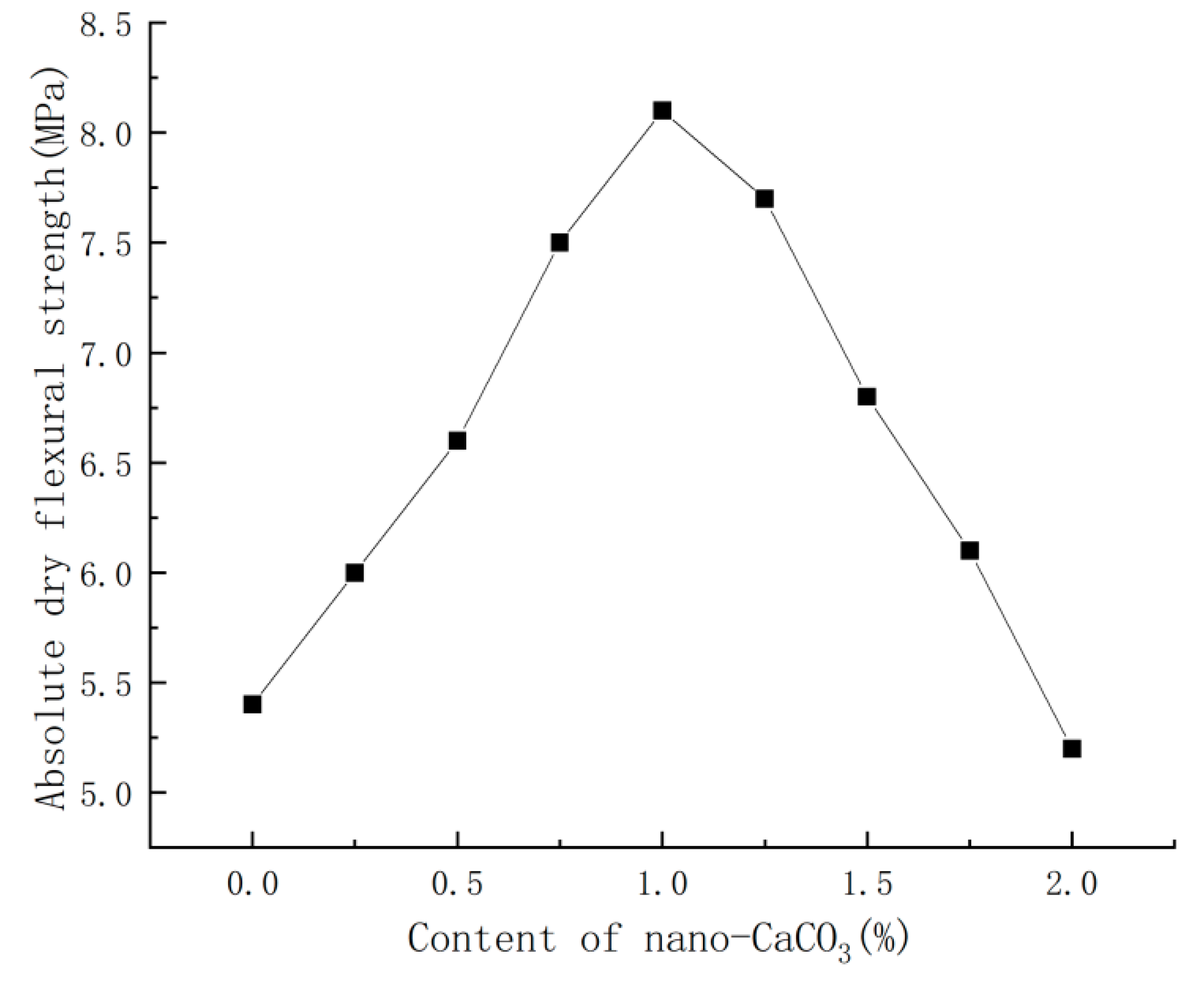

With the water requirement of standard consistency being unchanged, the content of nano-CaCO3 was varied to compare the corresponding changes in absolute dry flexural strength of PBG. The comparison results were shown in Figure 4.

Figure 4.

Effects of nano-CaCO3 on absolute dry flexural strength of PBG.

It could be seen from Figure 4 that, with the increase in nano-CaCO3 content, the absolute dry flexural strength of PBG showed a trend of first increasing then decreasing. When the content of nano-CaCO3 was 1%, the absolute dry flexural strength of PBG reached 8.1 MPa as the maximum, which was 50% higher than that of the blank group; when the content of nano-CaCO3 exceeded 1%, the absolute dry flexural strength of PBG began to decrease. When the content of nano-CaCO3 was 2%, the absolute dry flexural strength of PBG was 5.2 MPa, which was 4% lower than that of the blank group.

