Aging Process of Biocomposites with the PLA Matrix Modified with Different Types of Cellulose

Abstract

:1. Introduction

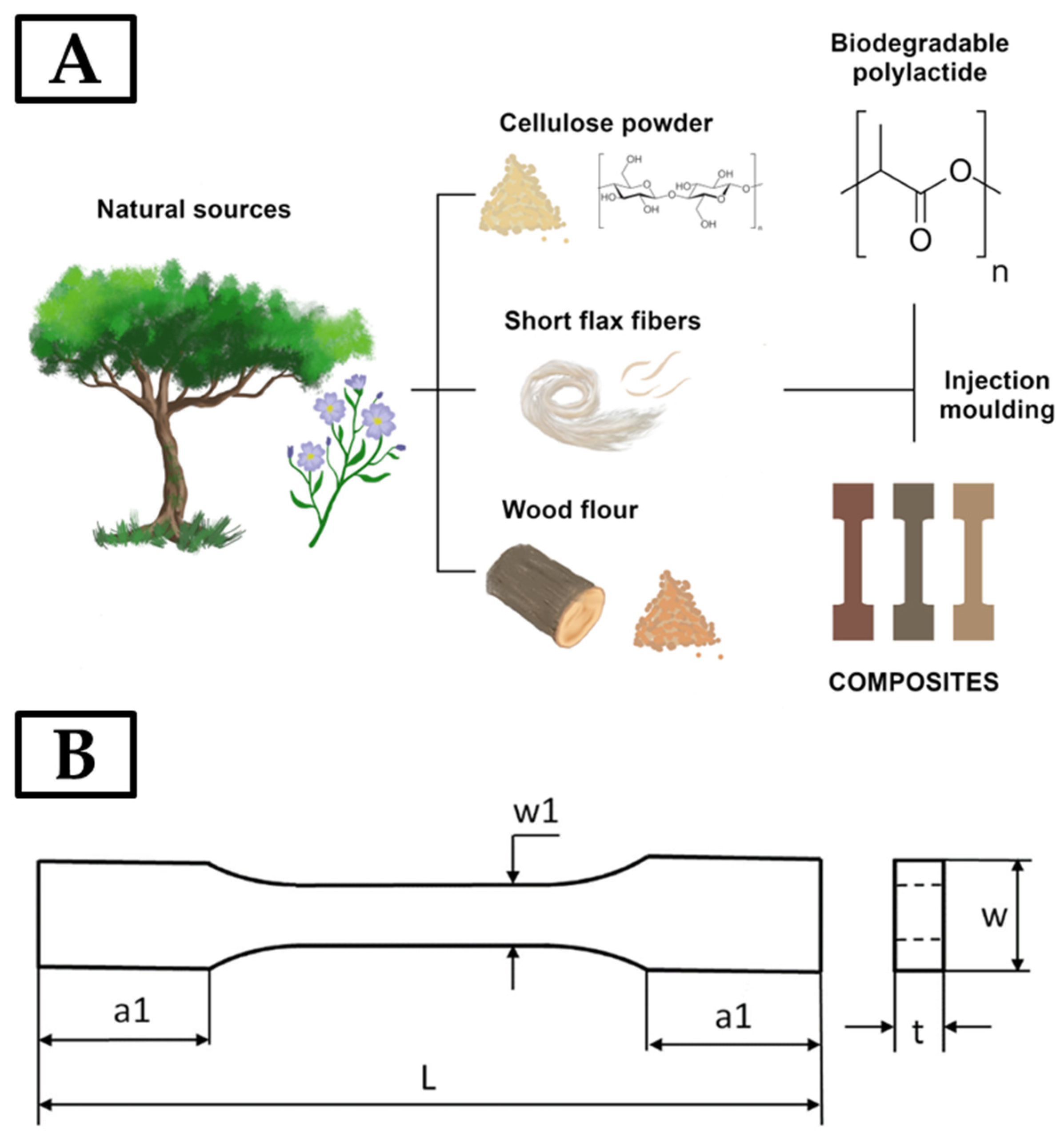

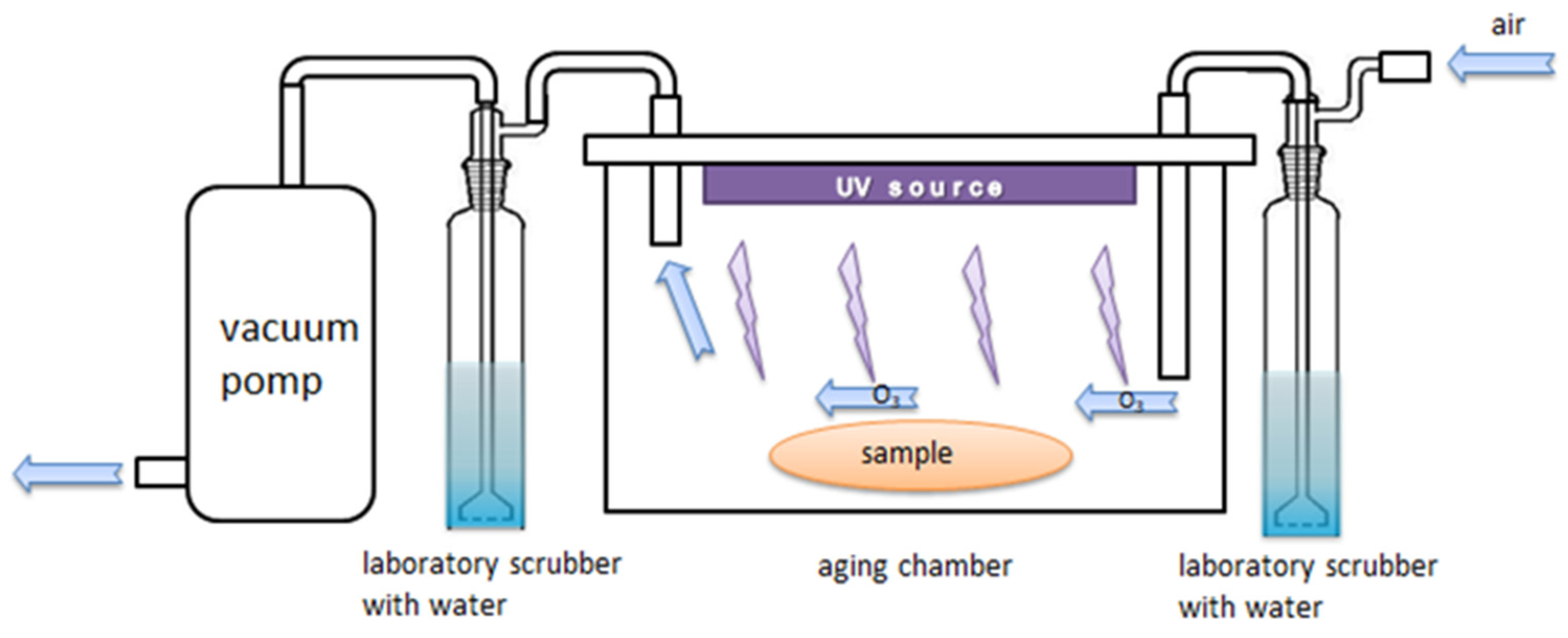

2. Materials and Methods

2.1. Mechanical Tests

- E—Young’s modulus (Pa),

- l—distance between supports (m),

- b—sample width (Pa),

- h—sample height (m),

- ΔF—change in Force (N),

- ΔS—change in deflection (m), for the initial straight-line portion of the load-deflection curve.

