Flexural Properties of Lattices Fabricated with Planar and Curved Layered Fused Filament Fabrication

Abstract

:1. Introduction

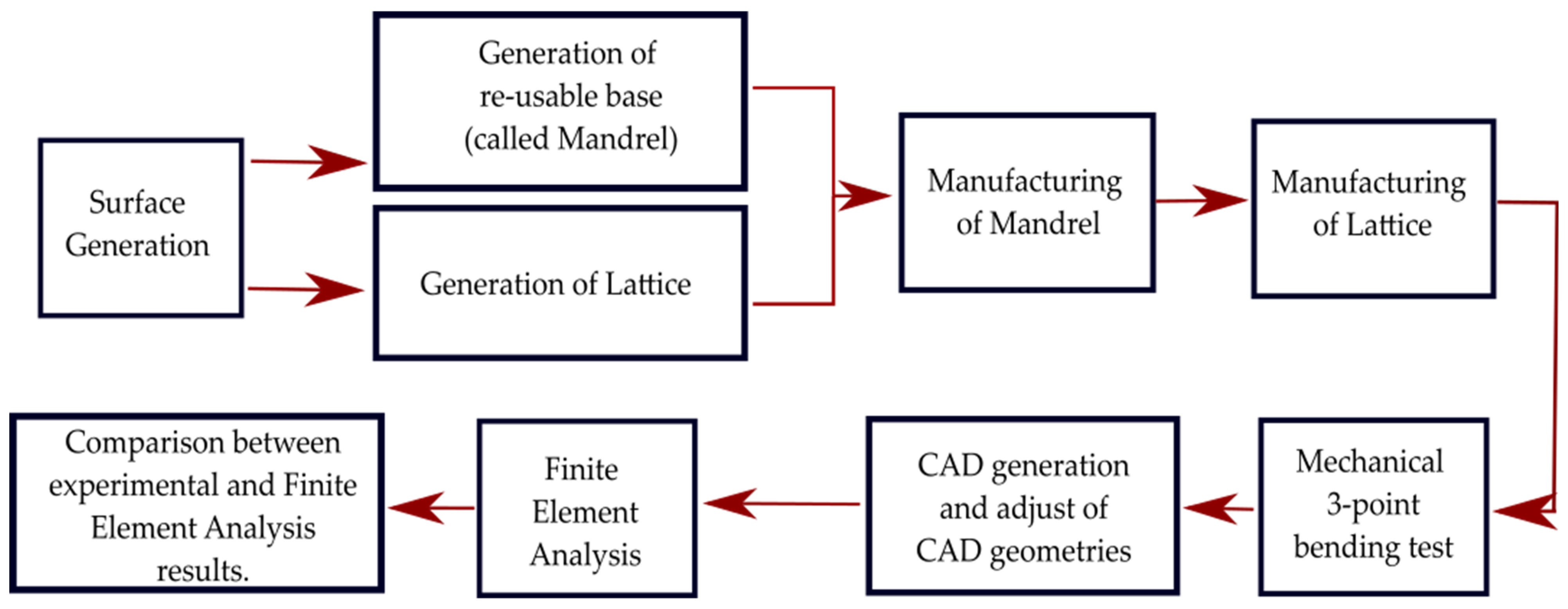

2. Materials and Methods

2.1. Desing and Manufacturing of Curved Layered Samples

2.1.1. Target Surface Generation for Mandrel and Lattices

2.1.2. Mandrel Generation and Additive Manufacturing

2.1.3. Lattices Generation and Additive Manufacturing of Samples

2.1.4. Mechanical Properties Characterization via 3-Point Bending Test

2.1.5. Curved-Lattice Models and Finite Element Analysis

3. Results

3.1. Manufacturing of Mandrel and Lattices

3.2. Mechanical Properties under 3-Point Bending Loading Scenario

3.2.1. Results of Simulation with CADs of Intended Designed Dimensions

3.2.2. Experimental Results and FEA Simulation with CADs with Adjusted Dimensions

3.2.3. Comparison of Results Based on Pattern (Diagonal vs. Square)

3.2.4. Comparison of Results Based on Printed Technology (CLFFF vs. FFF)

4. Discussion

5. Conclusions

Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Swetham, T.; Ketham Madhana, R.M.; Huggi, A.; Kumar, M.N. A Critical Review on of 3D Printing Materials and Details of Materials Used in FDM. Int. J. Sci. Res. Sci. Eng. Technol. 2017, 3, 353–361. [Google Scholar]

- García-Domínguez, A.; Claver, J.; Camacho, A.M.; Sebastián, M.A. Considerations on the Applicability of Test Methods for Mechanical Characterization of Materials Manufactured by FDM. Materials 2020, 13, 28. [Google Scholar] [CrossRef] [PubMed]