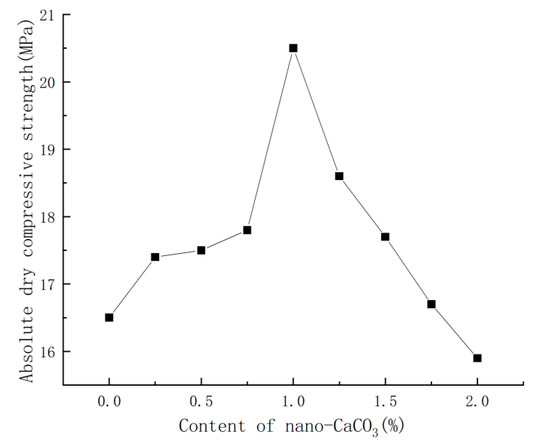

3.4. Effect of Nano-CaCO3 on Absolute Dry Compressive Strength of PBG

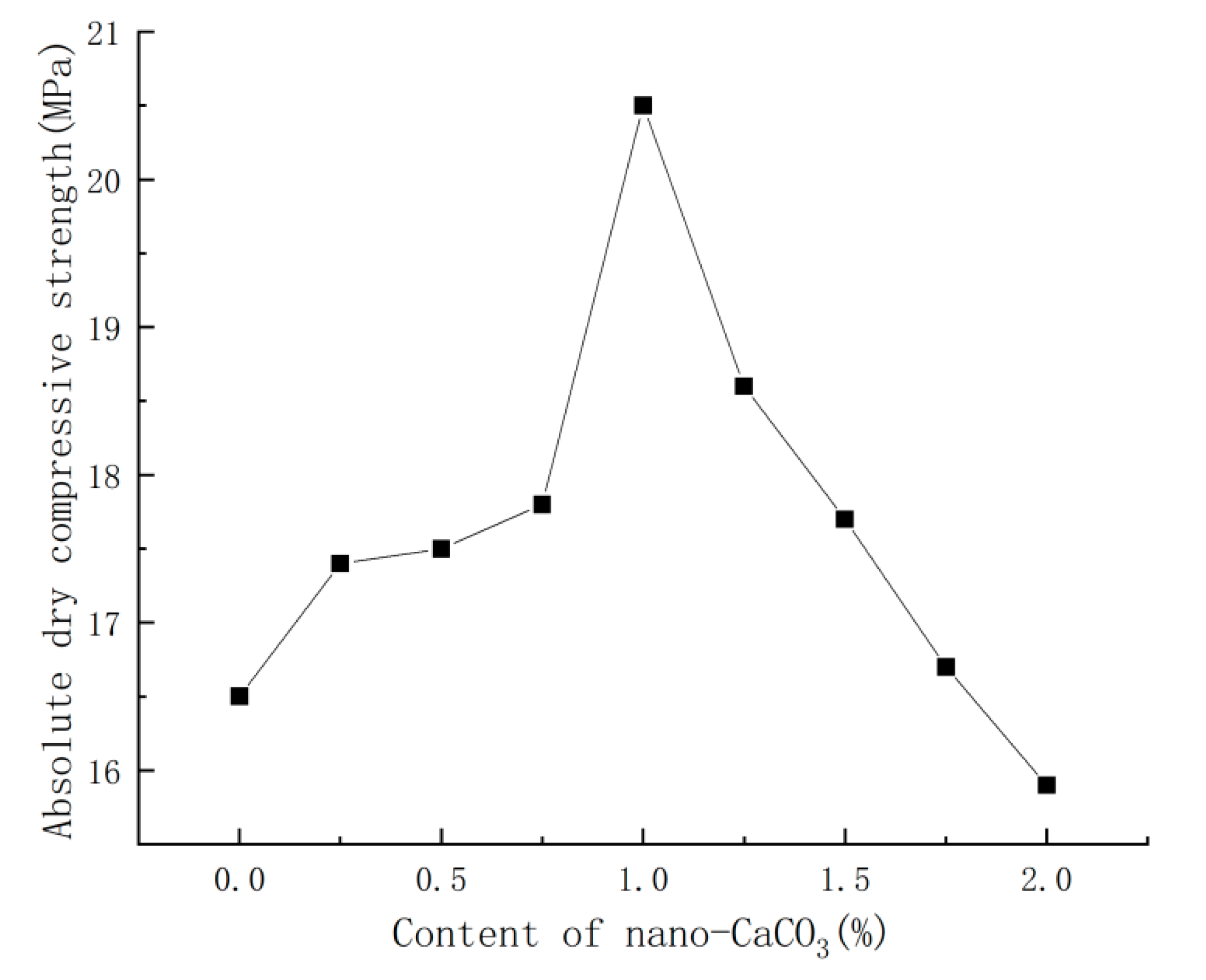

With the water requirement of standard consistency being unchanged, the content of nano-CaCO3 was varied to compare the corresponding changes in absolute dry compressive strength of PBG. The comparison results were shown in Figure 5.

Figure 5.

Effects of nano-CaCO3 on absolute dry compressive strength of PBG.

It could be seen from Figure 5 that, with the increase in nano-CaCO3 content, the absolute dry compressive strength of PBG showed a trend of first increasing then decreasing. When the content of nano-CaCO3 was 1%, the absolute dry compressive strength of PBG rose to 20.5 MPa as the maximum, which was 24% higher than that of the blank group; when the content of nano-CaCO3 exceeded 1%, the absolute dry compressive strength of PBG started to decrease. When the content of nano-CaCO3 reached 2%, the absolute dry compressive strength of PBG dropped to 15.9 MPa, which was 4% lower than that of the blank group.