- KI—initial pendulum energy (J),

- KII—final pendulum energy (J),

- m—mass of the pendulum (kg),

- g—standard gravity (m/s2),

- R—distance from the axis of the pendulum to the center of the sample (m),

- α—hammer pendulum fall angle,

- β—angle of swing of the pendulum after the sample’s breaking.

2.2. Surface Characterization by Optical Microscopy and Roughness Tests

2.3. Infrared Spectroscopy

3. Results

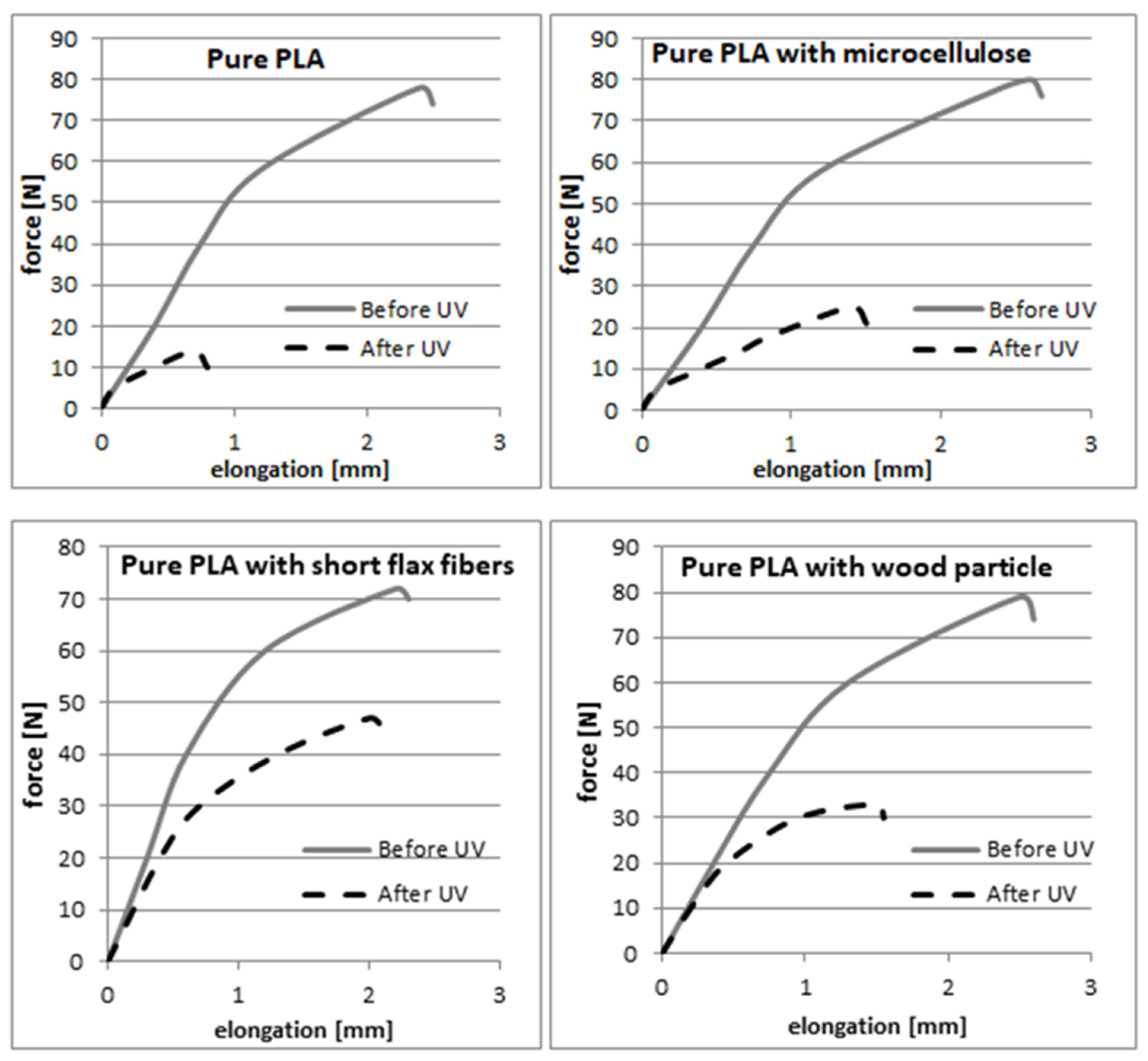

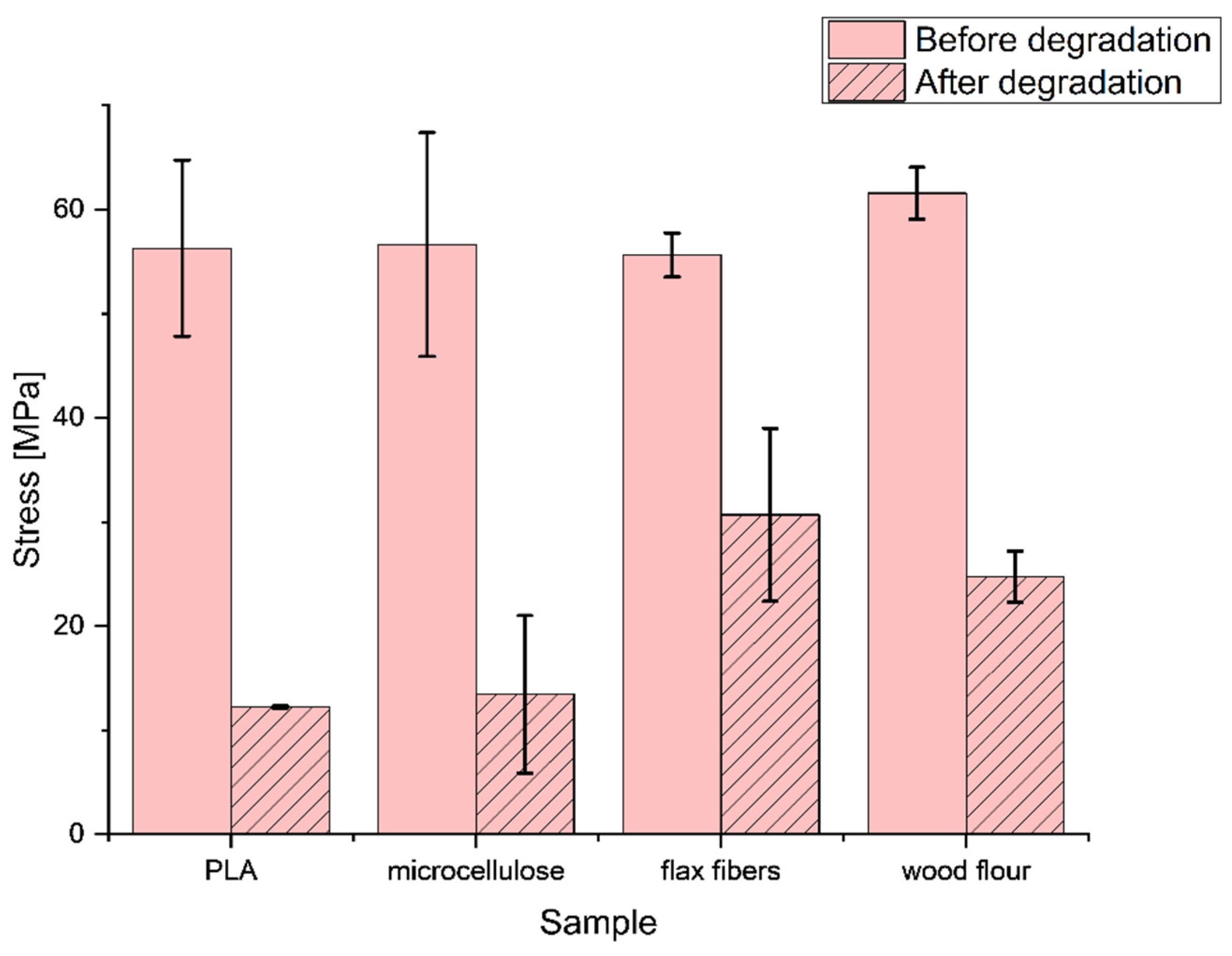

