In Situ Grown 1D/2D Structure of Dy3Si2C2 on SiCw for Enhanced Electromagnetic Wave Absorption

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials and Experiments

2.2. Characterizations

3. Results and Discussion

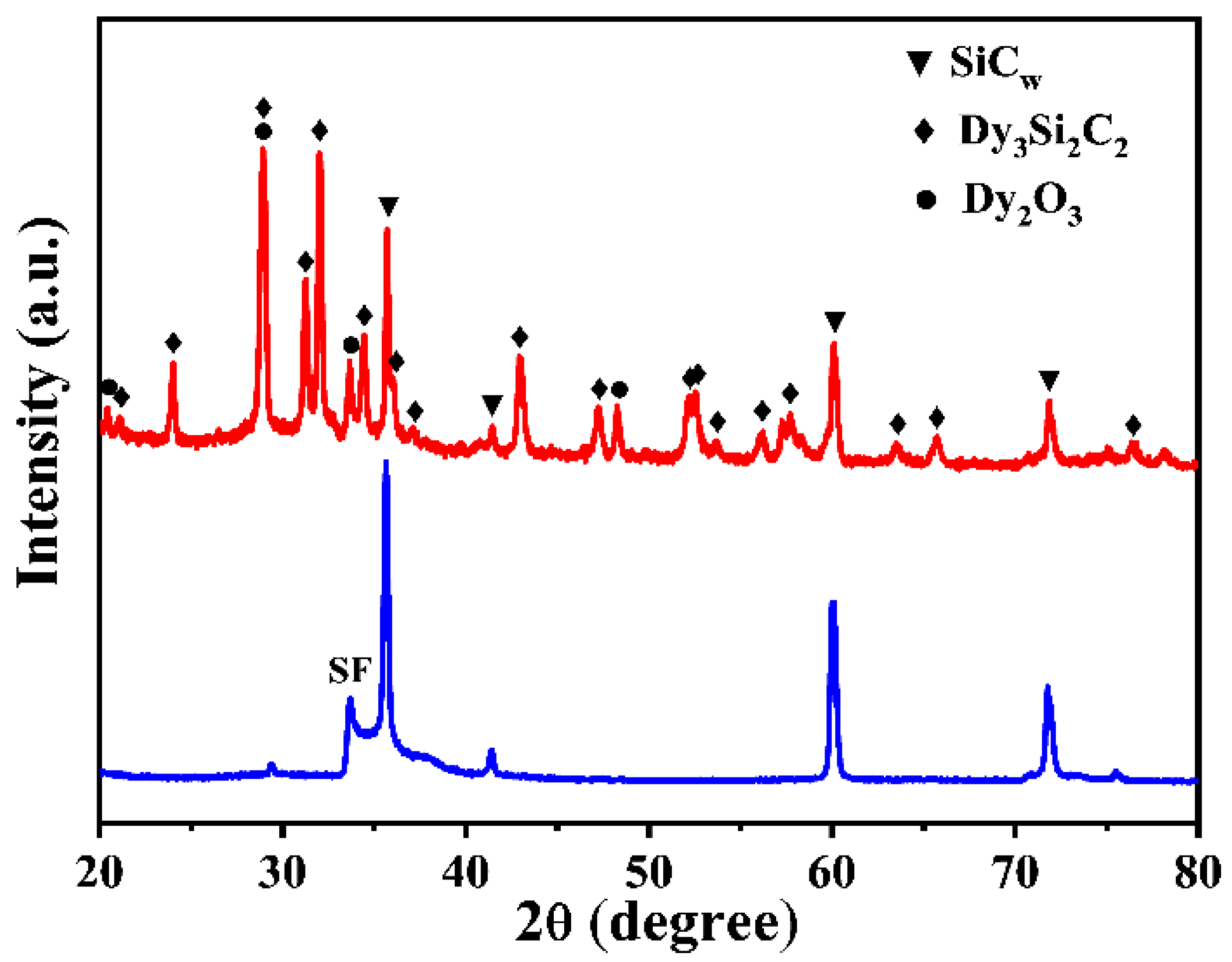

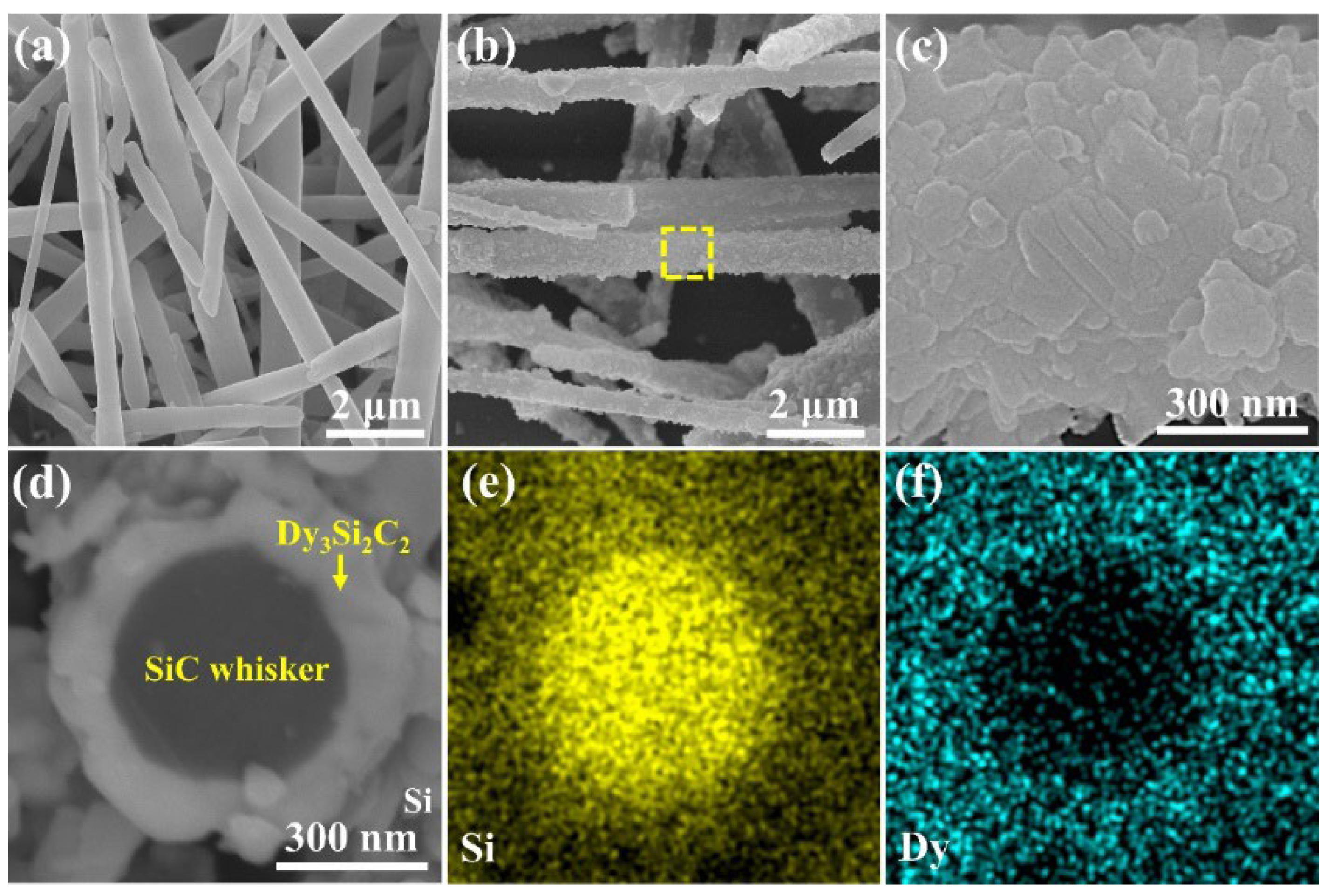

3.1. Microstructure and Phase Composition of SiCw/Dy3Si2C2

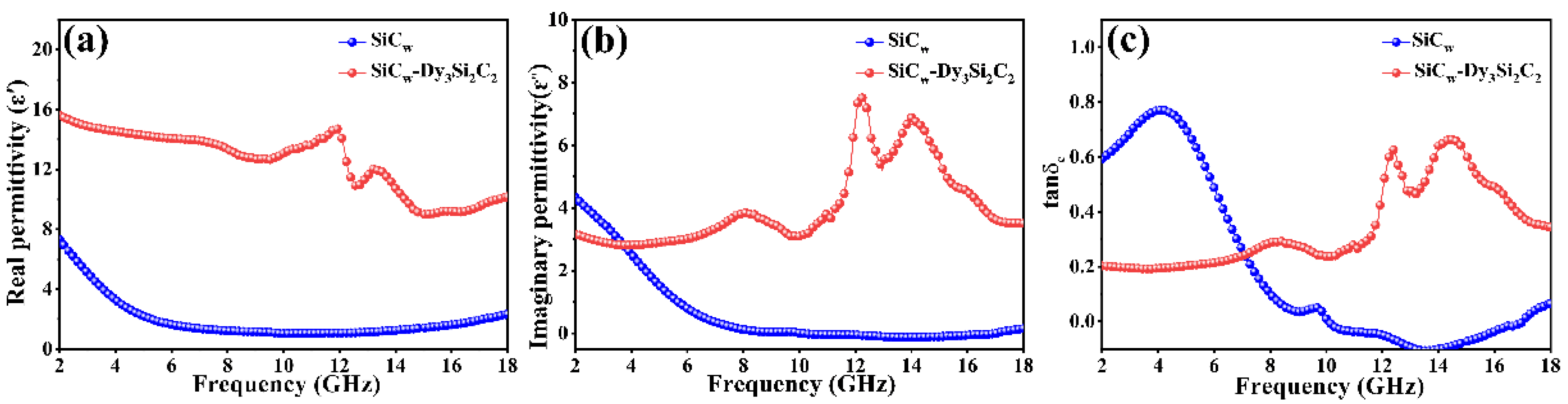

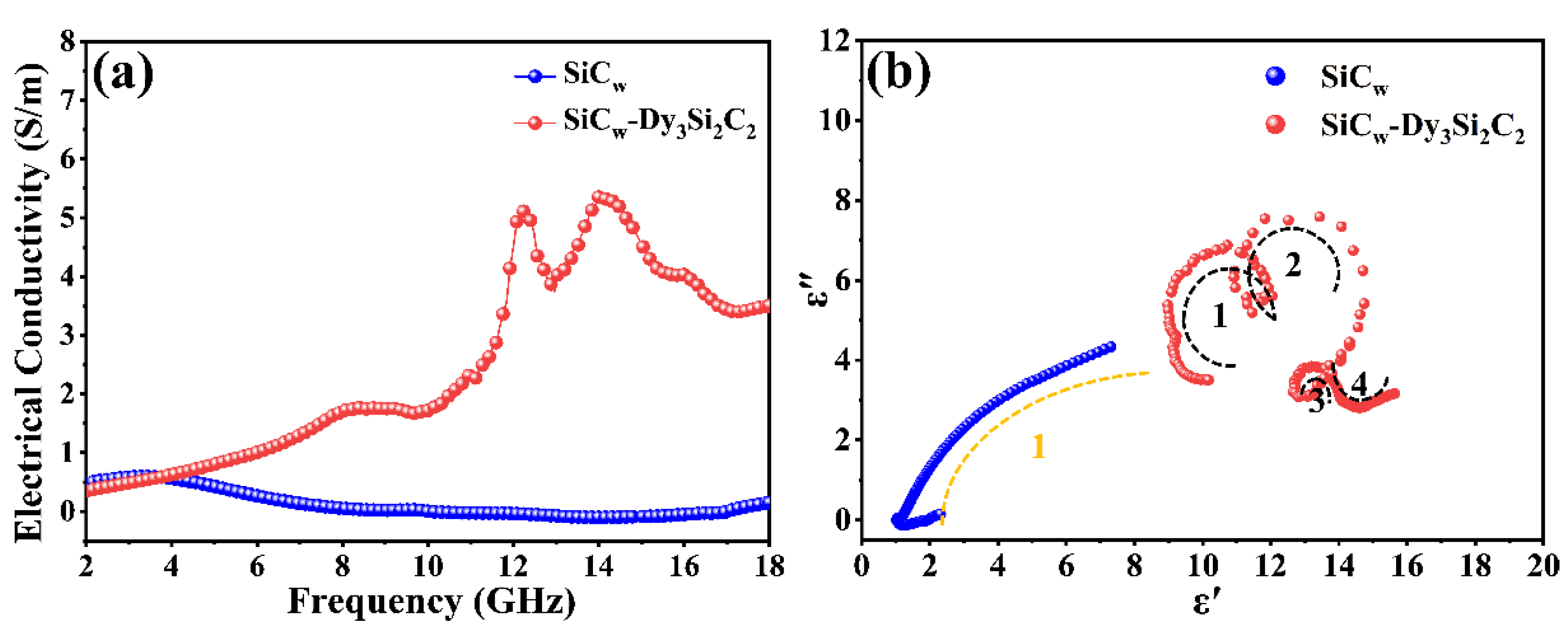

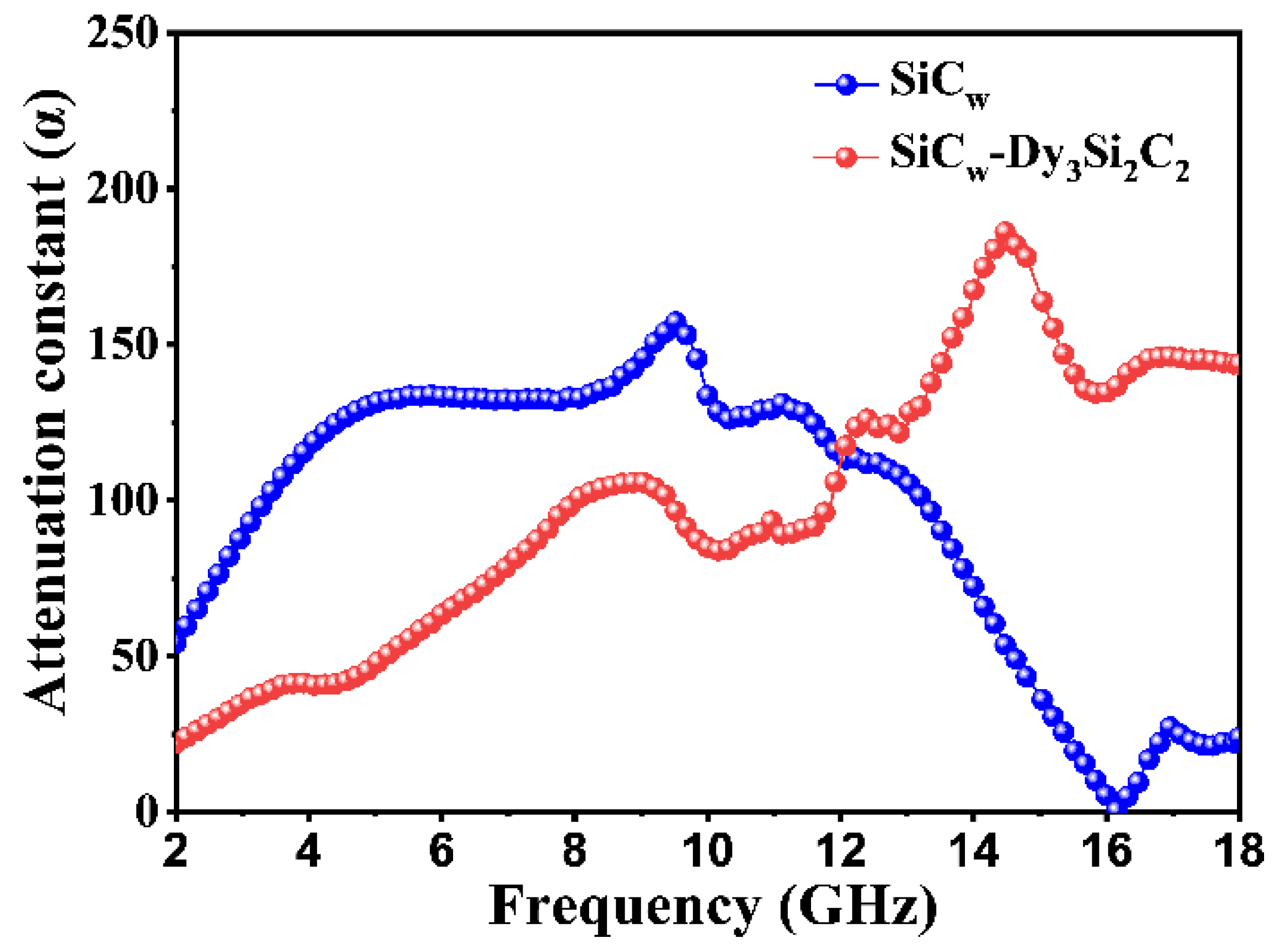

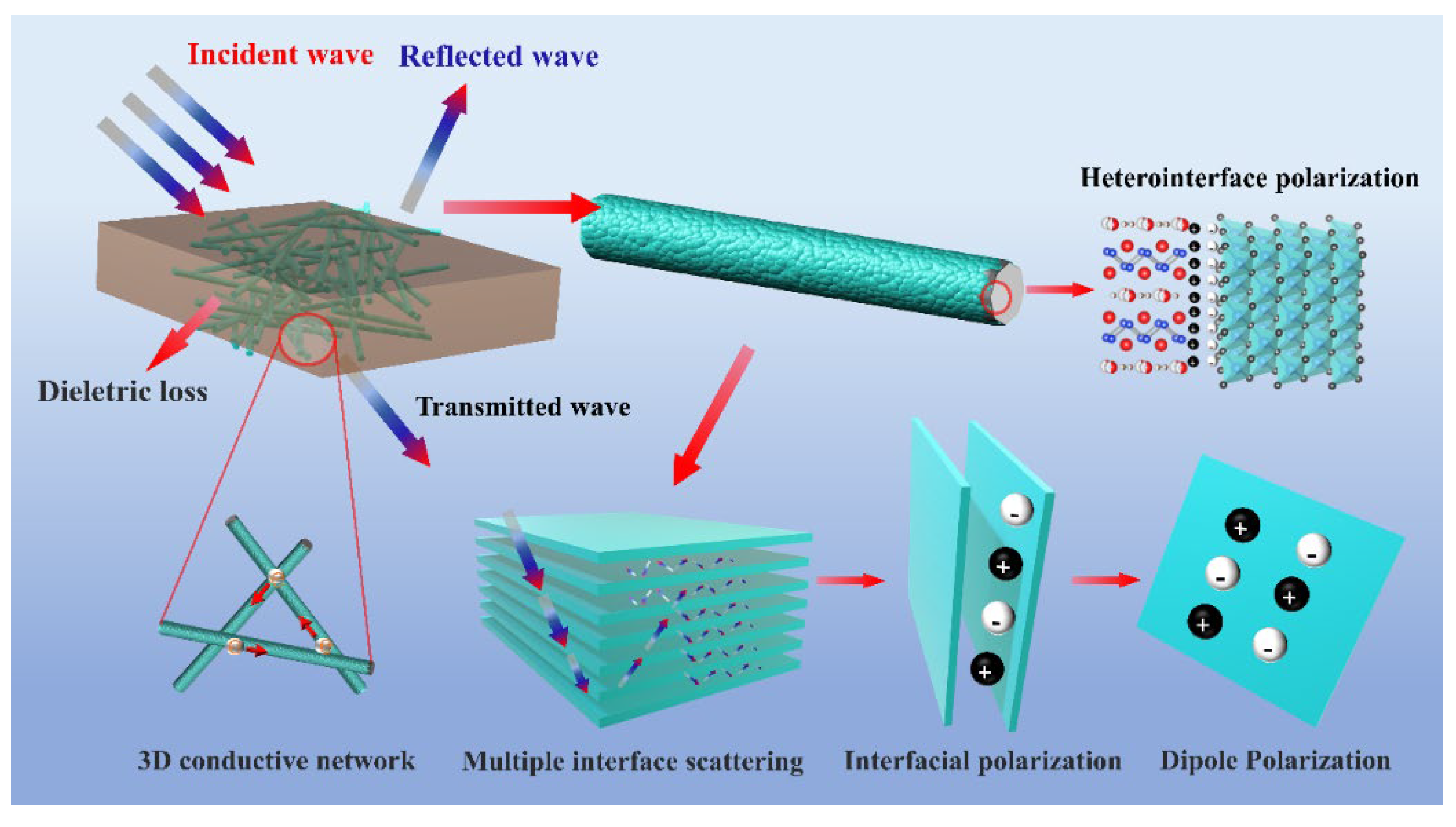

3.2. Dielectric Properties of SiCw/Dy3Si2C2

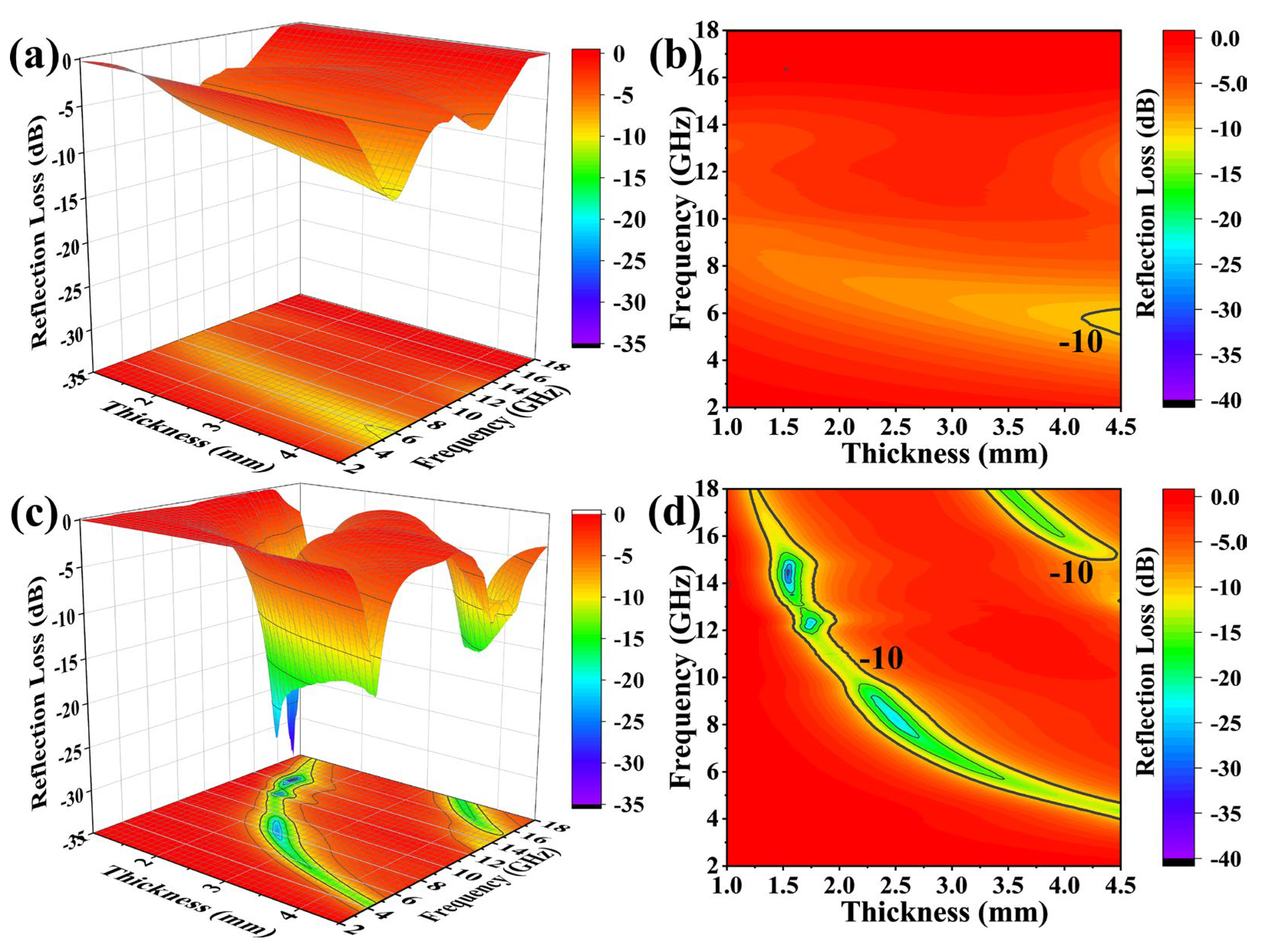

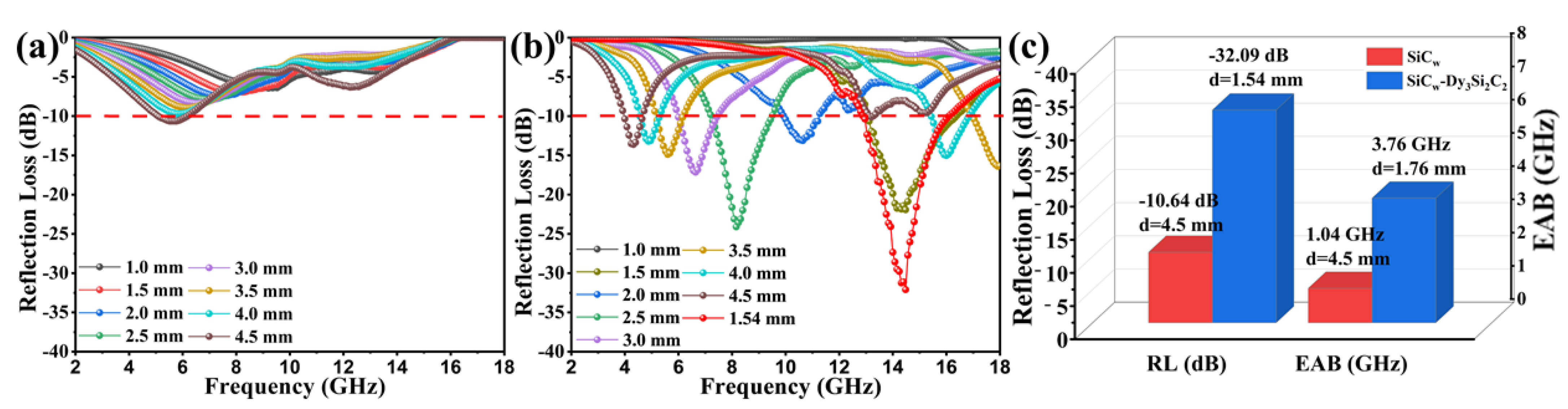

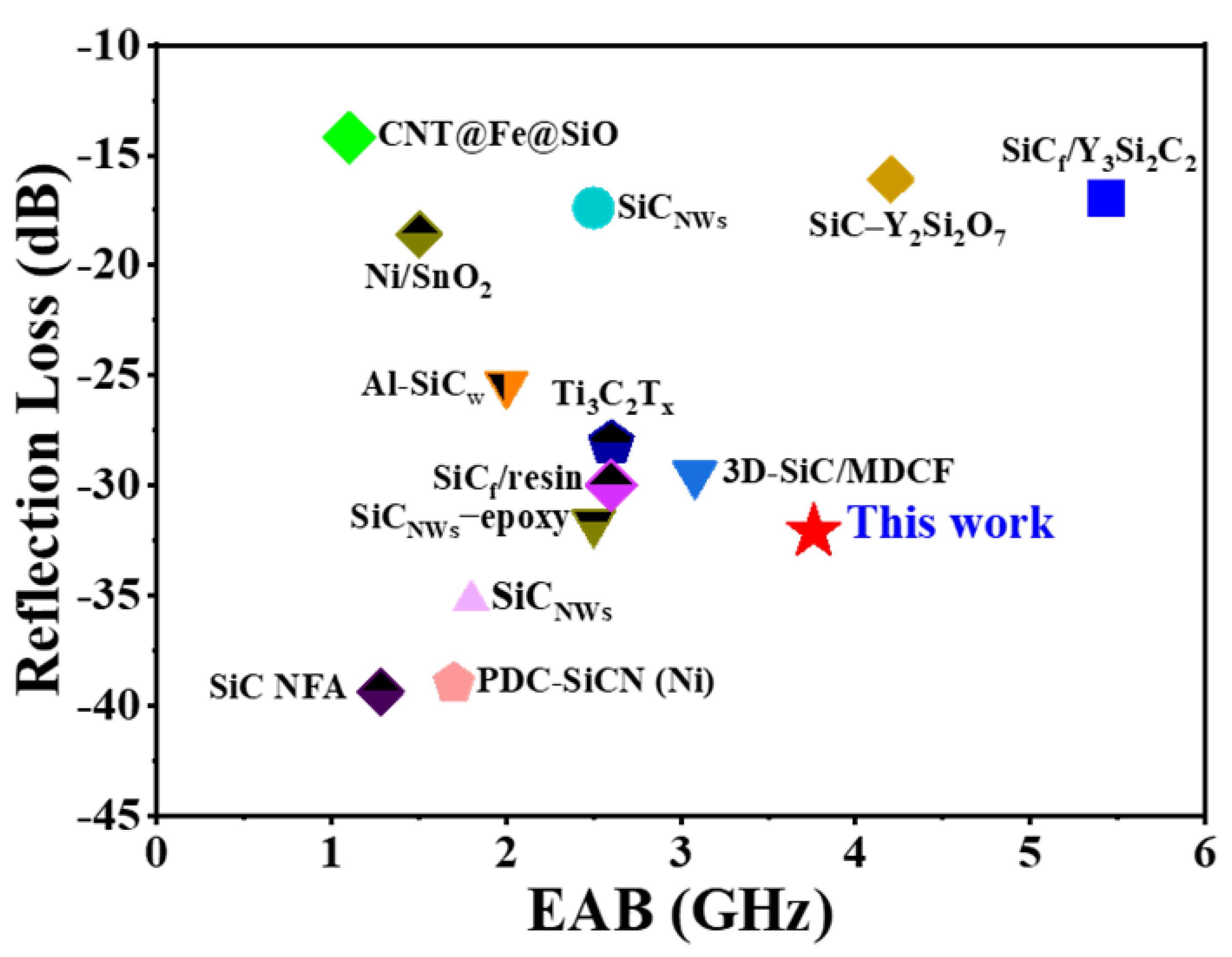