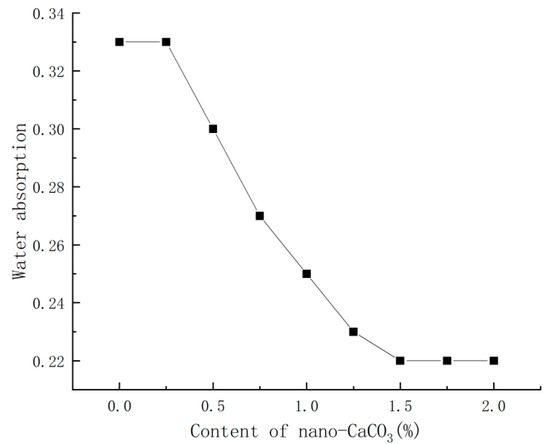

3.5. Effect of Nano-CaCO3 on Water Absorption of PBG

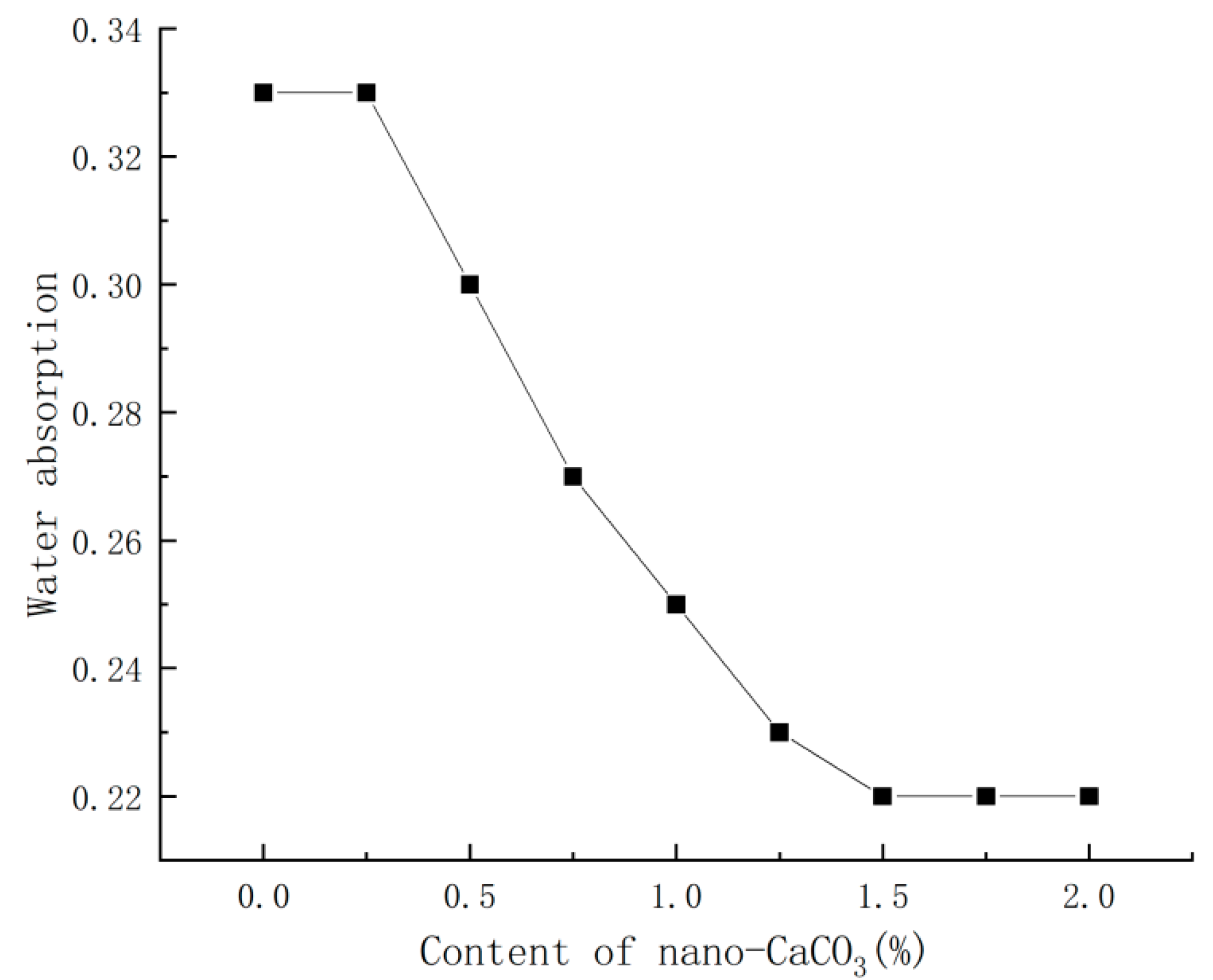

With the water requirement of standard consistency being unchanged, the content of nano-CaCO3 was varied to compare the corresponding changes in PBG’s water absorption. The comparison results were shown in Figure 6.

Figure 6.

Effects of nano-CaCO3 on water absorption of PBG.

It could be seen from Figure 6 that, with the increase in nano-CaCO3 content, the water absorption of PBG first decreased then stabilized. When the content of nano-CaCO3 reached 1.5%, the water absorption of PBG was 0.22, which was 33% lower than that of the blank group; when the content of nano-CaCO3 exceeded 1.5%, the water absorption of PBG gradually stabilized.

