“No-Primer” Resin Cementation of Lithium Disilicate Ceramic: A Microtensile Bond Strength Evaluation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimens’ Preparation

2.2. μTBS Evaluation

2.3. Failure Mode Assessment

2.4. Statistical Analysis

3. Results

3.1. μTBS

3.2. Failure Mode Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krämer, N.; Lohbauer, U.; Frankenberger, R. Adhesive luting of indirect restorations. Am. J. Dent. 2000, 13, 60d–76d. [Google Scholar] [PubMed]

- Blatz, M.B.; Sadan, A.; Kern, M. Resin-ceramic bonding: A review of the literature. J. Prosthet. Dent. 2003, 89, 268–274. [Google Scholar] [CrossRef] [PubMed]

- Conejo, J.; Nueesch, R.; Vonderheide, M.; Blatz, M.B. Clinical Performance of All-Ceramic Dental Restorations. Curr. Oral Health Rep. 2017, 4, 112–123. [Google Scholar] [CrossRef]

- Zarone, F.; Di Mauro, M.I.; Ausiello, P.; Ruggiero, G.; Sorrentino, R. Current status on lithium disilicate and zirconia: A narrative review. BMC Oral Health 2019, 19, 134. [Google Scholar] [CrossRef] [PubMed]

- Lubauer, J.; Belli, R.; Peterlik, H.; Hurle, K.; Lohbauer, U. Grasping the Lithium hype: Insights into modern dental Lithium Silicate glass-ceramics. Dent. Mater. 2022, 38, 318–332. [Google Scholar] [CrossRef]

- Phark, J.-H.; Duarte, S., Jr. Microstructural considerations for novel lithium disilicate glass ceramics: A review. J. Esthet. Restor. Dent. 2022, 34, 92–103. [Google Scholar] [CrossRef]

- Tian, T.; Tsoi, J.K.-H.; Matinlinna, J.P.; Burrow, M.F. Aspects of bonding between resin luting cements and glass ceramic materials. Dent. Mater. 2014, 30, e147–e162. [Google Scholar] [CrossRef]

- Lung, C.Y.; Matinlinna, J.P. Aspects of silane coupling agents and surface conditioning in dentistry: An overview. Dent. Mater. 2012, 28, 467–477. [Google Scholar] [CrossRef]

- Witucki, G.L. A silane primer: Chemistry and applications of alkoxy silanes. J. Coat. Technol. 1993, 65, 57. [Google Scholar]

- Shen, C.; Oh, W.S.; Williams, J.R. Effect of post-silanization drying on the bond strength of composite to ceramic. J. Prosthet. Dent. 2004, 91, 453–458. [Google Scholar] [CrossRef]

- Cuevas-Suárez, C.E.; de Oliveira da Rosa, W.L.; Vitti, R.P.; da Silva, A.F.; Piva, E. Bonding Strength of Universal Adhesives to Indirect Substrates: A Meta-Analysis of in Vitro Studies. J. Prosthodont. 2020, 29, 298–308. [Google Scholar] [CrossRef] [PubMed]

- Awad, M.M.; Albedaiwi, L.; Almahdy, A.; Khan, R.; Silikas, N.; Hatamleh, M.M.; Alkhtani, F.M.; Alrahlah, A. Effect of universal adhesives on microtensile bond strength to hybrid ceramic. BMC Oral Health 2019, 19, 178. [Google Scholar] [CrossRef] [PubMed]

- Awad, M.M.; Alhalabi, F.; Alshehri, A.; Salem, M.A.; Robaian, A.; Alghannam, S.; Alayad, A.S.; Almutairi, B.; Alrahlah, A. Silane-Containing Universal Adhesives Influence Resin-Ceramic Microtensile Bond Strength. Coatings 2023, 13, 477. [Google Scholar] [CrossRef]

- Yoshihara, K.; Nagaoka, N.; Maruo, Y.; Nishigawa, G.; Yoshida, Y.; Van Meerbeek, B. Silane-coupling effect of a silane-containing self-adhesive composite cement. Dent. Mater. 2020, 36, 914–926. [Google Scholar] [CrossRef] [PubMed]

