Sensors Based on Auxetic Materials and Structures: A Review

Abstract

1. Introduction

2. Evaluation Indicators of Auxetic Sensors

3. Resistive Auxetic Sensos

4. Piezoresistive Auxetic Sensor

5. Piezoelectric Auxetic Sensor

6. Capacitive Auxetic Sensor

7. Triboelectric Auxetic Sensor

8. Challenges and Future Prospects

- (1)

- The mechanism of how the auxetic material improves sensitivity has not been studied. Although some researchers have proposed that the special mechanical properties of auxetic materials may amplify small force or deformation and thereby enhance the corresponding electrical response signal, the specific details have not been systematically investigated and discussed.

- (2)

- There is no systematic study on the relationship between auxetic properties and sensing performance. Several studies have proposed a relationship between NPR and sensitivity based on a specific sensor structure, but still, no generally applicable rules or relationships have been provided, which requires more samples and data.

- (3)

- Insufficient utilization of auxetic structures. Currently, auxetic foams and re-entrant hexagonal structures are mostly used in sensors, while other auxetic structures, including rotating structures, chiral structures, and foldable structures, have little or no proportion. Researchers are expected to create more high-performance sensors based on various auxetic structures, which will not only help in the development of breakthrough sensors but also expand the library of auxetic sensors for subsequent systematic studies (including the studies on the first and second challenges).

- (4)

- The comfort of the auxetic sensor has not been carefully considered. Auxetic sensors show great potential in wearable applications such as sports rehabilitation, vital sign detection, and human–machine interaction due to their enhanced extensibility and sensitivity. However, few studies focused on their wearing comfort, including softness, skin-friendliness, breathability, etc.

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chan, N.; Evans, K.E. The mechanical properties of conventional and auxetic foams. Part II: Shear. J. Cell. Plast. 1999, 35, 166–183. [Google Scholar] [CrossRef]

- Novak, N.; Duncan, O.; Allen, T.; Alderson, A.; Vesenjak, M.; Ren, Z. Shear modulus of conventional and auxetic open-cell foam. Mech. Mater. 2021, 157, 103818. [Google Scholar] [CrossRef]

- Qiao, J.X.; Chen, C.Q. Impact resistance of uniform and functionally graded auxetic double arrowhead honeycombs. Int. J. Impact Eng. 2015, 83, 47–58. [Google Scholar] [CrossRef]

- Imbalzano, G.; Tran, P.; Ngo, T.D.; Lee, P.V. Three-dimensional modelling of auxetic sandwich panels for localised impact resistance. J. Sandw. Struct. Mater. 2017, 19, 291–316. [Google Scholar] [CrossRef]

- Rasburn, J.; Mullarkey, P.G.; Evans, K.E.; Alderson, A.; Ameer-Beg, S.; Perrie, W. Auxetic structures for variable permeability systems. AIChE J. 2001, 47, 2623–2626. [Google Scholar] [CrossRef]

- Prawoto, Y. Seeing auxetic materials from the mechanics point of view: A structural review on the negative Poisson’s ratio. Comput. Mater. Sci. 2012, 58, 140–153. [Google Scholar] [CrossRef]

- Alderson, A.; Alderson, K. Expanding materials and applications: Exploiting auxetic textiles. Tech. Text. Int. 2005, 14, 29–34. [Google Scholar]

- Baker, C.E. Auxetic Spinal Implants: Consideration of Negative Poisson’s Ratio in the Design of an Artificial Intervertebral Disc. Ph.D. Thesis, University of Toledo, Toledo, OH, USA, 2011. [Google Scholar]

- Wang, Z.; Hu, H. Auxetic materials and their potential applications in textiles. Text. Res. J. 2014, 84, 1600–1611. [Google Scholar] [CrossRef]

- Yanping, L.; Hong, H. A review on auxetic structures and polymeric materials. Sci. Res. Essays 2010, 5, 1052–1063. [Google Scholar]

- Cao, H.; Zulifqar, A.; Hua, T.; Hu, H. Bi-stretch auxetic woven fabrics based on foldable geometry. Text. Res. J. 2019, 89, 2694–2712. [Google Scholar] [CrossRef]

- Chan, N.; Evans, K.E. Fabrication methods for auxetic foams. J. Mater. Sci. 1997, 32, 5945–5953. [Google Scholar] [CrossRef]

- Fan, D.; Li, M.; Qiu, J.; Xing, H.; Jiang, Z.; Tang, T. Novel method for preparing auxetic foam from closed-cell polymer foam based on the steam penetration and condensation process. ACS Appl. Mater. Interfaces 2018, 10, 22669–22677. [Google Scholar] [CrossRef]

- Alderson, K.L.; Fitzgerald, A.; Evans, K.E. The strain dependent indentation resilience of auxetic microporous polyethylene. J. Mater. Sci. 2000, 35, 4039–4047. [Google Scholar] [CrossRef]

- Jiang, L.; Gu, B.; Hu, H. Auxetic composite made with multilayer orthogonal structural reinforcement. Compos. Struct. 2016, 135, 23–29. [Google Scholar] [CrossRef]

- Li, T.; Liu, F.; Wang, L. Enhancing indentation and impact resistance in auxetic composite materials. Compos. B Eng. 2020, 198, 108229. [Google Scholar] [CrossRef]

- Hu, H.; Zulifqar, A. Auxetic textile materials-a review. J. Text. Eng. Fash. Technol. 2016, 1, 00002. [Google Scholar] [CrossRef]

- Zhao, S.; Hu, H.; Kamrul, H.; Chang, Y.; Zhang, M. Development of auxetic warp knitted fabrics based on reentrant geometry. Text. Res. J. 2020, 90, 344–356. [Google Scholar] [CrossRef]

- Liu, S.; Pan, X.; Zheng, D.; Liu, G.; Du, Z. The manufacture and characterization of auxetic, self-curling, and self-folding woven fabrics by helical auxetic yarns. J. Ind. Text. 2020, 50, 3–12. [Google Scholar] [CrossRef]

- Dubrovski, P.D.; Novak, N.; Borovinšek, M.; Vesenjak, M.; Ren, Z. In-plane behavior of auxetic non-woven fabric based on rotating square unit geometry under tensile load. Polymers 2019, 11, 1040. [Google Scholar] [CrossRef]

- Sloan, M.R.; Wright, J.R.; Evans, K.E. The helical auxetic yarn–a novel structure for composites and textiles; geometry, manufacture and mechanical properties. Mech. Mater. 2011, 43, 476–486. [Google Scholar] [CrossRef]

- Ge, Z.; Hu, H.; Liu, S. A novel plied yarn structure with negative Poisson’s ratio. J. Text. Inst. 2016, 107, 578–588. [Google Scholar] [CrossRef]

