The Effect of Sintering on Zirconia Manufactured via Suspension-Enclosing Projection Stereolithography for Dental Applications: An In Vitro Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instruments

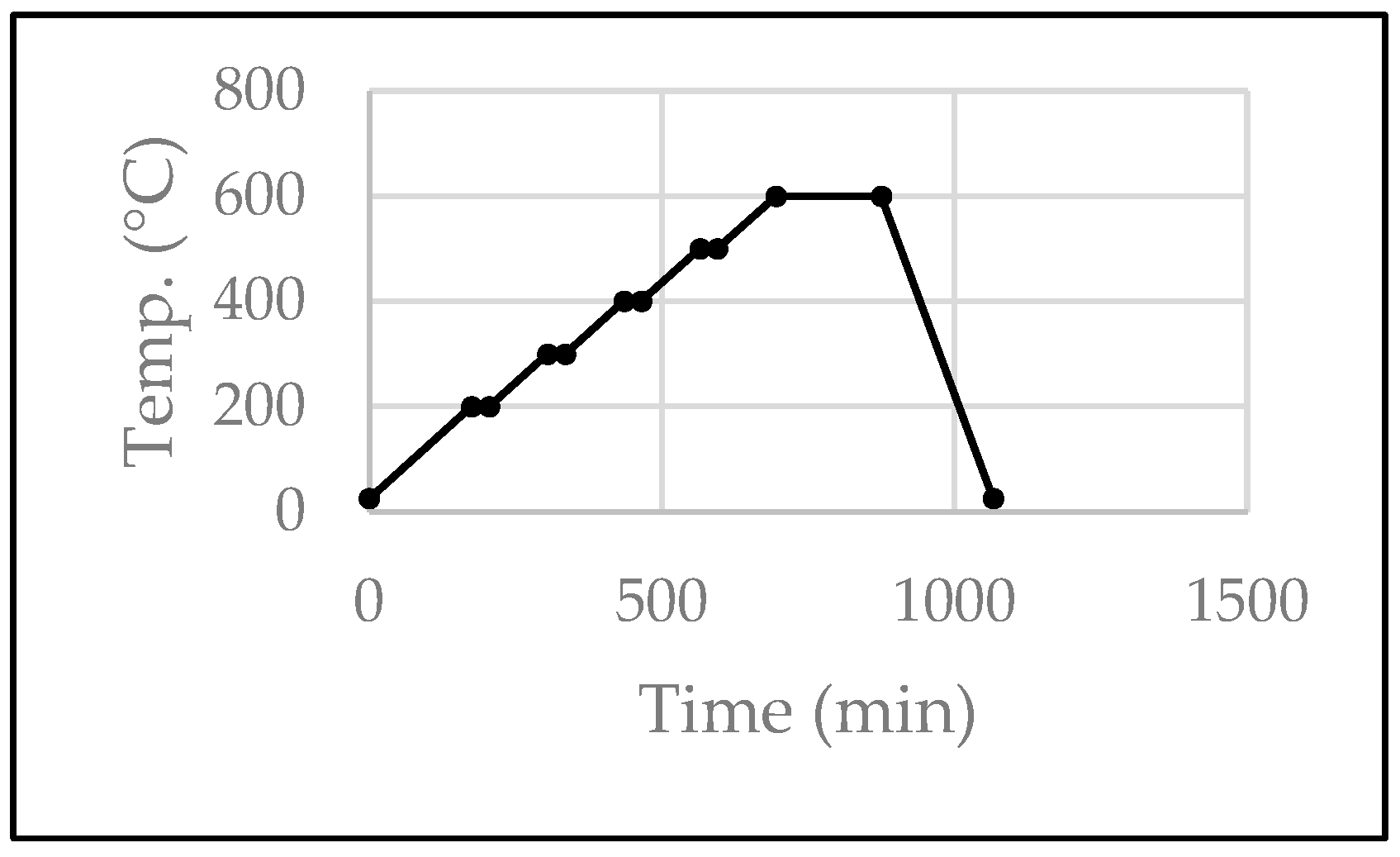

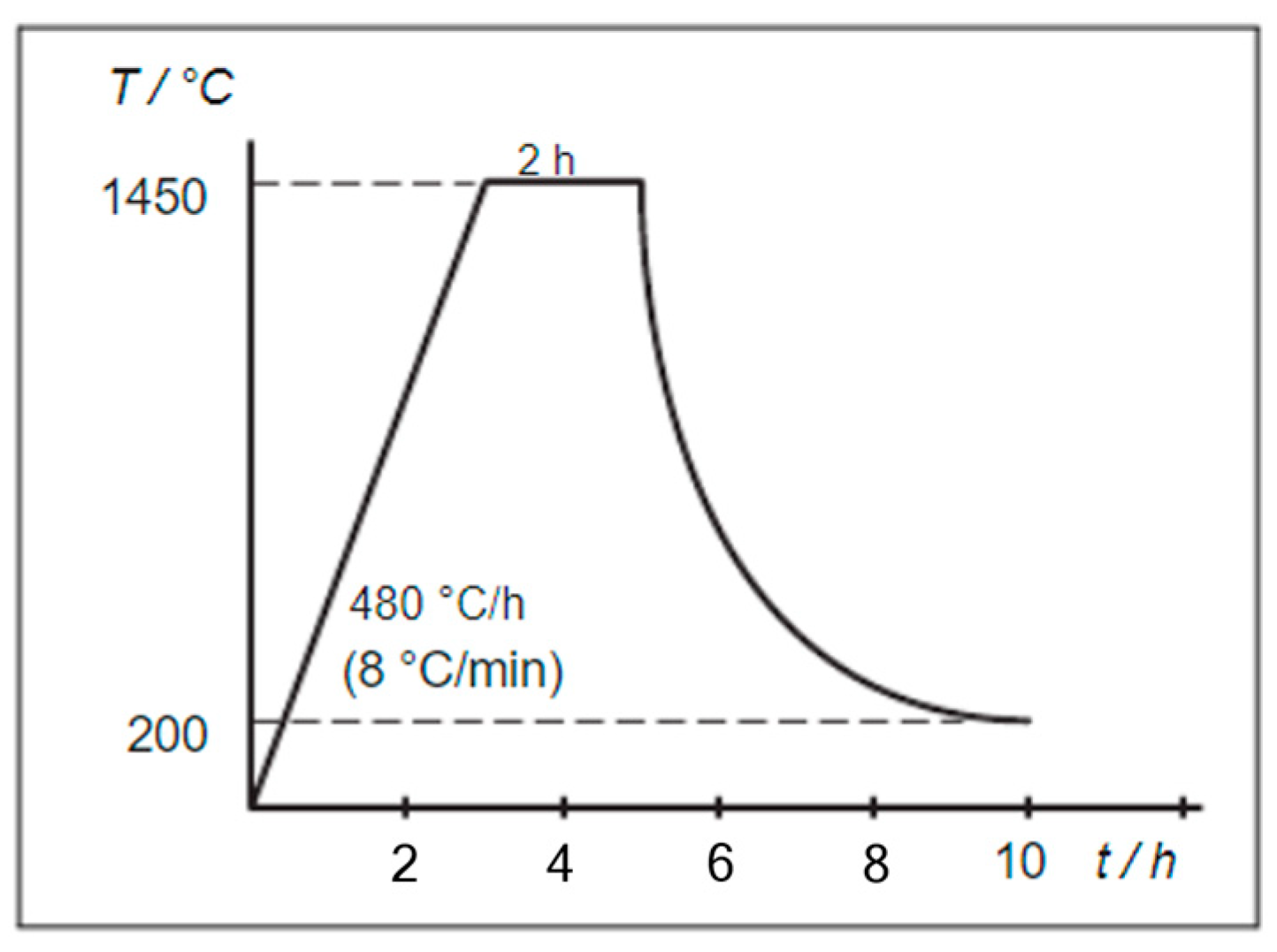

2.3. Specimen Preparation Protocol

2.4. Testing

2.4.1. Dimensional Accuracy and Flexural Strength Testing

2.4.2. Density Testing

2.4.3. Crystal Structure Analysis

2.4.4. Scanning Electron Microscopy (SEM) Analysis

2.5. Statistical Analysis

3. Results

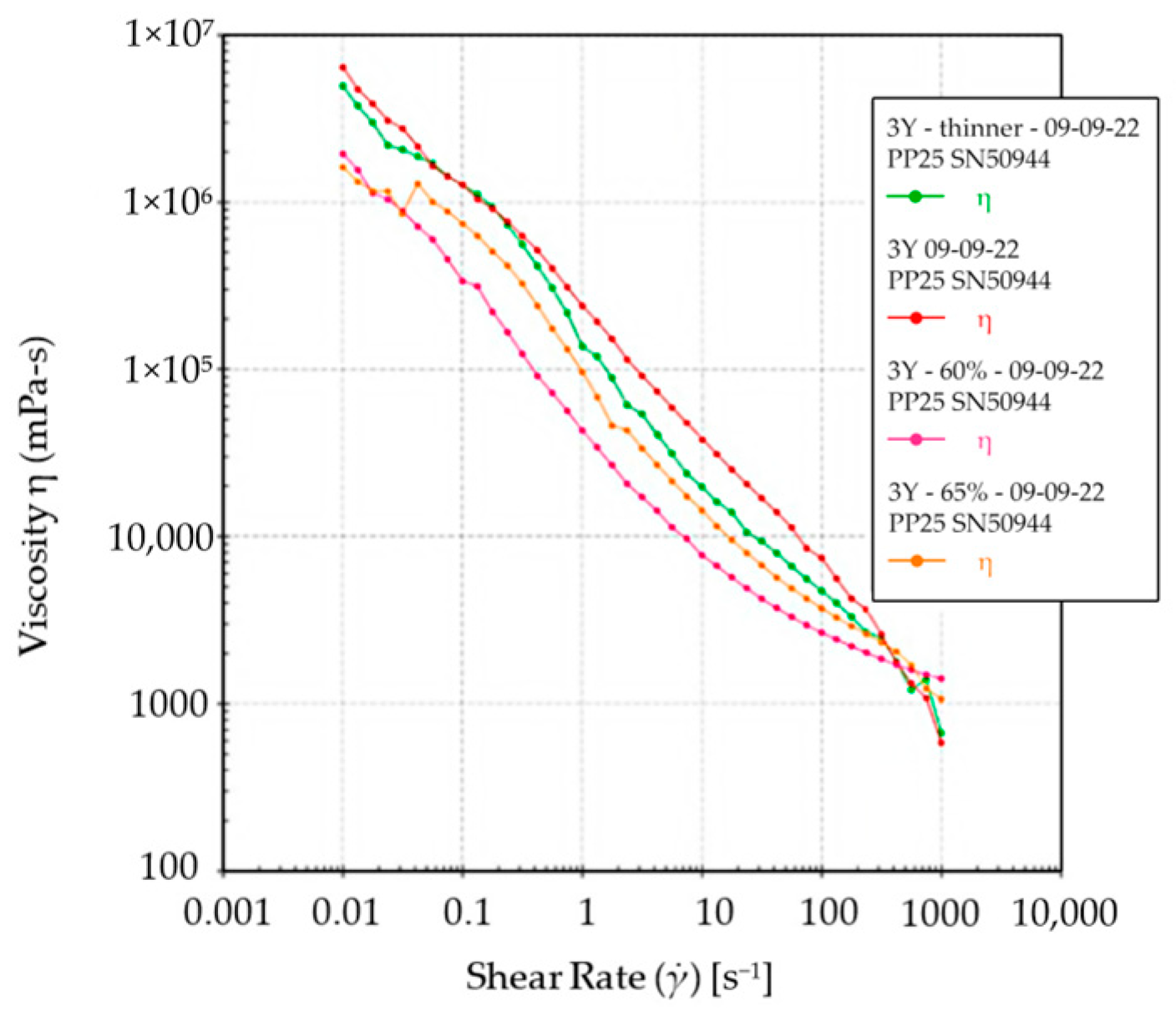