3.1. Mechanical Properties

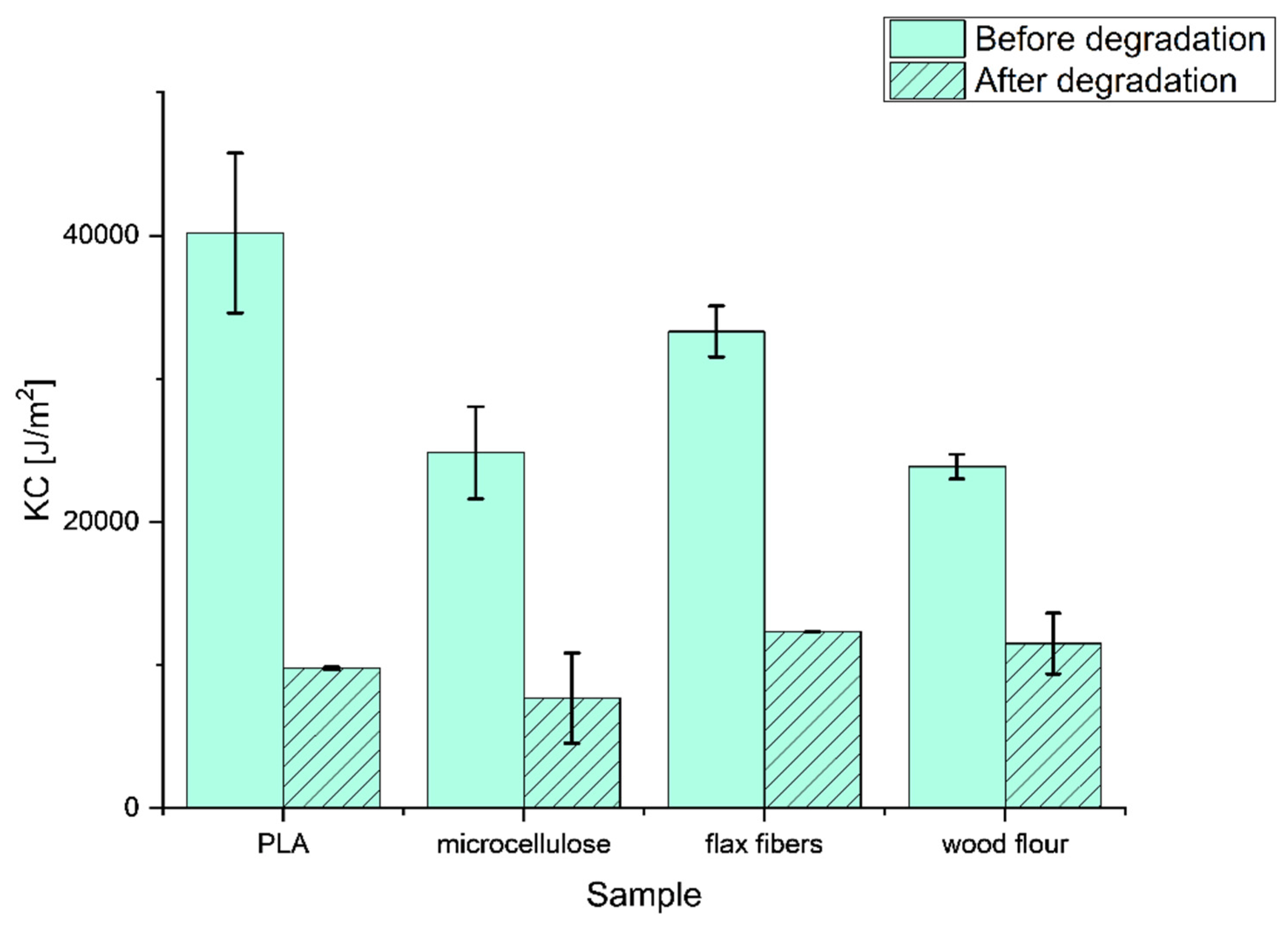

3.2. Impact Mechanical Characterization

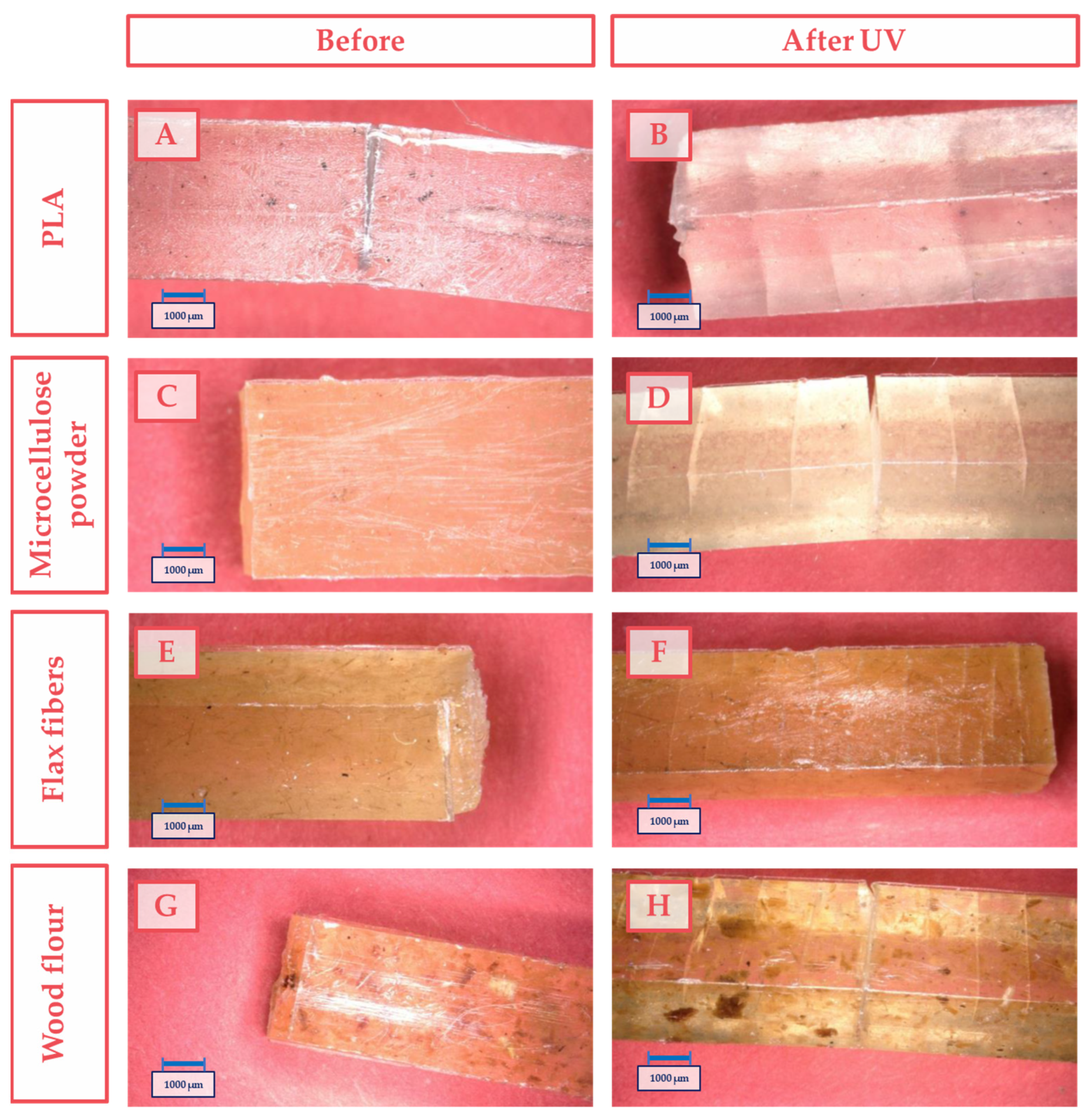

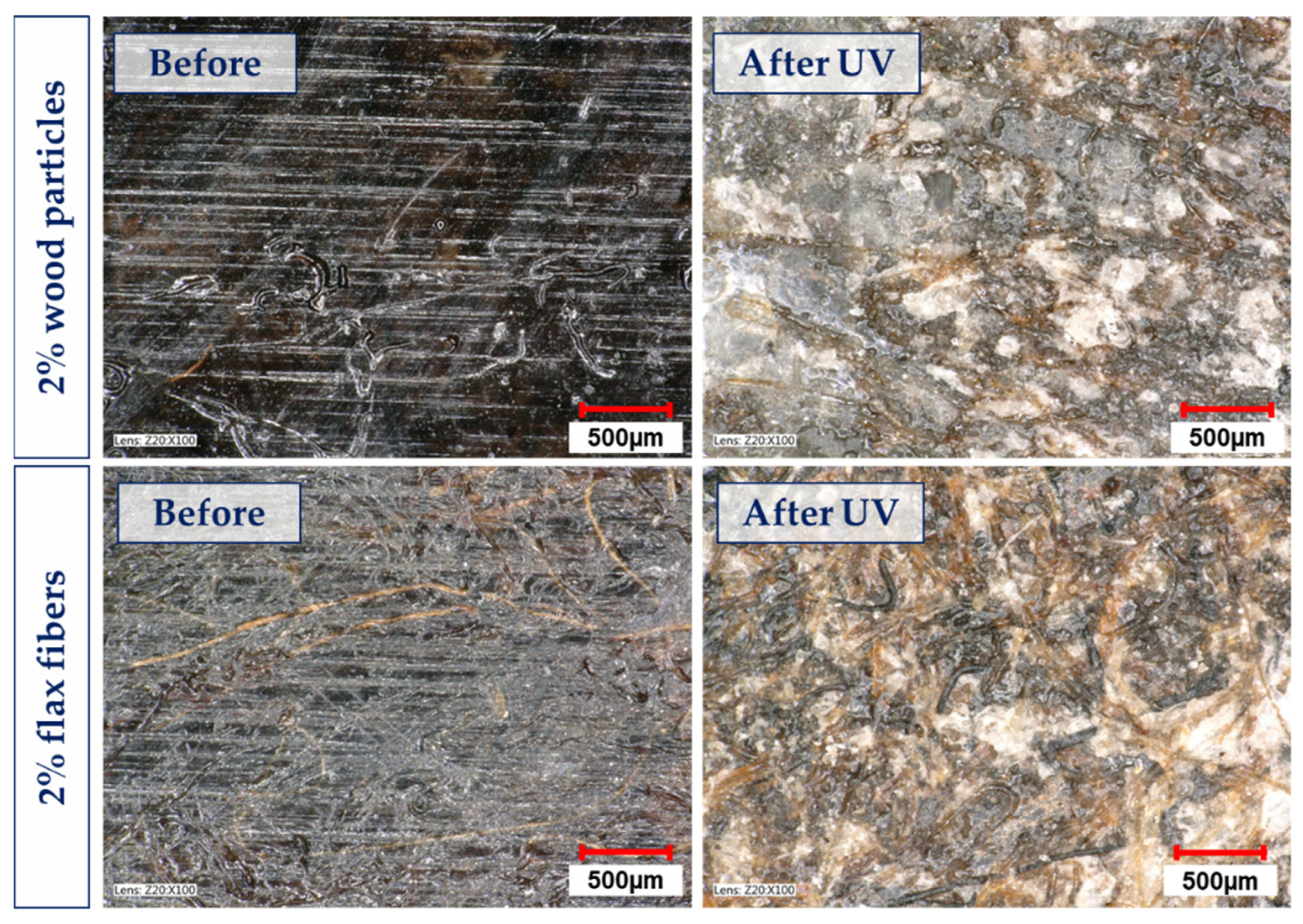

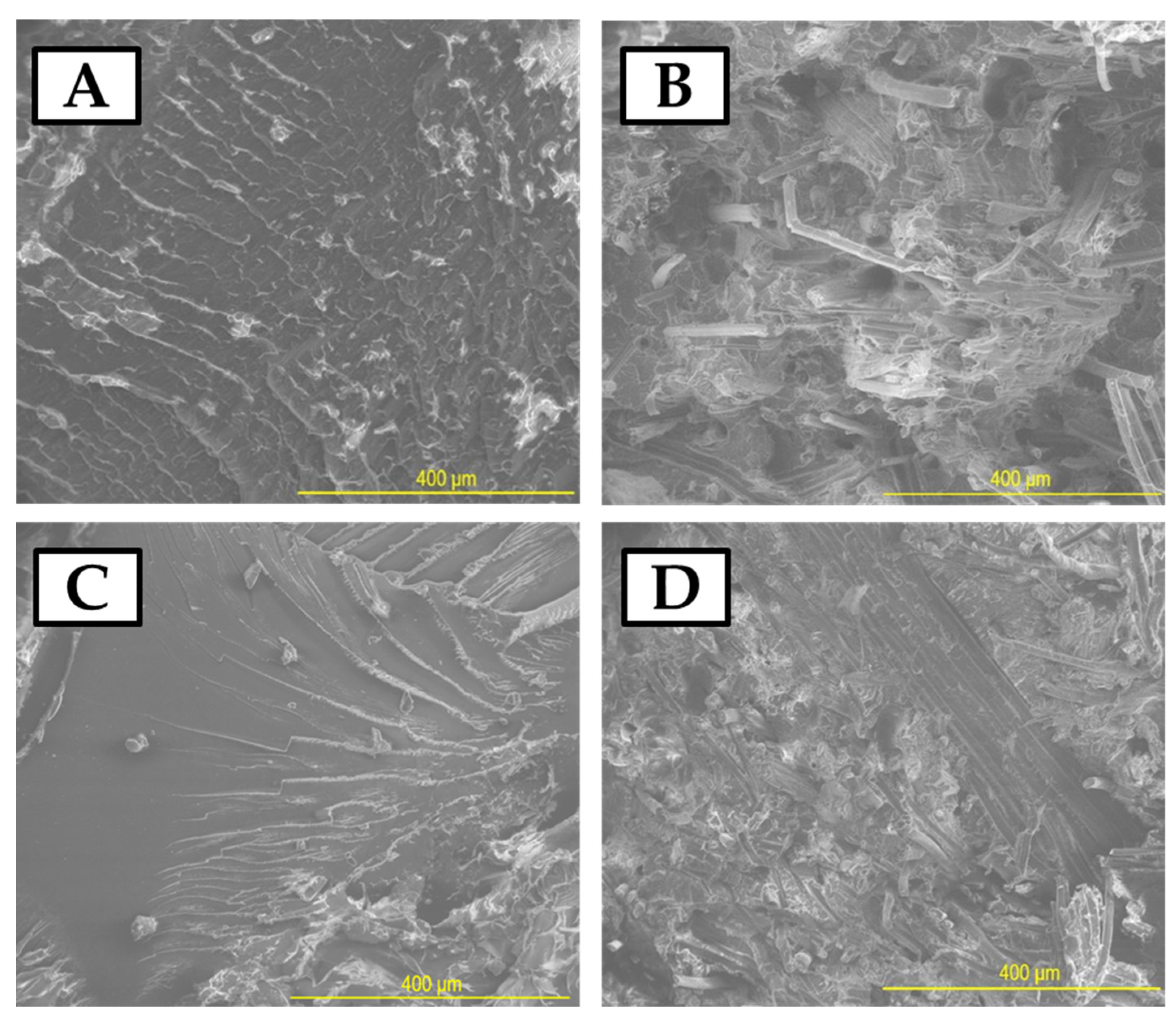