- Jiang, N.; Hu, H. Auxetic yarn made with circular braiding technology. Phys. Status Solidi B 2019, 256, 1800168. [Google Scholar] [CrossRef]

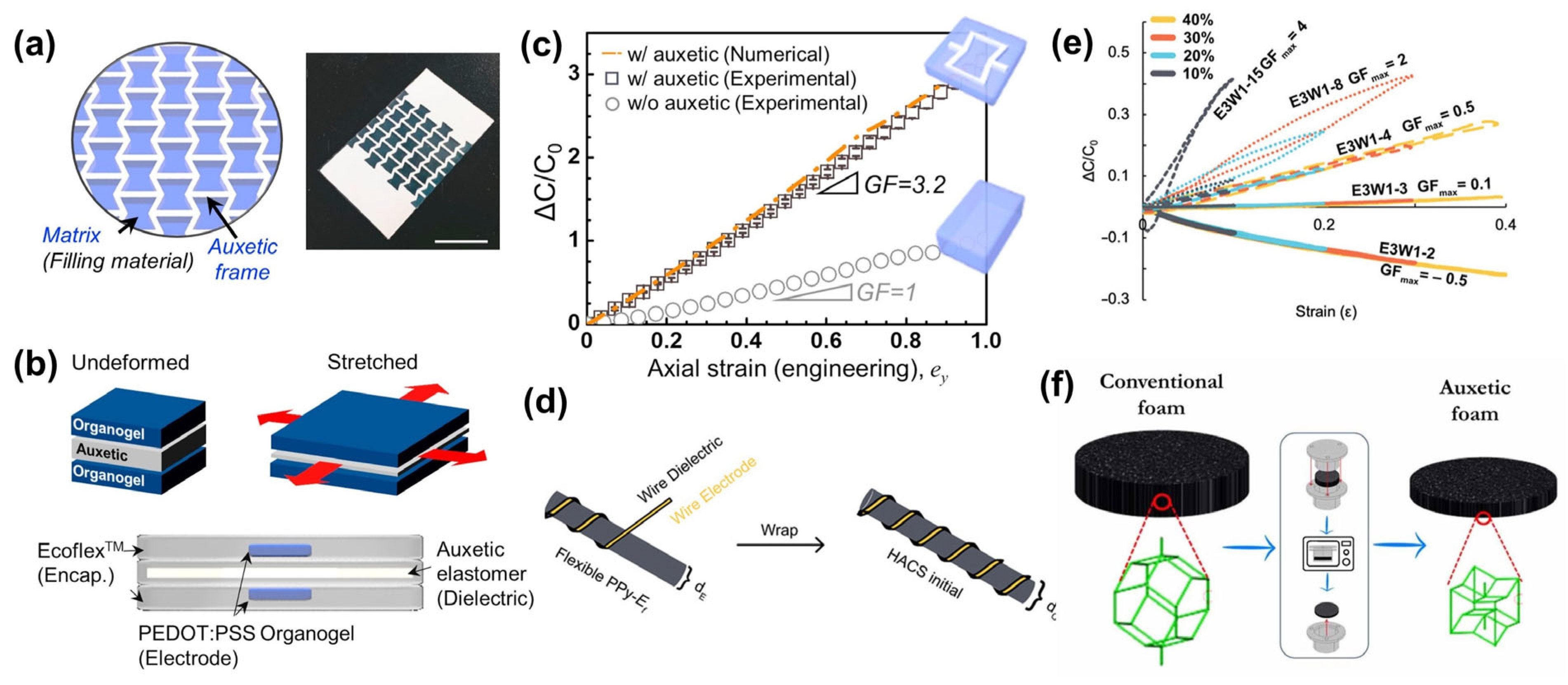

- Jiang, Y.; Liu, Z.; Matsuhisa, N.; Qi, D.; Leow, W.R.; Yang, H.; Yu, J.; Chen, G.; Liu, Y.; Wan, C.; et al. Auxetic mechanical metamaterials to enhance sensitivity of stretchable strain sensors. Adv. Mater. 2018, 30, 1706589. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.J.; Lim, S.M.; Yi, S.M.; Lee, J.H.; Kang, S.; Choi, G.M.; Han, H.N.; Sun, J.Y.; Choi, I.S.; Joo, Y.C. Auxetic elastomers: Mechanically programmable meta-elastomers with an unusual Poisson’s ratio overcome the gauge limit of a capacitive type strain sensor. Extrem. Mech. Lett. 2019, 31, 100516. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Schubert, D.W. Highly sensitive ultrathin flexible thermoplastic polyurethane/carbon black fibrous film strain sensor with adjustable scaffold networks. Nanomicro Lett. 2021, 13, 64. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, J.; Huang, Z.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 2018, 126, 360–371. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Sun, J.; Huang, Y.; Hu, H.; Jiang, R.; Gai, W.; Li, G.; Zhi, C. Polyurethane/cotton/carbon nanotubes core-spun yarn as high reliability stretchable strain sensor for human motion detection. ACS Appl. Mater. Interfaces 2016, 8, 24837–24843. [Google Scholar] [CrossRef]

- Beccai, L.; Roccella, S.; Ascari, L.; Valdastri, P.; Sieber, A.; Carrozza, M.C.; Dario, P. Development and experimental analysis of a soft compliant tactile microsensor for anthropomorphic artificial hand. IEEE ASME Trans. Mechatron. 2008, 13, 158–168. [Google Scholar] [CrossRef]

- Canavese, G.; Stassi, S.; Fallauto, C.; Corbellini, S.; Cauda, V.; Camarchia, V.; Pirola, M.; Pirri, C.F. Piezoresistive flexible composite for robotic tactile applications. Sens. Actuators A Phys. 2014, 208, 1–9. [Google Scholar] [CrossRef]

- Liu, X.; Liu, W.; Xia, Q.; Feng, J.; Qiu, Y.; Xu, F. Highly tough and strain sensitive plasma functionalized carbon nanotube/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 123–129. [Google Scholar] [CrossRef]

- Nguyen, V.; Melkote, S.N.; Deshamudre, A.; Khanna, M.; Walker, D. PVDF sensor based monitoring of single-point cutting. J. Manuf. Process. 2016, 24, 328–337. [Google Scholar] [CrossRef]

- Dong, W.; Xiao, L.; Hu, W.; Zhu, C.; Huang, Y.; Yin, Z. Wearable human–machine interface based on PVDF piezoelectric sensor. Trans. Inst. Meas. Control 2016, 39, 398–403. [Google Scholar] [CrossRef]