3.6. Effect of Nano-CaCO3 on Softening Coefficient of PBG

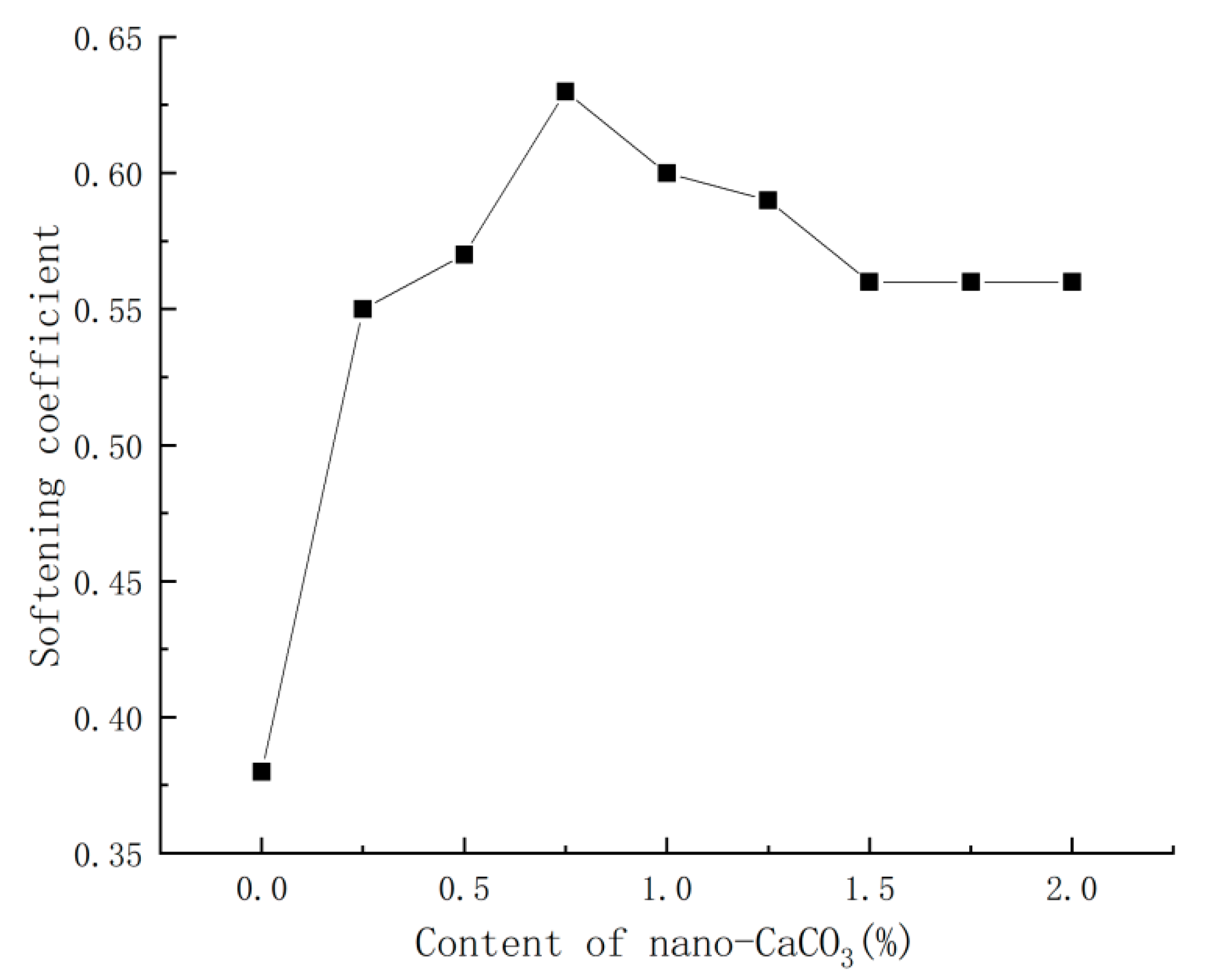

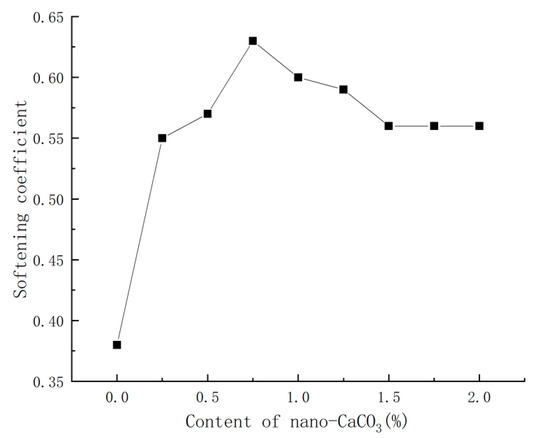

With the water requirement remaining unchanged, the content of nano-CaCO3 was varied for comparing the corresponding changes of PBG’s softening coefficient. The comparison results were shown in Figure 7.

Figure 7.

Effects of nano-CaCO3 on softening coefficient of PBG.

It could be seen from Figure 7 that, with the increase in nano-CaCO3 content, the softening coefficient of PBG first increased then decreased, before tending to stabilize. When the content of nano-CaCO3 was 0.75%, the softening coefficient of PBG rose to 0.63 as the maximum, which was 66% higher than that of the blank group; when the content of nano-CaCO3 exceeded 0.75%, the softening coefficient of PBG began to decrease; when the content of nano-CaCO3 reached 1.5%, the softening coefficient of PBG gradually stabilized. At that moment, the softening coefficient remained at 0.56, which was 47% higher than that of the blank group.