3.3. Electromagnetic Wave Absorption Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, H.; Yu, Y.; Jiang, F.; Xue, J.; Zhao, F.; Wang, Q. Carbon@SiC(SiCnws)-Sc2Si2O7 ceramics with multiple loss mediums for improving electromagnetic shielding performance. J. Eur. Ceram. Soc. 2022, 42, 2274–2281. [Google Scholar] [CrossRef]

- Wang, L.; Su, S.; Wang, Y. Fe3O4–Graphite Composites as a Microwave Absorber with Bimodal Microwave Absorption. ACS Appl. Nano Mater. 2022, 5, 17565–17575. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Y.; Li, Y.; Gou, Y.; Zhou, X. In-situ synthesis of ternary layered Y3Si2C2 ceramic on silicon carbide fiber for enhanced electromagnetic wave absorption. Ceram. Int. 2022, 48, 1908–1915. [Google Scholar] [CrossRef]

- Du, B.; Cai, M.; Wang, X.; Qian, J.; He, C.; Shui, A. Enhanced electromagnetic wave absorption property of binary ZnO/NiCo2O4 composites. J. Adv. Ceram. 2021, 10, 832–842. [Google Scholar] [CrossRef]

- Pongmuksuwan, P.; Salayong, K.; Lertwiriyaprapa, T.; Kitisatorn, W. Electromagnetic Absorption and Mechanical Properties of Natural Rubber Composites Based on Conductive Carbon Black and Fe3O4. Materials 2022, 15, 6532. [Google Scholar] [CrossRef] [PubMed]

- Mouchon, E.; Colomban, P. Microwave absorbent—Preparation, mechanical properties and rf-microwave conductivity of sic (and/or mullite) fibre reinforced nasicon matrix composites. J. Mater. Sci. 1996, 31, 323–334. [Google Scholar] [CrossRef]

- Zhao, W.; Shao, G.; Jiang, M.; Zhao, B.; Wang, H.; Chen, D.; Xu, H.; Li, X.; Zhang, R.; An, L. Ultralight polymer-derived ceramic aerogels with wide bandwidth and effective electromagnetic absorption properties. J. Eur. Ceram. Soc. 2017, 37, 3973–3980. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Y.; Yue, Y.; Wang, C.; Xu, Z.; Liu, D. Core-shell MXene/nitrogen-doped C heterostructure for wide-band electromagnetic wave absorption at thin thickness. Ceram. Int. 2022, 48, 30317–30324. [Google Scholar] [CrossRef]

- Huang, W.; Wang, S.; Yang, X.; Zhang, X.; Zhang, Y.; Pei, K.; Che, R. Temperature induced transformation of Co@C nanoparticle in 3D hierarchical core-shell nanofiber network for enhanced electromagnetic wave adsorption. Carbon 2022, 195, 44–56. [Google Scholar] [CrossRef]

- Shu, Y.; Zhao, T.; Li, X.; Yang, L.; Cao, S.; Ahmad, A.; Jiang, T.; Luo, H.; Jing, Z.; Ain, N.U. Flower-like Co@CoO nanohybrids assembled by crisp-rice-like quadrate flakes as high-performance electromagnetic wave absorber. Appl. Surf. Sci. 2022, 597, 153754. [Google Scholar] [CrossRef]

- Zhai, N.; Luo, J.; Xiao, M.; Zhang, Y.; Yan, W.; Xu, Y. In situ construction of Co@nitrogen-doped carbon/Ni nanocomposite for broadband electromagnetic wave absorption. Carbon 2023, 203, 416–425. [Google Scholar] [CrossRef]

- Trukhanov, S.V.; Trukhanov, A.V.; Kostishyn, V.G.; Panina, L.V.; Trukhanov, A.V.; Turchenko, V.A.; Tishkevich, D.I.; Trukhanova, E.L.; Oleynik, V.V.; Yakovenko, O.S.; et al. Magnetic, dielectric and microwave properties of the BaFe12−xGaxO19 (x ≤ 1.2) solid solutions at room temperature. J. Magn. Magn. Mater. 2017, 442, 300–310. [Google Scholar] [CrossRef]