- Shin, K.-Y.; Lee, J.S.; Jang, J. Highly sensitive, wearable and wireless pressure sensor using free-standing ZnO nanoneedle/PVDF hybrid thin film for heart rate monitoring. Nano Energy 2016, 22, 95–104. [Google Scholar] [CrossRef]

- Albrecht, A.; Trautmann, M.; Becherer, M.; Lugli, P.; Rivadeneyra, A. Shear-force sensors on flexible substrates using inkjet printing. J. Sens. 2019, 2019, 1864239. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E.; et al. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef]

- Demori, M.; Masud, M.; Bau, M.; Ferrari, M.; Ferrari, V. Passive LC sensor label with distance-independent contactless interrogation. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October–1 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–3. [Google Scholar]

- Liu, L.; Pan, J.; Chen, P.; Zhang, J.; Yu, X.; Ding, X.; Wang, B.; Sun, X.; Peng, H. A triboelectric textile templated by a three-dimensionally penetrated fabric. J. Mater. Chem. A 2016, 4, 6077–6083. [Google Scholar] [CrossRef]

- Seung, W.; Gupta, M.K.; Lee, K.Y.; Shin, K.S.; Lee, J.H.; Kim, T.Y.; Kim, S.; Lin, J.; Kim, J.H.; Kim, S.W. Nanopatterned textile-based wearable triboelectric nanogenerator. ACS Nano 2015, 9, 3501–3509. [Google Scholar] [CrossRef]

- Zheng, Q.; Zhang, H.; Shi, B.; Xue, X.; Liu, Z.; Jin, Y.; Ma, Y.; Zou, Y.; Wang, X.; An, Z.; et al. In vivo self-powered wireless cardiac monitoring via implantable triboelectric nanogenerator. ACS Nano 2016, 10, 6510–6518. [Google Scholar] [CrossRef]

- Ren, L.; Cong, M.; Tan, Y. An hourglass-shaped wireless and passive magnetoelastic sensor with an improved frequency sensitivity for remote strain measurements. Sensors 2020, 20, 359. [Google Scholar] [CrossRef]

- Lee, J.K.; Seung, H.M.; Park, C.I.; Lee, J.K.; Lim, D.H.; Kim, Y.Y. Magnetostrictive patch sensor system for battery-less real-time measurement of torsional vibrations of rotating shafts. J. Sound Vib. 2018, 414, 245–258. [Google Scholar] [CrossRef]

- Ren, L.; Cong, M.; Fu, Y.; Yu, K.; Tan, Y. A wireless and passive strain sensor with improved sensitivity enabled by negative Poisson’s ratio structure. IEEE Sens. J. 2020, 21, 4433–4441. [Google Scholar] [CrossRef]

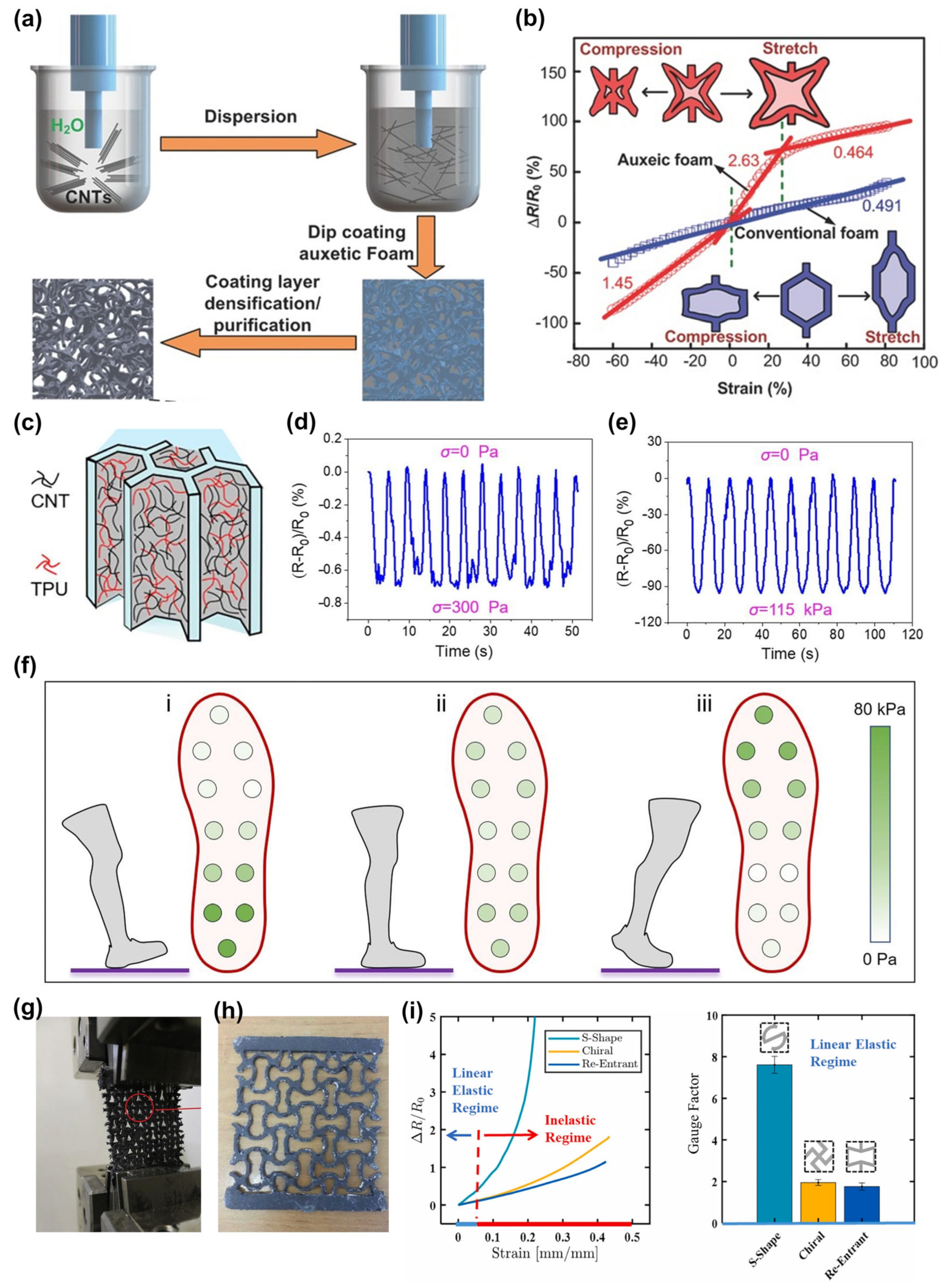

- Liu, H.; Li, Y.; Zhou, M.; Chen, B.; Chen, Y.; Zhai, W. Ambilateral convergent directional freeze casting meta-structured foams with a negative Poisson’s ratio for high-performance piezoresistive sensors. Chem. Eng. J. 2023, 454, 140436. [Google Scholar] [CrossRef]