3.7. Microanalysis

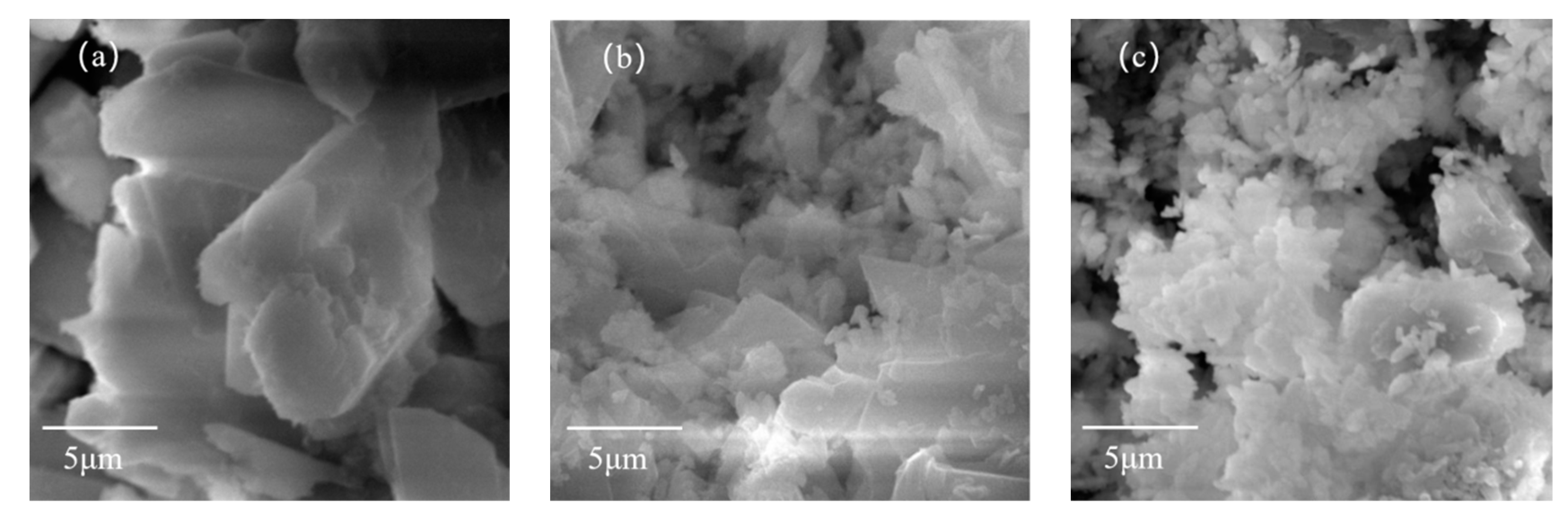

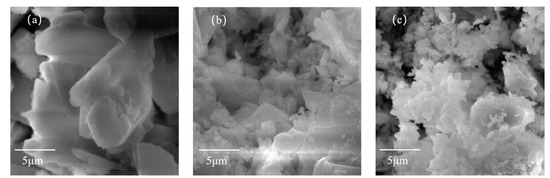

The microstructures of PBG prototypes and mixtures with nano-CaCO3 were separately observed by scanning electron microscopy (SEM). The results were shown in Figure 8.

Figure 8.

(a) SEM photo of PBG; (b) SEM photo of PBG mixed with 1% nano-CaCO3; (c) SEM photo of PBG mixed with 2% nano-CaCO3.

It could be seen from Figure 8a,b that, after adding nano-CaCO3, a lot of granular nano-CaCO3 with tiny particle size appeared on the surface of PBG. This nano-CaCO3 wrapped PBG crystals and filled the gaps between them, which reduced the total porosity and exerted the significant effect of micro-aggregation. However, when the added content became too high, CaCO3 would become unevenly dispersed. It could be seen from Figure 8c that the unevenly dispersed CaCO3 still wrapped the crystals of PBG. Although the porosity was further reduced, these unevenly dispersed parts generated stress concentration, which imposed an adverse impact on the strength of PBG.

