Influence of Strengthening Elements and Heat Treatment on Microstructure and Fracture Toughness of NiAl-Cr(Mo)-Based Eutectic Alloy

Abstract

:1. Introduction

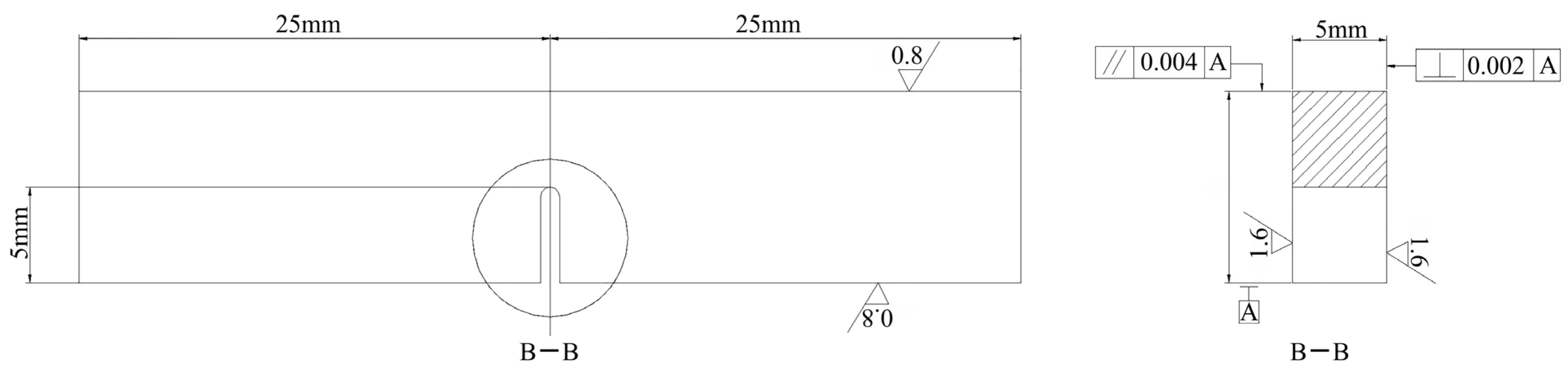