- De Munck, J.; Mine, A.; Poitevin, A.; Van Ende, A.; Cardoso, M.V.; Van Landuyt, K.L.; Peumans, M.; Van Meerbeek, B. Meta-analytical review of parameters involved in dentin bonding. J. Dent. Res. 2012, 91, 351–357. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, S.; Breschi, L.; Özcan, M.; Pfefferkorn, F.; Ferrari, M.; Van Meerbeek, B. Academy of Dental Materials guidance on in vitro testing of dental composite bonding effectiveness to dentin/enamel using micro-tensile bond strength (μTBS) approach. Dent. Mater. 2017, 33, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Südbeck, J.M.; Jacker-Guhr, S.; Lührs, A.K. Do Different Pretreatment Methods Influence the Microtensile Bond Strength of Composite Cements to Silicate Ceramic? J. Adhes. Dent. 2021, 23, 335–345. [Google Scholar] [CrossRef]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 27, 89–99. [Google Scholar] [CrossRef]

- Yoshihara, K.; Nagaoka, N.; Sonoda, A.; Maruo, Y.; Makita, Y.; Okihara, T.; Irie, M.; Yoshida, Y.; Van Meerbeek, B. Effectiveness and stability of silane coupling agent incorporated in ‘universal’ adhesives. Dent. Mater. 2016, 32, 1218–1225. [Google Scholar] [CrossRef]

- Kahn, F.J. Orientation of liquid crystals by surface coupling agents. Appl. Phys. Lett. 2003, 22, 386–388. [Google Scholar] [CrossRef]

- Matinlinna, J.P.; Lung, C.Y.K.; Tsoi, J.K.H. Silane adhesion mechanism in dental applications and surface treatments: A review. Dent. Mater. 2018, 34, 13–28. [Google Scholar] [CrossRef] [PubMed]

- Zakir, M.; Ashraf, U.; Tian, T.; Han, A.; Qiao, W.; Jin, X.; Zhang, M.; Tsoi, J.K.-H.; Matinlinna, J.P. The Role of Silane Coupling Agents and Universal Primers in Durable Adhesion to Dental Restorative Materials—A Review. Curr. Oral Health Rep. 2016, 3, 244–253. [Google Scholar] [CrossRef]

- Maruo, Y.; Nishigawa, G.; Yoshihara, K.; Minagi, S.; Matsumoto, T.; Irie, M. Does 8-methacryloxyoctyl trimethoxy silane (8-MOTS) improve initial bond strength on lithium disilicate glass ceramic? Dent. Mater. 2017, 33, e95–e100. [Google Scholar] [CrossRef] [PubMed]

- Yon, M.J.Y.; Matinlinna, J.P.; Tsoi, J.K.H.; Vallittu, P.K.; Lassila, L.V.J. Effect of Long-Chain Silane on Mechanical Properties of Experimental Resin Composites. Silicon 2023, 15, 5579–5586. [Google Scholar] [CrossRef]

- Koko, M.; Takagaki, T.; Abdou, A.; Inokoshi, M.; Ikeda, M.; Wada, T.; Uo, M.; Nikaido, T.; Tagami, J. Effects of the ratio of silane to 10-methacryloyloxydecyl dihydrogenphosphate (MDP) in primer on bonding performance of silica-based and zirconia ceramics. J. Mech. Behav. Biomed. Mater. 2020, 112, 104026. [Google Scholar] [CrossRef] [PubMed]

- Comba, L.; Tichy, A.; Bradna, P. The Effect of Censoring on the Statistical Evaluation of Composite-to-Composite Bond Strength. J. Adhes. Dent. 2020, 22, 183–193. [Google Scholar] [CrossRef]

- Aguiar, T.R.; de Oliveira, M.; Arrais, C.A.; Ambrosano, G.M.; Rueggeberg, F.; Giannini, M. The effect of photopolymerization on the degree of conversion, polymerization kinetic, biaxial flexure strength, and modulus of self-adhesive resin cements. J. Prosthet. Dent. 2015, 113, 128–134. [Google Scholar] [CrossRef]