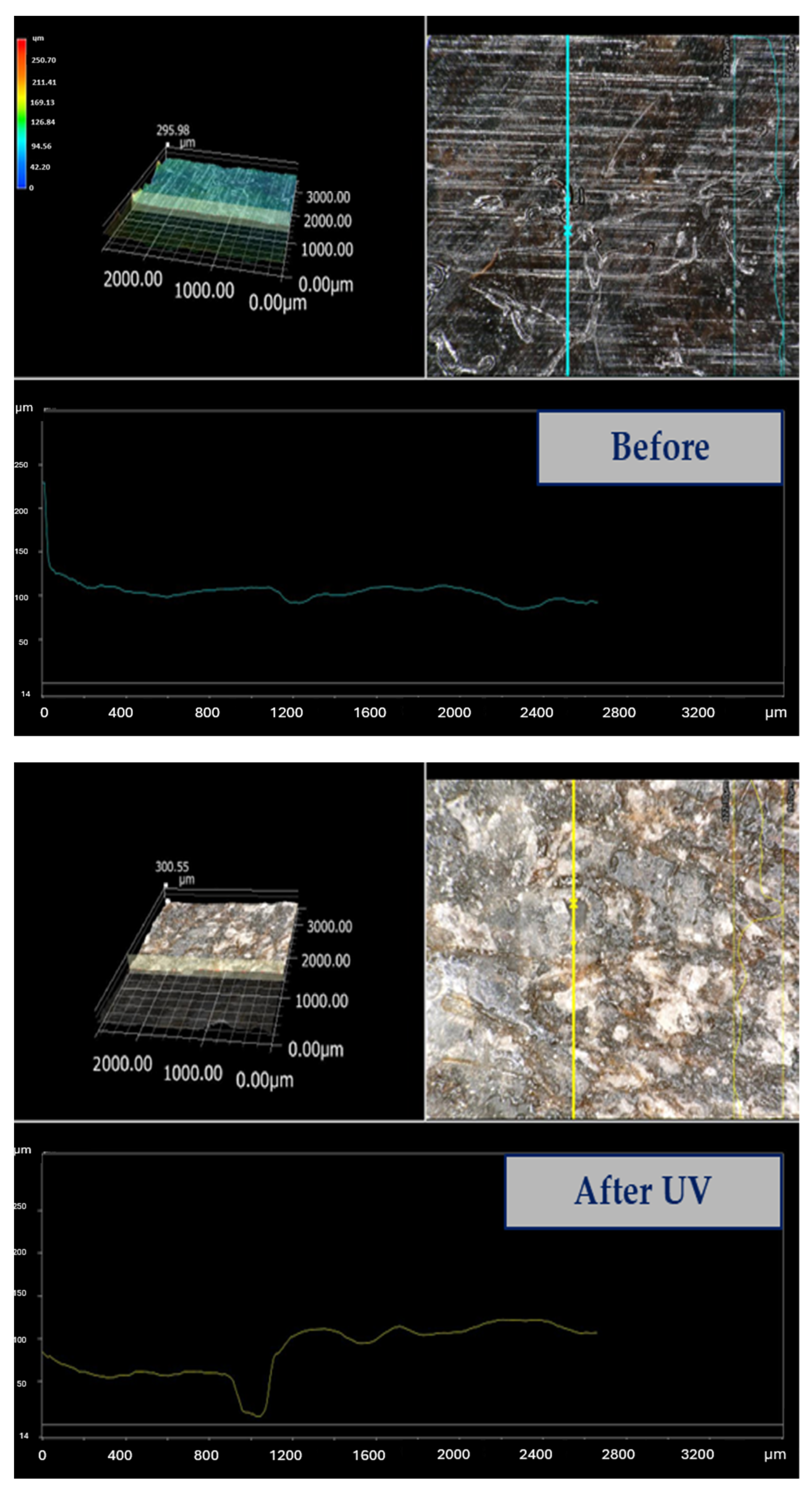

3.3. Investigation of Composites Topography before and after Aging

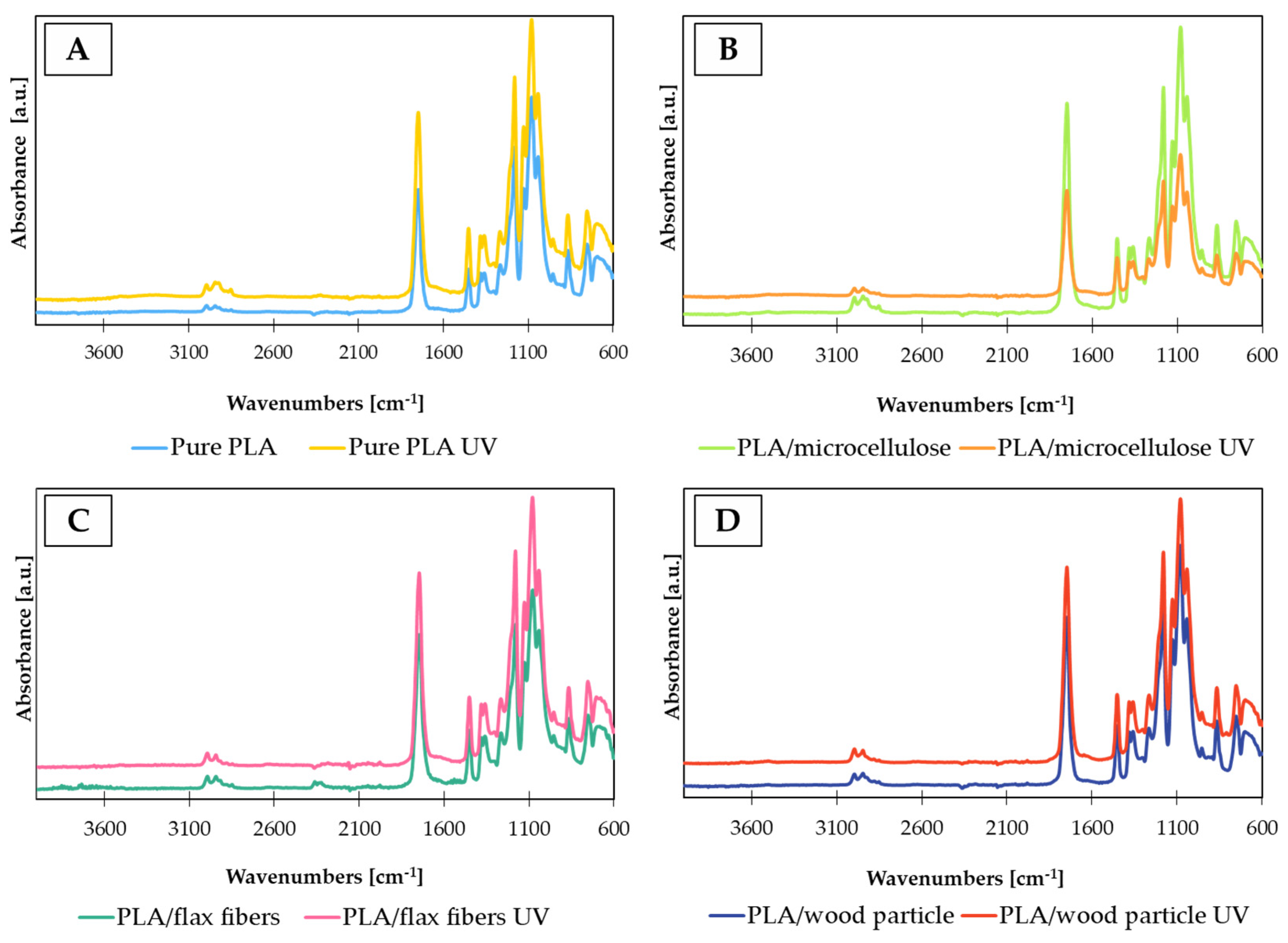

3.4. Structural Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anwer, M.A.S.; Naguib, H.E.; Celzard, A.; Fierro, V. Comparison of the Thermal, Dynamic Mechanical and Morphological Properties of PLA-Lignin & PLA-Tannin Particulate Green Composites. Compos. Part B Eng. 2015, 82, 92–99. [Google Scholar] [CrossRef]

