Anti-High-Power Microwave RFID Tag Based on Highly Thermal Conductive Graphene Films

Abstract

:1. Introduction

2. Preparation of Graphene Film

3. Antenna Design

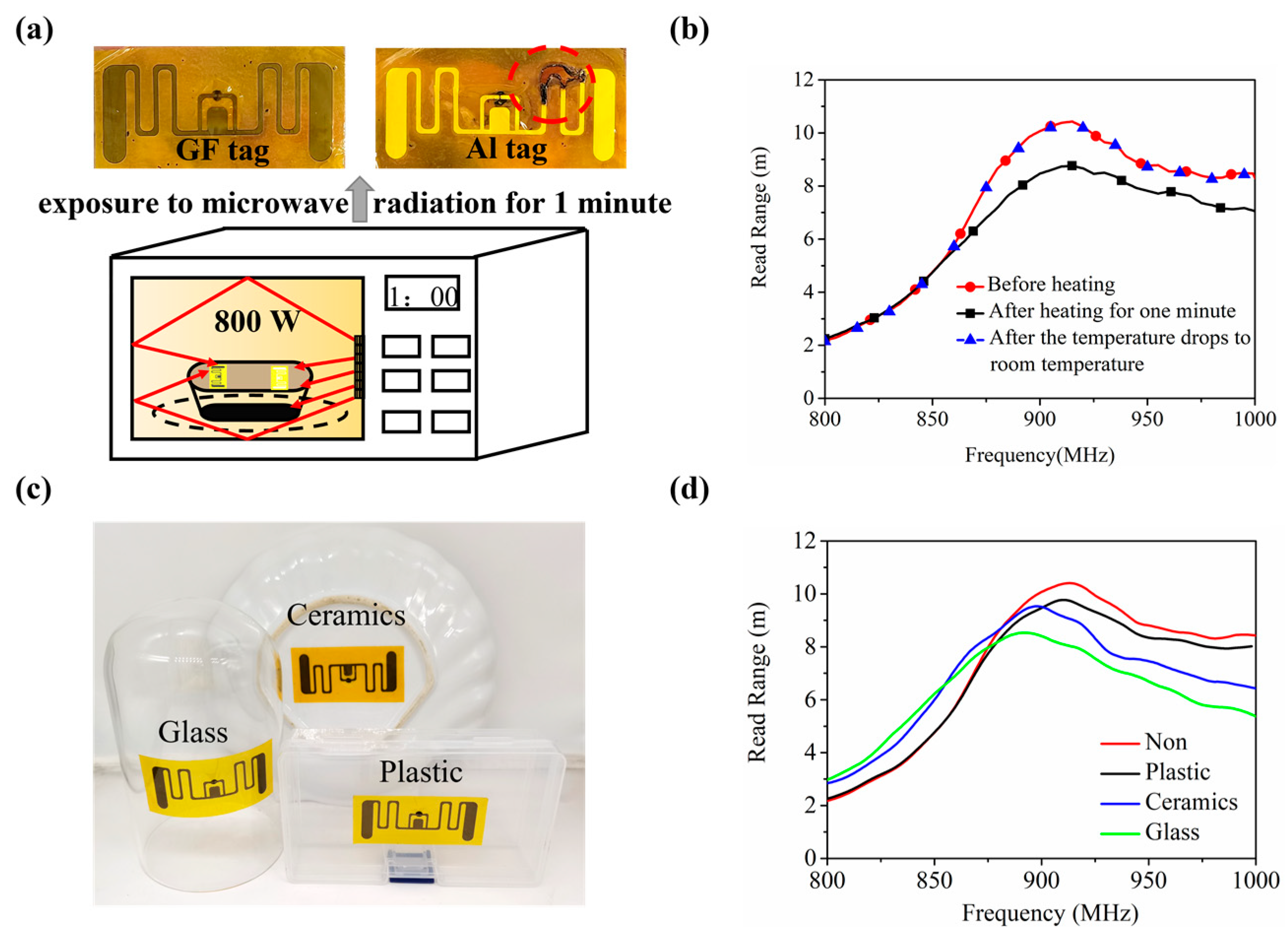

4. AMGFT Tests and Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramesh, G.; RamaMurthy, B. Implementation of High Performance UHF-RFID for Logistics Management System. J. Eng. Res. Appl. 2020, 10, 24–26. [Google Scholar]