- Bao, Y.; Guo, R.; Liu, C.; Li, S.; Ma, J. Design of magnetic triple-shell hollow structural Fe3O4/FeCo/C composite microspheres with broad bandwidth and excellent electromagnetic wave absorption performance. Ceram. Int. 2020, 46, 23932–23940. [Google Scholar] [CrossRef]

- Xiang, Z.; Song, Y.; Xiong, J.; Pan, Z.; Wang, X.; Liu, L.; Liu, R.; Yang, H.; Lu, W. Enhanced electromagnetic wave absorption of nanoporous Fe3O4@carbon composites derived from metal-organic frameworks. Carbon 2019, 142, 20–31. [Google Scholar] [CrossRef]

- Zdorovets, M.V.; Kozlovskiy, A.L.; Shlimas, D.I.; Borgekov, D.B. Phase transformations in FeCo—Fe2CoO4/Co3O4-spinel nanostructures as a result of thermal annealing and their practical application. J. Mater. Sci. Mater. Electron. 2021, 32, 16694–16705. [Google Scholar] [CrossRef]

- Qian, Y.; Tao, Y.; Li, W.; Li, Y.; Xu, T.; Hao, J.; Jiang, Q.; Luo, Y.; Yang, J. High electromagnetic wave absorption and thermal management performance in 3D CNF@C-Ni/epoxy resin composites. Chem. Eng. J. 2021, 425, 131608. [Google Scholar] [CrossRef]

- Xu, P.; He, H.; Fang, J.; Shang, T.; Wang, S.; Ge, S.; Wu, S.; Yue, X. Design and fabrication of a hollow nanobowl-like heterostructured PPy@Co/CoFe2O4@HNBC composite as a remarkable electromagnetic wave absorber. J. Alloys Compd. 2022, 926, 166749. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, S.; Ren, H.; Shi, S.Q.; Zhang, H.; Cai, L.; Li, J. Scalable fabrication of natural-fiber reinforced composites with electromagnetic interference shielding properties by incorporating powdered activated carbon. Materials 2015, 9, 10. [Google Scholar] [CrossRef] [Green Version]

- Jacobson, N.S.; Curry, D.M. Oxidation microstructure studies of reinforced carbon/carbon. Carbon 2006, 44, 1142–1150. [Google Scholar] [CrossRef] [Green Version]

- Wen, B.; Cao, M.; Lu, M.; Cao, W.; Shi, H.; Liu, J.; Wang, X.; Jin, H.; Fang, X.; Wang, W. Reduced graphene oxides: Light-weight and high-efficiency electromagnetic interference shielding at elevated temperatures. Adv. Mater. 2014, 26, 3484–3489. [Google Scholar] [CrossRef]

- Zhou, X.; Jing, L.; Kwon, Y.D.; Kim, J.-Y.; Huang, Z.; Yoon, D.-H.; Lee, J.; Huang, Q. Fabrication of SiCw/Ti3SiC2 composites with improved thermal conductivity and mechanical properties using spark plasma sintering. J. Adv. Ceram. 2020, 9, 462–470. [Google Scholar] [CrossRef]

- He, R.; Zhou, N.; Zhang, K.; Zhang, X.; Zhang, L.; Wang, W.; Fang, D. Progress and challenges towards additive manufacturing of SiC ceramic. J. Adv. Ceram. 2021, 10, 637–674. [Google Scholar] [CrossRef]

- Wang, C.; Chen, L.; He, H.; Ye, T.; Deng, Q.; Wei, H.; Zhao, F.; Wang, Q. Nano-SiC-decorated Y2Si2O7 ceramic for enhancing electromagnetic waves absorption performance. Ceram. Int. 2022, 48, 20168–20175. [Google Scholar] [CrossRef]

- Song, C.; Liu, Y.; Ye, F.; Cheng, L.; Zhang, P.; Chai, N. Enhanced mechanical property and tunable dielectric property of SiC f/SiC-SiBCN composites by CVI combined with PIP. J. Adv. Ceram. 2021, 10, 758–767. [Google Scholar] [CrossRef]

- Zhou, Q.; Yin, X.; Ye, F.; Tang, Z.; Mo, R.; Cheng, L. High temperature electromagnetic wave absorption properties of SiCf/Si3N4 composite induced by different SiC fibers. Ceram. Int. 2019, 45, 6514–6522. [Google Scholar] [CrossRef]

- Yuan, K.; Han, D.; Liang, J.; Zhao, W.; Li, M.; Zhao, B.; Liu, W.; Lu, H.; Wang, H.; Xu, H. Microwave induced in-situ formation of SiC nanowires on SiCNO ceramic aerogels with excellent electromagnetic wave absorption performance. J. Adv. Ceram. 2021, 10, 1140–1151. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, W.; Zhang, X.; Hu, P.; Han, J. Designable synthesis of core-shell SiCw@C heterostructures with thickness-dependent electromagnetic wave absorption between the whole X-band and Ku-band. Chem. Eng. J. 2018, 354, 767–776. [Google Scholar] [CrossRef]

- Cai, Z.; Su, L.; Wang, H.; Xie, Q.; Gao, H.; Niu, M.; Lu, D. Hierarchically assembled carbon microtube@SiC nanowire/Ni nanoparticle aerogel for highly efficient electromagnetic wave absorption and multifunction. Carbon 2022, 191, 227–235. [Google Scholar] [CrossRef]

- Kuang, J.; Jiang, P.; Ran, F.; Cao, W. Conductivity-dependent dielectric properties and microwave absorption of Al-doped SiC whiskers. J. Alloys Compd. 2016, 687, 227–231. [Google Scholar] [CrossRef]

- Lv, X.; Ye, F.; Cheng, L.; Zhang, L. 3D printing “wire-on-sphere” hierarchical SiC nanowires/SiC whiskers foam for efficient high-temperature electromagnetic wave absorption. J. Mater. Sci. Technol. 2022, 109, 94–104. [Google Scholar] [CrossRef]

- Wen, J.; Li, X.; Zhang, H.; Chen, M.; Wu, X. Enhancement of solar absorption performance using TiN@SiCw plasmonic nanofluids for effective photo-thermal conversion: Numerical and experimental investigation. Renew. Energy 2022, 193, 1062–1073. [Google Scholar] [CrossRef]

- Wang, P.; Cheng, L.; Zhang, Y.; Zhang, L. Flexible SiC/Si3N4 composite nanofibers with in situ embedded graphite for highly efficient electromagnetic wave absorption. ACS Appl. Mater. Interfaces 2017, 9, 28844–28858. [Google Scholar] [CrossRef] [PubMed]

- Bi, J.; Gu, Y.; Zhang, Z.; Wang, S.; Li, M.; Zhang, Z. Core–shell SiC/SiO2 whisker reinforced polymer composite with high dielectric permittivity and low dielectric loss. Mater. Des. 2016, 89, 933–940. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, X.; Hu, P.; Zhang, W.; Han, J.; Hu, P. Biomass-derived carbon and polypyrrole addition on SiC whiskers for enhancement of electromagnetic wave absorption. Chem. Eng. J. 2019, 359, 882–893. [Google Scholar] [CrossRef]