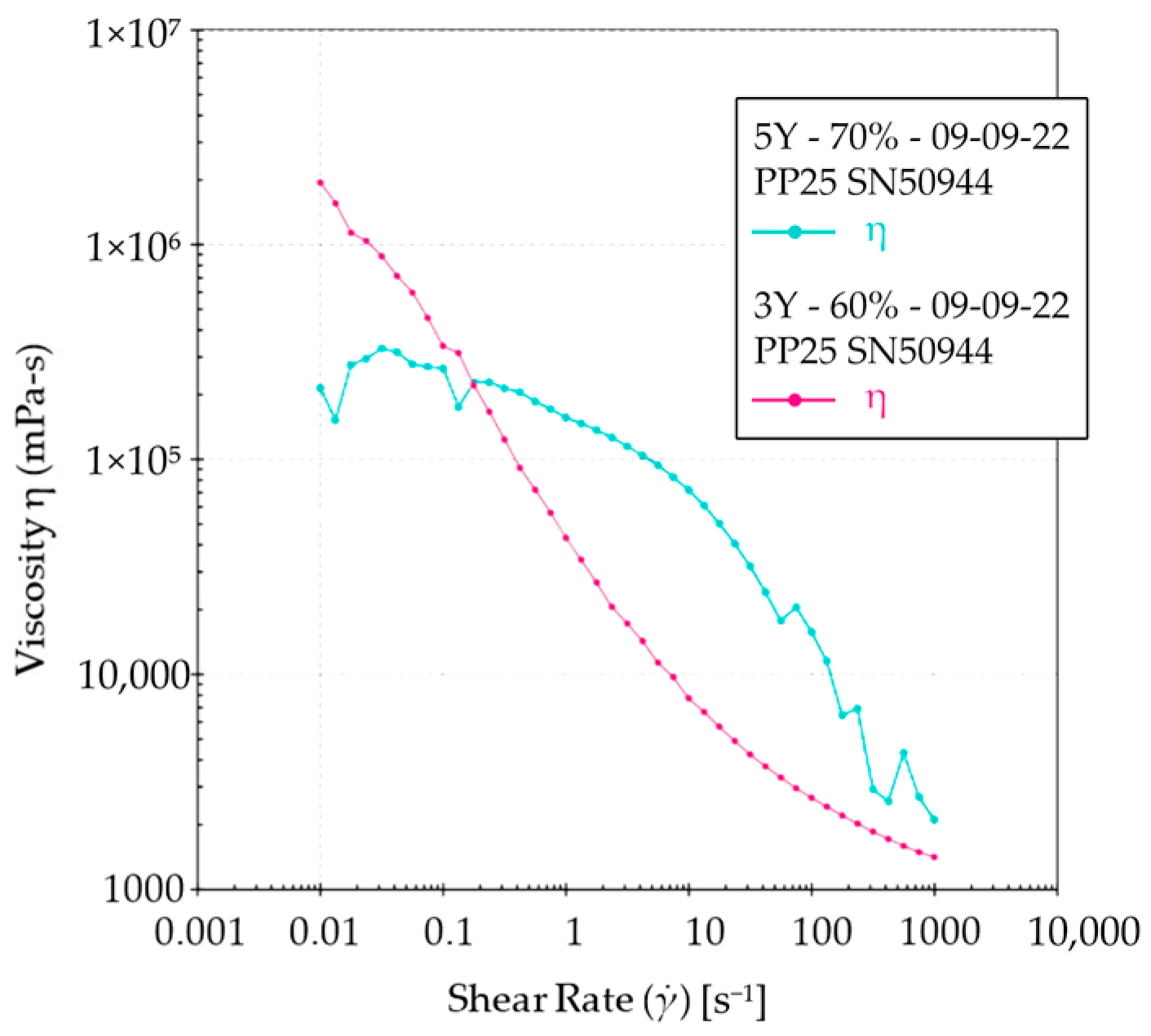

3.1. Rheological Properties—Ceramic Suspension

3.2. Physical Properties

3.2.1. Dimensional Accuracy

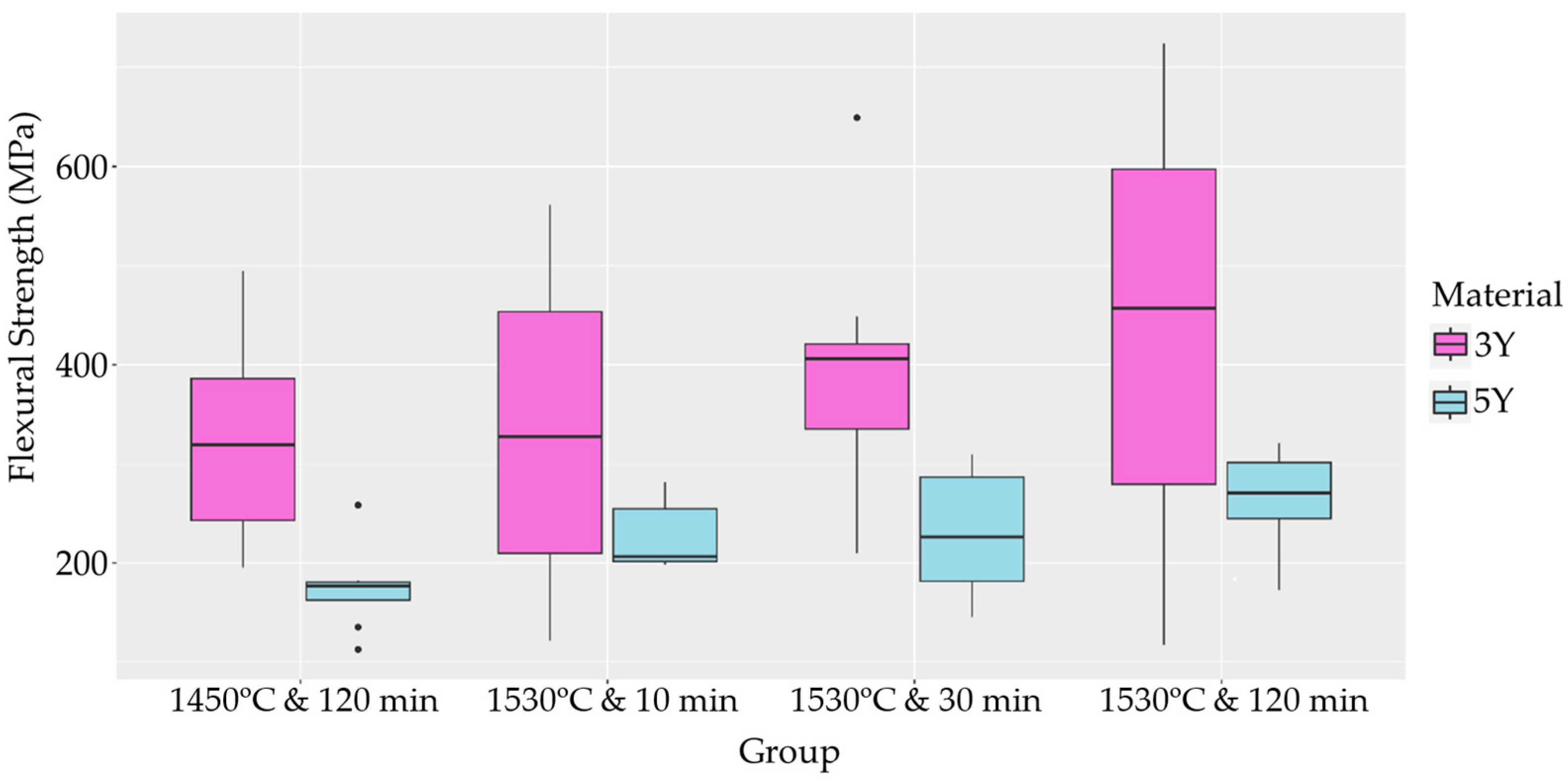

3.2.2. Flexural Strength and Density

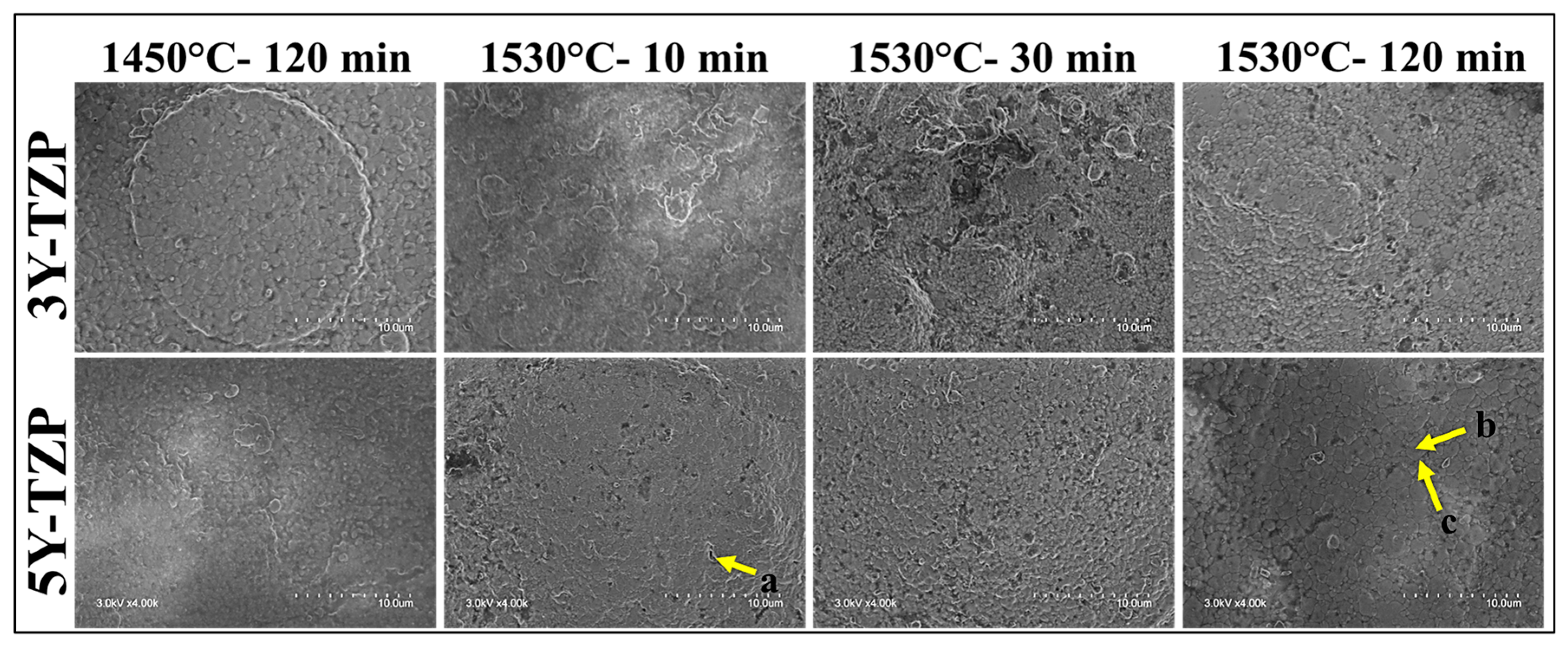

3.2.3. Phase Composition and Microstructure

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khanlar, L.N.; Salazar Rios, A.; Tahmaseb, A.; Zandinejad, A. Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review. Dent. J. 2021, 9, 104. [Google Scholar] [CrossRef]