- Kim, H.W.; Kim, T.Y.; Park, H.K.; You, I.; Kwak, J.; Kim, J.C.; Hwang, H.; Kim, H.S.; Jeong, U. Hygroscopic auxetic on-skin sensors for easy-to-handle repeated daily use. ACS Appl. Mater. Interfaces 2018, 10, 40141–40148. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.; Gong, A.T.; Defnet, P.A.; Meabe, L.; Beauchamp, B.; Sweet, R.M.; Sardon, H.; Cobb, C.L.; Nelson, A. 3D printing ionogel auxetic frameworks for stretchable sensors. Adv. Mater. Technol. 2019, 4, 1900452. [Google Scholar] [CrossRef]

- Choi, H.Y.; Shin, E.J.; Lee, S.H. Design and evaluation of 3D-printed auxetic structures coated by CWPU/graphene as strain sensor. Sci. Rep. 2022, 12, 7780. [Google Scholar] [CrossRef]

- Choi, H.Y.; Shin, E.J.; Lee, S.H. Piezo-resistive Sensor of Auxetic Structures Based on 3D-Printed TPU Coated by Castor-Oil-Based Waterborne Polyurethane/Graphene. Fibers Polym. 2023, 24, 15–28. [Google Scholar] [CrossRef]

- Lai, C.W.; Yu, S.S. 3D printable strain sensors from deep eutectic solvents and cellulose nanocrystals. ACS Appl. Mater. Interfaces 2020, 12, 34235–34244. [Google Scholar] [CrossRef]

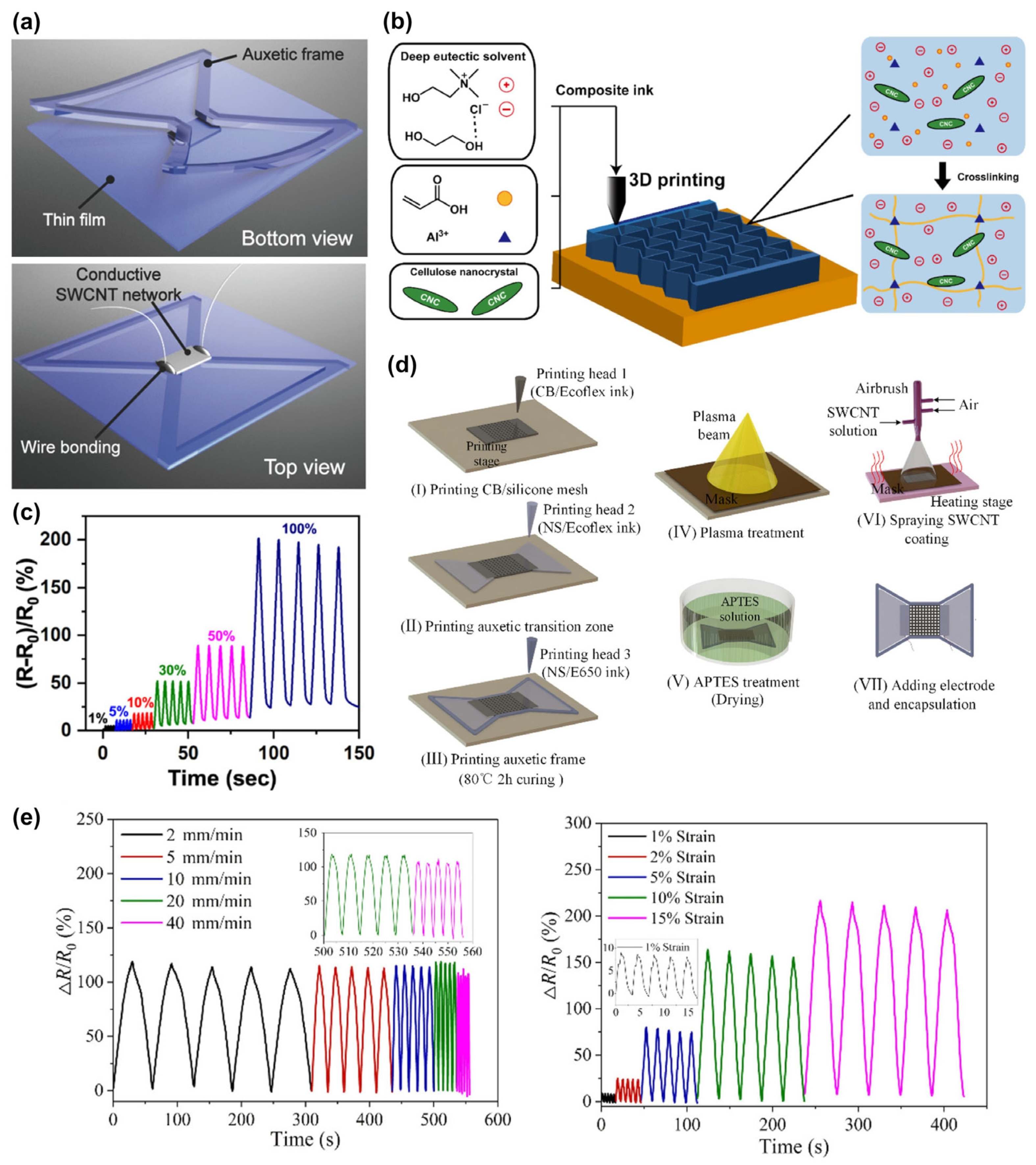

- Wang, Z.; Luan, C.; Liao, G.; Liu, J.; Yao, X.; Fu, J. High-performance auxetic bilayer conductive mesh-based multi-material integrated stretchable strain sensors. ACS Appl. Mater. Interfaces 2021, 13, 23038–23048. [Google Scholar] [CrossRef]

- Li, B.; Liang, W.; Zhang, L.; Ren, F.; Xuan, F. TPU/CNTs flexible strain sensor with auxetic structure via a novel hybrid manufacturing process of fused deposition modeling 3D printing and ultrasonic cavitation-enabled treatment. Sens. Actuator A Phys. 2022, 340, 113526. [Google Scholar] [CrossRef]

- Ko, J.; Bhullar, S.; Cho, Y.; Lee, P.C.; Jun, M.B. Design and fabrication of auxetic stretchable force sensor for hand rehabilitation. Smart Mater. Struct. 2015, 24, 075027. [Google Scholar] [CrossRef]