2. Materials and Methods

3. Results and Discussion

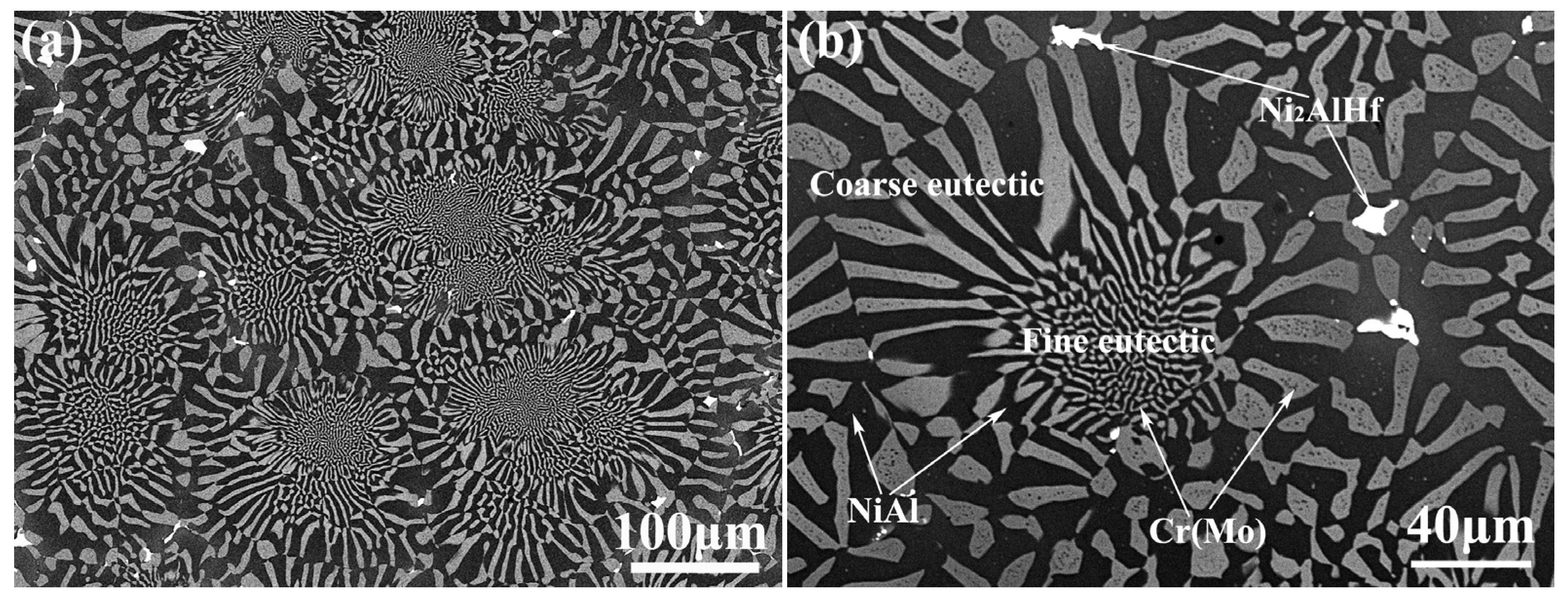

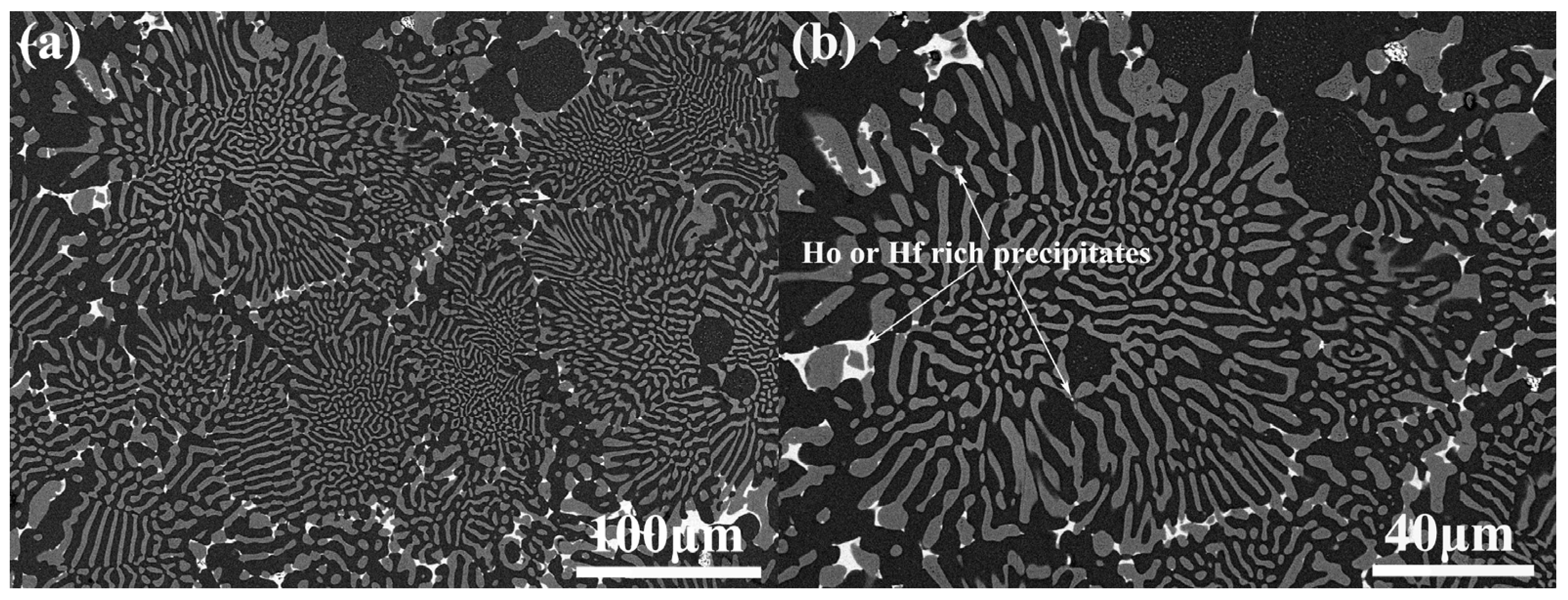

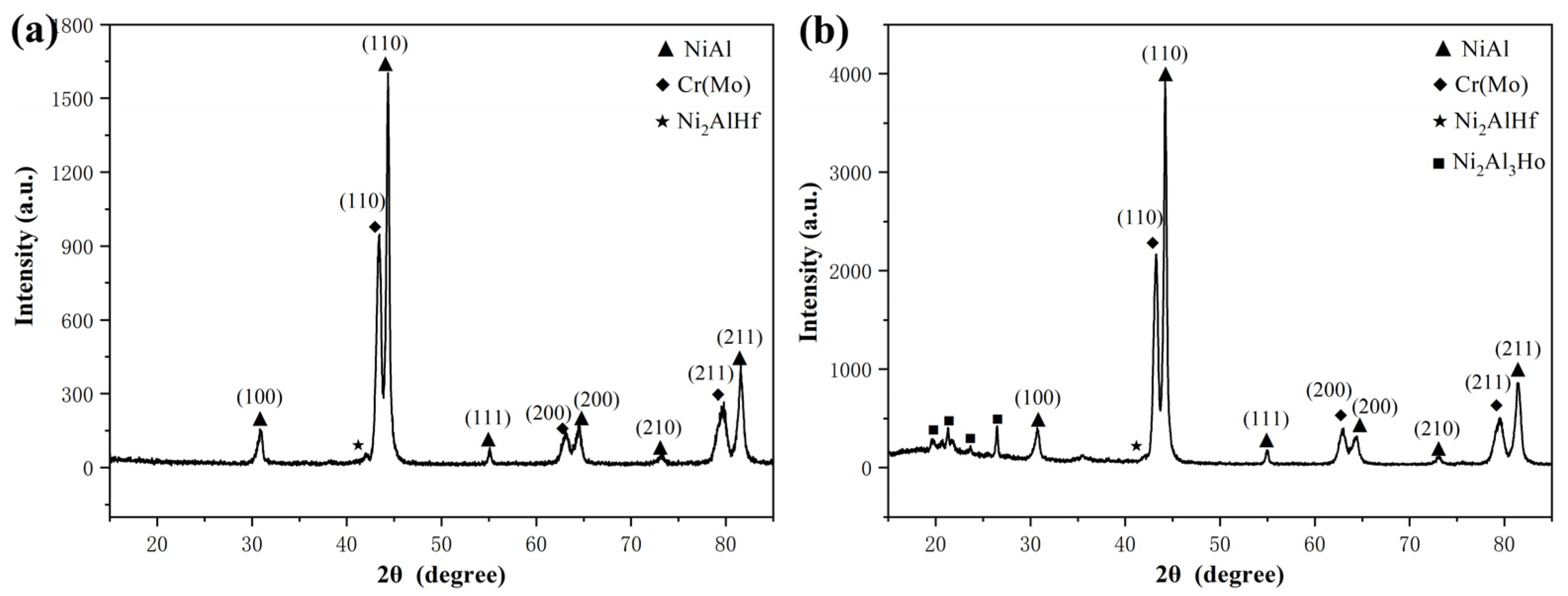