- Song, X.; Chen, Y.; Lee, T.W.; Wu, S.; Cheng, L. Ceramic fabrication using Mask-Image-Projection-based Stereolithography integrated with tape-casting. J. Manuf. Process. 2015, 20, 456–464. [Google Scholar] [CrossRef]

- Gruber, S. Lithography-Based Additive Manufacturing of Alumina Parts. Ph.D. Thesis, Vienna University of Technology, Vienna, Austria, 2013. [Google Scholar]

- Mitteramskogler, G. Generative Fertigung von Bauteilen aus TCP. Master’s Thesis, Vienna University of Technology, Vienna, Austria, 2011. [Google Scholar]

- Baysal, N.; Tuğba Kalyoncuoğlu, Ü.; Ayyıldız, S. Mechanical Properties and Bond Strength of Additively Manufactured and Milled Dental Zirconia: A Pilot Study. J. Prosthodont. 2022, 31, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Cabanes-Gumbau, G.; Soto-Peñaloza, D.; Peñarrocha-Diago, M.; Peñarrocha-Diago, M. Analogical and digital workflow in the design and preparation of the emergence profile of biologically oriented preparation technique (BOPT) crowns over implants in the working model. J. Clin. Med. 2019, 8, 1452. [Google Scholar] [CrossRef] [PubMed]

- Adobes Martin, M.; Lipani, E.; Bernes Martinez, L.; Alvarado Lorenzo, A.; Aiuto, R.; Garcovich, D. Reliability of Tooth Width Measurements Delivered by the Clin-Check Pro 6.0 Software on Digital Casts: A Cross-Sectional Study. Int. J. Environ. Res. Public Health 2022, 19, 3581. [Google Scholar] [CrossRef] [PubMed]

- Menchini-Fabris, G.B.; Crespi, R.; Toti, P.; Crespi, G.; Rubino, L.; Covani, U. A 3-year retrospective study of fresh socket implants: CAD/CAM customized healing abutment vs. cover screws. Int. J. Comput. Dent. 2020, 23, 109–117. [Google Scholar]

- Hwang, K.; Hsieh, Y. Comparative study of pore structure evolution during solvent and thermal debinding of powder injection molded parts. Metall. Mater. Trans. A 1996, 27, 245–253. [Google Scholar] [CrossRef]