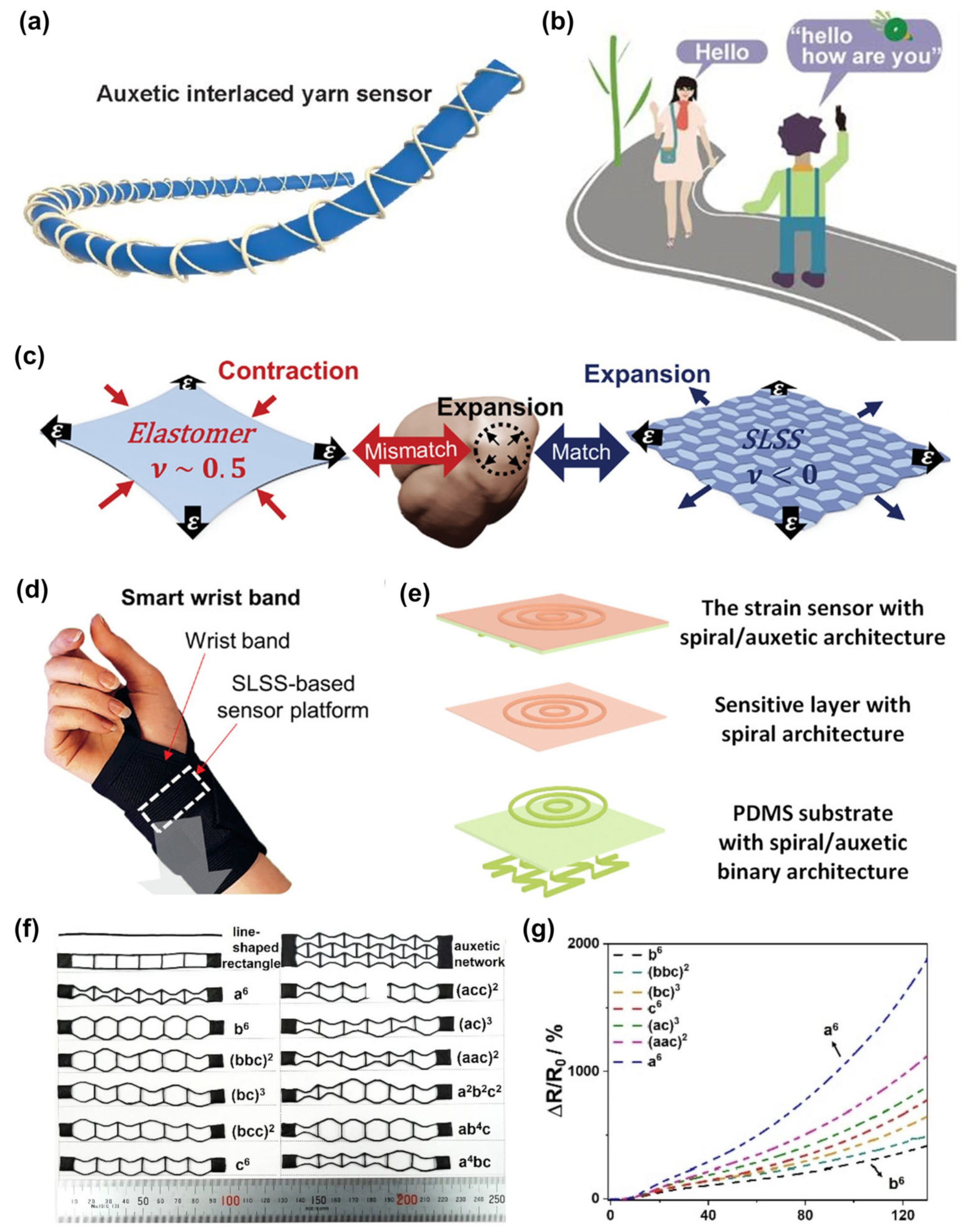

- Wu, R.; Seo, S.; Ma, L.; Bae, J.; Kim, T. Full-fiber auxetic-interlaced yarn sensor for sign-language translation glove assisted by artificial neural network. Nanomicro Lett. 2022, 14, 139. [Google Scholar] [CrossRef]

- Kim, M.S.; Lee, Y.; Ahn, J.; Kim, S.; Kang, K.; Lim, H.; Bae, B.S.; Park, I. Skin-like Omnidirectional Stretchable Platform with Negative Poisson’s Ratio for Wearable Strain–Pressure Simultaneous Sensor. Adv. Funct. Mater. 2023, 33, 2208792. [Google Scholar] [CrossRef]

- Yu, H.; Lian, Y.; Sun, T.; Yang, X.; Wang, Y.; Xie, G.; Du, X.; Gou, J.; Li, W.; Tai, H. Two-sided topological architecture on a monolithic flexible substrate for ultrasensitive strain sensors. ACS Appl. Mater. Interfaces 2019, 11, 43543–43552. [Google Scholar] [CrossRef]

- Mao, L.; Pan, T.; Ke, Y.; Yan, Z.; Huang, S.; Guo, D.; Gao, N.; Huang, W.; Yao, G.; Gao, M.; et al. Configurable direction sensitivity of skin-mounted microfluidic strain sensor with auxetic metamaterial. Lab Chip 2022, 22, 1630–1639. [Google Scholar] [CrossRef]

- Wu, C.; Wang, H.; Kim, T.; Kwon, S.J.; Lee, K.; Lee, S.B.; Um, M.K.; Byun, J.H.; Chou, T.W. Tailoring auxetic mechanical metamaterials to achieve patterned wire strain sensors with controllable high sensitivity. Chem. Eng. J. 2022, 442, 136317. [Google Scholar] [CrossRef]

- Engel, J.; Chen, J.; Liu, C. Strain sensitivity enhancement of thin metal film strain gauges on polymer microscale structures. Appl. Phys. Lett. 2006, 89, 221907. [Google Scholar] [CrossRef]

- Yap, L.W.; Gong, S.; Tang, Y.; Zhu, Y.; Cheng, W. Soft piezoresistive pressure sensing matrix from copper nanowires composite aerogel. Sci. Bull. 2016, 61, 1624–1630. [Google Scholar] [CrossRef]

- Vetrivel, S.; Mathew, R.; Sankar, R. Design and optimization of a doubly clamped piezoresistive acceleration sensor with an integrated silicon nanowire piezoresistor. Microsyst. Technol. 2017, 23, 3525–3536. [Google Scholar] [CrossRef]

- Kumar, S.S.; Pant, B.D. Polysilicon thin film piezoresistive pressure microsensor: Design, fabrication and characterization. Microsyst. Technol. 2015, 21, 1949–1958. [Google Scholar] [CrossRef]

- Coskun, M.B.; Qiu, L.; Arefin, M.S.; Neild, A.; Yuce, M.; Li, D.; Alan, T. Detecting subtle vibrations using Graphene–Based cellular elastomers. ACS Appl. Mater. Interfaces 2017, 9, 11345–11349. [Google Scholar] [CrossRef]