- Olewnik-Kruszkowska, E.; Koter, I.; Skopińska-Wiśniewska, J.; Richert, J. Degradation of Polylactide Composites under UV Irradiation at 25 4nm. J. Photochem. Photobiol. A Chem. 2015, 311, 144–153. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Kim, K.-H.; Park, J.-W.; Deep, A. Hydrolytic Degradation of Polylactic Acid (PLA) and Its Composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Sanchez-Garcia, M.D.; Gimenez, E.; Lagaron, J.M. Morphology and Barrier Properties of Solvent Cast Composites of Thermoplastic Biopolymers and Purified Cellulose Fibers. Carbohydr. Polym. 2008, 71, 235–244. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural Rubber Biocomposites Containing Corn, Barley and Wheat Straw. Polym. Test. 2017, 63, 84–91. [Google Scholar] [CrossRef]

- Lesaffre, N.; Bellayer, S.; Vezin, H.; Fontaine, G.; Jimenez, M.; Bourbigot, S. Recent Advances on the Ageing of Flame Retarded PLA: Effect of UV-Light and/or Relative Humidity. Polym. Degrad. Stab. 2017, 139, 143–164. [Google Scholar] [CrossRef]

- Rezvani Ghomi, E.; Khosravi, F.; Saedi Ardahaei, A.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef]

- Gironi, F.; Piemonte, V. Life Cycle Assessment of Polylactic Acid and Polyethylene Terephthalate Bottles for Drinking Water. Environ. Prog. Sustain. Energy 2011, 30, 459–468. [Google Scholar] [CrossRef]

- Maraveas, C. Environmental Sustainability of Plastic in Agriculture. Agriculture 2020, 10, 310. [Google Scholar] [CrossRef]

- Lach, A.; Szatkowski, P.; Pielichowski, K.; Pielichowska, K. Biocomposites and Biomaterials. In Thermal Analysis of Polymeric Materials: Methods and Developments; John Wiley & Sons: New York, NY, USA, 2022; Volume 2, pp. 429–456. [Google Scholar]

- Tyler, B.; Gullotti, D.; Mangraviti, A.; Utsuki, T.; Brem, H. Polylactic Acid (PLA) Controlled Delivery Carriers for Biomedical Applications. Adv. Drug Deliv. Rev. 2016, 107, 163–175. [Google Scholar] [CrossRef]

- Kong, J.; Li, Y.; Bai, Y.; Li, Z.; Cao, Z.; Yu, Y.; Han, C.; Dong, L. High-Performance Biodegradable Polylactide Composites Fabricated Using a Novel Plasticizer and Functionalized Eggshell Powder. Int. J. Biol. Macromol. 2018, 112, 46–53. [Google Scholar] [CrossRef]

- Laaziz, S.A.; Raji, M.; Hilali, E.; Essabir, H.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.e.K. Bio-Composites Based on Polylactic Acid and Argan Nut Shell: Production and Properties. Int. J. Biol. Macromol. 2017, 104, 30–42. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, Z.; Guo, G. Biodegradation Assessment of Poly (Lactic Acid) Filled with Functionalized Titania Nanoparticles (PLA/TiO2) under Compost Conditions. Nanoscale Res. Lett. 2019, 14, 56. [Google Scholar] [CrossRef]

- Erdal, N.B.; Hakkarainen, M. Degradation of Cellulose Derivatives in Laboratory, Man-Made, and Natural Environments. Biomacromolecules 2022, 23, 2713–2729. [Google Scholar] [CrossRef]

- Czechowski, L.; Kedziora, S.; Museyibov, E.; Schlienz, M.; Szatkowski, P.; Szatkowska, M.; Gralewski, J. Influence of UV Ageing on Properties of Printed PLA Containing Graphene Nanopowder. Materials 2022, 15, 8135. [Google Scholar] [CrossRef]

- Lv, J.; Yang, J.; Li, X.; Chai, Z. Size Dependent Radiation-Stability of ZnO and TiO2 Particles. Dye. Pigment. 2019, 164, 87–90. [Google Scholar] [CrossRef]

- Tsuji, H.; Sugiyama, H.; Sato, Y. Photodegradation of Poly(Lactic Acid) Stereocomplex by UV-Irradiation. J. Polym. Environ. 2012, 20, 706–712. [Google Scholar] [CrossRef]

- Kosowska, K.; Szatkowski, P. Influence of ZnO, SiO2 and TiO2 on the Aging Process of PLA Fibers Produced by Electrospinning Method. J. Therm. Anal. Calorim. 2020, 140, 1769–1778. [Google Scholar] [CrossRef]

- Akbari, A.; Majumder, M.; Tehrani, A. Polylactic Acid (PLA) Carbon Nanotube Nanocomposites. In Handbook of Polymer Nanocomposites. Processing, Performance and Application: Volume B: Carbon Nanotube Based Polymer Composites; Kar, K.K., Pandey, J.K., Rana, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 283–297. ISBN 978-3-642-45229-1. [Google Scholar]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic Acid Blends: The Future of Green, Light and Tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Islam, M.S.; Ramli, I.B.; Hasan, M.R.; Islam, M.M.; Islam, K.N.; Hasan, M.; Harmaen, A.S. Effect of Kenaf and EFB Fiber Hybridization on Physical and Thermo-Mechanical Properties of PLA Biocomposites. Fibers Polym. 2017, 18, 116–121. [Google Scholar] [CrossRef]

- Surface Treated Jute Fiber Induced Foam Microstructure Development in Poly(Lactic Acid)/Jute Fiber Biocomposites and Their Biodegradation Behavior. Fibers Polym. 2018, 19, pp. 648–659. Available online: https://link.springer.com/article/10.1007/s12221-018-7428-4 (accessed on 26 July 2023).