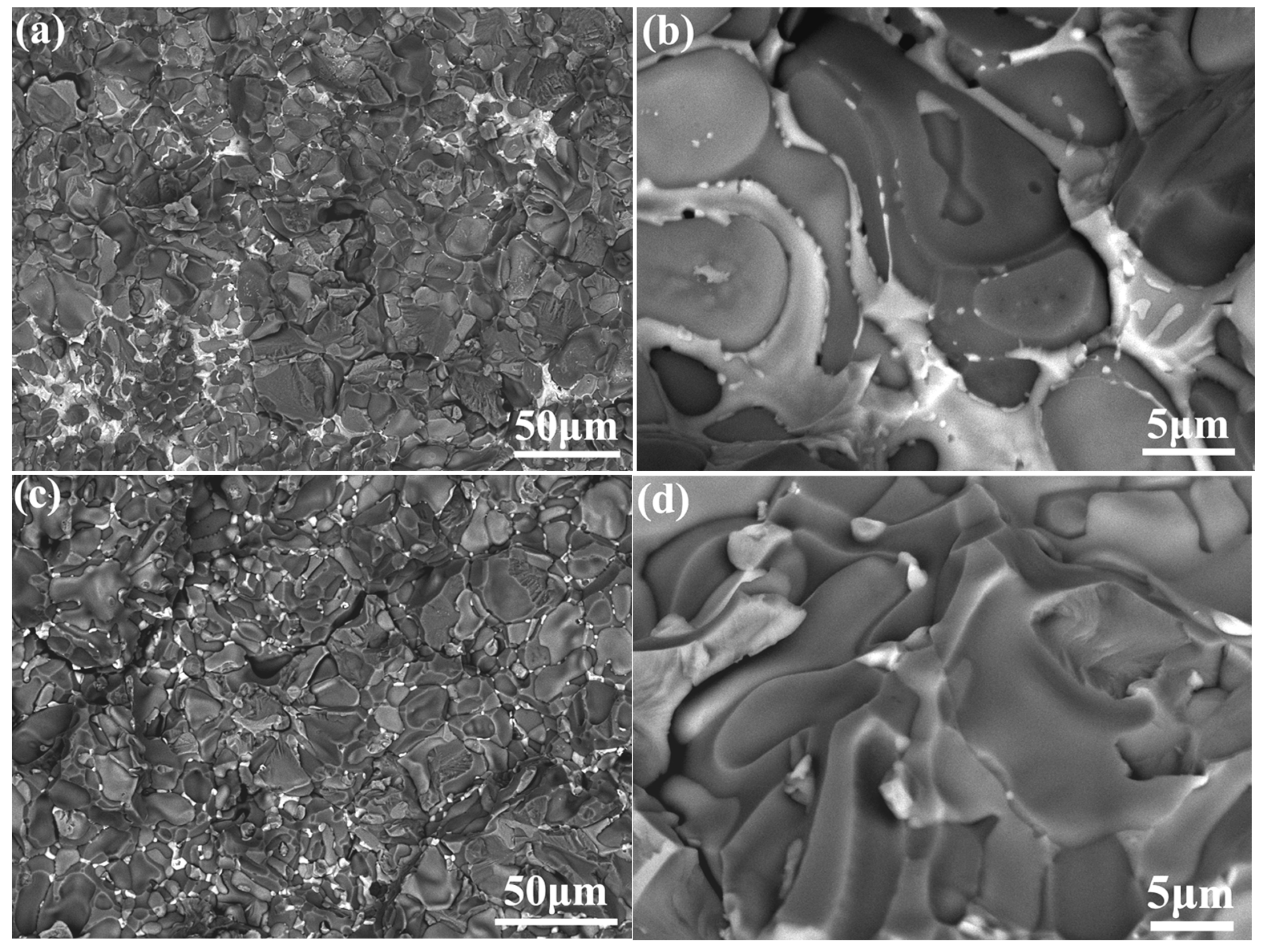

3.1. Microstructure Characteristic

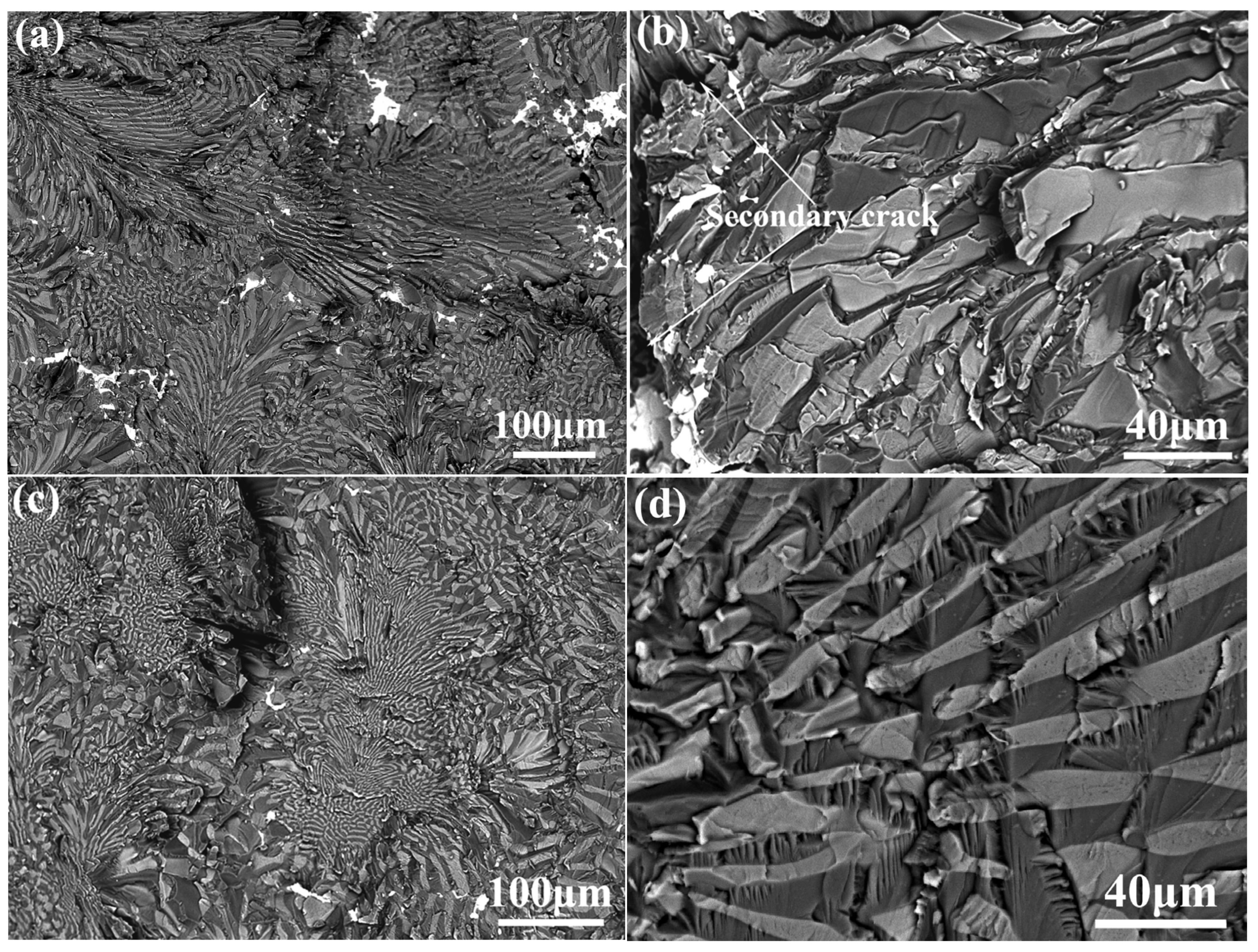

3.2. Mechanical Properties

4. Conclusions

- (1)