- Shang, S.; Yue, Y.; Wang, X. Piezoresistive strain sensing of carbon black/silicone composites above percolation threshold. Rev. Sci. Instrum. 2016, 87, 123910–123915. [Google Scholar] [CrossRef] [PubMed]

- Cravanzola, S.; Haznedar, G.; Scarano, D.; Zecchina, A.; Cesano, F. Carbon-based piezoresistive polymer composites: Structure and electrical properties. Carbon 2013, 62, 270–277. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Najafabadi, A.I.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human–motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Wang, B.; Lee, B.K.; Kwak, M.J.; Lee, D.W. Graphene/polydimethylsiloxane nanocomposite strain sensor. Rev. Sci. Instrum. 2013, 84, 105005. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Luo, S.; Yang, M.C.; Liang, R.; Zeng, C. Poisson ratio and piezoresistive sensing: A new route to high-performance 3D flexible and stretchable sensors of multimodal sensing capability. Adv. Funct. Mater. 2016, 26, 2900–2908. [Google Scholar] [CrossRef]

- Ahmed, M.F.; Li, Y.; Zeng, C. Stretchable and compressible piezoresistive sensors from auxetic foam and silver nanowire. Mater. Chem. Phys. 2019, 229, 167–173. [Google Scholar] [CrossRef]

- Taherkhani, B.; Azizkhani, M.B.; Kadkhodapour, J.; Anaraki, A.P.; Rastgordani, S. Highly sensitive, piezoresistive, silicone/carbon fiber-based auxetic sensor for low strain values. Sens. Actuator A Phys. 2020, 305, 111939. [Google Scholar] [CrossRef]

- Taherkhani, B.; Kadkhodapour, J.; Anaraki, A.P. Highly sensitive, stretchable, piezoresistive auxetic sensor based on graphite powders sandwiched between silicon rubber layers. Polym. Bull. 2023, 80, 3745–3760. [Google Scholar] [CrossRef]

- Taherkhani, B.; Chegini, M.M.; Rahmani, P. Highly sensitive, piezoresistive, silicon/graphite powder-based, auxetic sensor with linear sensing performance. Sens. Actuator A Phys. 2022, 345, 113776. [Google Scholar] [CrossRef]

- AlMahri, S.; Schneider, J.; Schiffer, A.; Kumar, S. Piezoresistive sensing performance of multifunctional MWCNT/HDPE auxetic structures enabled by additive manufacturing. Polym. Test 2022, 114, 107687. [Google Scholar] [CrossRef]

- Koruza, J.; Liu, H.; Höfling, M.; Zhang, M.H.; Veber, P. (K, Na)NbO3-based piezoelectric single crystals: Growth methods, properties, and applications. J. Mater. Res. 2020, 35, 990–1016. [Google Scholar] [CrossRef]

- Peddigari, M.; Kim, G.Y.; Park, C.H.; Min, Y.; Kim, J.W.; Ahn, C.W.; Choi, J.J.; Hahn, B.D.; Choi, J.H.; Park, D.S. A comparison study of fatigue behavior of hard and soft piezoelectric single crystal macro-fiber composites for vibration energy harvesting. Sensors 2019, 19, 2196. [Google Scholar] [CrossRef]

- Hao, J.; Li, W.; Zhai, J.; Chen, H. Progress in high-strain perovskite piezoelectric ceramics. Mater. Sci. Eng. R Rep. 2019, 135, 1–57. [Google Scholar] [CrossRef]

- Lifi, H.; Ennawaoui, C.; Hajjaji, A.; Touhtouh, S.; Laasri, S.; Yessari, M.; Benjelloun, M. Sensors and energy harvesters based on (1–x) PMN-xPT piezoelectric ceramics. Eur. Phys. J. Appl. Phys. 2019, 88, 10901. [Google Scholar] [CrossRef]

- Chen, B.O.; Li, H.; Tian, W.; Zhou, C. PZT based piezoelectric sensor for structural monitoring. J. Electron. Mater. 2019, 48, 2916–2923. [Google Scholar] [CrossRef]

- Qian, W.; Zhao, K.; Zhang, D.; Bowen, C.R.; Wang, Y.; Yang, Y. Piezoelectric material-polymer composite porous foam for efficient dye degradation via the piezo-catalytic effect. ACS Appl. Mater. Interfaces 2019, 11, 27862–27869. [Google Scholar] [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric materials for energy harvesting and sensing applications: Roadmap for future smart materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef]

- Fey, T.; Eichhorn, F.; Han, G.; Ebert, K.; Wegener, M.; Roosen, A.; Kakimoto, K.; Greil, P. Mechanical and electrical strain response of a piezoelectric auxetic PZT lattice structure. Smart Mater. Struct. 2015, 25, 015017. [Google Scholar] [CrossRef]

- Ferguson, W.J.G.; Kuang, Y.; Evans, K.E.; Smith, C.W.; Zhu, M. Auxetic structure for increased power output of strain vibration energy harvester. Sens. Actuator A Phys. 2018, 282, 90–96. [Google Scholar] [CrossRef]

- Tang, H.; Jiang, X.; Ling, L.; Li, L.; Hu, Y. Highly tailorable electromechanical properties of auxetic piezoelectric ceramics with ultra-low porosity. J. Am. Ceram. Soc. 2020, 103, 6330–6347. [Google Scholar] [CrossRef]

- Tang, H.; Jiang, X.; Li, L.; Ling, L.; Hu, Y. Electromechanical properties of ultra-low porous auxetic piezocomposite: From the perspective of Poisson’s ratio. J. Am. Ceram. Soc. 2021, 104, 2628–2645. [Google Scholar] [CrossRef]

- Farhangdoust, S.; Georgeson, G.; Ihn, J.B.; Chang, F.K. Kirigami auxetic structure for high efficiency power harvesting in self-powered and wireless structural health monitoring systems. Smart Mater. Struct. 2020, 30, 015037. [Google Scholar] [CrossRef]

- Chang, S.M.; Hur, S.; Park, J.; Lee, D.G.; Shin, J.; Kim, H.S.; Song, S.E.; Baik, J.M.; Kim, M.; Song, H.C.; et al. Optimization of Piezoelectric Polymer Composites and 3D Printing Parameters for Flexible Tactile sensors. Addit. Manuf. 2023, 67, 103470. [Google Scholar] [CrossRef]

- Cuthbert, T.J.; Hannigan, B.C.; Roberjot, P.; Shokurov, A.V.; Menon, C. HACS: Helical Auxetic Yarn Capacitive Strain Sensors with Sensitivity Beyond the Theoretical Limit. Adv. Mater. 2022, 35, 2209321. [Google Scholar] [CrossRef]