- Lührs, A.K.; Pongprueksa, P.; De Munck, J.; Geurtsen, W.; Van Meerbeek, B. Curing mode affects bond strength of adhesively luted composite CAD/CAM restorations to dentin. Dent. Mater. 2014, 30, 281–291. [Google Scholar] [CrossRef]

| Material | Code | Composition |

|---|---|---|

| GC Initial LiSi Block, GC corporation, Tokyo, Japan | - | Silicon dioxide, phosphorus oxide, potassium oxide, aluminum oxides, titanium oxide, and cerium oxide. |

| Panavia SA Cement Plus, Kuraray Noritake, Tokyo, Japan | PSAP | Paste A composition: 10-methacryloyloxydecyl dihydrogen phosphate, bisphenol A glycidyl methacrylate, triethylene glycol dimethacrylate, 2-hydroxyethyl methacrylate, fillers, initiator, pigment, and other components. Paste B composition: Methacrylate monomer, fillers, accelerator, pigment, other components. |

| Panavia SA Cement Universal, Kuraray Noritake, Tokyo, Japan | PSAU | Paste A composition: 10-methacryloyloxydecyl dihydrogen phosphate, bisphenol A glycidyl methac-rylate, triethylene glycol dimethacrylate, 2-hydroxyethyl methacrylate, fillers, initiator, pigment, and other components. Paste B composition: Methacrylate monomer, fillers, accelerator, pigment, long-chain silane, and other components. |

| Monobond N, Ivoclar Vivadent, Schaan, Liechtenstein | MBN | Alcohol, silane methacrylate, phosphoric acid methacrylate, and disulfide methacrylate. |