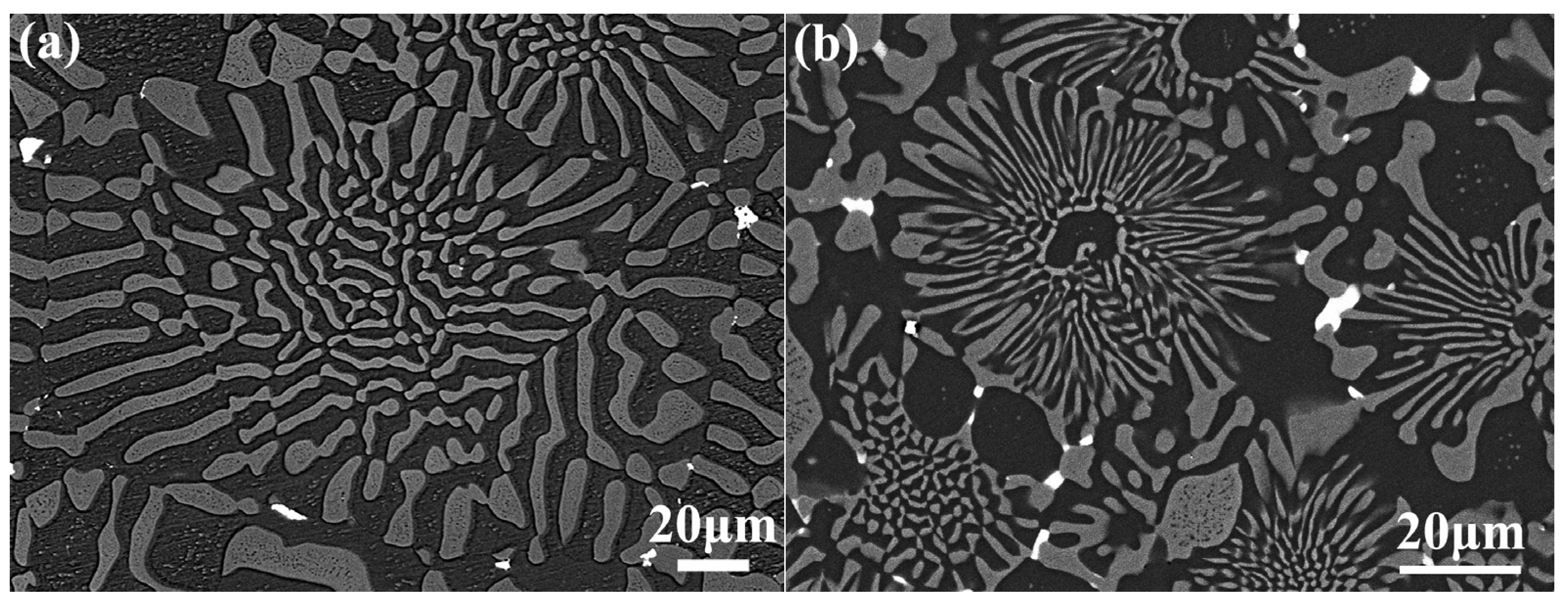

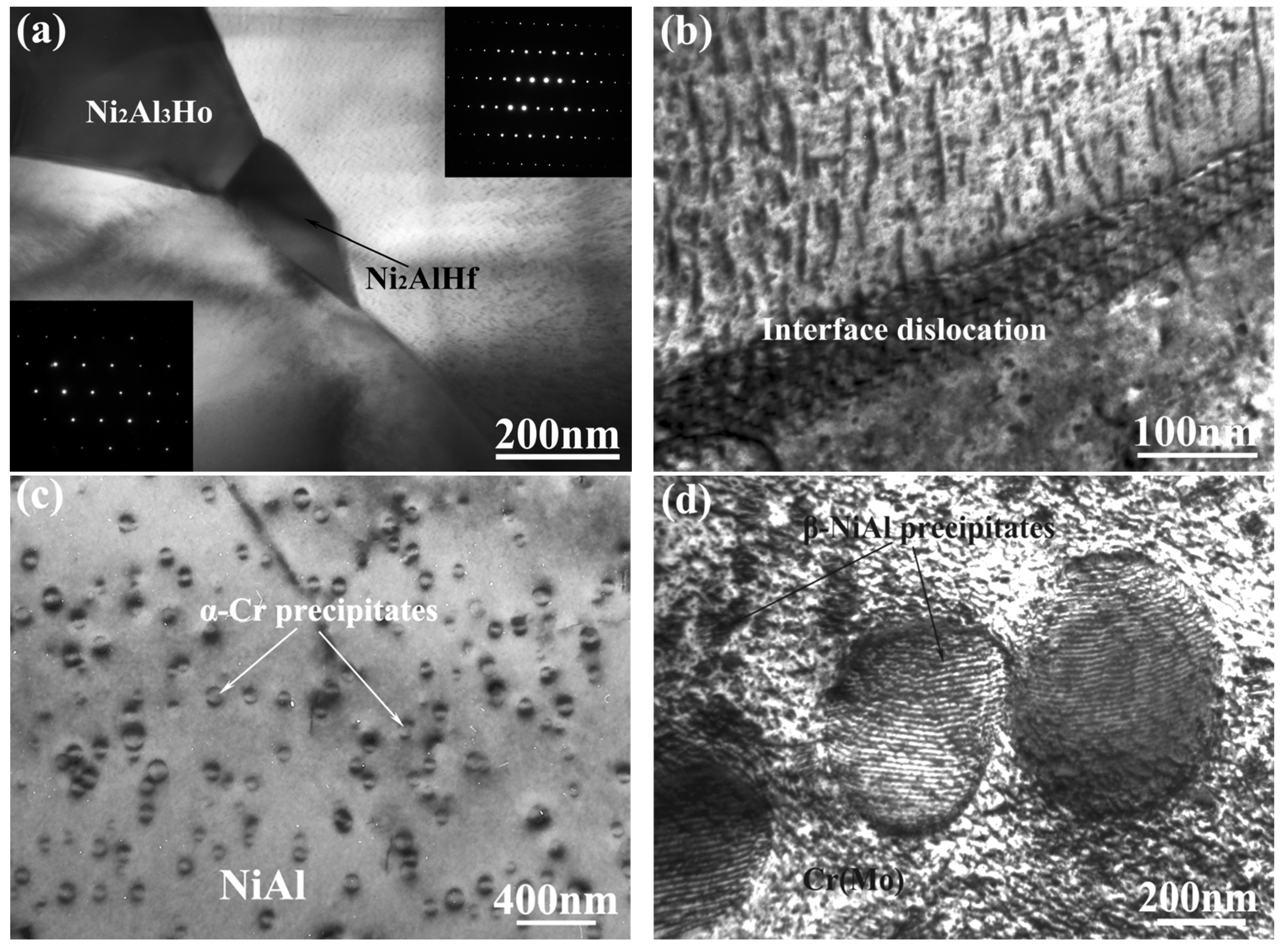

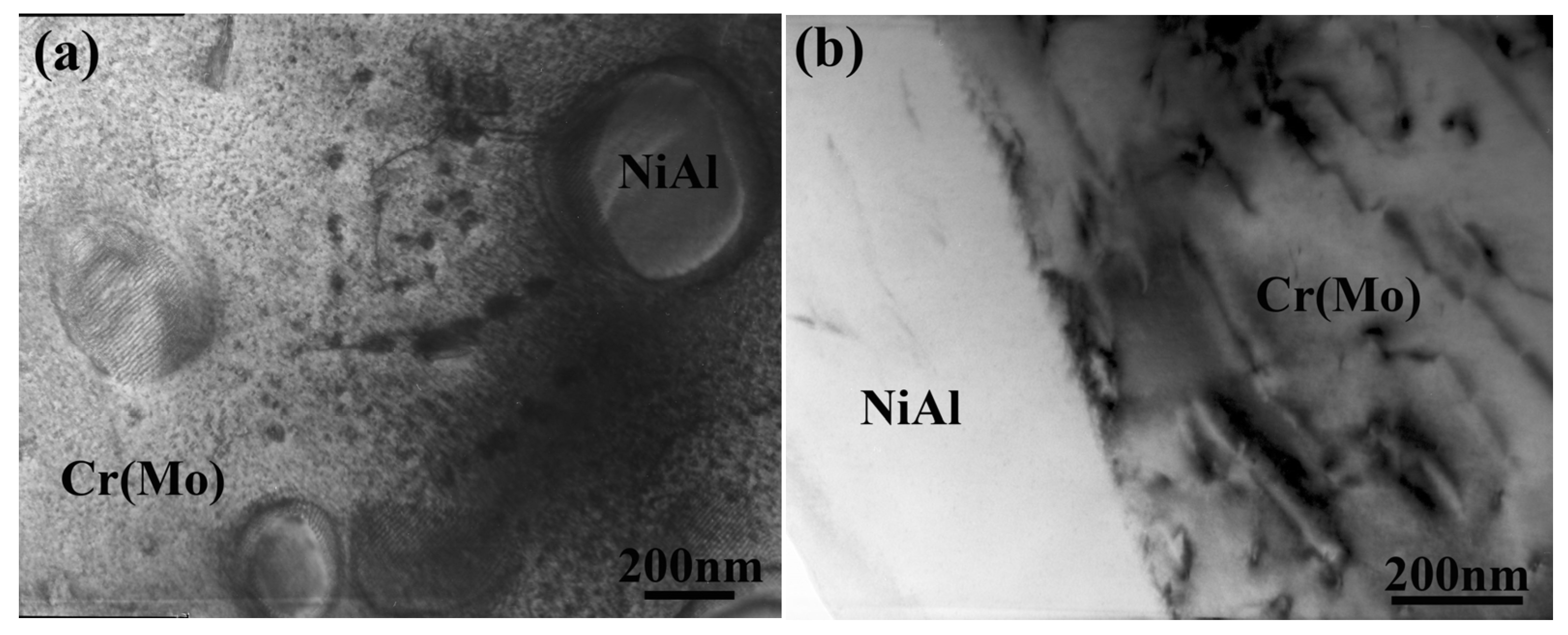

- The as-cast NiAl-Cr(Mo)-Hf eutectic alloy contains a relatively fine NiAl/Cr(Mo) eutectic lamella but coarse eutectic cell with Ni2AlHf phase embellished along the cell boundary. The minor Ho addition induces the formation of Ni2Al3Ho phase and refines the eutectic cells but coarsens the intercellular zone. In addition, the synergetic effect of Ho and Hf promotes the precipitation of Ni2Al3Ho and Ni2AlHf phases in the intercellular zone and increases the interface dislocations.

- (2)

- The heat treatment facilitates the solid solution of Ni2Al3Ho and Ni2AlHf phases, which benefits their size and distribution by secondary precipitation. For the NiAl-Cr(Mo)-Hf eutectic alloy, its NiAl/Cr(Mo) eutectic lamella in the eutectic cell becomes coarse, and the Ni2AlHf phase becomes fine and uniformly distributed. The heat treatment mainly optimizes the size and distribution of Ni2Al3Ho and Ni2AlHf phases in the NiAl-Cr(Mo)-Hf-Ho eutectic alloy.

- (3)

- The heat treatment helps to eliminate interface dislocations in the large NiAl precipitates and along the NiAl/Cr(Mo) phase interface, which also contributes to the fracture toughness by decreasing the stress concentration.