- Spiridon, I.; Tanase, C.E. Design, Characterization and Preliminary Biological Evaluation of New Lignin-PLA Biocomposites. Int. J. Biol. Macromol. 2018, 114, 855–863. [Google Scholar] [CrossRef] [PubMed]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Dimensional Stability and Mechanical Behaviour of Wood–Plastic Composites Based on Recycled and Virgin High-Density Polyethylene (HDPE). Compos. Part B Eng. 2008, 39, 807–815. [Google Scholar] [CrossRef]

- Wei, L.; Agarwal, U.P.; Matuana, L.; Sabo, R.C.; Stark, N.M. Performance of High Lignin Content Cellulose Nanocrystals in Poly(Lactic Acid). Polymer 2018, 135, 305–313. [Google Scholar] [CrossRef]

- Zaidi, L.; Kaci, M.; Bruzaud, S.; Bourmaud, A.; Grohens, Y. Effect of Natural Weather on the Structure and Properties of Polylactide/Cloisite 30B Nanocomposites. Polym. Degrad. Stab. 2010, 95, 1751–1758. [Google Scholar] [CrossRef]

- Kocaman, S.; Karaman, M.; Gursoy, M.; Ahmetli, G. Chemical and Plasma Surface Modification of Lignocellulose Coconut Waste for the Preparation of Advanced Biobased Composite Materials. Carbohydr. Polym. 2017, 159, 48–57. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical Characteristics of Wood, Ceramic, Metal and Carbon Fiber-Based PLA Composites Fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue Behavior of PLA-Wood Composite Manufactured by Fused Filament Fabrication. J. Mater. Res. Technol. 2020, 9, 8507–8516. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Agrawal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical Review of FDM 3D Printing of PLA Biocomposites Filled with Biomass Resources, Characterization, Biodegradability, Upcycling and Opportunities for Biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Wan Ishak, W.H.; Rosli, N.A.; Ahmad, I. Influence of Amorphous Cellulose on Mechanical, Thermal, and Hydrolytic Degradation of Poly(Lactic Acid) Biocomposites. Sci. Rep. 2020, 10, 11342. [Google Scholar] [CrossRef]

- Claro, P.I.C.; Neto, A.R.S.; Bibbo, A.C.C.; Mattoso, L.H.C.; Bastos, M.S.R.; Marconcini, J.M. Biodegradable Blends with Potential Use in Packaging: A Comparison of PLA/Chitosan and PLA/Cellulose Acetate Films. J. Polym. Environ. 2016, 24, 363–371. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Puglia, D.; Petrucci, R.; Kenny, J.M.; Torre, L. Study of Disintegrability in Compost and Enzymatic Degradation of PLA and PLA Nanocomposites Reinforced with Cellulose Nanocrystals Extracted from Posidonia Oceanica. Polym. Degrad. Stab. 2015, 121, 105–115. [Google Scholar] [CrossRef]

- Hegyesi, N.; Zhang, Y.; Kohári, A.; Polyák, P.; Sui, X.; Pukánszky, B. Enzymatic Degradation of PLA/Cellulose Nanocrystal Composites. Ind. Crop. Prod. 2019, 141, 111799. [Google Scholar] [CrossRef]

- Anushikha; Gaikwad, K.K. Lignin as a UV Blocking, Antioxidant, and Antimicrobial Agent for Food Packaging Applications. Biomass Conv. Bioref. 2023, 1, 13–16. [Google Scholar] [CrossRef]

- Park, S.Y.; Kim, J.-Y.; Youn, H.J.; Choi, J.W. Utilization of Lignin Fractions in UV Resistant Lignin-PLA Biocomposites via Lignin-Lactide Grafting. Int. J. Biol. Macromol. 2019, 138, 1029–1034. [Google Scholar] [CrossRef]

- PN-EN ISO 178; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- Szatkowski, P.; Czechowski, L.; Gralewski, J.; Szatkowska, M. Mechanical Properties of Polylactide Admixed with Carbon Nanotubes or Graphene Nanopowder. Materials 2021, 14, 5955. [Google Scholar] [CrossRef]

| Material | Work of Destruction (N·mm) | |

|---|---|---|

| Before UV | After UV | |

| PLA | 136.56 | 8.91 |

| Deviation | 2.15 | 0.65 |

| Different | 127.65 (88% ↓) | |

| PLA with flax fibers | 120.42 | 72.78 |

| Deviation | 2.04 | 1.58 |

| Different | 47.64 (60% ↓) | |

| PLA with microcellulose | 129.42 | 24.83 |

| Deviation | 2.56 | 1.43 |

| Different | 104.59 (81% ↓) | |

| PLA with wood flour | 131.43 | 38.53 |

| Deviation | 2.14 | 1.73 |

| Different | 92.90 (71% ↓) | |

| Material | Ra μm | Rt μm | Rz μm | |||

|---|---|---|---|---|---|---|

| Before UV | After UV | Before UV | After UV | Before UV | After UV | |

| PLA | 0.25 | 0.78 | 2.36 | 6.06 | 1.85 | 4.90 |

| Deviation | 0.04 | 0.09 | 0.15 | 0.26 | 0.11 | 0.24 |

| Difference | 0.53 | 3.70 | 3.05 | |||

| PLA with flax | 0.29 | 0.53 | 3.15 | 4.33 | 2.65 | 4.02 |

| Deviation | 0.03 | 0.07 | 0.17 | 0.15 | 0.15 | 0.23 |

| Difference | 0.28 | 1.18 | 1.37 | |||

| PLA with microcellulose | 0.31 | 0.39 | 2.01 | 4.16 | 1.63 | 3.34 |

| Deviation | 0.04 | 0.08 | 0.11 | 0.13 | 0.12 | 0.20 |

| Difference | 0.05 | 2.15 | 1.71 | |||

| PLA with wood flour | 0.42 | 0.81 | 3.05 | 5.78 | 1.99 | 4.23 |

| Deviation | 0.03 | 0.07 | 0.13 | 0.19 | 0.14 | 0.19 |

| Difference | 0.39 | 2.73 | 2.24 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szatkowski, P.; Gralewski, J.; Suchorowiec, K.; Kosowska, K.; Mielan, B.; Kisilewicz, M. Aging Process of Biocomposites with the PLA Matrix Modified with Different Types of Cellulose. Materials 2024, 17, 22. https://doi.org/10.3390/ma17010022

Szatkowski P, Gralewski J, Suchorowiec K, Kosowska K, Mielan B, Kisilewicz M. Aging Process of Biocomposites with the PLA Matrix Modified with Different Types of Cellulose. Materials. 2024; 17(1):22. https://doi.org/10.3390/ma17010022

Chicago/Turabian StyleSzatkowski, Piotr, Jacek Gralewski, Katarzyna Suchorowiec, Karolina Kosowska, Bartosz Mielan, and Michał Kisilewicz. 2024. "Aging Process of Biocomposites with the PLA Matrix Modified with Different Types of Cellulose" Materials 17, no. 1: 22. https://doi.org/10.3390/ma17010022

APA StyleSzatkowski, P., Gralewski, J., Suchorowiec, K., Kosowska, K., Mielan, B., & Kisilewicz, M. (2024). Aging Process of Biocomposites with the PLA Matrix Modified with Different Types of Cellulose. Materials, 17(1), 22. https://doi.org/10.3390/ma17010022