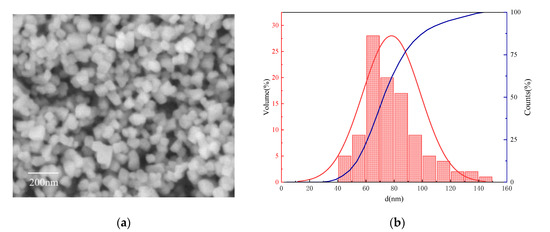

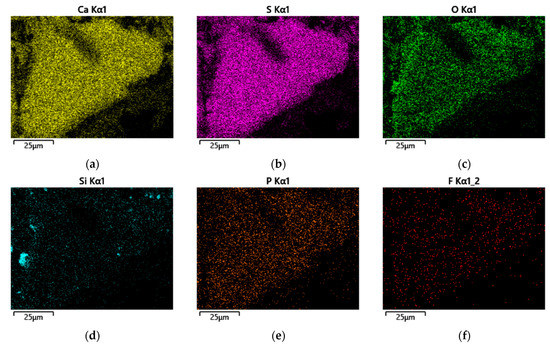

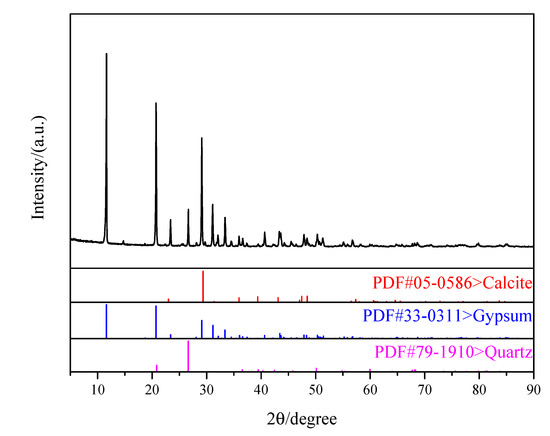

3.8. Composition Analysis of Hydration Products

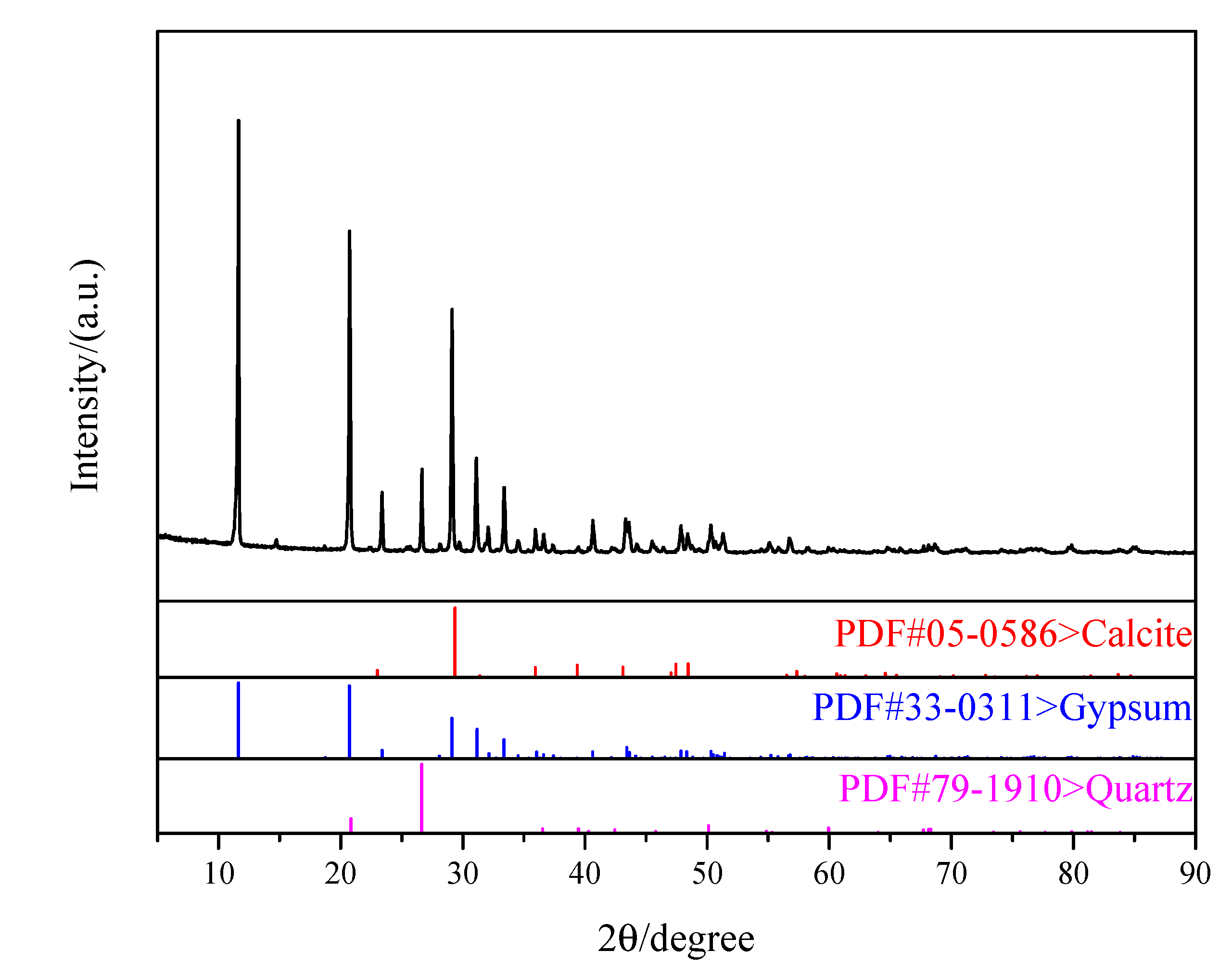

The EDS element mapping images and XRD patterns were characterized and shown in Figure 9 and Figure 10, respectively.

Figure 9.

EDS element mapping results of PBG mixed with 1% nano-CaCO3. (a) Ca mapping results; (b) S mapping results; (c) O mapping results; (d) Si mapping results; (e) P mapping results; (f) F mapping results.

Figure 10.

Composition of hydration products.

It could be seen from EDS and element mapping images (Figure 9a–f) that the main elements in the selected area were Ca (20.3%), S (18.1%) and O (60.5%), together with trace amounts of P (0.8%) and Si (0.3%). The P element in the sample was uniformly dispersed, while the Si element appeared as concentrated spots in very limited numbers, representing the quartz crystals detected by XRD (Figure 10). There were no P-containing crystals detected by XRD, due to its high dispersion (Figure 9e). This also could be seen from Figure 10 that, after adding nano-CaCO3 into PBG, these two had not yet directly reacted with each other and the main product from the hydration of PBG was still CaSO4·2H2O [32,33,34].

4. Discussion

It can be seen from the above test data that, after nano-CaCO3 was added into PBG, its fluidity and water absorption were both reduced, while its absolute dry flexural strength, absolute dry compressive strength and softening coefficient were all improved, with the absolute dry flexural strength seeing the largest improvement. The main reasons are as follows:

Filling effect: Since the average particle size of nano-CaCO3 is about 100 nm, which is far below that of PBG, a proper amount of nano-CaCO3 can fill both the micropores of PBG and the internal pores of PBG’s hydration product. Simultaneously, it can also improve the particle gradation and change the pore structure of PBG’s hydration product by reducing macropores, increasing micropores and lowering the total porosity. The ability to fill the space between PBG particles is greatly promoted, the PBG’s total porosity is reduced and the PBG’s structure is denser, which improves the PBG’s absolute dry flexural strength, absolute dry compressive strength and softening coefficient in all and reduces its water absorption as well.

Nucleation effect: The main component of PBG is CaSO4·1/2H2O and its hydration reaction is mainly with water to produce CaSO4·H2O. When PBG starts hydration, the hydrolysis of CaSO4·1/2H2O releases a large amount of Ca2+. After nano-CaCO3 is added to PBG, it does not directly participate in the hydration reaction, but, compared with ordinary CaCO3, the surface activity of nano-CaCO3 is relatively high, which, therefore, adsorbs the Ca2+ released by hydration. This causes the CaSO4·2H2O around nano-CaCO3 to nucleate in advance, which leads to the decrease in Ca2+ concentration in the solution and the increase in Ca2+ migration from CaSO4·1/2H2O, thus accelerating the hydration efficiency of PBG. Based on the original structure, a new one is formed around nano-CaCO3 as the crystal nucleus, which reduces both the internal surface area and porosity of PBG, increases its compactness and improves its various properties.

Pinning effect: Meanwhile, the existence of nano-CaCO3 particles in PBG also generates a “pinning effect”. This can be seen from Figure 8b, that some nano-CaCO3 particles are embedded into the gaps of PBG’s hydration product. When the hydration product is compressed to generate microcracks inside, their expansion is hindered by nano-CaCO3 particles and their energy is consumed, which limits the crack propagation and improves various properties of PBG [35].

With the increase in nano-CaCO3 content, the absolute dry flexural strength and absolute dry compressive strength of PBG both decrease. This is because the surface energy of nano-CaCO3 is relatively large and, when the content becomes too high, nano-CaCO3 agglomerates instead of evenly dispersing within PBG. While PBG is subjected to external force, these agglomerated nano-CaCO3 particles have stress concentration, which affects both the absolute dry flexural strength and absolute dry compressive strength of PBG [36].