- (4)

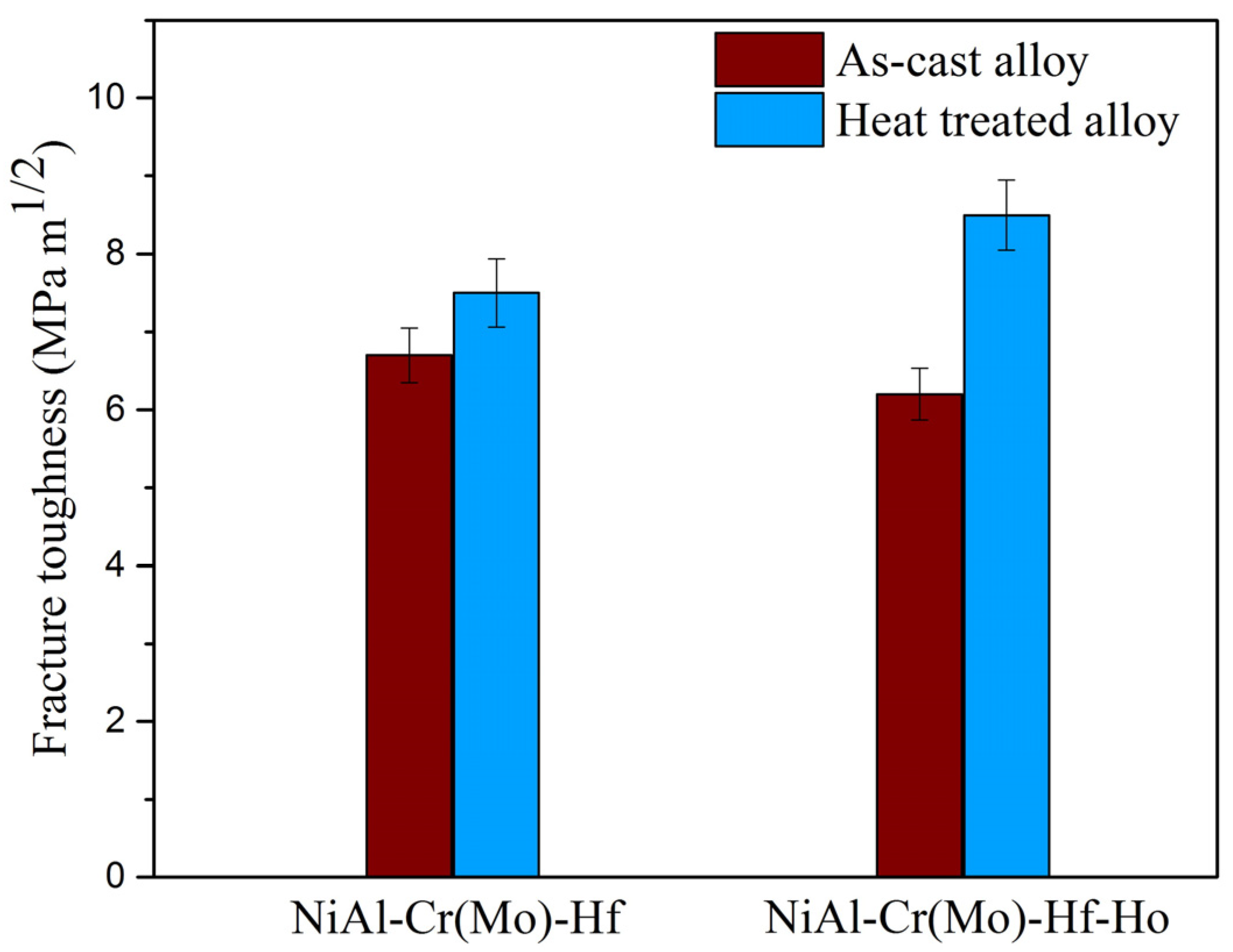

- Compared with the as-cast NiAl-Cr(Mo)-Hf eutectic alloy, the minor Ho addition decreases the fracture toughness from 6.7 to 6.1 MPa·m1/2, which should be mainly ascribed to the coarsened intercellular zone including Ni2Al3Ho and Ni2AlHf phases. The heat treatment increases the fracture toughness of NiAl-Cr(Mo)-Hf-Ho eutectic alloy from 6.1 to 8.2 MPa·m1/2, which is also higher than that of the heat-treated NiAl-Cr(Mo)-Hf eutectic alloy. The improved fracture toughness of heat-treated NiAl-Cr(Mo)-Hf-Ho eutectic alloy should be ascribed to the refined and well-distributed Ni2Al3Ho and Ni2AlHf phases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miracle, D.B. Overview No. 104 the physical and mechanical properties of NiAl. Acta Metall. Mater. 1993, 41, 649–684. [Google Scholar] [CrossRef]

- Zheng, L.; Sheng, L.Y.; Qiao, Y.X.; Yang, Y.; Lai, C. Influence of Ho and Hf on the microstructure and mechanical properties of NiAl and NiAl-Cr (Mo) eutectic alloy. Mater. Res. Express 2019, 6, 046502. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Guo, J.T.; Ye, H.Q. Microstructure evolution and mechanical properties of Ni3Al/Al2O3 composite during self-propagation high-temperature synthesis and hot extrusion. Mater. Sci. Eng. A 2012, 555, 131–138. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Tian, Y.X.; Guo, J.T. Microstructural Characteristics and Mechanical Properties of a Nb/Nb5Si3 based Composite with and without Directional Solidification. Adv. Compos. Lett. 2018, 27, 168–175. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, K.; Zhang, W.; Du, B.; Qi, D.; Li, W.; Song, M.; Sheng, Y.; Ye, H. Shear deformation determined by short-range configuration of atoms in topologically close-packed crystal. Acta Mater. 2019, 179, 396–405. [Google Scholar] [CrossRef]

- Noebe, R.D.; Bowman, R.R.; Nathal, M.V. Physical and mechanical properties of the B2 compound NiAl. Int. Mater. Rev. 2013, 38, 193–232. [Google Scholar] [CrossRef]

- Sheng, L.Y. Microstructure and wear properties of the quasi-rapidly solidified NiAl/Cr(Mo,Dy) hypoeutectic alloy. Strength Mater. 2016, 48, 107–112. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, Y.; Xi, T.F.; Guo, J.T. Investigation on microstructure and wear behavior of the NiAl-TiC-Al2O3 composite fabricated by self-propagation high-temperature synthesis with extrusion. J. Alloys Compd. 2013, 554, 182–188. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Du, B.N.; Zan, S.P.; Lai, C.; Jiao, J.K.; Gao, Y.B.; Xi, T.F. Optimization of the microstructure and mechanical properties of a laves phase-strengthened hypoeutectic NiAl/Cr (Mo, W) Alloy by suction casting. Strength Mater. 2018, 50, 504–514. [Google Scholar] [CrossRef]