- Unterhuber, A.R.; Iliev, S.; Biebl, E.M. Estimation Method for High-Speed Vehicle Identification with UHF RFID Systems. IEEE J. Radio Freq. Identif. 2020, 4, 343–352. [Google Scholar] [CrossRef]

- Alvarez-Narciandi, G.; Motroni, A.; Pino, M.R.; Buffi, A.; Nepa, P. A UHF-RFID Gate Control System Based on a Recurrent Neural Network. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 2330–2334. [Google Scholar] [CrossRef]

- Arboleya, A.; Laviada, J.; Alvarez-Lopez, Y.; Las-Heras, F. Real-Time Tracking System Based on RFID to Prevent Worker–Vehicle Accidents. IEEE Antennas Wirel. Propag. Lett. 2021, 20, 1794–1798. [Google Scholar] [CrossRef]

- Barge, P.; Biglia, A.; Comba, L.; Ricauda, A.D.; Tortia, C.; Gay, P. Radio Frequency Identification for Meat Supply-Chain Digitalisation. Sensors 2020, 20, 4957. [Google Scholar] [CrossRef]

- Thakur, M.; Møen-Tveit, G.; Vevle, G.; Yurt, T. A Framework for Traceability of Hides for Improved Supply Chain Coordination. Comput. Electron. Agric. 2020, 174, 105478. [Google Scholar] [CrossRef]

- Taoufik, S.; Dherbecourt, P.; El-Oualkadi, A.; Temcamani, F. Reliability and Failure Analysis of UHF RFID Passive Tags under Thermal Storage. IEEE Trans. Device Mater. Reliab. 2017, 17, 531–538. [Google Scholar] [CrossRef]

- Saarinen, K.; Frisk, L. Reliability Analysis of UHF RFID Tags under a Combination of Environmental Stresses. IEEE Trans. Device Mater. Reliab. 2013, 13, 119–125. [Google Scholar] [CrossRef]

- Ria, A.; Michel, A.; Singh, R.K.; Franchina, V.; Bruschi, P.; Nepa, P. Performance Analysis of a Compact UHF RFID Ceramic Tag in High-Temperature Environments. IEEE J. Radio Freq. Identif. 2020, 4, 461–467. [Google Scholar] [CrossRef]

- Wang, N.; Samani, M.K.; Li, H.; Dong, L.; Zhang, Z.; Su, P.; Chen, S.; Chen, J.; Huang, S.; Yuan, G.; et al. Tailoring the Thermal and Mechanical Properties of Graphene Film by Structural Engineering. Small 2018, 14, 1801346. [Google Scholar] [CrossRef]

- Kumar, P.; Shahzad, F.; Yu, S.; Hong, S.M.; Kim, Y.H.; Koo, C.M. Large-Area Reduced Graphene Oxide Thin Film with Excellent Thermal Conductivity and Electromagnetic Interference Shielding Effectiveness. Carbon 2015, 94, 494–500. [Google Scholar] [CrossRef]

- Huang, P.; Li, Y.; Yang, G.; Li, Z.X.; Li, Y.Q.; Hu, N.; Fu, S.Y.; Novoselov, K.S. Graphene Film for Thermal Management: A Review. Nano Mater. Sci. 2021, 3, 1–16. [Google Scholar] [CrossRef]

- Malekpour, H.; Chang, K.H.; Chen, J.C.; Lu, C.Y.; Nika, D.L.; Novoselov, K.S.; Balandin, A.A. Thermal Conductivity of Graphene Laminate. Nano Lett. 2014, 14, 5155–5161. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.; Wu, B.; Song, R.; Zhao, Y.; Zhang, Y.; He, D. Electromagnetic Shielding and Multi-Beam Radiation with High Conductivity Multilayer Graphene Film. Carbon 2019, 155, 506–513. [Google Scholar] [CrossRef]

- Zhang, J.; Song, R.; Zhao, X.; Fang, R.; Zhang, B.; Qian, W.; Zhang, J.; Liu, C.; He, D. Flexible Graphene-Assembled Film-Based Antenna for Wireless Wearable Sensor with Miniaturized Size and High Sensitivity. ACS Omega 2020, 5, 12937–12943. [Google Scholar] [CrossRef]