- Chen, J.-P.; Du, Y.-F.; Wang, Z.-F.; Liang, L.-L.; Jia, H.; Liu, Z.; Xie, L.-J.; Zhang, S.-C.; Chen, C.-M. Anchoring of SiC whiskers on the hollow carbon microspheres inducing interfacial polarization to promote electromagnetic wave attenuation capability. Carbon 2021, 175, 11–19. [Google Scholar] [CrossRef]

- Dong, S.; Lyu, Y.; Li, X.; Chen, J.; Zhang, X.; Han, J.; Hu, P. Construction of MnO nanoparticles anchored on SiC whiskers for superior electromagnetic wave absorption. J. Colloid Interface Sci. 2020, 559, 186–196. [Google Scholar] [CrossRef]

- Gerdes, M.H.; Witte, A.M.; Jeitschko, W.; Lang, A.; Künnen, B. Magnetic and Electrical Properties of a New Series of Rare Earth Silicide Carbides with the CompositionR3Si2C2 (R = Y, La–Nd, Sm, Gd–Tm). J. Solid State Chem. 1998, 138, 201–206. [Google Scholar] [CrossRef]

- Jeitschko, W.; Gerdes, M.H.; Witte, A.M.; Rodewald, U.C. Subcell structure and two different superstructures of the rare earth metal silicide carbides Y3Si2C2, Pr3Si2C2, Tb3Si2C2, and Dy3Si2C2. J. Solid State Chem. 2001, 156, 1–9. [Google Scholar] [CrossRef]

- Xu, K.; Chang, K.; Zhou, X.; Chen, L.; Liu, J.; Deng, Z.; Huang, F.; Huang, Q. Thermodynamic descriptions of the light rare-earth elements in silicon carbide ceramics. J. Am. Ceram. Soc. 2020, 103, 3812–3825. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, X.; Tatarko, P.; Yuan, Q.; Zhang, L.; Wang, H.; Huang, Z.; Huang, Q. Fabrication, microstructure, and properties of SiC/Al4SiC4 multiphase ceramics via an in-situ formed liquid phase sintering. J. Adv. Ceram. 2020, 9, 193–203. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.-K.; Zhou, X.; Dai, J.-Q.; Chen, K.; Huang, Z.; Huang, Q. Microstructure and properties of nano-laminated Y3Si2C2 ceramics fabricated via in situ reaction by spark plasma sintering. J. Adv. Ceram. 2021, 10, 578–586. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, J.; Zou, S.; Xu, K.; Chang, K.; Li, P.; Huang, F.; Huang, Z.; Huang, Q. Almost seamless joining of SiC using an in-situ reaction transition phase of Y3Si2C2. J. Eur. Ceram. Soc. 2020, 40, 259–266. [Google Scholar] [CrossRef]

- Yu, T.; Xu, J.; Zhou, X.; Tatarko, P.; Li, Y.; Huang, Z.; Huang, Q. Near-seamless joining of Cf/SiC composites using Y3Si2C2 via electric field-assisted sintering technique. J. Adv. Ceram. 2022, 11, 1196–1207. [Google Scholar] [CrossRef]

- Shi, L.-K.; Zhou, X.; Xu, K.; Chang, K.; Dai, J.-Q.; Huang, Z.; Huang, Q. Low temperature seamless joining of SiC using a Ytterbium film. J. Eur. Ceram. Soc. 2021, 41, 7507–7515. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, X.; Zou, S.; Chen, L.; Tatarko, P.; Dai, J.Q.; Huang, Z.; Huang, Q. Low-temperature Pr3Si2C2-assisted liquid-phase sintering of SiC with improved thermal conductivity. J. Am. Ceram. Soc. 2022, 105, 5576–5584. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, T.; Xu, J.; Li, Y.; Huang, Z.; Huang, Q. Ultrafast low-temperature near-seamless joining of Cf/SiC using a sacrificial Pr3Si2C2 filler via electric current field-assisted sintering technique. J. Eur. Ceram. Soc. 2022, 42, 6865–6875. [Google Scholar] [CrossRef]

- Yakovenko, O.S.; Matzui, L.Y.; Vovchenko, L.L.; Trukhanov, A.V.; Kazakevich, I.S.; Trukhanov, S.V.; Prylutskyy, Y.I.; Ritter, U. Magnetic anisotropy of the graphite nanoplatelet–epoxy and MWCNT–epoxy composites with aligned barium ferrite filler. J. Mat. Sci. 2017, 52, 5345–5358. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Shlimas, D.I.; Zdorovets, M.V. Synthesis, structural properties and shielding efficiency of glasses based on TeO2-(1-x)ZnO-xSm2O3. J. Mater. Sci. Mater. Electron. 2021, 32, 12111–12120. [Google Scholar] [CrossRef]

- Liu, P.; Ma, T.; Wang, X.; Zhang, Y.; Yan, M. Role of hydrogen in Nd–Fe–B sintered magnets with DyHx addition. J. Alloys Compd. 2015, 628, 282–286. [Google Scholar] [CrossRef]

- Liu, X.; Fechler, N.; Antonietti, M. Salt melt synthesis of ceramics, semiconductors and carbon nanostructures. Chem. Soc. Rev. 2013, 42, 8237–8265. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Fu, Q.; Chu, Y. Molten salt synthesis, formation mechanism, and oxidation behavior of nanocrystalline HfB2 powders. J. Adv. Ceram. 2020, 9, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Debye, P. Polar Molecules; The Chemical Catalog Company, Inc.: New York, NY, USA, 1929; pp. 77–108. [Google Scholar]

- Moitra, D.; Chandel, M.; Ghosh, B.K.; Jani, R.K.; Patra, M.K.; Vadera, S.R.; Ghosh, N.N. A simple ‘in situ’ co-precipitation method for the preparation of multifunctional CoFe2O4–reduced graphene oxide nanocomposites: Excellent microwave absorber and highly efficient magnetically separable recyclable photocatalyst for dye degradation. RSC Adv. 2016, 6, 76759–76772. [Google Scholar] [CrossRef]

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to Ceramics; John Wiley & Sons: Hoboken, NJ, USA, 1976; Volume 17. [Google Scholar]

- Wang, Y.; Zhou, W.; Zeng, G.; Chen, H.; Luo, H.; Fan, X.; Li, Y. Rational design of multi-shell hollow carbon submicrospheres for high-performance microwave absorbers. Carbon 2021, 175, 233–242. [Google Scholar] [CrossRef]

- Lou, Z.; Yuan, C.; Zhang, Y.; Li, Y.; Cai, J.; Yang, L.; Wang, W.; Han, H.; Zou, J. Synthesis of porous carbon matrix with inlaid Fe3C/Fe3O4 micro-particles as an effective electromagnetic wave absorber from natural wood shavings. J. Alloys Compd. 2019, 775, 800–809. [Google Scholar] [CrossRef]