- Richter, C.; Schmülling, S.; Ehrmann, A.; Finsterbusch, K. FDM Printing of 3D Forms with Embedded Fibrous Materials. In Design, Manufacturing and Mechatronics, Proceedings of the 2015 International Conference on Design, Manufacturing and Mechatronics (ICDMM2015), Wuhan, China, 17–18 April 2015; World Scientific Publishing Company: Singapore, 2015; pp. 961–969. [Google Scholar] [CrossRef]

- Tagliaferri, V.; Trovalusci, F.; Guarino, S.; Venettacci, S. Environmental and Economic Analysis of FDM, SLS and MJF Additive Manufacturing Technologies. Materials 2019, 12, 161. [Google Scholar] [CrossRef]

- McCaw, J.C.S.; Cuan-Urquizo, E. Curved-Layered Additive Manufacturing of Non-Planar, Parametric Lattice Structures. Mater. Des. 2018, 160, 949–963. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the Mechanical Properties of FFF Structures and Materials: A Review on the Experimental, Computational and Theoretical Approaches. Materials 2019, 16, 895. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A Review on the Various Processing Parameters in FDM. Mater. Today Proc. 2020, 37, 509–514. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of Material and Process Specific Factors on the Strength of Printed Parts in Fused Filament Fabrication: A Review of Recent Developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef]

- Patel, J.; Patel, C.; Patel, M. A Review on Various Approach for Process Parameter Optimization of Fused Deposition Modeling (FDM) Process and Taguchi Approach for Optimization. Int. J. Eng. 2012, 2, 361–365. [Google Scholar]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM Process Parameters Influence over the Mechanical Properties of Polymer Specimens: A Review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Fu, T.; Chen, Z.; Yu, H.; Wang, Z.; Liu, X. An Analytical Study of Sound Transmission through Corrugated Core FGM Sandwich Plates Filled with Porous Material. Compos. Part B Eng. 2018, 151, 161–172. [Google Scholar] [CrossRef]

- Fu, T.; Chen, Z.; Yu, H.; Li, C.; Zhao, Y. Thermal Buckling and Sound Radiation Behavior of Truss Core Sandwich Panel Resting on Elastic Foundation. Int. J. Mech. Sci. 2019, 161–162, 105055. [Google Scholar] [CrossRef]

- Zhou, X.; Li, J.; Qu, C.; Bu, W.; Liu, Z.; Fan, Y.; Bao, G. Bending Behavior of Hybrid Sandwich Composite Structures Containing 3D Printed PLA Lattice Cores and Magnesium Alloy Face Sheets. J. Adhes. 2022, 98, 1713–1731. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Álvarez-Trejo, A.; Robles Gil, A.; Tejada-Ortigoza, V.; Camposeco-Negrete, C.; Uribe-Lam, E.; Treviño-Quintanilla, C.D. Effective Stiffness of Fused Deposition Modeling Infill Lattice Patterns Made of PLA-Wood Material. Polymers 2022, 14, 337. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Bhaskar, A. Flexural Elasticity of Woodpile Lattice Beams. Eur. J. Mech. A/Solids 2018, 67, 187–199. [Google Scholar] [CrossRef]

- Tao, Y.; Li, P.; Zhang, H.; Shi, S.Q.; Zhang, J.; Yin, Q. Compression and Flexural Properties of Rigid Polyurethane Foam Composites Reinforced with 3D-Printed Polylactic Acid Lattice Structures. Compos. Struct. 2022, 279, 114866. [Google Scholar] [CrossRef]

- Zhao, G.; Fu, T. A Unit Compound Structure Design: Poisson’s Ratio Is Autonomously Adjustable from Negative to Positive. Materials 2023, 16, 1808. [Google Scholar] [CrossRef]

- Nguyen, C.H.P.; Kim, Y.; Choi, Y. Design for Additive Manufacturing of Functionally Graded Lattice Structures: A Design Method with Process Induced Anisotropy Consideration. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 29–45. [Google Scholar] [CrossRef]

- Leonardi, F.; Graziosi, S.; Casati, R.; Tamburrino, F.; Bordegoni, M. Additive Manufacturing of Heterogeneous Lattice Structures: An Experimental Exploration. Proc. Int. Conf. Eng. Des. ICED 2019, 1, 669–678. [Google Scholar] [CrossRef]

- Azmi, M.S.; Ismail, R.; Hasan, R. Investigation on the Static and Dynamic Behavior of BCC Lattice Structure with Quatrefoil Node Manufactured Using Fused Deposition Modelling Additive Manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 788, 012008. [Google Scholar] [CrossRef]