- Darolia, R. NiAl alloys for high-temperature structural applications. JOM 1991, 43, 44–49. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Xie, Y.; Xi, T.F.; Guo, J.T.; Zheng, Y.F.; Ye, H.Q. Microstructure characteristics and compressive properties of NiAl-based multiphase alloy during heat treatments. Mater. Sci. Eng. A 2011, 528, 8324–8331. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, L. Several important findings of studies on NiAl alloys. Mater. China 2015, 34, 97–110. [Google Scholar]

- Du, B.N.; Sheng, L.Y.; Cui, C.Y.; Yang, J.X.; Sun, X.F. Precipitation and evolution of grain boundary boride in a nickel-based superalloy during thermal exposure. Mater. Charact. 2017, 128, 109–114. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Guo, J.T.; Xi, T.F. Anomalous yield and intermediate temperature brittleness behaviors of directionally solidified nickel-based superalloy. Trans. Nonferrous Met. Soc. China 2014, 24, 673–681. [Google Scholar] [CrossRef]

- Han, B.; Ma, Y.; Peng, H.; Zheng, H.; Guo, H. Effect of Mo, Ta, and Re on high-temperature oxidation behavior of minor Hf doped β-NiAl alloy. Corros. Sci. 2016, 102, 222–232. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Guo, J.T.; Xi, T.F.; Ye, H.Q. Investigation on NiAl-TiC-Al2O3 composite prepared by self-propagation high temperature synthesis with hot extrusion. Compos. Part B-Eng. 2013, 45, 785–791. [Google Scholar] [CrossRef]

- Liang, Y.C.; Guo, J.T.; Xie, Y.; Sheng, L.Y.; Zhou, L.Z.; Hu, Z.Q. Effect of growth rate on the tensile properties of DS NiAl/Cr (Mo) eutectic alloy produced by liquid metal cooling technique. Intermetallics 2010, 18, 319–323. [Google Scholar] [CrossRef]

- Zaitsev, A.A.; Sentyurina, Z.A.; Levashov, E.A.; Pogozhev, Y.S.; Sanin, V.N.; Loginov, P.A.; Petrzhik, M.I. Structure and properties of NiAl-Cr(Co,Hf) alloys prepared by centrifugal SHS casting. Part 1-Room temperature investigations. Mater. Sci. Eng. A 2017, 690, 463–472. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Guo, J.T.; Xi, T.F.; Zhang, B.C.; Ye, H.Q. ZrO2 strengthened NiAl/Cr (Mo, Hf) composite fabricated by powder metallurgy. Prog. Nat. Sci. Mater. Int. 2012, 22, 231–236. [Google Scholar] [CrossRef]

- Fan, X.Z.; Huang, W.Z.; Zhou, X.; Zou, B.L. Preparation and characterization of NiAl-TiC-TiB2 intermetallic matrix composite coatings by atmospheric plasma spraying of SHS powders. Ceram. Int. 2020, 46, 10512–10520. [Google Scholar] [CrossRef]

- Hu, L.; Zhang, G.; Hu, W.; Gottstein, G.; Bogner, S.; Buehrig-Polaczek, A. Tensile creep of directionally solidified NiAl–9Mo in situ composites. Acta Mater. 2013, 61, 7155–7165. [Google Scholar] [CrossRef]

- Zhang, G.; Hu, L.; Hu, W.; Gottstein, G.; Bogner, S.; Bührig-Polaczek, A. Mechanical properties of NiAl-Mo composites produced by specially controlled directional solidification. MRS Online Proc. Libr. 2013, 1516, 255–260. [Google Scholar] [CrossRef]

- Hu, W.; Huang, Z.; Cai, L.; Lei, C.; Yu, W.; Zhai, H.; Wo, S.; Li, X.; Zhou, Y. Microstructural characterization and mechanical properties of a novel TiC based cermet bonded with Ni3(Al,Ti) and NiAl duplexalloy. Mater. Charact. 2018, 135, 295–302. [Google Scholar] [CrossRef]

- Yang, J.M.; Jeng, S.M.; Bain, K.; Amato, R.A. Microstructure and mechanical behavior of in-situ directional solidified NiAl/Cr(Mo) eutectic composite. Acta Mater. 1997, 45, 295–308. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Lai, C.; Guo, J.T. Microstructure and elevated temperature tensile behaviour of directionally solidified nickel based superalloy. Mater. Res. Innov. 2013, 17, 101–106. [Google Scholar] [CrossRef]

- Du, B.; Sheng, L.; Hu, Z.; Cui, C.; Yang, J.; Sun, X. Investigation on the microstructure and tensile behavior of a Ni-based IN792 superalloy. Adv. Mech. Eng. 2018, 10, 1–8. [Google Scholar] [CrossRef]

- Du, B.; Hu, Z.; Sheng, L.; Cui, C.; Yang, J.; Zheng, Y.; Sun, X. Tensile, creep behavior and microstructure evolution of an as-cast Ni-based K417G polycrystalline superalloy. J. Mater. Sci. Technol. 2018, 34, 1805–1816. [Google Scholar] [CrossRef]

- Du, B.; Sheng, L.; Lai, C.; Cui, C.; Yang, J.; Sun, X. Evolution and Structure Characterization of the Carbide and Boride during Creep in A Ni-based Superalloy. Rare Met. Mater. Eng. 2017, 46, 2123–2129. [Google Scholar]

- Sheng, L.Y.; Du, B.N.; Lai, C.; Guo, J.T.; Xi, T.F. Influence of Tantalum Addition on Microstructure and Mechanical Properties of the NiAl-Based Eutectic Alloy. Strength Mater. 2017, 49, 109–117. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Zheng, Y.F.; Guo, J.T. Improvement of compressive strength and ductility in NiAl-Cr(Nb)/Dy alloy by rapid solidification and HIP treatment. Intermetallics 2012, 27, 14–20. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Zhang, W.; Guo, J.T.; Wang, Z.S.; Ye, H.Q. Microstructure evolution and elevated temperature compressive properties of a rapidly solidified NiAl-Cr(Nb)/Dy alloy. Mater. Des. 2009, 30, 2752–2755. [Google Scholar] [CrossRef]