- Shivashankar, T.S.; German, R.M. Effective length scale for predicting solvent-debinding times of components produced by powder injection molding. J. Am. Ceram. Soc. 1999, 82, 1146–1152. [Google Scholar] [CrossRef]

- Omar, M.; Ibrahim, R.; Sidik, M.; Mustapha, M.; Mohamad, M. Rapid debinding of 316L stainless steel injection moulded component. J. Mater. Process. Technol. 2003, 140, 397–400. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Wang, M.-C.; Hon, M.-H. Solvent debinding mechanism for alumina injection molded compacts with water-soluble binders. Ceram. Int. 2003, 29, 745–756. [Google Scholar] [CrossRef]

- Oliveira, R.V.; Soldi, V.; Fredel, M.C.; Pires, A.T. Ceramic injection moulding: Influence of specimen dimensions and temperature on solvent debinding kinetics. J. Mater. Process. Technol. 2005, 160, 213–220. [Google Scholar] [CrossRef]

- Krauss, V.A.; Oliveira, A.; Klein, A.; Al-Qureshi, H.; Fredel, M. A model for PEG removal from alumina injection moulded parts by solvent debinding. J. Mater. Process. Technol. 2007, 182, 268–273. [Google Scholar] [CrossRef]

- Luthardt, R.G.; Holzhüter, M.; Sandkuhl, O.; Herold, V.; Schnapp, J.D.; Kuhlisch, E.; Walter, M. Reliability and Properties of Ground Y-TZP-Zirconia Ceramics. J. Dent. Res. 2002, 81, 487–491. [Google Scholar] [CrossRef] [PubMed]

- Jang, G.; Kim, H.; Choe, H.; Son, M. Fracture strength and mechanism of dental ceramic crown with zirconia thickness. Procedia Eng. 2011, 10, 1556–1560. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef] [PubMed]

- Inokoshi, M.; Zhang, F.; De Munck, J.; Minakuchi, S.; Naert, I.; Vleugels, J.; Van Meerbeek, B.; Vanmeensel, K. Influence of sintering conditions on low-temperature degradation of dental zirconia. Dent. Mater. 2014, 30, 669–678. [Google Scholar] [CrossRef] [PubMed]

- Ebeid, K.; Wille, S.; Hamdy, A.; Salah, T.; El-Etreby, A.; Kern, M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent. Mater. 2014, 30, e419–e424. [Google Scholar] [CrossRef]

- Öztürk, C.; Can, G. Effect of Sintering Parameters on the Mechanical Properties of Monolithic Zirconia. J. Dent. Res. Dent. Clin. Dent. Prospect. 2019, 13, 247–252. [Google Scholar] [CrossRef]

- Hjerppe, J.; Vallittu, P.K.; Fröberg, K.; Lassila, L.V. Effect of sintering time on biaxial strength of zirconium dioxide. Dent. Mater. 2009, 25, 166–171. [Google Scholar] [CrossRef]

- Uçar, Y.; Aysan Meriç, İ.; Ekren, O. Layered manufacturing of dental ceramics: Fracture mechanics, microstructure, and elemental composition of lithography-sintered ceramic. J. Prosthodont. 2019, 28, e310–e318. [Google Scholar] [CrossRef]

- Lian, Q.; Sui, W.; Wu, X.; Yang, F.; Yang, S. Additive manufacturing of ZrO ceramic dental bridges by stereolithography. Rapid Prototyp. J. 2018, 24, 114–119. [Google Scholar] [CrossRef]

- Li, R.; Wang, Y.; Hu, M.; Wang, Y.; Xv, Y.; Liu, Y.; Sun, Y. Strength and Adaptation of Stereolithography-Fabricated Zirconia Dental Crowns: An In Vitro Study. Int. J. Prosthodont. 2019, 32, 439–443. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Al-Haj Husain, N.; Ceballos, L.; Özcan, M. Flexural strength and Weibull characteristics of stereolithography additive manufactured versus milled zirconia. J. Prosthet. Dent. 2021, 125, 685–690. [Google Scholar] [CrossRef]

- Revilla-León, M.; Al-Haj Husain, N.; Barmak, A.B.; Pérez-López, J.; Raigrodski, A.J.; Özcan, M. Chemical Composition and Flexural Strength Discrepancies Between Milled and Lithography-Based Additively Manufactured Zirconia. J. Prosthodont. 2022, 31, 778–783. [Google Scholar] [CrossRef] [PubMed]

- Zandinejad, A.; Das, O.; Barmak, A.B.; Kuttolamadom, M.; Revilla-León, M. The Flexural Strength and Flexural Modulus of Stereolithography Additively Manufactured Zirconia with Different Porosities. J. Prosthodont. 2022, 31, 434–440. [Google Scholar] [CrossRef]

- He, L.; Song, X. Supportability of a High-Yield-Stress Slurry in a New Stereolithography-Based Ceramic Fabrication Process. JOM 2018, 70, 407–412. [Google Scholar] [CrossRef]

- He, L.; Fei, F.; Wang, W.; Song, X. Support-Free Ceramic Stereolithography of Complex Overhanging Structures Based on an Elasto-viscoplastic Suspension Feedstock. ACS Appl. Mater. Interfaces 2019, 11, 18849–18857. [Google Scholar] [CrossRef]

- Li, H.; Song, L.; Sun, J.; Ma, J.; Shen, Z. Stereolithography-fabricated zirconia dental prostheses: Concerns based on clinical requirements. Adv. Appl. Ceram. 2020, 119, 236–243. [Google Scholar] [CrossRef]

- Team, R.C. R: A Language and Environment for Statistical Computing. 2022. Available online: https://www.R-project.org/ (accessed on 29 October 2023).