- Shintake, J.; Nagai, T.; Ogishima, K. Sensitivity improvement of highly stretchable capacitive strain sensors by hierarchical auxetic structures. Front. Robot. AI 2019, 6, 127. [Google Scholar] [CrossRef]

- Rizzi, F.; Puce, S.; La Malfa, F.L.; Totaro, M.; Vittorio, M.D.; Beccai, L. Modeling and development of an auxetic foam-based multimodal capacitive strain gauge. Smart Mater. Struct. 2023, 32, 025013. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Gong, J.; Xu, B.; Guan, X.; Chen, Y.; Li, S.; Feng, J. Towards truly wearable energy harvesters with full structural integrity of fiber materials. Nano Energy 2019, 58, 365–374. [Google Scholar] [CrossRef]

- Xu, F.; Dong, S.; Liu, G.; Pan, C.; Guo, Z.H.; Guo, W.; Li, L.; Liu, Y.; Zhang, C.; Pu, X.; et al. Scalable fabrication of stretchable and washable textile triboelectric nanogenerators as constant power sources for wearable electronics. Nano Energy 2021, 88, 106247. [Google Scholar] [CrossRef]

- Kwak, S.S.; Kim, H.; Seung, W.; Kim, J.; Hinchet, R.; Kim, S.W. Fully stretchable textile triboelectric nanogenerator with knitted fabric structures. ACS Nano 2017, 11, 10733–10741. [Google Scholar] [CrossRef]

- Chen, J.; Wen, X.; Liu, X.; Cao, J.; Ding, Z.; Du, Z. Flexible hierarchical helical yarn with broad strain range for self-powered motion signal monitoring and human-machine interactive. Nano Energy 2021, 80, 105446. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, W.; Gong, W.; Ma, W.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. Abrasion resistant/waterproof stretchable triboelectric yarns based on fermat spirals. Adv. Mater. 2021, 33, e2100782. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, M.; Shen, J.; Qiu, Q.; Yu, J.; Ding, B. All-fiber structured electronic skin with high elasticity and breathability. Adv. Funct. Mater. 2020, 30, 1908411. [Google Scholar] [CrossRef]

- Cao, R.; Pu, X.; Du, X.; Yang, W.; Wang, J.; Guo, H.; Zhao, S.; Yuan, Z.; Zhang, C.; Li, C.; et al. Screen-printed washable electronic textiles as self-powered touch/gesture tribo-sensors for intelligent human–machine interaction. ACS Nano 2018, 12, 5190. [Google Scholar] [CrossRef]

- Fan, W.; He, Q.; Meng, K.; Tan, X.; Zhou, Z.; Zhang, G.; Yang, J.; Wang, Z.L. Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring. Sci. Adv. 2020, 6, eaay2840. [Google Scholar] [CrossRef]

- Dong, S.; Xu, F.; Sheng, Y.; Guo, Z.; Pu, X.; Liu, Y. Seamlessly knitted stretchable comfortable textile triboelectric nanogenerators for E-textile power sources. Nano Energy 2020, 78, 105327. [Google Scholar] [CrossRef]

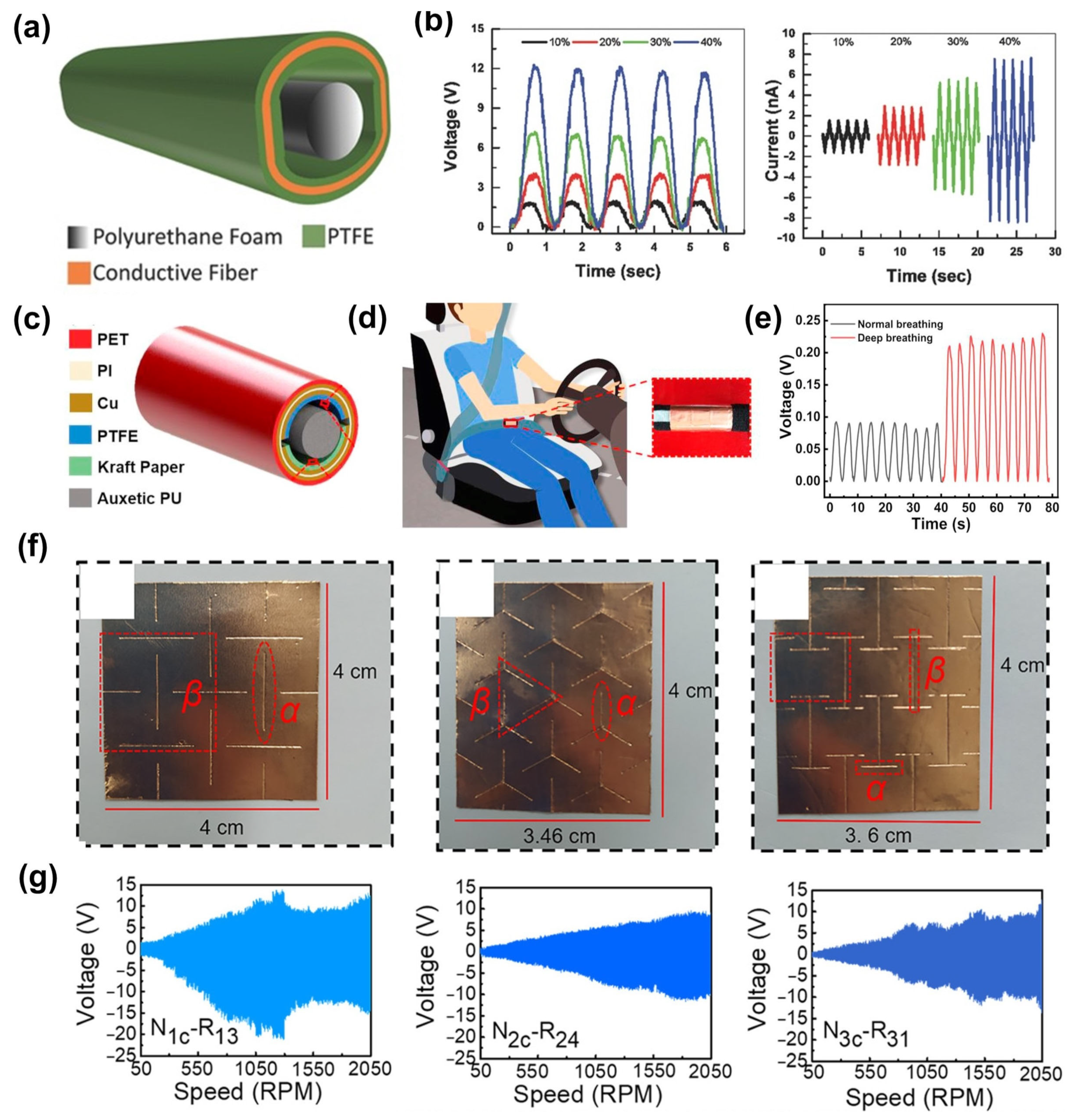

- Zhang, S.L.; Lai, Y.C.; He, X.; Liu, R.; Zi, Y.; Wang, Z.L. Auxetic foam-based contact-mode triboelectric nanogenerator with highly sensitive self-powered strain sensing capabilities to monitor human body movement. Adv. Funct. Mater. 2017, 27, 1606695. [Google Scholar] [CrossRef]