Moreover, the specific surface area of nano-CaCO3 is extremely large. After mixing with water, this surface adsorbs a large amount of water, which reduces the water required to participate in the hydration reaction of PBG. Therefore, with the increase in nano-CaCO3 content, PBG’s fluidity and setting time both decrease. If excessive nano-CaCO3 is added, PBG’s strength is also affected [37]. However, when the softening coefficient is measured, part of the PBG without hydration continues to hydrate, resulting in the supplement to the wet strength of PBG and less reduction compared to the absolute dry strength, so the softening coefficient is improved [38].

5. Potential Applications and Prospects

The composition of the PBG is relatively complicated, with substantial impurities, which have a negative impact on its performance. According to the results of this paper, it can be seen that, after doping with nano-CaCO3, various properties of the PBG have all been improved, which would meet the application requirements for building gypsum. Compared to other materials, nano-CaCO3 presents certain advantages, as listed in Table 5. Compared to other preparation methods, the method adopted in this paper also has advantages, in that there is no waste generated in the preparation process and it poses not only the merits of simplicity, environmental protection and low cost, but also the certain practical significance in production.

Table 5.

Comparing effects of nano-CaCO3 doping and other treatment methods.

6. Conclusions

- Nano-CaCO3 exerted a significant effect on the physical properties of PBG’s paste with the increase in nano-CaCO3 content: the fluidity and setting time of PBG were both decreased. Among them, the fluidity decreased by 33%, the initial setting time decreased by 38% and the final setting time decreased by 29%.

- Nano-CaCO3 also presented a significant impact on the mechanical properties of PBG: with the increase in nano-CaCO3 content, both the absolute dry flexural strength and absolute dry compressive strength of PBG first increased then decreased. When the content of nano-CaCO3 was 1%, the absolute dry flexural strength of PBG increased by 50% and the absolute dry compressive strength increased by 24%. When the content of nano-CaCO3 reached a certain level, it imposed a negative impact on the mechanical properties of PBG.

- Nano-CaCO3 also had a significant influence on other properties of PBG: with the increase in nano-CaCO3 content, the water absorption of PBG first decreased then stabilized gradually, decreasing by 33%, while the softening coefficient first increased, then decreased and finally tended to stabilize, with a maximum increase of 66%.

- After nano-CaCO3 was added into PBG, it could fill the voids within the hardened body and improve PBG’s pore structure. Meanwhile, based on the original structure, it could form a new one around nano-CaCO3 as the crystal nucleus, which reduced both the internal surface area and porosity of PBG, increased PBG’s compactness and improved PBG’s various properties.

Author Contributions

Conceptualization, Y.Z. and Z.T.; software, L.W.; data curation, Z.Z. (Zhiqi Zhang) and Z.Z. (Zhiman Zhao); writing—original draft preparation, Y.Z.; writing—review and editing, Z.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Key R&D Program of Yunnan Provincial Department of Science and Technology (202003AC100001), the Industrial High-Tech Project of Yunnan Provincial Department of Science and Technology (202003AA080032) and the Analysis and Testing Fund of Kunming University of Science and Technology (2021P20201110003).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting this study’s findings are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cui, Y.; Wang, Q.; Xue, J. Novel Foam Insulation Material Produced by Calcined Phosphogypsum and H2O2. J. Mater. Civ. Eng. 2020, 32, 04020379. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, Y.; Xue, J. Study on the improvement of the waterproof and mechanical properties of hemihydrate phosphogypsum-based foam insulation materials. Constr. Build. Mater. 2019, 230, 117014. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, Y.; Yan, Y. Utilization of original phosphogypsum as raw material for the preparation of self-leveling mortar. J. Clean. Prod. 2016, 127, 204–213. [Google Scholar] [CrossRef]

- Huang, Y.; Qian, J.; Kang, X.; Yu, J.; Fan, Y.; Dang, Y.; Zhang, W.; Wang, S. Belite-calcium sulfoaluminate cement prepared with phosphogypsum: Influence of P2O5 and F on the clinker formation and cement performances. Constr. Build. Mater. 2019, 203, 432–442. [Google Scholar] [CrossRef]

- Singh, M. Role of phosphogypsum impurities on strength and microstructure of selenite plaster. Constr. Build. Mater. 2005, 19, 480–486. [Google Scholar] [CrossRef]

- Mei, L.I.; Jiahui, P.; Jianxin, Z.; Huan, Z. Research on Characteristics of Phosphorus Building Gypsum and Its Modification. Bull. Chin. Ceram. Soc. 2012, 31, 553–558. [Google Scholar] [CrossRef]

- He, S.; Shi, Y.; Li, Q. Effect of Particle Gradation on Properties of Phosphogypsum–based Cement Paste Backfill. DEStech Trans. Environ. Energy Earth Sci. 2017. [Google Scholar] [CrossRef] [PubMed]

- Lei, W.U.; Zhiman, Z.; Rui, T.; Sichen, Q.; Yang, L.; Jiyuan, H.; Bo, W.; Haijian, D. Orthogonal Test of Modified Phosphogypsum by Polypropylene Fibers and Polyvinyl Alcohol. Bull. Chin. Ceram. Soc. 2018, 4022–4026. [Google Scholar] [CrossRef]

- Lei, W.; Zhiman, Z.; Rui, T.; Bo, W.; Jiyuan, H.; Yang, L.; Haijian, D. Study on Strength of Short-cut Polypropylene Fiber Reinforced Phosphate Building Gypsum. Non-Met. Mines. 2018, 41, 4–6. [Google Scholar]

- Wu, L.; Zhao, Z.-m.; Sichen, Q.; Cun, W.; Zhuo, L. Influence of Chopped Fiber on the Working Performance of Phosphorus Building Gypsum. Bull. Chin. Ceram. Soc. 2019, 38, 7. [Google Scholar] [CrossRef]