- Chavez, L.A.; Ibave, P.; Wilburn, B.; Alexander, D.; Stewart, C.; Wicker, R.; Lin, Y. The Influence of Printing Parameters, Post-Processing, and Testing Conditions on the Properties of Binder Jetting Additive Manufactured Functional Ceramics. Ceramics 2020, 3, 65–77. [Google Scholar] [CrossRef]

- Abualsaud, R.; Alalawi, H. Fit, Precision, and Trueness of 3D-Printed Zirconia Crowns Compared to Milled Counterparts. Dent. J. 2022, 10, 215. [Google Scholar] [CrossRef]

- Fonseca, Y.R.; Elias, C.N.; Monteiro, S.N.; Dos Santos, H.E.S.; Dos Santos, C. Modeling of the Influence of Chemical Composition, Sintering Temperature, Density, and Thickness in the Light Transmittance of Four Zirconia Dental Prostheses. Materials 2019, 12, 2529. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Reveron, H.; Spies, B.C.; Van Meerbeek, B.; Chevalier, J. Trade-off between fracture resistance and translucency of zirconia and lithium-disilicate glass ceramics for monolithic restorations. Acta Biomater. 2019, 91, 24–34. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Wu, J.-M.; Wu, H.-Q.; Chen, Y.; Li, C.-H.; Shi, Y.-S. Microstructure and mechanical properties of 3Y-TZP dental ceramics fabricated by selective laser sintering combined with cold isostatic pressing. Int. J. Lightweight Mater. Manuf. 2018, 1, 239–245. [Google Scholar] [CrossRef]

- Denry, I.; Abdelaal, M.; Dawson, D.V.; Holloway, J.A.; Kelly, J.R. Effect of crystalline phase assemblage on reliability of 3Y-TZP. J. Prosthet. Dent. 2021, 126, 238–247. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.; Tanaka, C.B.; Kaizer, M.R.; Zhang, Y. Characterization of three commercial Y-TZP ceramics produced for their high-translucency, high-strength and high-surface area. Ceram. Int. 2016, 42, 1077–1085. [Google Scholar] [CrossRef] [PubMed]

- Jansen, J.U.; Lümkemann, N.; Letz, I.; Pfefferle, R.; Sener, B.; Stawarczyk, B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. J. Prosthet. Dent. 2019, 122, 396–403. [Google Scholar] [CrossRef] [PubMed]

- Alves, M.F.R.P.; de Campos, L.Q.B.; Simba, B.G.; da Silva, C.R.M.; Strecker, K.; dos Santos, C. Microstructural Characteristics of 3Y-TZP Ceramics and Their Effects on the Flexural Strength. Ceramics 2022, 5, 798–813. [Google Scholar] [CrossRef]

- Ji, S.H.; Kim, D.S.; Park, M.S.; Yun, J.S. Sintering process optimization for 3YSZ ceramic 3D-printed objects manufactured by stereolithography. Nanomaterials 2021, 11, 192. [Google Scholar] [CrossRef]

- TOSOH. Ceramic Materials—Zirconia. 2023. Available online: https://www.tosoheurope.com/our-products/ceramic-materials (accessed on 29 October 2023).

- Kulyk, V.; Duriagina, Z.; Kostryzhev, A.; Vasyliv, B.; Marenych, O. Effects of Sintering Temperature and Yttria Content on Microstructure, Phase Balance, Fracture Surface Morphology, and Strength of Yttria-Stabilized Zirconia. Appl. Sci. 2022, 12, 11617. [Google Scholar] [CrossRef]

- Ferrini, F.; Paolone, G.; Di Domenico, G.L.; Pagani, N.; Gherlone, E.F. SEM Evaluation of the Marginal Accuracy of Zirconia, Lithium Disilicate, and Composite Single Crowns Created by CAD/CAM Method: Comparative Analysis of Different Materials. Materials 2023, 16, 2413. [Google Scholar] [CrossRef]

- Alharbi, N.; Osman, R.B.; Wismeijer, D. Factors Influencing the Dimensional Accuracy of 3D-Printed Full-Coverage Dental Restorations Using Stereolithography Technology. Int. J. Prosthodont. 2016, 29, 503–510. [Google Scholar] [CrossRef] [PubMed]

- Osman, R.B.; Alharbi, N.; Wismeijer, D. Build Angle: Does It Influence the Accuracy of 3D-Printed Dental Restorations Using Digital Light-Processing Technology? Int. J. Prosthodont. 2017, 30, 182–188. [Google Scholar] [CrossRef] [PubMed]

- Unkovskiy, A.; Bui PH, B.; Schille, C.; Geis-Gerstorfer, J.; Huettig, F.; Spintzyk, S. Objects build orientation, positioning, and curing influence dimensional accuracy and flexural properties of stereolithographically printed resin. Dent. Mater. 2018, 34, e324–e333. [Google Scholar] [CrossRef] [PubMed]