- Wang, Z.; Mao, B.; Wang, Q.; Yu, J.; Dai, J.; Song, R.; Pu, Z.; He, D.; Wu, Z.; Mu, S. Ultrahigh Conductive Copper/Large Flake Size Graphene Heterostructure Thin-Film with Remarkable Electromagnetic Interference Shielding Effectiveness. Small 2018, 14, 1704332. [Google Scholar] [CrossRef]

- Song, R.; Jiang, S.; Hu, Z.; Fan, C.; Li, P.; Ge, Q.; Mao, B.; He, D. Ultra-High Conductive Graphene Assembled Film for Millimeter Wave Electromagnetic Protection. Sci. Bull. 2022, 67, 1122–1125. [Google Scholar] [CrossRef]

- Song, R.; Wang, Z.; Zu, H.; Chen, Q.; Mao, B.; Wu, Z.P.; He, D. Wideband and Low Sidelobe Graphene Antenna Array for 5G Applications. Sci. Bull. 2021, 66, 103–106. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, C.; Wang, Y.; Wang, Z.; Liu, C.; He, D.; Wu, Z.P. Flexible Anti-Metal RFID Tag Antenna Based on High-Conductivity Graphene Assembly Film. Sensors 2021, 21, 1513. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Z.; Song, R.; Fu, H.; Zhao, X.; Zhang, C.; He, D.; Wu, Z.P. Passive UHF RFID Tags Made with Graphene Assembly Film-Based Antennas. Carbon 2021, 178, 803–809. [Google Scholar] [CrossRef]

- Zabek, D.; Seunarine, K.; Spacie, C.; Bowen, C. Graphene Ink Laminate Structures on Poly (Vinylidene Difluoride) (PVDF) for Pyroelectric Thermal Energy Harvesting and Waste Heat Recovery. ACS Appl. Mater. Interfaces 2017, 9, 9161–9167. [Google Scholar] [CrossRef] [PubMed]

- Song, R.; Zhao, X.; Wang, Z.; Fu, H.; Han, K.; Qian, W.; Wang, S.; Shen, J.; Mao, B.; He, D. Sandwiched Graphene Clad Laminate: A Binder-Free Flexible Printed Circuit Board for 5G Antenna Application. Adv. Eng. Mater. 2020, 22, 2000451. [Google Scholar] [CrossRef]

- Song, R.; Mao, B.; Wang, Z.; Hui, Y.; Zhang, N.; Fang, R.; Zhang, J.; Wu, Y.; Ge, Q.; Kostya, S.N.; et al. Comparison of Copper and Graphene-Assembled Films in 5G Wireless Communication and THz Electromagnetic-Interference Shielding. Proc. Natl. Acad. Sci. USA 2023, 120, e2209807120. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Lin, L.; Liu, Y.; Huang, X. LTPS TFT Process on Polyimide Substrate for Flexible AMOLED. J. Disp. Technol. 2015, 11, 666–669. [Google Scholar] [CrossRef]

| Parameter | Values (mm) | Parameter | Values (mm) |

|---|---|---|---|

| L | 58.64 | Tl | 16.06 |

| W | 25.00 | Tw | 9.00 |

| l1 | 3.70 | Cl | 3.00 |

| l2 | 2.50 | Cw | 5.00 |

| w1 | 18.00 | d1 | 1.20 |

| g | 0.15 | d2 | 5.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Song, R.; Fu, H.; Zhu, W.; Luo, K.; Xiao, Y.; Zhang, B.; Wang, S.; He, D. Anti-High-Power Microwave RFID Tag Based on Highly Thermal Conductive Graphene Films. Materials 2023, 16, 3370. https://doi.org/10.3390/ma16093370

Liu X, Song R, Fu H, Zhu W, Luo K, Xiao Y, Zhang B, Wang S, He D. Anti-High-Power Microwave RFID Tag Based on Highly Thermal Conductive Graphene Films. Materials. 2023; 16(9):3370. https://doi.org/10.3390/ma16093370

Chicago/Turabian StyleLiu, Xueyu, Rongguo Song, Huaqiang Fu, Wei Zhu, Kaolin Luo, Yang Xiao, Bohan Zhang, Shengxiang Wang, and Daping He. 2023. "Anti-High-Power Microwave RFID Tag Based on Highly Thermal Conductive Graphene Films" Materials 16, no. 9: 3370. https://doi.org/10.3390/ma16093370