- Peng, X.; Panda, B.; Garg, A.; Guan, H.; Savalani, M.M. Numerical Investigation of Flexural Properties of Curved Layer FDM Parts. In Soft Computing for Problem Solving: SocProS; Springer: Singapore, 2019; Volume 2, pp. 107–119. [Google Scholar] [CrossRef]

- Guan, H.W.; Savalani, M.M.; Gibson, I.; Diegel, O. Influence of Fill Gap on Flexural Strength of Parts Fabricated by Curved Layer Fused Deposition Modeling. Procedia Technol. 2015, 20, 243–248. [Google Scholar] [CrossRef]

- Huang, B.; Singamneni, S. Curved Layer Fused Deposition Modeling with Varying Raster Orientations. Appl. Mech. Mater. 2014, 446–447, 263–269. [Google Scholar] [CrossRef]

- Huang, B.; Singamneni, S.B. Curved Layer Adaptive Slicing (CLAS) for Fused Deposition Modelling. Rapid Prototyp. J. 2015, 21, 354–367. [Google Scholar] [CrossRef]

- McCaw, J.C.S.; Cuan-Urquizo, E. Mechanical Characterization of 3D Printed, Non-Planar Lattice Structures under Quasi-Static Cyclic Loading. Rapid Prototyp. J. 2020, 26, 707–717. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Heat Deflection Temperature (HDT) | 49–52 °C at 0.46 MPa |

| Tensile Strength | 61–66 MPa |

| Flexural Strength | 48–110 MPa |

| Young’s Modulus | 3.5 Gpa |

| Poisson’s Ratio | 0.3 |

| Parameter | Value |

|---|---|

| Bed temperature | 60 °C |

| Infill | 10% |

| Built Plate Adhesion | Raft |

| Material | Generic PLA |

| Nozzle Diameter | 0.4 mm |

| Hot end temperature | 205 °C |

| Printing Speed | 70 mm/s |

| Layer Height | 0.2 mm |

| Parameter | Value |

|---|---|

| Bed temperature | 25 °C |

| Hot end temperature | 210 °C |

| Feed rate (G0) | 3000 mm/s |

| Feed Rate (G1) | 375 mm/s |

| Pattern | Stiffness (N/mm) Mean ± Standard Deviation | Error between Experimental Result and FEA | |

|---|---|---|---|

| 0.05 | Square | 1.894 ± 0.193 | 2.8% |

| Diagonal | 1.643 ± 0.256 | 2.5% | |

| 0.06 | Square | 2.014 ± 0.058 | 9.9% |

| Diagonal | 1.576 ± 0.358 | 1.5% | |

| 0.13 | Square | 4.73 ± 0.291 | 6.7% |

| Diagonal | 2.74 ± 0.997 | 0.5% | |

| 0.14 | Square | 4.938 ± 0.561 | 1.7% |

| Diagonal | 4.451 ± 0.252 | 2.0% |

| Pattern | Stiffness (N/mm) Mean ± Standard Deviation | Error between Experimental Result and FEA | |

|---|---|---|---|

| 0.05 | Square | 1.953 ± 0.090 | 1.3% |

| Diagonal | 1.608 ± 0.213 | 7.2% | |

| 0.06 | Square | 2.522 ± 0.353 | 4.3% |

| Diagonal | 1.683 ± 0.317 | 2.3% | |

| 0.13 | Square | 4.976 ± 0.444 | 0.1% |

| Diagonal | 2.909 ± 1.023 | 3.4% | |

| 0.14 | Square | 4.983 ± 0.686 | 6.8% |

| Diagonal | 7.286 ± 0.294 | 6.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Castillo, J.L.; Mora, A.; Perez-Santiago, R.; Roman-Flores, A.; Ahmad, R.; Cuan-Urquizo, E. Flexural Properties of Lattices Fabricated with Planar and Curved Layered Fused Filament Fabrication. Materials 2023, 16, 3451. https://doi.org/10.3390/ma16093451

Pérez-Castillo JL, Mora A, Perez-Santiago R, Roman-Flores A, Ahmad R, Cuan-Urquizo E. Flexural Properties of Lattices Fabricated with Planar and Curved Layered Fused Filament Fabrication. Materials. 2023; 16(9):3451. https://doi.org/10.3390/ma16093451

Chicago/Turabian StylePérez-Castillo, José Luis, Angel Mora, Rogelio Perez-Santiago, Armando Roman-Flores, Rafiq Ahmad, and Enrique Cuan-Urquizo. 2023. "Flexural Properties of Lattices Fabricated with Planar and Curved Layered Fused Filament Fabrication" Materials 16, no. 9: 3451. https://doi.org/10.3390/ma16093451