- Monzón, M.; Ortega, Z.; Hernández, A.; Paz, R.; Ortega, F. Anisotropy of photopolymer parts made by digital light processing. Materials 2017, 10, 64. [Google Scholar] [CrossRef]

- Jang, K.-J.; Kang, J.-H.; Fisher, J.G.; Park, S.-W. Effect of the volume fraction of zirconia suspensions on the microstructure and physical properties of products produced by additive manufacturing. Dent. Mater. 2019, 35, e97–e106. [Google Scholar] [CrossRef]

- Mitteramskogler, G.; Gmeiner, R.; Felzmann, R.; Gruber, S.; Hofstetter, C.; Stampfl, J.; Ebert, J.; Wachter, W.; Laubersheimer, J. Light curing strategies for lithography-based additive manufacturing of customized ceramics. Addit. Manuf. 2014, 1, 110–118. [Google Scholar] [CrossRef]

- Hinczewski, C.; Corbel, S.; Chartier, T. Ceramic suspensions suitable for stereolithography. J. Eur. Ceram. Soc. 1998, 18, 583–590. [Google Scholar] [CrossRef]

| Group n = 10 | Debinding Temperature | Debinding Dwell Time | Sintering Temperature | Sintering Dwell Time | Total Time |

|---|---|---|---|---|---|

| 1 | 600 °C | 175 min | 1450 °C | 120 min | 24.03 h |

| 2 | 600 °C | 175 min | 1530 °C | 10 min | 22.56 h |

| 3 | 600 °C | 175 min | 1530 °C | 30 min | 22.81 h |

| 4 | 600 °C | 175 min | 1530 °C | 120 min | 24.13 h |

| Treatment (n = 10) | L (mm) 1 | W (mm) 1 | H (mm) 1 |

|---|---|---|---|

| 1450 °C & 120 min | 21.18 ± 0.18 | 3.15 ± 0.16 | 0.78 ± 0.04 |

| 1530 °C & 10 min | 21.22 ± 0.20 | 3.13 ± 0.13 | 0.84 ± 0.08 |

| 1530 °C & 30 min | 21.29 ± 0.26 | 3.21 ± 0.16 | 0.86 ± 0.08 |

| 1530 °C & 120 min | 21.23 ± 0.14 | 3.18 ± 0.11 | 0.89 ± 0.05 |

| Treatment (n = 10) | L (mm) 1 | W (mm) 1 | H (mm) 1 |

|---|---|---|---|

| 1450 °C & 120 min | 23.55 ± 0.07 | 3.39 ± 0.12 | 0.91 ± 0.07 |

| 1530 °C & 10 min | 23.77 ± 0.28 | 3.49 ± 0.12 | 0.98 ± 0.09 |

| 1530 °C & 30 min | 23.56 ± 0.19 | 3.46 ± 0.19 | 0.93 ± 0.06 |

| 1530 °C & 120 min | 23.59 ± 0.21 | 3.44 ± 0.05 | 0.96 ± 0.09 |

| Treatment | Flexural Strength (MPa, n = 10) 1 | Density (g/cm3, n = 10) 1 |

|---|---|---|

| 1450 °C & 120 min | 324.87 ± 101.52 | 6.02 ± 0.73 |

| 1530 °C & 10 min | 334.91 ± 160.14 | 5.75 ± 0.55 |

| 1530 °C & 30 min | 392.90 ± 116.83 | 5.98 ± 0.70 |

| 1530 °C & 120 min | 435.89 ± 204.10 | 6.66 ± 0.49 |

| Treatment | Flexural Strength (MPa, n = 10) 1 | Density (g/cm3, n = 10) 1 |

|---|---|---|

| 1450 °C & 120 min 2 | 174.16 ± 42.29 | 5.71 ± 0.56 |

| 1530 °C & 10 min | 224.78 ± 34.21 | 5.66 ± 0.24 |

| 1530 °C & 30 min | 228.47 ± 62.42 | 5.71 ± 0.57 |

| 1530 °C & 120 min | 268.34 ± 44.66 | 6.02 ± 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Unnadkat, A.; Kirby, L.; Kulanthaivel, S.; Rysavy, O.; Tsujimoto, A.; Song, X.; Teixeira, E.C. The Effect of Sintering on Zirconia Manufactured via Suspension-Enclosing Projection Stereolithography for Dental Applications: An In Vitro Study. Materials 2024, 17, 14. https://doi.org/10.3390/ma17010014

Unnadkat A, Kirby L, Kulanthaivel S, Rysavy O, Tsujimoto A, Song X, Teixeira EC. The Effect of Sintering on Zirconia Manufactured via Suspension-Enclosing Projection Stereolithography for Dental Applications: An In Vitro Study. Materials. 2024; 17(1):14. https://doi.org/10.3390/ma17010014

Chicago/Turabian StyleUnnadkat, Amit, Levi Kirby, Senthilguru Kulanthaivel, Oscar Rysavy, Akimasa Tsujimoto, Xuan Song, and Erica C. Teixeira. 2024. "The Effect of Sintering on Zirconia Manufactured via Suspension-Enclosing Projection Stereolithography for Dental Applications: An In Vitro Study" Materials 17, no. 1: 14. https://doi.org/10.3390/ma17010014