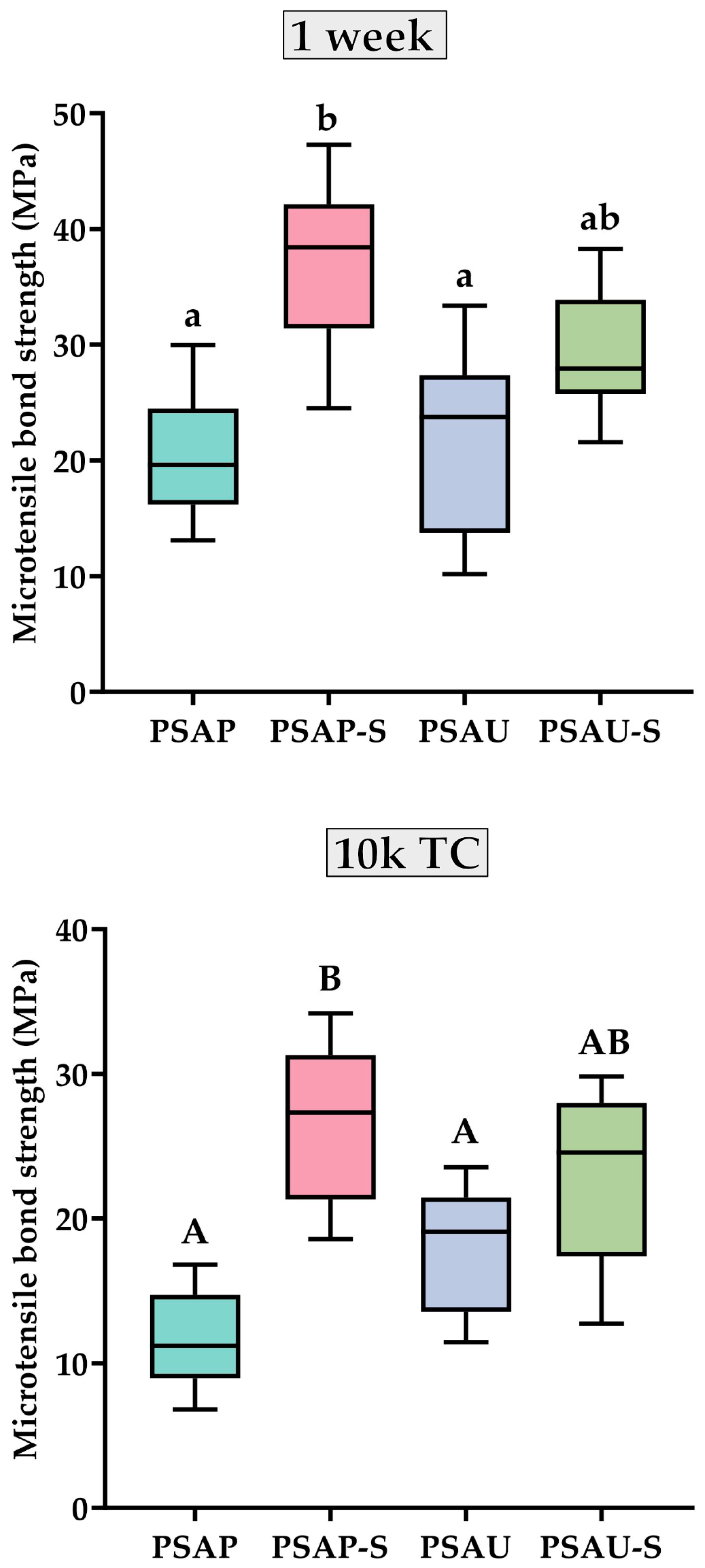

| µTBS (1 Week) | µTBS (10k TC) | |||

|---|---|---|---|---|

| Mean ± SD (MPa) | 1 PTF/2 n | Mean ± SD (MPa) | PTF/n | |

| PSAP | 20.35 ± 5.68 | 3/57 | 11.62 ± 3.47 * | 0/60 |

| PSAP-S | 37.12 ± 7.62 | 0/60 | 26.67 ± 5.68 * | 0/60 |

| PSAU | 21.89 ± 8.20 | 2/58 | 18.04 ± 4.42 | 0/60 |

| PSAU-S | 29.20 ± 5.63 | 0/60 | 23.01 ± 6.29 | 0/60 |

| Degrees of Freedom | Sum Squares | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|

| Resin cement | 1 | 61.2 | 61.2 | 1.293 | 0.269 |

| Priming | 1 | 870.1 | 870.1 | 18.390 | <0.001 * |

| Resin cement × Priming | 1 | 134.2 | 134.2 | 2.836 | 0.108 |

| Residuals | 20 | 946.2 | 47.3 |

| Degrees of Freedom | Sum Squares | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|

| Resin cement | 1 | 11.3 | 11.3 | 0.437 | 0.516 |

| Priming | 1 | 600.3 | 600.3 | 23.219 | <0.001 * |

| Resin cement × Priming | 1 | 152.6 | 152.6 | 5.904 | 0.0246 * |

| Residuals | 20 | 517.1 | 25.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awad, M.M.; Alhalabi, F.; Alanazi, A.A.; Alanazi, A.A.; Alshahrani, G.A.; Fu, C.; Albaijan, R.S.; Alkattan, R.; Fawzy, A.S. “No-Primer” Resin Cementation of Lithium Disilicate Ceramic: A Microtensile Bond Strength Evaluation. Materials 2024, 17, 137. https://doi.org/10.3390/ma17010137

Awad MM, Alhalabi F, Alanazi AA, Alanazi AA, Alshahrani GA, Fu C, Albaijan RS, Alkattan R, Fawzy AS. “No-Primer” Resin Cementation of Lithium Disilicate Ceramic: A Microtensile Bond Strength Evaluation. Materials. 2024; 17(1):137. https://doi.org/10.3390/ma17010137

Chicago/Turabian StyleAwad, Mohamed M., Feras Alhalabi, Abdulaziz Abdullah Alanazi, Abdulaziz Ali Alanazi, Ghanem Abdullah Alshahrani, Cheryl Fu, Refal Saad Albaijan, Rana Alkattan, and Amr S. Fawzy. 2024. "“No-Primer” Resin Cementation of Lithium Disilicate Ceramic: A Microtensile Bond Strength Evaluation" Materials 17, no. 1: 137. https://doi.org/10.3390/ma17010137

APA StyleAwad, M. M., Alhalabi, F., Alanazi, A. A., Alanazi, A. A., Alshahrani, G. A., Fu, C., Albaijan, R. S., Alkattan, R., & Fawzy, A. S. (2024). “No-Primer” Resin Cementation of Lithium Disilicate Ceramic: A Microtensile Bond Strength Evaluation. Materials, 17(1), 137. https://doi.org/10.3390/ma17010137