- Wen, B.; Cao, M.-S.; Hou, Z.-L.; Song, W.-L.; Zhang, L.; Lu, M.-M.; Jin, H.-B.; Fang, X.-Y.; Wang, W.-Z.; Yuan, J. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites. Carbon 2013, 65, 124–139. [Google Scholar] [CrossRef]

- Duan, Y.; Guan, H. Microwave Absorbing Materials; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Kim, S.; Jo, S.; Gueon, K.; Choi, K.; Kim, J.; Churn, K. Complex permeability and permittivity and microwave absorption of ferrite-rubber composite at X-band frequencies. IEEE Trans. Magn. 1991, 27, 5462–5464. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Zheng, Y.; Guo, C.; Yang, M.; Li, Z.; Wu, H.; Qiu, H.; Yan, H.; Qi, S. Preparation of polyaniline@MoS2@Fe3O4 nanowires with a wide band and small thickness toward enhancement in microwave absorption. ACS Appl. Nano Mater. 2018, 1, 5865–5875. [Google Scholar] [CrossRef]

- Yuan, X.; Li, H.; Sha, A.; Huang, S.; Li, B.; Guo, S. Flexible Mo2C-Modified SiC/C Nanofibers for BroadBand Electromagnetic Wave Absorption. Adv. Mater. Interfaces 2022, 9, 2200333. [Google Scholar] [CrossRef]

- Fan, B.; Ansar, M.T.; Wang, X.; Song, L.; Du, H.; Lu, H.; Zhao, B.; Zhang, R.; Fan, L.; Li, H. Two-Dimensional C/MoS2-Functionalized Ti3C2Tx Nanosheets for Achieving Strong Electromagnetic Wave Absorption. Adv. Electron. Mater. 2022, 8, 2200169. [Google Scholar] [CrossRef]

- He, P.; Cao, M.-S.; Cao, W.-Q.; Yuan, J. Developing MXenes from wireless communication to electromagnetic attenuation. Nano-Micro Lett. 2021, 13, 115. [Google Scholar] [CrossRef]

- Li, Y.; Meng, F.; Mei, Y.; Wang, H.; Guo, Y.; Wang, Y.; Peng, F.; Huang, F.; Zhou, Z. Electrospun generation of Ti3C2Tx MXene@graphene oxide hybrid aerogel microspheres for tunable high-performance microwave absorption. Chem. Eng. J. 2020, 391, 123512. [Google Scholar] [CrossRef]

- Hu, Q.; Yang, R.; Mo, Z.; Lu, D.; Yang, L.; He, Z.; Zhu, H.; Tang, Z.; Gui, X. Nitrogen-doped and Fe-filled CNTs/NiCo2O4 porous sponge with tunable microwave absorption performance. Carbon 2019, 153, 737–744. [Google Scholar] [CrossRef]

- Wu, R.; Zhou, K.; Yang, Z.; Qian, X.; Wei, J.; Liu, L.; Huang, Y.; Kong, L.; Wang, L. Molten-salt-mediated synthesis of SiC nanowires for microwave absorption applications. CrystEngComm 2013, 15, 570–576. [Google Scholar] [CrossRef]

- Chiu, S.-C.; Yu, H.-C.; Li, Y.-Y. High electromagnetic wave absorption performance of silicon carbide nanowires in the gigahertz range. J. Phys. Chem. C 2010, 114, 1947–1952. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Ai, S.; Hou, B.; Zhang, J.; Liang, X.; Zhou, Q.; Liu, H.; Cui, S. Porous SiC/melamine-derived carbon foam frameworks with excellent electromagnetic wave absorbing capacity. J. Adv. Ceram. 2019, 8, 479–488. [Google Scholar] [CrossRef] [Green Version]

- Kuang, J.; Xiao, T.; Hou, X.; Zheng, Q.; Wang, Q.; Jiang, P.; Cao, W. Microwave synthesis of worm-like SiC nanowires for thin electromagnetic wave absorbing materials. Ceram. Int. 2019, 45, 11660–11667. [Google Scholar] [CrossRef]

- Xu, W.; Li, S.; Hu, S.; Yu, W.; Zhou, Y. Effect of Ti3AlC2 precursor and processing conditions on microwave absorption performance of resultant Ti3C2Tx MXene. J. Mater. Sci. 2021, 56, 9287–9301. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, Y.; Gong, H.; Zhang, Y.; Lin, X.; Xie, B.; Mao, J. Electromagnetic wave absorption properties of nickel-containing polymer-derived SiCN ceramics. Ceram. Int. 2018, 44, 10945–10950. [Google Scholar] [CrossRef]

- Song, L.; Fan, B.; Chen, Y.; Wang, H.; Li, H.; Zhang, R. Multifunctional SiC nanofiber aerogel with superior electromagnetic wave absorption. Ceram. Int. 2022, 48, 25140–25150. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, L.; Yin, X.; Ye, F.; Liu, Y.; Cheng, L. The microstructure and electromagnetic wave absorption properties of near-stoichiometric SiC fibre. Ceram. Int. 2017, 43, 3267–3273. [Google Scholar] [CrossRef]

- Lv, H.; Ji, G.; Zhang, H.; Du, Y. Facile synthesis of a CNT@Fe@SiO2 ternary composite with enhanced microwave absorption performance. RSC Adv. 2015, 5, 76836–76843. [Google Scholar] [CrossRef]

- Zhao, B.; Shao, G.; Fan, B.; Li, W.; Pian, X.; Zhang, R. Enhanced electromagnetic wave absorption properties of Ni–SnO2 core–shell composites synthesized by a simple hydrothermal method. Mater. Lett. 2014, 121, 118–121. [Google Scholar] [CrossRef]

| No. | Composition in Atomic % | Probable Phases | |||

|---|---|---|---|---|---|

| Dy | Si | C | O | ||

| 1 | 45.92 | 23.11 | 15.72 | 15.25 | Dy3Si2C2, Dy2O3 |

| 2 | 0.39 | 59.29 | 36.12 | 4.20 | SiCw |

| 3 | 42.11 | 22.98 | 16.99 | 17.93 | Dy3Si2C2, Dy2O3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, G.; Li, Y.; Zhou, W.; Xu, H.; Hu, F.; Zhou, X. In Situ Grown 1D/2D Structure of Dy3Si2C2 on SiCw for Enhanced Electromagnetic Wave Absorption. Materials 2023, 16, 3455. https://doi.org/10.3390/ma16093455

Qin G, Li Y, Zhou W, Xu H, Hu F, Zhou X. In Situ Grown 1D/2D Structure of Dy3Si2C2 on SiCw for Enhanced Electromagnetic Wave Absorption. Materials. 2023; 16(9):3455. https://doi.org/10.3390/ma16093455

Chicago/Turabian StyleQin, Gang, Yang Li, Wei Zhou, Huidong Xu, Fang Hu, and Xiaobing Zhou. 2023. "In Situ Grown 1D/2D Structure of Dy3Si2C2 on SiCw for Enhanced Electromagnetic Wave Absorption" Materials 16, no. 9: 3455. https://doi.org/10.3390/ma16093455