- Feng, Y.; Huang, X.; Liu, S.; Guo, W.; Li, Y.; Wu, H. A self-powered smart safety belt enabled by triboelectric nanogenerators for driving status monitoring. Nano Energy 2019, 62, 197–204. [Google Scholar] [CrossRef]

- Chen, L.; Chen, C.; Jin, L.; Guo, H.; Wang, A.C.; Ning, F.; Xu, Q.; Du, Z.; Wang, F.; Wang, Z.L. Stretchable negative Poisson’s ratio yarn for triboelectric nanogenerator for environmental energy harvesting and self-powered sensor. Energy Environ. Sci. 2021, 14, 955–964. [Google Scholar] [CrossRef]

- Ye, X.; He, Y.; Li, S.; Hu, H.; Gan, L.; Huang, J. Auxetic Wearable Sensors Based on Flexible Triboelectric Polymers for Movement Monitoring. ACS Appl. Polym. Mater. 2022, 4, 4339–4346. [Google Scholar] [CrossRef]

| Type | Electrical Material | Auxetic Material/Structure | Fabrication Method | GF | Response Time | Application | Ref. |

|---|---|---|---|---|---|---|---|

| Resistive | SWCNT | PDMS re-entrant hexagonal frame | 3D printing, self-pinning | ≈835 | - | Pulse detection | [24] |

| Ag nanowires | PEG-DA gel serpentine network | UV crosslinking, spraying | 6.17 | - | ECG sensor, haptic device | [45] | |

| Ionogel | Re-entrant hexagonal structure | 3D printing | - | - | Wearable strain sensor | [46] | |

| Nanocomposite ionogel | Re-entrant honeycomb | 3D printing | 3.3 | - | Wearable motion sensor | [49] | |

| SWCNT | Silicone rubber re-entrant frame | 3D printing, ink spraying | ~ 13.4 | 160 ms | Monitoring of swallowing, respiration, and joint bending | [50] | |

| Silver-coated PA yarn | Auxetic yarn | Yarn-wrapping technology | - | 25 ms | Sign-language translation glove | [53] | |

| Ag/CNT | Glass fiber-based elastomer film | Deposition | 300 | - | Smart wristband | [54] | |

| Polyethylenimine-reduced graphene oxide | PDMS re-entrant hexagonal film | Laser scribing, coating | ~1744 | - | Monitoring human motions | [55] | |

| Graphene | Polyimide re-entrant hexagonal film | Laser cutting, casting, injecting, bonding | ~10 | - | Monitoring wrist movements | [56] | |

| TPU/ MWCNTs/ AgNWs | 2D auxetic network | Injecting, drying | 21.8 | - | Weight and displacement recognition | [57] | |

| Piezoresistive | CNT | Auxetic foam | Coating | 2.63 | - | Smart helmet, pulse monitoring, human–machine interaction | [67] |

| CNT | Auxetic porous foam | Ambilateral convergent directional freeze casting methodology | −5.4 kPa−1 | - | Gait monitoring | [44] | |

| Carbon fiber | Re-entrant hexagonal polymer frame | 3D printing | Sensitive at low strain (<6%) | - | Pulse and vibration detection | [69] | |

| Graphite powder | Silicon/graphite powder-based auxetic frame | Through a mold | 18% increase | - | - | [71] | |

| MWCNT | S-shaped cellular structure | Fused filament fabrication, 3D printing | 7.61 | - | Wearable electronics and self-sensing prosthetics | [72] | |

| Piezoelectric | Auxetic piezoelectric ceramics with ultra-low porosity | Model and geometry analysis | Highly tailorable electromechanical properties | Instruct design and application of the ultra-low porous auxetic piezoelectric materials. | [82] | ||

| PZT/PVDF auxetic piezoelectric composite | Finite element analysis | [83] | |||||

| Ceramic piezoelectric composite | 3D re-entrant hexagonal structure | 3D printing | Output voltage 6 V (three times higher than flat plate) | Tactile location-tracking sensor | [85] | ||

| Capacitive | PEDOT:PSS/poly-acrylamide conductive organogel | Auxetic elastomer frame (re-entrant hexagonal) | Cutting, filling | 3.2 | - | Wearable devices | [25] |

| Copper wire | Helically wound yarn | Wrapping | 4 | - | Wearable devices | [86] | |

| Liquid metal (eutectic gallium-indium) | Silicone elastomer rotating structure | Laser cutting, assembling | 1.61 | - | Soft robotic system | [87] | |

| CNT/PDMS/MEP conductive paste | Anisotropic auxetic PU sponge | Thermal compression, dipping | −2.8 | - | Smart wearables and perceptive soft robots | [88] | |

| Triboelectric | Conductive fiber, PTFE | Auxetic PU foam (core) | Assembling | 1.6 V cm−2 | - | Motion sensing, weight Sensing | [99] |

| Cu, PTFE, kraft paper | Auxetic PU foam (core) | Assembling | 0.89 V cm−2 | ~52 ms | Smart seat belt | [100] | |

| Silver-coated PA yarn, silicone rubber | Auxetic yarn | High-speed ring spinning, weaving | Output voltage 0.545 V | - | Self-counting yoga elastic band | [101] | |

| Cu, PVDF, PDMS | Rotating structures and an “I”-shaped structure | Cutting, heating | - | - | Monitoring human motions | [102] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Hu, H. Sensors Based on Auxetic Materials and Structures: A Review. Materials 2023, 16, 3603. https://doi.org/10.3390/ma16093603

Dong S, Hu H. Sensors Based on Auxetic Materials and Structures: A Review. Materials. 2023; 16(9):3603. https://doi.org/10.3390/ma16093603

Chicago/Turabian StyleDong, Shanshan, and Hong Hu. 2023. "Sensors Based on Auxetic Materials and Structures: A Review" Materials 16, no. 9: 3603. https://doi.org/10.3390/ma16093603

APA StyleDong, S., & Hu, H. (2023). Sensors Based on Auxetic Materials and Structures: A Review. Materials, 16(9), 3603. https://doi.org/10.3390/ma16093603