- Liang, X.; Fang, L.; Yaowen, X.; Zhennan, Y. Study on Modification of Hemihydrate Phosphogypsum with Ordinary Portland Cement and Its Hydration Mechanism. Non-Met. Mines 2018, 41, 45–47. [Google Scholar]

- Ma, Q.; Yuxiang, L.; Hongbin, T.; Meihui, T. Effect of Recycled Brick Powder on the Properties of Phosphorus Building Gypsum. Non-Met. Mines 2022, 45, 103–106. [Google Scholar]

- Li, L.; Li, B.; Yang, Y. Study on Inorganic Cementitious Material Composite Modified Phosphorus Building Gypsum. Non-Met. Mines 2022, 45, 102–106. [Google Scholar]

- Ji, M.; Jiang, B.; Huangfu, S. Study on the Effect of Carbon Nanotubes Modified Phosphorous Building Gypsum. Non-Met. Mines 2021, 4, 53–55. [Google Scholar]

- Zhao, B.; Zhiman, Z.; Sichen, Q.; Yi, Z.; Dan, L.; Sihua, W. Effect of Mineral Admixture on the Strength of Phosphorus Building Gypsum Mortar. Non-Met. Mines 2019, 42, 45–48. [Google Scholar]

- Nasir, M.; Aziz, M.A.; Zubair, M.; Manzar, M.S.; Ashraf, N.; Mu′Azu, N.D.; Al-Harthi, M.A. Recent review on synthesis, evaluation, and SWOT analysis of nanostructured cellulose in construction applications. J. Build. Eng. 2021, 46, 103747. [Google Scholar] [CrossRef]

- Ibrahim, M.; Nasir, M.; Hussaini, S. R; Najamuddin, S.K; Ewebajo, A.O. Performance of structurally viable green concrete derived from natural Pozzolan and Nanosilica. Mag. Civ. Eng. 2022, 107, 10710. [Google Scholar] [CrossRef]

- Lu, C.; Li, L.; Wang, W.; Feng, L. Bending strength properties of cement modified with nano-materials. Electron. J. Geotech. Eng. 2015, 20, 3647–3654. [Google Scholar]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L. Advances in the applied research of nano-material in concrete. Concrete 2004, 11, 4. [Google Scholar]

- Xiaoyan, G.; Bing, Z.; Yupeng, G. Synthesis and characterization of well-dispersed polyurethane/CaCO3 nanocomposites. Colloids Surf. A Physicochem. Eng. Asp. 2010, 371, 1–7. [Google Scholar]

- Kawashima, S.; Pengkun, H.; David, J. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2016, 36, 8–15. [Google Scholar] [CrossRef]

- Camiletti, J.; Soliman, A.M.; Nehdi, M.L. Effects of nano- and micro-limestone addition on early-age properties of ultra-high-performance concrete. Mater. Struct. 2012, 46, 881–898. [Google Scholar] [CrossRef]

- Liu, X.; Chen, L.; Liu, A.; Wang, X. Effect of nano-CaCO3 on properties of cement paste. Energy Procedia 2012, 16, 991–996. [Google Scholar] [CrossRef]

- Hawkins, P.; Tennis, P.D.; Detwiler, R.J. The Use of Limestone in Portland Cement: A State-of-the-Art Review; Portland Cement Association: Skokie, IL, USA, 1996; p. 36. [Google Scholar]

- Qian, K.L.; Meng, T.; Qian, X.Q.; Zhan, S.L. Research on Some Properties of Fly Ash Concrete with Nano-CaCO3 Middle Slurry. Key Eng. Mater. 2009, 405–406, 186–190. [Google Scholar] [CrossRef]

- GB/T 17669.4-1999.1999-02-08; Gypsum Plasters—Determination of Physical Properties of Pure Paste. State Bureau of Building Materials Industry: Beijing, China, 1999.

- GB/T 17669.3-1999.1999-02-08; Gypsum Plasters—Determination of Mechanical Properties. State Bureau of Building Materials Industry: Beijing, China, 1999.

- Mikailzade, F.; Önal, F.; Maksutoglu, M.; Zarbali, M.; Göktaş, A. Structure and magnetization of polycrystalline La0.66Ca0.33MnO3 and La0.66Ba0.33MnO3 films prepared using sol-gel technique. J. Supercond. Nov. Magn. 2018, 31, 4141–4145. [Google Scholar] [CrossRef]

- Altiner, M.; Top, S.; Kaymakoğlu, B.; Seçkin, İ.Y.; Vapur, H. Production of precipitated calcium carbonate particles from gypsum waste using venturi tubes as a carbonation zone. J. CO2 Util. 2019, 29, 117–125. [Google Scholar] [CrossRef]

- Mikailzade, F.; Türkan, H.; Önal, F.; Zarbali, M.; Göktaş, A.; Tumbul, A. Structural and magnetic properties of polycrystalline Zn1−xMnxO films synthesized on glass and p-type Si substrates using Sol–Gel technique. Appl. Phys. A 2021, 127, 408. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, F. Effects of Nano-materials on the Performance of UHPC. Mater. Rev. 2012, 26, 136–141. [Google Scholar]

- An, Y.X. Effect of nano materials on durability of high performance concrete. In Advanced Materials Research; Trans Tech Publications Ltd.: Shanghai, China, 2013; Volume 742, pp. 220–223. [Google Scholar]

- Zhang, H.; Wu, Y. Influence of nano SiO2 on mechanical property of the high performance concrete. New Build. Mater. 2012, 39, 78–80. [Google Scholar]

- Liu, Z.; Yang, J.; Bing, C. Experimental Study on Properties of Modified Raw Soil Material adding Phosphogypsum and Fly Ash. Fly Ash Compr. Util. 2016, 1, 3–6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).