- Cui, C.Y.; Guo, J.T.; Ye, H.Q. Precipitation behavior of Heusler phase (Ni2AlHf) in multiphase NiAl alloy. J. Mater. Sci. 2006, 41, 2981–2987. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Nan, L.; Zhang, W.; Guo, J.T.; Ye, H.Q. Microstructure and Mechanical Properties Determined in Compressive Tests of Quasi-Rapidly Solidified NiAl-Cr(Mo)-Hf Eutectic Alloy After Hot Isostatic Pressure and High Temperature Treatments. J. Mater. Eng. Perform. 2010, 19, 732–736. [Google Scholar] [CrossRef]

- Sheng, L.; Yang, F.; Xi, T.; Zheng, Y.; Guo, J. Microstructure and room temperature mechanical properties of NiAl-Cr(Mo)-(Hf,Dy) hypoeutectic alloy prepared by injection casting. Trans. Nonferrous Met. Soc. China 2013, 23, 983–990. [Google Scholar] [CrossRef]

- Guo, J.T.; Sheng, L.Y.; Tian, Y.X.; Zhou, L.Z.; Ye, H.Q. Effect of Ho on the microstructure and compressive properties of NiAl-based eutectic alloy. Mater. Lett. 2008, 62, 3910–3912. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Zhang, W.; Guo, J.T.; Zhou, L.Z.; Ye, H.Q. Microstructure evolution and mechanical properties’ improvement of NiAl-Cr(Mo)-Hf eutectic alloy during suction casting and subsequent HIP treatment. Intermetallics 2009, 17, 1115–1119. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Wang, L.J.; Xi, T.F.; Zheng, Y.F.; Ye, H.Q. Microstructure, precipitates and compressive properties of various holmium doped NiAl/Cr (Mo, Hf) eutectic alloys. Mater. Des. 2011, 32, 4810–4817. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Guo, J.T.; Zhang, W.; Zhou, L.Z.; Ye, H.Q. Microstructure and mechanical properties of NiAl-Cr(Mo)-Hf/Ho near-eutectic alloy prepared by suction casting. Int. J. Mater. Res. 2009, 100, 1602–1606. [Google Scholar] [CrossRef]

- Sheng, L.; Zhang, W.; Guo, J.; Ye, H. Microstructure and mechanical properties of Hf and Ho doped NiAl-Cr(Mo) near eutectic alloy prepared by suction casting. Mater. Charact. 2009, 60, 1311–1316. [Google Scholar] [CrossRef]

- Song, L.L.; Liu, S.; Mao, X. A new method for fast statistical measurement of interfacial misfit strain around nano-scale semicoherent particles. RSC Adv. 2017, 7, 28506–28515. [Google Scholar] [CrossRef]

- Wang, J.; Meng, L.; Zhang, Z.; Sa, B.; Fu, X.; Sheng, L.; Xu, D.; Zheng, Y. Investigation on the crystal structure and mechanical properties of the ternary compound Mg11-xZnxSr combined with experimental measurements and first-principles calculations. J. Magnes. Alloys, 2021, in press. [CrossRef]

- Wicht, D.; Kauffmann, A.; Schneider, M.; Heilmaier, M.; Böhlke, T. On the impact of the mesostructure on the creep response of cellular NiAl-Mo eutectics. Acta Mater. 2022, 226, 117626. [Google Scholar] [CrossRef]

- Ning, H.; Wang, D.; Wang, B.; Liu, G. Investigations on the NiAl-Cr(Mo) eutectic alloy with optimized microstructure and improved room-temperature compressive properties. Mater. Sci. Eng. A 2021, 813, 141138. [Google Scholar] [CrossRef]

- Wang, L.; Yao, C.; Shen, J.; Zhang, Y.; Wang, T.; Xu, H.; Gao, L.; Zhang, G. Microstructures and compressive properties of NiAl-Cr(Mo) and NiAl-Cr eutectic alloys with different Fe contents. Mater. Sci. Eng. A 2019, 774, 593–603. [Google Scholar] [CrossRef]

| Alloy | Phase | Ni | Al | Cr | Mo | Hf | Ho |

|---|---|---|---|---|---|---|---|

| As-cast NiAl-Cr(Mo)-Hf | NiAl | 47.06 | 49.23 | 3.42 | 0.08 | 0.21 | — |

| Cr(Mo) | 6.76 | 5.49 | 70.92 | 16.83 | — | — | |

| Ni2AlHf | 47.64 | 27.82 | 1.49 | 0.06 | 22.99 | — | |

| As-cast NiAl-Cr(Mo)-Hf-Ho | NiAl | 51.38 | 46.31 | 2.04 | — | 0.27 | — |

| Cr(Mo) | 4.95 | 8.04 | 76.93 | 10.08 | — | — | |

| Ni2AlHf | 51.77 | 25.32 | 2.62 | — | 18.53 | 1.76 | |

| Ni2Al3Ho | 33.64 | 45.21 | 1.96 | — | 1.16 | 18.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Li, R.; Xie, W.; Yang, F.; Du, B.; Sheng, L. Influence of Strengthening Elements and Heat Treatment on Microstructure and Fracture Toughness of NiAl-Cr(Mo)-Based Eutectic Alloy. Materials 2023, 16, 3362. https://doi.org/10.3390/ma16093362

Wang Q, Li R, Xie W, Yang F, Du B, Sheng L. Influence of Strengthening Elements and Heat Treatment on Microstructure and Fracture Toughness of NiAl-Cr(Mo)-Based Eutectic Alloy. Materials. 2023; 16(9):3362. https://doi.org/10.3390/ma16093362

Chicago/Turabian StyleWang, Qiaoli, Rui Li, Weixin Xie, Fang Yang, Beining Du, and Liyuan Sheng. 2023. "Influence of Strengthening Elements and Heat Treatment on Microstructure and Fracture Toughness of NiAl-Cr(Mo)-Based Eutectic Alloy" Materials 16, no. 9: 3362. https://doi.org/10.3390/ma16093362

APA StyleWang, Q., Li, R., Xie, W., Yang, F., Du, B., & Sheng, L. (2023). Influence of Strengthening Elements and Heat Treatment on Microstructure and Fracture Toughness of NiAl-Cr(Mo)-Based Eutectic Alloy. Materials, 16(9), 3362. https://doi.org/10.3390/ma16093362